wiring BMW 318i 1995 E36 Manual PDF

[x] Cancel search | Manufacturer: BMW, Model Year: 1995, Model line: 318i, Model: BMW 318i 1995 E36Pages: 759

Page 383 of 759

NOTE

-

Sometimes

the

color

of

en

installed

wire

may

be

differ-

ent

than

the

one

on

the

wiring

diagram

.

Don't

be

con-

cerned

.

Just

be

sure

lo

confirm

that

the

wire

connects

lo

the

proper

terminals

.

Wire

color

codes

"

BLU

.........

.

..

..

...

.

.................

Blue

"

BRN

....:....

.

..

..

...

..

...............

Brown

"

YEL

.........

.

..

..

...................

.Yellow

"

GRN

.........

.

..

..

...

.

................

creen

"

G

RY

.......

.

.

.

..

..

.....................

G

ray

"

ORG

.........

.

..

..

...

.

..............

.Orange

"

RED

......

...

.

.

..

.....................

.Red

"

BLK

.........

.

..

..

...

.

................

Black

"

VIO

..........

.

..

...

..

..

.......

.

.......

Violet

"

WHT

.........

.

.

....

.

...

:..............

White

Table

a

.

Terminal

and

Circuit

Numbers

Number

1

Circuít

description

1

j

Low

voltage

switched

terminal

of

coi¡

4

1

High

voltage

center

termina¡

of

coi¡

+x

Originates

atignition

switch

.

Supplies

powerwhen

the

ignition

switch

is

in

the

PARK,

RUN,

or

START

position

15

Originates

atignition

switch

.

Supplies

powerwhen

ignition

switch

is

in

RUN

or

START

position

30

Battery

positive

(+)

voltage

.

Supplies

power

whenever

battery

is

connected

.

(Not

dependent

on

ignition

switch

position,

unfused)

31

1

Ground,

battery

negative

(-)

terminal

50

Supplies

power

from

battery

to

starter

solenoid

when

ignition

switch

isin

START

position

only

+54

Originates

atignition

switch

.

Supplies

power

when

ignition

switch

isin

the

RUN

position

only

85

1

Ground

side

(-)

ofrelay

coil

86

1

Power-in

side

(+)

ofrelay

coil

87

1

Relay

actuatedcontact

D

Alternator

warning

light

and

field

energizing

circuit

ELECTRICAL

SYSTEM-GENERAL

600-

3

Additional

abbreviations

shown

in

the

wiring

diagrams

are

given

below

.

Abbreviations

"

ABS

........

.

...

.

...

.

..........

antilock

brakes

"

A/C

........

.

...

..

..

.

.........

.airconditioning

"

AST/ASC+T

.......

...

.

.

.......

al¡

season

traction

"

CONV

.......

.

.

...

.................

convertible

"

DME

........

.

.

...

.......

digital

motor

electronics

"

ECM

.......

.

...

..

..

.

..

electronic

control

module

"

EWS/EWS

II

......

...

.

.

coded

driveaway

protection

"

SRS

........

.

supplemental

restraint

system-airbag

"

TCM

........

.

..

....

.

transmission

control

module

"

ZKE

(94-98

models)

..

..

.

...

central

body

electronics

"

ZVM

(92-93

models)

...

.

.

..

.

.......

central

locking

ELECTRICAL

TROUBLESHOOTING

Most

terminals

are

identified

by

numbers

on

the

compo-

nents

and

harness

connectors

.

The

terminal

numbers

for

ma-

Four

things

are

required

for

current

toflow

in

any

electrical

jor

electrical

connections

are

shown

in

the

diagrams

.

Though

circuit

:

a

voltagesource,

wires

or

connections

to

transport

the

many

terminal

numbers

appear

only

once,

severa¡other

num-

voltage,

a

load

or

device

that

uses

the

electricity,

and

a

con-

bers

appear

in

numerous

places

throughout

the

electrical

sys-

nection

to

ground

.

Most

problemscanbefound

using

a

digital

tem

and

identify

certain

types

ofcircuits

.

Some

of

the

most

multimeter

(volt/ohm/amp

meter)to

check

for

voltage

supply,

common

circuit

numbers

are

listed

below

in

Table

a

.

for

breaks

in

the

wiring

(infinite

resistance/no

continuity),

orfor

a

path

to

ground

that

completesthe

circuit

.

Electric

current

is

logical

in

its

flow,

always

moving

from

the

voltage

sourcetoward

ground

.

Electricalfaults

can

usually

be

located

through

a

process

of

elimination

.

When

troubleshoot-

ing

a

complex

circuit,

separate

the

circuit

into

smaller

parts

.

The

general

testsoutlined

below

may

be

helpful

in

finding

electrical

problems

.

The

information

is

most

helpful

when

used

with

the

wiring

diagrams

.

Be

sure

to

analyze

the

problem

.

Use

the

wiring

diagrams

to

determine

the

most

likely

cause

.

Getan

understanding

of

how

the

circuit

works

by

following

the

circuit

from

groundback

to

the

power

source

.

When

making

test

connections

at

connectors

andcompo-

nents,

use

care

to

avoidspreading

or

damaging

the

connec-

tors

or

terminals

.

Some

tests

may

require

jumper

wires

to

bypass

components

or

connections

in

the

wiring

harness

.

When

connecting

jumper

wires,

use

bladeconnectors

at

the

wire

ends

that

match

the

size

of

the

terminal

being

tested

.

The

small

interna¡

contacts

are

easily

spread

apart,

and

this

can

cause

intermittent

or

faultyconnections

that

can

leadto

more

problems

.

ELECTRICAL

TROUBLESHOOTING

Page 385 of 759

Continuity,

checking

Short

Circuits

from

Battery

CAUTION-

Use

only

a

high

quality

digital

ohmmeter

having

high

input

impedance

when

checking

electronic

componente

.

The

internal

power

source

used

in

most

analog

(swing-need1e)

meterscan

damage

solidstate

components

.

0013239

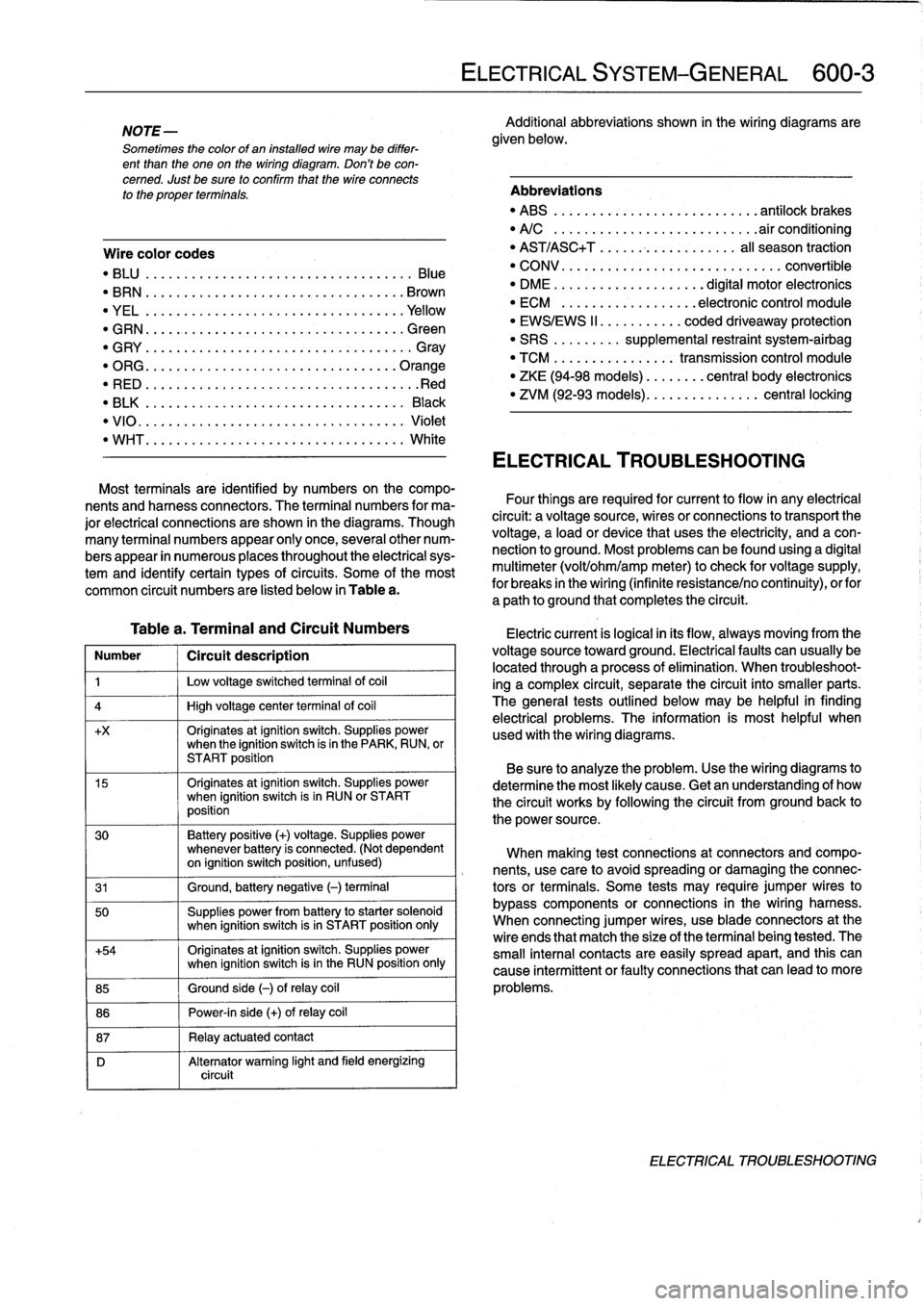

Fig

.

2

.

Digital

multimeter

being

used

to

check

for

voltage

drop

across

a

switch

.

The

continuity

test

can

beused

to

check

a

circuit

or

switch

.

Because

most

automotive

circuits

are

designed

to

have

little

or

no

resistance,

a

circuit

or

part

of

a

circuit

canbe

easily

checked

for

faults

using

an

ohmmeter

.

An

open

circuit

or

a

cir-

cuit

withhigh

resistance

will

not

allow

current

to

flow

.

A

círcuit

with

little

or

no

resistanceallows

current

to

flow

easily

.

When

checking

continuity,

the

ignition

should

be

off

.

On

cir-

cuits

that

are

powered

at

all

times,

the

battery

should

be

dis-

connected

.

Using

the

appropriate

wiring

diagram,

a

circuit

can

be

easily

tested

for

faulty

connections,

wires,

switches,

relays,

and

engine

sensorsby

checking

forcontinuity

.

For

a

continu-

ity

check

on

a

brake

light

switch,

see

Fig

.

3

..

A

short

circuit

is

exactly

what

the

narre

implies

.

The

circuit

takes

a

shorter

paththan

it

was

designed

to

take

.

The

most

common

short

that

causes

problems

is

a

short

to

ground

where

the

insulation

on

a

positive

(+)

wire

wears

away

and

the

metal

wire

is

exposed

.

When

the

wire

rubs

against

a

metal

partof

thecar

or

other

ground

source,

the

circuit

is

shorted

to

ground

.

If

the

exposed

wire

is

live

(positive

battery

voltage),

a

Puse

will

blow

and

the

circuit

may

possibly

be

damaged

.

ELECTRICAL

SYSTEM

-

GENERAL

600-

5

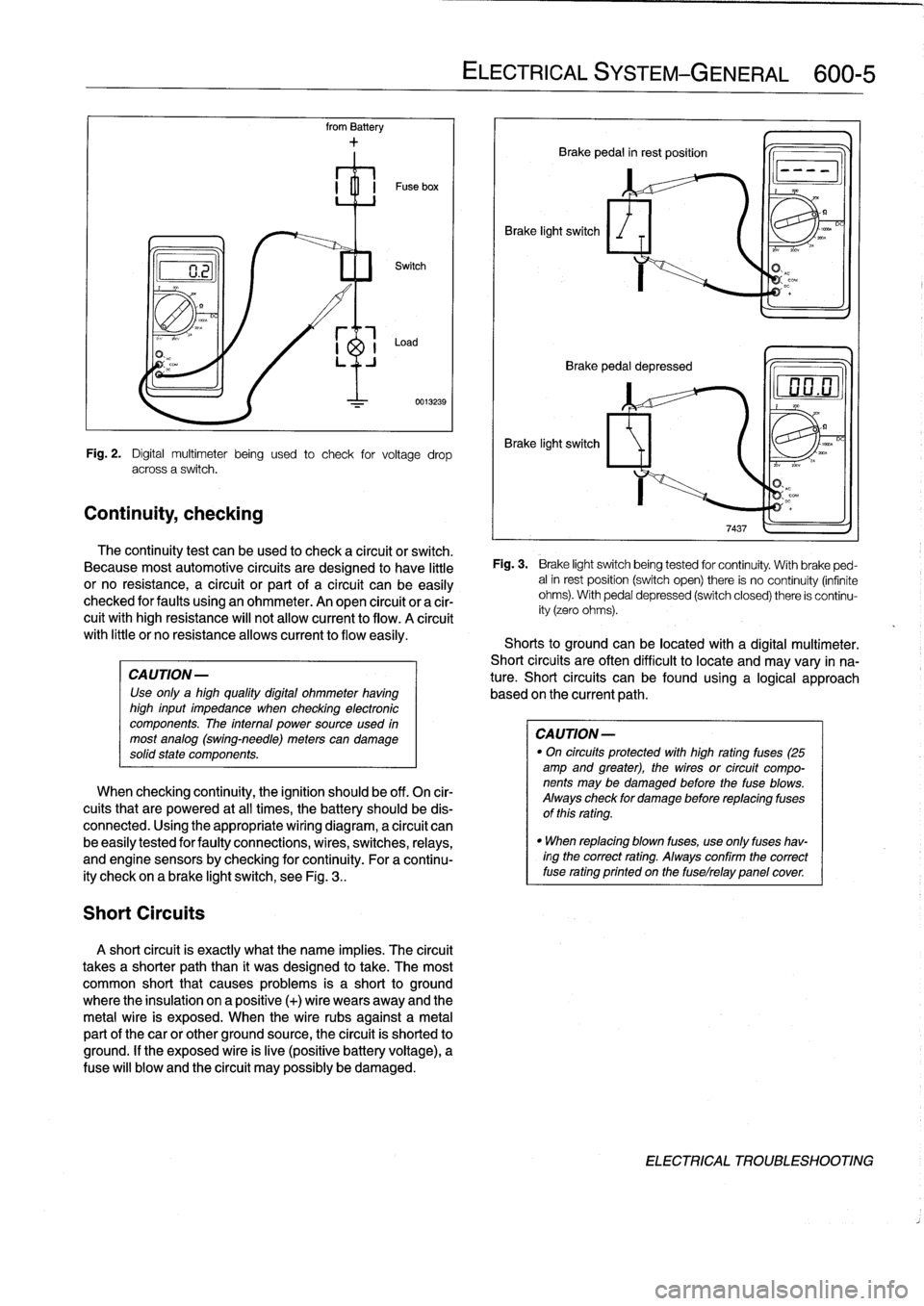

Brake

light

switch

Brake

pedal

in

rest

position

Q

Brake

pedal

depressed

Brake

light

switch

Fig

.

3

.

Brake

light

switchbeing

tested

for

continuity

.

With

brake

ped-

alin

rest

position

(switch

open)

there

is

no

continuity

(infinite

ohms)

.

With

pedal

depressed

(switch

closed)

there

is

continu-

ity

(zero

ohms)

.

Shorts

to

groundcanbe

located

with

a

digital

multimeter

.

Short

circuits

are

often

difficult

to

locate

and

may

vary

in

na-

ture

.

Short

circuits

can

befound

using

a

logical

approach

based

onthe

current

path

.

CAUTION

-

"

On

circuits

protected

with

high

rating

fuses

(25

amp

and

greater),

the

wires

or

circuit

compo-

nents

may

be

damaged

before

the

fuse

blows

.

Always

check

for

damage

before

replacing

fuses

of

this

rating

.

"

When

replacing

blown

fuses,

use

only

fuses

hav-

ingthe

correct

rating

.

Always

confirm

the

correct

fuse

rating

printed

on

the

fuselrelay

panelcover

DC

ELECTRICAL

TROUBLESHOOTING

Page 387 of 759

610

Electrical

Component

Locations

GENERAL

...........

.

.

.

.

.

.

.

.

.

........

610-1

FOSE

POSITION

TABLES

..

.

.

.

.

.

.....

.

610-19

FUSE

AND

RELAY

POSITIONS

.

...

.

.

.

.

.

610-1

Fuse

Positions

.

.

.

................

.

.

.

.

.

610-1

Relay

Positions

.

.

.

.....

.

.

.

........

.

.

.

.

.

610-2

Auxiliary

RelayPanel

.....

.

...

.

........

.

610-2

SplicePanel,

Left

.

.

.

...

.

.

.

...

.

........

.

610-2

SplicePanel,

Right

.

.

.

.

.

.

.

.

...

.

.........

610-3

COMPONENT

LOCATIONS

.

.

.

.

.......

.

.610-3

Component

Location

Table

.

.

.

.

.

.

.........

610-9

GENERAL

FUSE

AND

RELAY

POSITIONS

This

repair

group

covers

f

use,

relay,

and

control

module

lo-

The

front

power

distribution

box,

an

auxiliary

relay

panel,cation

information

.

Electrical

equipment

and

accessories

in-

and

two

auxiliary

splice

panels

contain

most

of

the

fuses

and

stalled

varies

depending

on

model

and

model

year

.

Always

relays

in

E36

vehicles

.

Refer

to

the

component

location

later

confirm

that

the

proper

electrical

component

has

been

identi-

in

this

section,

as

well

as

the

tables

at

the

end

of

this

repair

fied

by

using

the

electrical

wiring

diagrams

.

group

for

electrical

component

location

.

WARNING

-

On

cars

equipped

with

airbags,

special

precautionsapply

to

any

electrical

system

testing

orrepair

.

Air-

bag

units

areexplosive

devices

and

mustbe

han-

dled

with

extremecare

.

Before

starting

any

work

onan

airbag

equipped

car,

refer

to

the

wamings

and

cautions

in

721

Airbag

System

(SRS)

.

CAUTION

-

"

Prior

to

disconnectiog

the

battery,

read

the

bat-

tery

disconnection

cautions

given

at

the

front

of

this

manual

on

page

viii

.

"

Relay

and

fuse

positions

are

subject

to

changeand

may

varyfrom

car

to

car

.

If

questions

arise,

an

authorized

BMW

dealer

is

the

best

source

for

the

most

accurate

and

up-to-date

information

.

"

A

good

way

to

verify

a

relay

position

isto

com-

pare

the

wiring

colors

at

the

relay

socket

to

thecolors

indicated

on

the

wiring

diagrams

located

at

the

rear

of

this

manual

.

"

Always

switchthe

ignition

off

and

disconnect

the

negative

(-)

battery

cable

before

removing

any

electrical

components

.

"

Connect

and

disconnect

ignition

system

wires,

multiple

connectors,

and

ignition

test

equipment

leads

only

while

the

ignition

is

switched

off

.

"

Only

usea

digital

multimeter

for

electrical

tests

.

ELECTRICAL

COMPONENT

LOCATIONS

610-1

TABLES

a

.

E36Component

Locations

...........

.

.

..

...

610-10b

.

1992

E36

Fuse

Positions

..........

..

.

.

.....

610-20c

.

1993

E36

Fuse

Positions

..........

..

..

.

....

610-22d

.

1994

E36

Fuse

Positions

.........

...

.......

610-24e

.

1995

E36

Fuse

Positions

.........

...

.......

610-26

f

.

1996

E36

Fuse

Positions

.........

...

.......

610-28g

.

1997-1998

E36

Fuse

Positions

..

.

..

...

.......

610-30

Fuse

Positions

CAUTION

-

"

Replace

fuses

with

those

of

the

same

rating

.

In-

stalling

a

fuse

with

higher

rating

can

lead

to

cir-

cuit

failure

and

may

also

start

a

fire

.

"

Relay/fuse

positions

vary

by

model

and

equip-

ment

.

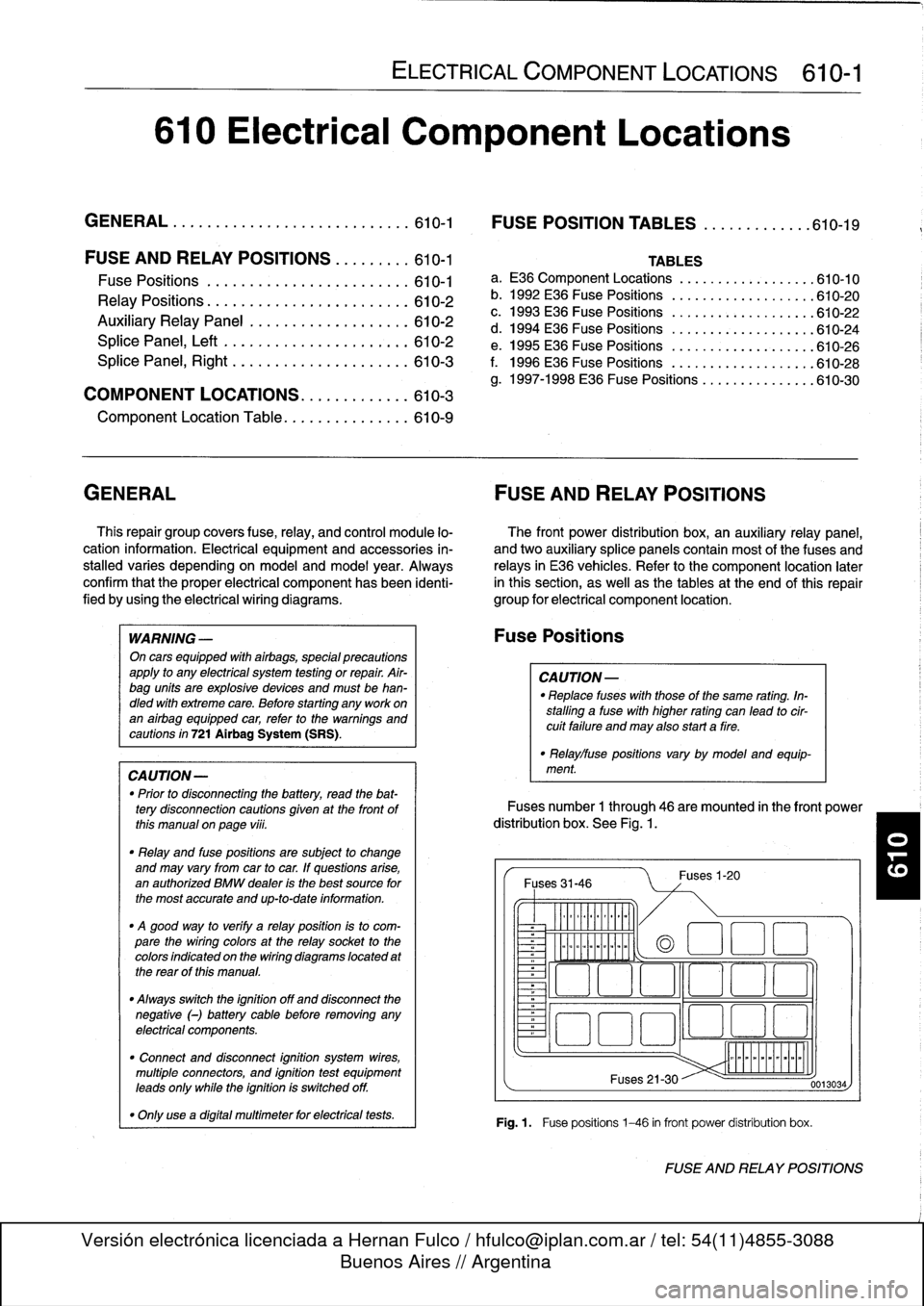

Fuses

number

1

through

46

are

mounted

in

the

front

power

distribution

box

.

See

Fig

.

1.

Fuses

31-46

~

Illlllllllll

°

-

Ilmmlmomlmoi

Fuses

1-20

(a

1

:1

E

El

~

~O!7

L~~n

4~

i

Fuses

21-30

Fig

.1.

Fuse

positions

1-46

in

front

power

distribution

box

.

0013034

FUSE

AND

RELAY

POSITIONS

Page 419 of 759

611

Wipers

and

Washers

GENERAL

..

.

.

.

.

.

.

.

.

.

.

.

.

.

.....

.

......

.

611-1

Windshield

wiper

motor,

removing

and

installing

.

...............

.611-8

WIPER

BLADES

.

.

.

.....

.

.

.

.

.

.

...

....

.611-1

Wiper

Blade

Cleaning

Problems

.

.

.

.

.

.

.....

611-1

Wiper

blades,replacing

...

.

.

.

.

.

.

.

.

.

.....

611-1

Wiper

blade

inserts,

replacing

.

.

.

.

.

.

.

.

.....

611-2

Wiper

arms,

removing

and

installing

.

.

.

.....

611-2

WINDSHIELD

WIPER

ASSEMBLY

.

.

.....

611-3

Windshield

wiper

assembly,

removing

and

installing

(4-door

models)

.

.

.

.

.

.

.....

611-3

Windshield

wiper

assembly,

removing

and

installing

(2-door

models)

.

.

.

.

.

.

.....

611-5

GENERAL

This

repair

group

covers

windshield

wiper

and

washer

sys-

tem

repair

information

.

Please

note

that

some

procedures

are

different

for

2-

and

4-door

models

.

The

windshield

wiper/washer

stalk

switch

assembly

is

cov-

ered

in

612

Switches

and

Electrical

Accessories

.

Electrical

NOTE-

wiring

diagrams

and

relays

for

the

wiper/washer

system

are

BMwhas

available

a

special

toollgauge

(BMWspecial

covered

in

Electrical

Wiring

Diagrams

.

tool

no

.

00

9210)

to

align

the

angle

of

the

wiper

arm

to

the

windshield

glass

.

WIPERBLADES

CA

UTION-

Never

turn

on

the

wiper

blades

while

the

hood

is

open

.

Damage

to

the

wiper

system

and

hood

may

occur

.

Toensure

safetyduring

wiper

biade

system

procedures,

remove

the

windshieldwiper

fuse

.

See

610

Electrical

Component

Locations

.

Wiper

Blade

Cleaning

Problems

Common

cleaning

problems

with

thewipers

includestreak-

ing

or

sheeting,

waterdrops

after

wiping,

and

blade

chatter

.

Streaking

is

usually

caused

when

wiper

blades

are

coated

with

road

film

or

car

wash

wax

.

Clean

the

blades

using

soapy

water

.

If

cleaning

does

not

cure

the

problem,

the

blades

should

be

replaced

.

BMW

recommends

replacing

the

wiper

blades

twice

a

year,

before

and

after

the

cold

season

.

WIPERS

AND

WASHERS

611-1

WINDSHIELD

CLEANING

SYSTEM

......

611-9

Windshield

spray

nozzle,

removing

and

installing

.......

.

........

.611-9

Washer

fluid

reservoir,

replacing

.........

.611-9

Windshield

washer

fluid

pump,

replacing

..

.

......

.

........

.611-9

Washer

fluid

level

sensor,

replacing

(models

with

check

control)

.

.

.

.

........

611-10

Wiper

blade

chatter

may

be

caused

by

dirty

or

worn

blades,

or

by

wiper

arms

that

areout

of

alignment

.

Clean

the

blades

and

windshield

as

described

above

.

Adjust

the

wiper

arm

so

that

there

is

even

pressure

along

the

blade,

and

so

that

the

blade

at

rest

is

perpendicular

to

the

windshield

.

If

problems

persist,

theblades

and

wiper

arms

should

be

replaced

.

The

wiper

blades

can

be

renewed

in

one

of

two

ways

:

either

by

replacing

the

complete

blade

or

by

replacing

just

therubber

insert

.

Insert

replacement

is

the

mosteconomicalmethod,

al-

though

overtime

the

wiperblade

itselfwill

become

worn

.

One

ruleof

thumb

wouldbe

to

replace

just

the

inserts

every

second

time

.

Wiper

blades,

replacing

1

.

Pivot

wiper

arm

off

windshield

.

2

.

Position

wiperblade

approximately

perpendicular

to

wiper

arm

.

3

.

Remove

wiperblade

from

wiper

arm

by

depressing

re-

taining

tab

and

sliding

blade

out

of

arm

.

See

Fig

.

1

.

Drops

that

remain

behind

after

wiping

are

usually

caused

by

NOTE-

oil,

road

film,

or

diesel

exhaust

residue

onthe

glass

.

Use

an

Some

wiperblade

versions

may

havetwo

retaining

alcohol

or

ammonia

solution

or

a

non-abrasive

cleaner

(such

tabs

.

a

s

Bon-Ami

to

clean

the

windshield

.

GENERAL

Page 422 of 759

611-

4

WIPERS

AND

WASHERS

2

.

Remove

wiper

arms

as

described

earlier

.

3

.

Place

engine

hood

in

service

position

.

See

410

Fend-

ers,

Engine

Hood

.

4

.

Unclip

engine

bulkhead

plenum

grille

at

base

of

wind-

shield

and

pulí

it

away

from

rubbergasket

.

See

Fig

.

5

.

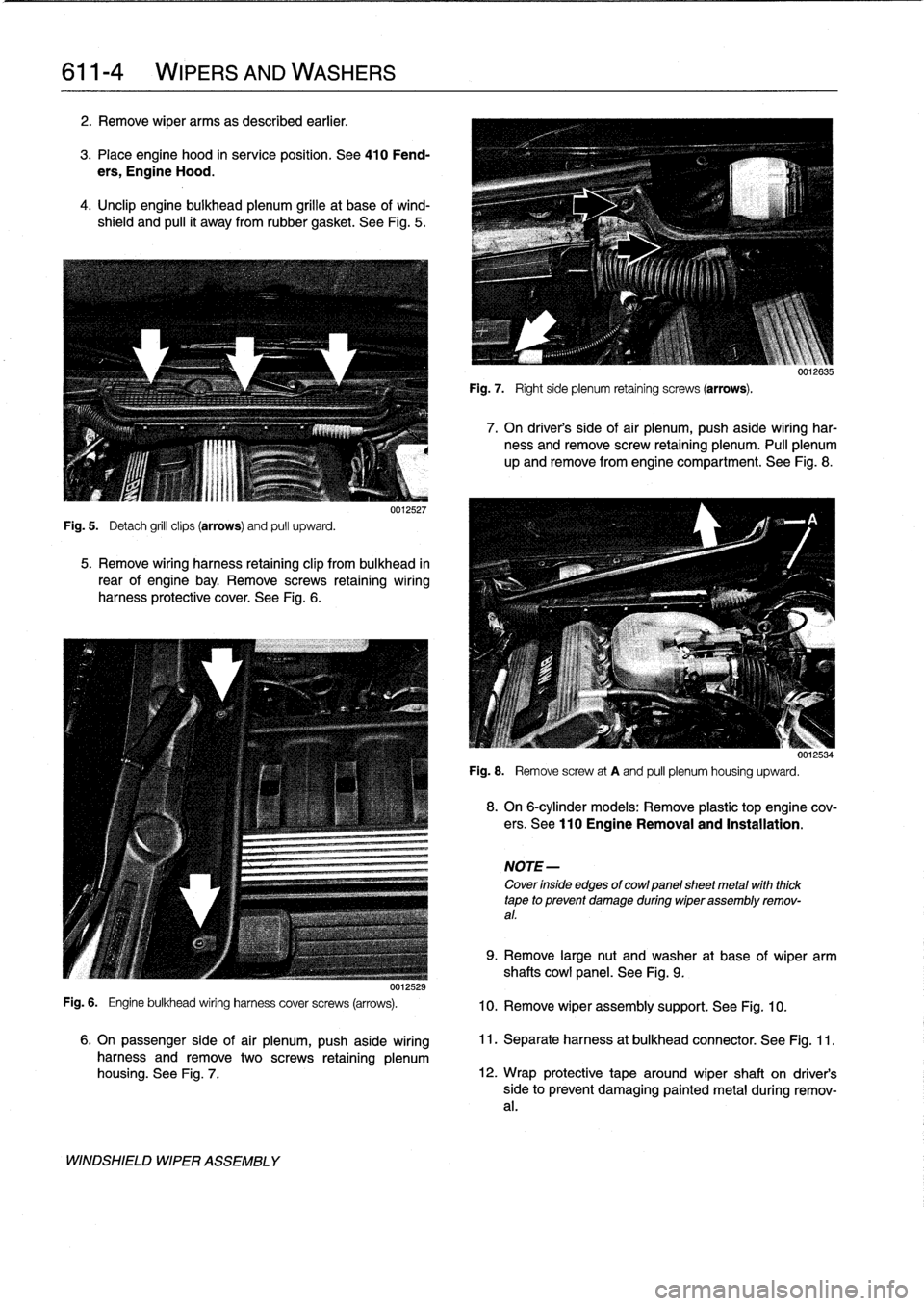

Fig

.

5

.

Detach

grill

clips

(arrows)

and

pull

upward

.

0012527

5

.

Remove

wiring

harness

retaining

clip

frombulkhead

in

rear

of

engine

bay

.

Remove

screws

retaining

wiring

harness

protective

cover

.

See

Fig

.

6

.

0012529

Fig

.

6

.

Engine

bulkhead

wiring

harness

cover

screws

(arrows)

.

WINDSHIELD

WIPER

ASSEMBLY

Fig

.

7

.

Right

side

plenum

retaining

screws

(arrows)

.

7

.

On

driver's

side

of

air

plenum,

push

aside

wiring

har-

ness

and

remove

screw

retaining

plenum

.

Pull

plenum

up

andremove

from

engine

compartment

.

See

Fig

.

8

.

001¿534

Fig

.

8

.

Remove

screw

at

A

and

pull

plenum

housing

upward

.

8

.

On

6-cylinder

models

:

Remove

plastic

top

engine

cov-

ers

.

See

110Engine

Removal

and

Installation

.

NOTE-

Cover

ínside

edges

of

cowlpanelsheet

metal

with

thick

tape

to

prevent

damage

during

wiper

assembly

remov-

al

.

9

.

Remove

large

nut

and

washer

at

base

of

wiper

arm

shafts

cowi

panel

.

See

Fig

.

9

.

10

.

Remove

wiper

assembly

support

.

See

Fig

.

10

.

6

.

On

passenger

side

of

air

plenum,

push

aside

wiring

11

.

Separateharness

at

bulkhead

connector

.

See

Fig

.

11

.

harness

and

remove

twoscrews

retaining

plenum

housing

.

See

Fig

.

7

.

12

.

Wrap

protective

tape

around

wiper

shaft

on

driver's

side

to

prevent

damaging

painted

metal

during

remov-

al

.

Page 423 of 759

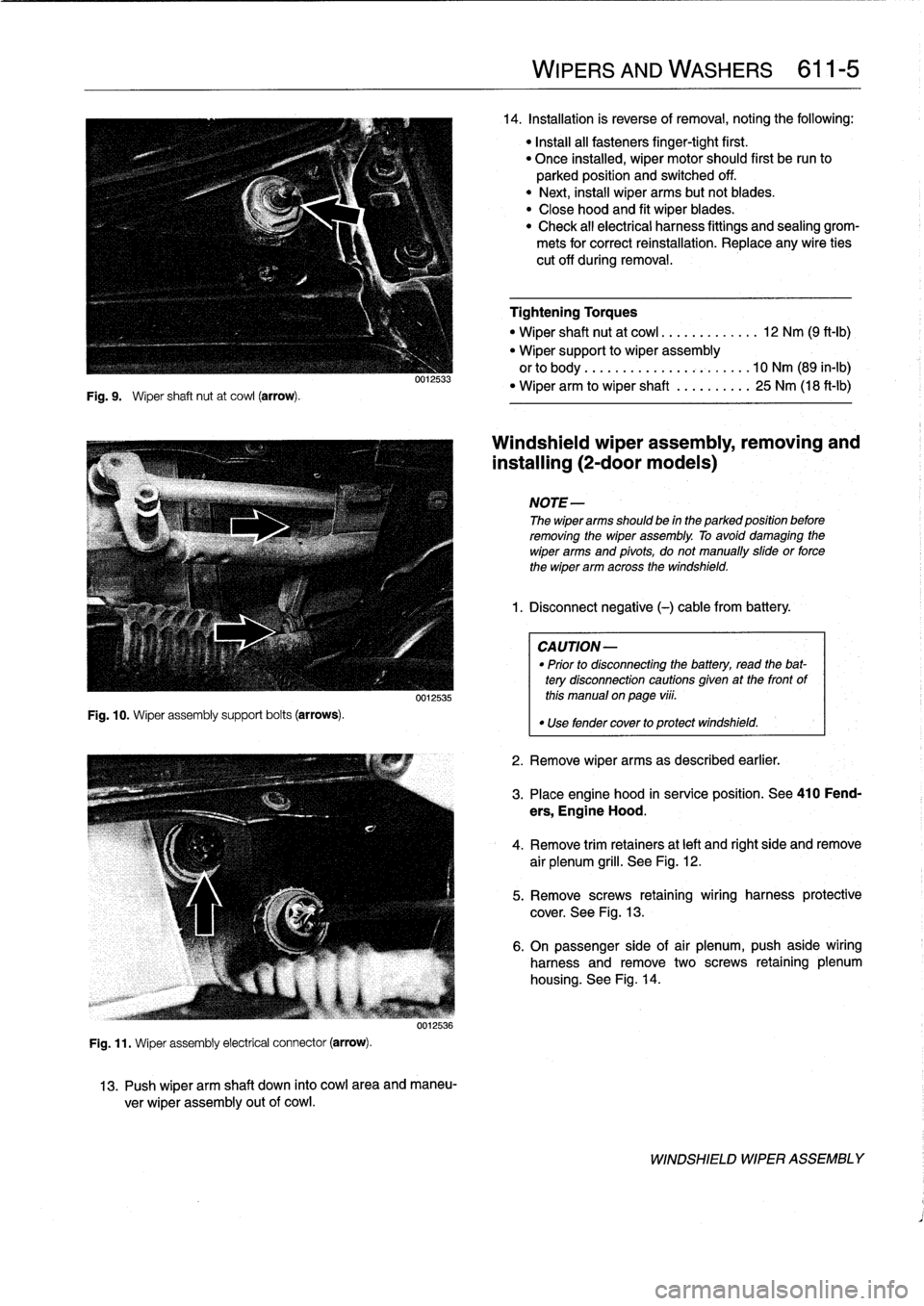

Fig

.

9

.

Wiper

shaft

nut

at

cowl

(arrow)

.

Fig

.

10

.

Wiper

assembly

support

bolts

(arrows)

.

0012533

0012535

Fig

.

11

.

Wiper

assembly

electrical

connector

(arrow)

.

0012536

13

.

Push

wiper

arm

shaft

down

into

cowl

area

and

maneu-

ver

wiper

assembly

out

of

cowl

.

WIPERS

AND

WASHERS

611-

5

14

.

Installation

is

reverse

of

removal,noting

the

following

:

"

Install

all

fasteners

finger-tight

first

.

"

Once

installed,

wiper

motor

should

first

be

run

to

parked

position

and

switched

off

.

"

Next,

instaf

wiper

arms

butnotblades

.

"

Close

hood

and

fit

wiper

blades

.

"

Check

all

electrical

harness

fittings

and

sealing

grom-

mets

for

correct

reinstallation

.

Replace

any

wire

ties

cut

off

during

removal

.

Tightening

Torques

"

Wiper

shaft

nut

at

cowl

.............

12

Nm

(9

ft-Ib)

"

Wiper

support

to

wiper

assembly

orto

body

..

..

..

.

...............

10

Nm

(89

in-lb)

"

Wiper

arm

to

wiper

shaft

..........

25

Nm

(18

ft-lb)

Windshieldwiper

assembly,

removing

and

installing

(2-door

modeis)

NOTE-

The

wiper

arms

should

be

in

the

parked

position

before

removing

the

wiper

assembly

.

To

avoid

damaging

the

wiper

arms

and

pivots,

donotmanually

sidde

or

force

the

wiper

arm

across

the

windshield

.

1

.

Disconnect

negative

(-)cablefrom

battery

.

CAUTION-

"

Prior

to

disconnectiog

the

battery,

read

the

bat-

tery

disconnection

cautionsgiven

at

the

front

of

this

manual

on

page

viii

.

"

Use

fendercover

to

protect

windshield

.

2

.

Remove

wiper

arms

as

described

earlier

.

3

.

Place

engine

hood

in

service

position

.

See410

Fend-

ers,

Engine

Hood

.

4

.

Remove

trim

retainers

at

left

and

right

side

and

remove

air

plenum

grill

.

See

Fig

.

12

.

5

.

Remove

screws

retaining

wiring

harness

protective

cover

.

See

Fig

.

13

.

6

.

On

passenger

side

of

air

plenum,push

aside

wiring

harness

and

remove

two

screws

retaining

plenum

housing

.

See

Fig

.

14

.

WINDSHIELD

WIPER

ASSEMBLY

Page 424 of 759

611-

6

WIPERS

AND

WASHERS

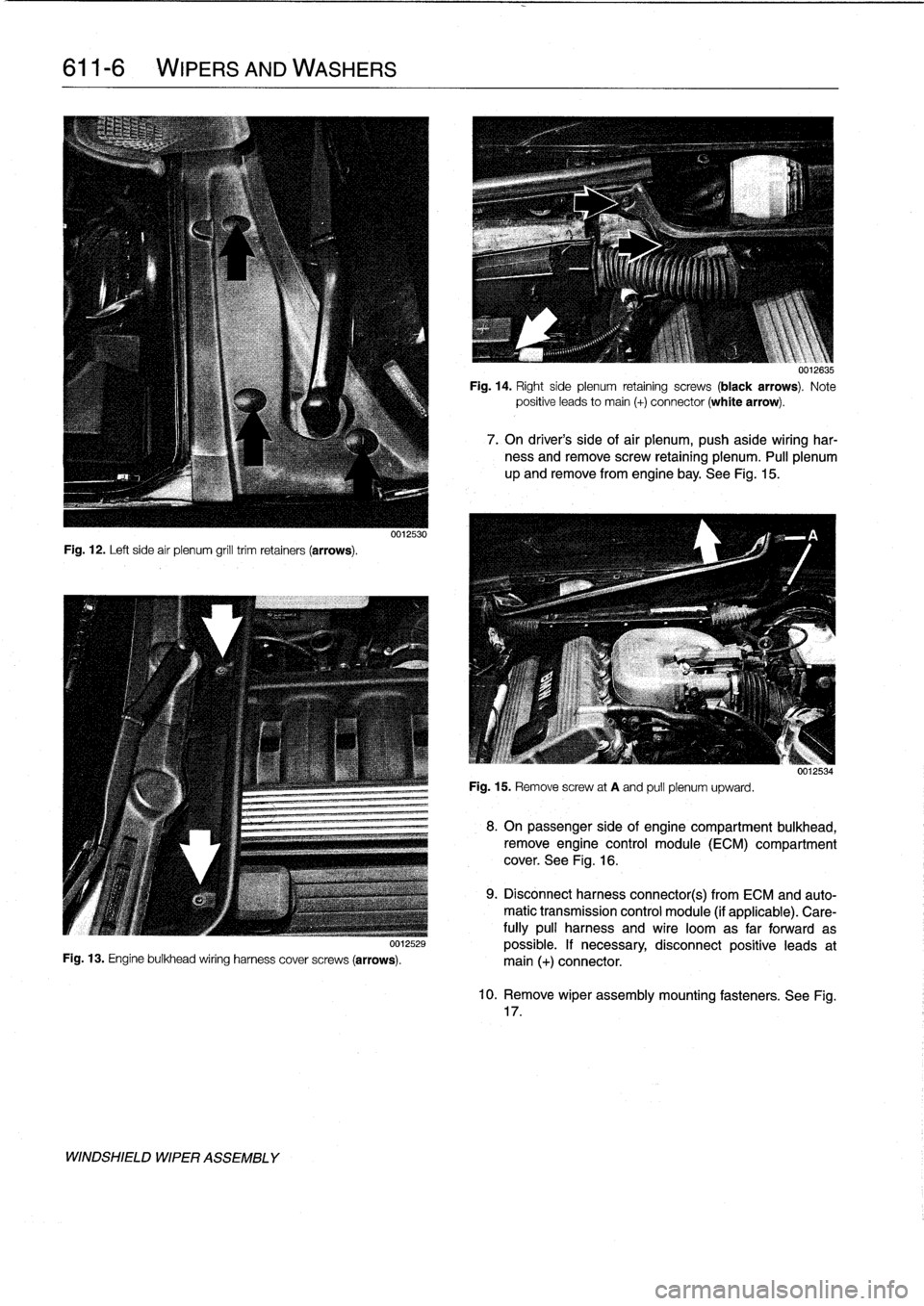

Fig

.

12

.

Left

side

air

plenum

grill

trim

retainers

(arrows)

.

uu12529

Fig

.

13

.

Engine

bulkhead

wiring

harness

cover

screws

(arrows)

.

WINDSHIELD

WIPER

ASSEMBLY

Fig

.

15

.

Remove

screw

at

A

and

pull

plenum

upward

.

0012635

Fig

.

14

.

Right

side

plenum

retaining

screws

(black

arrows)

.

Note

positive

leads

to

main

(+)

connector

(white

arrow)

.

7

.

On

driver's

side

of

air

plenum,

push

aside

wiring

har-

ness

and

remove

screw

retaining

pienum

.

Pull

plenum

up

and

remove

from

engine

bay

.

See

Fig

.

15

.

8

.

On

passenger

side

of

engine

compartment

bulkhead,

remove

engine

control

module

(ECM)

compartment

cover

.

See

Fig

.

16

.

9

.

Disconnectharness

connector(s)

from

ECM

and

auto-

matic

transmission

control

module

(if

applicable)

.

Care-

fully

pull

harness

and

wire

loomas

far

forward

as

possible

.

If

necessary,disconnect

positive

leads

at

main

(+)

connector

.

10

.

Remove

wiper

assembly

mounting

fasteners

.

See

Fig

.

17

.

Page 429 of 759

612

Switches

and

Electrical

Accessories

GENERAL

.

.

.

.

.

.

.

.

.

...

.

.

.

.

.

...

.

......

.612-1

Headlight

switch,

replacing

..

.

...

.

.

.

.

.

.

.

.

.

612-5

Foglight

switch,

replacing

....

.

.

.

.

.

.

.

.

.

.

.

.

.

612-5

INTERIOR

SWITCHES

.

.

...

.

.

.

.

.

.

.

.....

612-1

Hazard

warning

switch,

replacing

.

.

.

.

.

.

.

.

.

.612-5

Turn

signal

switch

and

wiper

switch,

Powerwindow

switch,

replacing

.

.

.

...

.

.

.

.

.

612-5

replacing

.

.

.

.

.

.

.

...

.

.

.

.....

.

....

.

.

.

.

612-1

Outside

mirrorswitch,

replacing

.

.

.

.

.....

.

.

.612-6

Ignition

Switch

Assembly

.

.

.

.

.

.

.

.

....

.

...

612-3

Ignition

electrical

switch,

replacing

.

...

.

....

612-3

INTERIOR

LIGHTS

.

.

................

.

..

612-6

Ignition

lock

cylinder,

replacing

.

.

.

.

.....

.

..

612-4

Dome

light,

rear

map

lights,

trunk

light,

Headlight

and

Foglight

Switch

Assembly

.

.

.

.

612-5

replacing

bulbs

.

......

.

.

.

.

.

.

.

.

.

.....

.

.612-7

GENERAL

Turn

signal

switch

and

wiper

switch,

replacing

Thissection

covers

replacement

of

interior

switches

and

accessories

.

The

procedures

for

removing

the

turn

signal

stalk

switch

and

the

wiper

system

stalk

switchare

similar

.

When

working

on

electrical

switches,

always

disconnect

the

negative

(-)

cable

from

the

battery

and

insulate

the

cable

end

to

prevent

accidental

re-connection

.

CAUTION-

Prior

to

disconnectiog

the

battery,

read

the

battery

disconnection

cautions

given

at

the

front

of

this

manual

on

page

viii

.

WARNING

-

The

cars

covered

by

this

manual

are

equipped

with

a

Supplemental

Restraint

System

(SRS)

that

auto-'

matically

deploys

one

or

more

airbags

.

Each

airbag

unit

houses

an

explosive

powerful

charge

.

Any

work

involving

the

SRS

system

should

only

be

per-

formed

byan

authorized

BMW

dealer

.

Making

re-

pairs

without

the

proper

knowledge

and

special

test

equipment

may

cause

serious

personal

injury

.

See

721

Airbag

System

(SRS)

3

.

With

front

wheels

pointed

straight

ahead,

remove

steer-

"

Testing

and

replacement

information

for

the

oil

ores-

¡ng

wheel

.

See

320

Steering

and

Wheel

Alignment

.

sure

switch

is

covered

in

119

Lubrication

System

.

NOTE-

"

Wirfng

diagramscan

be

found

in

Electrical

Wiring

Diagrams

.

"

Fuse,

relay

and

electrical

component

locations

can

be

found

in

610

Electrical

Component

Locations

.

"

Replacement

information

for

thetransmission

gear

position/neutral

safety

switch

is

covered

in

250

Gear-

shift

Unkage

.

INTERIOR

SWITCHES

NOTE

-

To

preventmarring

interior

trim,

wrap

the

tips

of

screw-

drivers

and

pliers

with

tape

beforeprying

out

switches

or

electrical

accessories

.

SWITCHES

AND

ELECTRICAL

ACCESSORIES

612-1

1

.

Disconnect

negative

(-)

cable

from

battery

and

cover

terminal

with

insulating

material

.

2

.

Remove

airbag

unit

from

steering

wheel

.

See

721

Air-

bag

System

(SRS)

.

Store

airbag

unit

in

a

safe

placew¡th

pad

facing

up

.

NOTE

-

To

helo

with

reassembly,

mark

steering

wheel

and

col-

umn

before

disassembly

.

4

.

Remove

trim

panel

from

lower

left

side

of

instrument

panel

.

See513

Interior

Trim

.

INTERIOR

SWITCHES

Page 440 of 759

620-

4

INSTRUMENTS

MULTI-INFORMATION

DISPLAY

(MID)

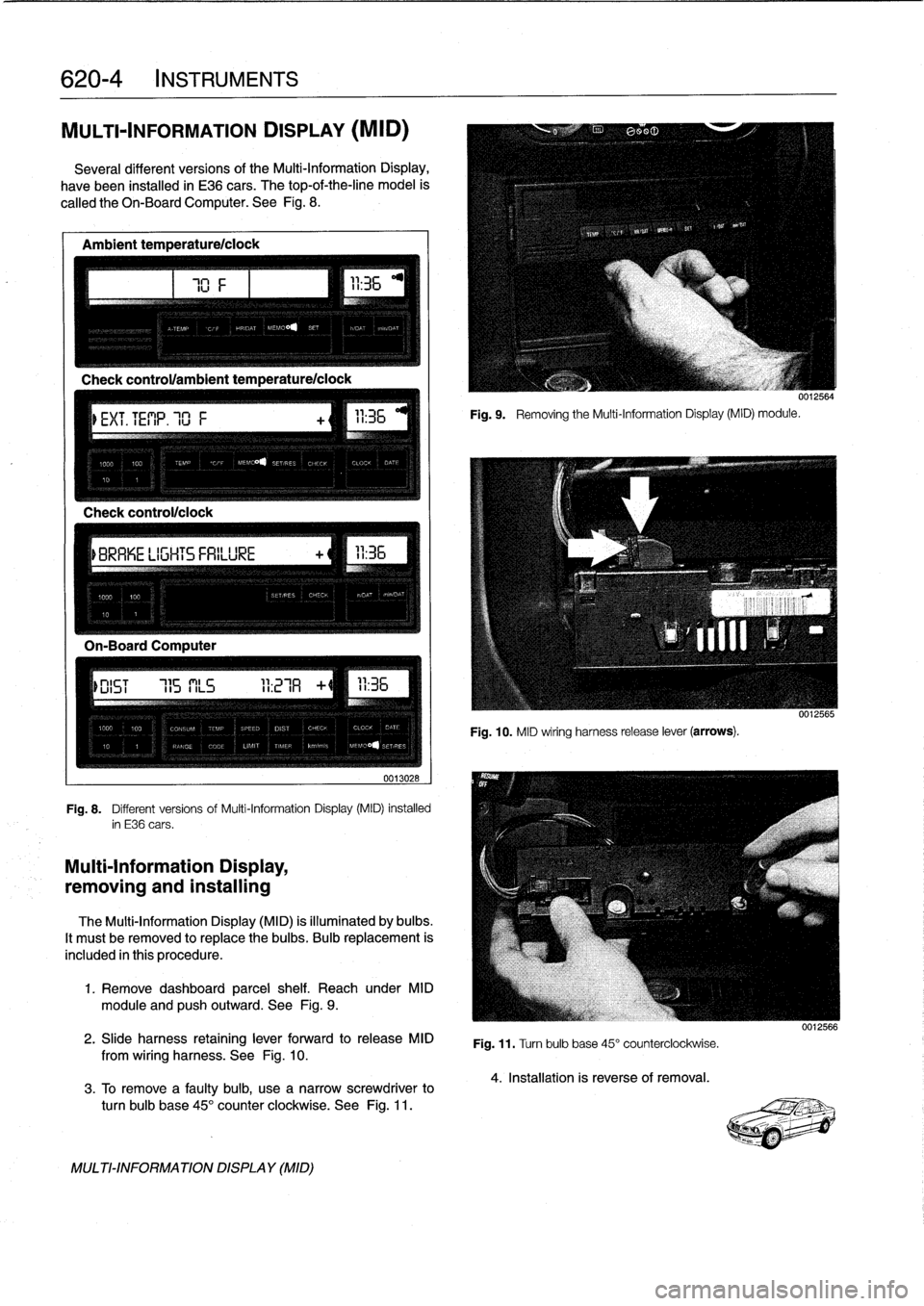

Severa¡

different

versionsof

the

Multi-Information

Display,

have

been

installed

in

E36

cars

.

The

top-of-the-line

model

is

called

the

Oh-BoardComputer

.

See

Fig

.

8

.

Ambient

temperature/ciock

Check

control/clock

0013028

Fig

.

8

.

Different

versions

of

Multi-Information

Display

(MID)

installed

in

E36

cars

.

Multi-Information

Display,

removing

and

installing

The

Multi-Information

Display

(MID)

is

illuminated

by

bulbs

.

It

mustbe

removed

to

replace

the

bulbs

.

Bulb

replacement

is

included

in

this

procedure

.

1

.

Remove

dashboard

parcel

shelf

.

Reach

under

MID

module

and

pushoutward

.

See

Fig

.

9

.

2

.

Slide

harness

retaining

lever

forward

to

release

MID

from

wiring

harness

.

See

Fig

.

10

.

3

.

To

Rmove

a

faulty

bulb,

use

anarrow

screwdriver

to

turn

bulb

base

45°

counter

clockwíse

.

See

Fig

.

11

.

MULTI-INFORMATIONDISPLAY

(MID)

111

Fig

.

9

.

Removing

the

Multi-Information

Display(MID)

module

.

0012564

Fig

.

10

.

MID

wiring

harness

release

lever

(arrows)

.

Fig

.

11

.

Turn

bulb

base

45°

counterclockwise

.

4

.

Installation

is

reverse

of

removal

.

0012566

Page 448 of 759

640-2

HEATING

AND

AIR

CONDITIONING

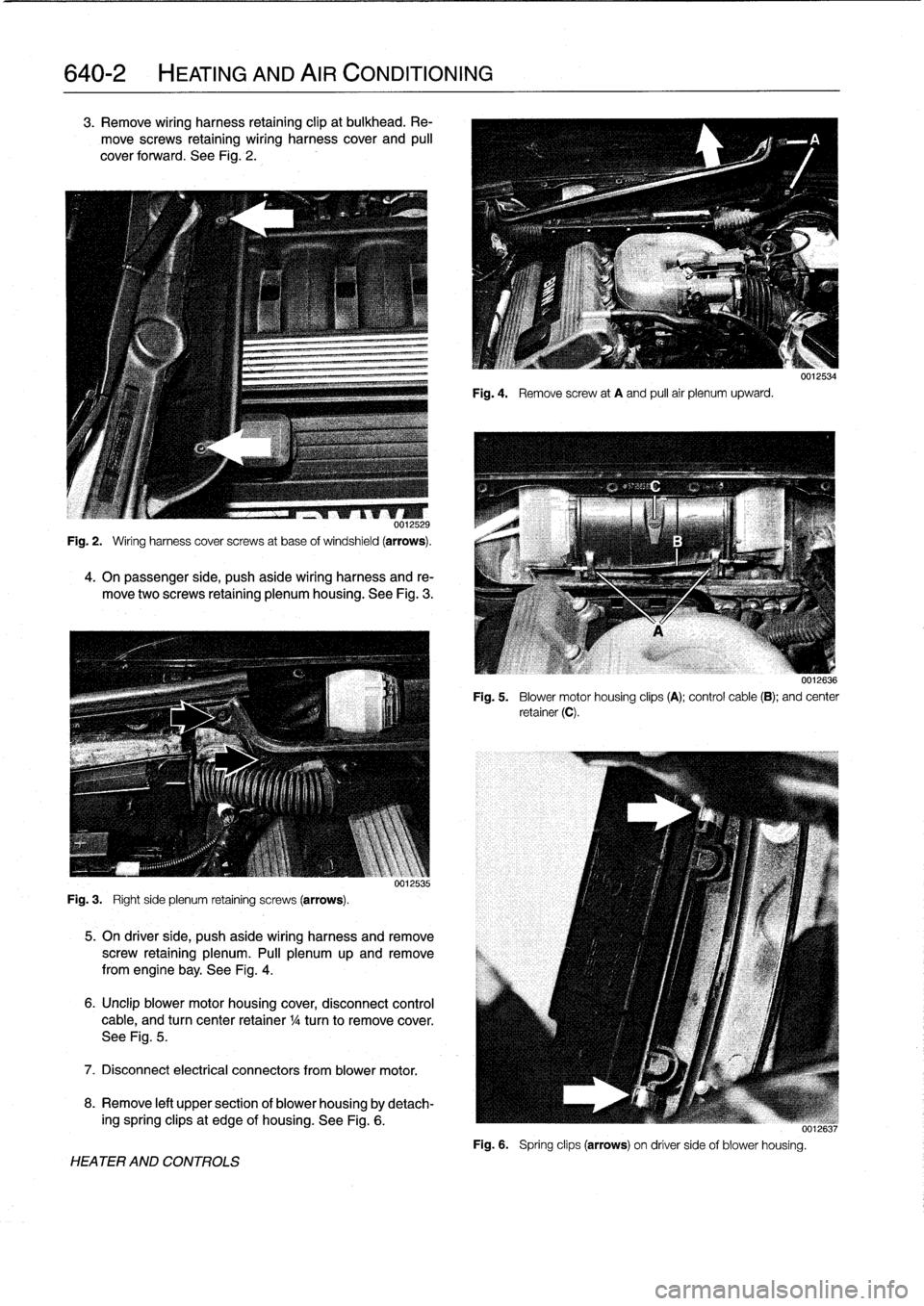

3

.

Remove

wiring

harness

retaining

clip

at

bulkhead

.

Re-

move

screws

retaining

wiring

harness

cover

and

pull

cover

forward

.

See

Fig

.

2

.

0012529

Fig

.

2

.

Ming

harness

cover

screws

at

base

ofwindshield

(arrows)

.

4

.

On

passenger

side,

push

aside

wiring

harness

and

re-

move

two

screws

retaining

plenum

housing

.

See

Fig

.

3

.

Fig

.

3

.

Ríghtside

plenum

retaining

screws

(arrows)

.

VU1L535

5

.

On

driverside,

push

aside

wiring

harness

and

remove

screw

retaining

plenum

.

Pull

plenum

up

and

remove

from

engine

bay

.

See

Fig

.

4

.

6

.

Unclip

blower

motor

housing

cover,

disconnect

control

cable,

and

turn

center

retainer

1

/4

turn

to

remove

cover

.

See

Fig

.

5

.

7

.

Disconnect

electrical

connectors

from

blower

motor

.

8

.

Remove

left

upper

section

of

blower

housingby

detach-

ing

spring

clipsat

edge

of

housing

.

See

Fig

.

6

.

HEATER

AND

CONTROLS

Fig

.

4

.

Remove

screw

at

A

and

pull

air

plenumupward

.

0012534

0012636

Fig

.

5

.

Blower

motor

housing

clips

(A)

;

control

cable

(B)

;

and

center

retainer(C)

.

i

[u6,

Fig

.

6

.

Spring

clips

(arrows)

on

driver

sideof

blower

housing

.