windshield BMW 318i 1995 E36 User Guide

[x] Cancel search | Manufacturer: BMW, Model Year: 1995, Model line: 318i, Model: BMW 318i 1995 E36Pages: 759

Page 311 of 759

ENGINE

HOOD

Hood,

raising

to

service

position

CA

UTION-

Do

not

switch

on

the

windshield

wipers

wlth

the

engine

hood

raised

.

As

a

precaution,

remove

the

wiper

motor

fuse

.

See

610

Electrical

Compo-

nent

Locations

.

1

.

4-door

models

:

Open

hood

fully

.

Remove

bolt

from

hood

hinge

behind

hood

supports

(left

and

right)

.

Raise

hood

to

service

position

.

See

Fig

.

5

.

2

.

2-door

models

:

Open

hood

fully

.

Fig

.

5

.

Hood

support

bracket

boltto

be

removed

(A)

on

4-door

cars

.

Remove

bolts

at

left

and

right

hinges

.

Swing

bracket

in

direc-

tion

of

arrow

to

raise

hood

into

service

position

.

"

Remove

ground

cable

atright

hood

hinge

.

"

Whilean

assistant

supports

hood,

detach

both

hood

supportsfrom

hood

.

"

Remove

detent

screws

at

back

of

hood

hinges

.

See

Fig

.

6

.

"

Lift

hood

while

pulling

hinge

forward

.

Support

hood

at

higher

position

.

3

.

When

service

work

is

complete,

return

hood

to

lower

position

and

instaf

screws

or

bolts

.

FENDERS,

ENGINE

HOOD

410-

3

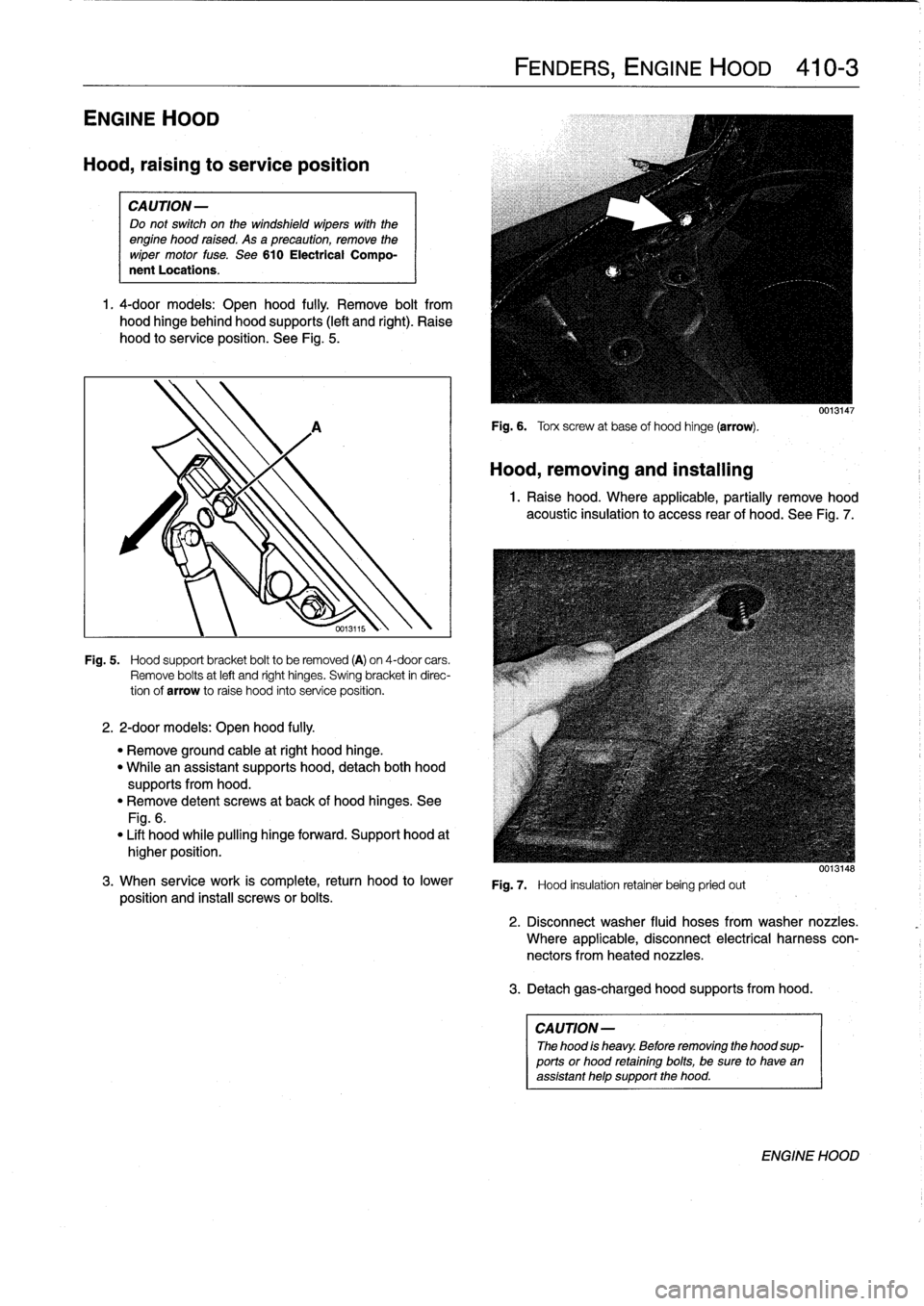

Fig

.

6

.

Torx

screw

at

base

of

hood

hinge

(arrow)

.

Hood,

removing

and

installing

0013147

1

.

Raise

hood

.

Where

applicable,

partially

remove

hood

acoustic

insulation

to

access

rear

of

hood

.

See

Fig

.

7

.

Fig

.

7

.

Hood

insulation

retainer

being

pried

out

3

.

Detachgas-charged

hood

supportsfrom

hood

.

CAUTION

-

The

hood

is

heavy

.

Before

removing

the

hood

sup-

ports

or

hood

retainingbolts,

be

sure

to

have

an

assistant

help

support

the

hood

.

0013148

2

.

Disconnect

washer

fluid

hoses

from

washer

nozzles

.

Where

applicable,

disconnect

electrical

harness

con-

nectors

fromheated

nozzles

.

ENGINE

HOOD

Page 331 of 759

GENERAL

......

.

........

.

.

.

.

.

.

.

...

.

.

.

512-1

WINDOW

SERVICE,

Front

door

window,

initializing

..

.

.........

.

512-1

2-DOOR

MODELS

.

...

.

......

.

........

.512-5

WINDOW

SERVICE,

Front

door

window,

removing

and

installing

(2-door

models)

.

.

...

.

...............

.

512-5

4-DOOR

MODELS

.

.

.

.

................

.

512-2

Front

door

window,

adjusting

Front

door

window,

removing

and

installing

(2-door

models)

.

.

.

.

.

.

.........

.

.

.

...

.512-7

(4-door

models)

.

.

.

.

.

...

.

.

.

.

.

.

.

.

.

.....

512-2

Rear

vent

window

or

vent

latch,

Front

door

window,

adjusting

replacing

(2-door

models)

....

.

.

.

.

.

.

.

...

512-11

(4-door

models)

.

.

.

.

.

...

.

...

.

.

.

.

.

.....

512-3

Rear

door

window,

removing

and

installing

WINDOW

REGULATOR

SERVICE

.

.

.

..

.512-12

(4-door

models)

.

.

.

.....

.

.

.

.

...

.

.

.....

512-4

Door

window

regulator

and

motor,

Rear

door

fixed

glass,

removing

and

installing

removing

and

installing

.

.

.

...

.

.

.

.

.

.

.

.

.

.

512-12

(4-door

models)

.

.

.

.

.

...

.

.

.

.

.

.

.

.

.

.....

512-4

GENERAL

Front

door

window,

initializing

This

heading

covers

door

glass,

window

regulator

and

pow-

er

window

motor

repair

information

.

Before

proceeding

with

window

repairs,

specifically

on

late

cars

fitted

with

front

side-

impact

airbags,

read

the

procedure

through

to

determine

the

scope

of

the

repair

.

The

bonded

windshield

and

rear

glass

are

replaced

using

special

adhesives

and

tools

.

It

is

recommended

that

bonded

glass

replacement

bedone

by

a

professional

glass

installer

.

WARNING

-

"

Always

wear

hand

and

eye

protection

when

workíng

with

broken

glass

.

"

ff

a

window

is

broken,

all

of

the

glass

bits

should

be

vacuumed

out

of

the

door

cavity

.

Use

a

blunt

screwdriver

to

clean

out

any

remaining

glass

pieces

from

the

window

guide

rails

.

CAUTION-

ff

battery

power

is

lost

or

the

battery

has

been

dis-

connected,

windows

mustbe

re-initialized

.

Both

one

touch

up/down

and

pinch-protection

will

be

in-

active

until

windows

are

re-initialized

.

Sea

below

.

512

Door

Windows

DOOR

WINDOWS

512-1

The

front

door

windows

incorporate

a

pinch-protection

fea-

ture

as

well

as

one-touch

up/down

(1994

and

later

models)

.

In

order

for

these

featuresto

work

correctly,

the

mechanical

stop

reference

point

must

be

re-initialized

after

repairs

are

carried

out

.

1

.

Closedoor

and

turn

ignition

keyon

.

Fully

open

front

window

.

2

.

Fully

close

front

window

.

4

.

Repeat

for

remaining

window

.

5

.

The

windows

should

now

be

initialized

and

the

anti-

pinch

and

one-touch

up/down

functions

should

be

en-

abled

.

GENERAL

Page 347 of 759

Dashboard,

removing

and

installing

1

.

Disconnect

negative

(-)

cable

from

battery

and

cover

terminal

with

insulating

material

.

CAUTION-

Prior

to

disconnectiog

the

battery,

read

the

battery

disconnection

cautionsgiven

at

the

front

of

this

manual

onpage

vi¡¡

.

2

.

Remove

center

console

as

described

earlier

.

3

.

Remove

glove

compartment

as

described

earlier

.

4

.

Remove

lower

left

dash

trim

piece

as

described

above

.

Remove

lower

right

dash

trim

panel

.

See

Fig

.

4

.

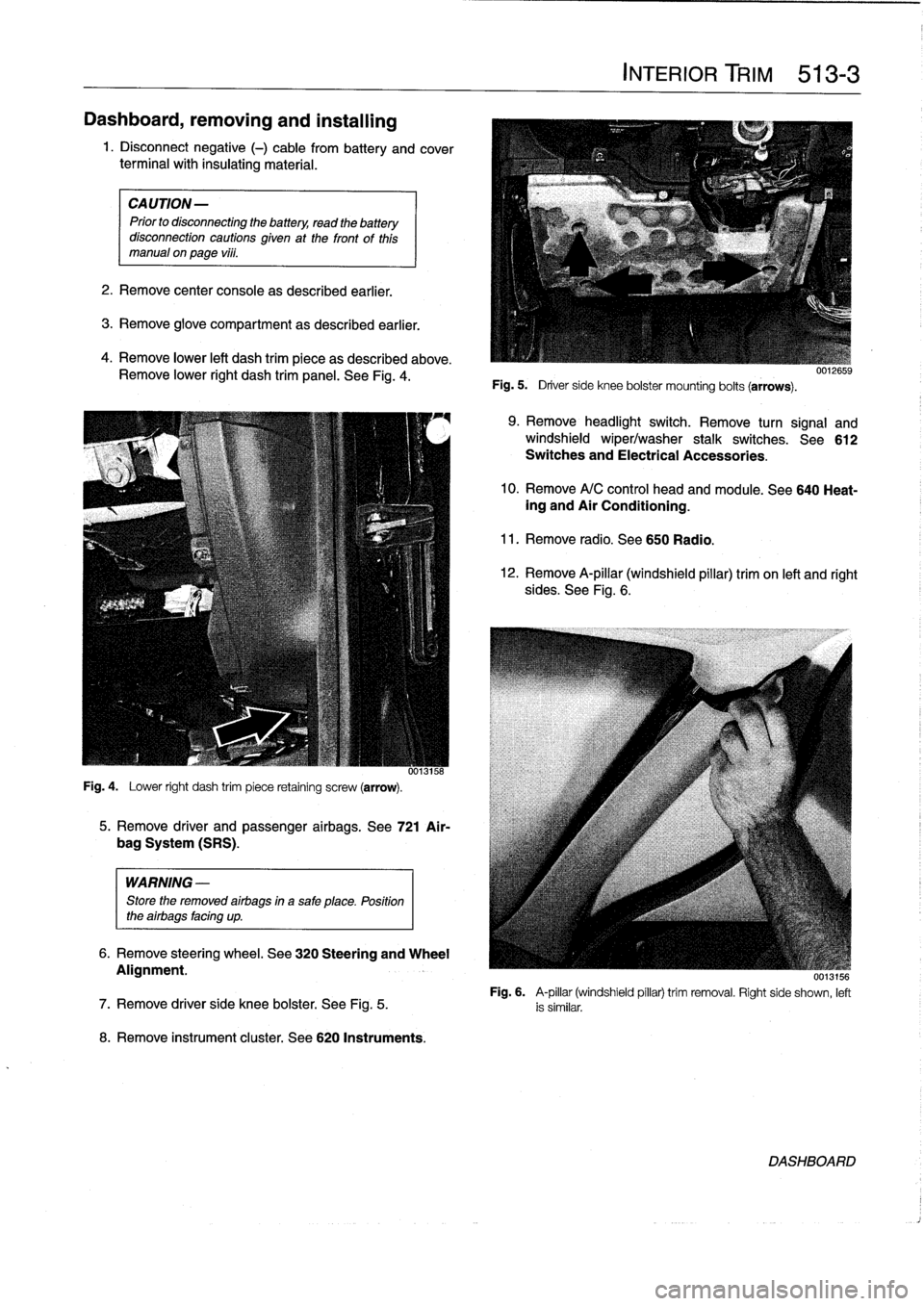

Fig

.

4

.

Lower

right

dash

trim

piece

retaining

screw

(arrow)

.

WARNING

-

Store

the

removed

airbags

in

a

safe

place

.

Position

the

airbags

facing

up

.

8

.

Remove

instrument

cluster

.

See

620

Instruments

.

5

.

Remove

driver

and

passenger

airbags

.

See

721

Air-

bag

System

(SRS)

.

6

.

Remove

steering

wheel

.

See

320

Steering

and

Wheel

Alignment

.

INTERIOR

TRIM

513-

3

Fig

.

5

.

Driver

side

knee

bolster

mounting

bolts

(arrows)

.

9

.

Remove

headlight

switch

.

Remove

turn

signal

and

windshield

wiper/washer

stalk

switches

.

See612

Switches

and

Electrical

Accessories

.

10

.

Remove

A/C

control

head

and

module

.

See

640

Heat-ing

and

Air

Conditioning

.

11

.

Remove

radio

.

See650

Radio

.

12

.

Remove

A-pillar

(windshield

pillar)

trim

on

left

and

right

sides

.

See

Fig

.

6

.

UU13156

Fig

.

6

.

A-pillar

(windshield

pillar)

trim

removal

.

Right

side

shown,

left

7

.

Remove

driver

side

knee

bolster

.

See

Fig

.

5

.

is

similar

.

DASHBOARD

Page 348 of 759

513-

4

INTERIOR

TRIM

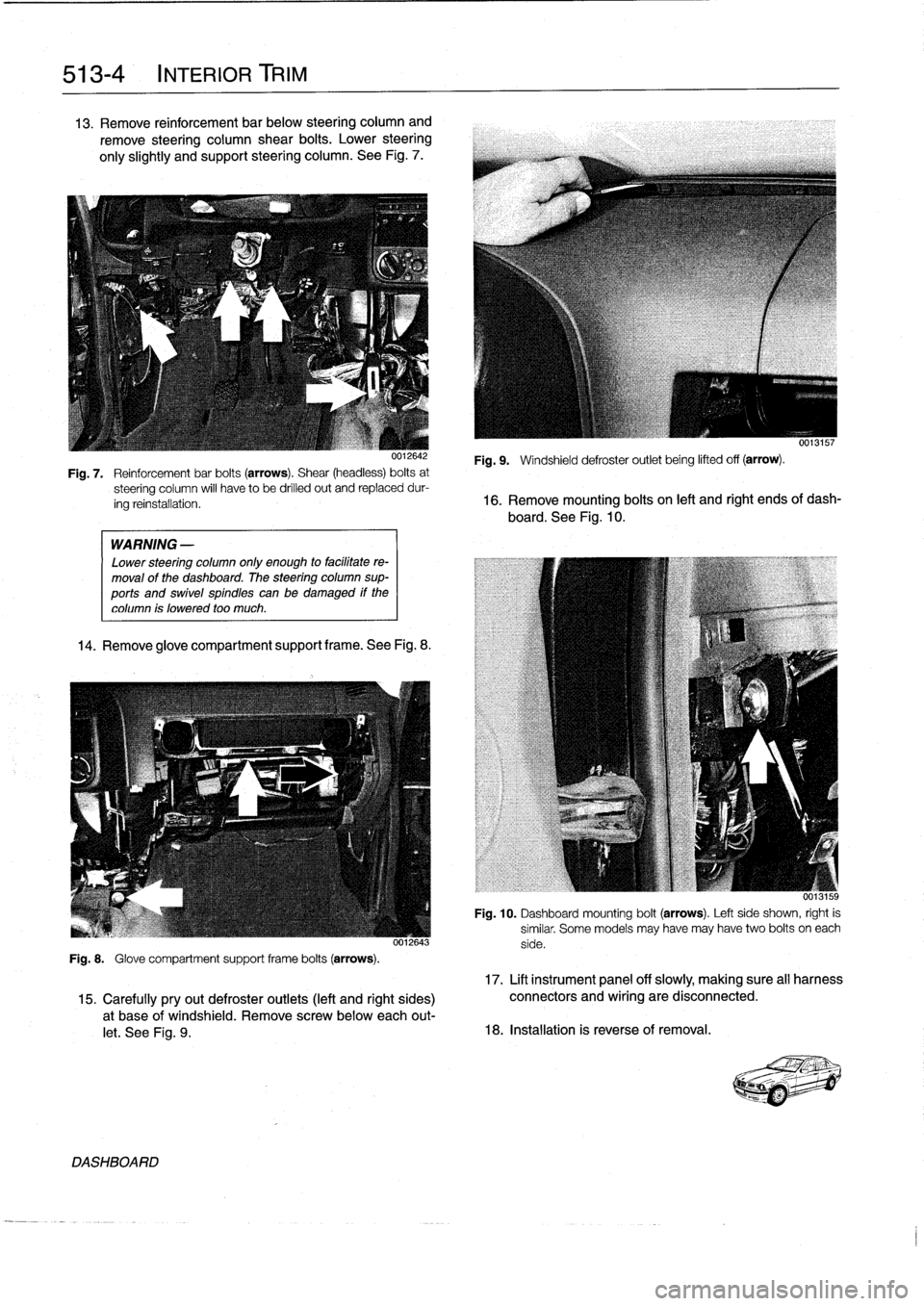

13

.

Remove

reinforcement

bar

below

steering

column

and

remove

steering

column

shear

bolts

.

Lower

steering

only

slightly

and

support

steering

column

.

See

Fig

.

7

.

WARNING

-

Lower

steering

column

only

enough

to

facilitate

re-

moval

of

the

dashboard

.

The

steering

column

sup-

ports

and

swivel

spindles

canbe

damaged

if

the

column

is

lowered

too

much

.

14

.

Remove

glove

compartment

support

frame

.See

Fig

.

8

.

0012643

Fig

.

8

.

Glove

compartment

support

frame

bolts

(arrows)

.

DASHBOARD

0013157

Fig

.

9

.

Windshield

defroster

outlet

being

lifted

off

(arrow)

.

Fig

.

7

.

Reinforcementbar

bolts

(arrows)

.

Shear

(headless)

bolts

at

steering

column

will

have

to

be

drilled

out

and

replaceddur-

ing

reinstallation

.

16

.

Remove

mounting

bolts

on

left

and

right

ends

of

dash-

board

.

See

Fig

.

10

.

Fig

.

10

.

Dashboard

mounting

bolt

(arrows)

.

Left

side

shown,

right

is

similar

.

Some

models

may

have

may

have

two

bolts

oneach

side

.

17

.

Lift

instrument

panel

off

slowly,

making

sure

all

harness

15

.

Carefullypryout

defroster

outlets

(left

and

right

sides)

connectors

and

wiring

are

disconnected

.

a

t

base

of

windshield

.

Remove

screwbelow

each

out-

let

.

See

Fig

.

9

.

18

.

Installation

is

reverse

of

removal

.

Page 371 of 759

GENERAL

.

...

.

.

.

......

.

.

.

.

.

.

.

.

.

......

541-1

Visor

Latch

Plate

.....

.

....

.

.

.

.

.

...

.

...

.541-4

Visor

Latch

..

.

............

.

.

.

..........

541-4

MANUAL

CONVERTIBLE

TOP

.

.

.

.

...

.

..

541-1

Visor

Latch

Motor

...

.......

.

.

.

..

........

541-5

Visor

Latch

Plate

.

.

......

.

.

.

...

.

.

.

.

.

.

.

..

541-1

Convertible

top

and

frame,

replacing

........

541-5

VisorLatch

.

.

.

.

.

.

.

.

..........

.

.....

.

.

.541-1

Convertible

top

drive

motor,

replacing

......

541-7

Convertible

Top

Lid

Release

Mechanism

.

.

.

.

541-2

Convertible

Top

Emergency

Operation

.....

.541-7

Convertible

top

and

frame,

replacing

....

.

.

.

541-2

Convertible

Top

Lid

.

.

.

.

...........

.

.....

541-9

POWER

CONVERTIBLE

TOP

.

.

.

.

....

.

.

.

541-2

ROLLOVER

PROTECTION

SYSTEM

..

.

.

541-9

FrontLatching

Mechanism

.

.

.

.

.

.

.

.

......

.

541-4

GENERAL

The

convertible

top

comes

in

three

versions

:

a

manually

op-erated

top,

a

semi-automatic

power

top

and

a

fully

automatic

power

top

.

NOTE-

The

convertible

top

control

module

(CVM)

is

located

behind

the

left

rearside

trim

panel

.

For

the

location

of

other

convertible

top

electric

components

see610

Electrical

Component

Locations

.

The

rear

window

in

the

convertible

models

is

made

of

a

strong,

flexible

vínyl

which

is

available

separately

.

Replace-

ment

of

the

rear

window

is

not

covered

in

this

manual

.

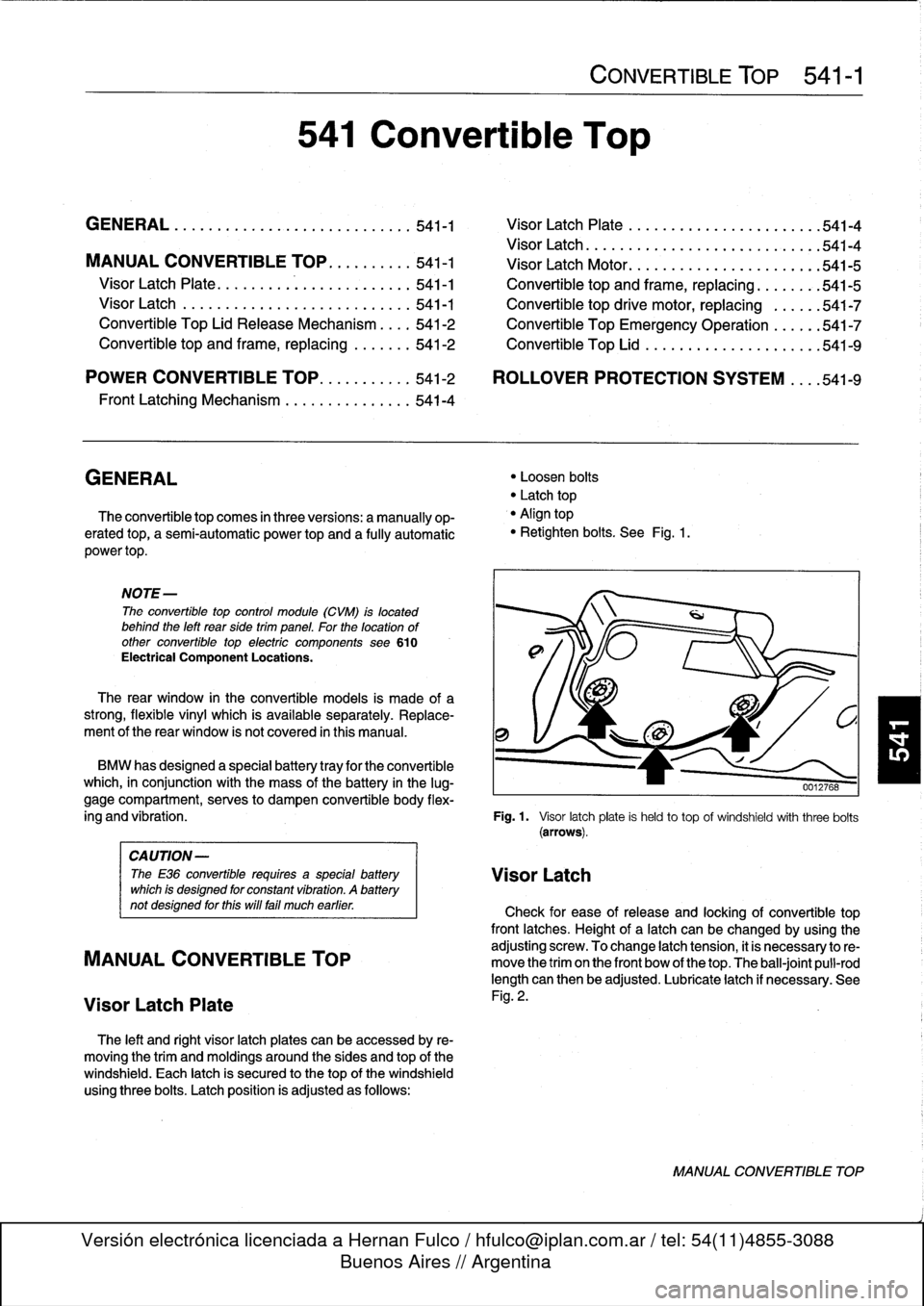

The

left

and

right

visor

latch

plates

can

be

accessed

by

re-

moving

the

trim

and

moldings

around

the

sides

and

top

of

the

windshield

.

Each

latch

is

secured

to

thetop

of

the

windshield

usingthree

bolts

.

Latch

position

is

adjusted

as

follows

:

541

Convertible

Top

CONVERTIBLE

TOP

541-1

"

Loosen

bolts

"

Latch

top

"

Align

top

"

Retighten

bolts

.

See

Fig

.

1

.

BMW

has

designed

a

specialbattery

tray

for

the

convertible

which,

in

conjunction

with

the

mass

of

the

battery

in

the

lug-

gage

compartment,

serves

to

dampen

convertible

body

flex

ing

and

vibration

.

Fig

.

1.

Visor

latchplate

is

held

to

top

of

windshieldwith

three

bolts

(arrows)

.

CAUTION-

The

E36

convertible

requires

a

specialbattery

VisorLatch

which

is

designed

for

constant

vibration

.

A

battery

not

designed

forthis

will

fa¡¡

much

earlier

.

Check

for

ease

of

release

and

locking

of

convertible

top

front

latches

.

Height

of

a

latch

can

be

changed

by

using

the

adjusting

screw

.

To

change

latch

tension,

it

is

necessary

to

re-

MANUAL

CONVERTIBLE

TOP

move

the

trim

on

the

front

bow

of

thetop

.

The

ball-joint

pull-rod

length

can

then

be

adjusted

.

Lubricate

latch

if

necessary

.

See

Visor

Latch

Plate

Fig

.

2

.

MANUAL

CONVERTIBLE

TOP

Page 374 of 759

541-

4

CONVERTIBLE

TOP

Folding

roof

Frontlatches

Convertible

topframe

i

Lower

mounting

pata

Horizontal

positioning

~~-

bolt

Manual

front

8

e

latch

1

handle

~

O

Visor

latchplata

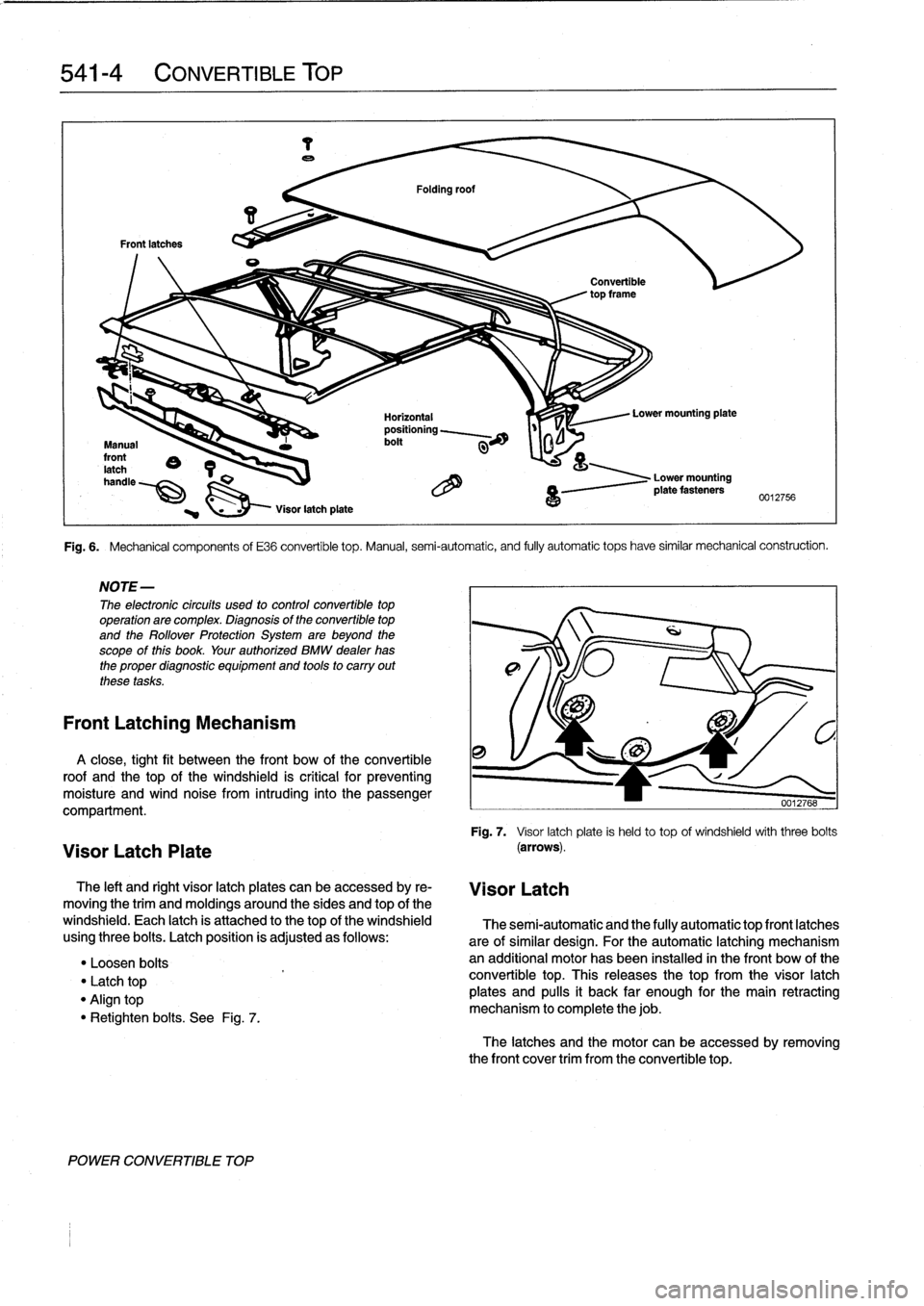

Fig

.

6

.

Mechanical

components

of

E36

convertible

top

.

Manual,

semi-automatic,

and

fully

automatic

tops

have

similar

mechanical

construction

.

NOTE-

The

electronic

circuits

used

to

controlconvertible

top

operation

arecomplex

.

Diagnosis

of

the

convertible

top

and

the

Rollover

Protection

System

are

beyond

the

scope

of

this

book

.

Your

authorized

BMW

dealer

has

the

proper

diagnostic

equipment

and

tools

to

carry

out

these

tasks

.

Front

Latching

Mechanism

A

close,

tight

fit

between

the

front

bow

of

the

convertible

roof

and

the

top

of

the

windshield

is

critical

for

preventing

moisture

and

wind

noise

from

intruding

into

the

passenger

compartment

.

Visor

Latch

Plate

The

left

and

right

visor

latch

plates

can

be

accessed

by

re-

moving

the

trim

and

moldings

aroundthe

sides

and

top

of

the

windshield

.

Each

latch

is

attached

to

thetop

of

the

windshield

using

three

bolts

.

Latch

position

is

adjusted

as

follows

:

"

Loosen

bolts

Latch

top

"

Align

top

"

Retighten

bolts

.

See

Fig

.

7

.

POWER

CONVERTIBLE

TOP

4

a

0012756

Visor

Latch

0012768

Fig

.

7

.

Visor

latchplate

is

heldto

top

of

windshieldwiththreebolts

(arrows)

.

The

semi-automatic

and

the

fully

automatic

top

front

latches

are

of

similar

design

.

For

the

automatic

latching

mechanism

an

additional

motor

has

been

installed

in

the

front

bow

of

the

convertible

top

.

This

releases

the

top

from

the

visor

latch

plates

and

pulís

it

back

far

enough

for

the

main

retracting

mechanism

to

complete

thejob

.

The

latches

and

the

motor

can

be

accessed

byremovingthe

front

cover

trim

from

the

convertible

top

.

Page 390 of 759

610-4

ELECTRICAL

COMPONENT

LOCATIONS

--J

L

Windshield

washertank

&

pump

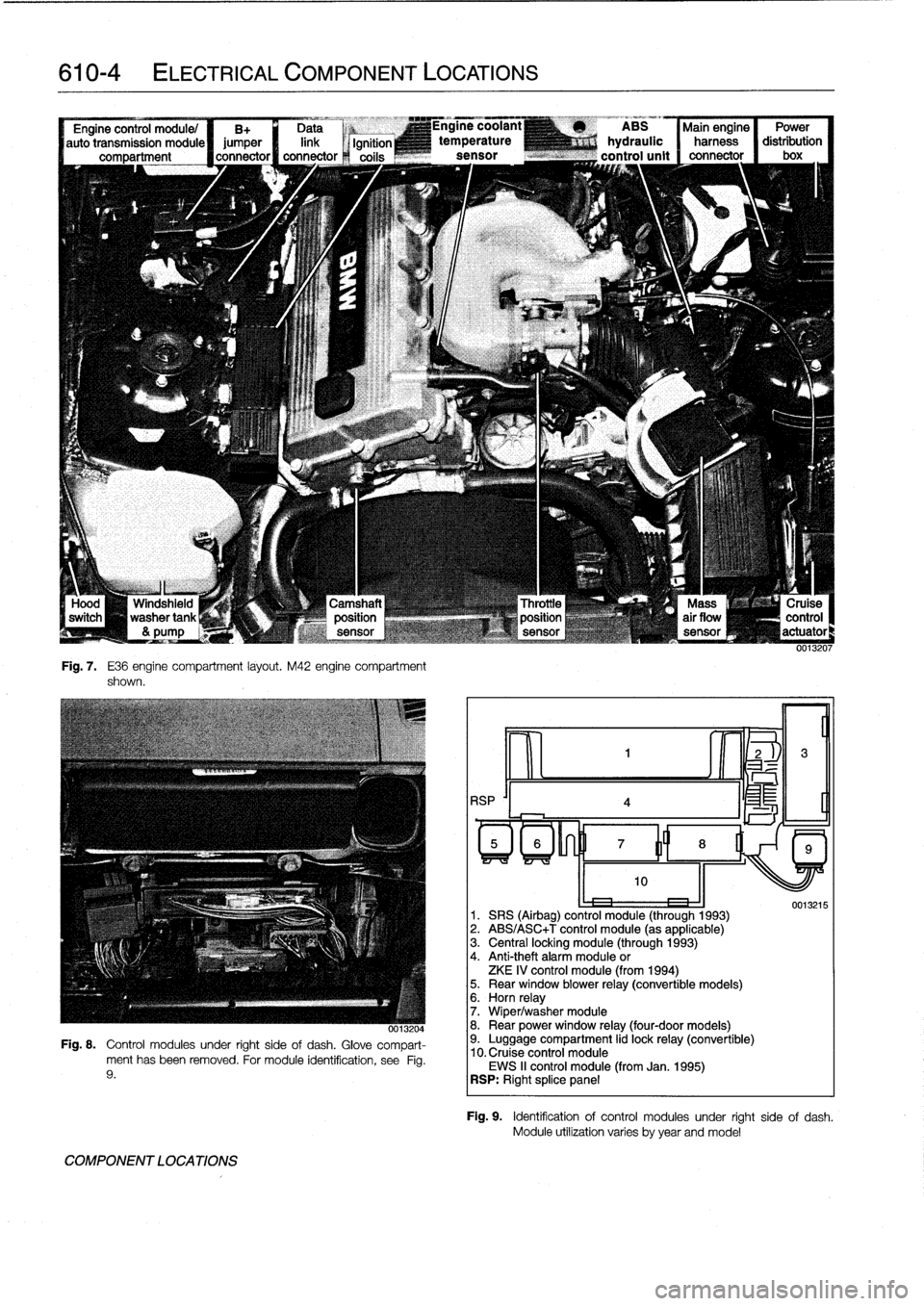

Fig

.

7

.

E36

engine

compartment

layout

.

M42

engine

compartment

shown

.

-,x

0013204

Fig

.

8

.

Control

modules

under

right

sideof

dash

.

Glove

compart-

ment

has

been

removed

.

For

module

identification,

see

Fig

.

9

.

COMPONENT

LOCATIONS

RSP

'I

4

ABS

Main

engine

Power

hydraulic

harness

distribution

control

unit

connector

I

box

oe

1

.

SRS

(Airbag)

control

module

(through

1993)

2

.

ABS/ASC+T

control

module

(as

applicable)

3

.

Central

locking

module

(through

1993)

4

.

Anti-theft

alarm

module

or

ZKE

IV

control

module

(from

1994)5

.

Rear

window

blower

relay

(convertible

models)6

.

Horn

relay

7

.

Wiper/washer

module

8

.

Rear

power

window

relay

(four-door

models)9

.

Luggage

compartment

lid

lock

relay

(convertible)

10

.

Cruise

control

module

EWS

II

control

module

(from

Jan

.

1995)

RSP

:

Right

splice

panel

0013215

Fig

.

9

.

Identificationof

control

modules

under

right

side

of

dash

.

Module

utilízation

varies

byyear

andmodel

Page 404 of 759

610-18

ELECTRICAL

COMPONENT

LOCATIONS

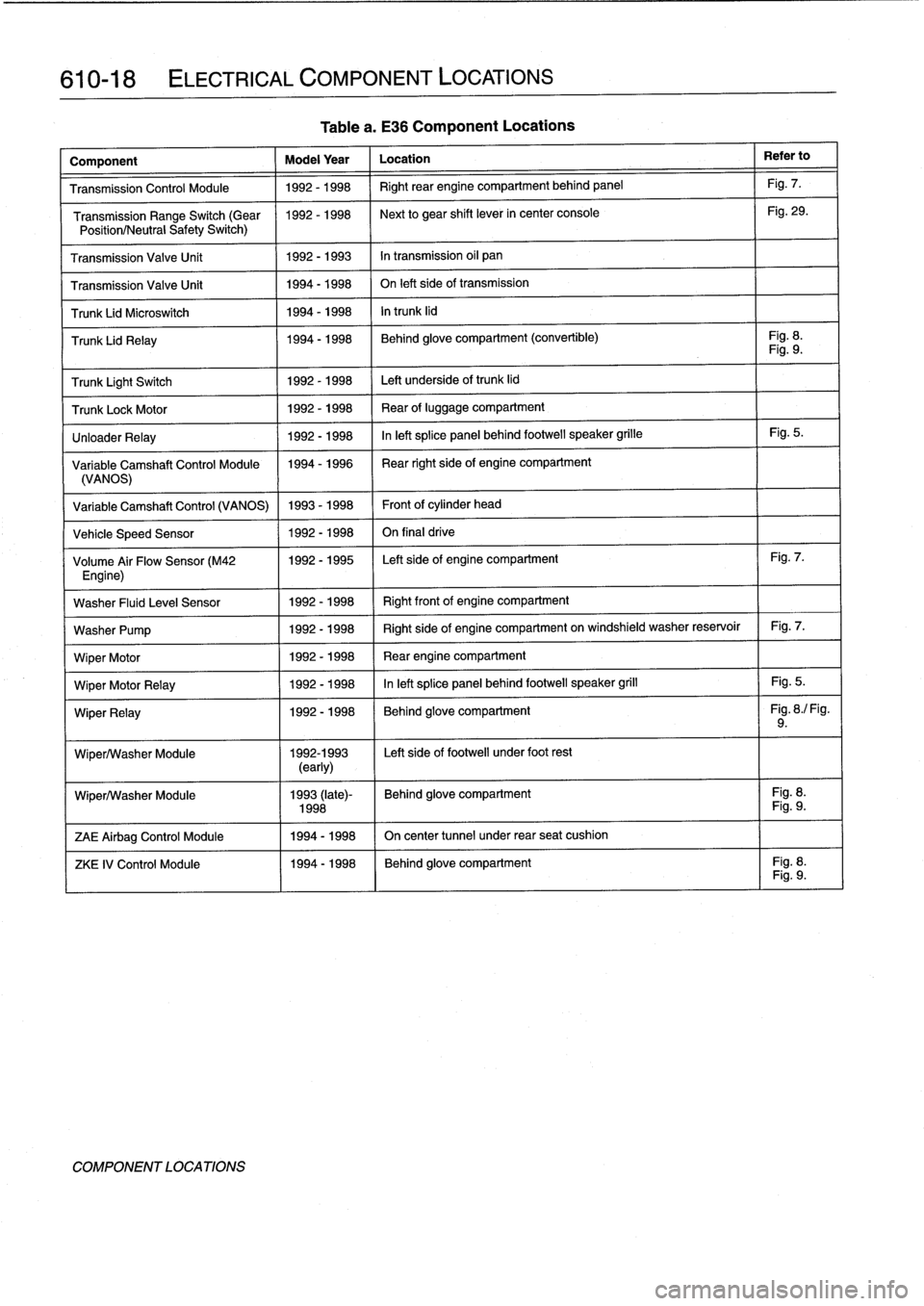

Tablea

.

E36

Component

Locations

Component

Model

Year

Location

Refer

to

Transmission

Control

Module

1992-1998

Right

rear

engine

compartment

behíndpanel

Fig

.

7

.

Transmission

Range

Switch

(Gear

1992-1998

Next

to

gear

shift

lever

in

center

console

Fig

.

29

.

Position/Neutra

l

Safety

Switch)

Transmission

Valve

Unít

1992-1993

In

transmission

oil

pan

Transmission

Valve

Unit

1994-1998

On

left

side

of

transmission

Trunk

Lid

Microswitch

1994-1998

In

trunk

lid

Trunk

Lid

Relay

1994-1998

Behind

glove

compartment

(convertible)

Fig

.

8

.

Fig

.

9

.

Trunk

Light

Switch

1992-1998

Left

underside

of

trunk

lid

TrunkLockMotor

1992-1998

Rear

of

luggage

compartment

UnloaderRelay

1992-1998

Inleft

splice

panel

behind

footwell

speaker

grille

Fig

.

5

.

Variable

Camshaft

Control

Module

1994-1996

I

Rear

right

side

of

engine

compartment

(VANOS)

Variable

Camshaft

Control

(VANOS)

1993-1998

Front

ofcylinder

head

Veh¡cle

Speed

Sensor

1992-1998

On

final

drive

Volume

Air

Flow

Sensor

(M42

1992-1995

Left

side

of

engine

compartment

Fig

.

7

.

Engine)

Washer

Fluid

Leve¡

Sensor

1992-1998

Right

frontof

engine

compartment

Washer

Pump

1992-1998

Right

side

of

engine

compartment

on

windshield

washer

reservoir

Fig

.

7

.

Wiper

Motor

1992-1998

Rear

engine

compartment

Wiper

Motor

Relay

1992-1998

Inleft

splice

panel

behind

footwell

speaker

grill

Fig

.

5

.

Wiper

Relay

1992-1998

(

Behind

glove

compartment

I

Fig

.

8

./

Fig

.

9

.

Wiper/Washer

Module

1992-1993

Left

side

of

footwell

under

foot

rest

(early)

Wiper/Washer

Module

1993

(late)-

Behind

glove

compartment

Fig

.

8

.

1998

1

Fig

.

9

.

ZAE

Airbag

Control

Module

1

1994-1998

1

On

center

tunnel

under

rear

seat

cushion

ZKE

IV

Control

Module

1994-1998

I

Behind

glove

compartment

Fig

.

8

.I

Fig

.

9

.

COMPONENT

LOCATIONS

Page 419 of 759

611

Wipers

and

Washers

GENERAL

..

.

.

.

.

.

.

.

.

.

.

.

.

.

.....

.

......

.

611-1

Windshield

wiper

motor,

removing

and

installing

.

...............

.611-8

WIPER

BLADES

.

.

.

.....

.

.

.

.

.

.

...

....

.611-1

Wiper

Blade

Cleaning

Problems

.

.

.

.

.

.

.....

611-1

Wiper

blades,replacing

...

.

.

.

.

.

.

.

.

.

.....

611-1

Wiper

blade

inserts,

replacing

.

.

.

.

.

.

.

.

.....

611-2

Wiper

arms,

removing

and

installing

.

.

.

.....

611-2

WINDSHIELD

WIPER

ASSEMBLY

.

.

.....

611-3

Windshield

wiper

assembly,

removing

and

installing

(4-door

models)

.

.

.

.

.

.

.....

611-3

Windshield

wiper

assembly,

removing

and

installing

(2-door

models)

.

.

.

.

.

.

.....

611-5

GENERAL

This

repair

group

covers

windshield

wiper

and

washer

sys-

tem

repair

information

.

Please

note

that

some

procedures

are

different

for

2-

and

4-door

models

.

The

windshield

wiper/washer

stalk

switch

assembly

is

cov-

ered

in

612

Switches

and

Electrical

Accessories

.

Electrical

NOTE-

wiring

diagrams

and

relays

for

the

wiper/washer

system

are

BMwhas

available

a

special

toollgauge

(BMWspecial

covered

in

Electrical

Wiring

Diagrams

.

tool

no

.

00

9210)

to

align

the

angle

of

the

wiper

arm

to

the

windshield

glass

.

WIPERBLADES

CA

UTION-

Never

turn

on

the

wiper

blades

while

the

hood

is

open

.

Damage

to

the

wiper

system

and

hood

may

occur

.

Toensure

safetyduring

wiper

biade

system

procedures,

remove

the

windshieldwiper

fuse

.

See

610

Electrical

Component

Locations

.

Wiper

Blade

Cleaning

Problems

Common

cleaning

problems

with

thewipers

includestreak-

ing

or

sheeting,

waterdrops

after

wiping,

and

blade

chatter

.

Streaking

is

usually

caused

when

wiper

blades

are

coated

with

road

film

or

car

wash

wax

.

Clean

the

blades

using

soapy

water

.

If

cleaning

does

not

cure

the

problem,

the

blades

should

be

replaced

.

BMW

recommends

replacing

the

wiper

blades

twice

a

year,

before

and

after

the

cold

season

.

WIPERS

AND

WASHERS

611-1

WINDSHIELD

CLEANING

SYSTEM

......

611-9

Windshield

spray

nozzle,

removing

and

installing

.......

.

........

.611-9

Washer

fluid

reservoir,

replacing

.........

.611-9

Windshield

washer

fluid

pump,

replacing

..

.

......

.

........

.611-9

Washer

fluid

level

sensor,

replacing

(models

with

check

control)

.

.

.

.

........

611-10

Wiper

blade

chatter

may

be

caused

by

dirty

or

worn

blades,

or

by

wiper

arms

that

areout

of

alignment

.

Clean

the

blades

and

windshield

as

described

above

.

Adjust

the

wiper

arm

so

that

there

is

even

pressure

along

the

blade,

and

so

that

the

blade

at

rest

is

perpendicular

to

the

windshield

.

If

problems

persist,

theblades

and

wiper

arms

should

be

replaced

.

The

wiper

blades

can

be

renewed

in

one

of

two

ways

:

either

by

replacing

the

complete

blade

or

by

replacing

just

therubber

insert

.

Insert

replacement

is

the

mosteconomicalmethod,

al-

though

overtime

the

wiperblade

itselfwill

become

worn

.

One

ruleof

thumb

wouldbe

to

replace

just

the

inserts

every

second

time

.

Wiper

blades,

replacing

1

.

Pivot

wiper

arm

off

windshield

.

2

.

Position

wiperblade

approximately

perpendicular

to

wiper

arm

.

3

.

Remove

wiperblade

from

wiper

arm

by

depressing

re-

taining

tab

and

sliding

blade

out

of

arm

.

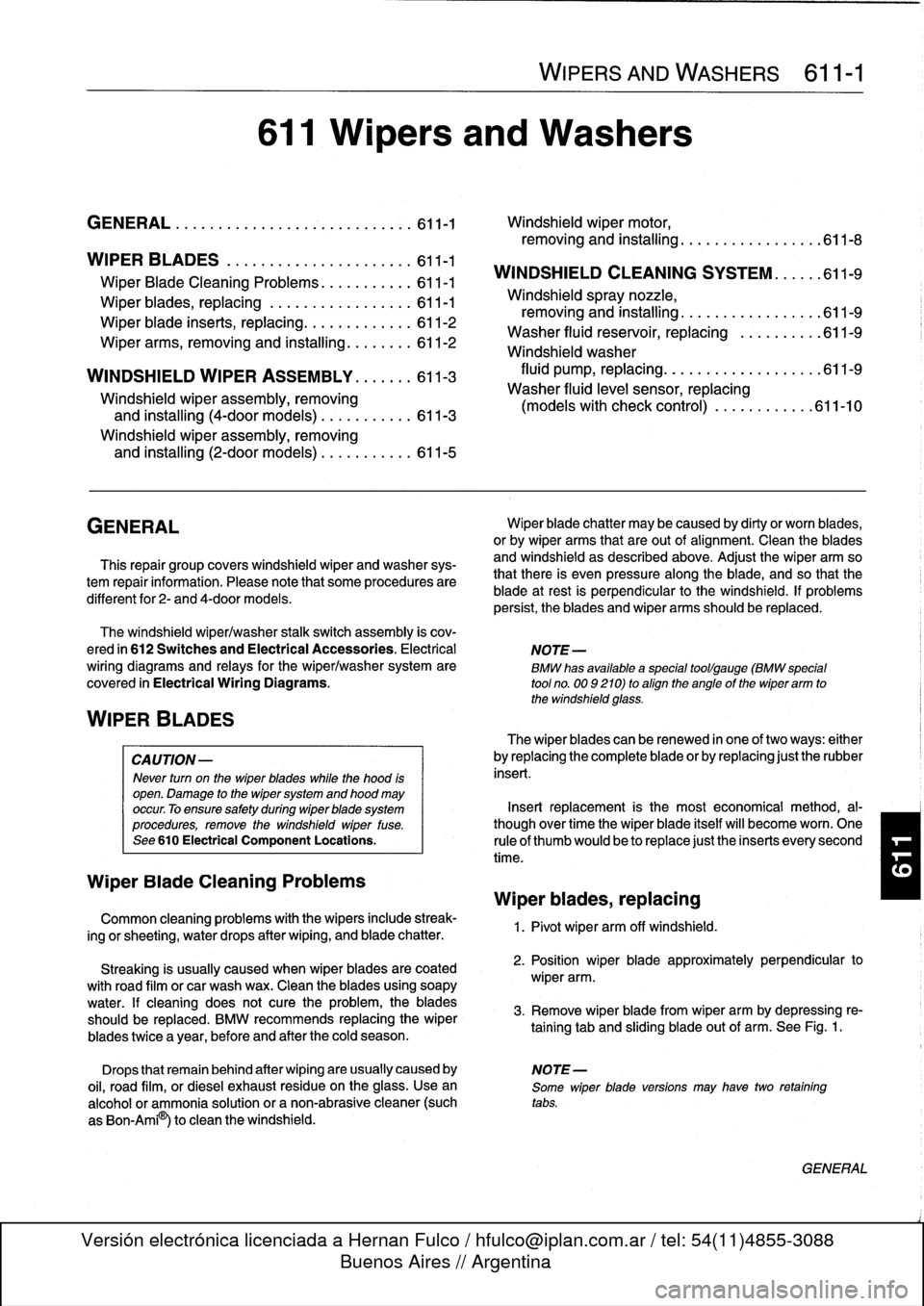

See

Fig

.

1

.

Drops

that

remain

behind

after

wiping

are

usually

caused

by

NOTE-

oil,

road

film,

or

diesel

exhaust

residue

onthe

glass

.

Use

an

Some

wiperblade

versions

may

havetwo

retaining

alcohol

or

ammonia

solution

or

a

non-abrasive

cleaner

(such

tabs

.

a

s

Bon-Ami

to

clean

the

windshield

.

GENERAL

Page 420 of 759

611-2

WIPERS

AND

WASHERS

5

.

Slide

new

insert

through

wiperblade

guides

.

Lock

in-

sert

m

place

at

end

gudes

.

.,

\

-

-

--

,

1

Wiper

arms,

removing

and

installing

Fig

.

1

.

Windshield

wiper

biade

retaining

tab

.

Press

in

on

tab

(arrow)

to

release

bfade

from

arm

.

4

.

Installation

is

reverse

of

removal

.

Instan

wiperblade

to

wiper

arm

until

retaining

tab

can

be

heard

toclickinto

position

.

Wiper

biade

inserts,

replacing

1

.

Remove

wiper

blade

as

described

earlier

.

2

.

Unhook

end

of

wiper

blade

insert

fromwiper

arm

guides

.

See

Fig

.

2

.

0011784

Fig

.

2

.

Unhook

wiperbiade

insert

from

wiper

arm

guide

.

If

necessary,

guide

slightly

usingneed1e

nose

pliers

.

3

.

Pull

old

insert

fromwiper

arm

guides,

noting

installation

position

.

4

.

Remove

metal

support

strips

from

old

insert

and

instan

intoslots

in

new

insert,

noting

installation

direction

of

cutouts

in

support

strips

.

GENERAL

NOTE

-

The

notched

cutouts

in

the

retaining

strips

should

en-

gage

the

molded

notches

in

the

inserts

.

NOTE-

On

2-door

models

it

may

be

necessary

to

raise

the

hood

to

the

service

position

.

See

410

Fenders,

Engine

Hood

.

CAUTION-

"

Use

fender

cover

to

protect

windshield

.

"

Remove

windshield

wiper

fuse

to

prevent

acci-

dents

.

1.

With

engine

hood

in

closed

position,

remove

both

wiper

blades

.

2

.

Open

hood

.

Remove

cap

covering

wiper

arm

retaining

nutsby

inserting

anarrow

screwdriver

biade

in

slot

be-

low

capand

prying

upward

.

NOTE

-

Marking

position

of

wiper

arm

on

shaft

will

aid

installa-tion

.

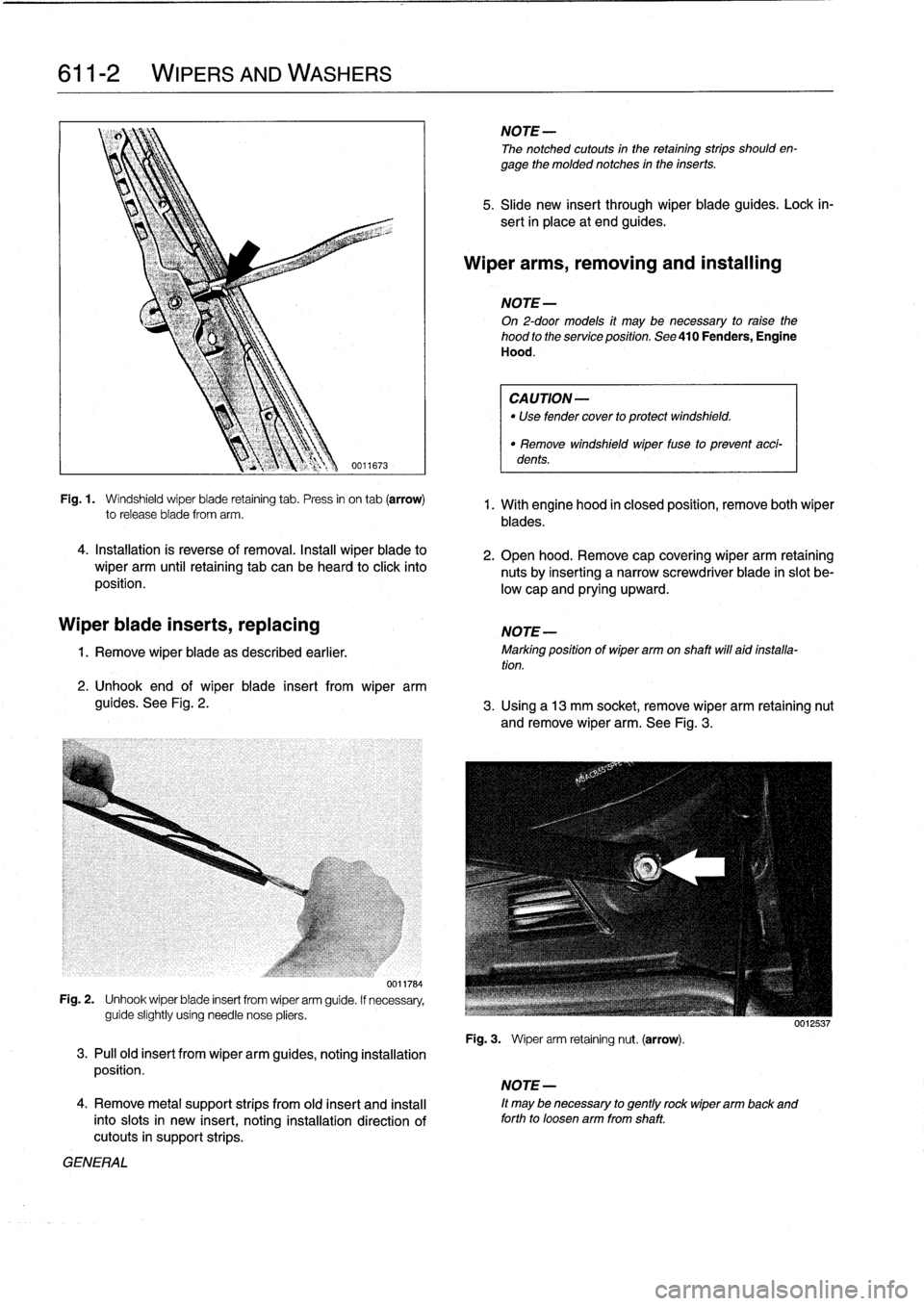

3

.

Using

a13

mm

socket,

remove

wiper

arm

retaining

nut

andremove

wiper

arm

.

See

Fig

.

3

.

Fig

.

3

.

Wiper

arm

retaining

nut

.

(arrow)

.

,

NOTE

-

ft

may

benecessary

to

gently

rock

wiper

arm

back

and

forth

to

loosen

arm

from

shaft

.