Interior BMW 318i 1997 E36 Repair Manual

[x] Cancel search | Manufacturer: BMW, Model Year: 1997, Model line: 318i, Model: BMW 318i 1997 E36Pages: 759

Page 454 of 759

640-8

HEATING

AND

AIR

CONDITIONING

0012649

Fig

.

22

.

A/

C

control

head

faceplate

screwson

rotary

knob

version

(ar-

rows)

.

Once

screws

are

removed,

faceplate

must

be

un-

clipped

from

control

head

.

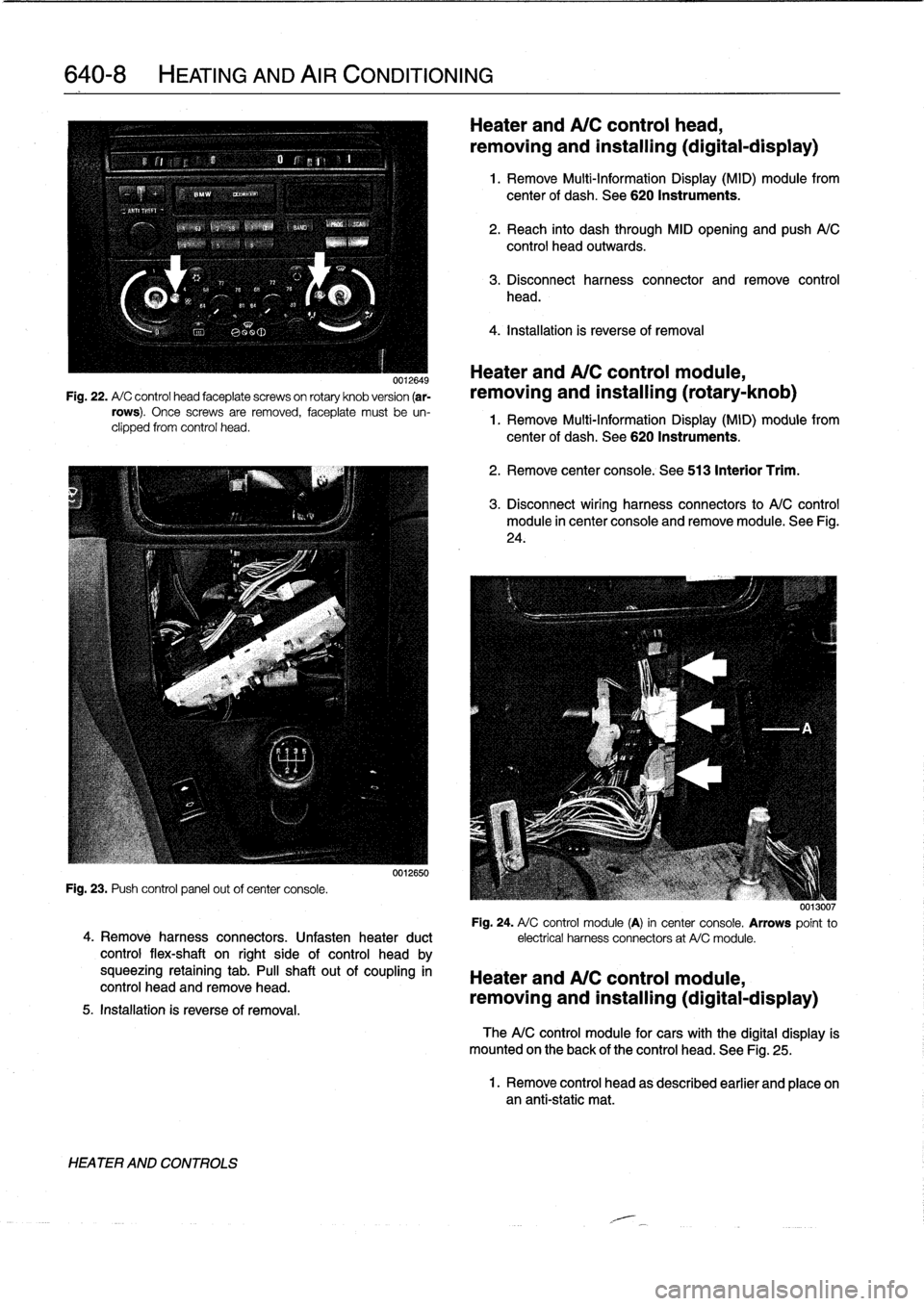

Fig

.

23

.

Push

control

panel

out

ofcenter

console

.

4

.

Remove

harness

connectors

.

Unfasten

heater

duct

control

flex-shaft

on

right

side

of

control

head

by

squeezing

retaining

tab

.

PA

shaftout

of

coupling

in

control

head

and

remove

head

.

5

.

Installation

is

reverseof

removal

.

HEATER

AND

CONTROLS

0012650

Heater

and

A/C

control

head,

removing

and

installing(digital-display)

1

.

Remove

Multi-Information

Display

(MID)

module

from

center

of

dash

.

See

620

Instruments

.

2

.

Reach

into

dash

through

MID

opening

and

push

A/C

control

head

outwards

.

3

.

Disconnect

harness

connector

and

remove

control

head

.

4

.

Installation

is

reverse

of

removal

Heater

andA/C

control

module,

removing

and

installing

(rotary-knob)

1

.

Remove

Multi-Information

Display

(MID)

module

from

center

of

dash

.

See

620

Instruments

.

2

.

Remove

center

console

.

See

513

Interior

Trim

.

3

.

Disconnect

wiring

harness

connectors

to

A/C

control

module

in

center

console

and

removemodule

.

See

Fig

.

24

.

0013007

Fig

.

24

.

A/

C

control

module

(A)

in

center

console

.

Arrows

point

to

electrical

harness

connectors

at

A/Cmodule

.

Heater

and

A/C

control

module,

removing

and

installing(digital-display)

TheA/C

control

module

for

cars

with

the

digital

display

is

mounted

on

the

back

of

the

control

head

.

See

Fig

.

25

.

1

.

Remove

control

head

as

described

earlier

and

place

onan

anti-static

mat

.

Page 455 of 759

Sensor

fan

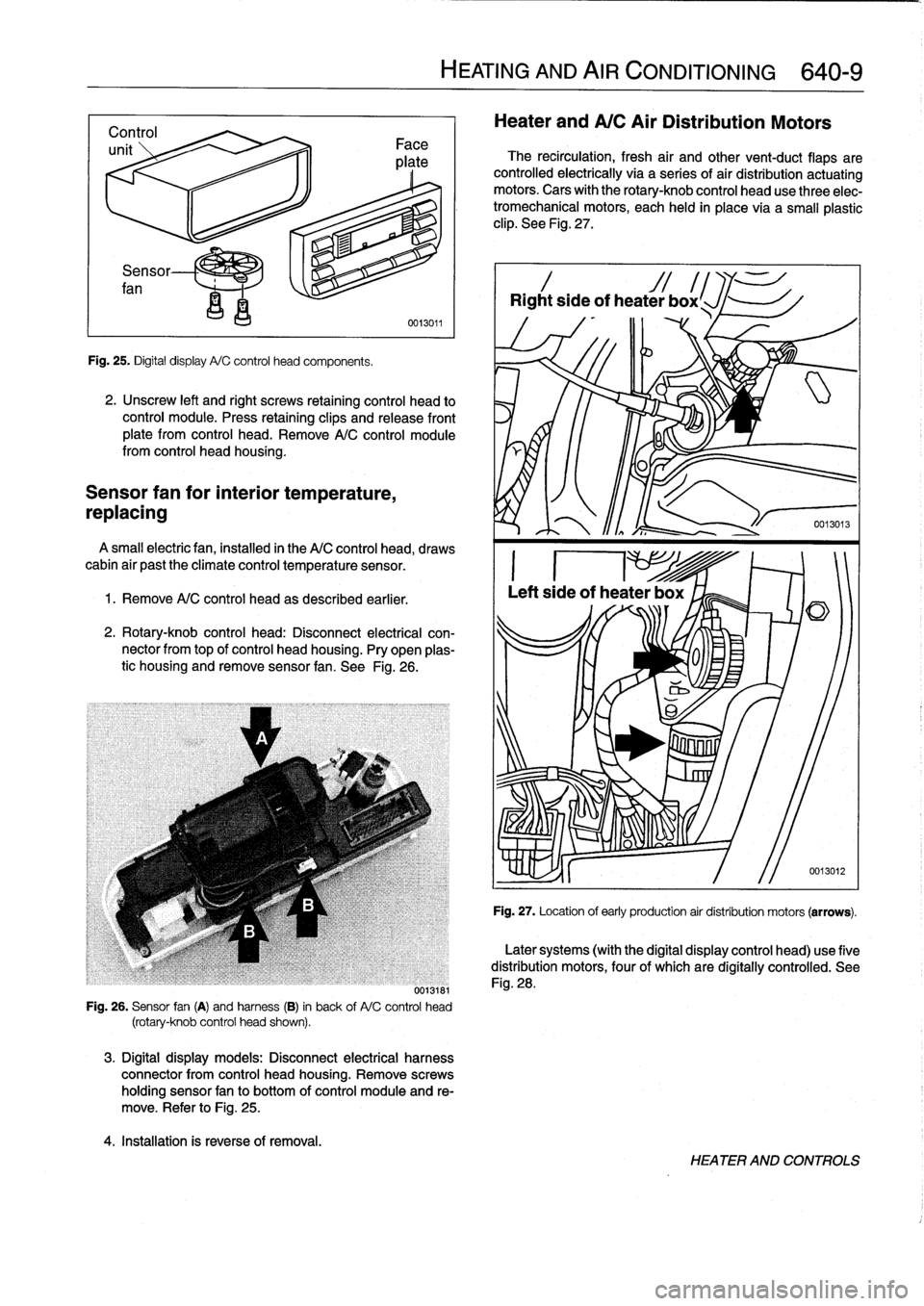

Fig

.

25

.

Digital

display

A/C

control

head

components

.

2

.

Unscrew

left

and

right

screws

retaining

control

head

to

control

module

.

Press

retaining

clips

and

release

front

plate

from

control

head

.

Remove

A/C

control

module

from

control

head

housing

.

Sensor

fan

for

interior

temperature,

repiacing

A

small

electricfan,installed

in

the

A/C

control

head,

draws

cabin

air

past

the

climate

control

temperature

sensor

.

1.

Remove

A/C

control

head

as

described

earlier

.

2

.

Rotary-knob

control

head

:

Disconnect

electrical

con-

nector

from

top

of

control

head

housing

.

Pry

open

plas-

tic

housing

and

remove

sensor

fan

.

See

Fig

.

26

.

0013181

Fig

.

26

.

Sensor

fan

(A)

and

harness

(B)

in

back

of

A/C

control

head

(rotary-knob

control

head

shown)

.

3

.

Digital

display

models

:

Disconnect

electrical

harness

connector

from

control

head

housing

.

Remove

screws

holding

sensor

fan

to

bottom

of

control

moduleand

re-

move

.

Refer

to

Fig

.

25

.

4

.

Installation

is

reverse

of

removal

.

HEATING

AND

AIR

CONDITIONING

640-

9

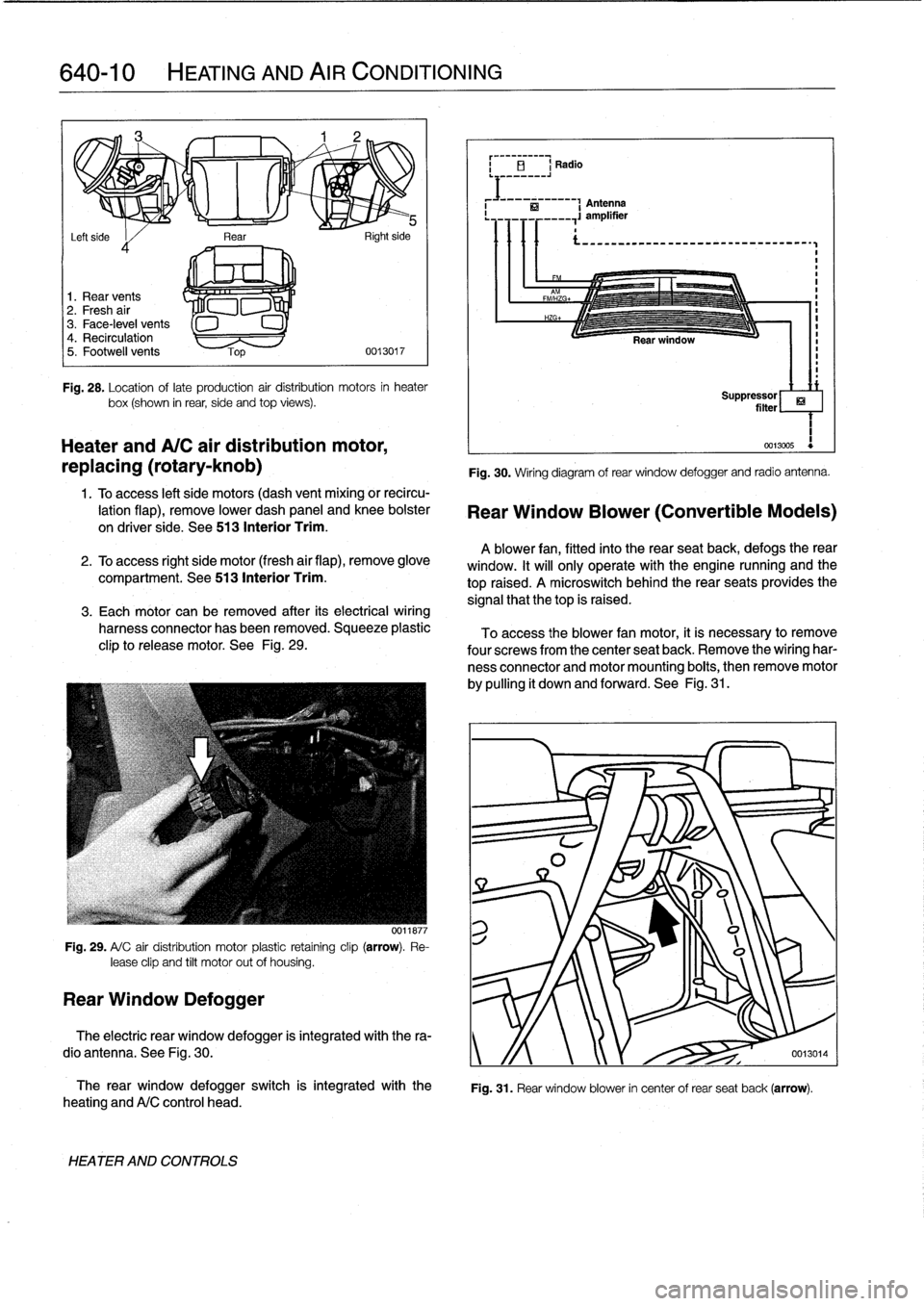

Heater

and

A/C

Air

Distribution

Motors

The

recirculation,

fresh

air

and

othervent-duct

flaps

are

controlled

electrically

via

a

series

of

air

distribution

actuating

motors

.

Cars

with

the

rotary-knob

control

head

use

three

elec-

tromechanical

motors,

each

held

in

place

via

a

small

plastic

clip

.

See

Fig

.

27

.

Rightside

of

heater

box

l

Fig

.

27

.

Location

of

early

production

air

distribution

motors

(arrows)

.

Later

systems

(with

the

digital

display

control

head)

use

five

distribution

motors,

four

of

which

are

digítally

controlled

.

See

Fig

.

28

.

HEATER

AND

CONTROLS

Page 456 of 759

640-10

HEATING

AND

AIR

CONDITIONING

i

El

Radio

Antenna

Rear

.

,

si,-

Left

side

I

d

1

.

Rear

vents

2

.

Fresh

air

3

.

Face-level

vents

4

.

Recirculation

5

.

Footwell

vents

0013017

Fig

.

28

.

Location

oflate

production

air

distribution

motors

in

heater

box(shown

in

rear,

side

and

top

views)

.

Heater

andA/C

air

distribution

motor,

replacing

(rotary-knob)

1

.

Toaccess

left

side

motors

(dash

vent

mixing

or

recircu-

lation

flap),

remove

lower

dash

panel

and

knee

bolster

on

driver

side

.

See

513

Interior

Trim

.

2

.

To

access

right

side

motor

(fresh

air

flap),

remove

glove

compartment

.

See513

Interior

Trim

.

3

.

Each

motor

can

be

removed

after

its

electrical

wiring

harness

connector

has

been

removed

.

Squeeze

plastic

clip

to

release

motor

.

See

Fig

.

29

.

Fig

.

29

.

A/

C

air

distribution

motor

plastic

retaíning

clip

(arrow)

.

Re-

lease

clip

and

tilt

motor

out

of

housing

.

Rear

Window

Defogger

0011877

The

rear

window

defogger

switch

is

integrated

with

the

heating

andA/C

control

head

.

HEATER

AND

CONTROLS

Fig

.

30

.

Wiring

diagram

of

rear

window

defogger

and

radio

antenna

.

Rear

Window

Blower

(Convertible

Models)

A

blower

fan,

fitted

into

the

rear

seatback,

defogs

therear

window

.

It

will

only

operate

with

the

engine

nunning

and

the

top

raised

.

A

microswitch

behindthe

rear

seats

provides

the

signal

that

thetop

is

raised

.

To

access

the

blower

fan

motor,

it

is

necessary

to

remove

four

screwsfrom

the

center

seat

back

.

Remove

the

wiring

har-

ness

connector

and

motor

mounting

boits,

then

remove

motor

by

pulling

it

down

and

forward

.

See

Fig

.

31

.

ri

Suppressor

filter

1

0013005

Fig

.

31

.

Rear

window

blower

in

center

of

rear

seat

back

(arrow)

.

The

electric

rear

window

defogger

is

integrated

with

the

ra-

dio

antenna

.

See

Fig

.

30

.

y

/f

0013014

Page 462 of 759

640-16

HEATING

AND

AIR

CONDITIONING

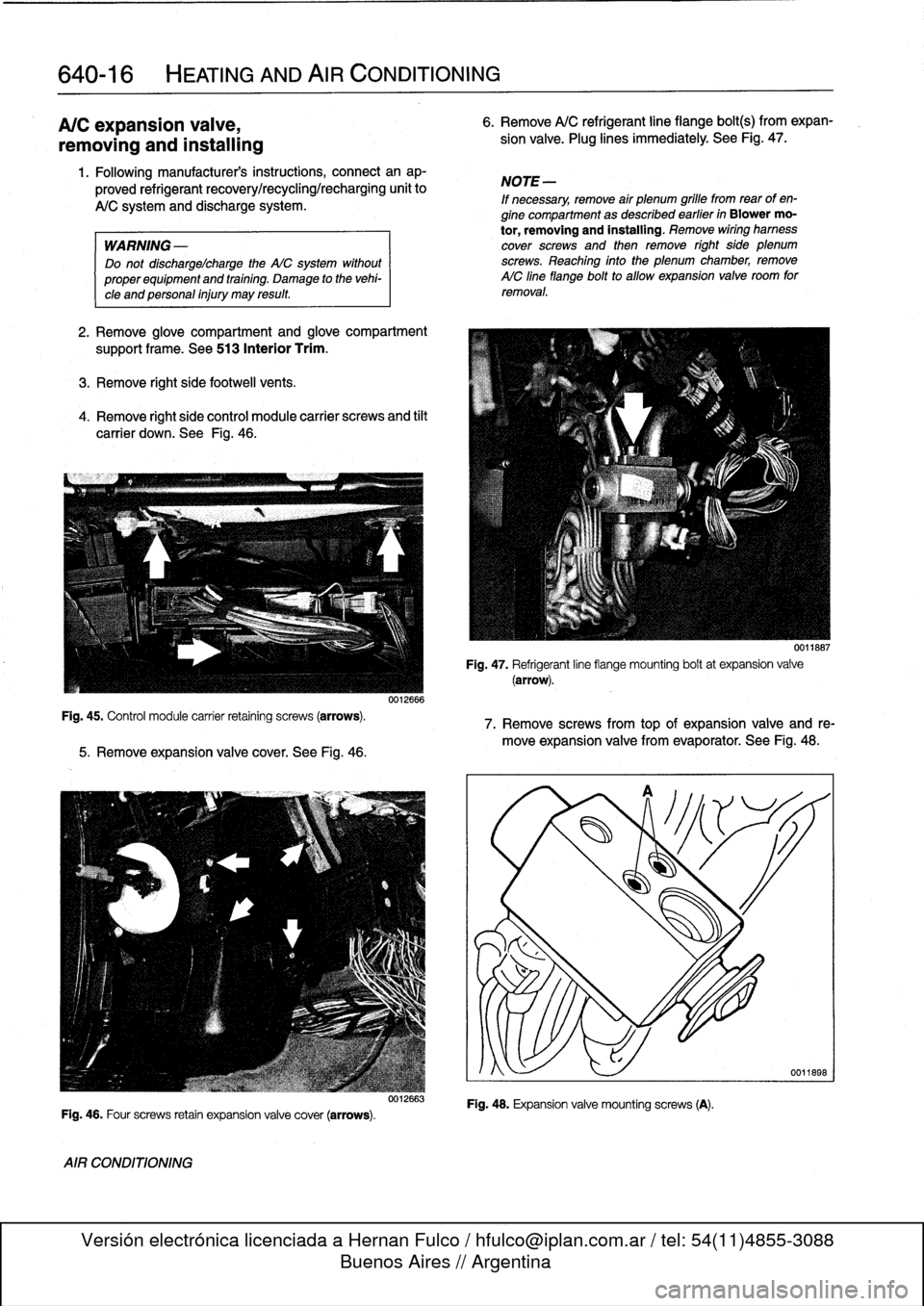

A/C

expansion

valve,

removing

and

installing

Fig

.

45

.

Control

module

carrier

retaining

screws

(arrows)

.

1

.

Following

manufacturers

instructions,

connectanap-

proved

refrigerant

recovery/recycling/recharging

unit

to

A/C

system

and

discharge

system

.

WARNING

-

Do

not

discharge%harge

the

WC

system

without

properequipmentand

training

.

Damage

to

the

vehi-

cle

and

personal

injury

may

result

.

2

.

Remove

glove

compartment

and

glove

compartment

support

frame

.

See513

Interior

Trim

.

3

.

Remove

right

side

footwell

vents

.

4

.

Remove

right

side

control

module

carrier

screws

and

tilt

carrier

down

.

See

Fig

.

46

.

5

.

Remove

expansion

valve

cover

.

See

Fig

.

46

.

Fig

.

46

.

Four

screws

retain

expansion

valve

cover

(arrows)

.

AIR

CONDITIONING

0012666

0012663

6

.

Remove

A/C

refrigerant

line

fiange

bolt(s)

from

expan-

sion

valve

.

Plug

lines

immediately

.

See

Fig

.

47

.

NOTE

-

If

necessary,

remove

air

plenum

grille

fromrear

of

en-

gine

compartment

as

described

earlier

in

Blower

mo-

tor,

removing

and

installing

.

Remove

wiring

hamess

cover

screws

and

then

remove

right

side

plenum

screws

.

Reaching

finto

the

plenum

chamber,

remove

AIC

fine

flange

bolt

to

allow

expansion

valve

room

for

removal

.

Fig

.

47

.

Refrigerant

line

fiange

mounting

boltat

expansion

valve(arrow)

.

7

.

Remove

screws

from

top

of

expansion

valve

and

re-

move

expansion

valve

from

evaporator

.

See

Fig

.

48

.

Fig

.

48

.

Expansion

valve

mountingscrews

(A)

.

0011667

Page 463 of 759

CAUTION

-

Always

replace

O-rings

when

reconnecting

refrig-

erant

fines

.

9

.

Before

recharging,

evacuate

system

for

at

least

30

min

.

Recharge

system

following

equipment

manufacturer's

instructions

.

See

Table

d

.

A/C

System

Refrigerant

Capacities

.

A/C

evaporator,

removing

and

installing

1

.

Followingmanufacturer's

instructions,

connectanap-proved

refrigerant

recovery/recycling/recharging

unit

to

A/C

system

and

discharge

system

.

2

.

Remove

complete

heater

boxas

described

earlier

.

3

.

Remove

expansion

valve

as

described

earlier

.

4

.

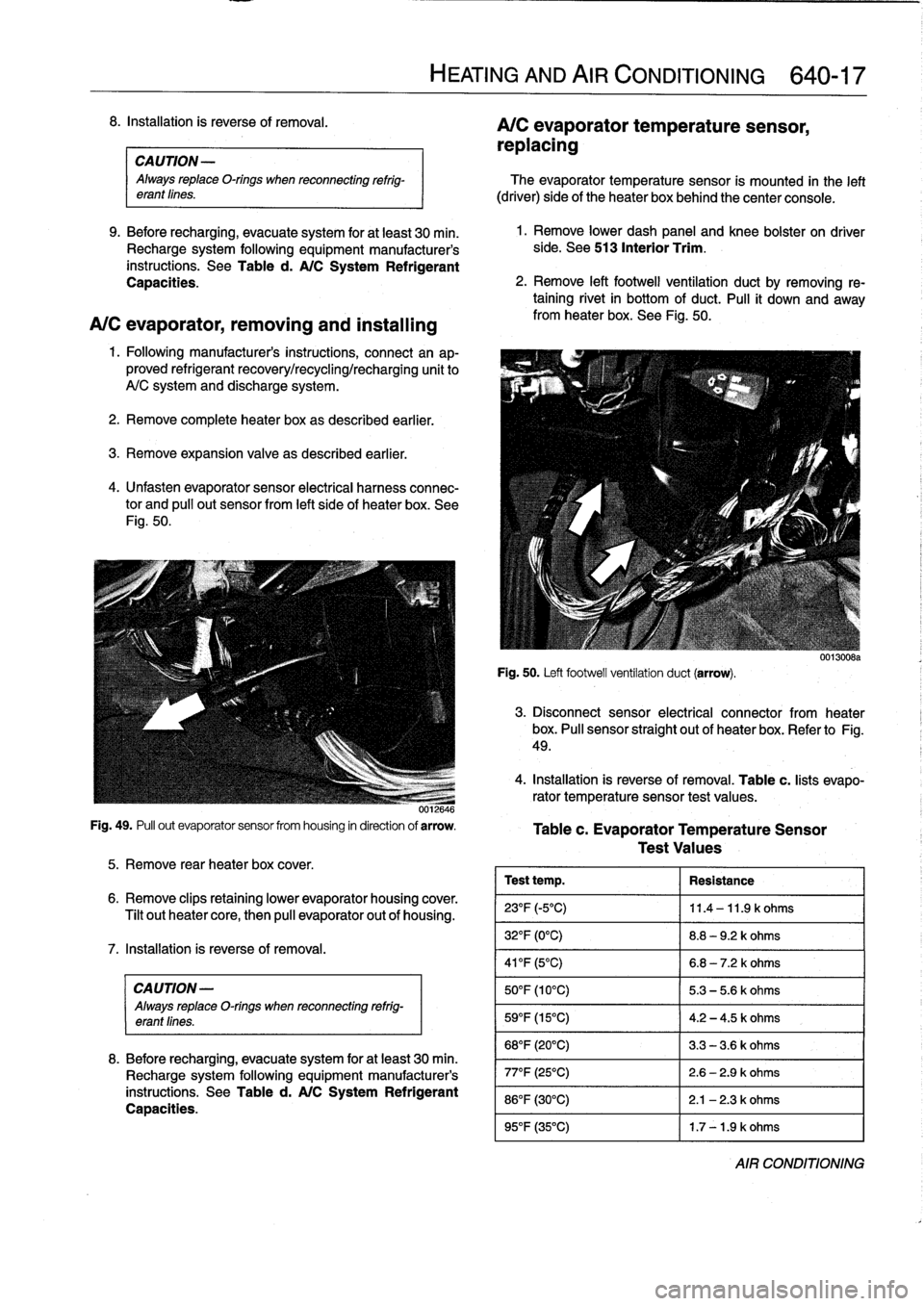

Unfasten

evaporator

sensor

electrical

harness

connec-

tor

and

puli

out

sensor

from

ieft

side

of

heater

box

.

See

Fig

.

50

.

Fig

.

49

.

Pull

out

evaporator

sensor

from

housing

in

direction

of

arrow

.

5

.

Remove

rear

heater

box

cover

.

6

.

Remove

clips

retaining

lower

evaporator

housingcover

.

Tilt

outheater

core,

then

pull

evaporator

out

of

housing

.

7

.

Installation

is

reverse

of

removal

.

CAUTION

-

Always

reptace

O-rings

when

reconnecting

refrtg-

erant

fines

.

8

.

Before

recharging,

evacuate

system

for

at

least

30

min

.

Recharge

system

following

equipment

manufacturer's

instructions

.

See

Table

d

.

A/C

System

Refrigerant

Capacities

.

HEATING

AND

AIR

CONDITIONING

640-17

8

.

Installation

is

reverse

of

removal

.

A/C

evaporator

temperature

sensor,

replacing

ou12b46

The

evaporator

temperature

sensor

is

mounted

in

the

left

(driver)

side

of

theheater

box

behind

thecenter

console

.

1

.

Remove

lower

dash

panel

and

knee

boister

on

driver

side

.

See

513

Interior

Trim

.

2

.

Remove

left

footwell

ventilation

duct

byremoving

re-

taining

rivet

in

bottom

of

duct

.

Pull

it

down

and

away

from

heater

box

.

See

Fig

.

50

.

Fig

.

50

.

Left

footwellventilatíon

duct

(arrow)

.

0o1300ba

3

.

Disconnect

sensor

electrical

connector

from

heater

box

.

Pull

sensor

straight

out

of

heater

box

.

Refer

to

Fig

.

49

.

4

.

Installation

is

reverse

of

removal

.

Table

c

.

lists

evapo-

rator

temperature

sensor

test

values

.

Tablec

.

Evaporator

Temperature

Sensor

Test

Values

Test

temp

.

Resistance

23°F

(-5°C)

11

.4

-11

.9

k

ohms

32°F

(0°C)

8

.8

-

9

.2

k

ohms

41

°F

(5°C)

6

.8

-

7

.2

k

ohms

50°F

(10°C)

5

.3-5

.6

k

ohms

59

°

F

(15°C)

4

.2

-4

.5

k

ohms

68°F

(20°C)

3

.3

-

3

.6

k

ohms

77°F

(25°C)

2

.6-2

.9

k

ohms

86°F

(30°C)

2

.1

-

2

.3

k

ohms

95°F

(35°C)

1

.7

-1

.9

k

ohms

AIR

CONDITIONING

Page 464 of 759

640-18

HEATING

AND

AIR

CONDITIONING

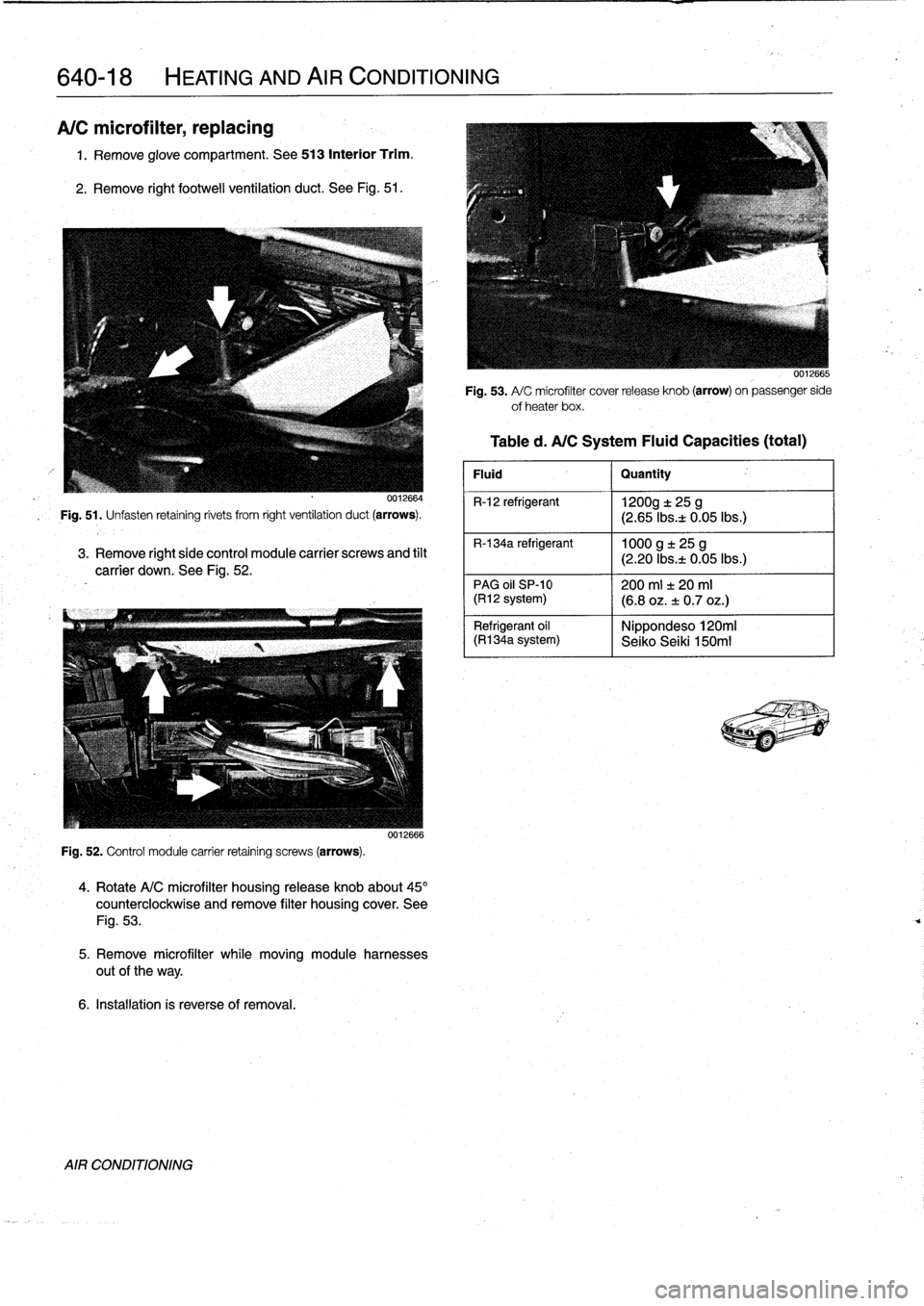

A/C

microfilter,

replacing

1

.

Remove

glove

compartment

.

See

513

Interior

Trim

.

2

.

Remove

right

footwell

ventilation

duct

.

See

Fig

.

51

.

0012664

Fig

.

51

.

Unfasten

retaining

rivets

from

right

ventilation

duct

(arrows)

.

3

.

Remove

right

side

control

module

carrier

screws

and

tilt

carrier

down

.

See

Fig

.

52

.

Fig

.

52

.

Control

module

carrier

retaining

screws

(arrows)

.

0012666

4

.

Rotate

A/C

microfilter

housing

release

knob

about45°

counterclockwise

and

remove

filter

housing

cover

.

See

Fig

.

53

.

5

.

Remove

microfilter

while

moving

module

harnesses

out

of

the

way

.

6

.

Installation

is

reverse

of

removal

.

AIR

CONDITIONING

Fig

.

53

.

A/

C

microfilter

cover

release

knob

(arrow)

on

passenger

side

ofheater

box

.

Table

d

.

A/CSystem

Fluid

Capacities

(total)

Fluid

I

Quantity

R-12

refrigerant

1200g

t

25

g

(2

.65

Ibsa

0

.05lbs

.)

R-134a

refrigerant

1000

g

±

25

g

(2

.20

Ibs

.t

0

.05lbs

.)

PAG

oil

SP-10

1200

ml

f

20

ml(R12

system)

(6

.8

oz

.

±

0

.7

oz

.)

Nippondeso120mi

Refrigerant

oil

(R1

34a

system)

I

Seiko

Seiki

150m1

Page 482 of 759

721-

6

AIRBAG

SYSTEM

(SRS)

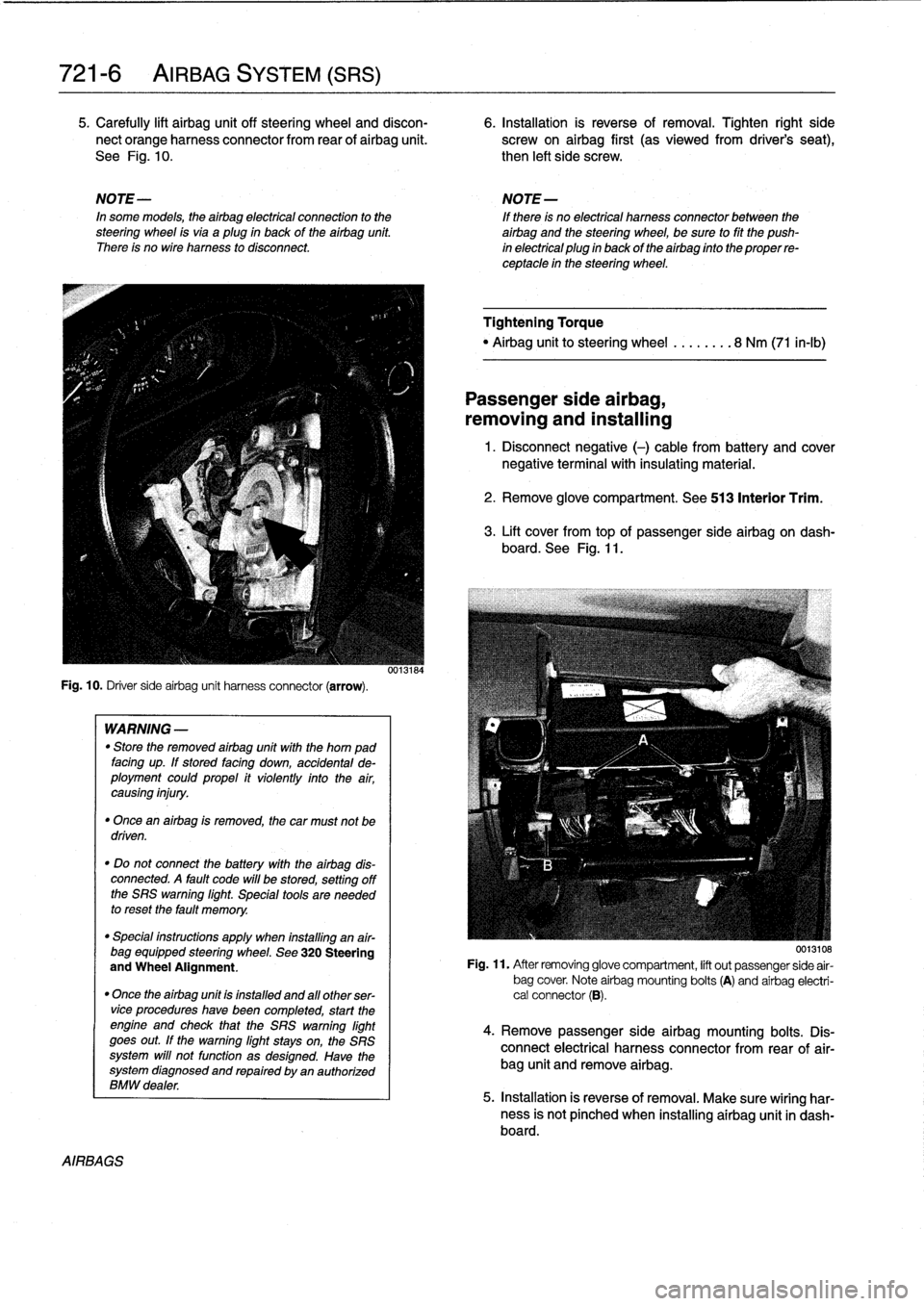

5

.

Carefully

lift

airbag

unit

off

steering

wheel

and

discon-

6

.

Installation

is

reverse

of

removal

.

Tighten

right

side

nect

orange

harness

connector

from

rear

of

airbag

unit

.

screw

on

airbag

first

(as

viewedfrom

driver's

seat),

See

Fig

.

10

.

then

left

side

screw

.

NOTE-

NOTE-

In

some

models,

theairbag

electrical

connection

to

the

If

there

is

no

electrical

harness

connector

between

the

steering

wheel

isvia

aplug

in

back

of

the

airbag

unit

.

airbag

and

the

steering

wheel,

be

sure

to

fit

the

push

There

is

no

wire

harness

to

disconnect

.

in

electrical

plug

in

back

of

the

airbag

finto

the

proper

re-

ceptacle

in

the

steering

wheel

.

Fig

.

10

.

Driver

sideairbag

unit

harness

connector

(arrow)

.

AIRBAGS

WARNING

-

"

Store

the

removed

airbag

unit

with

the

horn

pad

facing

up

.

If

stored

facing

down,

accidental

de-

ployment

couldpropel

it

violently

into

the

air,

causing

injury

.

"

Once

an

airbag

is

removed,

the

car

must

not

be

driven

.

"

Do

not

connect

the

battery

with

the

airbag

dis-

connected

.

A

fault

code

will

be

stored,

setting

off

the

SRS

warning

light

.

Special

tools

are

needed

to

reset

the

fault

memory

.

"

Special

instructions

apply

when

installing

an

air-

bag

equipped

steering

wheel

.

See

320

Steering

and

Wheel

Alignment

.

"

Once

the

airbag

unit

is

installnd

and

all

other

ser-vice

procedureshave

been

completed,

start

the

engíne

and

check

that

the

SRS

warning

light

goes

out

.

If

the

warning

light

stays

on,

the

SRS

system

will

not

function

as

designed

.

Have

the

system

diagnosed

and

repaired

by

an

authorized

BMW

dealer

.

0013184

Tightening

Torque

"

Airbag

unitto

steering

wheel

........

8

Nm

(71

in-lb)

Passenger

side

airbag,

removing

and

installing

1

.

Disconnect

negative

(-)

cable

from

battery

and

cover

negative

terminal

with

insulating

material

.

2

.

Remove

glove

compartment

.

See

513

Interior

Trim

.

3

.

Lift

cover

from

topof

passenger

sideairbag

on

dash-

board

.

See

Fig

.

11

.

0013108

Fig

.

11

.

After

removing

glove

compartment,

lift

out

passenger

side

air-

bag

cover

.

Note

airbag

mounting

bolts

(A)

and

airbag

electri-

cal

connector

(B)

.

4

.

Remove

passenger

sideairbag

mounting

bolts

.

Dis-

connect

electrical

harness

connector

from

rear

of

air-

bag

unit

and

remove

airbag

.

5

.

Installation

is

reverse

of

removal

.

Make

sure

wiring

har-

ness

is

not

pínched

when

installing

airbag

unit

in

dash-board

.

Page 485 of 759

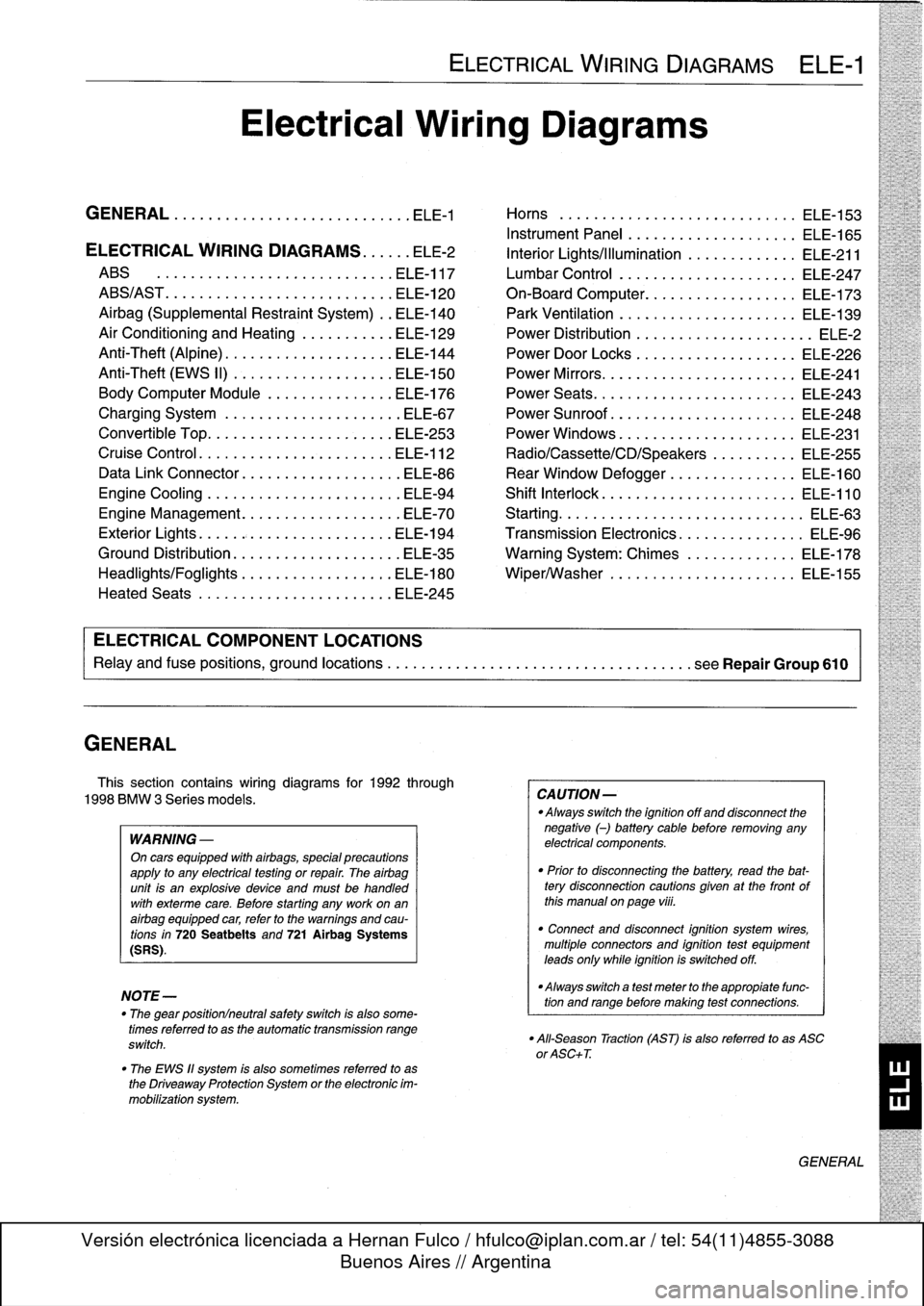

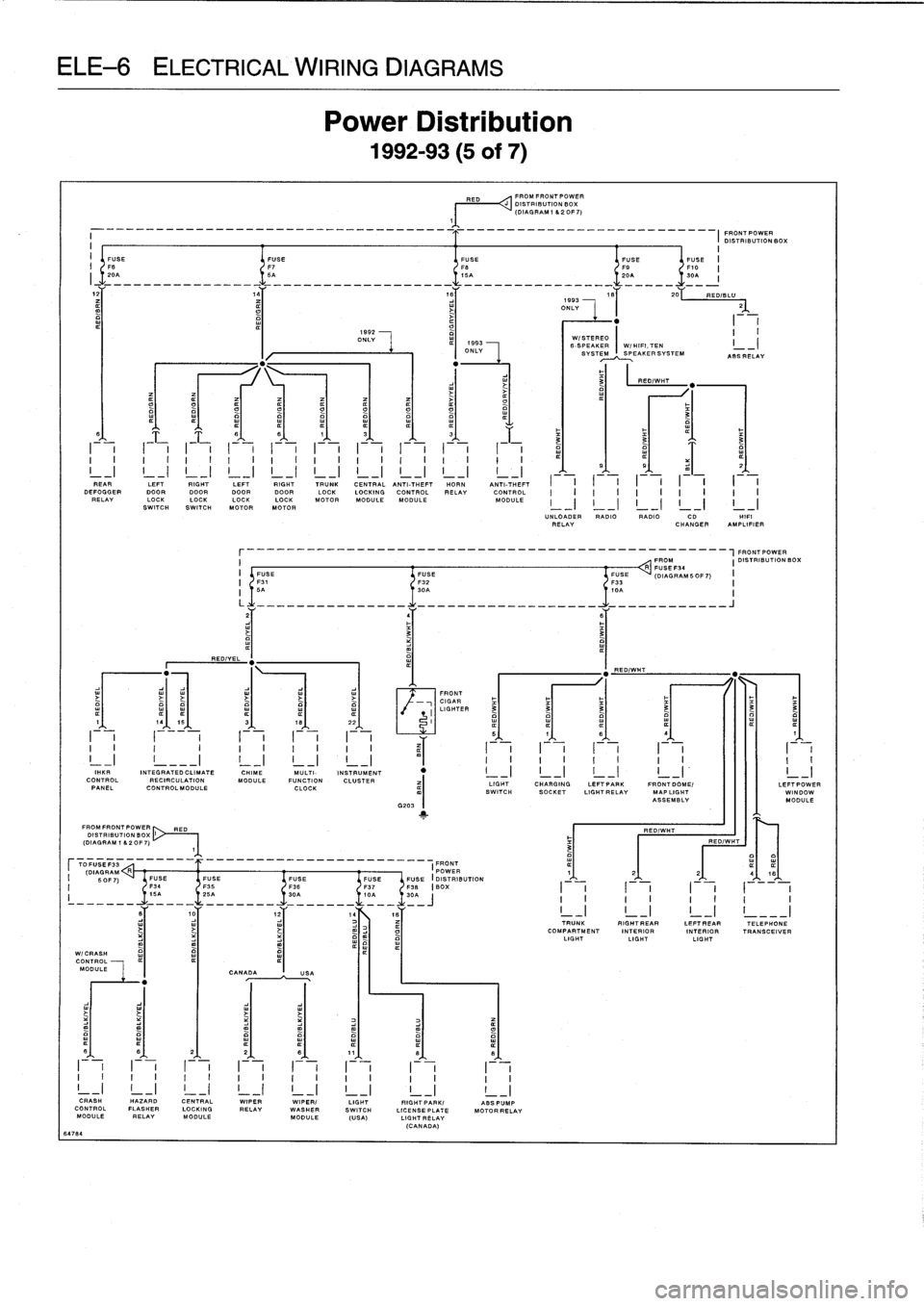

GENERAL

This

section

contains

wiring

diagrams

for

1992

through

1998

BMW

3

Series

models

.

WARNING

-

On

cars

equipped

with

airbags,

special

precautions

apply

to

any

electrical

testing

or

repair

.

The

airbag

unit

is

an

explosive

device

and

must

be

handled

with

exterme

care

.

Before

starting

any

work

onan

airbag

equipped

car,

refer

to

the

warnings

and

cau-

tions

in

720

Seatbelts

and

721

Airbag

Systems

(SRS)

.

NOTE-

The

"

gear

position/neutral

safetyswitch

is

also

some-

timesreferred

to

as

the

automatic

transmission

range

switch

.

"

The

EWS

11

system

is

also

sometimes

referred

to

as

the

Driveaway

Protection

System

or

the

electronic

im-

mobilization

system

.

ELECTRICAL

WIRING

DIAGRAMS

ELE-1

Electrical

Wiring

Diagrams

GENERAL

.

.

.

.

.

.

.

.

.

................

.

.

.

ELE-1

Horns

.....

.

.....

.

.

.

....

.

.

.

.

.

...

.

.

ELE-153

Instrument

Panel

.

.

.

.

.

.

..............

ELE-165

ELECTRICAL

WIRING

DIAGRAMS

...

.

.

.

ELE-2

Interior

Lights/Illumination

.............

ELE-211

ABS

..............

.

.

.

.....

.

.....

ELE-117

Lumbar

Control

.

....................

ELE-247

ABS/AST

.............

.

.

.

...

.

.

.

.....

ELE-120

On-Board

Computer

..................

ELE-173

Airbag

(Supplemental

Restraint

System)

..

ELE-140

Park

Ventilation

.

.

.

...........

.

...

.

..

ELE-139

Air

Conditioning

and

Heating

.

.

.

.

.

.

.....

ELE-129

Power

Distribution

......

.

...

.

.

.

.

.

.

.

...

.

ELE-2

Anti-Theft

(Alpine)

..........

.

.

.

...

.

...

ELE-144

Power

Door

Locks

.

.

......

.

.

.

.

.

.

.

.

.

..

ELE-226

Anti-Theft

(EWS

II)

.

........

.

.

.

...

.

...

ELE-150

Power

Mirrors

...

.

.

.

......

.

.

.

.

.

.

.

.

.

..

ELE-241

Body

Computer

Module

.....

.

.....

.

...

ELE-176

Power

Seats

......

.

......

.

.

.

...

.

.

.

..

ELE-243

Charging

System

.

.

................

.

.

.

ELE-67

Power

Sunroof

.

.

.

.

.

.

.

...............

ELE-248

Convertible

Top

.

.

.

.

................

.

.

ELE-253

Power

Windows

.

.

.

.

.

.

.....

.

.........

ELE-231

Cruise

Control

..

.

.

.

...........

.

....

.

.

ELE-112

Radio/Cassette/CD/Speakers

..........

ELE-255

Data

Link

Connector

................

.

.

.

ELE-86

Rear

Window

Defogger

...............

ELE-160

Engine

Cooling

.......

.

.......

.

....

.

.

.

ELE-94

Shift

Interlock

.

.

.

.

.

.

.

.

...............

ELE-110

Engine

Management

...

.

.......

.

....

.

.

.

ELE-70

Starting

....

.

.

.

.

.

...

.

................

ELE-63

Exterior

Lights

........

.

.

.

.

.

.

.

.

.

......

ELE-194

Transmission

Electronics

.

..............

ELE-96

Ground

Distribution

....

.

.

.

.

.

.

.

.

.

.......

ELE-35

Warning

System

:

Chimes

.............

ELE-178

Headlights/Foglights

...

.

.

.

.

.

.

.

.

.

......

ELE-180

Wiper/Washer

.

.....

.

...............

ELE-155

Heated

Seats

........

.

.

.

.

.

.

.

.

.

......

ELE-245

ELECTRICAL

COMPONENT

LOCATIONS

Relayand

fuse

positions,

ground

locations

...........

.

.

.

.

.

.

.

.

.

................

seeRepair

Group

610

CAUTION-

Always

switchthe

ignition

off

and

disconnect

the

negative

(-)

battery

cablebefore

removing

any

electrical

components

.

"

Prior

to

disconnecting

the

battery,

read

the

bat-tery

disconnection

cautions

given

at

the

front

of

this

manual

on

page

viii

.

"

Connect

and

disconnect

ignition

system

wires,

multiple

connectors

and

ignition

test

equipment

leads

only

while

ignition

is

switched

off

.

-Always

switch

a

test

meter

to

the

appropiate

func-

tion

and

range

before

making

test

connections

.

"

All-Season

Traction

(AST)

is

also

referred

to

as

ASC

or

ASC+T

.

GENERAL

Page 490 of 759

CALWIRING

DIAGF

Power

Di

:

1992-93

RED

FROMFRONTPOWER

DISTRIBUTION

BOX

(DIAGRAM

1

620F7)

1

FRONTPOWER

DISTRIBUTION

BOX

i

I

I

1592

II

ONLY

WI

STEREO

-

I

ONLY

6-

SVS

SPEAKER

I

W/HIFI,TEN

I

TE~~PEAKERSYSTEM

ASSRELAY

3

RED/WHT

O

t7

0

t7

3

6

6

8

1

3

¢

3

F

~

~

3

a

a

o

I

I

I

II

I

I

I

I

I

I

I

I

I

I

I

I

I

i

I

¢

5

s

z

I

REAR

I

I

LEFT

I

I

RIGHT

I

I

LEFT

I

I

RIGHT

I

I

TRUNK

I

CENT

RA

I

L

ANTI-THEFT

I

HORN

I

ANTI-THEFT

I

I

I

I

I

I

I

I

I

I

DEFOGGERDOOR

DOOR

DOORDOOR

LOCK

LOCKING

CONTROL

RELAY

CONTROL

II

I

IIIIIII

RELAY

LOCK

LOCKLOCKLOCK

MOTOR

MODULEMODULE

MODULE

I

_

II

-

II

_

II

-

II

_

I

SWITCHSWITCH

MOTORMOTOR

UNLOADER

RADIO

RADIO

CD

HIF'

RELAY

CHANGER

AMPLIFIER

r________________________________________________-FRONT

POWER

I

FROM

I

DISTRIBUTION

BOXR

FUSE

I

FUSE

FUSE

FUSE

(DIAGRAMSOF7)

I

F31

F32

F33

II

5A

30A

I,0

OA

I

L

-----

______

.......

.

.

.

.

.

.

.

.

.

..

________J

z

4

6

3

3

a

"

"

REDIYEL

RED/WHT

"

FRONT

Y

CIGAR

I

LIGHTED

3

3

3

3

3

3

1

-

19

15

3

-

18

-

22

-

I

_

_I

I

I

iI

(

I

II

5

1

s

s

1

I

I

I

I

II

I

I

II

~

(-

I

I

I

I

-

I

II

IiI

_I

!

___I

!

_I

!

_I

i

-I_

I

I

I

I

I

I

I

I

I

I

I"

KIM

INTEGRATED

CLIMATE

CHIME

MULTI-

INSTRUMENT

"

I

_I

I

-

I

I

~I

I

-I

I

_I

CONTROL

RECIRCULATION

MODULE

FUNCTION

CLUSTER

LIGHT

CHARGING

LEFTPAPK

FRONT

DOME/

LEFT

POW

PANEL

CONTROLMODULE

CLOCK

SWITCH

SOCKET

LIGHTRELAV

MAP

LIGHT

WINDON

ASSEMBLY

MODULE

G203

1

FROMFRONTPOWER

RED

RED/WHT

DISTRIBUTION

BOX

(DIAGRAM

1

82OF7)

RED/WIT

3

TFUSEF33

FRONT

ODAORAM

R

______

__________________-

I

POWER

¢

1

2

2

416

I

SOFT)

FUSE

FUSE

FUSE

FUSE

FUSEFUSE

(DISTRIBUTION

F34

136

F37

F38

BOX

I

I

II

III

I

z'235

A-____

t0A

-

30=~

IIIII11I

10

1z

14Es

TRUNK

RIGHTREAR

LEFTREAR

TELEPHONE

COMPARTMENT

INTERIOR

INTERIOR

TRANSCEIVER

LIGHT

LIGHTLIGHT

P

W1

C

RASH

CONTROL

MODULE

CANADAUSA

fl

6

2

2

8

11

8

0

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

II

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

CRASH

HAZARD

CENTRAL

WIPER

WIPER/

LIGHT

RIGHTPARK/

ABSPUMP

CONTROLFLASHER

LOCKING

RELAY

WASHER

SWITCH

LICENSEPLATE

MOTORRELAV

MODULE

RELAY

MODULE

MODULE

(USA)

LIGHTRELAV

(CANADA)

64784

Page 500 of 759

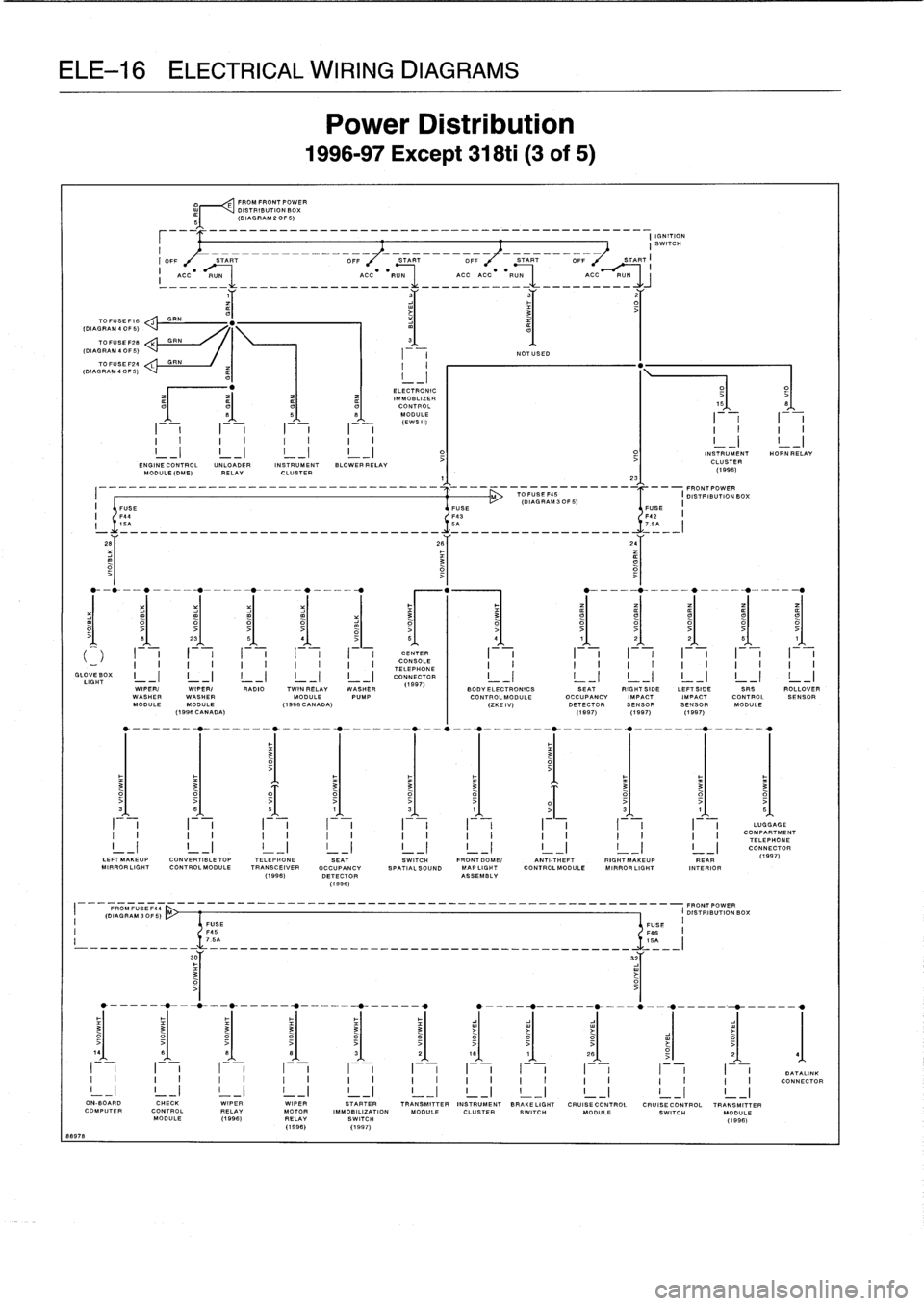

ELE-16

ELECTRICAL

WIRING

DIAGRAMS

88978

TO

FUSE

F16

yDIAGRAM

4

OF

5)

70FU

SEF28

K

GRN

(DIAGRAM

4OF5)

___

--------

_---------------------

______________

I

IGNITION

I

SWITCH

I

_

_

_-_-__-

-----------

I

OFF

START

OFF

START

OFF

START

F,

START

FROM

FRONT

POWER

r

<

DISTRIBUTION

BOX

(DIAGRAM

2OF5)

=OC---U-

-_-_---_-__-ACC--RU=

____CC_CC--R=N-

CC-PUN

Power

Distribution

1996-97

Except

318ti

(3

of

5)

ELECTRONICIMMOBLIZER

CONTROL

MODULE

(EWS11)

NOTUSED

2_

.

15

t

I

I

II

II

F-,

II

II

I

I

II

I

I

I

I

I

-I

L-1

INSTRUMENT

HORN

RELAY

ENGINECONTROL

UN

LOADER

INSTRUMENT

BLOWERRELAY

CLUSTER

No

DULE(DME)

RELAY

CLUSTER

°_

(1996)

-----

-------

1

1'

--

FRONTPOWER

I

M

TO

1111111

IDISDISTRIBUTION

BOX

(DIAGRAM

3

OF5)

II

FUSE

FUSE

USE

I

1'44

F43

42

I

!

'________________________________

5A

~

_________________

5=

el

231

51

41

51

51

41

1

J

1

2

J

1

2

J

1

5~

1),

1

I

.+

.

1

1

1

CE

.N+

TER

I

I

.+

.

i

I

.

1

I

.

1

I

.

1

1

1

1

1

I

I

II

II

I

I

I

I

CONSOLE

TELEPHONE

GLOVE

BOX

I

-

.

I

I

-

I

I

-)

I

-

I

I

-

I

CONNECTOR

LIGHT

(1987)

WIPER/

WIPER/

RADIO

TWIN

RELAY

WASHERWASHER

WASHER

MODULE

PUMPMODULE

MODULE

(1996

CANADA)

(1996

CANADA)

SEAT

RIGHTSIDE

LEFT

SIDE

SRS

ROLLOVER

OCCUPANCY

IMPACTIMPACT

CONTROLSENSOR

DETECTOR

SENSORSENSOR

MODULE

(1997)(1997)(1997)

O~

31

1~

~

1

31

11

51

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

LUG

AGE

I

I

II

II

I

I

II

I

I

II

II

I

I

COMPARTMENT

TELEPHONE

CONNECTOR

LEF7MAKEUP

CONVERTIBLETOP

TELEPHONE

SEAT

SWITCH

FRONTDOME/

ANTI-THEFT

RIGHTMAKEUP

REAR

(1997)

MI

PROFLIGHT

CONTROLMODULE

TRANSCEIVER

OCCUPANCY

SPATIALSOUND

MAPLIGHT

CONTROLMODULE

MIRROR

LIGHT

INTERIOR

(1996)

DETECTOR

ASSEMBLY

(199fi)

FROMFISE

141

---

(DIAGRAM

30F5)

M

________--_--_________________-_----------------

FRONTPOWER

DISTRIBUTIONBOX

(

FUSE

FUSE

1I

F45

F4fi

I

'S

7

.5A--______________-________________-______

___

30Y

32Y

I

i

F-

,I

iF-

,I

i

I

-

F

-

,

I-

ON-BOAR

CHECK

WIPER

WIPER

STARTER

TRANSMITTER

INSTRUMENT

BRAKELIGHT

CRUISECONTROL

CRUISECONTROL

TRANSMITTER

COMPUTER

CONTROL

RELAY

MOTOR

IMMOBILIZATION

MODULE

CLUSTER

SWITCH

MODULE

SWITCH

MODULE

MODULE

(1996)

RELAY

SWITCH

(1996)

(1998)

(1997)

0

TALINK

CONNECTOR