valv cover BMW 318i 1997 E36 Repair Manual

[x] Cancel search | Manufacturer: BMW, Model Year: 1997, Model line: 318i, Model: BMW 318i 1997 E36Pages: 759

Page 462 of 759

640-16

HEATING

AND

AIR

CONDITIONING

A/C

expansion

valve,

removing

and

installing

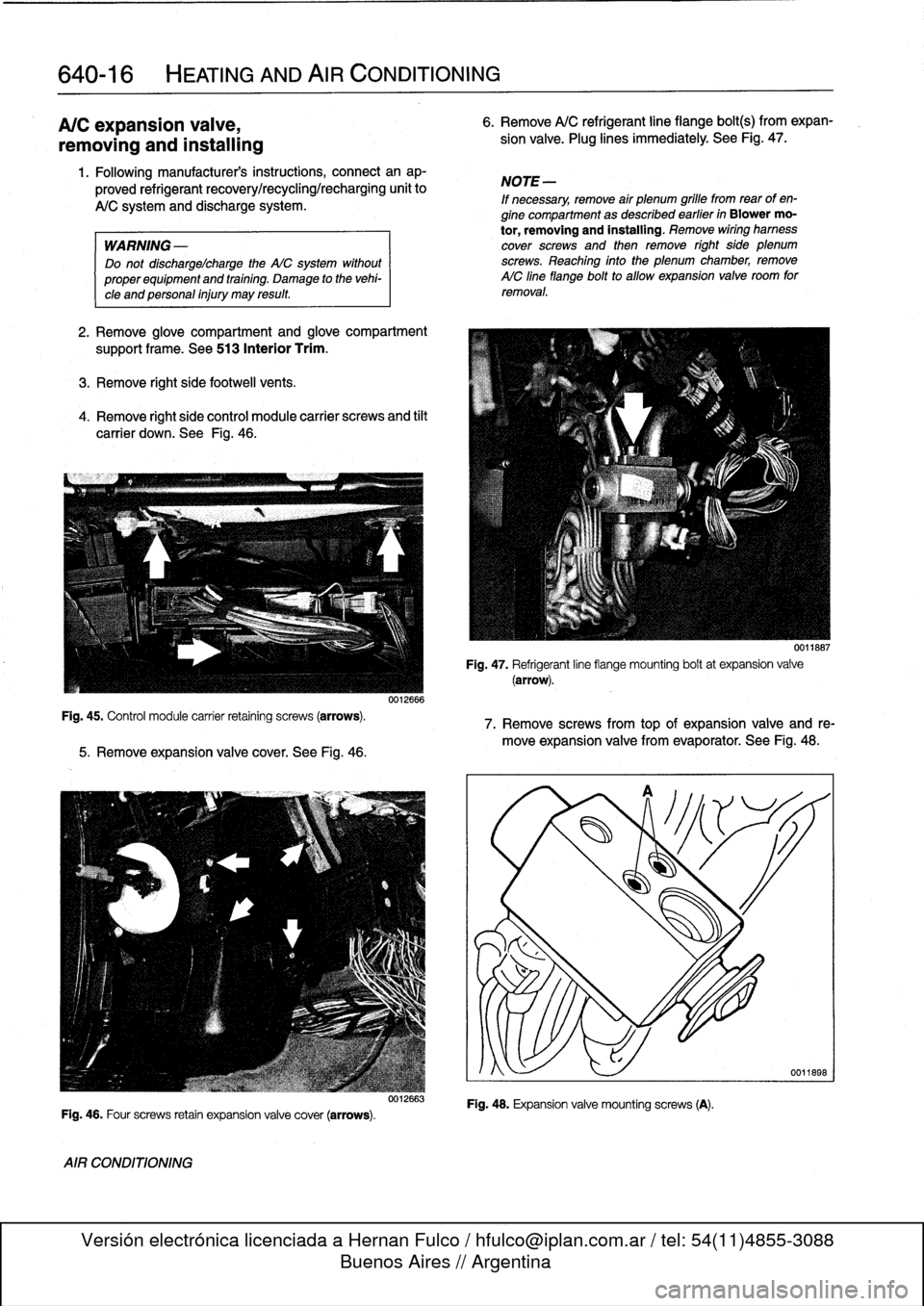

Fig

.

45

.

Control

module

carrier

retaining

screws

(arrows)

.

1

.

Following

manufacturers

instructions,

connectanap-

proved

refrigerant

recovery/recycling/recharging

unit

to

A/C

system

and

discharge

system

.

WARNING

-

Do

not

discharge%harge

the

WC

system

without

properequipmentand

training

.

Damage

to

the

vehi-

cle

and

personal

injury

may

result

.

2

.

Remove

glove

compartment

and

glove

compartment

support

frame

.

See513

Interior

Trim

.

3

.

Remove

right

side

footwell

vents

.

4

.

Remove

right

side

control

module

carrier

screws

and

tilt

carrier

down

.

See

Fig

.

46

.

5

.

Remove

expansion

valve

cover

.

See

Fig

.

46

.

Fig

.

46

.

Four

screws

retain

expansion

valve

cover

(arrows)

.

AIR

CONDITIONING

0012666

0012663

6

.

Remove

A/C

refrigerant

line

fiange

bolt(s)

from

expan-

sion

valve

.

Plug

lines

immediately

.

See

Fig

.

47

.

NOTE

-

If

necessary,

remove

air

plenum

grille

fromrear

of

en-

gine

compartment

as

described

earlier

in

Blower

mo-

tor,

removing

and

installing

.

Remove

wiring

hamess

cover

screws

and

then

remove

right

side

plenum

screws

.

Reaching

finto

the

plenum

chamber,

remove

AIC

fine

flange

bolt

to

allow

expansion

valve

room

for

removal

.

Fig

.

47

.

Refrigerant

line

fiange

mounting

boltat

expansion

valve(arrow)

.

7

.

Remove

screws

from

top

of

expansion

valve

and

re-

move

expansion

valve

from

evaporator

.

See

Fig

.

48

.

Fig

.

48

.

Expansion

valve

mountingscrews

(A)

.

0011667

Page 463 of 759

CAUTION

-

Always

replace

O-rings

when

reconnecting

refrig-

erant

fines

.

9

.

Before

recharging,

evacuate

system

for

at

least

30

min

.

Recharge

system

following

equipment

manufacturer's

instructions

.

See

Table

d

.

A/C

System

Refrigerant

Capacities

.

A/C

evaporator,

removing

and

installing

1

.

Followingmanufacturer's

instructions,

connectanap-proved

refrigerant

recovery/recycling/recharging

unit

to

A/C

system

and

discharge

system

.

2

.

Remove

complete

heater

boxas

described

earlier

.

3

.

Remove

expansion

valve

as

described

earlier

.

4

.

Unfasten

evaporator

sensor

electrical

harness

connec-

tor

and

puli

out

sensor

from

ieft

side

of

heater

box

.

See

Fig

.

50

.

Fig

.

49

.

Pull

out

evaporator

sensor

from

housing

in

direction

of

arrow

.

5

.

Remove

rear

heater

box

cover

.

6

.

Remove

clips

retaining

lower

evaporator

housingcover

.

Tilt

outheater

core,

then

pull

evaporator

out

of

housing

.

7

.

Installation

is

reverse

of

removal

.

CAUTION

-

Always

reptace

O-rings

when

reconnecting

refrtg-

erant

fines

.

8

.

Before

recharging,

evacuate

system

for

at

least

30

min

.

Recharge

system

following

equipment

manufacturer's

instructions

.

See

Table

d

.

A/C

System

Refrigerant

Capacities

.

HEATING

AND

AIR

CONDITIONING

640-17

8

.

Installation

is

reverse

of

removal

.

A/C

evaporator

temperature

sensor,

replacing

ou12b46

The

evaporator

temperature

sensor

is

mounted

in

the

left

(driver)

side

of

theheater

box

behind

thecenter

console

.

1

.

Remove

lower

dash

panel

and

knee

boister

on

driver

side

.

See

513

Interior

Trim

.

2

.

Remove

left

footwell

ventilation

duct

byremoving

re-

taining

rivet

in

bottom

of

duct

.

Pull

it

down

and

away

from

heater

box

.

See

Fig

.

50

.

Fig

.

50

.

Left

footwellventilatíon

duct

(arrow)

.

0o1300ba

3

.

Disconnect

sensor

electrical

connector

from

heater

box

.

Pull

sensor

straight

out

of

heater

box

.

Refer

to

Fig

.

49

.

4

.

Installation

is

reverse

of

removal

.

Table

c

.

lists

evapo-

rator

temperature

sensor

test

values

.

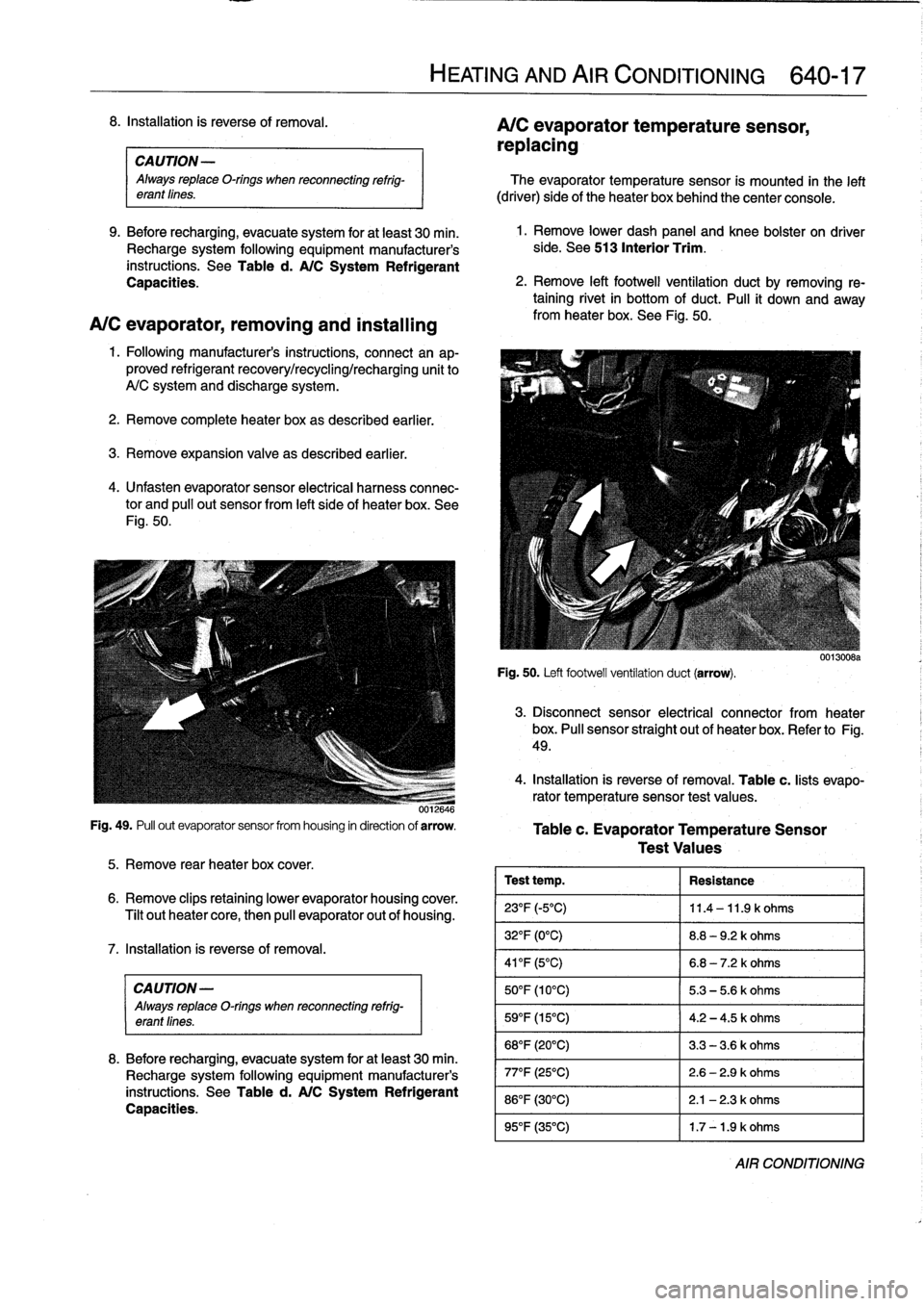

Tablec

.

Evaporator

Temperature

Sensor

Test

Values

Test

temp

.

Resistance

23°F

(-5°C)

11

.4

-11

.9

k

ohms

32°F

(0°C)

8

.8

-

9

.2

k

ohms

41

°F

(5°C)

6

.8

-

7

.2

k

ohms

50°F

(10°C)

5

.3-5

.6

k

ohms

59

°

F

(15°C)

4

.2

-4

.5

k

ohms

68°F

(20°C)

3

.3

-

3

.6

k

ohms

77°F

(25°C)

2

.6-2

.9

k

ohms

86°F

(30°C)

2

.1

-

2

.3

k

ohms

95°F

(35°C)

1

.7

-1

.9

k

ohms

AIR

CONDITIONING