wiring BMW 318i 1995 E36 User Guide

[x] Cancel search | Manufacturer: BMW, Model Year: 1995, Model line: 318i, Model: BMW 318i 1995 E36Pages: 759

Page 61 of 759

14

.

Unbolt

power

steering

fluid

reservoir

from

íts

mounting

bracket

.

Use

stiff

wire

to

hang

reservoir

to

one

side

.

Do

not

disconnect

fluid

lines

.

15

.

Remove

power

steering

pump

drive

belt

and

remove

pump

from

its

mounting

bracket

.

Use

stiff

wire

to

hang

pump

from

body

.

16

.

On

cars

with

automatic

transmission

remove

front

and

rear

brackets

holding

automatic

transmission

cooler

linesto

engine

.

17

.

Remove

A/C

compressor

from

its

mounting

bracket

without

disconnecting

any

refrigerantlines

.

See

Fig

.

5

.

ENGINE

REMOVAL

AND

INSTALLATION

110-

3

21

.

Remove

front

exhaust

pipefrom

exhaust

manifold

.

See

Fig

.

6

.

22

.

Install

an

engine

lifting

device

and

raise

engine

until

its

weight

is

supported

.

Remove

nuts

and

ground

strap

from

left

and

right

engine

mounts

.

0011967

Fig

.

6

.

Front

exhaustpipe

to

exhaust

mounting

nuts

(arrows),

as

viewed

from

below

on

4-cylinder

engine

.

23

.

Carefully

raíse

engine

out

of

car,

checking

for

any

wir-

ing

harnesses,

fuel

lines,

or

mechanical

parts

that

might

become

snagged

as

engine

is

removed

.

24

.

Installation

is

reverse

of

removal,

noting

the

following

:

"

Replace

all

gaskets,

O-rings

and

seals

.

"

Change

engine

oil

and

filter

and

check

al¡

other

fluid

levels

.

See020

Maintenance

Program

.

"

Refill

and

bleed

cooling

system

.

See

170

Radiator

and

Cooling

System

.

"

Insta¡¡

the

front

exhaust

pipes

using

new

gaskets

and

self-locking

nuts

.

Use

copper

pasteon

threads

.

See

180

Exhaust

System

.

Tightening

Torques

"

Coolant

drain

plug

to

cylinder

block

.

25

Nm

(18

ft-Ib)

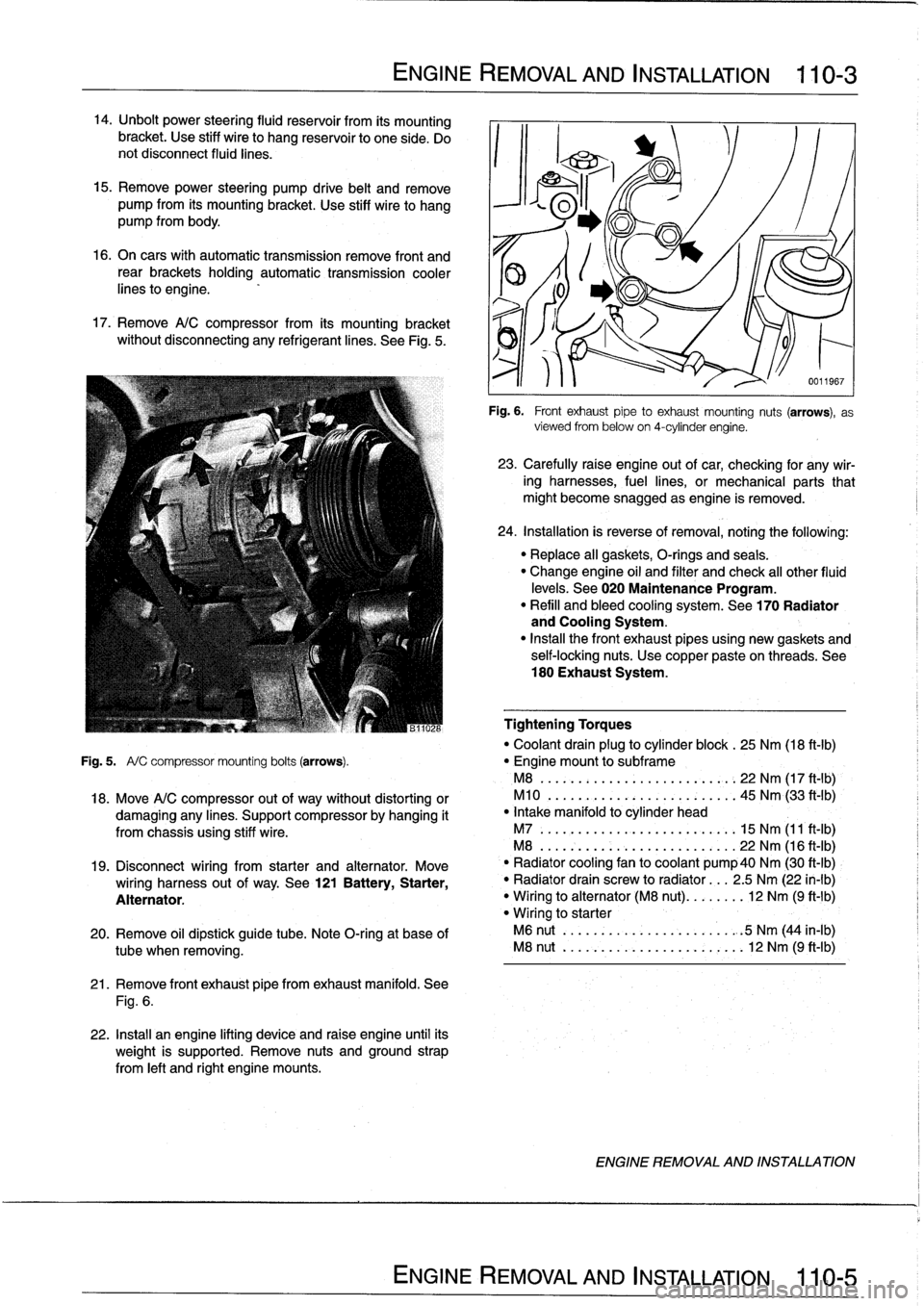

Fig

.

5

.

A/

C

compressor

mounting

bolts

(arrows)

.

"

Engine

mount

to

subframe

M8

......:...

..

..

..

......,:..

22

Nm

(17

ft

-

1b)

,

18

.

Move

A/C

compressor

out

of

way

without

distorting

or

M10

.

...

.

..

...

.

.

...........

45

Nm

(33

ft'-Ib)

damaging

any

lines

.

Support

compressor

by

hanging

it

"

Intake

manifold

to

cylinder

head

from

chassis

using

stiff

wire

.

M7

.....

.

..

...

..

..

...........

15

Nm

(11

ft-Ib)

M8

...

.

.

.

..

..

...

..

...........

22

Nm

(16

ft-Ib)

19

.

Disconnect

wiring

from

starter

and

alternator

.

Move

`

"

Radiator

cooling

fan

to

coolant

pump40

Nm

(30

ft-Ib)

wiring

harness

out

of

way

.

See

121

Battery,

Starter,

"

Radiator

drain

screw

to

radiator

...

2

.5

Nm

(22

in-lb)

Alternator

.

"

Wiring

to

alternator

(M8

nut)

........

12

Nm

(9

ft-1b)

"

Wiring

to

starter

20

.

Remove

oil

dipstick

guide

tube

.

Note

O-ring

at

base

of

M6

nut

..

.

..

..

...

..

...........

.

:5

Nm

(44

in-lb)

tube

when

removing

.

M8

nut

..

.

..

..

...

..

............

12

Nm

(9

ft-Ib)

ENGINE

REMOVAL

AND

INSTALLATION

Page 65 of 759

22

.

Move

A/C

compressor

out

of

the

way

without

distorting

26

.

Carefully

raise

engine

out

ofcar,

checking

for

any

wir-

or

damaging

any

lines

.

Support

compressor

by

hanging

ing,fuel

lines,

or

mechanical

parts

that

might

become

it

from

chassis

using

stiff

wire

.

snagged

as

engine

is

removed

.

23

.

Disconnect

wiring

from

starter

and

alternator

.

Move

27

.

Installation

is

reverse

of

removal,

noting

the

following

:

wiring

harness

out

of

the

way

.

See

121

Battery,

Start-

Replace

al¡

gaskets,

O-rings

and

seals

.

er,

Alternator

.

"

Change

engine

oil

and

filter

and

check

all

other

fluid

24

.

Remove

Fontexhaust

pipe

fromexhaust

manifold

.

See

levels

.

See

020

Maintenance

Program

.

"

Refill

and

bleed

cooling

system

.

See

170

Radiator

Fig

.

16

.

and

Cooling

System

.

"

Check

that

engine

drivebelts

properly

engage

the

pul-

ley

grooves

.

"

Install

the

Font

exhaust

pipesusing

new

gaskets

and

seif-locking

nuts

.

Use

copper

paste

on

threads

.

See

180

Exhaust

System

.

0012525

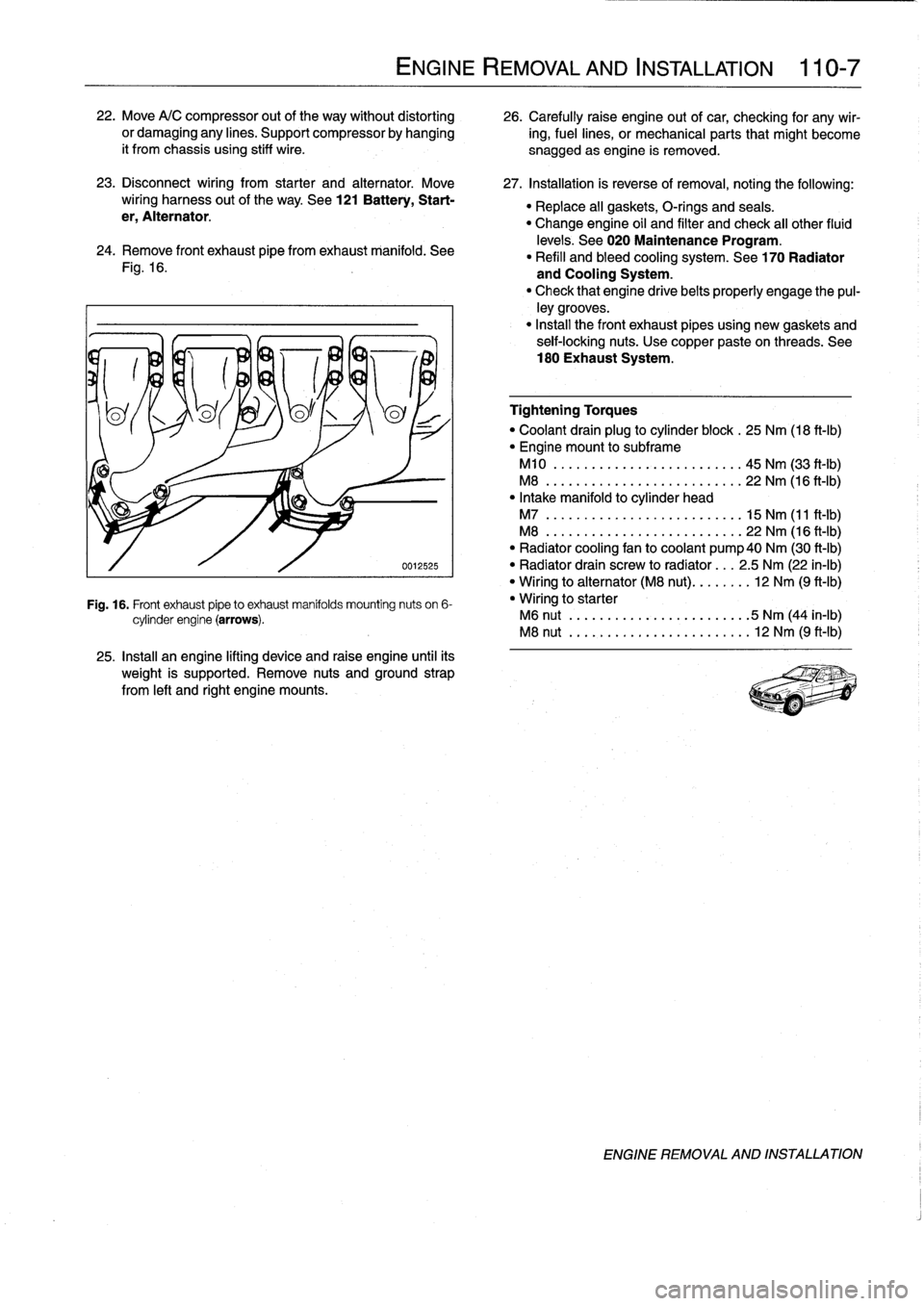

Fig

.

16

.

Front

exhaust

pipeto

exhaust

manifolds

mounting

nuts

on

6-

cylinder

engine

(arrows)

.

25

.

Install

an

engine

lifting

device

and

raise

engine

until

its

weight

is

supported

.

Remove

nuts

and

ground

strap

from

left

and

right

engine

mounts

.

ENGINE

REMOVAL

AND

INSTALLATION

110-

7

Tightening

Torques

"

Coolant

drain

plug

to

cylinder

block

.

25

Nm

(18

ft-Ib)

"

Engine

mount

to

subframe

M10

..

.

.

.

...

..............

..

.

45

Nm

(33

ft-Ib)

M8

..

..

.

..

................

...

22

Nm

(16

ft-Ib)

"

Intake

manifold

to

cylinder

head

M7

..

..

..

...

................

.

15

Nm

(11

ft-Ib)

M8

...

.

..

...

................

.

22

Nm

(16

ft-Ib)

"

Radiator

cooling

fan

to

coolant

pump40

Nm

(30

ft-Ib)

"

Radiator

drain

screw

to

radíator

...

2

.5

Nm

(22

in-lb)

"

Wiring

to

alternator

(M8

nut)

........

12

Nm

(9

ft-Ib)

"

Wiring

to

starter

M6

nut

.

..

...

..................

5

Nm

(44

in-lb)

M8

nut

.....

..

.

.

.

.

.............

12

Nm

(9

ft-Ib)

ENGINE

REMOVAL

AND

INSTALLATION

Page 68 of 759

113-2

CYLINDER

HEAD

REMOVAL

AND

INSTALLATION

0011s6i

-

0Fig

.

1

.

Front

exhaust

pipe

to

exhaust

manifold

mountíng

nuts

(arrows)

.

-1

~~

0013023

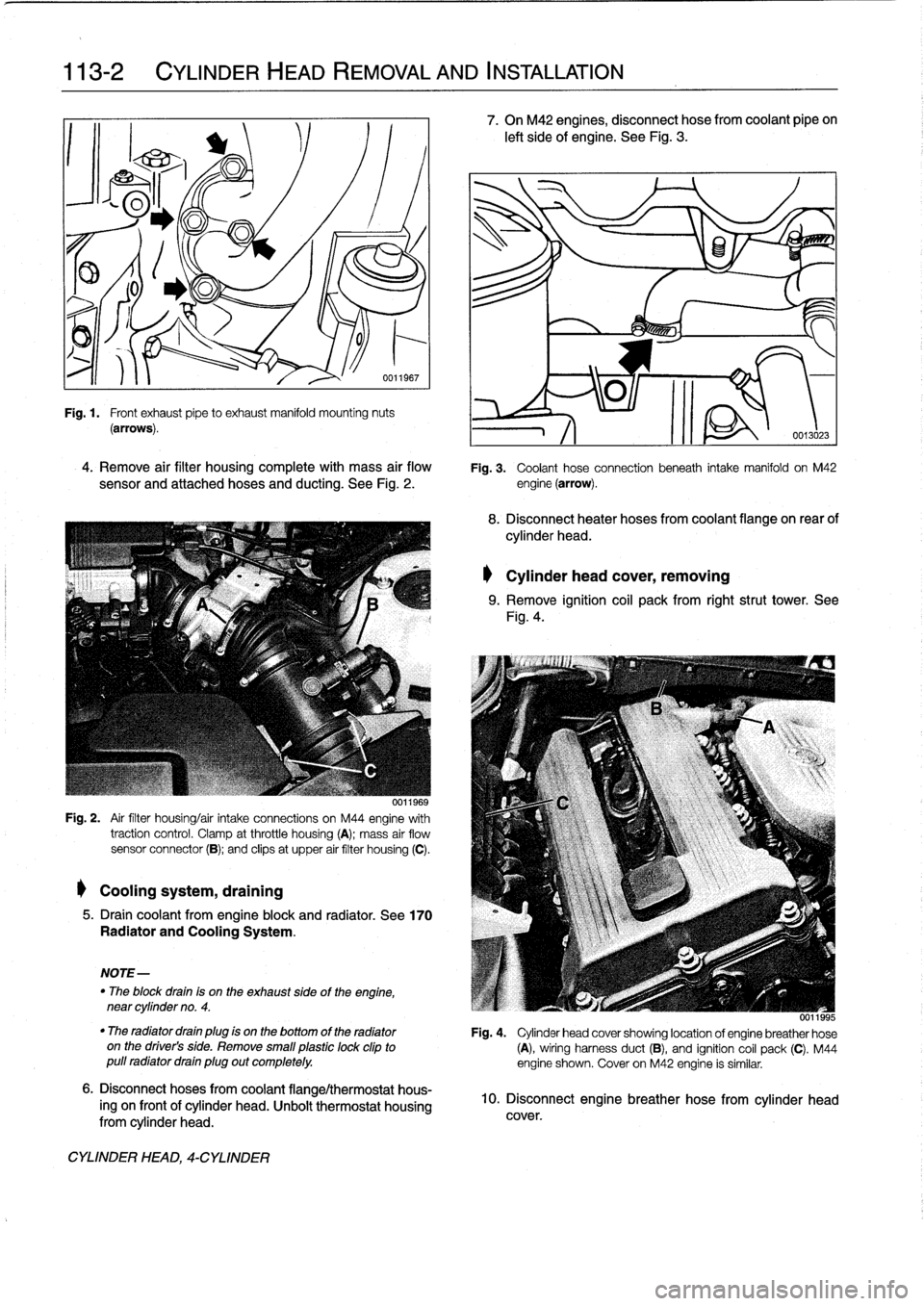

4

.

Remove

air

filter

housing

complete

with

mass

air

flow

Fig

.

3

.

Coolant

hose

connection

beneath

intake

manifold

on

M42

sensor

and

attached

hoses

and

ducting

.

See

Fig

.

2

.

engine

(arrow)

.

0011969

Fig

.

2

.

Air

filter

housing/air

intake

connections

on

M44

engine

with

traction

control

.

Clamp

atthrottle

housing

(A)

;

mass

air

flow

sensor

connector

(B)

;

and

clips

at

upper

air

filter

housing

(C)

.

Coolingsystem,

draining

5

.

Draincoolant

from

engine

block

and

radiator

.

See

170

Radiator

and

Cooling

System

.

NOTE-

"

The

block

drain

is

on

the

exhaust

sideof

the

engine,

near

cylinder

no

.

4

.

6

.

Disconnect

hoses

from

coolant

flange/thermostat

hous-

ing

on

frontof

cylinder

head

.

Unbolt

thermostat

housing

from

cylinder

head

.

CYLINDER

HEAD,

4-CYLINDER

7

.

On

M42

engines,

disconnect

hose

from

coolant

pipe

on

left

side

of

engine

.

See

Fig

.

3

.

8

.

Disconnect

heater

hoses

from

coolant

flange

on

rear

of

cylinder

head

.

Cylinder

head

cover,

removing

9

.

Remove

ignition

coil

pack

from

rightstrut

tower

.

See

Fig

.

4

.

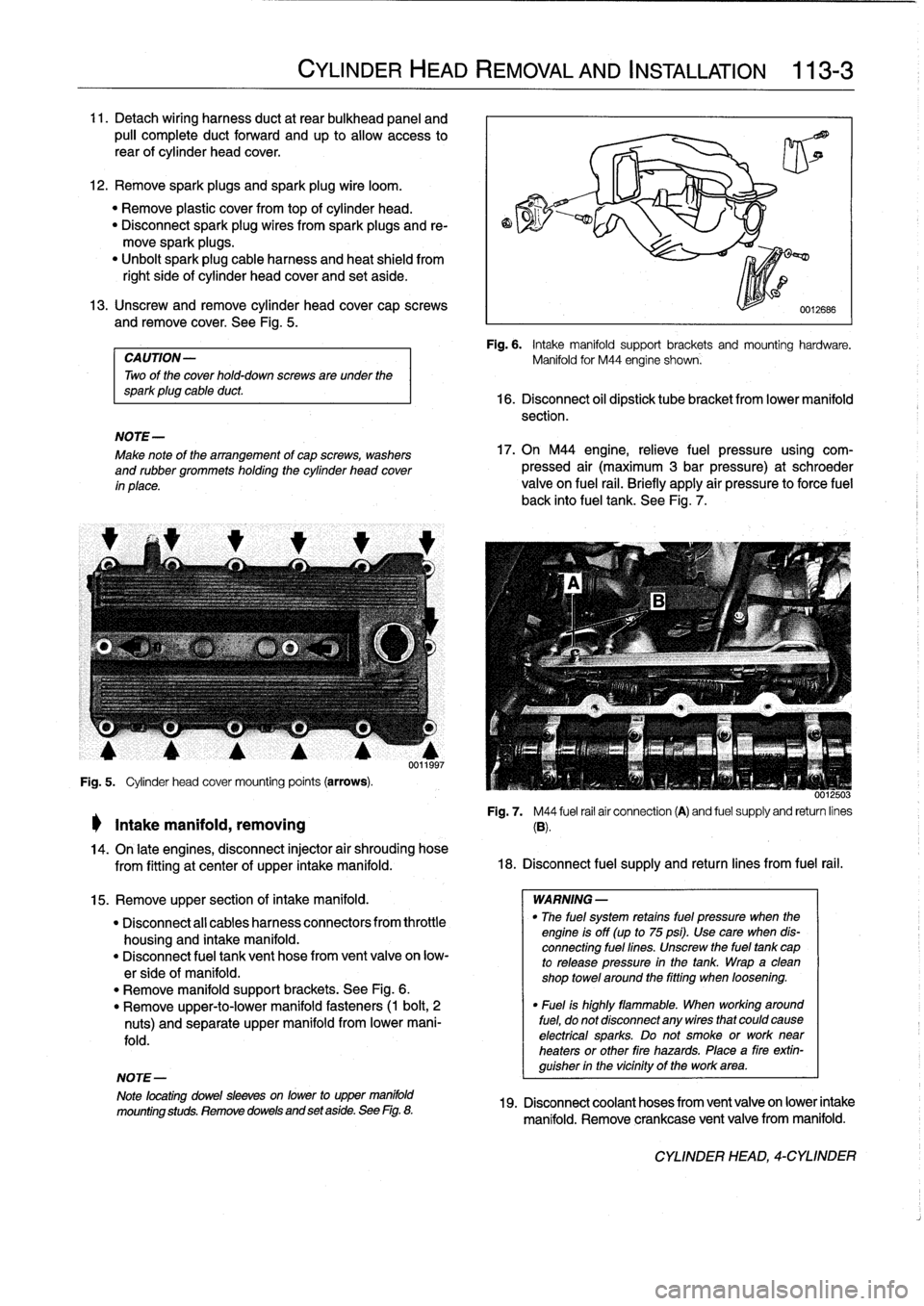

0011995

"

The

radiator

drain

plug

is

on

the

bottomof

the

radiator

Fig

.

4

.

Cylinder

head

cover

showing

location

of

engine

breather

hose

on

the

driver's

side

.

Remove

small

plastic

lock

clipto

(A),

wiring

harness

duct

(B),

and

ignition

coil

pack

(C)

.

M44

pull

radiator

drain

plug

out

completely

.

engine

shown

.

Cover

on

M42

engine

is

similar

.

10

.

Disconnect

engine

breather

hose

from

cylinder

head

cover

.

Page 69 of 759

11

.

Detach

wiring

harness

duct

at

rear

bulkhead

panel

and

pull

complete

duct

forward

and

up

to

allow

access

to

rear

of

cylinder

head

cover

.

12

.

Remove

spark

plugs

and

spark

plugwire

loom

.

"

Remove

plastic

cover

from

top

of

cylinder

head

.

"

Disconnect

spark

plug

wires

fromspark

plugs

and

re-

move

spark

plugs

.

"

Unbolt

spark

plug

cable

harness

and

heat

shield

from

right

side

of

cylinder

head

cover

and

set

aside

.

13

.

Unscrew

andremove

cylinder

head

cover

cap

screws

and

remove

cover

.

See

Fig

.

5

.

CAUTION-

Two

of

the

cover

hold-down

screws

are

under

the

spark

plug

cable

duct

.

NOTE-

Make

note

of

the

arrangement

of

cap

screws,

washers

and

rubber

grommets

holding

the

cylinder

head

cover

in

place

.

Fig

.

5

.

Cylinder

head

cover

mounting

points

(arrows)

.

Fig

.

7

.

M44

fuel

rail

air

connection

(A)

and

fuel

supply

and

return

lines

Intake

manifold,

removing

(B)

.

14

.

On

late

engines,

disconnect

injector

air

shrouding

hose

from

fitting

at

center

of

upper

intake

manifold

.

18

.

Disconnect

fuel

supply

and

return

lines

from

fuel

rail

.

15

.

Remove

upper

section

of

intake

manifold

.

"

Disconnect

ali

cables

harness

connectors

from

throttle

housing

and

intake

manifold

.

"

Disconnect

fuel

tank

vent

hose

fromvent

valve

on

low-

er

sitie

of

manifold

.

"

Remove

manifold

support

brackets

.

See

Fig

.

6

.

"

Remove

upper-to-lower

manifold

fasteners

(1

bolt,

2

nuts)

and

separate

upper

manifold

from

lowermani-

fold

.

Note

locating

dowei

sleeves

on

lower

to

upper

manifold

mounting

studs

.

Remove

dowels

and

set

aside

.

See

Fig

.

8

.

CYLINDER

HEAD

REMOVAL

AND

INSTALLATION

113-3

0012686

Fig

.

6

.

Intake

manifold

support

brackets

and

mountinghardware

.

Manifold

for

M44

engine

shows

.

16

.

Disconnect

oil

dipstick

tube

bracket

from

lower

manifold

section

.

17

.

On

M44

engine,

relieve

fuel

pressure

using

com-

pressed

air

(maximum

3

bar

pressure)

at

schroeder

valve

on

fuel

rail

.

Briefly

apply

air

pressure

to

force

fuel

back

intofuel

tank

.

See

Fig

.

7

.

WARNING

-

"

The

fuel

system

retains

fuel

pressure

when

the

engine

is

off

(up

to

75

psi)

.

Use

care

when

dis-

connecting

fuel

lines

.

Unscrew

the

fuel

tank

cap

to

retease

pressure

in

the

tank

.

Wrap

a

clean

shop

towel

around

the

fitting

when

loosening

.

"

Fuel

is

highly

flammable

.

When

working

around

fuel,

do

not

disconnect

any

wires

that

could

cause

electrical

sparks

.

Do

not

smoke

or

worknear

heaters

or

other

tire

hazards

.

Placea

tire

extin-

guisher

in

the

vicinity

of

the

work

area

.

19

.

Disconnect

coolant

hoses

from

vent

valve

on

lower

intake

manifold

.

Remove

crankcase

vent

valve

from

manifold

.

CYLINDER

HEAD,

4-CYLINDER

Page 70 of 759

113-4

CYLINDER

HEAD

REMOVAL

AND

INSTALLATION

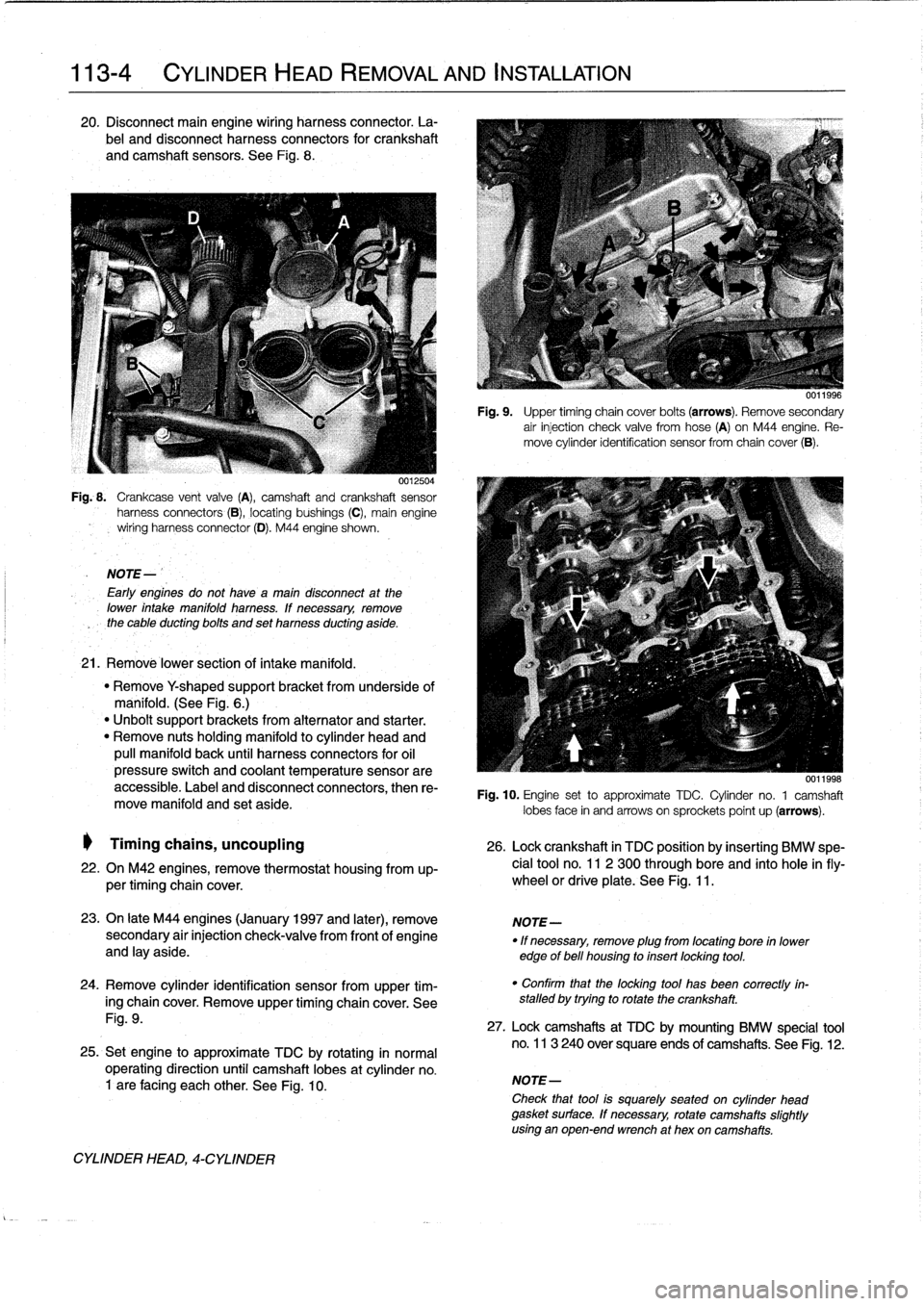

20

.

Disconnect

main

engine

wiring

harness

connector

.

La-

bel

and

disconnect

harness

connectors

for

crankshaft

and

camshaft

sensors

.

See

Fig

.

8

.

0012504

Fig

..

Crankcase

vent

valve

(A),

camshaft

and

crankshaft

sensor

harness

connectors

(B),

locating

bushings

(C),

main

engine

wiring

harnessconnector

(D)

.

M44

engine

shown

.

NOTE-

Early

engines

do

not

havea

maín

disconnect

at

the

lower

intake

manifold

harness

.

lf

necessary,

remove

the

cable

ducting

bolts

and

set

harness

ducting

aside

.

21

.

Remové

lower

section

of

intake

manifold

.

"

Remove

Y

shaped

supportbracket

from

underside

of

manifold

.

(See

Fig

.

6

.)

"

Unbolt

support

brackets

from

alternator

and

starter

.

"

Remove

nuts

holding

manifold

to

cylinder

head

and

pull

manifold

back

until

harness

connectors

for

oil

pressure

switch

and

coolant

temperature

sensorare

accessible

.

Label

and

disconnect

connectors,

then

re-

move

manifold

and

set

aside

.

Timing

chains,

uncoupling

26

.

Lock

crankshaft

in

TDC

position

by

insertíng

BMW

spe-

22

.

On

M42

engines,

remove

thermostat

housing

from

up-

cial

tool

no

.

11

2

300

through

bore

and

into

hole

infly-

per

timing

chaincover

.

wheel

or

driveplate

.

See

Fig

.

11

.

23

.

On

late

M44

engines

(January

1997

and

later),

remove

NOTE-

secondary

air

injection

check-valve

from

front

of

engine

"

If

necessary,

remove

plug

from

locating

bore

in

lower

and

lay

aside

.

edge

of

bell

housing

to

insert

locking

tool

.

24

.

Remove

cylinder

identification

sensor

from

upper

tim-

ing

chaincover

.

Remove

upper

timing

chaincover

.

See

Fig

.

9

.

25

.

Set

engine

to

approximate

TDC

by

rotating

in

normal

operating

direction

until

camshaft

lobes

at

cylinder

no

.

1

are

facing

each

other

.

See

Fig

.

10

.

CYLINDER

HEAD,

4-CYLINDER

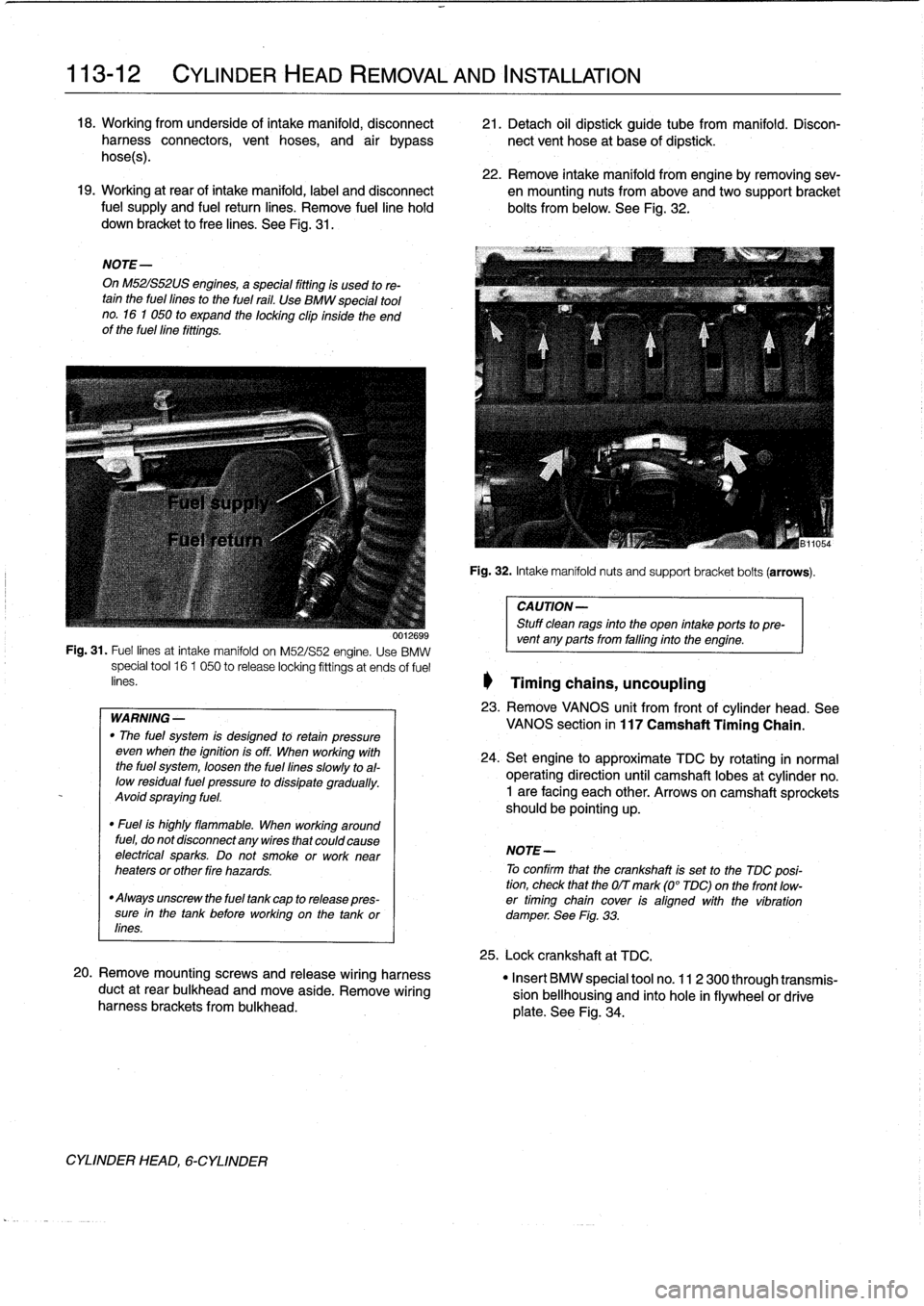

Fig

.

9

.

Upper

timing

chain

cover

bolts

(arrows)

.

Remove

secondary

air

injection

check

valve

fromhose

(A)

on

M44

engine

.

Re-

move

cylinder

identification

sensor

from

chaincover

(B)

.

0011998

Fig

.

10

.

Engine

set

to

approximate

TDC

.

Cylinder

no

.

1

camshaft

lobes

face

in

and

arrows

on

sprockets

poínt

up

(arrows)

.

"

Confirm

that

the

locking

tool

has

been

correctly

in-

stalled

by

trying

to

rotate

the

crankshaft

.

27

.

Lock

camshafts

at

TDC

by

mounting

BMW

specíal

tool

no

.

113

240

over

square

ends

of

camshafts

.

See

Fig

.

12

.

NOTE-

Check

that

tool

is

squarely

seated

on

cylinder

head

gasket

surface

.

If

necessary,

rotate

camshafts

slightly

using

an

open-end

wrench

at

hex

oncamshafts

.

Page 78 of 759

113-12

CYLINDER

HEAD

REMOVAL

AND

INSTALLATION

18

.

Working

from

underside

of

intake

manifold,

disconnect

21

.

Detach

oil

dipstick

guide

tube

from

manifold

.

Disconharness

connectors,

vent

hoses,

and

air

bypass

nectvent

hose

at

base

of

dipstick

.

hoses)

.

22

.

Remove

intake

manifold

from

engine

byremoving

sev-19

.

Working

at

rear

of

intake

manifold,

label

and

disconnect

en

mounting

nuts

from

above

andtwo

support

bracket

fuel

supply

and

fuel

return

lines

.

Remove

fuelline

hold

bolts

from

below

.

See

Fig

.

32

.

down

bracket

to

free

lines

.

See

Fig

.

31

.

NOTE-

On

M52IS52US

engines,

a

special

fitting

is

used

to

re-tain

the

fuel

fines

to

the

fuel

rail

.

Use

BMW

special

tool

no

.

16

1

050

to

expand

the

locking

clip

inside

the

end

of

the

fuellíne

fittings

.

WARNING

-

"

The

fuel

system

is

desígned

to

retan

pressure

even

wheh

the

ignition

is

off

.

When

working

with

the

fuel

system,

loosen

the

fuel

lines

slowly

toal-

low

residual

fuel

pressure

to

dissipate

gradually

.

Avoid

spraying

fuel

.

"

Fuel

is

highly

flammable

.

When

working

around

fuel,

do

not

disconnect

any

wires

that

could

cause

electrfcal

sparks

.

Do

not

smoke

orwork

near

heaters

or

other

fire

hazards

.

"

Always

unscrew

the

fuel

tank

cap

to

release

pres-

sure

in

the

tank

before

working

on

the

tank

or

lines

.

20

.

Remove

mountingscrews

and

release

wiring

harness

duct

at

rear

bulkhead

and

move

aside

.

Remove

wiring

harness

brackets

frombulkhead

.

CYLINDER

HEAD,

6-CYLINDER

Fig

.

32

.

Intake

manifoldnuts

and

support

bracket

bolts

(arrows)

.

CAUTION-

Stuff

clean

rags

into

the

open

intake

ports

topre-

001269s

vent

any

ports

from

falfing

into

the

engine

.

Fig

.

31

.

Fuel

lines

at

intake

manifold

on

M52/S52

engine

.

Use

BMW

special

tool

16

1

050

to

release

locking

fittings

at

ends

of

fuel

enes

.

1

Timing

chains,

uncoupling

23

.

Remove

VANOS

unit

from

frontof

cylinder

head

.

See

VANOS

section

in

117

Camshaft

Timing

Chain

.

24

.

Setengine

to

approximate

TDC

by

rotating

in

normal

operating

direction

until

camshaft

lobes

at

cylinder

no

.

1

are

facing

each

other

.

Arrows

on

camshaft

sprockets

should

be

pointing

up

.

NOTE-

To

confirm

that

the

crankshaft

is

set

to

the

TDC

posi-

tion,

check

that

the

OIT

mark

(0°

TDC)on

the

front

low-

er

timing

chain

cover

ís

aligned

with

the

víbration

damperSee

Fig

.

33

.

25

.

Lock

crankshaft

at

TDC

.

"

Insert

BMW

special

tool

no

.

11

2

300

through

transmis-

sion

bellhousing

and

finto

hole

in

flywheelor

drive

plate

.

See

Fig

.

34

.

Page 116 of 759

119-2

LUBRICATION

SYSTEM

NOTE-

Component

Location

If

the

light

does

not

go

out,

thewiring

to

theswitch

is"

Oil

pressure

switch

most

likely

grounded

somewhere

between

the

switch

all

engines

.......

...

.

..

......

ora

oil

filter

housing

terminal

and

the

warning

light

.

Sea

Electrical

Wiring

Diagrams

atrearof

manual

for

electrical

schematics

.

CAUTION-

Some

oil

may

drain

out

as

the

oil

pressure

switch

is

removed

.

Use

a

rag

to

soak

up

any

spills

.

2

.

Install

pressure

gauge

in

place

of

switch

.

3

.

With

gauge

instalied,

start

engine

and

allow

to

reach

operating

temperature

.

Check

oil

pressureboth

cold

and

hot

.

NOTE-

For

the

most

accurate

test

results,

the

engine

oil

(and

filter)

shouldbe

newand

of

the

correct

grade

.

Oil

Pressure

"

¡dle

(mínimum)

..

.

.

..............

.

.

0

.5

bar

(7psi)

"

Regulated

pressure

(elevated

engine

speed)

4-cylinder

engines

..

......

4

.3

±

0

.2

bar

(63

t3

psi)

6-cylinder

engines

.

.

.............

.

4

.0

bar

(59

psi)

4

.

Remove

pressure

gauge

and

reinstall

pressure

switch

.

If

testing

shows

low

oil

pressure,

one

or

more

of

the

follow-

ing

conditions

may

be

indicated

:

OIL

PAN

"

Worn

or

faulty

oii

pump

.

"

Worn

or

faulty

engine

bearings

The

oil

pancan

be

removed

with

the

engine

instalied,

al-

Severe

engine

wear

.

though

specíal

enginesupport

equipment

will

be

needed

.

Al¡

of

these

conditionsindicate

the

need

for

major

repairs

.

Oil

pressure

warning

system,

testing

When

the

ignition

is

tumed

ora,

the

oil

pressure

warning

light

comes

ora

.

When

the

engine

ís

started

and

the

oil

pressure

ris-

es

slightly,

the

oil

pressure

switch

opens

and

thewarning

light

goes

out

.

Make

sure

the

oil

leve¡

is

correct

before

making

tests

.

1

.

Turra

ignition

switch

ora

.

"

Warning

light

ora

instrument

panel

must

light

up

.

2

.

Remove

connector

from

oil

pressure

switch

.

"

Warning

light

ora

instrument

panel

must

go

out

.

OIL

PAN

3

.

If

warning

light

does

not

light

when

ignition

is

ora,

re-

move

connector

from

oil

pressure

switch

anduse

a

jumper

wire

to

ground

connector

terminal

to

a

clean

metal

surface

.

NOTE

-

If

the

warning

light

comes

ora,

check

the

switch

as

de-

scríbed

in

the

nextstep

.

If

the

warning

light

does

not

come

ora,

thewiring

to

the

instrument

cluster

or

to

the

light

itself

isfaulty

.

4

.

To

test

switch,

connect

ara

ohmmeter

between

terminal

in

switch

body

and

ground

.

With

engine

off,

these

should

be

continuity

.

With

engine

running,

oil

pressure

should

opera

switch

and

there

should

beno

continuity

Replace

a

faulty

switch

.

WARNING

-

Keep

in

mind

that

low

oil

pressure

may

be

prevent-

ing

the

switch

from

tuming

the

light

out

.

If

the

light

remains

ora

while

the

engine

is

running,

check

the

oil

pressure

asdescribed

earlier

.

Do

not

drive

the

car

until

the

problem

is

corrected

.

Theengine

may

be

severely

damaged

.

Oil

pan,

removing

and

installing

(4-cylinder

engines)

1

.

Raise

car

arad

place

securely

ora

jackstands

.

2

.

Remove

splash

shíeld(s)

from

under

engine,

where

ap-

plicable

.

3

.

Drain

engine

oil

as

described

in

020

Maintenance

Pro-

gram

.

4

.

Disconnect

vacuum

hose

adapter

from

vacuum

brake

booster

at

rear

of

engine

compartment

.

5

.

Remove

oil

dipstick

guide

tube

mounting

nut

and

pull

guide

tube

from

oil

pan

.

See

Fig

.

2

.

Page 120 of 759

119-

6

LUBRICATION

SYSTEM

17

.

Raise

engine

as

much

as

possible

.

Check

carefully

for

22

.

Installation

is

reverse

of

removal

.

obstructions,

wiring

harness

clearance

and

pinched

hoses

or

lines

as

engine

is

raised

.

"

When

installing

oil

pan,

apply

a

b

d

of

non-hardening

sealing

compound

(3-Bond

1209

0

or

equivalent)

to

18

.

Remove

oil

pan

mounting

bolts

and

lower

oil

pan

to

front

and

rear

end

cover

seam

areas

on

block

.

subframe

crossmember

.

"

Position

oil

pump

pickup

tube

and

oil

pan

onto

block

and

install

pickup

tube

using

a

new

gasket

.

"

Be

sure

tab

on

gasket

faces

down

towards

intake

of

NOTE-

pickup

tube

.

If

the

oil

pan

does

not

separate

easily

from

the

engine

"

Tightenforward

oil

pan

screws

first,

then

tighten

rear

.

cylinder

block,

afew

taps

with

arubber

mallet

should

"

Fill

engine

with

oil

as

described

in

020

Maintenance

break

it

free

.

Do

not

pry

the

oil

pan

loose

.

Program

.

"

After

adding

engine

oil,

start

and

run

engine

.

Raise

en-

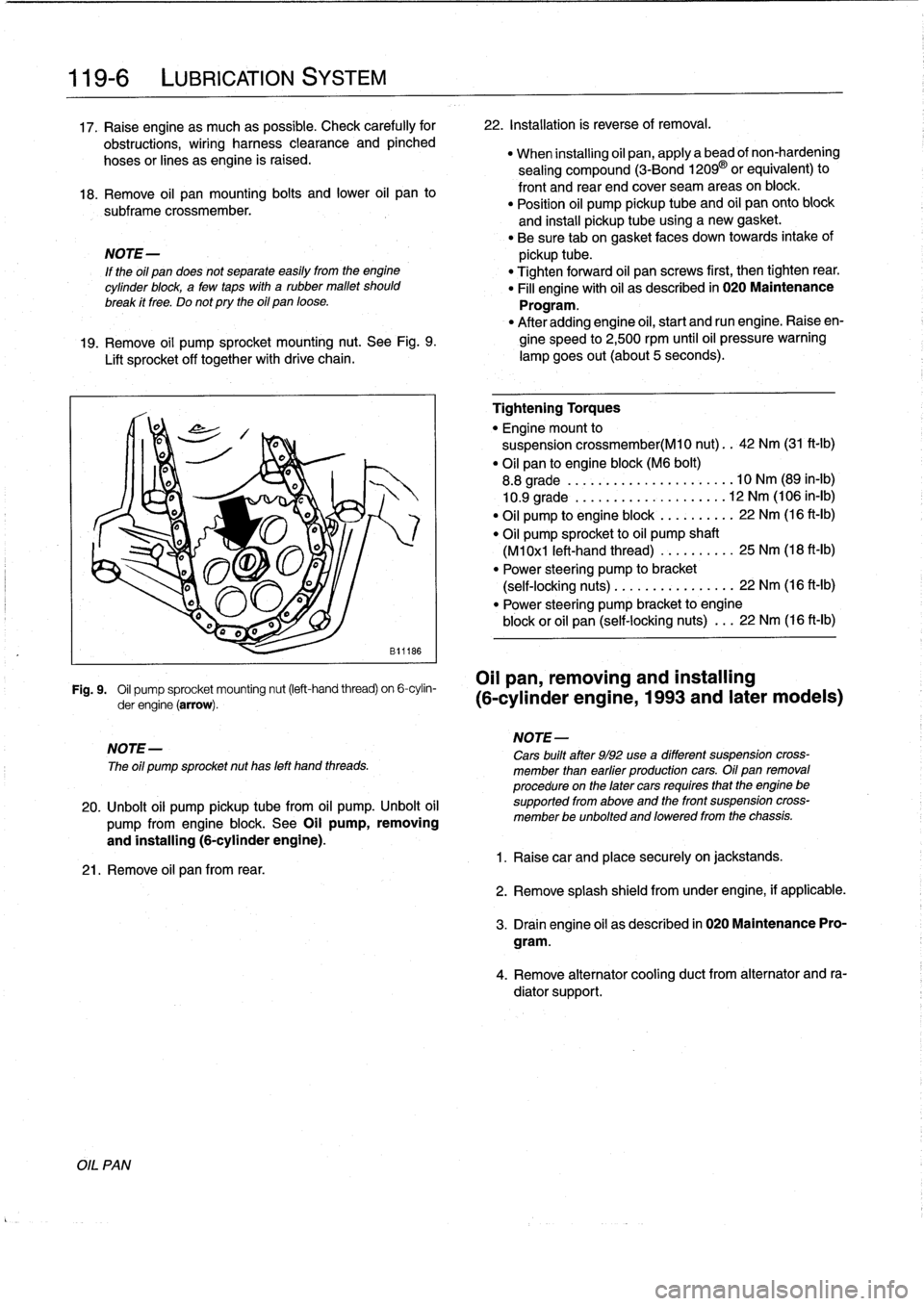

19

.

Remove

oil

pump

sprocket

mounting

nut

.

See

Fig

.

9

.

gine

speed

to

2,500

rpm

until

oil

pressure

warning

Lift

sprocket

off

together

with

drive

chain

.

lampgoes

out(about

5seconds)

.

Fig

.

9

.

Oil

pump

sprocket

mounting

nut

(left-hand

thread)

on

6-cylin-

OII

pan,

removing

and

installing

derengine(arrow)

.

(6-cylinder

engine,

1993

and

later

modeis)

NOTE-

The

oíl

pump

sprocket

nut

has

left

hand

threads

.

20

.

Unbolt

oil

pump

pickup

tubefrom

oil

pump

.

Unbolt

oil

pump

from

engine

block

.

See

Oil

pump,

removing

and

installing

(6-cylinder

engine)

.

21

.

Remove

oil

pan

from

rear

.

Tightening

Torques

"

Engine

mount

to

suspension

crossmember(M10

nut)

..

42

Nm

(31

ft-Ib)

"

Oil

pan

to

engine

block

(M6

bolt)

8

.8

grade

....

..

.

...

...

.

........

10

Nm

(89

in-lb)

10

.9

grade

.

.

..

.

..

...

.

.

.

.

.

.....

12

Nm

(106

in-lb)

"

Oil

pump

to

engine

block

.

...

...

.

..

22

Nm

(16

ft-Ib)

"

Oil

pump

sprocket

to

oil

pump

shaft

(M1

0x1

left-hand

thread)

...

..

.

.

..

.

25

Nm

(18

ft-Ib)

"

Power

steering

pump

to

bracket

(self-locking

nuts)

.....

.

....

..

.

...

22

Nm

(16

ft-lb)

"

Power

steering

pump

bracket

to

engine

block

or

oil

pan

(self-locking

nuts)

.

..

22

Nm

(16

ft-Ib)

NOTE-

Cars

built

after

9/92

use

a

different

suspension

cross-

member

¡han

earfier

productíon

cars

.

Oil

pan

removal

procedure

on

the

later

cars

requíres

that

the

engine

be

supported

from

aboye

and

the

front

suspension

cross-

member

be

unbolted

and

loweredfrom

the

chassis

.

1

.

Raisecar

and

place

securely

on

jackstands

.

2

.

Remove

splash

shield

fromunder

engine,

if

applicable

.

3

.

Drain

engine

oil

as

descríbed

in

020

Maintenance

Pro-

gram

.

4

.

Remove

alternator

cooling

duct

from

alternator

and

ra-

diator

support

.

Page 128 of 759

120-

4

IGNITION

SYSTEM

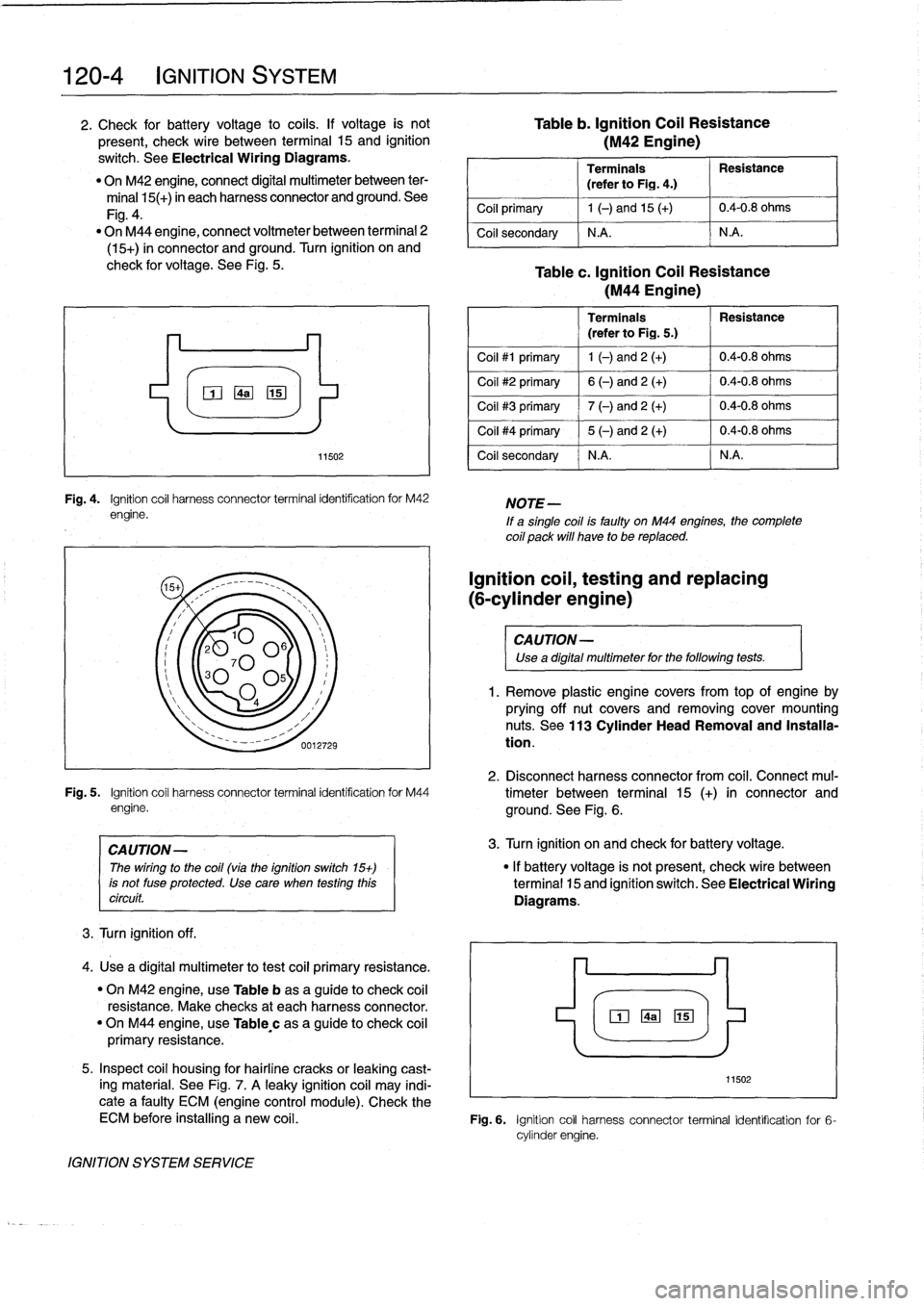

2

.

Check

for

battery

voltage

o

cofs

.

If

voltage

is

not

Table

b

.

Ignition

Coil

Resistance

present,

check

wire

between

terminal

15

and

ignition

(M42

Engine)

switch

.

See

Electrical

Wiring

Diagrams

.

"

On

M42

engine,

connect

digital

multimeter

between

ter-

minal

15(+)

in

each

harness

connector

and

ground

.

See

Fig

.

4

.

"

On

M44

engine,

connect

voltmeter

between

terminal

2

(15+)

in

connector

and

ground

.

Turn

ignition

on

and

check

for

voltage

.

See

Fig

.

5

.

3

.

Turn

ignition

off

.

0

4a15

Fig

.

4

.

Ignition

coil

harness

connector

terminal

identification

for

M42

engine

.

Fig

.

5

.

Ignition

coil

harness

connector

terminal

identification

for

M44

engine

.

CAUTION-

The

wiring

to

the

coil(via

the

ignition

switch

15+)

is

not

fuse

protected

.

Use

care

when

testing

thiscircuit

.

4

.

Use

a

digital

multimeter

totest

coil

primary

resistance

.

"

On

M42

engine,

use

Table

b

asa

guide

to

check

coil

resistance

.

Make

checks

at

each

harness

connector

.

"

On

M44

engine,

use

Table,c

as

a

guide

to

check

coil

primary

resistance

.

5

.

Inspect

coil

housing

for

hairline

cracks

or

leaking

cast-

ing

material

.

See

Fig

.

7

.

A

leaky

ignition

coil

may

indi-

11502

cate

a

faulty

ECM

(engine

control

module)

.

Check

the

ECM

before

installing

a

new

coil

.

Fig

.

6

.

Ignition

coil

harnessconnector

terminal

identification

for

6-

cylinder

engine

.

IGNITION

SYSTEM

SERVICE

11502

Terminals

Resistance

(refer

to

Fig

.

4

.)

Coil

primary

1

(-)

and

15

(+)

10

.4-0

.8

ohms

Coil

secondary

N

.A

.

N

.A

.

Table

c

.

Ignition

Coil

Resistance

(M44

Engine)

Terminais

Resistance

(referto

Fig

.

5

.)

Coil

#1

primary

1

(-)

and

2

(+)

0

.4-0

.8

ohms

Coil

#2

primary

6

(-)

and2

(+)

0

.4-0

.8

ohms

Coil

#3

primary

7

(-)

and

2

(+)

0

.4-0

.8

ohms

Coil

#4

primary

5

(-)

and2

(+)

0

.4-0

.8

ohms

Coil

secondary

N

.A

.

N

.A

.

NOTE-

If

a

single

coilís

faulty

on

M44

engines,

the

complete

coil

pack

will

have

to

be

replaced

.

Ignition

coil,

testing

and

replacing

(6-cylinder

engine)

CAUTION-

Use

a

digital

multimeter

for

the

following

tests

.

1.

Remove

plastic

enginecovers

from

top

of

engine

by

prying

off

nut

covers

and

removingcover

mounting

nuts

.

See

113

Cylinder

HeadRemoval

and

Installa-

tion

.

2

.

Disconnect

harnessconnectorfromcof

.

Connect

mul-

timeter

between

terminal

15

(+)

in

connector

and

ground

.

See

Fig

.

6

.

3

.

Turn

ignition

on

and

check

for

batteryvoltage

.

"

If

batteryvoltage

is

not

present,

check

wire

between

terminal

15

and

ignition

switch

.

See

Electrical

Wiring

Diagrams

.

"mozo

Page 129 of 759

CAUTION

-

The

wiring

to

termina¡

15

(+)

of

the

coil(vía

the

ig-

nition

switch)

is

not

fuse

protected

.

Use

care

when

testíng

thiscircuit

.

4

.

Turn

ignition

off

.

5

.

Use

a

multimeter

to

test

coil

primary

resistanceat

coil

terminals

.

See

Table

d

.

Table

d

.

Ignition

Coil

Resistance

(6-cylinder

Engine)

Terminals

Resistance

(referto

Fig

.

4

.)

Coil

primary

1

1

(-)

and

15

(+)

X

0

.4-0

.8

ohms

Coil

secondary

l

N

.A

.

N

.A

.

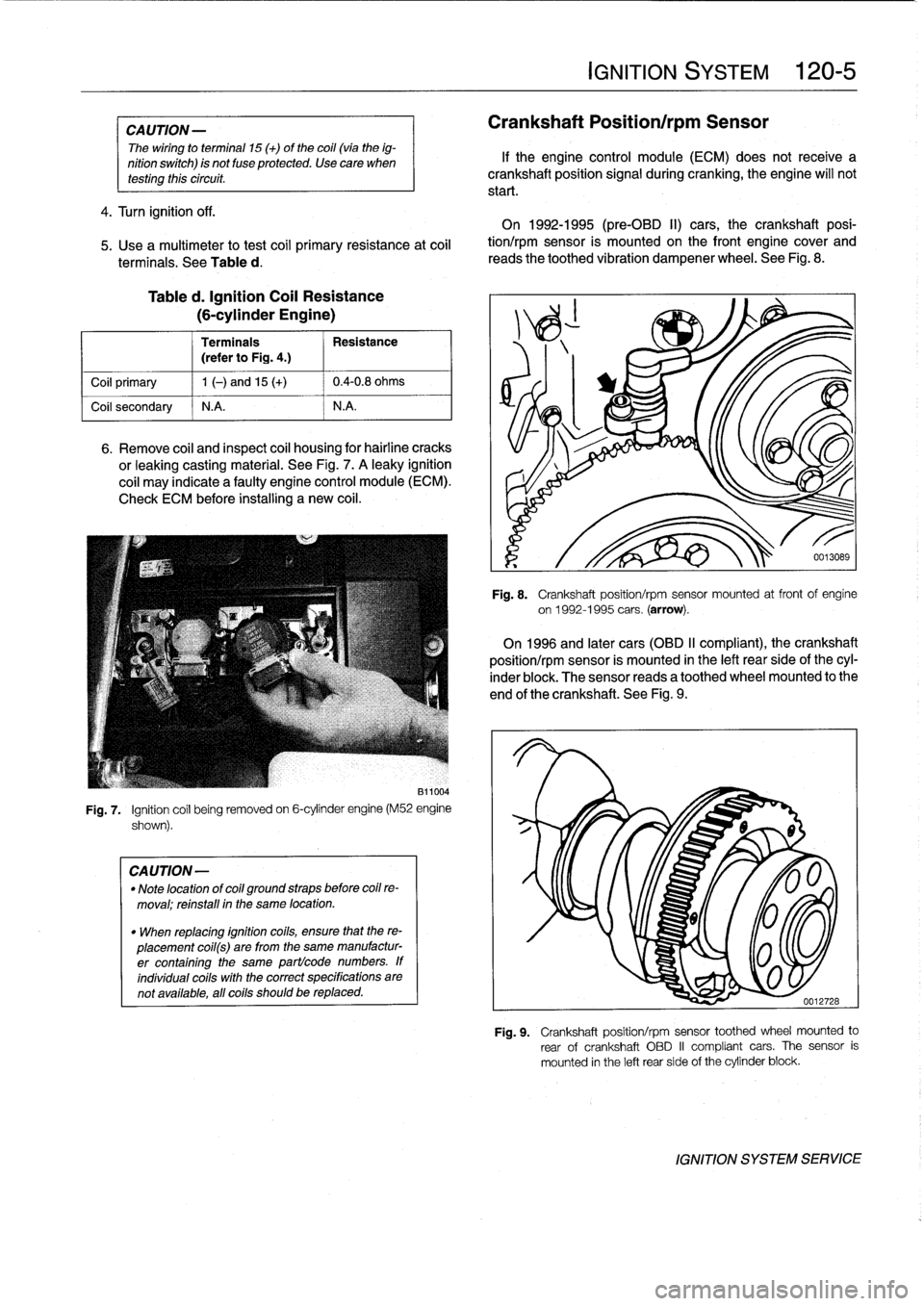

6

.

Remove

coil

and

inspect

coil

housing

for

hairline

cracks

or

leaking

casting

material

.

See

Fig

.

7

.

A

leaky

ignition

coil

may

indícate

a

faulty

engine

control

module

(ECM)

.

Check

ECM

before

installing

a

new

coil

.

811004

Fig

.

7

.

Ignition

coil

being

removed

on

6-cylinder

engine

(M52

engine

shown)

.

CA

UTION-

"

Note

location

of

coil

ground

straps

before

coilre-

moval

;

reinstallin

the

same

location

.

"

When

replacing

ignition

coils,

ensure

that

the

re-

placement

coil(s)

are

from

the

same

manufactur-

er

containing

the

same

partlcode

numbers

.

If

individual

coils

with

the

correct

specifications

are

not

available,

all

coils

should

be

replaced

.

IGNITION

SYSTEM

120-

5

Crankshaft

Position/rpm

Sensor

If

the

engine

control

module

(ECM)

does

not

receive

a

crankshaft

position

signal

during

cranking,

the

engine

will

not

start

.

On

1992-1995(pre-OBD

II)

cars,

the

crankshaft

posi-

tion/rpm

sensor

is

mounted

on

the

front

engine

cover

and

reads

the

toothed

vibration

dampener

wheel

.

See

Fig

.

8

.

Fig

.

8

.

Crankshaft

position/rpm

sensor

mounted

at

front

of

engine

on

1992-1995

cars

.

(arrow)

.

On

1996

and

latee

cars

(OBD

II

compliant),

the

crankshaft

position/rpm

sensor

is

mounted

in

the

left

rear

side

of

the

cyl-

inderblock

.

The

sensor

reads

a

toothed

wheel

mounted

to

the

end

of

the

crankshaft

.

See

Fig

.

9

.

Fig

.

9

.

Crankshaft

position/rpm

sensor

toothed

wheel

mounted

to

rear

of

crankshaft

OBD

II

compliant

cars

.

The

sensor

is

mounted

in

the

left

rear

side

of

the

cylinder

block

.

IGNITION

SYSTEM

SERVICE