Systems main relay BMW 323i 1992 E36 Workshop Manual

[x] Cancel search | Manufacturer: BMW, Model Year: 1992, Model line: 323i, Model: BMW 323i 1992 E36Pages: 759

Page 147 of 759

GENERAL

.

.

.

.

.

.

.

.

.

...

.

.

.

.

.

.

.

.........

130-2

Intake

air

temperature

(IAT)

sensor,

Principles

of

Operatinn

.

.

.

.

.

.

.

.

.

.........

130-2

testing

and

replacing

...

.

...

.

.

.

.......

.

130-19

Basic

Engine

Settings

.

.

.

.

.

.

.

.

.

.

.

.

.

.

...

:

.

130-3

Throttle

position

sensor

(TPS),

DISA

(Dual

Resonance

Intake

System)

.

.

.

.

.

130-3

testing

and

replacing

...

.

...

.

.

.

.

.

...

.

.

.130-19

On-Board

Diagnostics

(OBD)

Idle

speed

control

valve,

testing

.

.

.

.

.

.

.

.

.

.

130-20

and

Fault

Diagnosis

.

.

....

.

......

.

.

.

...

130-4

Idle

speed

control

valve,

replacing

.

.

.

.

.

.

..

130-21

SecondaryAir

Injection

.

.

.....

.

.........

.

130-5

BOSCH

DME

M5

.2

COMPONENT

Warnings

and

Cautions

.

.

...

.

.

.

.........

.

130-6

REPLACEMENT

.....

.

......

.

....

.

.

.

..

130-21

ELECTRICAL

CHECKSAND

Mass

air

flow

sensor,

replacing

.

.

....

.

....

130-22

COMPONENT

TESTING

.

.

.

.

.

.

.

.

...

.

.

.

.

.

130-7

Engine

coolant

temperature

(ECT)

Main

sensor,

replacing

..

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

130-22

rela

y

testing

130

-7

,...

.

.

.

.

.

.

.

.

.

...

.

.

.

.

.

.

.

Intake

air

temperature

(IAT)

sensor,

Fuel

pump

relay,

testing

.

.

.

.

.

.

.

...

.

.

.

.

.

.

.

130-7

rep

lacin

.

.

.

.

.

.

.

.

.

.

.g

.

.

.

.

.

.

.

...

.

.

.

..

.130-22

Oxygen

sensor,

testing

(Boschsystems

only)

130-8

Throttle

poson

sensor

(TPS)

replacing

13022

,

..

.-

FUEL

DELIVERY

TESTS

...

.

....

.

.

.

...

.

130-9

Idle

speed

control

valve,

replacing

...

.

....

.130-23

Operating

fuel

pump

for

tests

.

.

.......

.

...

130-9

SIEMENS

MS

41

.1

COMPONENT

Relieving

fuel

pressure

and

REPLACEMENT

.

...

.

.

.

.

.

.......

.

....

.130-23

connecting

fuel

pressure

gauge

......

.

..

130-10

Residual

fuel

pressure,

testing

.

.....

.

.

.

.

.

130-10

Mass

air

flow

sensor,

replacing

.

.......

.

.

.130-25

Fuel

pressure

regulator

response

Engine

coolant

temperature

(ECT)

to

engine

load,

testing

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

130-11

sensor,

replacing

.....

.

.

.

.

.

.........

.130-25

Fuel

rail

and

injectors,

checking

...

.

.

.

.

.

.

.

130-11

Intake

air

temperature

(IAT)

sensor,

replacing

.

.

.

.

.

.....

.

.

.

.

.

.

.

.......

.

.

.130-25

Fuel

rail

and

injectors,

replacing

..

.

.

.

.

.

.

.

130-12

Throttleposition

sensor

(TPS),

replacing

.

.

.

130-26

Fuel

PressureRegulator

.........

.

.

.

.

.

.

.

130-13

Idle

s

eed

control

valve,

re

lacin

130-26

Fuel

pressure

regulatorreplacing

p

p

g

.'''...

.

'

,

(fuel

rail

mount)

...

.

.

.

.

.

.............

130-13

ECM

PIN

ASSIGNMENTS

.............

.

.

130-26

Fuel

pressure

regulator,

replacing

Engine

control

module

(ECM),

accessing

...

130-26

(undercar

mount)

.

.

.

.

.

.

.

.

.........

.

.

130-14

BOSCH

DME

M1

.7

COMPONENT

TESTS

AND

REPAIRS

.

.

.

.

.

...

.

.

.

.

.

.

.

.

130-14

Air

flow

sensor,

testing

and

replacing

.

.

.

.

.

.

130-14

Engine

coolant

temperature

(ECT)

sensor,

testing

and

replacing

...

.

.

.

.

.

.

.

.

130-15

Throttle

position

sensor

(TPS),

testing

and

replacing

.

..........

.

.....

130-16

Idle

speed

control

valve,

testing

and

replacing

.

.

.

.

.

............

130-16

BOSCH

DME

M3

.1

AND

M33

.1

COMPONENT

TESTS

AND

REPAIRS

.

.

.

130-17

Mass

Air

Flow

Sensor

.

.

.

.

.

.

.

.

.....

.

.

.

.

.130-17

Mass

air

flow

sensor

(hotwire),testing

and

replacing

.

.

.

.

.

.....

.

.

.

.

.

.

.

130-17

Mass

air

flow

sensor

(hot

film),

testíng

and

replacing

.

.

.

.....

.

.

.

.

.

.

.

.

.

130-18

Engine

coolant

temperature

(ECT)

sensor,

testing

and

replacing

..

.

.

.

.

.

...

.

130-18

130

Fuel

i

n

jection

FUEL

INJECTION

130-1

TABLES

a

.

Engine

Management

System

Variants

.........

.130-2

b

.

Mass

Air

Flow

Sensor

Variants

..

.

..

..........

.130-2

c

.

Fuel

Pressure

Specifications

..

.

.

...

..........

130-11

d

.

Engine

Coolant

Temperature

Sensor

or

Intake

Air

Temperature

Sensor

Test

Values

(DME

1

.7)

...

.

130-15

e

.

ThrottlePosition

Sensor

Tests

(DME

1

.7)

......

.130-16

f

.

Engine

Coolant

Temperature

Sensor

or

Intake

Air

Temperature

Sensor

Test

Values

(DME

3

.1/3

.3

.1)130-19

g

.

Throttle

Position

Sensor

Tests

(DME

3

.1/3.3

.1)

.

.130-20

h

.

ECM

Pin

Assignment-Bosch

DME

M1

.7

....

.

..

.130-28

i.

ECM

Pin

Assignment-Bosch

DME

M3

.1

.......

.130-30

j

.

ECM

Pin

Assignment-Bosch

DME

M3

.3

.1

.....

.130-32

k

.

ECM

Pin

Assignment-Bosch

DME

M5

.2

.......

.

130-34

I.

ECM

Pin

Assignment-Siemens

DME

MS

41

.1

..

.

130-36

Page 153 of 759

ELECTRICAL

CHECKS

AND

COMPONENT

TESTING

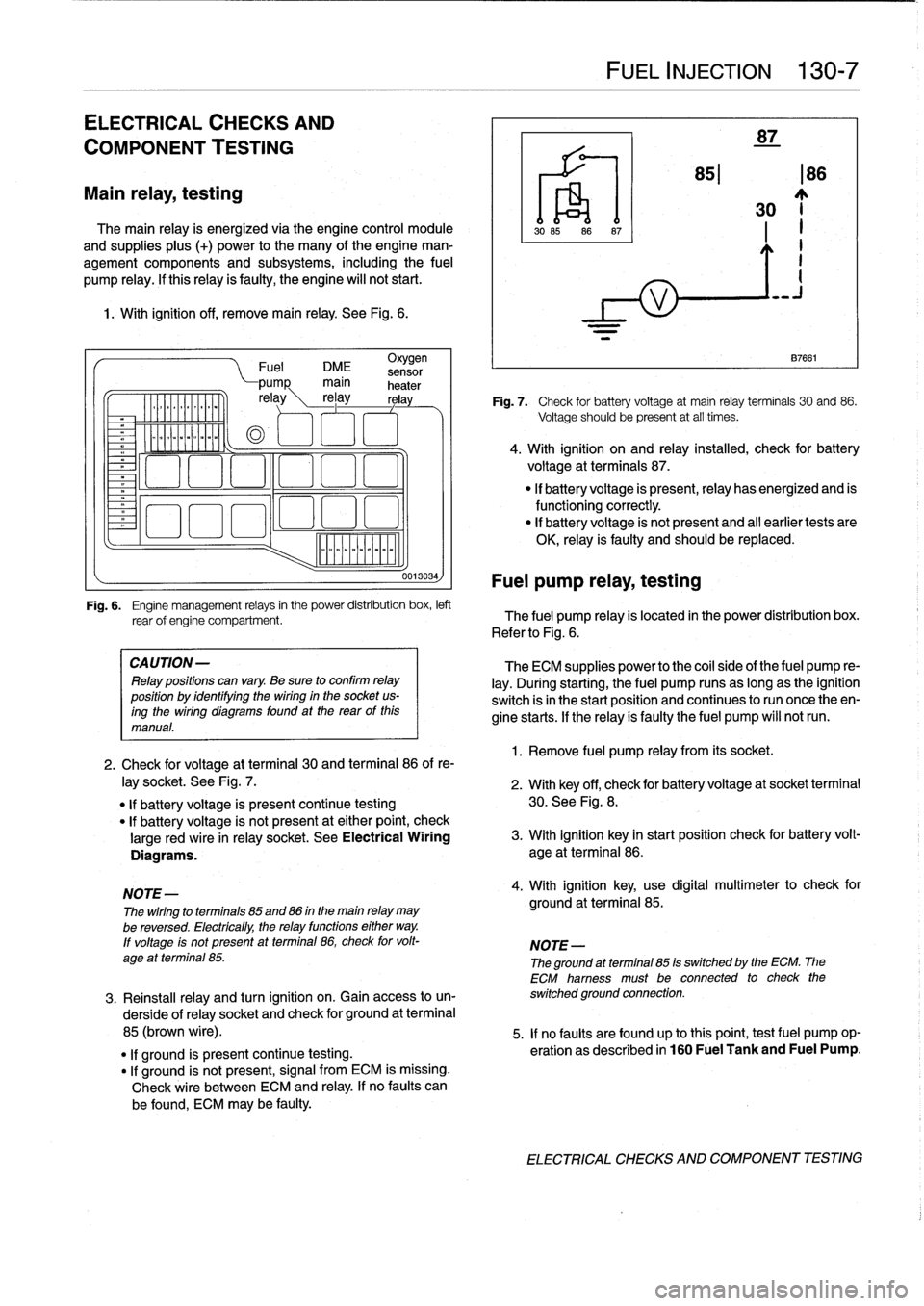

Main

relay,

testing

The

main

relay

is

energized

via

the

engine

control

module

and

supplies

plus

(+)

power

to

the

many

of

the

engine

man-

agement

components

and

subsystems,

including

the

fuel

pump

relay

.

If

this

relay

is

faulty,

the

engine

will

not

start

.

1

.

With

ignition

off,

remove

main

relay

.

See

Fig

.

6

.

.

iommooommmoi

~

"""

Fuel

DME

sensor

CA

UTION-

Relay

positions

can

vary

.

Be

sure

to

confirm

relay

position

by

identífyíng

the

wiring

in

the

socket

us-

ingthe

wiring

diagramsfound

at

the

rearof

this

manual

.

0013034)

Fuel

pump

relay,

testing

FUEL

INJECTION

130-

7

87

851186

30

~j

1

.

Remove

fuel

pump

relay

from

its

socket

.

87661

Fig

.

7

.

Check

for

battery

voltage

at

main

relay

terminals

30

and

86

.

Voltage

should

be

present

at

all

times

.

4

.

With

ignition

on

and

relay

installed,

check

for

battery

voltage

at

terminals

87

.

"

If

battery

voltage

is

present,relay

has

energized

and

is

functioningcorrectly

.

"

lf

battery

voltage

is

not

present

and

al¡

earlier

tests

are

OK,

relay

is

faulty

and

should

be

replaced

.

Fig

.

6

.

Engine

management

relays

in

the

power

distribution

box,

left

rear

of

engine

compartment

.

The

fuel

pump

relay

is

located

in

the

power

distribution

box

.

Refer

to

Fig

.

6

.

The

ECM

supplies

power

to

the

coil

side

of

the

fuel

pump

re-

lay

.

During

starting,

the

fuel

pump

runs

as

long

as

the

ignition

switch

isin

the

start

position

and

continues

to

run

once

theen-

gine

starts

.

If

the

relay

ís

faulty

the

fuel

pump

will

notrun

.

2

.

Check

for

voltage

at

terminal

30

and

terminal

86

of

re-

¡ay

socket

.

See

Fig

.

7

.

2

.

With

key

off,

check

for

batteryvoltage

at

socket

terminal

"

If

battery

voltage

is

present

continue

testing

30

.

See

Fig

.

8

.

"

lf

battery

voltage

is

not

present

at

either

point,

check

large

red

wire

in

relay

socket

.

See

Electrical

Wiring

3

.

With

ignition

key

in

start

position

check

for

battery

volt-

Diagrams

.

age

at

terminal

86

.

NOTE-

4

.

With

ignition

key,

use

digital

multimeter

to

check

for

The

wiring

to

terminals

85

and

86

in

the

main

relay

may

ground

at

terminal

85

.

be

reversed

.

Electrically,

the

relay

functions

either

way

.

lf

voltage

ís

not

present

at

terminal

86,

check

for

volt-

NOTE-

age

at

terminal

85

.

The

ground

atterminal

85

is

switched

by

the

ECM

.

The

ECM

hamess

must

be

connected

to

check

the

3

.

Reinstall

relay

and

turn

ignition

on

.

Gainaccess

to

un-

switched

ground

connection

.

derside

of

relay

socket

and

check

for

ground

at

terminal

85

(brown

wire)

.

5

.

If

no

faults

are

found

up

tothis

point,

testfuel

pump

op-

"

lf

ground

is

present

continue

testing

.

eration

as

described

in

160

Fuel

Tank

and

Fuel

Pump

.

"

If

ground

is

not

present,

signal

from

ECM

is

missing

.

Check

wire

between

ECM

and

relay

.

If

no

faults

can

be

found,

ECM

may

be

faulty

.

ELECTRICAL

CHECKS

AND

COMPONENT

TESTING

Page 163 of 759

BOSCH

DME

MM

AND

M33

.1

COMPONENT

TESTS

AND

REPAIRS

Consult

Table

a

for

engine

application

information

for

the

Bosch

DME

3

.1

and

3

.3.1

systems

.

The

DME

3

.1

and

DME

3

.3

.1

systems

are

similar

in

opera-

tion,

with

knock

control

and

VANOS

operation

being

the

key

differences

.

DME

3

.1

engines

arenot

equipped

with

VANOS

or

knock

detectors,

while

the

DM

E3

.3

.1

system

is

.

CA

UTION-

Use

onty

a

digital

multimeter

when

testing

wiring

.

Use

of

an

analog

VOM

may

damage

the

engine

control

module

.

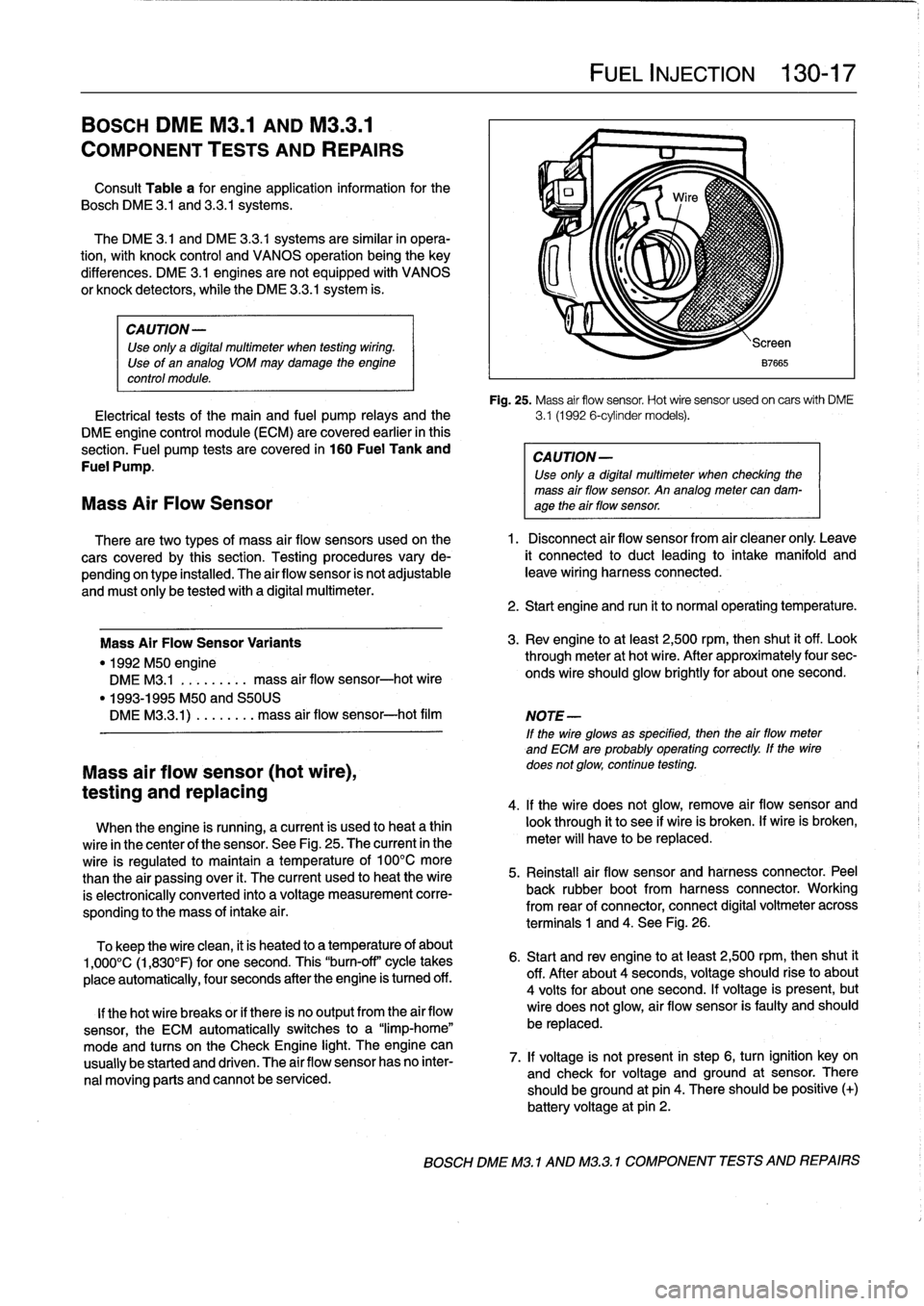

Fig

.

25

.

Mass

air

flow

sensor

.

Hot

wire

sensor

usedon

carswith

DME

Electrical

tests

of

the

main

and

fuel

pump

relays

and

the

3

.1

(1992

6-cylinder

models)

.

DME

engine

control

module

(ECM)

are

covered

earlier

in

this

section

.

Fuel

pump

tests

are

covered

in

160

Fuel

Tank

and

CAUTION-

Fuel

Pump

.

Use

only

a

digital

multimeter

when

checking

the

mass

air

flow

sensor

.

An

analog

meter

can

dam-

Mass

Air

Flow

Sensor

age

theair

flow

sensor

.

There

are

two

types

of

mass

air

flow

sensors

used

onthe

1

.

Disconnect

air

flow

sensor

from

air

cleaner

only

.

Leave

cars

covered

by

this

section

.

Testing

procedures

vary

de-

it

connected

to

duct

leading

to

intake

manifold

and

pending

on

type

installed

.

The

airflow

sensor

is

not

adjustable

leave

wiring

harness

connected

.

and

must

only

be

tested

with

a

digital

multimeter

.

Mass

Air

FlowSensor

Variants

"

1992

M50

engine

DME

M3

.1

.

.

.

.

...

..

mass

air

flow

sensor-hot

wire

"

1993-1995

M50

and

S50US

DMEM33

.1)

.

...

...

.

mass

air

flow

sensor-hot

film

Mass

air

flow

sensor

(hot

wire),

testing

and

replacing

When

the

engine

is

running,

a

current

is

used

to

heat

a

thin

wire

in

the

center

of

the

sensor

.

See

Fig

.

25

.

The

current

in

the

wire

is

regulated

to

maintain

a

temperature

of

100°C

more

than

the

air

passing

over

it

.

The

current

used

to

heat

the

wire

is

electronically

conneced

into

a

voltage

measurement

corre-

sponding

to

the

mass

of

intake

a¡

r

.

To

keep

the

wire

clean,

it

is

heated

to

a

temperature

of

about

1,000°C

(1,830°F)

for

one

second

.

This

"burn-off"

cycle

takes

place

automatically,

four

seconds

after

the

engine

is

tumed

off

.

lf

thehot

wire

breaks

or

if

there

is

no

output

from

the

air

flow

sensor,

the

ECM

automatically

switches

to

a

"limp-home"

mode

and

tucos

on

the

Check

Engine

light

.

The

engine

can

usually

be

started

and

driven

.

The

air

flow

sensor

has

no

inter-

nal

moving

parts

and

cannot

be

serviced

.

FUEL

INJECTION

130-

1

7

2

.

Start

engine

and

run

it

to

normal

operating

temperature

.

3

.

Rev

engine

toat

least

2,500

rpm,then

shut

it

off

.

Look

through

meter

at

hot

wire

.

After

approximately

four

sec-

onds

wire

should

glow

brightly

for

about

one

second

.

NOTE

-

If

the

wire

glowsas

specified,

then

the

airflow

meter

and

ECM

are

probably

operating

correctly

.

lf

the

wire

does

not

glow,

continue

testing

.

4

.

lf

the

wire

does

not

glow,

remove

air

flow

sensor

and

look

through

it

to

see

if

wire

is

broken

.

lf

wire

is

broken,

meter

will

have

to

be

replaced

.

5

.

Reinstall

air

flow

sensor

and

harness

connector

.

Peel

back

rubber

bootfrom

harness

connector

.

Working

from

rear

of

connector,

connect

digital

voltmeter

across

terminals

1

and

4

.

See

Fig

.

26

.

6

.

Start

and

rev

engine

toat

least

2,500

rpm,thenshut

it

off

.

After

about

4

seconds,

voltage

should

riseto

about

4

volts

for

about

one

second

.

lf

voltage

is

present,

but

wire

does

not

glow,

air

flow

sensor

is

faulty

and

should

be

replaced

.

7

.

lf

voltage

is

not

present

in

step

6,

turn

ignition

key

on

and

check

for

voltage

and

ground

at

sensor

.

There

should

beground

at

pin

4

.

There

should

be

positive

(+)

battery

voltage

at

pin

2

.

BOSCH

DME

M3

.1

AND

M32

.1

COMPONENT

TESTS

AND

REPAIRS

Page 254 of 759

300-6

SUSPENSION,

STEERING

AND

BRAKES-GENERAL

BATTE

RY

KL

30

ECM

MAIN

C~

RELAY

KL

15

DSC

SWITCH

LF1

;1~lZZ~

nSLn

l'

z

sJ

WHEEL

RF

c_

.

LR

r_

.

>

RR

ELECTRONIC

BRAKE

LIGHT

SWITCH

SPEED

SENSORS

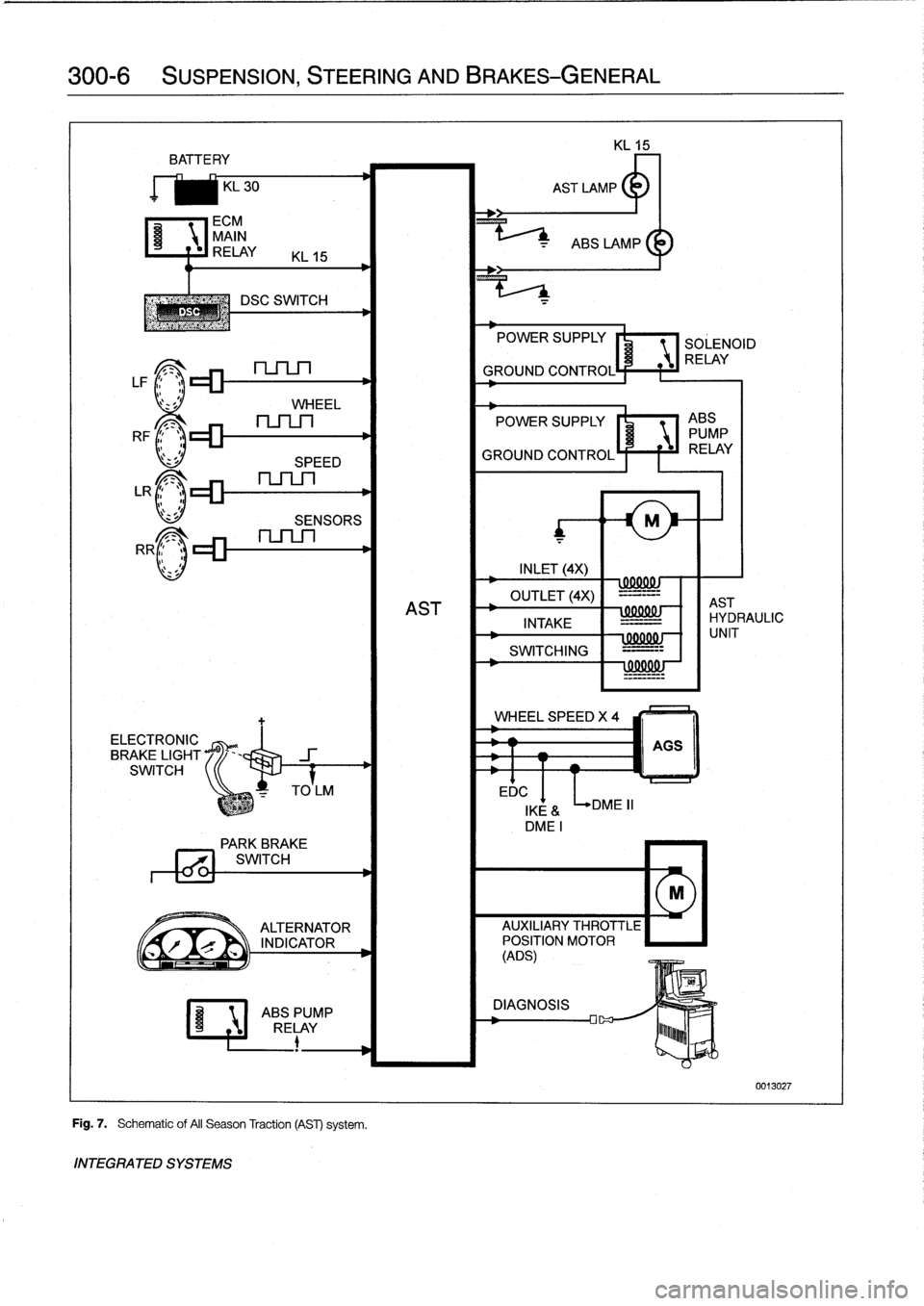

Fig

.

7

.

Schematic

of

AII

Season

Traction

(AST)

system

.

INTEGRATED

SYSTEMS

EDC

POWER

SUPPLY

SOLENOID

RELAY

GROUND

CONTROL

POWER

SUPPLY

I'

1

ABS

PUMP

GROUND

CONTROLÍ

F

f

iJ

RELAY

INLET

(4X)

wxxuw

OUTLET

(4X)

-=-=--

AST

AST

INTAKE

IHYDRAULIC

-

=-

SWITCHING

=---

!

99001

!J

WHEEL

SPEED

X

4

DME

II

000001

-

f

1

UNIT

AGS

IKE

&

DMEI

PARK

BREVE

771

SWITCH

M

ALTERNATOR

AUXILIARY

THROTTLE

r

`

INDICATOR

POSITION

MOTOR

(ADS)

ABSPUMP

DIAGNOSIS

RELAY

lu~~~b

0013027

Page 752 of 759

WARNING

Your

common

sense,

good

judge-

ment,

and

general

alertness

are

cru-

cial

to

safe

and

successful

service

work

.

Befcre

attempting

any

work

on

your

BMW,

read

the

warnings

and

cautions

on

page

vi¡

and

the

copyright

page

at

the

frontof

the

manual

.

Review

these

warnings

and

cautions

each

time

you

prepare

to

workon

your

BMW

.

Please

also

read

any

warnings

and

cautions

that

accom-

pany

the

procedures

in

the

manual

.

Door

glass

See

Door

windows

Door

windows

general

information

512-1

front

door

window

(2-door

models)

adjusting

512-7

removing/installing

512-5

front

door

window

(4-door

models)

initíalizing

512-1

removing/installing

512-2

rear

door

window

(4-door

models)

removing/installing

512-4

fixed

glass,

removing/installing

512-

4

rear

vent

window

or

vent

latch,

replacing

(2-door

models)

512-11

window

regulator

and

motor,

removing/installing

512-12

window

regulator

service

512-12Doorcheck

See

DoorsDoor

handle

See

Centrallocking

and

anti-theft

Door

panel

See

Doors

Doors

general

information

411-1

door

adjustment

411-2door

check,

replacing

411-2

door

panels

411-3

doors411-1

front

orrear

door,removing/installing

411-1

front

door

panel,

removing/installing

411-3

rear

door

panel,

removing/installing

411-4

rearsidepanel,

removing/installing

(two-door

model)

411-4

Drive

axle

See

Rear

suspension

Driveability

troubleshooting

See

Engine-general

Driveshaft

general

information

260-1

center

bearing

assembly,

replacing

260-6

driveshaft,

aligning

260-3

driveshaft,

installing

260-4

Driveshaft

(cont

.)

driveshaft,

removing260-4

driveshaftservice

260-3

flex-disc,

replacing

260-5

front

centering

guide,

replacing

260-7

guibo

See

flex-disc

troubleshooting260-1

ECM

(engine

control

module)

pin

assignment

See

Fuel

injection

Electrical

circuit

See

Electrical

system-general

Electrical

component

locations

general

information

610-1

auxíliary

relay

panel

610-2

component

location

table

610-9

component

locations

610-3

fuse

position

tables

610-19

fuse

positions

610-1

relay

positions

610-2

splice

panel,

left

610-2

splice

panel,

right

610-3

Electrical

system-general

general

information

600-1

continuity,

checking

600-5

electrical

test

equipment

600-2

safety

precautions

600-1

short

circuits

600-5

short

circuit,

testing

with

ohmmeter

600-6

short

circuit,

testing

with

voltmeter

600-6

troubleshooting

600-3

voltage,

measuring600-4

voltage

and

polarity

600-1

voltage

and

voltage

drops

600-4

voltage

drop,

testing

600-4

wiring

codes

and

abbreviations

600-2

wiring

diagrams

600-2

wiring,

fuses

and

relays

600-1

Electrical

wiring

diagrams

general

information

ELE-1

wiring

diagrams

ELE-2

ABS

ELE-117

ABS/AST

ELE-120

airbag

(supplemental

restraint

system)

ELE-140

air

conditioning

and

heating

ELE-

129

anti-theft

(Alpine)

system

ELE-144

anti-theft

(EWS

II)

ELE-150

body

computer

module

ELE-176

charging

system

ELE-67

convertible

top

ELE-253

cruise

control

ELE-112

data

link

connector

ELE-86

engine

cooling

ELE-94

engine

management

ELE-70

exterior

lights

ELE-194

ground

distribution

ELE-35

headlights/foglights

ELE-180

INDEX

3

Electrical

wiring

diagrams

(cont

.)

heated

seats

ELE-245

horns

ELE-153

instrument

panel

ELE-165

interior

lights/illumination

ELE-211

lumbar

control

ELE-247

on-board

computer

ELE-173

park

ventilation

ELE-139

power

distribution

ELE-2

power

door

locks

ELE-226

power

mirrors

ELE-241

power

seats

ELE-243

power

sunroof

ELE-248

power

windows

ELE-231

radio/cassette/CD/speakers

ELE-

255

rear

window

defogger

ELE-160

shift

interlock

ELE-110

starting

ELE-63

transmission

electronics

ELE-96

warning

systems`

.

chimes

ELE-178

wiper/washer

ELE-154

Emergencies

See

Fundamentals

for

the

do-it-

yourself

owner

Engine-general

general

information

100-1

air

flow

measurement

and

vacuum

leaks

100-12

basic

engine

settings

100-11

basic

requirements

100-11

battery

voltage

100-12connecting

rods

and

pistons

100-1

cooling

system

100-5

cylinder

block

and

crankshaft100-1

cylinder

compression,

checking

100-6

cylinder

head

and

valvetrain

100-2

DISA

(dual

resonance

intake

system)

100-3,130-3

driveability

troubleshooting

100-8

engine

management

system

100-3

fuel

delivery

100-5

fuel

supply

100-14ground

connections

100-13

ignition

100-5

lubrication

system100-5

mechanical

troubleshooting

100-5

on-board

diagnostics

(OBD)

100-8

oxygen

sensors

100-11

preventive

maintenance

100-11

VANOS

(variable

valve

timing)

100-2warningsand

cautions

100-5

wiring

andharness

connections100-

13Engine

control

module

(ECM)

See

Fuel

injection

Engine

removal

and

installation

general

information

110-1

engine,

removing/installing(4-cylinder

engines)

110-1

engine,

removing/installing

(6-cylinder

engines)

110-4

Engine

coolant

temperature

(ECT)

sensor

See

Fuel

injection

Engine

hood

See

Fenders,

enginehood

Page 753 of 759

4

INDEX

Evaporator

See

Air

conditioning

EWS

(Electronic

immobilization

system)

515-8

Exhaust

system

See

also

Maintenance

program

general

information

180-1

exhaust

manifolds,

removingAnstalling

180-5

exhaustsystem,

removing/installing

180-3

Expansion

valve

See

Air

conditioning

Exterior

lighting

general

information

630-1

center

brake

light

housing,

replacing

(4-door

and

coupe

models)

630-5

foglight

assembly,

removing/installing

630-3

front

turn

signal

assembly,

removing/

installing

630-4

headlight

assembly,removing/

installing

630-2

headlight

bulb,

replacing

630-1

license

plate

light,

removing/installing

630-6

side

marker

lights

630-4

taillight

assembly,

removing/installing

630-5

taillight

bulbs,

replacing

630-4

Exterior

trim,

bumpers

general

information

510-1

BMW

embiem,

removing/installing

510-7

body

side

molding,

replacing

-7

bumper

height,

adjusting

510-6

front

bumper,

removing/installing

510-3

front

bumper

impact

absorber,

replacing

510-4

front

panel,

removing/installing

510-7

outside

rear

view

mirrors

510-1

mirror

housing,

removing/installing

510-1

mírror,

removing/installing

510-2

mirror

glass,

replacing

510-1

radiator

grille,

removing/installing

510-7

rear

bumper,

removingfinstalling

510-

4

rear

bumper

impact

absorber,

replacing

510-4

F

Fenders,

engine

hood

general

information

410-1

front

fenders

410-1

front

fender,

removing/installing

410-1

hood

aligning

410-4

hood,

raising

to

service

position

410-2

hood

release

cable

and

latches,

adjusting

410-4

hood,

removing/installing

410-3

Finaldrive

general

information

331-1

final

drive

se

rvice

331-1

flange

oil

sea¡,

replacing

331-2

inputshaft

oil

sea¡,

replacing

331-3

oil,

draining/filling

331-1

oil

seals331-1

removing/installing

331-3

Final

drive

carrier

See

Rear

suspension

Firing

order

See

Ignition

system

Flexdisc

See

DriveshaftFluids

and

lubricants

See

Maintenance

program

Foglight

See

Exterior

lighting

Front

suspension

general

information

310-1

ball

joint

See

outer

control

arm

ball

joint

control

arm,

removing/installing

310-5

control

arm

bushing,

replacing

310-7

control

arms

310-5

front

wheel

bearing,

replacing

310-8

front

wheel

bearings

310-8

outer

control

arm

ball

joint,

replacing

(except

M3)310-6

ride

height

310-4shock

absorbers

and

springs

310-2

stabilizer

bar

310-9

stabilizer

bar,

removing/installing

310-9

strut

assembly,disassembling/

assembling310-4

strut

assembly,

removing/installing

310-2subframe

crossmember

310-9subframe

crossmember,

removing/

installing

310-9

Fuel

injection

general

information

130-2

basic

engine

settings

130-2

principies

of

operatínn

130-2

Bosch

DME

Ml

.7

component

tests

and

repairs

130-14

air

floiv

sensor,testing/replacing

130-14

engine

coolant

temperature

(ECT)

sensor,

testing/replacing

130-15

¡dle

speed

control

valve,

testing/

replacing

130-16

throttle

position

sensor

(TPS),

testing/replacing

130-16

Bosch

DME

M3

.1

and

M3

.3

.1

component

tests

and

repairs

130-17

engine

coolant

temperature

(ECT)

sensor,

testing/replacing

130-18

¡dle

speed

control

valve,

replacing

130-21

¡dle

speed

control

valve,

testing

130-

20

intake

air

temperature

(IAT)

sensor,

testing/replacing

130-19

mass

air

flow

sensor130-17

Bosch

DME

M3

.1

and

M3

.3.1

(cont)

mass

air

flow

sensor

(hot

film)

testing/replacing

130-18

mass

air

flow

sensor

(hot

wire)

testing/replacing

130-17

throttle

position

sensor

(TPS),

testing/replacing

130-19

Bosch

DME

M5

.2

component

replacement

130-21engine

coolant

temperature

(ECT)

sensor,

replacing

130-22

ldle

speed

control

valve,

replacing

130-23

intake

air

temperature

(IAT)

sensor,

replacing

130-22

mass

air

flow

sensor,

replacing

130-

22

throttle

position

sensor

(TPS),

replacing

130-22

DISA

(dual

resonance

intake

system)

130-3

ECM

pin

assignments130-26

electrical

checks

andcomponent

testing

130-7engine

control

module(ECM),

accessing

130-26

fuel

delivery

tests

130-9

fuel

pressure

regulator

response

to

engine

load,

testing

130-11

fuel

pressure

regulator

130-13

fuel

pressure

regulator,

replacing

(fuel

rail

mount)130-13

fuel

pressure

regulator,

replacing

(under

car

mount)130-14

fuel

pump

relay,

testing

130-7

fuel

rail

and

injectors,

checking

130-11

fuel

rail

and

injectors,

replacing

130-

12

fuel

delivery

tests

(cont

.)

operatíng

fuel

pump

for

tests

130-9

relieving

fuel

pressure

and

connecting

fuel

pressure

gauge

130-10

residual

fuel

pressure,

testing

130-10

main

relay,

testing

130-7on-board

diagnostics

(OBD)

and

fault

diagnosis

130-4

oxygen

sensor,

testing

(Bosch

systems

only)

130-8

secondary

air

injection

130-5

Siemens

MS

41

.1

component

replacement

130-23

engine

coolant

temperature

(ECT)

sensor,

replacing

130-25

¡dle

speed

control

valve,

replacing

130-26

lntake

air

temperature

(IAT)

sensor,

replacing

130-25

mass

air

flow

sensor,

replacing

130-

25

throttle

position

sensor

(TPS),

replacing

130-26warnings

and

cautions

130-6

Fuel

filter

See

Maintenance

program