Iat sensor BMW 318i 1995 E36 Owner's Manual

[x] Cancel search | Manufacturer: BMW, Model Year: 1995, Model line: 318i, Model: BMW 318i 1995 E36Pages: 759

Page 169 of 759

001ía4

i

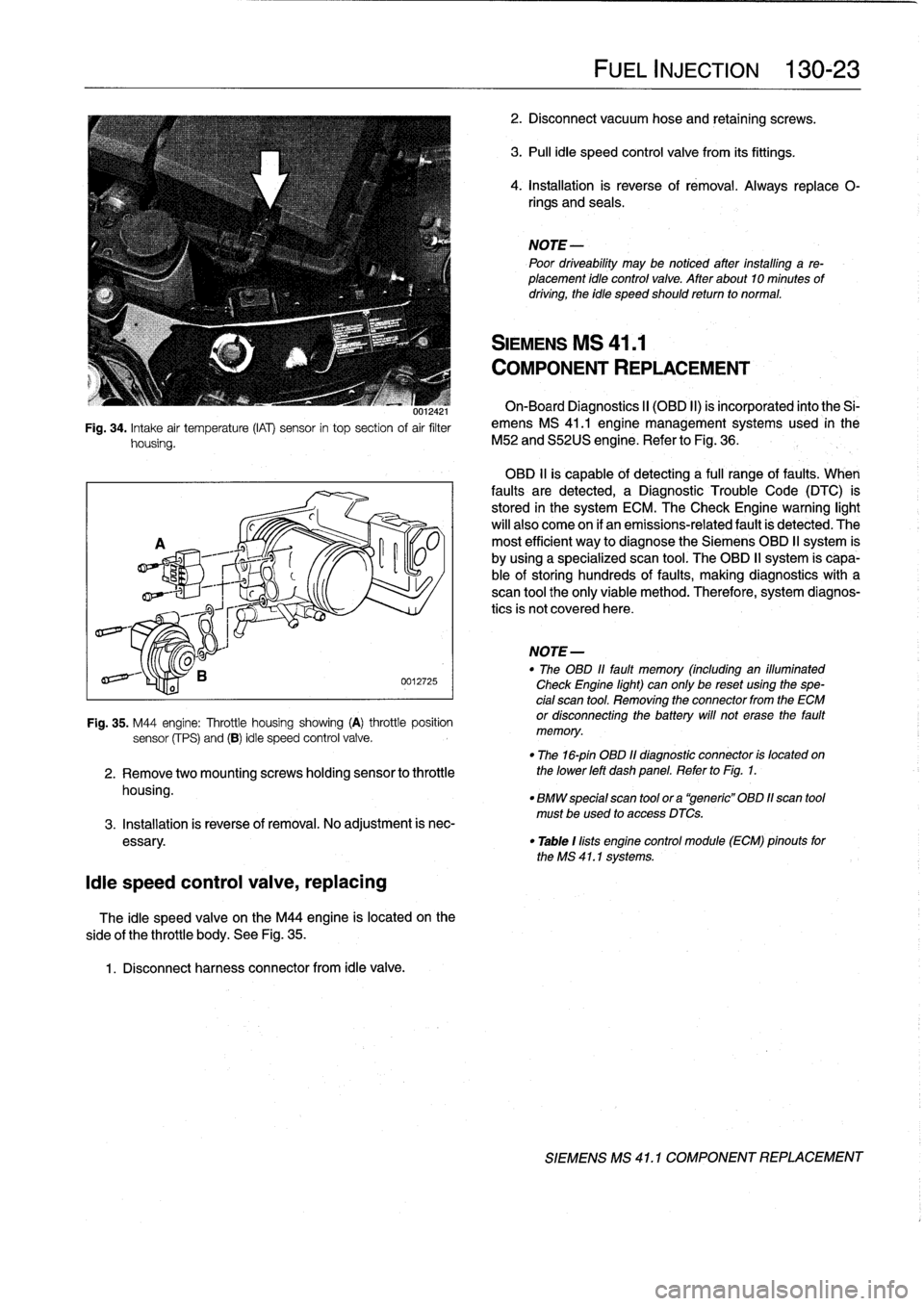

Fig

.

34

.

Intake

air

temperature

(IAT)

sensor

in

top

section

of

air

filter

housing

.

¡die

speed

control

valve,

replacing

side

of

the

throttle

body

.

See

Fig

.

35

.

1

.

Disconnect

harness

connector

from

¡die

valve

.

0012725

Fig

.

35

.

M44

engine

:

Throttle

housing

showing

(A)

throttle

position

sensor

(fPS)

and

(B)

¡die

speed

control

valve

.

2

.

Remove

twomountingscrews

holding

sensor

to

throttle

housing

.

The

¡die

speed

valve

on

the

M44

engine

is

located

on

the

FUEL

INJECTION

130-23

2

.

Disconnect

vacuum

hose

and

retaining

screws

.

3

.

Pull

¡die

speed

control

valve

from

its

fittings

.

4

.

Installation

is

reverse

of

rémoval

.

Always

replace

0-

rings

and

seals

.

NOTE

Poor

driveability

may

be

notíced

after

installing

a

re-

placement

¡dio

control

valve

.

After

about10

minutes

of

driving,

the

idie

speed

should

retum

to

normal

.

SIEMENS

MS

41

.1

COMPONENT

REPLACEMENT

On-Board

Diagnostics

II

(OBD

II)

is

incorporated

into

the

Si-

emens

MS

41

.1

engine

management

systems

used

in

the

M52

and

S52US

engine

.

Refer

to

Fig

.

36

.

OBD

11

is

capable

of

detecting

a

fui¡

range

offaults

.

When

faults

are

detected,

a

Diagnostic

Trouble

Code

(DTC)

is

stored

in

the

system

ECM

.

The

Check

Engine

warning

light

will

also

come

on

if

an

emissions-related

fault

is

detected

.

The

most

efficient

way

to

diagnose

the

Siemens

OBD

II

system

is

by

using

a

specialized

scan

tool

.

The

OBD

II

system

is

capa-

ble

of

storing

hundreds

of

faults,

making

diagnostics

with

a

scan

tool

the

only

viable

method

.

Therefore,

system

diagnos-

tics

is

not

covered

here

.

NOTE

-

"

The

OBD

11

fault

memory

(including

an

illuminated

Check

Engine

light)

can

only

be

reset

using

the

spe-

cial

scan

tool

.

Removing

the

connector

from

the

ECM

or

disconnecting

the

battery

will

not

erase

the

fault

memory

.

"

The

16-pin

OBD

11

diagnostic

connector

is

located

on

the

lower

left

dash

panel

.

Refer

to

Fig

.

1

.

"

BMW

special

scan

tool

ora

"generic"

OBD

11scan

tool

must

be

used

to

access

DTCs

.

3

.

Installation

is

reverse

of

removal

.

No

adjustment

is

nec

essary

.

"

Table

1

lists

engine

control

module

(ECM)

pinouts

forthe

MS

41

.1

systems

.

SIEMENS

MS

41

.

1

COMPONENT

REPLACEMENT

Page 171 of 759

Mass

air

flow

sensor,

replacing

1

.

Disconnect

harness

connector

and

intake

air

boots

from

air

flow

sensor

.

See

Fig

.

37

.

Fig

.

37

.

Mass

air

flow

sensor

(arrow)

on

M52

engine

.

2

.

Installation

is

reverse

of

removal

.

"

No

adjustment

to

aír

flow

sensor

is

possible

.

"

Check

intake

hoses

for

cracks

and

vacuum

leaks

.

Engine

coolant

temperature(ECT)

sensor,

replacing

The

ECT

sensor

is

a

dual

temperature

sensor

.

One

circuit

provides

coolant

temperature

information

to

the

ECM

while

the

other

circuit

provides

coolant

temperature

information

to

the

instrument

cluster

.

1

.

Remove

left-side

top

engine

cover

.

4

.

Remove

sensor

.

5

.

Installation

is

reverse

of

removal

.

"

Replace

any

lost

coolant

.

0012703

"

Use

a

new

copper

sealing

washer

when

installing

new

Tightening

Torque

"

Engine

coolant

temperature

to

cylinder

head

.....

..

.

...

......

13

Nm

(10

ft-Ib)

FUEL

INJECTION

130-

25

0012704b

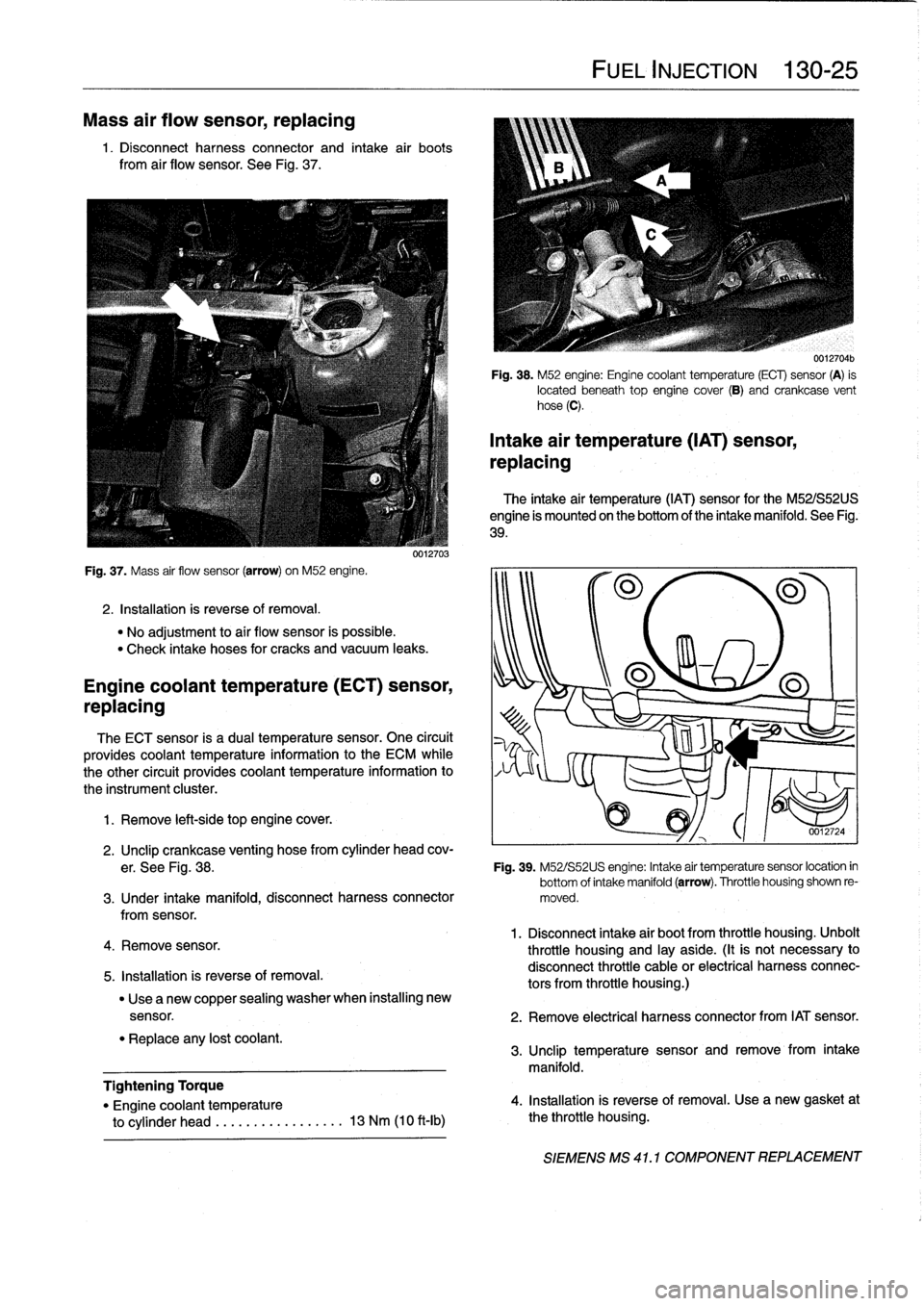

Fig

.

38

.

M52

engine

:

Engine

coolant

temperature

(ECT)

sensor

(A)

is

located

beneath

top

engine

cover

(8)

and

crankcase

vent

hose

(C)

.

Intake

air

temperature

(IAT)

sensor,

replacing

The

intake

air

temperature

(IAT)

sensor

for

the

M52/S52US

engine

is

mounted

on

the

bottom

of

the

intake

manifold

.

See

Fig

.

39

.

2

.

Unclip

crankcase

venting

hose

from

cylinder

head

cov-

er

.

See

Fig

.

38

.

Fig

.

39

.

M52/S52US

engine

:

Intake

air

temperaturesensor

location

in

bottom

of

intake

manifold(arrow)

.

Throttle

housing

shown

re

3

.

Under

intake

manifold,

disconnect

harness

connector

moved

.

fromsensor

.

1

.

Disconnect

intake

air

bootfrom

throttle

housing

.

Unbolt

throttle

housing

and

¡ay

aside

.

(It

is

not

necessary

to

disconnect

throttle

cable

or

electrical

harnessconnec-

tors

from

throttle

housing

.)

sensor

.

2

.

Remove

electrical

harness

connector

from

IAT

sensor

.

3

.

Unclip

temperature

sensor

and

remove

from

intake

manifold

.

4

.

Installation

is

reverse

of

removal

.

Use

a

new

gasket

at

the

throttle

housing

.

SIEMENS

MS

41

.1

COMPONENT

REPLACEMENT

Page 175 of 759

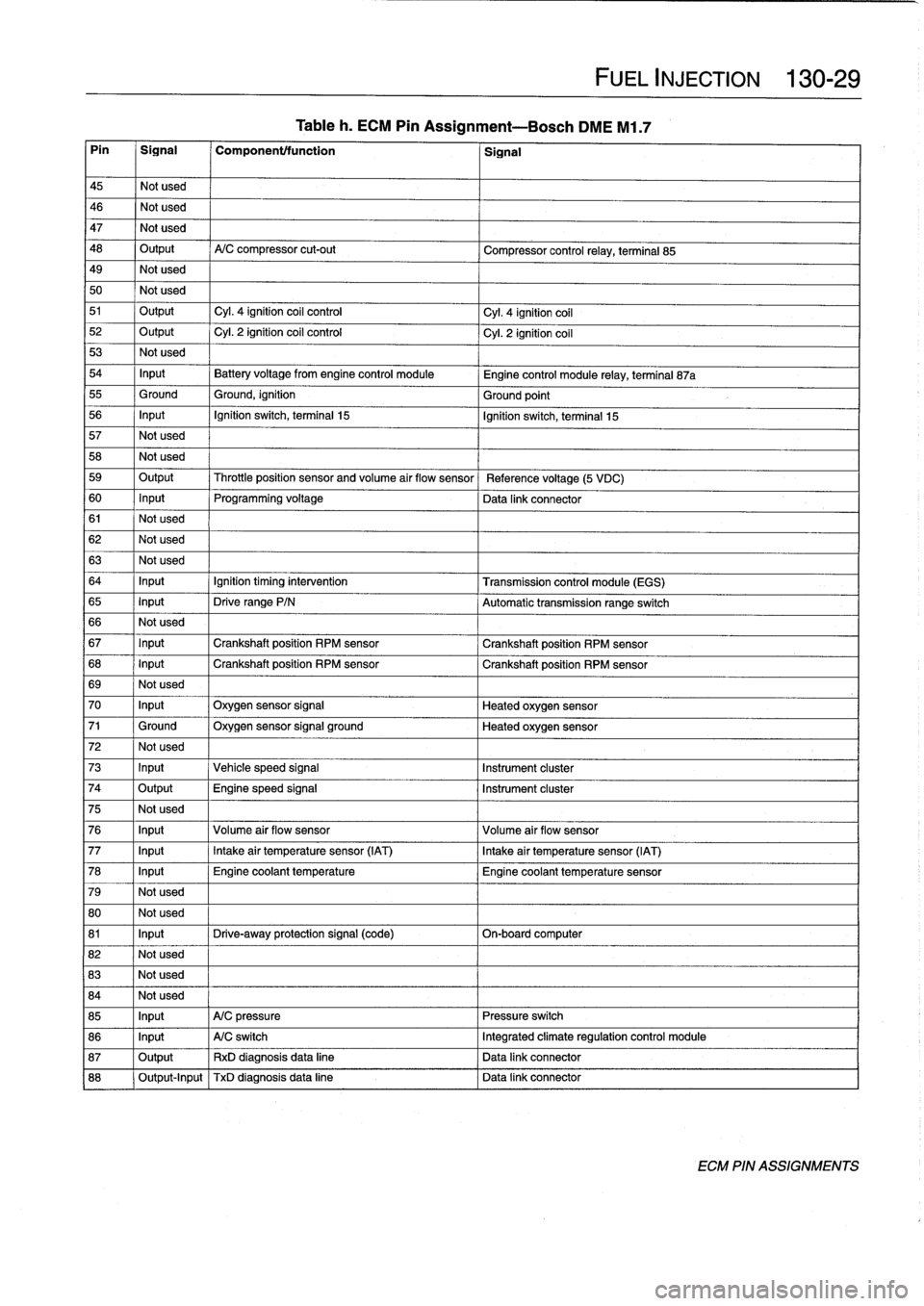

Tableh

.

ECM

Pin

Assignment--Bosch

DME

M1

.7

Pin

1

Signal

1

Component/function

1

Signal

45

Notused

46

Notused

47

Notused

48

Output

A/C

compressor

cut-out

Compressor

control

relay,

terminal

85

49

Notused

50

Notused

51

Output

Cyl

.

4

ignition

coil

control

Cyl

.

4

ignition

coil

52

Output

Cyl

.

2

ignition

coil

control

Cyl

.

2

ignition

coil

53

Not

used

54

Input

Battery

voltage

from

engine

control

module

Engine

control

module

relay,

terminal

87a

55

Ground

Ground,

ignition

Ground

point

56

Input

Ignition

switch,

terminal

15

Ignition

switch,

terminal

15

57

Notused

58

Not

used

59

Output

Throttleposition

sensor

and

volume

air

flow

sensor

Reference

voltage

(5

VDC)

60

Input

Programming

voltage

Data

link

connector

61

Notused

62

Notused

63

Notused

64

Input

Ignition

timing

intervention

Transmission

control

module

(EGS)

65

Input

Drive

range

P/N

Automatic

transmission

range

switch

66

Notused

67

Input

Crankshaft

position

RPM

sensor

Crankshaft

position

RPM

sensor

68

Input

Crankshaft

position

RPM

sensor

Crankshaft

position

RPM

sensor

69

Notused

70

Input

Oxygen

sensor

signal

Heated

oxygen

sensor

71

Ground

Oxygen

sensor

signal

ground

Heated

oxygen

sensor

72

Notused

73

Input

Vehicle

speed

signal

Instrument

cluster

74

Output

Engine

speed

signal

Instrument

cluster

75

Not

used

76

Input

Volume

air

flow

sensor

Volume

air

flow

sensor

77

Input

Intake

air

temperature

sensor

(IAT)

Intake

air

temperature

sensor

(IAT)

78

Input

Engine

coolant

temperature

Engine

coolant

temperature

sensor

79

Notused

80

Not

used

81

Input

Drive-away

protection

signal

(code)

On-boardcomputer

82

Not

used

83

Notused

84

Not

used

85

Input

A/C

pressure

Pressure

switch

86

Input

A/C

switch

Integrated

climate

regulation

control

module

87

Output

RxD

diagnosisdata

line

Data

link

connector

88

Output-Input

TxD

diagnosisdata

line

l

Data

link

connector

FUEL

INJECTION

130-

2

9

ECM

PIN

ASSIGNMENTS

Page 176 of 759

130-

3

0

FUEL

INJECTION

Pin

Signal

Component/function

Signal

ECM

PIN

ASSIGNMENTS

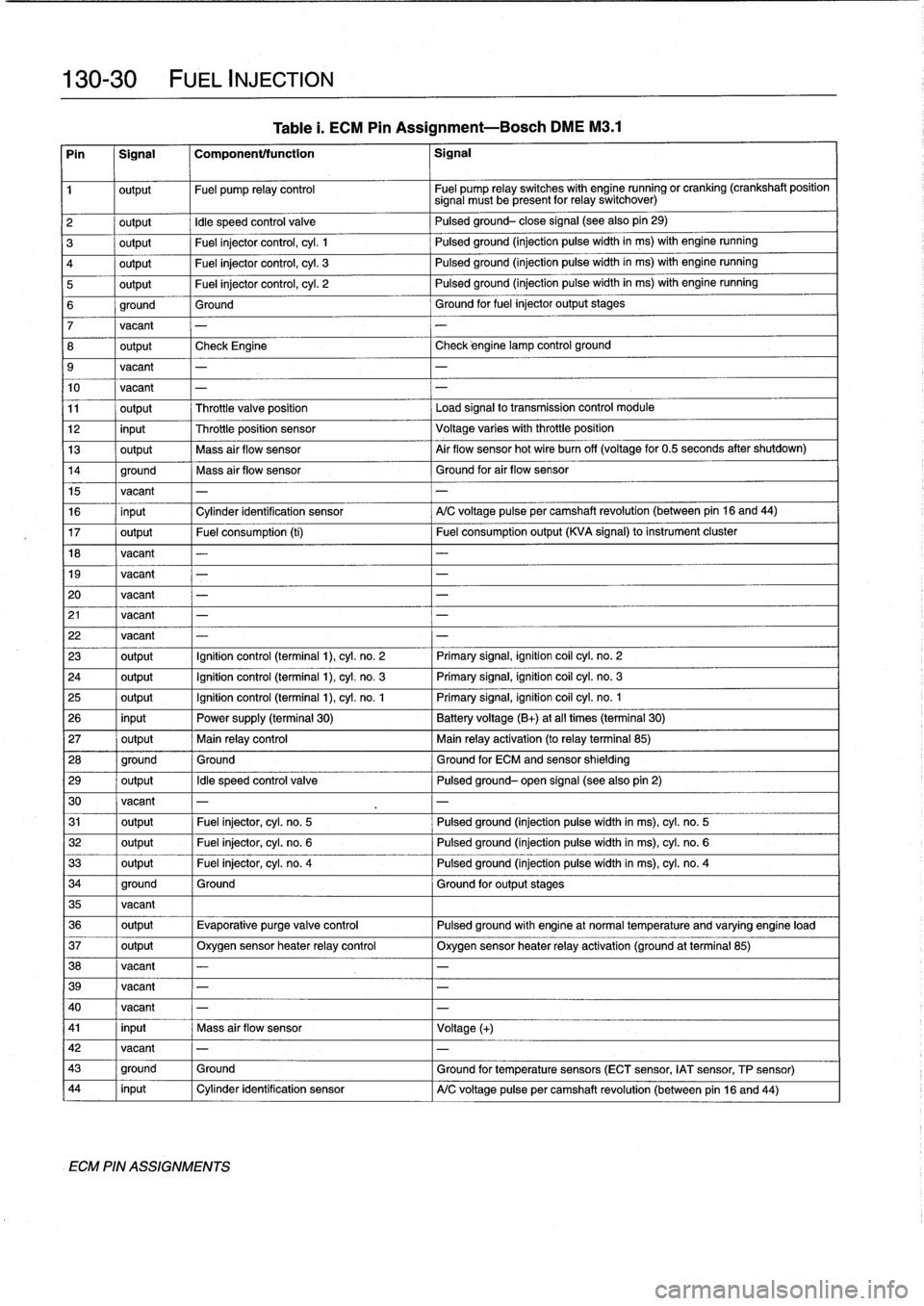

Table

1.

ECM

Pin

Assignment-Bosch

DME

M3

.1

1

output

Fuel

pump

relay

control

Fuel

pump

relay

switches

with

engine

runningor

cranking

(crankshaft

position

Signal

mustbe

present

for

relay

switchover)

2

1

output

1

Idle

speed

control

valve

1

Pulsad

ground-

close

signal

(seealsopin29)

3

output

Fuel

injectorcontrol,

cyl

.

1

Pulsedground

(injection

pulsewidth

in

ms)

with

engine

running

4

output

Fuel

injectorcontrol,

cyl

.

3

Pulsedground

(injection

pulsewidth

in

ms)

with

engine

running

5

output

Fuel

injector

control,

cyl

.

2

Pulsedground

(injection

pulse

width

in

ms)

with

enginerunning

6

ground

Ground

Ground

for

fuel

injector

output

stages

7

vacant

-

-

8

output

Check

Engine

Check

éngine

lamp

control

ground

9

vacant

-

-

10

vacant

-

-

11

output

Throttle

valve

position

Load

signal

to

transmission

control

module

12

input

Throttle

position

sensor

Voltage

varies

with

throttle

position

13

output

Mass

air

flow

sensor

Air

flow

sensor

hotwire

burn

off

(voltage

for

0

.5

seconds

after

shutdown)

14

ground

Mass

air

flow

sensor

Ground

for

air

flow

sensor

15

vacant

-

-

16

input

Cylinder

identification

sensor

A/C

voltage

pulse

per

camshaft

revolution

(between

pin

16

and

44)

17

output

Fuel

consumption

(ti)

Fuel

consumption

output

(KVA

Signal)

to

instrument

cluster

18

vacant

-

-

19

vacant

-

-

20

vacant

-

-

21vacant

-

-

22

vacant

-

-

23

output

Ignition

control

(terminal

1),

cyl

.

no

.

2

Primary

Signal,

ignition

coil

cyl

.

no

.

2

24

output

Ignition

control

(terminal

1),

cyl

.

n

o

.

3

Primary

signal,

ignition

coil

cyl

.

no

.

3

25

output

Ignition

control

(terminal

1),

cyl

.

n

o

.

1

Primary

signal,

ignitioh

coil

cyl

.

no

.

1

26

input

Power

supply

(terminal

30)

Battery

voltage

(B+)

at

al¡

times

(terminal

30)

27

output

Main

relay

control

Main

relay

activation

(to

relay

terminal

85)

28

ground

Ground

Ground

for

ECM

and

sensor

shielding

29

output

Idle

speed

control

valve

Pulsed

ground-

open

signal

(see

also

pin

2)

30

vacant

-

-

31

output

Fuel

injector,cyl

.

no

.

5

Pulsedground

(injection

pulsewidth

in

ms),

cyl

.

no

.

5

32

output

Fuel

injector,cyl

.

no

.

6

Pulsedground

(injection

pulse

width

in

ms),

cyl

.

no

.

6

33

output

Fuel

injector,cyl

.

no

.

4

Pulsedground

(injection

pulsewidth

in

ms),

cyl

.

no

.

4

34

ground

Ground

Ground

for

output

stages

35

vacant

36

output

Evaporative

purgevalve

control

Pulsed

ground

with

engine

at

normal

temperature

and

varying

engine

load

37

output

Oxygen

sensor

heater

relay

control

Oxygen

sensor

heater

relayactivation

(ground

at

terminal

85)

38

vacant

-

-

39

vacant

-

-

40

vacant

-

41

input

Mass

air

flow

sensor

Voltage

(+)

42

vacant

-

-

43

ground

Ground

Ground

for

temperatura

sensors

(ECT

sensor,

IAT

sensor,

TP

sensor)

44

input

Cylinder

identification

sensor

A/C

voltagepulseper

camshaft

revolution

(between

pin

16

and

44)

Page 177 of 759

Table

i

.

ECM

Pin

Assignment-Bosch

DME

M3

.1

Pin

Signal

Component/function

2

ignal

FUEL

INJECTION

130-

3

1

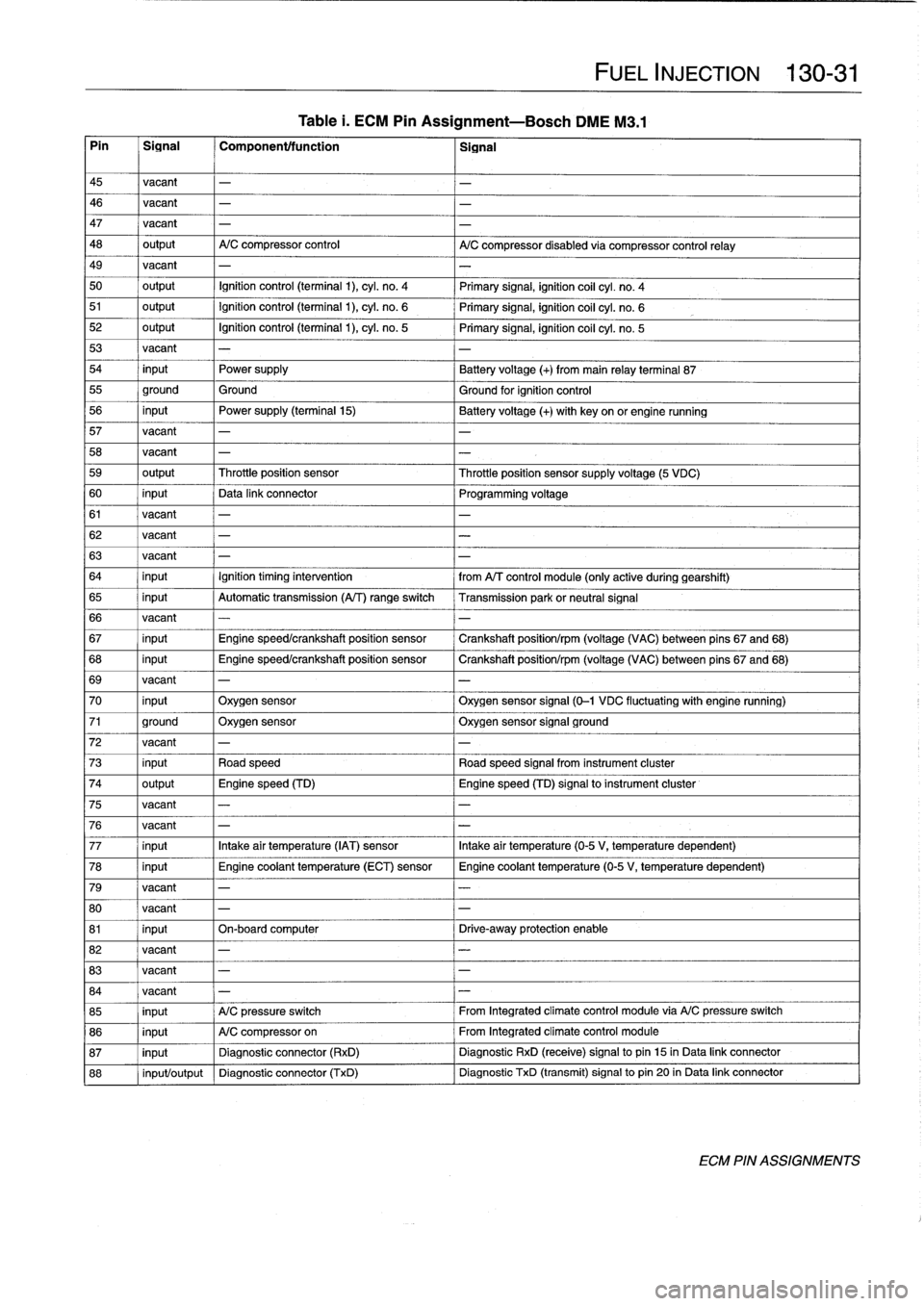

45

vacant

-

46

vacant

-

-

47

vacant

-

-

48

output

A/C

compressor

control

A/C

compressor

disabled

via

compressor

control

relay

49

vacant

-

-

50

output

Ignition

control

(terminal

1),cyl

.

n

o

.

4

Primary

signal,

ignition

coil

cyl

.

n

o

.

4

51

output

Ignition

control

(terminal

1),cyl

.

n

o

.

6

Primary

signal,

ignition

coil

cyl

.

no

.

6

52

output

Ignition

control

(terminal

1),cyl

.

n

o

.

5

Primary

signal,

ignitioncoil

cyl

.

no

.

5

53

vacant

-

54

input

Power

supply

Battery

voltage

(+)

from

main

relay

terminal

87

55

ground

Ground

Ground

for

ignition

control

56

input

Power

supply

(terminal

15)

Batteryvoltage

(+)

with

key

on

or

engine

running

57

vacant

-

-

58

vacant

-

-

59

output

Throttleposition

sensor

Throttleposition

sensorsupply

voltage

(5

VDC)

60

input

Data

link

connector

Programming

voltage

61

vacant

-

-

62

vacant

-

-

63

vacant

-

-

64

input

Ignition

timing

intervention

from

A/T

control

module

(only

active

during

gearshift)

65

input

Automatic

transmission

(A/T)

range

switch

Transmission

park

or

neutral

signal

66

vacant

-

-

67

input

Engine

speed/crankshaft

position

sensor

Crankshaft

position/rpm

(voltage

(VAC)

between

pins

67

and

68)

68

input

Engine

speed/crankshaft

position

sensor

Crankshaft

position/rpm

(voltage

(VAC)

between

pins

67

and

68)

69

vacant

-

-

70

input

Oxygen

sensor

Oxygen

sensor

signal

(0-1

VDC

fluctuating

with

engine

running)

71

ground

Oxygen

sensor

Oxygen

sensor

signal

ground

72

vacant

-

-

73

input

Road

speed

Road

speed

signal

from

instrument

cluster

74

output

Engine

speed

(TD)

Engine

speed

(TD)

signalto

instrument

cluster

75

vacant

-

-

76

vacant

-

-

77

input

Intakeair

temperature

(IAT)

sensor

Intake

air

temperature

(0-5

V,

temperaturedependent)

78

input

Engine

coolant

temperature

(ECT)

sensor

Engine

coolant

temperature

(0-5V,

temperature

dependent)

79

vacant

-

-

80

vacant

-

-

81

input

On-boardcomputer

Drive-away

protection

enable

82

vacant

-

-

83

vacant

-

-

84

vacant

-

-

85

input

A/C

pressure

switch

From

Integrated

climate

control

module

via

A/C

pressure

switch

86

input

A/C

compressor

on

From

Integrated

climate

control

module

87

input

Diagnostic

connector

(RxD)

Diagnostic

RxD

(receive)signal

to

pin

15

in

Data

link

connector

88

input/output

Diagnostic

connector

(TxD)

Diagnostic

TxD

(transmit)

signal

to

pin

20

in

Data

link

connector

ECM

PIN

ASSIGNMENTS

Page 182 of 759

130-

3

6

FUEL

INJECTION

Pin

1

Signal

1

Componentffunction

1

Signal

1

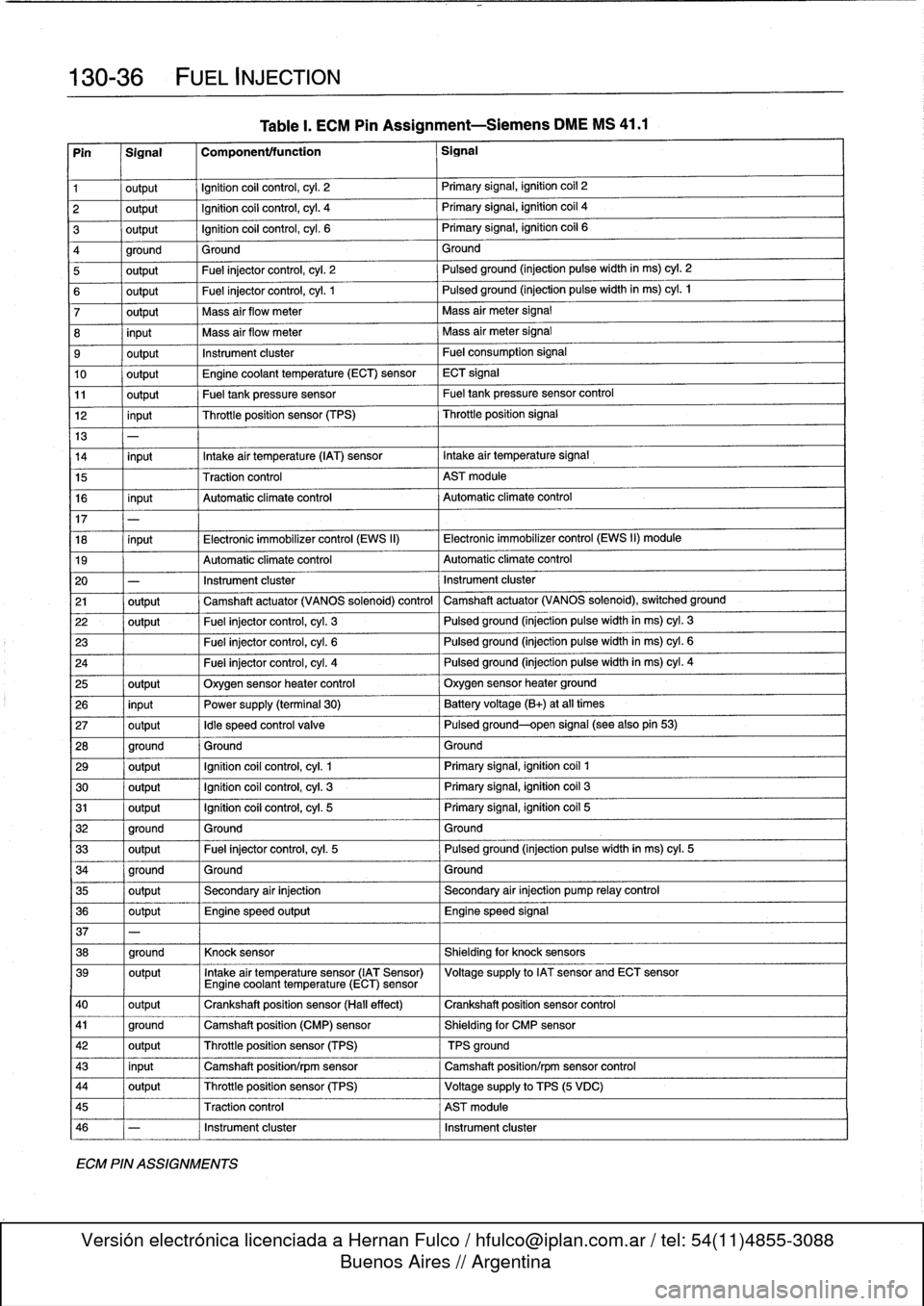

output

Ignition

coil

control,

cyl

.

2

Primary

signal,

ignition

coil

2

2

output

Ignition

coil

control,

cyl

.

4

Primary

signal,

ignitioncoil

4

3

output

Ignition

coil

control,

cyl

.

6

Primary

signal,

ignition

coil

6

4

ground

Ground

Ground

5

output

Fuel

injectorcontrol,

cyl

.

2

Pulsed

ground

(injection

pulse

width

in

ms)

cyl

.

2

6

output

Fuel

injectorcontrol,

cyl

.

1

Pulsed

ground

(injection

pulse

width

in

ms)

cyl

.

1

7

output

Mass

air

flow

meter

Mass

air

meter

signal

8

input

Mass

air

flow

meter

Mass

air

meter

signal

9

output

Instrument

cluster

Fuel

consumption

signal

10

output

Engine

coolant

temperature

(ECT)

sensor

ECT

signal

11

output

Fueltankpressure

sensor

Fueltankpressure

sensor

control

12

input

Throttleposition

sensor

(TPS)

Throttleposition

signal

13

-

14

input

Intake

air

temperature

(IAT)

sensor

Intake

air

temperature

signal

15

Traction

control

AST

module

16

input

Automatic

climate

control

Automatic

climate

control

17

18

input

Electronic

immobilizer

control

(EWS

II)

Electronic

immobilizer

control

(EWS

II)

module

19

Automatic

climate

control

Automatic

climate

control

20

-

Instrument

cluster

Instrument

cluster

21

output

Camshaft

actuator

(VANOS

solenoid)

control

Camshaft

actuator

(VANOS

solenoid),

switched

ground

22

output

Fuel

injectorcontrol,

cyl

.

3

Pulsed

ground

(injection

pulse

width

in

ms)

cyl

.

3

23

Fuel

injectorcontrol,

cyl

.

6

Pulsed

ground

(injection

pulse

width

in

ms)

cyl

.

6

24

Fuel

injectorcontrol,

cyl

.

4

Pulsed

ground

(injection

pulse

width

in

ms)

cyl

.

4

25

output

Oxygen

sensor

heater

control

Oxygen

sensor

heater

ground

26

input

Power

supply

(terminal

30)

Battery

voltage(B+)

at

all

times

27

output

Idle

speed

control

valve

Pulsed

ground-open

signal

(see

also

pin

53)

28

ground

Ground

Ground

29

output

Ignition

coil

control,

cyl

.

1

Primary

signal,

ignition

coíl

1

30

output

Ignition

coil

control,

cyl

.

3

Primary

signal,

ignition

coil

3

31

output

Ignition

coil

control,

cyl

.

5

Primary

signal,

ignition

coil

5

32

ground

Ground

Ground

33

output

Fuel

injector

control,

cyl

.

5

Pulsedground

(injection

pulsewidth

in

ms)

cyl

.

5

34

ground

Ground

Ground

35

output

Secondary

air

injection

Secondary

air

injection

pump

relay

control

36

output

Engine

speed

output

Engine

speed

signal

37

-

38

ground

Knock

sensor

Shielding

for

knock

sensors

39

output

Intake

air

temperature

sensor

(IAT

Sensor)

Voltagesupply

to

IAT

sensor

and

ECT

sensorEngine

coolant

temperature

(ECT)

sensor

40

output

Crankshaft

position

sensor

(Hall

effect)

Crankshaft

position

sensor

control

41

ground

Camshaft

position

(CMP)

sensor

Shielding

for

CMP

sensor

42

output

Throttle

position

sensor

(TPS)

TPS

ground

43

input

Camshaft

position/rpm

sensor

Camshaft

position/rpm

sensor

control

44

output

Throttle

position

sensor

(TPS)

Voltagesupply

to

TPS

(5

VDC)

45

Traction

control

AST

module

46

-

Instrument

cluster

Instrument

cluster

ECM

PIN

ASSIGNMENTS

Table

I.

ECM

Pin

Assignment-Siemens

DME

MS

41

.1

Page 195 of 759

170

Radiator

and

Cooling

System

GENERAL

.

.

.....

.

...

.

.

.

.

.

....

.

.

.

.

.

.

.

.170-1

Coolant

Pump

and

Thermostat

........

.

.

.

.

170-1

Radiator

and

Expansion

Tank

.........

.

...

170-1

Cooling

Fans

.

....

.

.

.

.

.

.

.

.

.

.....

.

......

170-2

Warnings

and

Cautions

.

.

.

.

.

.

.

.

.

.

.

.

...

.

.

.

170-2

TROUBLESHOOTING

...

.

.

.

...

.

.

.

.

.

.

.

.

.170-2

Cooling

System

Pressure

Test

...

.

.

.

.

.

.

.

.

.

170-3

Thermostat

Quick

Check

.

.

.

.

...

.

.

.

.

.

.

.

.

.

170-3

Temperature

Gauge

Quick

Check

.

.

.

.

.

.

.

.

.

170-3

Cooling

fan,

testing

.

.

.

.

........

.

.

.

.

.

.

.

.

.

170-4

COOLING

SYSTEM

SERVICE

.

.

.

.

.

.

.

.

.

.

170-5

Coolant,draining

and

filling

.

.

......

.

.

.

.

.

..

170-5

Cooling

system,

bleeding

(radiator

with

integral

expansion

tank)

.....

170-6

GENERAL

This

section

covers

repair

and

troubleshooting

information

for

the

engine

cooling

system

.

For

heater

core

and

related

heating

and

air

conditioning

components,

see640

Heating

and

Air

Conditioning

.

Coolant

Pump

and

Thermostat

A

centrifuga¡-type

coolant

pump

is

mounted

to

the

front

of

the

engíne

.

The

belt-driven

pump

circulates

coolant

through

the

system

whenever

the

engíne

is

running

.

A

thermostat

con-

trols

the

flow

of

coolant

into

the

radiator

.

When

the

engíne

is

cold

the

thermostat

is

closed

so

coolant

bypasses

the

radiator,

recirculating

from

the

engíne

directly

back

to

the

pump

.

When

the

engíne

reaches

operating

tem-

perature,

the

thermostat

opens

and

coolant

circulates

through

the

whole

system

including

the

radiator

.

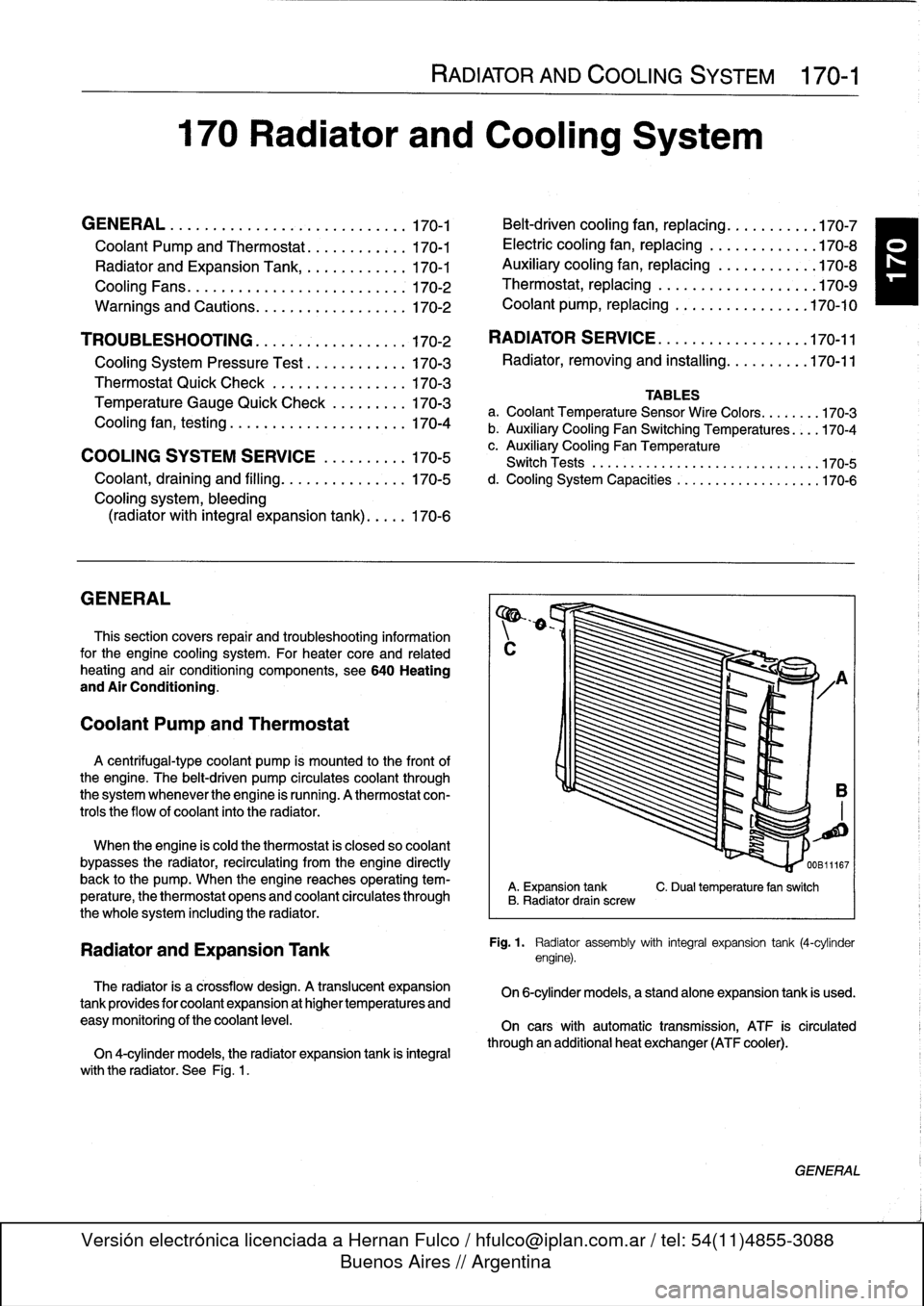

Radiator

and

Expansion

Tank

The

radiator

is

a

crossflow

design

.

A

translucent

expansion

tank

provides

for

coolant

expansion

at

higher

temperatures

and

easy

monitoringof

the

coolant

leve¡

.

On

4-cylinder

modeis,

the

radiator

expansion

tank

is

integral

with

the

radiator

.

See

Fig

.

1

.

RADIATOR

AND

COOLING

SYSTEM

170-1

Belt-driven

cooling

fan,

replacing

.

.......

.

.

.

170-7

Electric

cooling

fan,

replacing

.

.

.

.....

.

.

.

.

.

170-8

Auxiliary

cooling

fan,

replacing

.

.

.....

.

.

.

.

.

170-8

Thermostat,

replacing

.

.

.

.

.

.

.

.

.

.....

.

.

.

.

.

170-9

Coolant

pump,

replacing

..........

.

.

.

.

.

.

170-10

RADIATOR

SERVICE

.....

.

......

.

.

.

.

.

.

170-11

Radiator,

removing

and

installing

....

.

.

.

.

.

.

170-11

TABLES

a

.

Coolant

Temperature

Sensor

Wire

Colors

...

.

..

.

.

170-3b

.

Auxiliary

Cooling

Fan

Switching

Temperatures

.:.

.170-4

c

.

Auxiliary

Cooling

Fan

Temperature

Switch

Tests

..

..

.

...

...

.

.............

.

..

.

.

170-5d

.

Cooling

System

Capacities

..............

..

.

.

.

170-6

A

.

Expansion

tank

C

.

Dualtemperature

fan

switch

B

.

Radiator

drain

screw

Fig

.

1

.

Radiator

assembly

with

integral

expansion

tank

(4-cylinder

engine)

.

On

6-cylinder

models,

a

standalone

expansion

tank

is

used

.

On

cars

with

automatic

transmission,

ATF

is

circulated

through

an

additional

heat

exchanger

(ATF

cooler)

.

GENERAL

Page 197 of 759

Cooling

System

Pressure

Test

If

the

engine

overheats

and

no

other

cooling

system

testsindicate

trouble,

the

radiator

may

have

some

pluggedpassag-

A

cooling

system

pressure

test

is

used

to

check

for

internal

es

that

are

restricting

coolant

flow

.

leaks

.

Some

of

the

common

sources

ofinternal

leaks

are

a

faulty

cylinder

head

gasket,

a

cracked

cylinder

head,

or

a

Temperature

Gauge

Quick

Check

cracked

cylinder

block

.

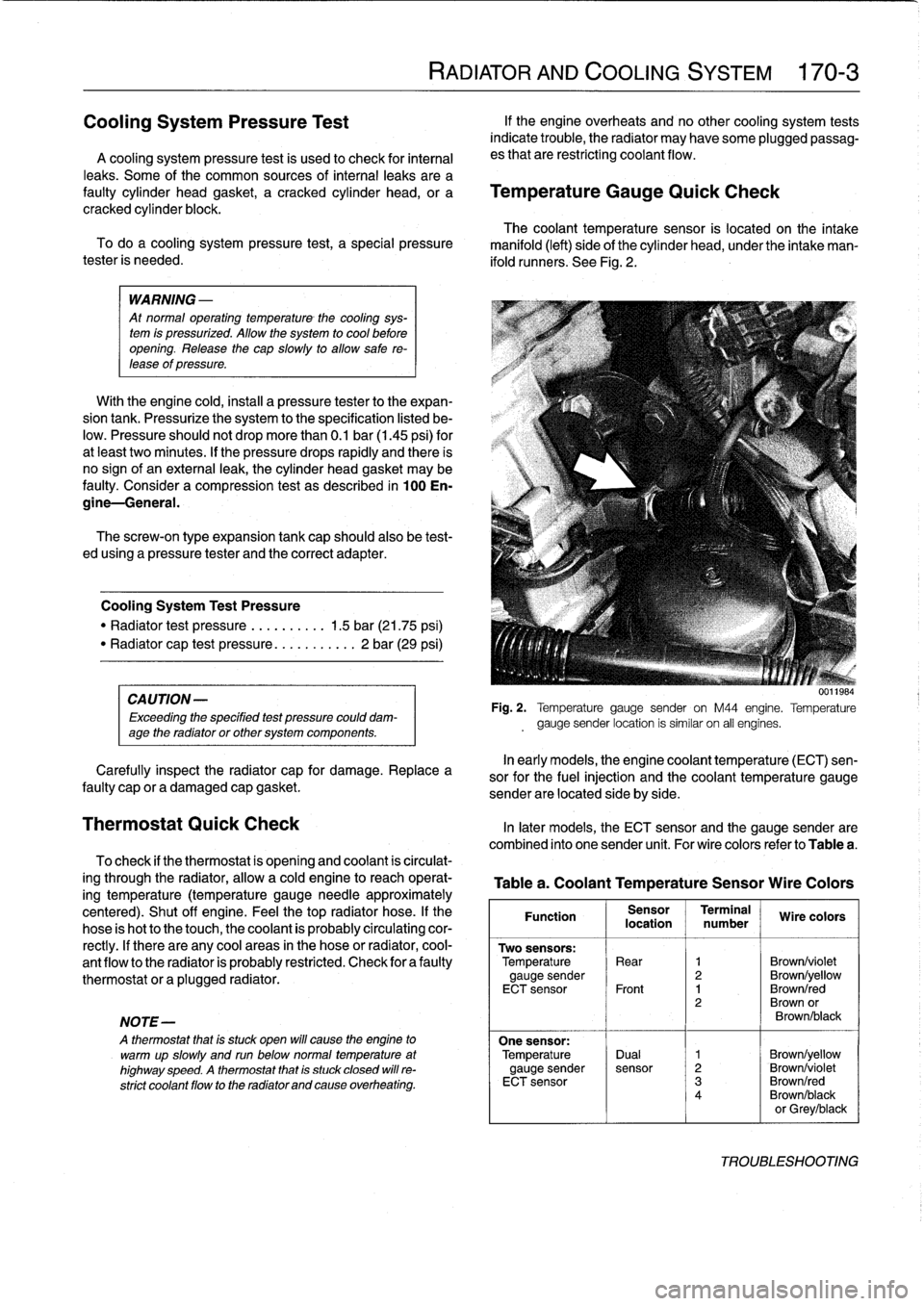

The

coolant

temperature

sensor

is

located

on

the

intake

To

doa

cooling

system

pressure

test,

a

special

pressure

manifold

(left)

side

of

the

cylinder

head,

under

the

intake

man-

tester

is

needed

.

ifold

runners

.

See

Fig

.

2

.

WARNING

-

At

normal

operating

temperature

-

the

cooling

sys-

tem

is

pressurized

.

Allow

the

system

to

cool

before

opening

.

Release

the

cap

slowly

to

allow

sale

re-

tease

of

pressure

.

With

the

engine

cold,instan

a

pressure

tester

to

the

expan-

sion

tank

.

Pressurize

thesystem

to

the

specification

listed

be-

low

.

Pressure

should

not

drop

more

than

0

.1

bar

(1

.45

psi)

for

at

leakt

two

minutes

.

If

the

pressure

drops

rapidly

and

there

is

no

sign

of

an

externa¡

leak,

the

cylinder

head

gasket

may

be

faulty

.

Considera

compression

test

as

described

in

100

En-

gine-General

.

The

screw-on

type

expansion

tank

cap

should

also

be

test-

ed

using

a

pressure

tester

and

the

correct

adapter

.

Cooling

System

Test

Pressure

"

Radiator

test

pressure

.........

.

1

.5

bar

(21

.75

psi)

"

Radiator

cap

test

pressure

..

.

........

2

bar

(29

psi)

CA

UTION-

Exceeding

the

speclfied

test

pressure

could

dam-

age

the

radiatoror

other

system

components

.

Carefully

inspect

the

radiator

cap

for

damage

.

Replace

a

faulty

cap

or

a

damaged

cap

gasket

.

Thermostat

Quick

Check

In

later

models,

the

ECT

sensor

and

the

gauge

sender

are

combined

into

one

sender

unit

.

For

wire

colors

refer

to

Table

a

.

To

check

if

the

thermostat

is

opening

and

coolant

is

circulat-

ing

through

the

radiator,

allow

a

cold

engine

to

reach

operat-

ing

temperature

(temperature

gauge

needieapproximately

centered)

.

Shut

off

engine

.

Feel

the

top

radiator

hose

.

If

the

hose

is

hot

to

the

touch,

the

coolant

is

probably

circulating

cor-

rectly

.

If

there

are

any

cool

areas

in

the

hose

or

radiator,

cool-

ant

flow

to

the

radiator

is

probably

restricted

.

Check

for

a

faulty

thermostat

or

aplugged

radiator

.

NOTE-

A

thermostat

that

is

stuck

open

will

cause

the

engine

to

warmup

slowly

and

run

belownormal

temperature

at

highway

speed

.

A

thermostat

that

is

stuck

closed

will

re-

strict

coolant

flow

to

the

radiator

and

cause

overheating

.

RADIATOR

AND

COOLING

SYSTEM

170-

3

U

.¡ig

.v

Fig

.

2

.

Temperature

gauge

sender

on

M44

engine

.

Temperature

gauge

sender

location

is

similar

on

al]

engines

.

In

early

models,

the

engine

coolant

temperature

(ECT)

sen-

sor

for

the

fuel

injection

and

the

coolant

temperature

gauge

sender

are

located

side

by

side

.

Table

a

.

Coolant

Temperature

Sensor

Wire

Colors

Function

Sensor

Terminal

Wire

colors

location

number

Two

sensors

:

Temperature

Rear

1

Brown/violet

gauge

sender

2

Brown/yellow

ECT

sensor

Front

1

Brown/red

2

Brown

or

Brown/black

One

sensor

:

Temperature

Dual

1

Brown/yellow

gauge

sender

sensor

2

Brown/violet

ECT

sensor

3

Brown/red

4

Brown/black

or

Grey/black

TROUBLESHOOTING

Page 198 of 759

170-

4

RADIATOR

AND

COOLING

SYSTEM

A

quick

testat

the

coolant

temperature

gauge

sender

can

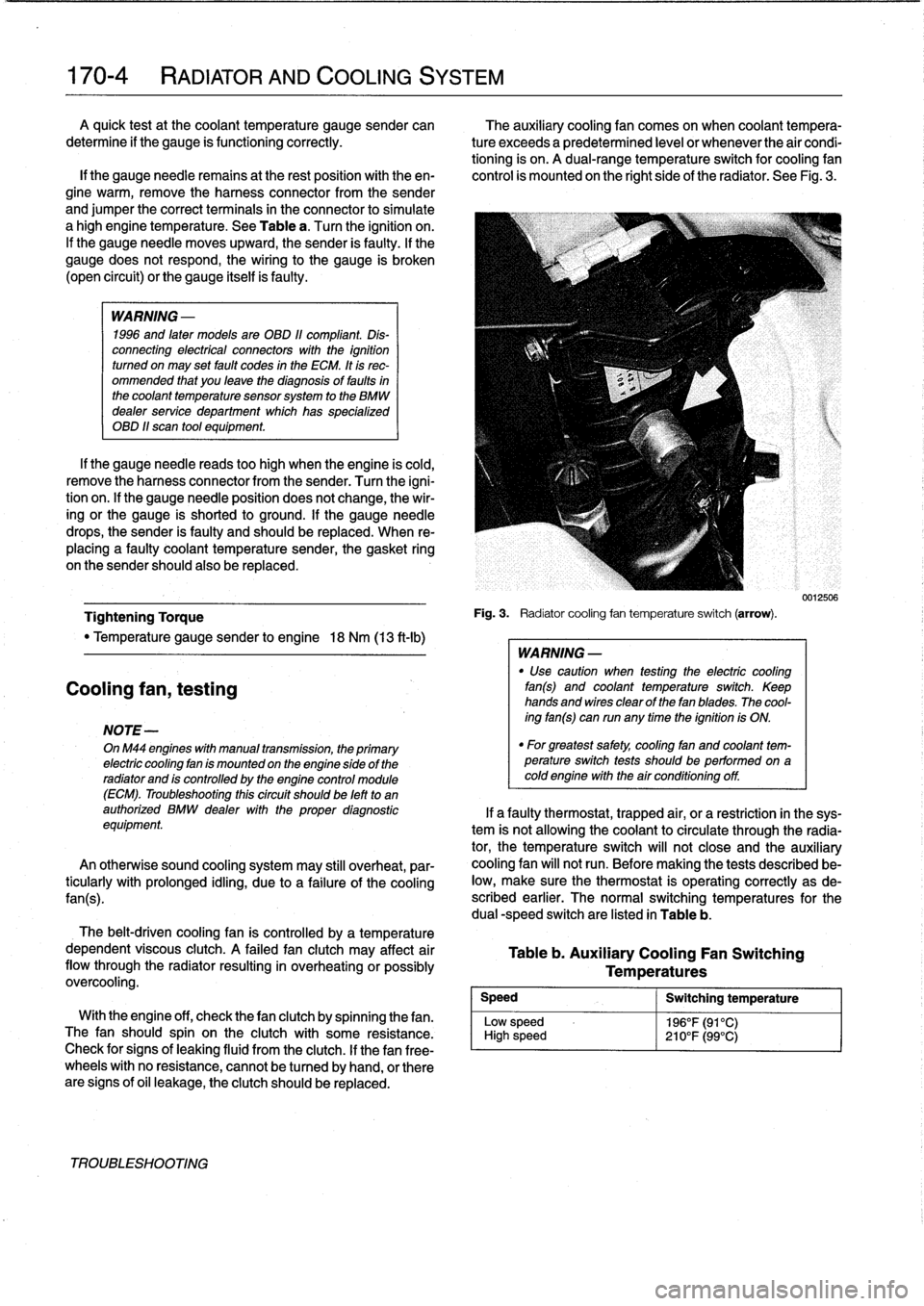

The

auxiliary

cooling

fan

comes

on

when

coolant

tempera

determine

if

the

gauge

is

functioning

correctly

.

ture

exceeds

a

predetermined

leve¡

or

whenever

the

air

condi-

tioning

is

on

.

A

dual-range

temperature

switch

for

cooling

fan

lf

the

gauge

needie

remains

at

the

rest

position

with

theen-

control

is

mounted

on

the

right

side

of

the

radiator

.

See

Fig

.

3

.

gine

warm,

remove

the

harness

connector

from

the

sender

and

jumper

the

correct

terminals

in

the

connector

to

simulate

a

high

engine

temperature

.

See

Table

a

.

Turn

the

ignition

on

.

If

the

gauge

needle

moves

upward,

the

sender

is

faulty

.

If

the

gauge

does

not

respond,

the

wiring

to

the

gauge

is

broken

(open

circuit)

or

the

gauge

itselfis

faulty

.

WARNING

-

1996

and

laten

models

are

OBD

11

compliant

.

Dis-

connecting

electrical

connectors

wíth

the

ignition

turned

on

may

set

fault

codes

in

the

ECM

.

It

is

rec-

ommended

that

you

leave

the

diagnosis

of

faults

in

the

coolant

temperature

sensorsystem

to

the

BMW

dealer

service

department

which

has

specialized

OBD

11

scan

tool

equipment

.

If

the

gauge

needle

reads

too

high

when

the

engine

is

cold,

remove

the

harness

connector

from

the

sender

.

Turn

the

igni-

tion

on

.

lf

the

gauge

needle

position

does

not

change,

the

wir-

ing

or

the

gauge

is

shorted

to

ground

.

If

the

gauge

needle

drops,

the

sender

is

faulty

and

should

be

replaced

.

When

re-

placing

a

faulty

coolant

temperature

sender,

the

gasket

ring

on

the

sender

should

also

be

replaced

.

Tightening

Torque

"

Temperature

gauge

sender

to

engine

18

Nm

(13

ft-Ib)

Cooling

fan,

testing

NOTE-

OnM44

engines

with

manual

transmission,

the

primary

electric

cooling

fan

is

mounted

on

the

engine

side

of

the

radiator

and

is

controlled

by

the

engine

control

module

(ECM)

.

Troubleshooting

thiscircuit

should

be

left

to

an

authorized

BMW

dealer

with

the

proper

diagnostic

equipment

An

otherwise

sound

cooling

system

may

still

overheat,

par-

ticularly

with

prolonged

idling,

due

to

a

failure

of

the

coolíng

fan(s)

.

The

belt-driven

cooling

fan

is

controlled

by

a

temperature

dependent

viscous

clutch

.

A

failed

fan

clutch

may

affect

air

flow

through

the

radiator

resulting

in

overheating

orpossibly

overcooling

.

Speed

Low

sp

High

s

With

the

engine

off,

check

thefan

clutch

by

spinning

thefan

.

eed

The

fan

should

spin

on

the

clutch

with

some

resistance

.

peed

Check

for

signs

of

leaking

fluid

from

the

clutch

.

If

thefan

free-

wheels

with

no

resistance,

cannot

be

tu

rned

by

hand,

or

there

are

signs

of

oil

leakage,

the

clutch

should

be

replaced

.

TROUBLESHOOTING

Fig

.

3

.

Radiatorcooling

fan

temperature

switch

(arrow)

.

WARNING

-

"

Use

caution

when

testing

the

electric

cooling

fan(s)

and

coolant

temperature

switch

.

Keep

hands

and

wires

clear

of

thefan

blades

.

The

cool-

ing

fan(s)

can

run

any

time

the

ignition

is

ON

.

"

For

greatest

safety,

coolíng

fan

and

coolant

tem-perature

switch

tests

shouldbe

performed

on

acoldengine

with

the

air

conditioning

off

.

Table

b

.

Auxiliary

Cooling

Fan

Switching

Temperatures

Switching

temperature

196°F(91°C)

210°F(99°C)

0012506

If

a

faulty

thermostat,

trapped

air,

or

a

restriction

in

the

sys-

tem

is

not

allowing

the

coolant

to

circulate

through

the

radia-

tor,

the

temperature

switch

will

not

close

and

the

auxiliary

cooling

fan

will

not

run

.

Before

making

the

tests

described

be-

low,

make

sure

the

thermostat

is

operating

correctly

as

de-

scribed

earlier

.

The

normal

switching

temperatures

for

the

dual

-speed

switch

are

listed

in

Table

b

.

Page 205 of 759

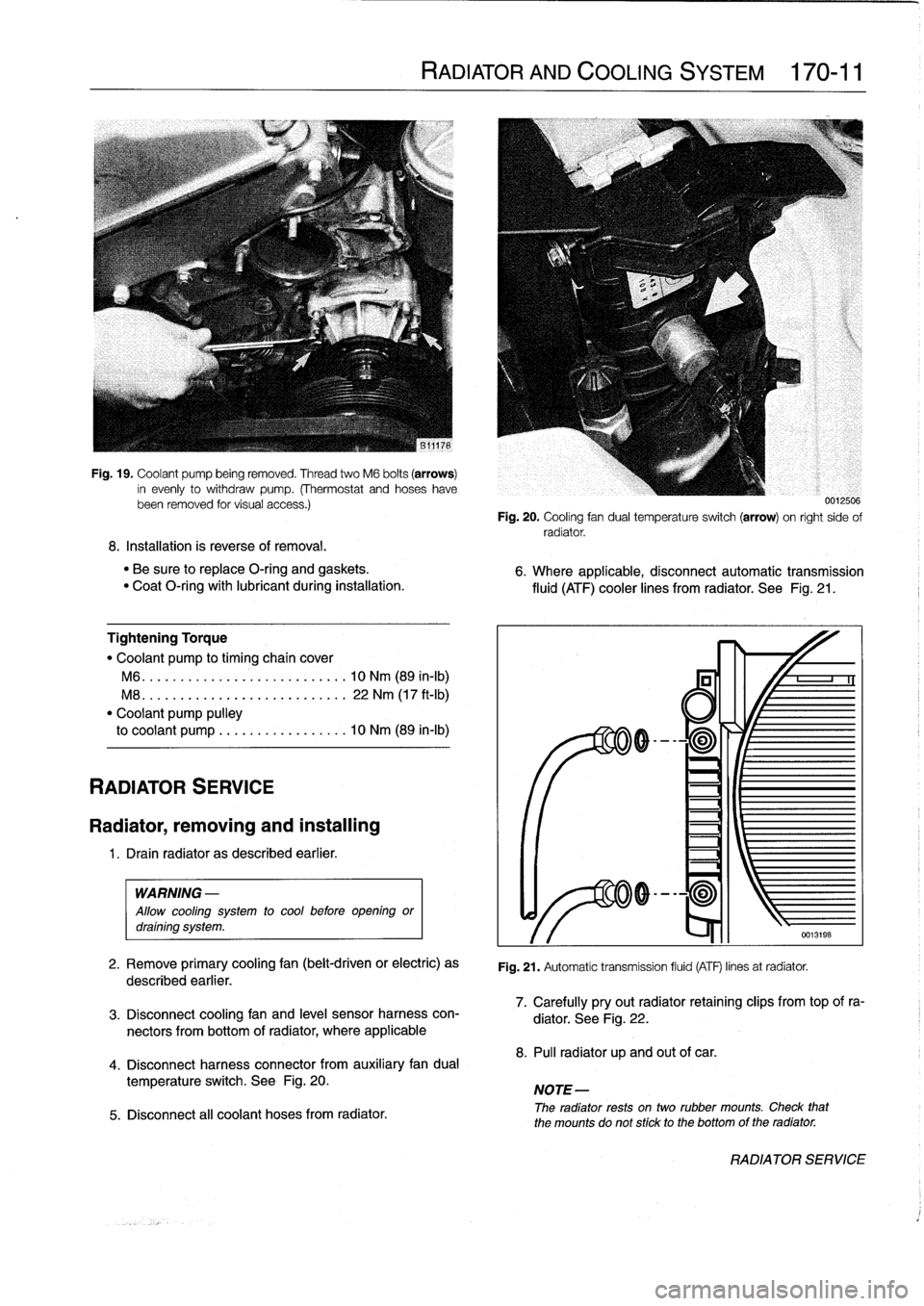

Fig

.

19

.

Coolant

pump

being

removed

.

Thread

two

M6

bolts

(arrows)

in

evenly

to

withdraw

pump

.

(Thermostat

and

hoseshavebeen

removed

tor

visual

access

.)

8

.

Installation

is

reverse

of

removal

.

"

Be

sure

to

replace

O-ring

and

gaskets

.

"

Coat

O-ring

with

lubricant

during

installation

.

Tightening

Torque

"

Coolant

pump

to

timing

chaincover

M6

...

.

...................

..

.

.

10

Nm

(89

in-lb)

M8

.

..

.

....................

.

.

.

22

Nm

(17

ft-Ib)

"

Coolant

pump

pulley

to

coolant

pump

.................

10

Nm

(89

in-lb)

RADIATOR

SERVICE

Radiator,

removing

and

installing

1

.

Drain

radiator

as

described

earlier

.

WARNING

-

Allow

cooling

system

to

cool

before

opening

ordraining

system

.

2

.

Remove

primary

cooling

fan

(belt-driven

or

electric)

as

described

earlier

.

3

.

Disconnect

coolingfan

and

leve¡

sensor

harness

con-

nectors

from

bottom

of

radiator,

where

applicable

4

.

Disconnect

harness

connector

from

auxiliary

fandual

temperature

switch

.

See

Fig

.

20

.

5

.

Disconnect

all

coolant

hoses

from

radiator

.

RADIATOR

AND

COOLING

SYSTEM

170-11

0012500

Fig

.

20

.

Cooling

fan

dual

temperatura

switch

(arrow)

on

right

sido

of

radiator

.

6

.

Where

applicable,

disconnectautomatic

transmission

fluid

(ATF)

cooler

lines

from

radiator

.

See

Fig

.

21

.

Fig

.

21

.

Automatic

transmission

fluid

(ATF)

linos

at

radiator

.

7

.

Carefully

pryout

radiator

retaining

clips

from

top

of

ra-

diator

.

See

Fig

.

22

.

8

.

Pul¡

radiator

up

and

out

of

car

.

NOTE-

The

radiator

rests

ontwo

rubber

mounts

.

Check

that

the

mounts

do

not

stick

to

the

bottomof

the

radiator

.

RADIATOR

SERVICE