relay BMW 318i 1996 E36 Owner's Guide

[x] Cancel search | Manufacturer: BMW, Model Year: 1996, Model line: 318i, Model: BMW 318i 1996 E36Pages: 759

Page 176 of 759

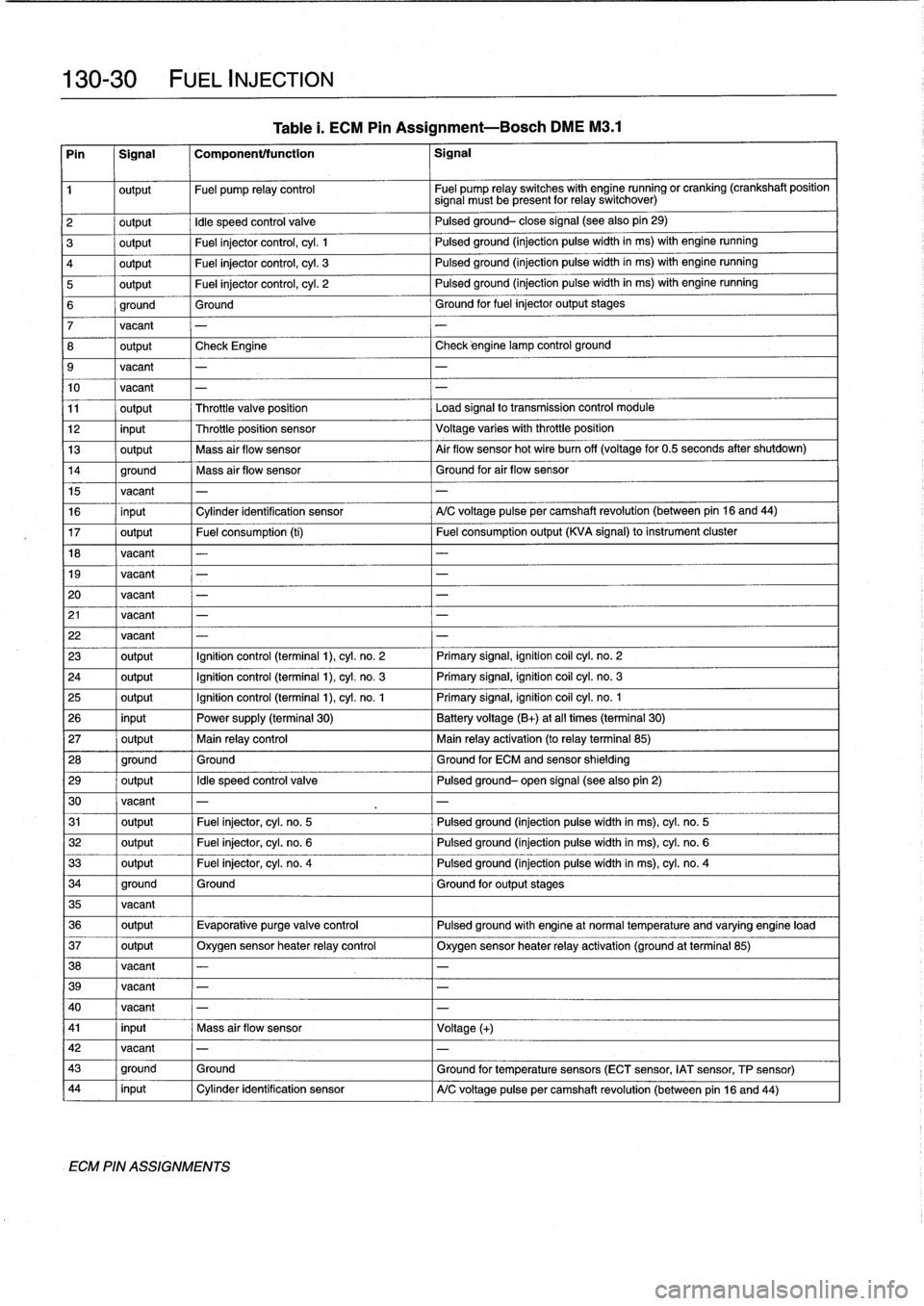

130-

3

0

FUEL

INJECTION

Pin

Signal

Component/function

Signal

ECM

PIN

ASSIGNMENTS

Table

1.

ECM

Pin

Assignment-Bosch

DME

M3

.1

1

output

Fuel

pump

relay

control

Fuel

pump

relay

switches

with

engine

runningor

cranking

(crankshaft

position

Signal

mustbe

present

for

relay

switchover)

2

1

output

1

Idle

speed

control

valve

1

Pulsad

ground-

close

signal

(seealsopin29)

3

output

Fuel

injectorcontrol,

cyl

.

1

Pulsedground

(injection

pulsewidth

in

ms)

with

engine

running

4

output

Fuel

injectorcontrol,

cyl

.

3

Pulsedground

(injection

pulsewidth

in

ms)

with

engine

running

5

output

Fuel

injector

control,

cyl

.

2

Pulsedground

(injection

pulse

width

in

ms)

with

enginerunning

6

ground

Ground

Ground

for

fuel

injector

output

stages

7

vacant

-

-

8

output

Check

Engine

Check

éngine

lamp

control

ground

9

vacant

-

-

10

vacant

-

-

11

output

Throttle

valve

position

Load

signal

to

transmission

control

module

12

input

Throttle

position

sensor

Voltage

varies

with

throttle

position

13

output

Mass

air

flow

sensor

Air

flow

sensor

hotwire

burn

off

(voltage

for

0

.5

seconds

after

shutdown)

14

ground

Mass

air

flow

sensor

Ground

for

air

flow

sensor

15

vacant

-

-

16

input

Cylinder

identification

sensor

A/C

voltage

pulse

per

camshaft

revolution

(between

pin

16

and

44)

17

output

Fuel

consumption

(ti)

Fuel

consumption

output

(KVA

Signal)

to

instrument

cluster

18

vacant

-

-

19

vacant

-

-

20

vacant

-

-

21vacant

-

-

22

vacant

-

-

23

output

Ignition

control

(terminal

1),

cyl

.

no

.

2

Primary

Signal,

ignition

coil

cyl

.

no

.

2

24

output

Ignition

control

(terminal

1),

cyl

.

n

o

.

3

Primary

signal,

ignition

coil

cyl

.

no

.

3

25

output

Ignition

control

(terminal

1),

cyl

.

n

o

.

1

Primary

signal,

ignitioh

coil

cyl

.

no

.

1

26

input

Power

supply

(terminal

30)

Battery

voltage

(B+)

at

al¡

times

(terminal

30)

27

output

Main

relay

control

Main

relay

activation

(to

relay

terminal

85)

28

ground

Ground

Ground

for

ECM

and

sensor

shielding

29

output

Idle

speed

control

valve

Pulsed

ground-

open

signal

(see

also

pin

2)

30

vacant

-

-

31

output

Fuel

injector,cyl

.

no

.

5

Pulsedground

(injection

pulsewidth

in

ms),

cyl

.

no

.

5

32

output

Fuel

injector,cyl

.

no

.

6

Pulsedground

(injection

pulse

width

in

ms),

cyl

.

no

.

6

33

output

Fuel

injector,cyl

.

no

.

4

Pulsedground

(injection

pulsewidth

in

ms),

cyl

.

no

.

4

34

ground

Ground

Ground

for

output

stages

35

vacant

36

output

Evaporative

purgevalve

control

Pulsed

ground

with

engine

at

normal

temperature

and

varying

engine

load

37

output

Oxygen

sensor

heater

relay

control

Oxygen

sensor

heater

relayactivation

(ground

at

terminal

85)

38

vacant

-

-

39

vacant

-

-

40

vacant

-

41

input

Mass

air

flow

sensor

Voltage

(+)

42

vacant

-

-

43

ground

Ground

Ground

for

temperatura

sensors

(ECT

sensor,

IAT

sensor,

TP

sensor)

44

input

Cylinder

identification

sensor

A/C

voltagepulseper

camshaft

revolution

(between

pin

16

and

44)

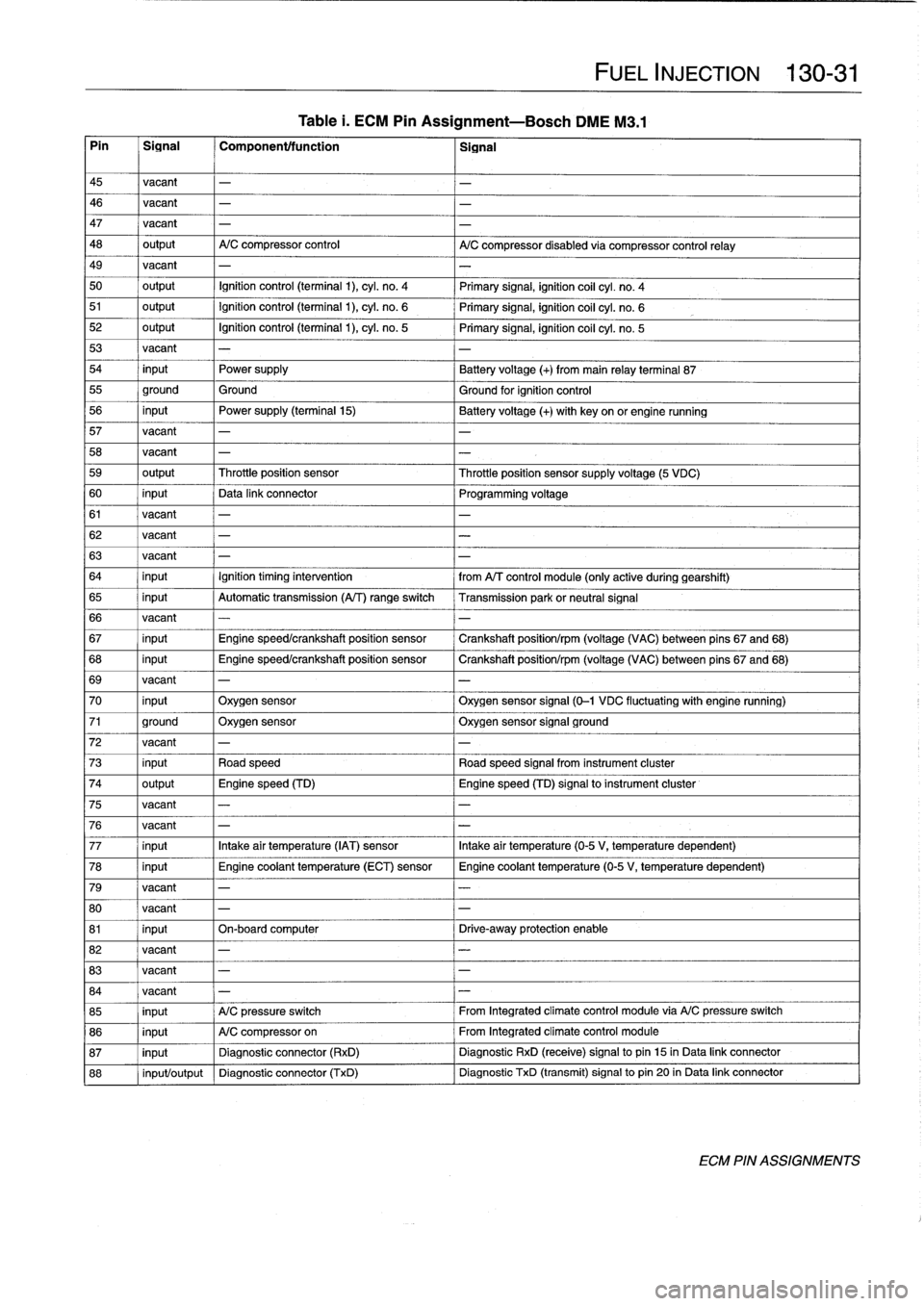

Page 177 of 759

Table

i

.

ECM

Pin

Assignment-Bosch

DME

M3

.1

Pin

Signal

Component/function

2

ignal

FUEL

INJECTION

130-

3

1

45

vacant

-

46

vacant

-

-

47

vacant

-

-

48

output

A/C

compressor

control

A/C

compressor

disabled

via

compressor

control

relay

49

vacant

-

-

50

output

Ignition

control

(terminal

1),cyl

.

n

o

.

4

Primary

signal,

ignition

coil

cyl

.

n

o

.

4

51

output

Ignition

control

(terminal

1),cyl

.

n

o

.

6

Primary

signal,

ignition

coil

cyl

.

no

.

6

52

output

Ignition

control

(terminal

1),cyl

.

n

o

.

5

Primary

signal,

ignitioncoil

cyl

.

no

.

5

53

vacant

-

54

input

Power

supply

Battery

voltage

(+)

from

main

relay

terminal

87

55

ground

Ground

Ground

for

ignition

control

56

input

Power

supply

(terminal

15)

Batteryvoltage

(+)

with

key

on

or

engine

running

57

vacant

-

-

58

vacant

-

-

59

output

Throttleposition

sensor

Throttleposition

sensorsupply

voltage

(5

VDC)

60

input

Data

link

connector

Programming

voltage

61

vacant

-

-

62

vacant

-

-

63

vacant

-

-

64

input

Ignition

timing

intervention

from

A/T

control

module

(only

active

during

gearshift)

65

input

Automatic

transmission

(A/T)

range

switch

Transmission

park

or

neutral

signal

66

vacant

-

-

67

input

Engine

speed/crankshaft

position

sensor

Crankshaft

position/rpm

(voltage

(VAC)

between

pins

67

and

68)

68

input

Engine

speed/crankshaft

position

sensor

Crankshaft

position/rpm

(voltage

(VAC)

between

pins

67

and

68)

69

vacant

-

-

70

input

Oxygen

sensor

Oxygen

sensor

signal

(0-1

VDC

fluctuating

with

engine

running)

71

ground

Oxygen

sensor

Oxygen

sensor

signal

ground

72

vacant

-

-

73

input

Road

speed

Road

speed

signal

from

instrument

cluster

74

output

Engine

speed

(TD)

Engine

speed

(TD)

signalto

instrument

cluster

75

vacant

-

-

76

vacant

-

-

77

input

Intakeair

temperature

(IAT)

sensor

Intake

air

temperature

(0-5

V,

temperaturedependent)

78

input

Engine

coolant

temperature

(ECT)

sensor

Engine

coolant

temperature

(0-5V,

temperature

dependent)

79

vacant

-

-

80

vacant

-

-

81

input

On-boardcomputer

Drive-away

protection

enable

82

vacant

-

-

83

vacant

-

-

84

vacant

-

-

85

input

A/C

pressure

switch

From

Integrated

climate

control

module

via

A/C

pressure

switch

86

input

A/C

compressor

on

From

Integrated

climate

control

module

87

input

Diagnostic

connector

(RxD)

Diagnostic

RxD

(receive)signal

to

pin

15

in

Data

link

connector

88

input/output

Diagnostic

connector

(TxD)

Diagnostic

TxD

(transmit)

signal

to

pin

20

in

Data

link

connector

ECM

PIN

ASSIGNMENTS

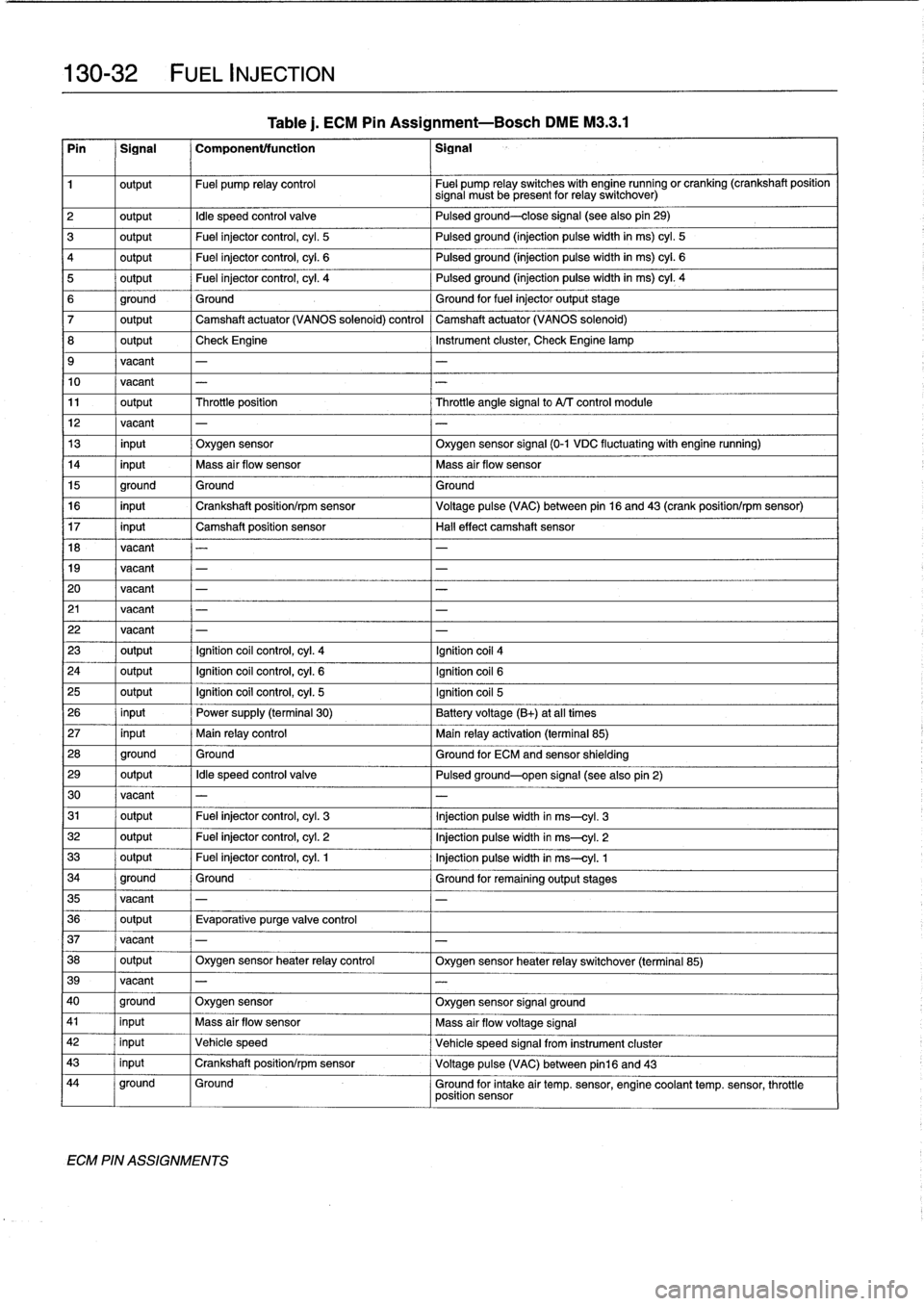

Page 178 of 759

130-

3

2

FUEL

INJECTION

Pin

1

Signal

1

Component/function

1

Signal

1

output

Fuel

pump

relay

control

Fuel

pump

relay

switches

with

engine

running

or

cranking

(crankshaft

position

signal

must

be

present

for

relay

switchover)

2

output

Idle

speed

control

valve

Pulsed

ground-close

signal

(seealso

pin

29)

3

output

Fuel

ínjectorcontrol,

cyl

.

5

Pulsed

ground

(injection

pulsewidth

in

ms)

cyl

.

5

4

output

Fuel

injectorcontrol,

cyl

.

6

Pulsed

ground

(injection

pulsewidth

in

ms)

cyl

.

6

5

output

Fuel

injectorcontrol,

cyl

.

4

Pulsed

ground

(injection

pulsewidth

in

ms)

cyl

.

4

6

ground

Ground

Ground

for

fuel

injector

output

stage

7

output

Camshaft

actuator

(VANOS

solenoid)

control

Camshaft

actuator

(VANOS

solenoid)

8

output

Check

Engine

Instrument

cluster,

Check

Engine

lamp

9

vacant

-

-

10

vacant

-

-

11

output

Throttle

position

Throttle

angle

signal

to

A/T

control

module

12

vacant

-

-

13

input

Oxygen

sensor

Oxygen

sensor

signal

(0-1

VDC

fluctuating

with

engine

running)

14

input

Mass

air

flow

sensor

Mass

air

flow

sensor

15

ground

Ground

Ground

16

input

Crankshaft

position/rpm

sensor

Voltage

pulse

(VAC)

between

pin

16

and

43

(crank

position/rpm

sensor)

17

input

Camshaft

position

sensor

Halleffect

camshaft

sensor

18

vacant

-

-

19

vacant

-

-

20

vacant

-

-

21

vacant

-

-

22

vacant

-

-

23

output

Ignition

coil

control,

cyl

.

4

Ignition

coil

4

24

output

Ignition

coil

control,

cyl

.

6

Ignition

coil

6

25

output

Ignition

coil

control,

cyl

.

5

Ignition

coil

5

26

input

Power

supply

(terminal

30)

Battery

voltage(B+)

at

all

times

27

input

Main

relay

control

Main

relayactivation

(terminal

85)

28

ground

Ground

Ground

for

ECM

and

sensor

shielding

29

output

Idle

speed

control

valve

Pulsed

ground-open

signal

(seealsopin

2)

30

vacant

-

-

31

output

Fuel

injectorcontrol,

cyl

.

3

Injection

pulse

wicith

in

ms-cyl

.

3

32

output

Fuel

injectorcontrol,

cyl

.

2

Injection

pulse

wicith

in

ms-cyl

.

2

33

output

Fuel

injectorcontrol,

cyl

.

1

Injection

pulsewidth

in

ms-cyl

.

1

34

ground

Ground

Ground

for

remaining

output

stages

35

vacant

-

-

36

output

Evaporative

purge

valve

control

37

vacant

-

-

38

output

Oxygen

sensor

heater

relay

control

Oxygen

sensor

heater

relay

switchover

(terminal

85)

39

vacant

-

-

40

ground

Oxygen

sensor

Oxygen

sensor

signal

ground

41

input

Mass

air

flow

sensor

Mass

air

flow

voltage

signal

42

input

Vehicle

speed

Vehicle

speed

signal

from

instrument

cluster

43

input

Crankshaft

position/rpm

sensor

Voltage

pulse

(VAC)

between

pin16

and

43

44

ground

Ground

Ground

for

intake

air

temp

.

sensor,

engine

coolant

temp

.

sensor,

throttle

position

sensor

ECM

PIN

ASSIGNMENTS

Table

j

.

ECM

Pin

Assignment-Bosch

DME

M3

.3

.1

Page 179 of 759

Table

j.

ECM

Pin

Assignment-Bosch

DME

M3

.3

.1

Pin

~

Signal

1

Componentffunction

1

signal

FUEL

INJECTION

130-

33

45

ground

Ignition

circuit

shield

Ground

shieldfor

ignition

circuit

monitoring

46

output

Fuel

consumption

(KVA

signal)

To

instrument

cluster

47

output

Crankshaft

rpm

Engine

speed

(TD)

signal

to

instrument

cluster

48

output

A/C

compressor

control

A/C

compressor

relay

terminal

85

49

vacant

-

-

50

output

Ignition

coil

control,

cyl

.

1

Primary

signal,

ignition

coil

1

51

output

Ignition

coil

control,

cyl

.

2

Primary

signal,

ignition

coil

2

52

output

Ignition

coil

control,

cyl

.

3

Primary

signal,

ignition

coil

3

53

vacant

-

-

54

input

Power

supply

Battery

voltagefrom

main

relay

(terminal

87a)

55

ground

Ground

Ground

for

ignition

control

56

input

Power

supply

(terminal15)

Batteryvoltage

with

key

on

or

engine

running

57

input

Ignition

timing

intervention

From

A/T

control

module

58

vacant

-

-

59

output

Throttleposition

sensor

(TPS)

Voltage

supply

to

TPS

(5

VDC)

60

input

Programming

voltage

Data

link

connector

61

vacant

-

-

62

vacant

-

-

63

vacant

-

-

64

input

A/C

on

signal

From

integrated

climate

control

module

65

input

A/C

pressure

signal

From

integrated

climate

control

module

via

A/C

pressure

switch

66

input

On-board

computer

Drive-away

protection

enable

(starter

immobilization

relay)

67

vacant

-

-

68

vacant

-

-

69

input

Knock

sensor

#2

(cyl

.

4,5,

6)

Knock

sensor

#2

signal

70

input

Knock

sensor

#1

(cyl

.

1,2,

3)

Knock

sensor

#1

signal

71

ground

Ground

Ground

for

knock

sensors

and

shields

72

vacant

-

-

73

input

Throttleposition

sensor

(TPS)

Throttleposition

signal

74

vacant

-

75

vacant

-

-

76

vacant

-

77

input

Intakeair

temperatura

Intakeair

temperatura

sensor

(0-5

VDC)

78

input

Engine

coolant

temperature

Engine

coolant

temperature

sensor

(0-5

VDC)

79

vacant

-

80

vacant

-

-

81

input

Automatic

transmission

gear

positionlneutral

A/T

parkor

neutral

position

signal

safetyswitch

82

vacant

-

-

83

vacant

-

-

84

vacant

-

-

85

vacant

-

-

86

vacant

-

-

87

input

Diagnostic

connector

(RxD)

Diagnostic

RxD

(receive)

signal

to

pin

15

in

Data

link

connector

88

input/output

Diagnostic

connector

(TxD)

Diagnostic

TxD

(transmit)

signal

to

pin

20

in

Data

link

connector

ECM

PIN

ASSIGNMENTS

Page 180 of 759

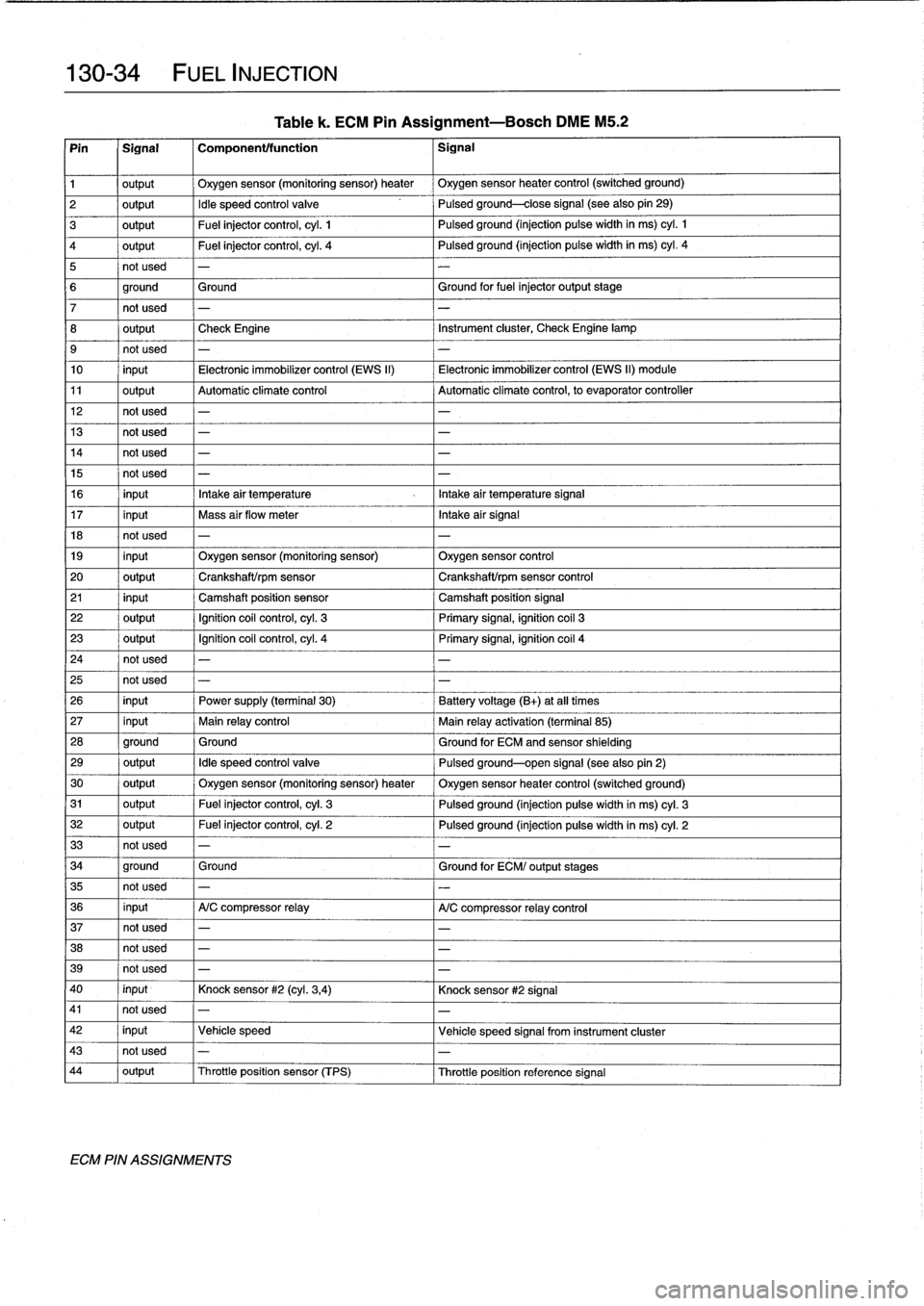

130-

34

FUEL

INJECTION

Pin

i

Signal

1

Component/function

1

Signal

1

output

Oxygen

sensor

(monitoring

sensor)heater

Oxygen

sensor

heater

control

(switched

ground)

2

output

Idle

speed

control

valve

Pulsed

ground-close

signal

(see

also

pin

29)

3

output

Fuel

injector

control,

cyl

.

1

Pulsed

ground

(injection

pulsewidth

in

ms)

cyl

.

1

4

output

Fuel

injector

control,

cyl

.

4

Pulsed

ground

(injection

pulse

width

in

ms)

cyl

.

4

5

not

used

-

-

6

ground

Ground

Ground

for

fuel

injector

output

stage

7

not

used

-

8

1

output

1

Check

Engine

1

Instrument

cluster,

Check

Engine

lamp

9

not

used

-

-

10

input

Electronic

immobilizer

control

(EWS

II)

Electronic

immobilizer

control

(EWS

II)

module

11

output

Automatic

climate

control

Automatic

climate

control,

to

evaporator

controlier

12

not

used

-

-

13

not

used

-

-

14

not

used

-

-

15

not

used

-

-

16

input

Intake

air

temperature

Intake

air

temperature

Signal

17

input

Mass

air

flow

meter

Intake

air

signal

18

not

used

-

-

19

input

Oxygen

sensor

(monitoring

sensor)

Oxygen

sensor

control

20

output

Crankshaft/rpm

sensor

Crankshaft/rpm

sensor

control

21

input

Camshaft

position

sensor

Camshaft

position

signal

22

output

Ignition

coil

control,

cyl

.

3

Primary

signal,

ignitioncoil

3

23

output

Ignition

coil

control,

cyl

.

4

Primary

signal,

ignitioncoil

4

24

not

used

-

-

25

not

used

-

-

26

input

Power

supply

(terminal

30)

Battery

voltage

(B+)

at

al¡

times

27

input

Main

relay

control

Main

relay

activation

(terminal

85)

28

ground

Ground

Ground

for

ECM

and

sensor

shielding

29

output

Idle

speed

control

valve

Pulsed

ground-open

signal

(seealsopin

2)

30

output

Oxygen

sensor

(monitoring

sensor)

heater

Oxygen

sensor

heater

control

(switched

ground)

31

output

Fuel

injectorcontrol,

cyl

.

3

Pulsed

ground

(injection

pulsewidth

in

ms)

cyl

.

3

32

output

Fuel

injector

control,

cyl

.

2

Pulsed

ground

(injection

pulsewidth

in

ms)

cyl

.

2

33

I

not

used

40

input

Knock

sensor

#2

(cyl

.

3,4)

Knock

sensor

#2

signal

41

not

used

-

-

42

input

Vehicle

speed

Vehicle

speed

signal

from

instrument

cluster

43

not

used

-

-

44

output

Throttleposition

sensor

(TPS)

Throttleposition

reference

signal

ECM

PIN

ASSIGNMENTS

Table

k

.

ECM

Pin

Assignment-Bosch

DME

M5

.2

34

ground

Ground

Ground

for

ECM/

output

stages

35

not

used

-

-

36

input

A/C

compressor

relay

A/C

compressor

relay

control

37

not

used

-

-

38

not

used

-

-

39

not

used

-

-

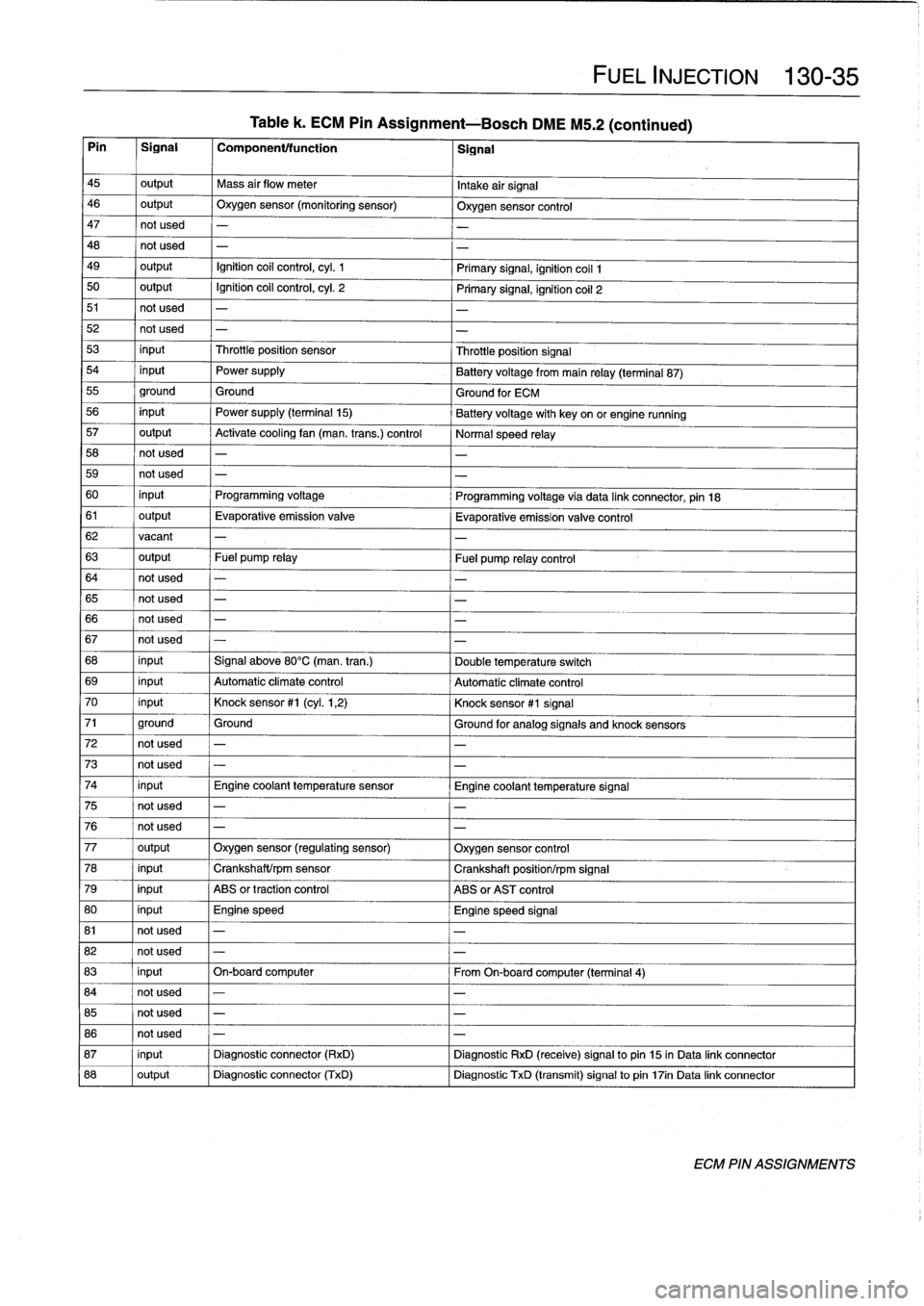

Page 181 of 759

Table

k

.

ECM

Pin

Assignment-Bosch

DME

M5

.2

(continued)

Pin

I

Signal

1

Componentltunction

1

Signal

45

I

output

I

Mass

air

flow

meter

I

Intake

airSignal

46

output

Oxygen

sensor

(monitoring

sensor)

Oxygen

sensor

control

47

not

used

-

48

not

used

-

49

output

Ignition

coil

control,

cyl

.

1

Primary

signal,

ignition

coil

1

50

output

Ignition

coil

control,

cyl

.

2

Primary

signal,

ignition

coil

2

51

not

used

-

52

not

used

-

53

input

Throttleposition

sensor

Throttleposition

Signal

54

input

Power

supply

Batteryvoltage

from

main

relay

(terminal

87)

55

ground

Ground

Ground

for

ECM

56

input

Power

supply

(terminal

15)

Battery

voltage

with

key

on

or

engine

running

57

output

Activate

cooling

fan

(man

.

trans

.)

control

Normal

speed

relay

58

not

used

-

-

59

not

used

-

-

60

input

Programming

voltage

Programming

voltage

via

data

link

connector,

pin

18

61

output

Evaporative

emissionvalve

Evaporative

emission

valve

control

62

vacant

-

-

63

output

Fuel

pump

relay

Fuel

pump

relay

control

64

not

used

-

65

not

used

-

-

66

not

used

-

-

67

not

used

-

-

68

input

Signal

above

80°C(man

.

tran

.)

Double

temperature

switch

69

input

Automatic

climate

control

Automatíc

climate

control

70

input

Knock

sensor

#1

(cyl

.

1,2)

Knock

sensor

#1

Signal

71

ground

Ground

Ground

for

analog

signals

and

knock

sensors

72

not

used

-

-

73

not

used

-

-

74

input

Engine

coolant

temperature

sensor

Engine

coolant

temperatura

Signal

75

not

used

-

-

76

not

used

-

-

77

output

Oxygen

sensor

(regulating

sensor)

Oxygen

sensor

control

78

input

Crankshaft/rpm

sensor

Crankshaft

position/rpmSignal

79

input

ABS

or

traction

control

ABS

or

AST

control

80

input

Engine

speed

Engine

speed

Signal

81

not

used

-

-

82

not

used

-

-

FUEL

INJECTION

130-

3

5

83

input

On-board

computar

From

On-boardcomputer

(terminal

4)

84

not

used

-

-

85

not

used

-

-

86

not

used

-

-

87

input

Diagnostic

connector

(RxD)

Diagnostic

RxD

(receive)signal

to

pin

15

in

Data

link

connector

88

output

I

Diagnostic

connector

(TxD)

Diagnostic

TxD

(transmit)

signal

to

pin

17in

Data

link

connector

ECM

PIN

ASSIGNMENTS

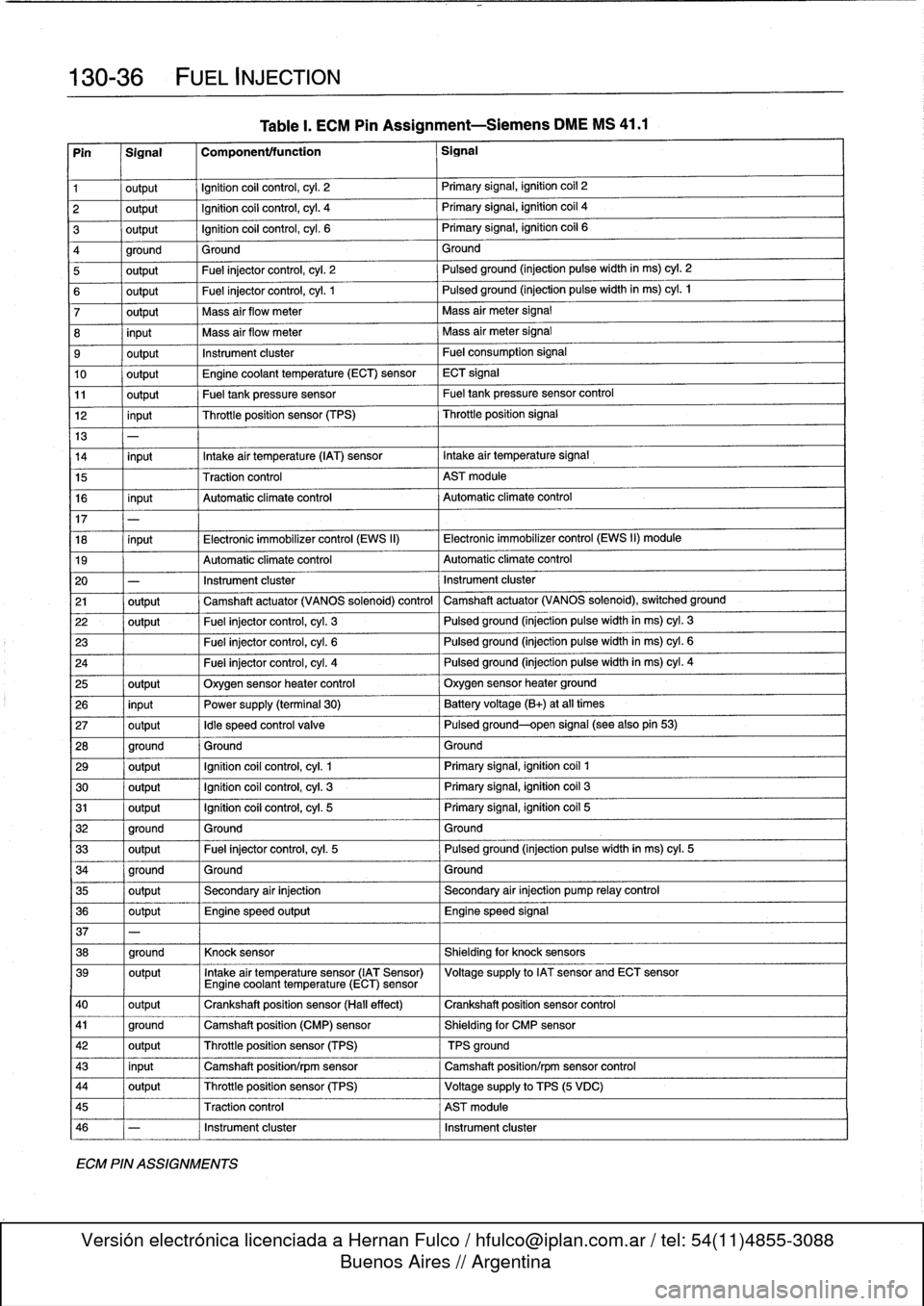

Page 182 of 759

130-

3

6

FUEL

INJECTION

Pin

1

Signal

1

Componentffunction

1

Signal

1

output

Ignition

coil

control,

cyl

.

2

Primary

signal,

ignition

coil

2

2

output

Ignition

coil

control,

cyl

.

4

Primary

signal,

ignitioncoil

4

3

output

Ignition

coil

control,

cyl

.

6

Primary

signal,

ignition

coil

6

4

ground

Ground

Ground

5

output

Fuel

injectorcontrol,

cyl

.

2

Pulsed

ground

(injection

pulse

width

in

ms)

cyl

.

2

6

output

Fuel

injectorcontrol,

cyl

.

1

Pulsed

ground

(injection

pulse

width

in

ms)

cyl

.

1

7

output

Mass

air

flow

meter

Mass

air

meter

signal

8

input

Mass

air

flow

meter

Mass

air

meter

signal

9

output

Instrument

cluster

Fuel

consumption

signal

10

output

Engine

coolant

temperature

(ECT)

sensor

ECT

signal

11

output

Fueltankpressure

sensor

Fueltankpressure

sensor

control

12

input

Throttleposition

sensor

(TPS)

Throttleposition

signal

13

-

14

input

Intake

air

temperature

(IAT)

sensor

Intake

air

temperature

signal

15

Traction

control

AST

module

16

input

Automatic

climate

control

Automatic

climate

control

17

18

input

Electronic

immobilizer

control

(EWS

II)

Electronic

immobilizer

control

(EWS

II)

module

19

Automatic

climate

control

Automatic

climate

control

20

-

Instrument

cluster

Instrument

cluster

21

output

Camshaft

actuator

(VANOS

solenoid)

control

Camshaft

actuator

(VANOS

solenoid),

switched

ground

22

output

Fuel

injectorcontrol,

cyl

.

3

Pulsed

ground

(injection

pulse

width

in

ms)

cyl

.

3

23

Fuel

injectorcontrol,

cyl

.

6

Pulsed

ground

(injection

pulse

width

in

ms)

cyl

.

6

24

Fuel

injectorcontrol,

cyl

.

4

Pulsed

ground

(injection

pulse

width

in

ms)

cyl

.

4

25

output

Oxygen

sensor

heater

control

Oxygen

sensor

heater

ground

26

input

Power

supply

(terminal

30)

Battery

voltage(B+)

at

all

times

27

output

Idle

speed

control

valve

Pulsed

ground-open

signal

(see

also

pin

53)

28

ground

Ground

Ground

29

output

Ignition

coil

control,

cyl

.

1

Primary

signal,

ignition

coíl

1

30

output

Ignition

coil

control,

cyl

.

3

Primary

signal,

ignition

coil

3

31

output

Ignition

coil

control,

cyl

.

5

Primary

signal,

ignition

coil

5

32

ground

Ground

Ground

33

output

Fuel

injector

control,

cyl

.

5

Pulsedground

(injection

pulsewidth

in

ms)

cyl

.

5

34

ground

Ground

Ground

35

output

Secondary

air

injection

Secondary

air

injection

pump

relay

control

36

output

Engine

speed

output

Engine

speed

signal

37

-

38

ground

Knock

sensor

Shielding

for

knock

sensors

39

output

Intake

air

temperature

sensor

(IAT

Sensor)

Voltagesupply

to

IAT

sensor

and

ECT

sensorEngine

coolant

temperature

(ECT)

sensor

40

output

Crankshaft

position

sensor

(Hall

effect)

Crankshaft

position

sensor

control

41

ground

Camshaft

position

(CMP)

sensor

Shielding

for

CMP

sensor

42

output

Throttle

position

sensor

(TPS)

TPS

ground

43

input

Camshaft

position/rpm

sensor

Camshaft

position/rpm

sensor

control

44

output

Throttle

position

sensor

(TPS)

Voltagesupply

to

TPS

(5

VDC)

45

Traction

control

AST

module

46

-

Instrument

cluster

Instrument

cluster

ECM

PIN

ASSIGNMENTS

Table

I.

ECM

Pin

Assignment-Siemens

DME

MS

41

.1

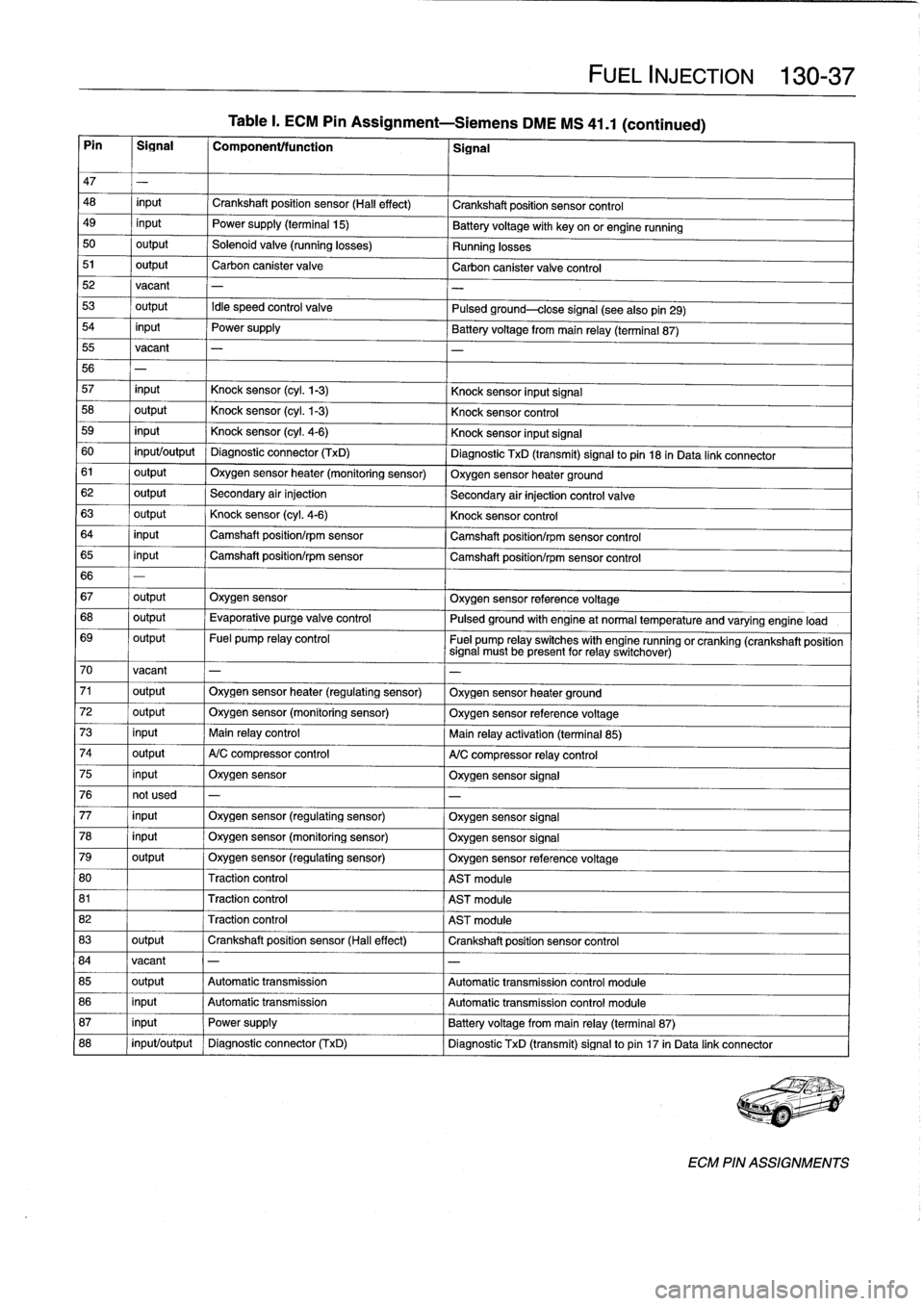

Page 183 of 759

Table

I

.

ECM

Pin

Assignment-Siemens

DME

MS

41

.1

(continued)

Pin

I

Signal

I

Component/function

1

Signal

FUEL

INJECTION

130-

37

47

-

48

input

Crankshaft

position

sensor

(Hall

effect)

Crankshaft

position

sensor

control

49

input

Power

supply

(terminal

15)

Batteryvoltage

with

key

onor

engine

running

50

output

Solenoid

valve

(running

losses)

Running

losses

51

output

Carbon

canister

valve

Carbon

canister

valve

control

52vacant

-

53

output

Idle

speed

control

valve

Pulsed

ground-close

signal

(seealsopin29)

54

input

Power

supply

Battery

voltagefrom

main

relay

(terminal

87)

55

vacant

-

56

-

57

input

Knock

sensor

(cyl

.

1-3)

Knock

sensor

input

Signal

58

output

Knock

sensor

(cyl

.

1-3)

Knock

sensor

control

59

input

Knock

sensor

(cyl

.

4-6)

Knock

sensor

input

Signal

60

input/output

Diagnostic

connector

(TxD)

Diagnostic

TxD

(transmit)

signal

to

pin

18

in

Data

link

connector

61

output

Oxygen

sensor

heater

(monitoring

sensor)

Oxygen

sensor

heater

ground

62

output

Secondary

air

injection

Secondary

air

injection

control

valve

63

output

Knock

sensor

(cyl

.

4-6)

Knock

sensor

control

64

input

Camshaft

position/rpm

sensor

Camshaft

position/rpm

sensor

control

65

input

Camshaft

position/rpm

sensor

Camshaft

position/rpm

sensor

control

66

-

67

output

Oxygen

sensor

Oxygen

sensor

reference

voltage

68

output

Evaporative

purge

valve

control

Pulsed

ground

with

engine

at

normal

temperature

and

varyingengine

load

69

output

Fuel

pump

relay

control

Fuel

pump

relay

switches

with

engine

runningorcranking

(crankshaft

position

signal

must

be

present

for

relay

switchover)

70

vacant

-

-

71

output

Oxygen

sensor

heater

(regulating

sensor)

Oxygen

sensor

heater

ground

72

output

Oxygen

sensor

(monitoring

sensor)

Oxygen

sensor

referencevoltage

73

input

Main

relay

control

Main

relay

activation

(terminal

85)

74

output

A/C

compressor

control

A/C

compressor

relay

control

75

input

Oxygen

sensor

Oxygen

sensor

signal

76

not

used

-

-

77

input

Oxygen

sensor

(regulating

sensor)

Oxygen

sensor

signal

78

input

Oxygen

sensor

(monitoring

sensor)

Oxygen

sensor

signal

79

output

Oxygen

sensor

(regulating

sensor)

Oxygen

sensor

referencevoltage

80

Traction

control

AST

module

81

Traction

control

AST

module

82

Traction

control

AST

module

83

output

Crankshaft

position

sensor

(Hall

effect)

Crankshaft

position

sensor

control

84

vacant

-

-

85

output

Automatic

transmission

Automatic

transmission

control

module

86

input

Automatic

transmission

Automatic

transmissíon

control

module

87

input

Power

supply

Battery

voltage

from

main

relay

(terminal

87)

88

input/output

Diagnostic

connector

(TxD)

Diagnostic

TxD

(transmit)

signal

to

pin

17

in

Data

link

connector

ECM

PIN

ASSIGNMENTS

Page 185 of 759

160

Fuel

Tank

and

Fuel

Pump

GENERAL

.

.

.

.

.

.

...........

.

....

.

.

.

.

.

.

160-1

Operating

fuel

pump

for

tests

.

.

.

.

.

.

.......

.160-6

Fuel

Pump

Electrical

Tests

.

.

.

.

.

.

.

...

.

.

.

.

.

160-7

FUEL

TANK

AND

LINES

..

.

.

.

..........

160-2

Fuel

pump

electrical

circuit,

testing.

...

.

.

.

.

.

160-7

Fuel

tank,

draining

..

.

.

.

.

.

.

.

.

.

..........

160-2

Fuel

pump

power

consumption,

testing

.

.

.

.

.

.

160-7

Fuel

tank,

removing

and

installing

.........

160-3

Fuel

Delivery

Tests

....

.

.

.

...

.

.....

.

.

.

..

160-8

Fuel

Tank

Evaporative

Control

System

.....

160-4

Relieving

fuel

pressure

and

connecting

fuel

pressure

gauge

..

.

...........

.

.

.

..

160-8

FUEL

LEVEL

SENDERS

.

.

.

.

.

.......

.

.

.

160-4

System

pressure,

testing

.................

160-9

Fuel

level

senders,

testing

.

.

.

.

.

.......

.

.

.

160-5

Fuel

delivery

volume,

testing

.............

160-10

Fuel

leve¡

sender

and

fuel

pump

(right

side),

emoving

and

installing

.

.

.

.

.

.

160-5

TABLES

Fuel

leve¡

sender

(left

side),

a

.

FuelLeve¡

Sender

Resistances

...........

.

.

..

.160-5

removing

and

installing

.........

.

.

.

.

.

.

.

160-6

b

.

Fuel

Pump

Current

...

.................

..

...

160-8

c

.

Fuel

Pressure

Specifications

..............

.

..

160-10

FUEL

PUMP

.

.

.

................

.

.

.

.

.

.

.

160-6

d

.

Fuel

Pump

Delivery

Specifications

.........

.

..

160-10

Fuel

Pump

Fuse

and

Relay

.

.

.

....

.

.

.

.

.

.

.

160-6

GENERAL

This

repair

group

covers

service

information

specifically

for

The

cautions

and

warnings

on

this

page

should

beob

the

fuel

supply

system

.

Information

on

the

fue¡

injection

sys-

served

when

servicing

the

fuel

system

.

tem

is

covered

in

130

Fuel

Injection

.

NOTE-

Fue¡

filter

replacement

is

covered

in

020

Maintenance

Program

.

WARNING

-

"

The

fuel

system

is

designed

to

retain

pressure

even

when

the

ignition

isoff

.

When

working

with

the

fuel

system,

loosen

the

fuel

lines

slowly

toal-

low

residual

fuel

pressure

to

dissipate

gradually

.

Avoid

spraying

fuel

.

"

Before

beginning

any

work

on

the

fuel

system,

place

a

tire

extinguisher

in

the

vicinity

of

the

work

area

.

"

Fuel

is

highly

flammable

.

When

working

around

fuel,

do

not

disconnect

any

wires

that

could

cause

electrical

sparks

.

Do

not

smoke

or

work

near

heaters

or

other

tire

hazards

.

"

Always

unscrew

the

fuel

tank

cap

to

release

pres-

sure

in

the

tank

before

working

on

the

tank

or

fines

.

"

Do

not

use

a

work

light

near

any

fuel

.

Fuel

may

spray

onto

the

hot

bulb

causing

a

tire

.

"

Make

sure

the

work

area

is

properly

ventifated

.

FUEL

TANK

AND

FUEL

PUMP

160-1

CAUTION-

"

Prior

to

disconnecting

the

battery,

read

the

bat-tery

disconnection

cautions

given

at

the

front

of

this

manual

onpage

viü

.

"

Before

making

any

electrical

tests

with

the

ignition

tumed

on,

disable

the

ignition

system

as

de-

scribed

in

120

Ignition

System

.

Be

sure

the

bat-tery

is

disconnected

when

replacing

components

.

"

To

prevent

damage

to

the

ignition

system

or

the

electronic

fuel

system

components,

including

the

control

unit,

aiways

connect

and

disconnect

wires

and

test

equipment

with

the

ignition

off

.

"

Cleanliness

is

essential

when

working

with

the

fuel

system

.

Thoroughly

clean

the

fuel

fine

unionsbefore

disconnecting

any

of

the

fines

.

"

Use

only

clean

tools

.

Keep

removed

parts

clean

and

sealed

or

covered

with

a

clean,

lint-free

cloth,

especially

if

completion

of

the

repair

is

delayed

.

"

Do

not

move

the

car

while

the

fuel

system

is

open

.

"

Avoid

using

high

pressure

compressed

air

to

blow

out

fines

and

componente

.

High

pressure

can

rupture

infernal

seals

and

gaskets

.

"

Always

replace

seals

and

O-rings

.

GENERAL

Page 190 of 759

160-

6

FUEL

TANK

AND

FUEL

PUMP

Fig

.

7

.

Fuel

sender

and

pump

assembly

.

To

operate

the

fuel

pump

for

testing

purposes

without

hav-

Fuel

leve¡

sender

(left

side),

ing

to

runthe

engine,

the

fuel

pump

relay

can

be

bypassed

to

removing

and

installing

powerthe

pump

directly

.

The

procedure

for

removing

and

replacing

the

left

side

fuel

To

runthe

fuel

pump,

remove

the

relay

and

connect

the

leve¡

sender

is

similar

tothat

used

for

the

right

side

.

There

is

socket

for

relayterminal

30

to

the

socket

for

relay

terminal

no

.

no

fuel

pump

on

the

left

side

.

87

with

afused

jumper

wire

.

Relay

terminal

identification

is

shown

in

Fig

.

9

.

After

completing

the

tests,

remove

the

jumper

wire

.

FUEL

PUMP

The

electric

fuel

pump

ís

mounted

in

the

fuel

tank

in

tandem

with

the

right

side

fuelleve¡

sender

.

The

fuel

pump

delivers

fuel

at

high

pressure

to

the

fuel

injection

system

.

A

pressure

regulator

maintains

system

pressure

.

The

quantity

of

fuel

sup-

plied

exceeds

demand,

so

excess

fuel

retums

to

the

fuel

tank

via

a

retum

líne

.

See

130

Fuel

Injection

for

more

information

on

system

pressure

and

the

fuel

pressure

regulator

.

NOTE

-

Fuel

pump

removalprocedures

are

given

earlier

under

Fuel

leve¡

sender

(right

side)

and

fuel

pump,

remov-

íng

and

installing

.

Fuel

Pump

Fuse

and

Relay

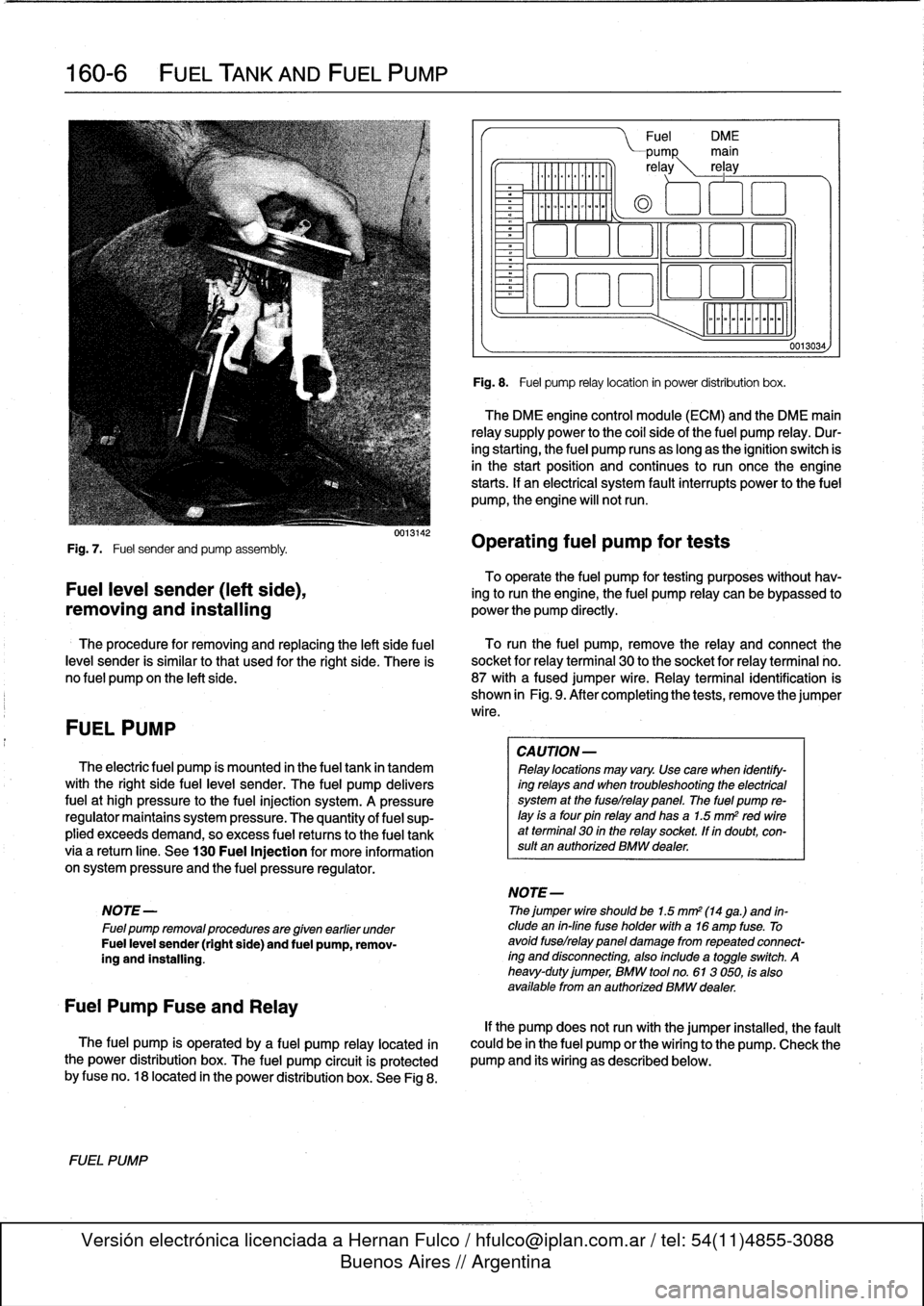

The

fuel

pump

is

operated

by

a

fuel

pump

relay

located

ín

the

power

distribution

box

.

The

fuel

pump

circuit

is

protected

by

fuse

no

.

18

located

in

the

power

distribution

box

.

See

Fig

8

.

FUEL

PUMP

0013142

Fuel

DM

E

PUMP

main

re

ay

rel

ay

0

aoo

o

~a

aao

ó

Fig

.

8

.

Fuel

pump

relay

location

in

power

distribution

box

.

The

DME

engine

control

module

(ECM)

and

the

DME

main

relay

supply

power

to

the

coi¡

sideof

the

fuel

pump

relay

.

Dur-

ing

starting,

the

fuel

pump

runs

as

long

as

the

ignition

switch

is

in

the

start

position

and

continues

to

run

oncethe

engine

starts

.

If

an

electrical

system

fault

interrupts

power

to

the

fuel

pump,

the

engine

will

notrun

.

Operating

fuel

pump

for

tests

CA

UTION-

Relay

locations

may

vary

.

Use

care

when

identify-

ing

relays

and

when

troubleshooting

the

electrical

system

at

the

fuselrelay

panel

.

The

fuel

pump

re-

¡ay

is

a

four

pin

relay

and

has

a

1.5

mm

2

red

wireat

terminal

30

in

the

relay

socket,

lf

in

doubt,

con-

sult

an

authorized

BMW

dealer

.

NOTE-

Thejumper

wire

shouldbe

1.5

mm2

(14

ga

.)

and

in-

clude

en

in-fine

fuse

holder

with

a16

amp

fuse

.

To

avoid

fuselrelay

panel

damage

fromrepeated

connect-

íng

and

disconnecting,

also

include

a

toggleswitch

.

A

heavy-duty

jumper,

BMW

tool

no

.

613

050,

fs

also

available

from

en

authorized

BMW

dealer

.

0013034,

If

the

pump

does

notrun

with

the

jumper

installed,

the

fault

could

be

in

the

fuel

pump

or

the

wiring

to

the

pump

.

Check

the

pump

and

its

wiring

as

described

below

.