general bolt BMW 318i 1994 E36 User Guide

[x] Cancel search | Manufacturer: BMW, Model Year: 1994, Model line: 318i, Model: BMW 318i 1994 E36Pages: 759

Page 213 of 759

GENERAL

..

.

......

.

.

.

.....

.

...

.

.

.

.

.

.

.

.

200-1

Manual

Transmission

.

.

.....

.

.

.

.'

.

.

.

.

.

.

.

.

200-1

Automatic

Transmission

.........

.

.

.

.

.

.

.

.

200-1

Transmission

ID

Codes

..........

.

.

.

.

.

.

.

.

200-2

GENERAL

E36

models

areequipped

with

a

longitudinal

drivetrain

.

The

transmission

is

bolted

directly

to

the

rear

of

the

engine

.

A

driveshaft

connects

the

output

shaft

of

thetransmission

to

the

final

drive

.

The

final

drive

is

mounted

lo

the

rear

suspension

and

the

body

.

Individual

drive

axles

with

integrated

constant

velocity

joints

transfer

rotational

power

to

the

rear

wheels

.

Manual

Transmission

Due

to

different

power

characteristics

and

performance

re-

quirements,

four

different

manual

transmissions

are

used

in

the

models

coveredby

this

manual

.

Manual

transmission

ap-

plications

are

given

in

Table

a

.

TRANSMISSION-GENERAL

200-1

200

Transmission-General

TABLES

a

.

Manual

Transmission

Applications

..

...........

200-1

b

.

Automatic

Transmission

Applications

...........

200-1

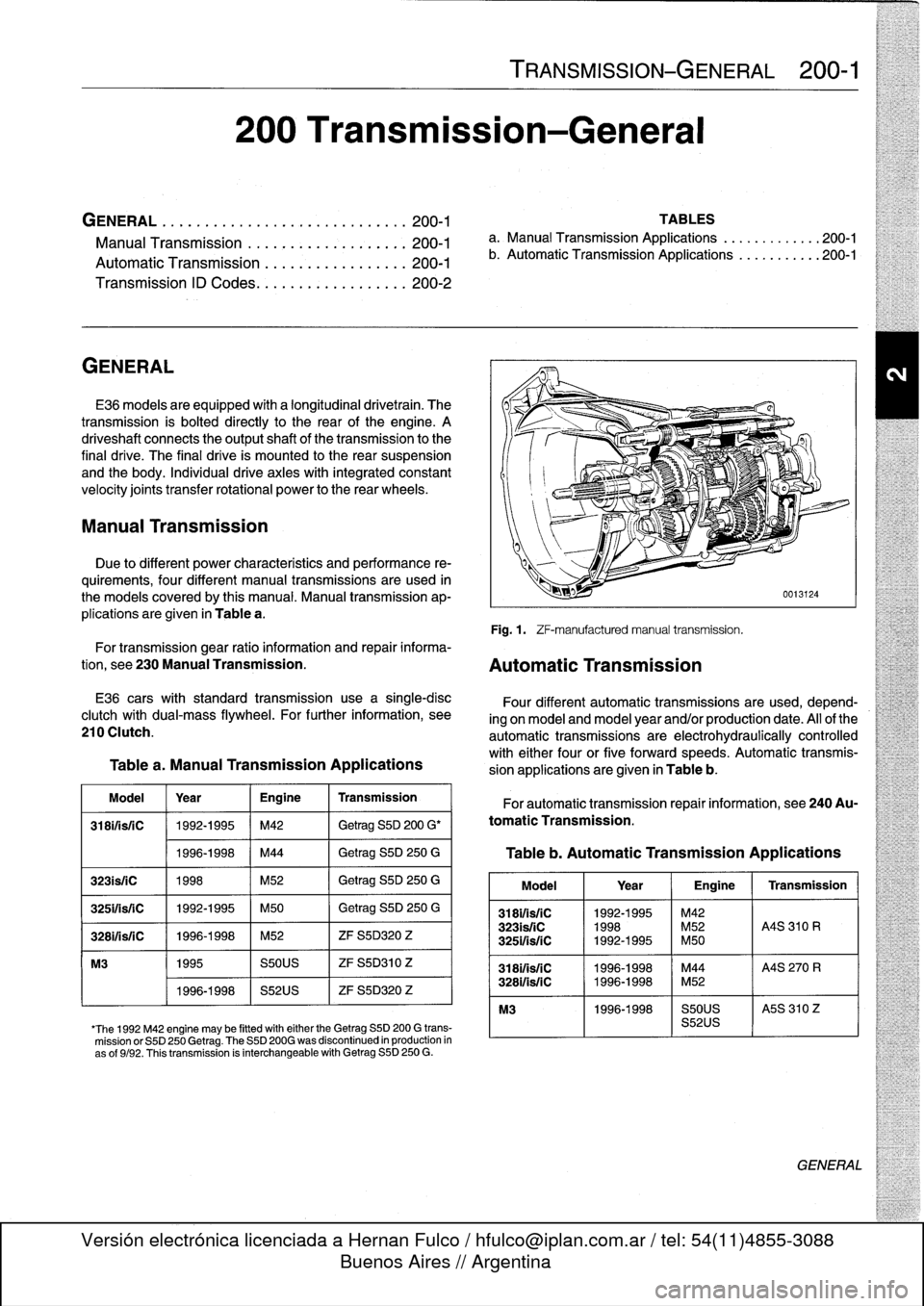

Fig

.

1

.

ZF-manufacturedmanual

transmission

.

For

transmission

gear

ratio

information

and

repair

informa-

tion,

see

230

Manual

Transmission

.

Automatic

Transmission

E36

carswith

standard

transmission

use

a

single-disc

clutch

with

dual-mass

flywheel

.

For

further

information,

see

210

Clutch

.

Table

a

.

Manual

Transmission

Applications

Model

Year

Engine

Transmission

318ifisfC

1992-1995

M42

Getrag

S5D

200

G'

1996-1998

M44

Getrag

S5D

250

G

323is/iC

1998

M52

Getrag

S5D

250

G

325ifsriC

1992-1995

M50

Getrag

S5D

250

G

3281/isfC

1996-1998

M52

ZF

S5D320

Z

M3

1995

S50US

ZF

S5D310

Z

1996-1998

S52US

ZF

S5D320

Z

'The

1992

M42

engine

may

be

fitted

witheither

the

Getrag

SSD

200

G

trans-

mission

or

S5D

250

Getrag

.

The

S5D

200G

was

discontinued

in

production

in

as

of

9/92

.

Thistransmission

is

interchangeable

with

Getrag

S5D

250

G

.

Four

different

automatic

transmissions

are

used,

depend-

ing

on

model

and

model

year

and/or

production

date

.

All

of

the

automatic

transmissions

are

electrohydraulically

controlled

with

either

four

or

five

forward

speeds

.

Automatic

transmis-

sion

applications

are

given

in

Table

b

.

For

automatic

transmission

repair

information,

see

240Au-

tomatic

Transmission

.

Table

b

.

Automatic

Transmission

Applications

Model

1

Year

1

Engine

1

Transmission

318i1is/1C

1992-1995

~

M42

323isfiC

1998

M52

A4S

310

R

3251/is/1C

1992-1995

M50

3181/isfC

11996-1998

M44

A4S

270

R

328i/is/1C

1996-1998

M52

M3

1996-1998

S50US

I

A5S

310

Z

S52US

GENERAL

Page 215 of 759

GENERAL

..

.

.

.

.

.

.

.

.

.

.

.

.

.

......

.

......

210-1

CLUTCH

MECHANICAL

.

.

.

.

.

...

.

.....

.

.

210-3

CLUTCH

HYDRAULICS

.

.

.

.............

210-1

Clutch,

removing

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

...

.

.

.

.

210-4

Clutch,inspecting

and

installing

.

.

.

.

.

.

.

.

.

.

.

.210-5Clutch

hydraulic

system,

Transmission

pilot

bearing,replacing

.

.

.

.

...

210-6

bleeding

and

flushing

.

.

.

.

.

.......

.

.....

210-2

Clutch

master

cylinder,

replacing

..

.

.

.

.

.

...

210-2

Table

Clutch

slave

cylinder,

replacing

...

.

.

.

.

.

.

.

.

210-3

a

.

Clutch

Disc

Diameter

.............

..

..

.

......

210-3

GENERAL

CLUTCH

HYDRAULICS

This

repair

group

covers

replacement

of

the

clutch

mechan-

The

Clutch

is

hydraulically

actuated

by

the

master

and

slave

¡cal

and

hydraulic

components

.

Special

tools

may

be

required

cylinders

.

Clutch

disc

wear

is

automatically

taken

upby

the

for

some

of

the

procedures

.

Read

the

procedure

through

be-

pushrod

travelof

the

slave

cylinder,

making

periodic

adjust-fore

beginning

a

job

.

ments

unnecessary

.

NOTE-

See200

Transmission-General

for

transmission

applicatíon

information

.

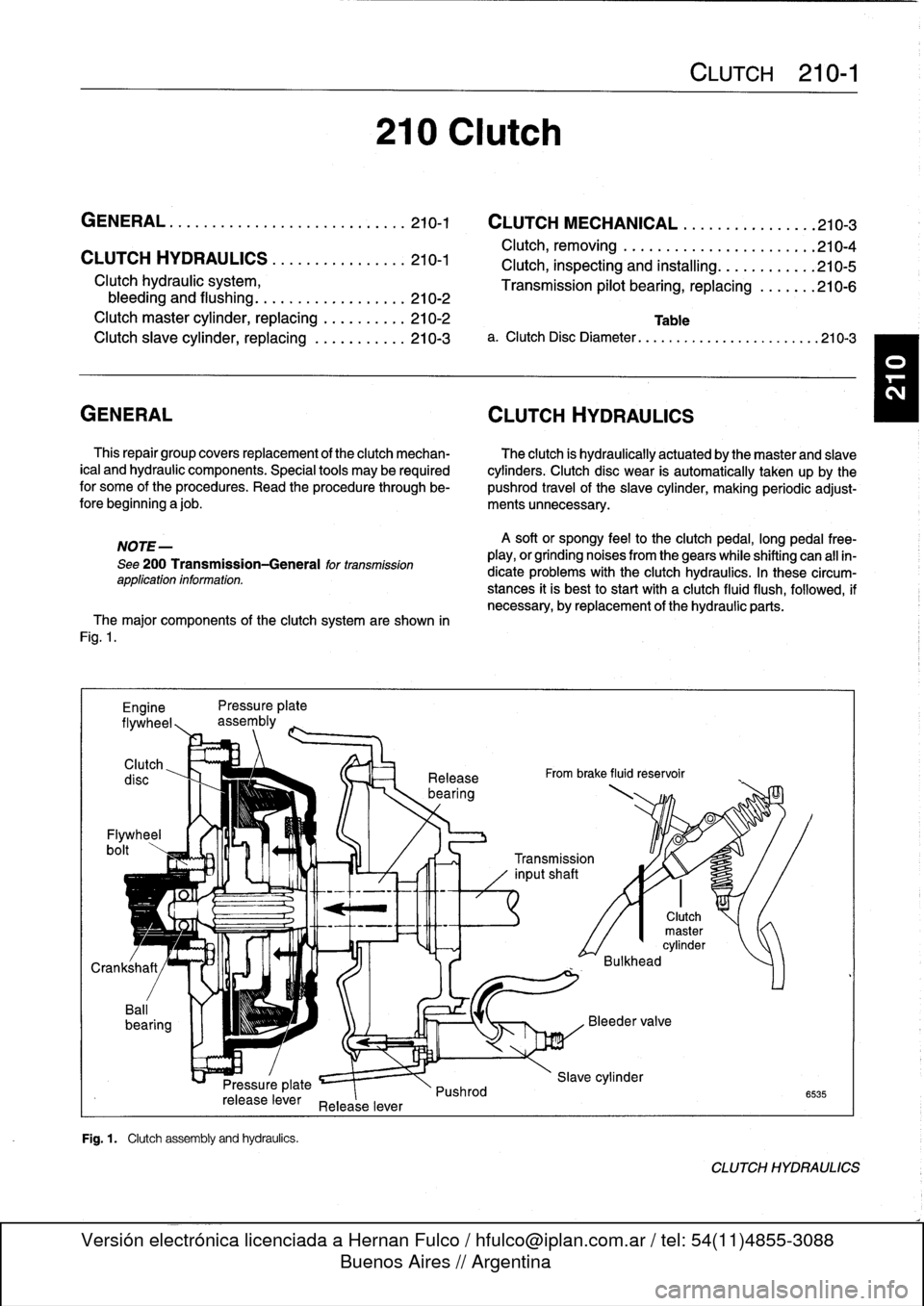

The

major

components

of

the

clutch

system

are

shown

in

Fig

.

1

.

Engine

Pressure

plate

flywheel,,

assembly

Clutch

Flywheel

bolt

Pressure

plate

release

lever

Release

lever

Fig

.

1

.

Clutch

assembly

and

hydraufcs

.

210

Clutch

Release

bearing

Pushrod

A

soft

or

spongy

feel

to

the

clutchpedal,

long

pedal

free-

play,

or

grinding

noises

from

thegears

while

shifting

can

all

in-

dicate

problems

with

the

Clutch

hydraulics

.

In

these

circum-

stances

it

is

best

to

start

with

a

clutch

fluid

flush,

followed,

if

necessary,

byreplacement

of

the

hydraulic

parts

.

From

brake

fluid

reservoir

CLUTCH

210-1

0

0

Transmission

inputshaft

Clutch

master

cylinder

Bulkhead

Slave

cylinder

6535

CLUTCH

HYDRAULICS

Page 243 of 759

Symptom

1

Probable

cause

4

.

Vibration,

audible

a

.

Front

centering

guide

worn,

or

a

.

Check

front

centering

guide

and

replace

if

necessary

.

Check

rumble

over35

mph

driveshaft

mounting

flanges

out

of

runout

of

driveshaft

mounting

flanges

.

(60

km/h)

.

round

or

damaged

.

b

.

Mounting

flange

bolts

loose

or

holes

b

.

Remove

driveshaft

and

check

transmissionoutput

flange

and

worn

.

final

drive

input

flange

.

Replace

if

necessary

.

c

.

Driveshaft

unbalanced

.

c

.

Check

driveshaft

for

loose

or

missing

balance

weights

.

Have

driveshaft

rebalanced

or

replace

if

necessary

.

DRIVESHAFT

SERVICE

Driveshaft,

aligning

d

.

Universal

joints

worn

or

seized

.

d

.

Check

universal

joint

play

and

movement

.

Replace

driveshaft

if

necessary

.

e

.

Sliding

coupling

seized

.

e

.

Remove

driveshaft

and

check

movement

of

sliding

coupling

.

1

Clean

coupling

splines

or

replace

parts

asnecessary

.

f

.

Incorrect

preload

of

center

bearing

.

f

.

Check

preload

of

center

bearing

.

Readjust

if

necessary

.

g

.

Center

bearing

faulty

.

g

.

Replace

center

bearing

.

h

.

Final

drive

rubber

mount

faulty

h

.

Inspect

final

drive

rubber

mount

and

replace

if

necessary

.i.

Driveshaft

misaligned

.

i.

Check

driveshaft

alignment

.

Repair

kits

for

the

universal

joints

are

not

available,

and

it

is

not

common

practice

to

repair

the

universal

joints

on

BMW

driveshafts

.

Worn

or

damaged

universal

joints

usually

require

replacement

of

that

section

of

the

driveshaft

.

The

driveshaft

is

balanced

to

cose

tolerances

.

Whenever

it

is

to

be

removed

or

disassembied,

the

mounting

flanges

and

driveshaft

sections

should

bemarked

with

paint

or

a

punch

before

proceeding

with

work

.

This

will

ensure

that

the

drive-

shaft

can

be

reassembled

or

installed

in

exactlythe

same

ori-

entation

.

Universal

joint

play

"

Maximum

allowable

...........

0.15

mm

(0.006

in

.)

The

alignment

of

the

driveshaft

does

not

normally

need

to

be

checked

unless

the

engine/transmission

orthe

final

drive

havebeen

removed

and

installed

.

If,

however,

all

other

parts

of

the

driveshaft

havebeen

inspected

and

found

to

be

okay,

butthere

is

still

noise

or

vibration,

driveshaft

alignment

should

be

checked

.

There

aretwo

important

driveshaft

alignment

checks

.

The

first

is

to

make

sure

that

the

driveshaft

runs

straight

from

the

transmission

to

the

final

drive

;

without

any

variation

from

side-

to-side

caused

by

misalignment

ofthe

engine/transmission

in

its

mounts

.

Make

a

basic

check

by

sighting

along

the

drive-

shaft

from

back

lo

front

.

Any

misalignmentshould

be

apparent

from

the

center

bearingforward

.

To

adjustthe

side-to-side

alignment,

loosen

the

transmission

or

engine

mounts

to

repo-

sition

them,

then

retighten

the

mounts

:

The

driveshaft

should

be

exactly

centered

in

the

driveshaft

tunnel

.

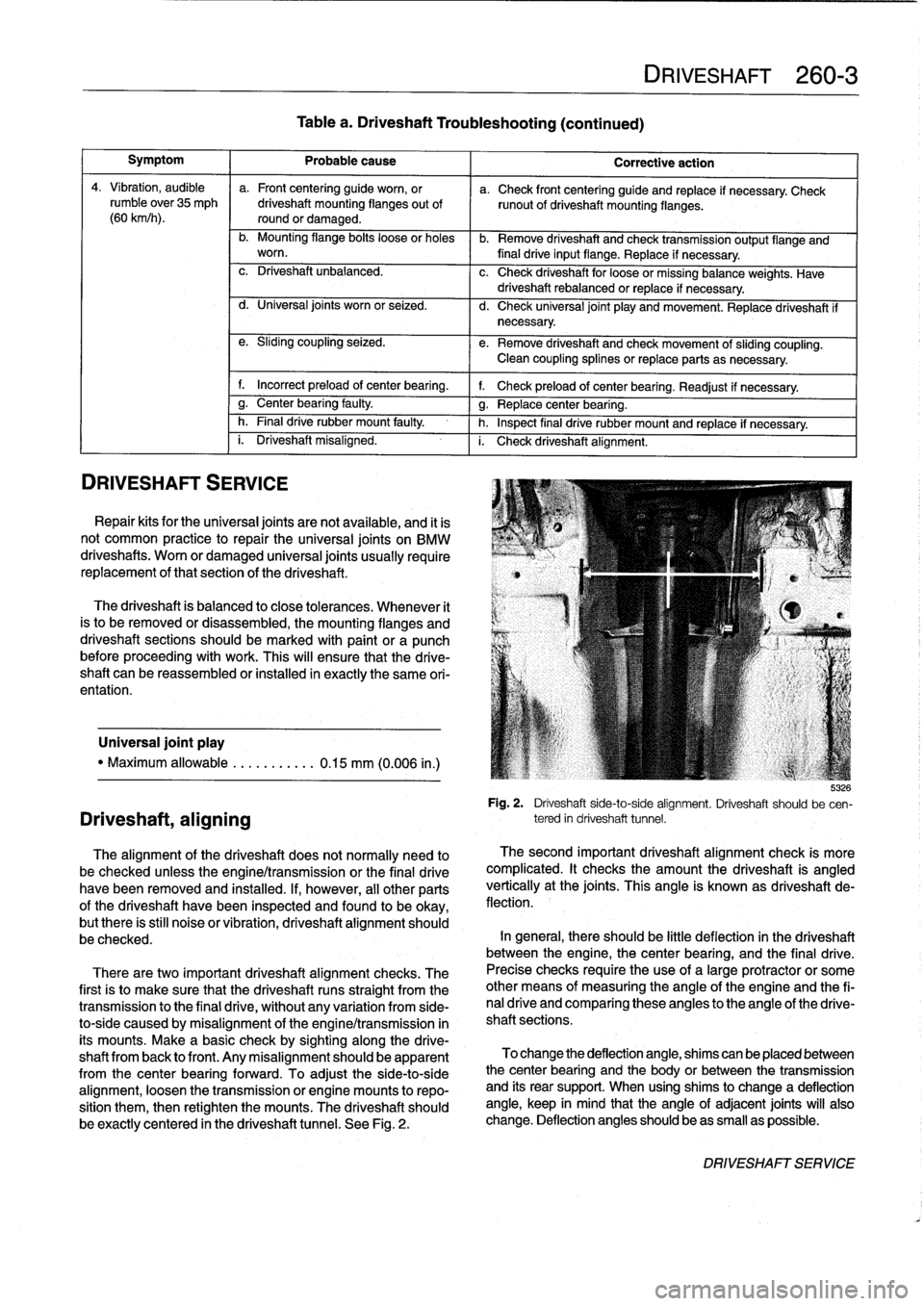

See

Fig

.

2

.

Table

a

.

Driveshaft

Troubleshooting

(continued)

DRIVESHAFT

260-3

Corrective

action

b

:izó

Fig

.

2

.

Driveshaft

side-to-side

alignment

.

Driveshaft

should

be

cen-

tered

in

driveshaft

tunnel

.

The

second

important

driveshaft

alignment

check

is

more

complicated

.

It

checks

the

amount

the

driveshaft

is

angled

vertically

at

the

joints

.

This

angle

is

known

as

driveshaft

de-

flection

.

In

general,

there

should

be

little

deflection

in

the

driveshaft

between

the

engine,

thecenter

bearing,

and

the

final

drive

.

Precise

checks

require

theuse

of

a

large

protractor

or

some

other

means

of

measuring

the

angle

of

the

engine

and

the

fi-

nal

drive

and

comparing

these

angles

to

the

angle

of

the

drive-

shaft

sections

.

To

change

the

deflection

angle,

shims

can

be

placed

between

the

center

bearing

and

the

body

or

between

the

transmission

and

íts

rear

support

.

When

using

shims

to

change

a

deflection

angle,

keep

in

mind

that

the

angle

of

adjacent

joints

will

also

change

.

Deflection

anglesshould

beas

small

as

possible

.

DRIVESHAFTSERVICE

Page 256 of 759

300-8

SUSPENSION,

STEERING

AND

BRAKES-GENERAL

Tableb

.

Suspension

and

Steering

Troubleshooting

Symptom

1

Probable

cause

Repairs

(Repair

Groups

shown

in

bold)

Car

pulís

to

one

side,

wanders

a

.

Incorrect

tire

pressure

a

.

Check

and

correct

tire

pressures

.

020

b

.

Incorrect

wheel

alignment

b

.

Check

and

adjust

wheel

alignment

.

320

c

.

Faulty

brakes

(pulls

only

when

braking)

I

c

.

Check

for

sticking/damaged

front

caliper

.

340

Steering

heavy,

poor

return-

a

.

Worn

upper

strut

bearing(s)

a

.

Replace

strut

bearings

.

310

to-center

b

.

Incorrect

tire

pressure

b

.

Check

and

correct

tire

pressures

.

020

c

.

Power

steering

system

faulty

c

.

Check

power

steering

fluid

level

.

Test

system

pressure

.

320

Front-end

or

rear-end

vibra-

a

.

Worn

strut

cartridgesor

shock

absorbers

a

.

Replace

strut

cartridges

.

310,

330

tion

or

shimmy

b

.

Worn

suspension

bushings

(control

arm

or

trail-

b

.

Replace

worn

bushings

.

310,

330

ing

arm)

c

.

Worn

front

suspension

ball

joints

(control

arm,

c

.

Replace

worn

ball

joints

.

310

steering

arm

orsteering

tie-rod

end)d

.

Unbalanced

or

bent

wheels/tires

d

.

Balance

tires

.

Check

tiresfor

uneven

wear

pat-

terns

.

Check

wheels

for

damage

.

e

.

Loose

wheel

lug

boits

e

.

Tighten

lug

boits

to

proper

torque

.

Poor

stability,

repeated

bounc-

I

a

.

Worn

strut

cartridgesor

shock

absorbers

I

a

.

Replace

strut

cartridges

.

310,

330

ing

after

bumps,

suspension

bottoms

outeasily

Suspension

noise

(especially

a

.

Worn

front

upper

strut

bearings

a

.

Replaceupper

strut

bearings

.

310

over

bumps)

b

.

Loose

front

strut

cartridge

b

.

Check/tighten

strut

cartridge

collar

nut

.

310

c

.

Worn

suspensionbushings

(control

arm

or

trail-

c

.

Replace

worn

bushings

.

310,

330

ing

arm)d

.

Worn

stabilizer

bar

rubber

mounts

d

.

Replace

stabilizer

bar

rubber

mounts

.

310,

330

e

.

Loose

suspension

crossmember

e

.

Check

crossmember

for

damage

.

Tighten

mounting

boits

.

Uneven

ride

height

a

.

Incorrect

coil

springs

a

.

Measure

ride

height

and

replacesprings

as

re-

quired

.

310,

330

b

.

Bent

or

damaged

suspension

components

b

.

Inspect,

repair/replace

asnecessary

.

310,

330

c

.

Sagging

coil

springs

c

.

Measure

ride

height

and

replace

springs

as

re-

quired

.

310,

330

Wheel

noise,

continuous

I

a

.

Worn

wheel

bearing

I

a

.

Replacewheel

bearing

.

310,

330

growling,

may

be

more

notíce-

able

when

turning

Steering

loose,

imprecise

a

.

Incorrect

tire

pressure

a

.

Check

and

correct

tire

pressures

.

020

-

b

.

Loose

steering

gearmounting

bolt(s)

b

.

Inspect

and

tighten

boits

.

320

c

.

Worn

tie

rodend(s)

c

.

Replace

tie

rod(s)

and

align

wheels

.

320

d

.

Faulty

front

wheel

bearing

d

.

Replace

wheel

bearing

.

310

e

.

Worn

or

damaged

steering

gear

e

.

Adjust

or

replace

steering

gear

.

320

f

.

Worn

tires

f

.

Replace

tires

.

010

SUSPENSION

AND

STEERING

TROUBLESHOOTING

Page 267 of 759

320

Steering

and

Wheel

Alignment

GENERAL

...

.

.

.

...

.

....

.

.

.

.

.

.

.

.

.

...

.

.

320-1

Outer

tie

rod

end,

replacing

.

...

.

.

.

.

.

.

.

...

.

320-4

Tie

rod,

replacing

.

.

.

.

.

.

.

.......

.

.

.

.

.

...

.

320-5

STEERING

WHEEL

320-1

Steering

wheel,

removing

and

installing

.....

320-1

WHEEL

ALIGNMENT

.

.

.

.........

.

.....

.320-5

POWER

STEERING

SYSTEM

.

.

.

.

.

.

.....

320-2

Front

Toe-in

and

Toe

Difference

Angle

.

.

...

.

320-6

Power

steering

pump,

Rear

Toe-in

.

.

.

.

.

.

.

...

.

................

320-6

removing

and

installing

..

.

.

.

.

.

.

.

.

.

.....

320-2

Wheel

Alignment

Specifications

.....

.

......

320-6

Power

steering

system,

bleeding

and

filling

.

.

320-3

STEERING

GEAR

.

.

.

.

...

.

.

.

.

.

.

.

.

.

.....

320-3

Steering

gear

rack,

removing

and

installing

.

...

.

..

.

..

..

..

.

..

.

320-3

GENERAL

STEERING

WHEEL

This

repair

group

covers

servicing

of

the

mechanical

and

The

BMW

E36

is

equipped

with

an

SRS

airbag

mounted

in

hydraulic

components

of

the

steering

system,

including

wheel

the

steering

wheel

.

Improper

handling

of

the

airbag

could

alignment

information

.

cause

serious

injury

.

The

airbag

is

an

explosivedevice

and

should

be

treated

with

extreme

caution

.

Always

follow

the

air-

The

variable-assist

power

steering

system

consistsof

an

bag

removal

procedure

as

outlined

in

721

Airbag

System

engine-driven

hydraulic

pump,

a

rack-and-pinion

steering

(SRS)

.

gear

assembly

with

an

integral

hydraulic

control

valve,

and

connecting

linkage

to

the

road

wheels

.

WARNING-

"

The

BMW

Supplemental

Restraint

System

(SRS)

At

lowspeeds,

maximum

power

assist

is

provided

to

ease

is

complex

and

special

precautions

must

be

ob-

parking

and

city

driving

.

At

high

speeds,

assist

is

reduced

to

served

when

servicing

.

Serious

injury

may

result

ensure

stability

.

The

power

steering

system

varies

assist

if

system

service

is

attempted

by

persons

unfa-

based

on

engine

speed

.

miliar

with

the

BMW

SRS

and

its

approved

ser-

vice

procedures

.

BMW

specifies

that

all

ING-

inspection

and

service

shouldbe

performed

by

WARN

an

authorized

BMW

dealer

.

"

Do

not

reuse

self-locking

nuts

.

They

are

de-signed

to

beused

only

once

and

may

failif

re-

"

BMW

Supplemental

Restraint

Systems

(SRS)

used

.

Always

replace

them

with

new

locking

nuts

.

are

equipped

with

a

back-up

power

supply

inside

the

SRS

control

module

.

A

10minute

waiting

"

Do

not

ínstall

bolts

and

nuts

coated

with

under-

shouldbe

observed

after

the

battery

cable

has

coating

wax,

as

correct

tightening

torque

cannot

been

disconnected

.

This

will

allow

the

reserve

be

assured

.

Always

clean

the

threads

with

sol-

power

supply

to

discharge

.

vent

before

installation,

or

install

new

parts

.

"

Do

not

attempt

to

weldor

straighten

any

steering

components

.

Always

replace

damaged

parts

.

NOTE-

For

information

on

steering

column-mounted

switches

and

the

ignition

lock,

see

612

Switches

and

Electrical

Accessories

.

STEERING

AND

WHEEL

ALIGNMENT

320-1

Caster

and

Camber

.

.

.

.

.

...........

.

....

320-5

TABLES

a

.

Front

Wheel

Alignment

Specifications

.

...

.......

320-6

b

.

Rear

Wheel

Alignment

Specifications

.

...

.......

320-6

Steering

wheel,

removing

and

installing

1

.

Center

steering

wheel

.

Make

sure

front

wheelsare

pointed

straight

ahead

.

2

.

Disconnect

negative

(-)

cable

from

battery

and

cover

terminal

with

insulating

material

.

CAUTION-

Prior

to

disconnectiog

the

battery,

read

the

battery

disconnection

cautions

given

at

the

front

of

this

manual

on

page

viii

.

STEERING

WHEEL

Page 291 of 759

Brake

rotor,

removing

and

installing

.

.

.

.

.

.

.

.

340-7

MASTER

CYLINDER

............

.

.

.

.

.

.

.340-7

Master

cylinder,

removing

and

installing

.

...

.

340-7

GENERAL

TROUBLESHOOTING

WARNING

-

"

Although

semi-metallic

and

metallic

Brake

friction

materials

in

Brake

pads

or

shoes

no

longer

con-

tain

asbestos,

they

produce

dangerous

dust

.

"

Brake

fluid

is

poisonous,

highly

corrosive

and

dangerous

to

the

environment

Wear

safety

glasses

and

rubber

gloves

when

working

with

Brake

fluid

.

Do

not

siphonBrake

fluid

with

your

mouth

.

Immediately

clean

away

any

fluid

spilled

on

painted

surfaces

and

wash

with

water,

asBrake

fluid

will

remove

paint

.

"

Always

use

new

Brake

fluid

froma

fresh,

un-

opened

container

.

Brake

fluid

will

absorb

mois-

ture

from

the

air

.

This

canlead

to

corrosion

problems

in

the

brakingsystem,

and

will

also

low-

er

the

Brake

fluid's

boiling

point

.

Dispose

of

Brake

fluid

properly

.

"

Do

notreuse

self-locking

nuts,bolts

or

fasteners

.

They

are

designed

to

be

used

only

once

and

may

failif

reused

.

Always

replace

them

with

new

self-

locking

fasteners

.

BMW

E36

models

areequipped

with

vacuum

power-assist-

ed

four-wheel

disc

brakes

with

an

integral

Antilock

Brake

Sys-

tem

(ABS)

.

Single-pistoncalipers

act

on

solid

or

vented

front

rotors

and

solid

rear

rotors

.

A

brake

pad

wear

sensor

for

each

axle

indicates

when

brake

padsneed

replacement

.

The

dual

drum-type

parking

brakesystem

is

integrated

with

the

rear

brake

rotors

.

NOTE-

M3

models

havevented

directional

Brake

rotors

on

the

rearaxle

as

well

ason

the

front

.

340

Brakes

BRAKES

340-1

GENERAL

.

.

.

.

.

.

.........

.

.

.

..........

340-1

BRAKE

BOOSTER

.........

.

.

.

.

.

...

.

.

.

.

340-8

TROUBLESHOOTING

.......

.

......

.

...

340-1

Brake

booster,

removing

and

installing

....

.

.

340-8

PARKING

BRAKE

.

.....

.

...

.

.

.

.....

.

.

.

340-10

BLEEDING

BRAKES

.

.

.

.

.

.

.

.

..........

340-3

Parking

brake,adjusting

.

.

.

.

.

.

.

.

.

.

.....

.

340-10

Pressure

bleeding

brakes

Parking

brake

shoes,

removing

and

installing

.

340-11(except

cars

with

AST)

.

.

.

.

.

.

.

.

.

...

.

.

.

.

.340-3

Parking

Brake

cable,

replacing

.

.

.

.

.

.

.

.

.

.

.

.

340-11

BRAKE

PADS,

CALIPERS,

ANTILOCK

BRAKE

SYSTEM

(ABS)

.

.

.

.340-11

AND

ROTORS

..........

.

.......

.

.

.

.

.

.

.

340-3

ABS

System

Inspection

.

...

.

.......

.

.

.

..

340-12

Brake

pads,

replacing

............

.

.

.

.

.

.

.

340-4

ABS

wheel

speed

sensors,

replacing

.

.

.

.

..

340-12

Brake

caliper,

removing

and

installing

.

..

..

.

340-6

TABLES

a

.

Brake

System

Troubleshooting

.....

...

.

.

.....

.340-2

b

.

Brake

Rotor

Reconditioning

Specifications

.

.....

.340-7

Brakeperformance

is

mainly

affected

by

three

things

:

the

leve¡

and

condition

of

the

brake

fluid,

the

system's

abilíty

to

create

and

maintain

hydraulic

pressure,

and

the

condition

of

the

friction

components

.

Air

in

the

Brake

fluid

will

make

the

Brake

pedal

feel

spongy

during

braking

or

will

increase

the

Brake

pedalforce

required

to

stop

.

Fluid

contaminated

by

moisture

or

dirt

can

corrode

the

system

.

Inspect

the

Brake

fluid

inside

the

reservoir

.

Ifit

is

dirty

or

murky,

or

is

over

a

year

old,

the

fluid

should

be

replaced

.

Visually

check

the

hydraulic

system

startingat

the

master

cylinder

.

To

check

the

function

of

the

master

cylinder

hold

the

brake

pedal

down

hard

with

the

engine

running

.

The

pedal

should

feelsolid

and

stay

solid

.

If

the

pedal

slowly

falls

to

the

floor,

either

the

master

cylinder

is

leaking

internally,

or

fluid

is

leaking

externally

.

If

no

leaks

canbe

found,

the

master

cylin-

der

is

faulty

and

should

be

replaced

.

Check

all

Brake

fluid

lines

and

couplings

for

leaks,

kinks,

chafing

and

corrosion

.

Check

the

Brake

booster

by

pumping

the

Brake

pedal

ap-

proximately

10

times

with

the

engine

off

.

Hold

the

pedal

down

and

start

the

engine

.

The

pedal

should

fa¡¡

slightly

.

If

not,

check

for

any

visiblefaults

before

suspecting

a

faulty

brake

booster

.

Check

for

strong

vacuum

at

the

vacuum

hose

fitting

at

the

booster,

and

check

the

non-retum

valve

for

one-way

flow

.

Worn

or

contaminated

brake

pads

will

cause

poor

braking

performance

.

Oil-contaminated

or

glazed

pads

will

cause

stopping

distances

to

increase

.

Inspect

the

rotors

for

glazing,

discoloration

and

scoring

.

Steering

wheel

vibration

while

braking

at

speed

is

often

caused

by

warped

rotors,

but

can

also

be

caused

byworn

suspension

components

.

TROUBLESHOOTING

Page 304 of 759

400-2

BODY-GENERAL

4-door

Sedan

Coupe

-

saas3

.7""

351

/

37

.3

O

I

x

`-193

267

o

oa

'3281

model

"M3

model

Convertible

BODYASSEMBLY

55

ass

.e

iss

""

-

66

.9

-

Fig

.

2

.

E36

body

dimensíons

.

BODY

ASSEMBLY

29

.4

29

4

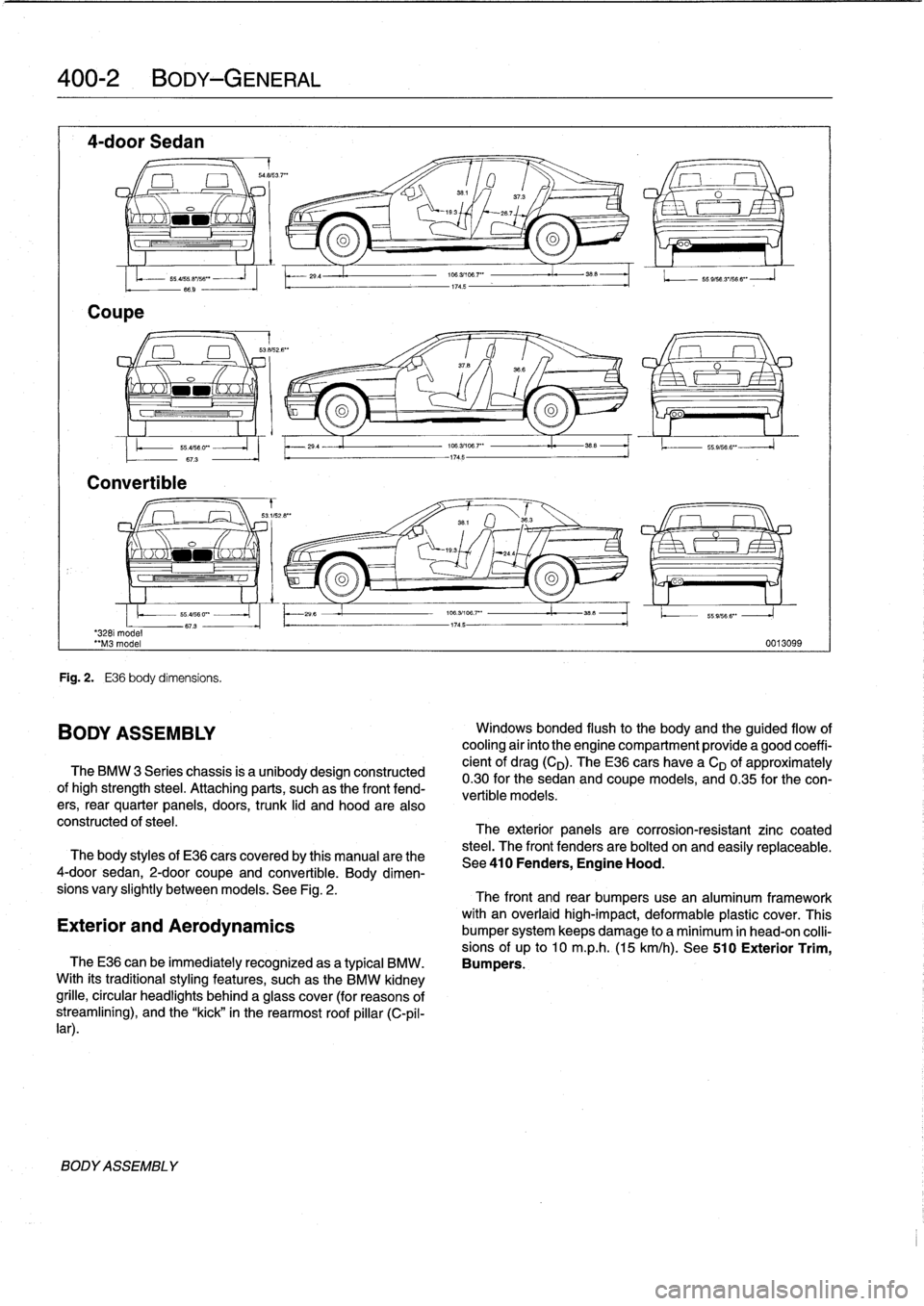

The

BMW

3

Series

chassis

is

a

unibodydesign

constructed

ofhigh

strength

steel

.

Attaching

parts,

suchas

the

front

fend-

ers,

rear

quarter

panels,

doors,

trunk

lid

and

hood

are

also

constructed

of

steel

.

706

.31108

.7"

I

38

.5

174

.5

174

.5

O

oo

196

.3/106

.7'

"

35_5

1.

.

55

.9,566

".

106

.3/196

.7""

i.

358

-1745-

55

9/56

3'/56

6"

-

J

0013099

Windows

bonded

flush

to

the

body

and

the

guided

flow

of

cooling

air

into

the

engine

compartment

provide

a

good

coeffi-

cient

of

drag(CD)

.

TheE36

cars

have

a

CD

of

approximately

0

.30for

the

sedan

and

coupe

models,

and

0

.35

for

the

con-

vertible

models

:

The

exterior

panels

are

corrosion-resistant

zinc

coated

steel

.

The

front

fenders

are

bolted

on

and

easily

replaceabie

.

The

body

styles

of

E36

cars

coveredby

this

manual

arethe

See410

Fenders,

Engine

Hood

.

4-door

sedan,

2-door

coupe

and

convertible

.

Body

dimen-

sions

vary

slightly

betweenmodels

.

See

Fig

.

2

.

The

front

and

rear

bumpers

use

an

aluminum

framework

with

an

overlaid

high-impact,

deformable

plastic

cover

.

This

Exterior

and

Aerodynamics

bumper

system

keeps

damage

to

a

minimum

in

head-on

colli-

sions

of

up

to

10

m

.p

.h

.

(15

km/h)

.

See

510

Exterior

Trim,

TheE36

can

be

immediatelyrecognized

asa

typical

BMW

.

Bumpers

.

With

its

traditionalstyling

features,

suchas

the

BMW

kidney

grille,

circular

headlights

behind

a

glass

cover

(for

reasons

of

streamliníng),

and

the

"kick"

in

the

rearmost

roof

pillar

(C-pil-

lar)

.

Page 309 of 759

GENERAL

This

repair

group

covers

replacement

of

the

front

fenders

and

removal

and

installation

of

the

engine

hood

.

NOTE-

The

body

is

painted

at

the

factoryafter

assembly

.

Re-

alignment

of

body

panels

may

expose

unpainted

metal

.

Paint

all

exposed

metal

once

the

work

fs

complete

.

FRONT

FENDERS

Front

fender,

removing

and

installing

1

.

Raise

hood

.

Raise

and

safely

support

front

of

vehicle

.

WARNING

-

"

When

raising

thecar

using

a

floor

jack

or

a

hy-

draulic

lift,

carefully

position

the

jack

pad

to

pre-

vent

damaging

thecar

body

.

A

suitable

liner

(wood,

rubber,

etc

.)

should

be

placed

between

the

jack

and

the

car

to

prevent

body

damage

.

"

Watch

the

jack

closely

.

Make

sure

it

stays

stable

and

does

not

shift

or

tilt

.

As

the

car

is

raised,

the

car

may

roll

slightly

and

the

jack

may

shift

.

2

.

Remove

front

wheel

.

Remove

inner

plastic

liner

from

wheel

well

.

3

.

Remove

front

bumper

.

See510

Exterior

Trim,

Bumpers

.

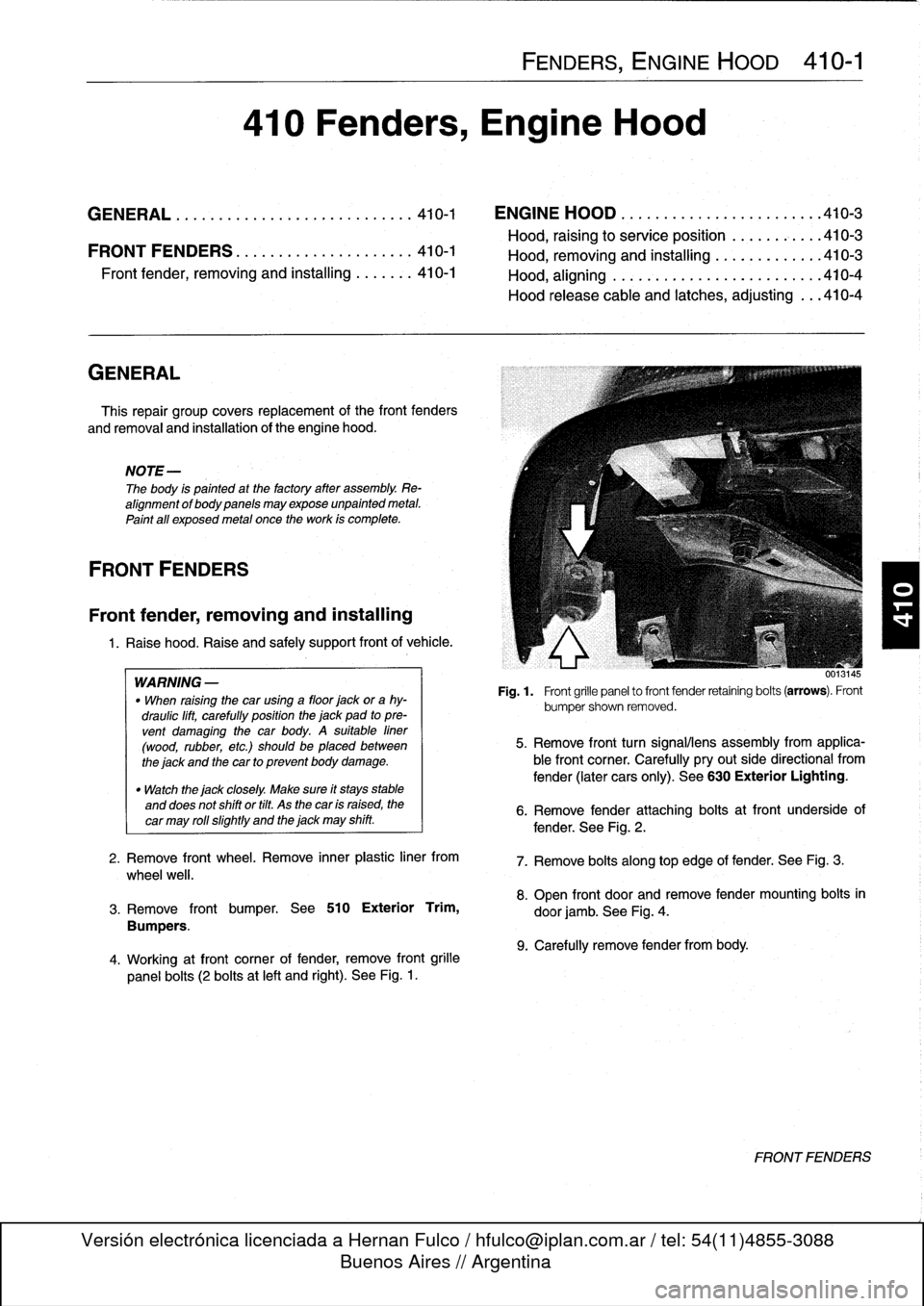

4

.

Working

atfront

corner

of

fender,

remove

front

grille

panel

bolts

(2

bolts

at

left

and

right)

.

See

Fig

.

1

.

FENDERS,

ENGINE

HOOD

410-1

410

Fenders,

Engine

Hood

GENERAL

...............

.

.

.

.

.

.

.

.

.

.

.

..

410-1

ENGINE

HOOD

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

...

.

.410-3

Hood,

raising

to

service

position

.

.

.

.

.

.

.

.

...

410-3

FRONTFENDERS

........

.

.

.

.

.

.

.

.

.

.

.

.

.410-1

Hood,

removin

and

installin

410-3

Front

Pender,

removing

and

installing

.

.

.

....

410-1

Hood,

aligning

...

.

.

.

.

.

.

.

.....

.

.

.

.

.

.

.

...

410-4

Hood

release

cable

and

latches,

adjusting

...

410-4

001

.145

Fig

.

1

.

Front

grille

panel

to

front

fender

retaining

bolts

(arrows)

.

Front

bumpershown

removed

.

5

.

Remove

front

turn

signalliens

assembly

from

applica-

ble

front

corner

.

Carefully

pryout

side

directional

from

fender

(later

cars

only)

.

See

630

Exterior

Lighting

.

6

.

Remove

fender

attaching

bolts

atfront

underside

of

fender

.

See

Fig

.

2

.

7

.

Remove

bolts

along

top

edge

of

fender

:

See

Fig

.

3

.

8

.

Open

front

door

and

remove

fender

mounting

bolts

in

door

jamb

.

See

Fig

.

4

.

9

.

Carefully

remove

fender

from

body

.

FRONTFENDERS

Page 315 of 759

GENERAL

This

repair

group

covers

front

and

rear

door

repair

informa-

tion,

including

removal

and

installationof

the

interior

doorpan-

els

.

DOORS

WARNING

-

Late

M3

moddis

havealuminum

doors

.

Use

extra

care

in

handling

aluminum

parts

in

order

to

avoid

damage

from

gouging

or

corrosión

.

NOTE-

"

For

information

on

the

power

door

windows

and

door

glass

replacement,

sea512Door

Windows

.

"

Forinformation

on

the

power

door

locking

system,

see

515

Central

Locking

and

Anti-Theft

.

WARNING

-

Some

1997

and

all

1998

cars

are

fitted

with

side-im-

pact

airbags

in

the

front

doors

.

When

servicing

doors

on

cars

with

front

side-impact

airbags,

always

dis-

connect

the

negative

(-)

battery

terminal

.

See

721

Airbag

System

(SRS)

for

cautions

and

procedures

relating

to

the

airbag

system

.

Front

orrear

door,

removing

and

installing

1

.

If

workingon

front

door

with

side-impact

airbag,

discon-

nect

negative

(-)

battery

cable

.

CAUTION

-

Prior

to

disconnectiog

the

battery,

read

the

battery

disconnection

cautions

given

at

the

front

of

this

manual

on

page

vüi

.

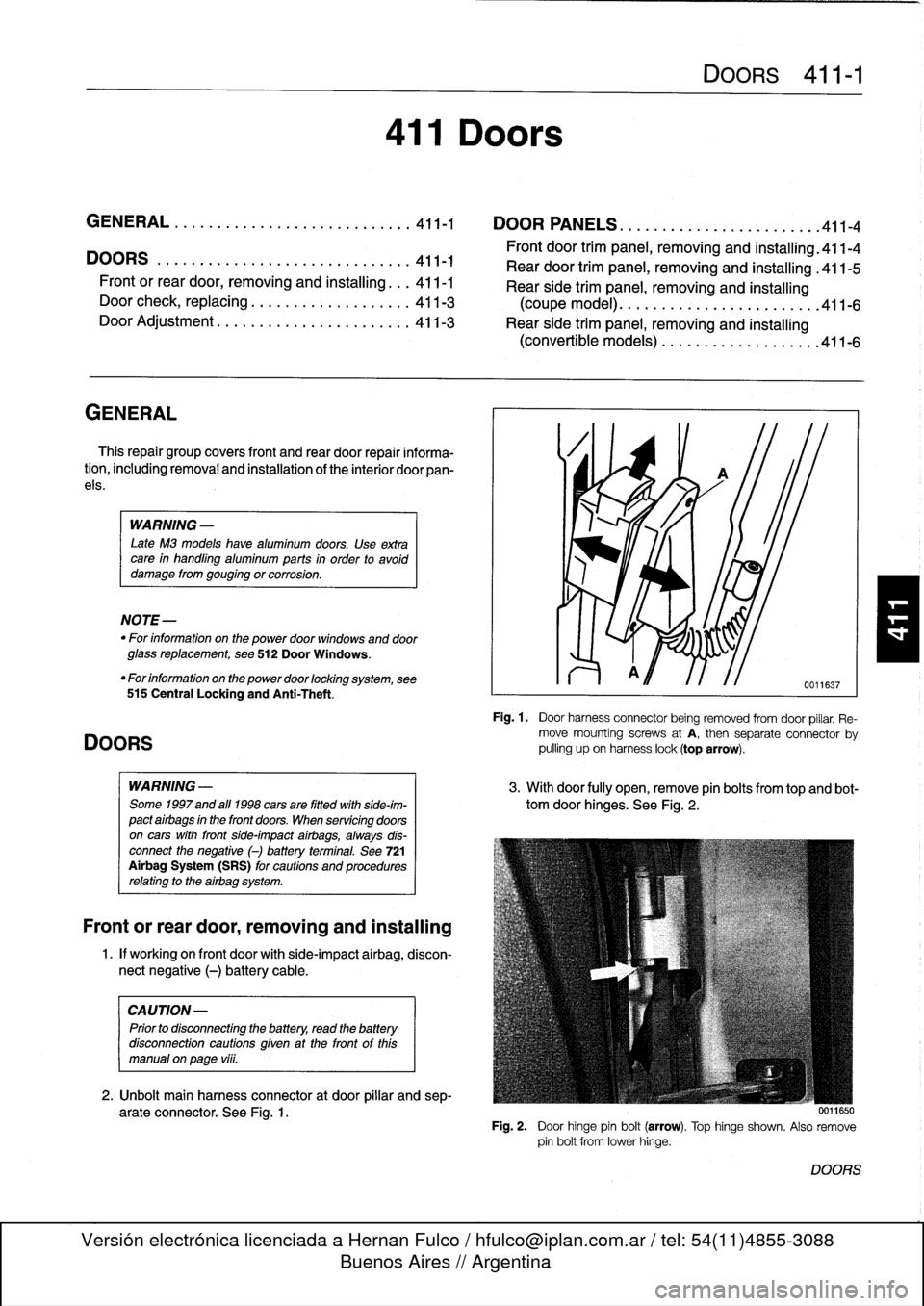

2

.

Unbolt

main

harness

connector

at

door

pillar

and

sep-

arate

connector

.

See

Fig

.

1

.

411

Doors

GENERAL

.............

.

.

.

.

.

.

.

.

.

.

.

.

.

..

411-1

DOOR

PANELS

.

.

.

.

.

.

.

...

.

.

.

.

.

.

.

.

.

...

.

.

411-4

Front

door

trim

panel,

removing

and

installing

.411-4

DOORS

..

.

.

.

.

.

.

.

.

.

...

.

.......

.

....

.

.

.

411-1

Rear

door

trim

panel,

removing

and

installing

.411-5

Front

or

reardoor,

removing

and

installing

..

.

411-1

Rear

side

trim

panel,

removing

and

installing

Door

check,

replacing

.

.

.

.

.

.

.

.

.

.

.

.

.......

411-3

(coupemodel)

.

.

.

.

.

.

....

.

.............

411-6

Door

Adjustment

.......

.

.

.

.

.

.

.

.

.

.

.

.....

411-3

Rear

side

trim

panel,

removing

and

installing

(convertible

models)

.

...

.

.

.

.

.

.

.

.

.

.

.

...

.

411-6

DOORS

411-1

Fig

.

1

.

Door

harness

connector

being

removed

fromdoor

pillar

.

Re-

move

mountingscrews

atA,

then

separate

connector

by

pulling

upon

harness

lock(top

arrow)

.

3

.

Withdoor

fully

open,

remove

pin

bolts

from

top

and

bot-

tom

door

hinges

.

See

Fig

.

2

.

0011650

Fig

.

2

.

Door

hinge

pin

bolt

(arrow)

.

Top

hinge

shown

.

Also

remove

pin

bolt

from

lowerhinge

.

DOORS

Page 321 of 759

GENERAL

This

repair

group

covers

trunk

lid

removal

and

installation

.

Also

inciuded

here

arereplacement

procedures

for

the

gas-

charged

support

struts

that

hold

the

trunk

lid

in

the

up

position

.

NOTE

-

The

body

ís

painted

at

the

factory

after

assembly

.

Re-

alignment

of

body

panels

may

expose

unpainted

metal

.

Paint

all

exposed

metal

once

the

work

is

complete

.

TRUNK

LID

Trunk

lid,

removing

and

installing

1

.

Raise

trunk

lid

.

Open

tool

kit

and

remove

screws

at-

taching

tool

kit

lo

trunk

lid

.

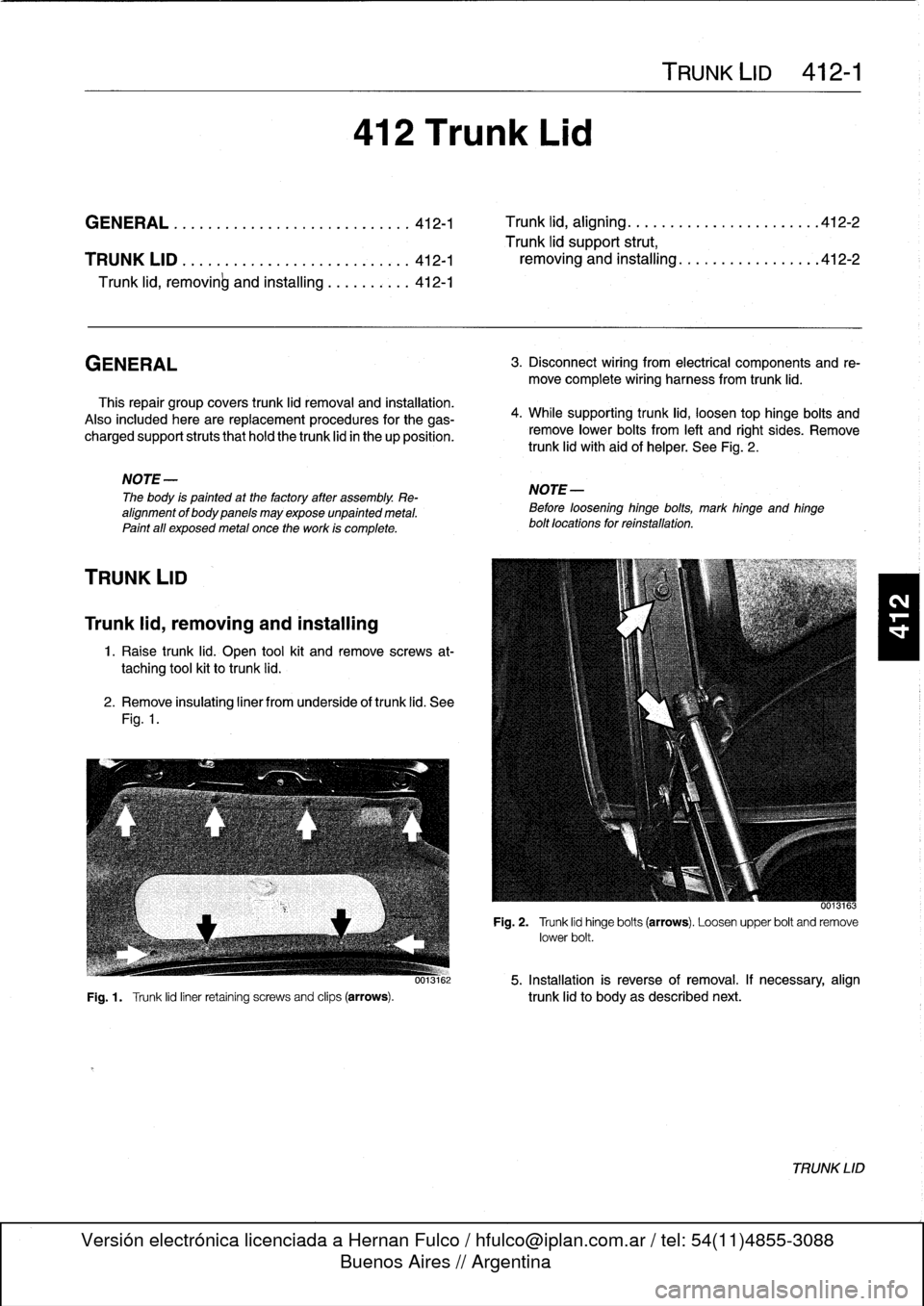

2

.

Remove

insulating

liner

from

underside

of

trunk

lid

.

See

Fig

.

1

.

412

Trunk

Lid

TRUNK

LID

412-1

GENERAL

............

.

...

.

.....

.

...

.

.

412-1

Trunk

lid,

aligning

.

.

.

.

.

.....

.

...

.

.

.

.

.

.

.

..

412-2

Trunk

lid

support

strut,

TRUNK

LID

.

.

.

............

.

.

.

...

.

.

.

.

.

.

412-1

removing

and

installing

..

.

.

.

.

.

.

.

.

.

...

.

.

.

412-2

Trunk

lid,

removinb

and

installing

......

.

.

.

.

412-1

3

.

Disconnect

wiring

from

electrical

components

and

re-

move

complete

wiring

harness

from

trunk

lid

.

4

.

While

supporting

trunk

lid,

loosen

top

hinge

bolts

and

remove

lower

bolts

from

left

and

right

sides

.

Remove

trunk

lid

with`aid

of

helper

.

See

Fig

.

2

.

NOTE-

Before

loosening

hinge

bolts,

mark

hinge

and

hinge

bolt

locations

for

reínstallation

.

0013163

Fig

.

2

.

Trunk

lid

hinge

bolts

(arrows)

.

Loosen

upper

bolt

and

remove

lower

bolt

.

0013162

5

.

Installation

is

reverse

of

removal

.

If

necessary,

align

Fig

.

1

.

Trunk

lid

liner

retaining

screws

and

clips

(arrows)

.

trunk

lid

to

body

as

described

next

.

TRUNK

LID