ignition BMW 323i 1996 E36 Manual PDF

[x] Cancel search | Manufacturer: BMW, Model Year: 1996, Model line: 323i, Model: BMW 323i 1996 E36Pages: 759

Page 178 of 759

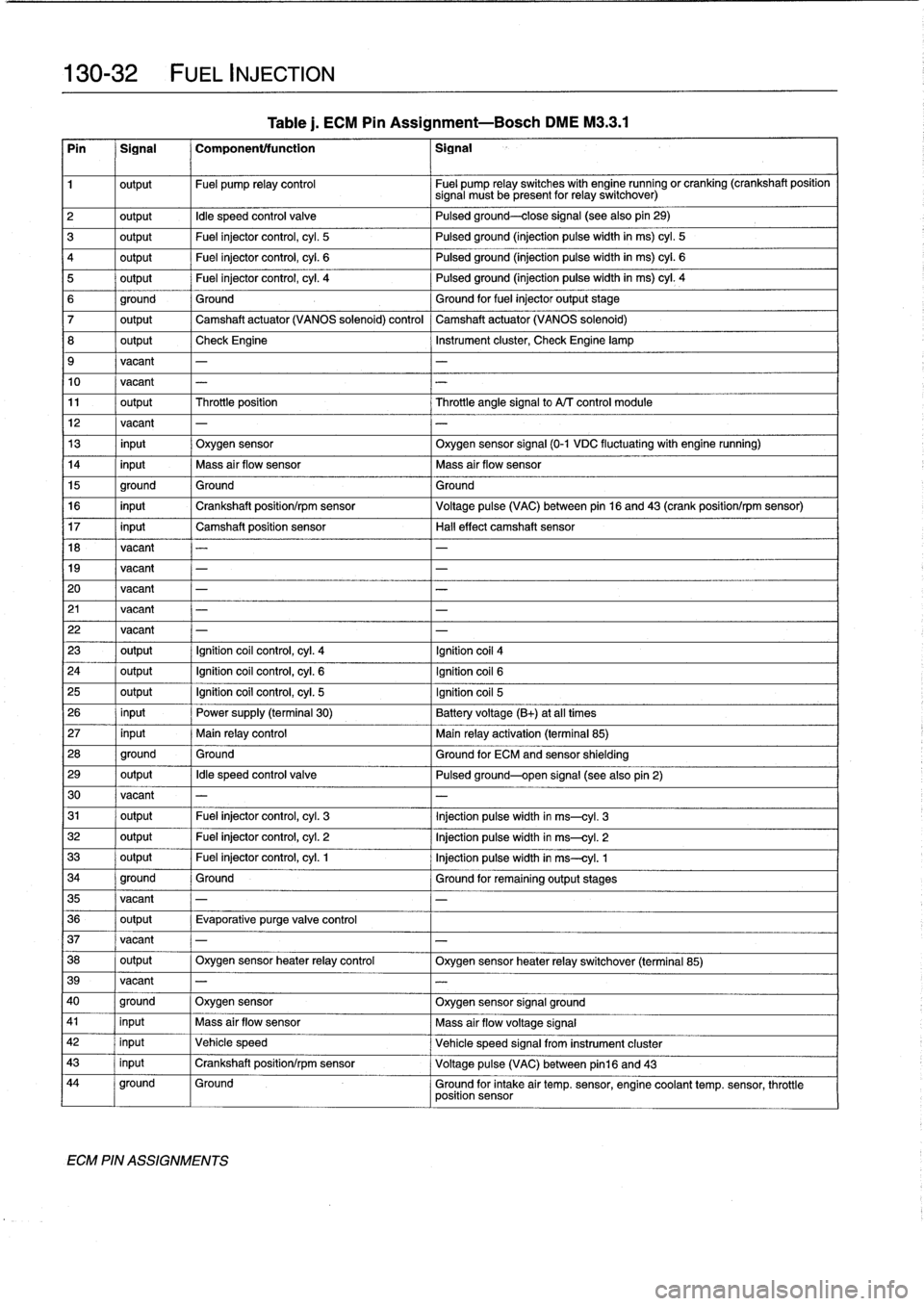

130-

3

2

FUEL

INJECTION

Pin

1

Signal

1

Component/function

1

Signal

1

output

Fuel

pump

relay

control

Fuel

pump

relay

switches

with

engine

running

or

cranking

(crankshaft

position

signal

must

be

present

for

relay

switchover)

2

output

Idle

speed

control

valve

Pulsed

ground-close

signal

(seealso

pin

29)

3

output

Fuel

ínjectorcontrol,

cyl

.

5

Pulsed

ground

(injection

pulsewidth

in

ms)

cyl

.

5

4

output

Fuel

injectorcontrol,

cyl

.

6

Pulsed

ground

(injection

pulsewidth

in

ms)

cyl

.

6

5

output

Fuel

injectorcontrol,

cyl

.

4

Pulsed

ground

(injection

pulsewidth

in

ms)

cyl

.

4

6

ground

Ground

Ground

for

fuel

injector

output

stage

7

output

Camshaft

actuator

(VANOS

solenoid)

control

Camshaft

actuator

(VANOS

solenoid)

8

output

Check

Engine

Instrument

cluster,

Check

Engine

lamp

9

vacant

-

-

10

vacant

-

-

11

output

Throttle

position

Throttle

angle

signal

to

A/T

control

module

12

vacant

-

-

13

input

Oxygen

sensor

Oxygen

sensor

signal

(0-1

VDC

fluctuating

with

engine

running)

14

input

Mass

air

flow

sensor

Mass

air

flow

sensor

15

ground

Ground

Ground

16

input

Crankshaft

position/rpm

sensor

Voltage

pulse

(VAC)

between

pin

16

and

43

(crank

position/rpm

sensor)

17

input

Camshaft

position

sensor

Halleffect

camshaft

sensor

18

vacant

-

-

19

vacant

-

-

20

vacant

-

-

21

vacant

-

-

22

vacant

-

-

23

output

Ignition

coil

control,

cyl

.

4

Ignition

coil

4

24

output

Ignition

coil

control,

cyl

.

6

Ignition

coil

6

25

output

Ignition

coil

control,

cyl

.

5

Ignition

coil

5

26

input

Power

supply

(terminal

30)

Battery

voltage(B+)

at

all

times

27

input

Main

relay

control

Main

relayactivation

(terminal

85)

28

ground

Ground

Ground

for

ECM

and

sensor

shielding

29

output

Idle

speed

control

valve

Pulsed

ground-open

signal

(seealsopin

2)

30

vacant

-

-

31

output

Fuel

injectorcontrol,

cyl

.

3

Injection

pulse

wicith

in

ms-cyl

.

3

32

output

Fuel

injectorcontrol,

cyl

.

2

Injection

pulse

wicith

in

ms-cyl

.

2

33

output

Fuel

injectorcontrol,

cyl

.

1

Injection

pulsewidth

in

ms-cyl

.

1

34

ground

Ground

Ground

for

remaining

output

stages

35

vacant

-

-

36

output

Evaporative

purge

valve

control

37

vacant

-

-

38

output

Oxygen

sensor

heater

relay

control

Oxygen

sensor

heater

relay

switchover

(terminal

85)

39

vacant

-

-

40

ground

Oxygen

sensor

Oxygen

sensor

signal

ground

41

input

Mass

air

flow

sensor

Mass

air

flow

voltage

signal

42

input

Vehicle

speed

Vehicle

speed

signal

from

instrument

cluster

43

input

Crankshaft

position/rpm

sensor

Voltage

pulse

(VAC)

between

pin16

and

43

44

ground

Ground

Ground

for

intake

air

temp

.

sensor,

engine

coolant

temp

.

sensor,

throttle

position

sensor

ECM

PIN

ASSIGNMENTS

Table

j

.

ECM

Pin

Assignment-Bosch

DME

M3

.3

.1

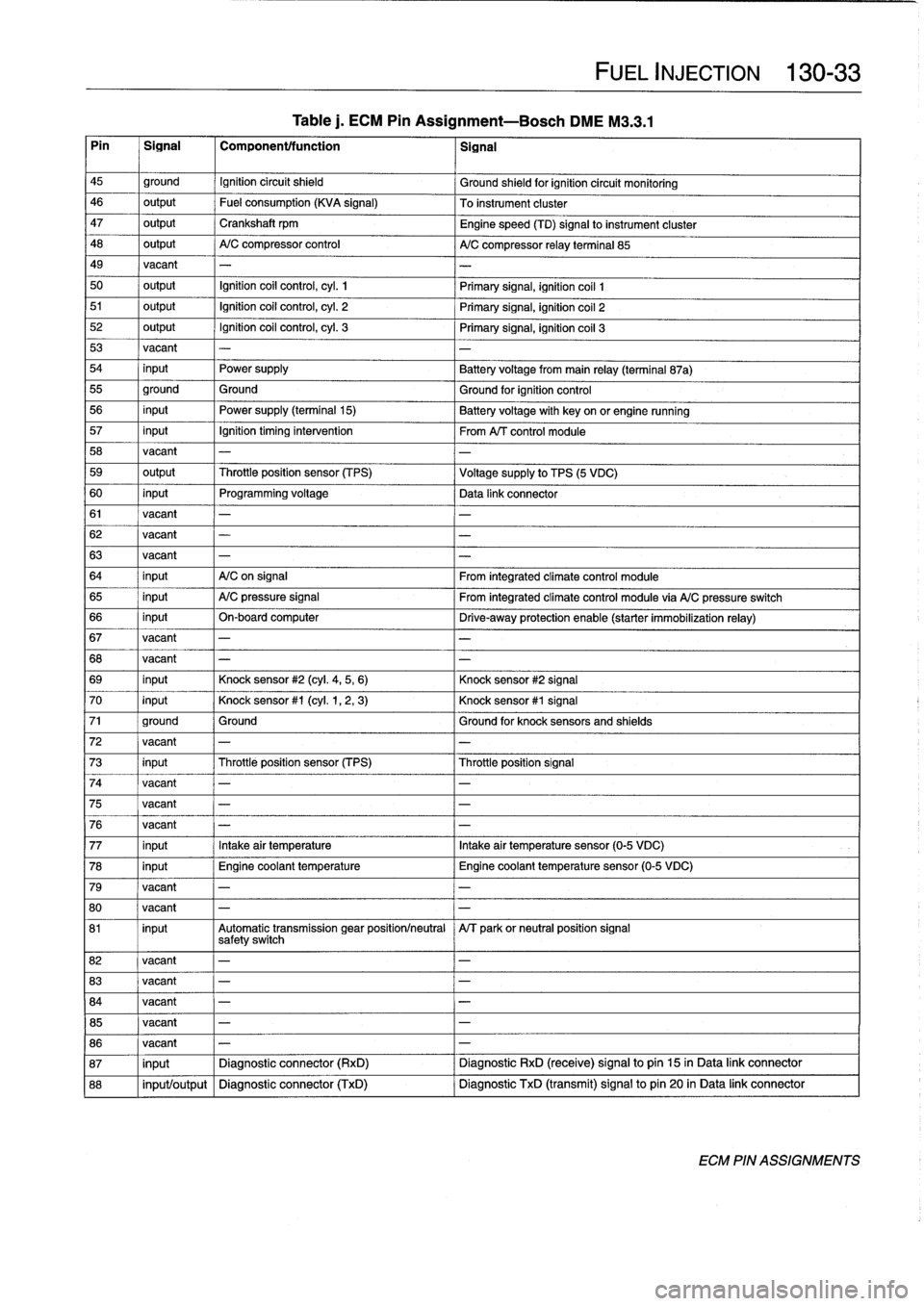

Page 179 of 759

Table

j.

ECM

Pin

Assignment-Bosch

DME

M3

.3

.1

Pin

~

Signal

1

Componentffunction

1

signal

FUEL

INJECTION

130-

33

45

ground

Ignition

circuit

shield

Ground

shieldfor

ignition

circuit

monitoring

46

output

Fuel

consumption

(KVA

signal)

To

instrument

cluster

47

output

Crankshaft

rpm

Engine

speed

(TD)

signal

to

instrument

cluster

48

output

A/C

compressor

control

A/C

compressor

relay

terminal

85

49

vacant

-

-

50

output

Ignition

coil

control,

cyl

.

1

Primary

signal,

ignition

coil

1

51

output

Ignition

coil

control,

cyl

.

2

Primary

signal,

ignition

coil

2

52

output

Ignition

coil

control,

cyl

.

3

Primary

signal,

ignition

coil

3

53

vacant

-

-

54

input

Power

supply

Battery

voltagefrom

main

relay

(terminal

87a)

55

ground

Ground

Ground

for

ignition

control

56

input

Power

supply

(terminal15)

Batteryvoltage

with

key

on

or

engine

running

57

input

Ignition

timing

intervention

From

A/T

control

module

58

vacant

-

-

59

output

Throttleposition

sensor

(TPS)

Voltage

supply

to

TPS

(5

VDC)

60

input

Programming

voltage

Data

link

connector

61

vacant

-

-

62

vacant

-

-

63

vacant

-

-

64

input

A/C

on

signal

From

integrated

climate

control

module

65

input

A/C

pressure

signal

From

integrated

climate

control

module

via

A/C

pressure

switch

66

input

On-board

computer

Drive-away

protection

enable

(starter

immobilization

relay)

67

vacant

-

-

68

vacant

-

-

69

input

Knock

sensor

#2

(cyl

.

4,5,

6)

Knock

sensor

#2

signal

70

input

Knock

sensor

#1

(cyl

.

1,2,

3)

Knock

sensor

#1

signal

71

ground

Ground

Ground

for

knock

sensors

and

shields

72

vacant

-

-

73

input

Throttleposition

sensor

(TPS)

Throttleposition

signal

74

vacant

-

75

vacant

-

-

76

vacant

-

77

input

Intakeair

temperatura

Intakeair

temperatura

sensor

(0-5

VDC)

78

input

Engine

coolant

temperature

Engine

coolant

temperature

sensor

(0-5

VDC)

79

vacant

-

80

vacant

-

-

81

input

Automatic

transmission

gear

positionlneutral

A/T

parkor

neutral

position

signal

safetyswitch

82

vacant

-

-

83

vacant

-

-

84

vacant

-

-

85

vacant

-

-

86

vacant

-

-

87

input

Diagnostic

connector

(RxD)

Diagnostic

RxD

(receive)

signal

to

pin

15

in

Data

link

connector

88

input/output

Diagnostic

connector

(TxD)

Diagnostic

TxD

(transmit)

signal

to

pin

20

in

Data

link

connector

ECM

PIN

ASSIGNMENTS

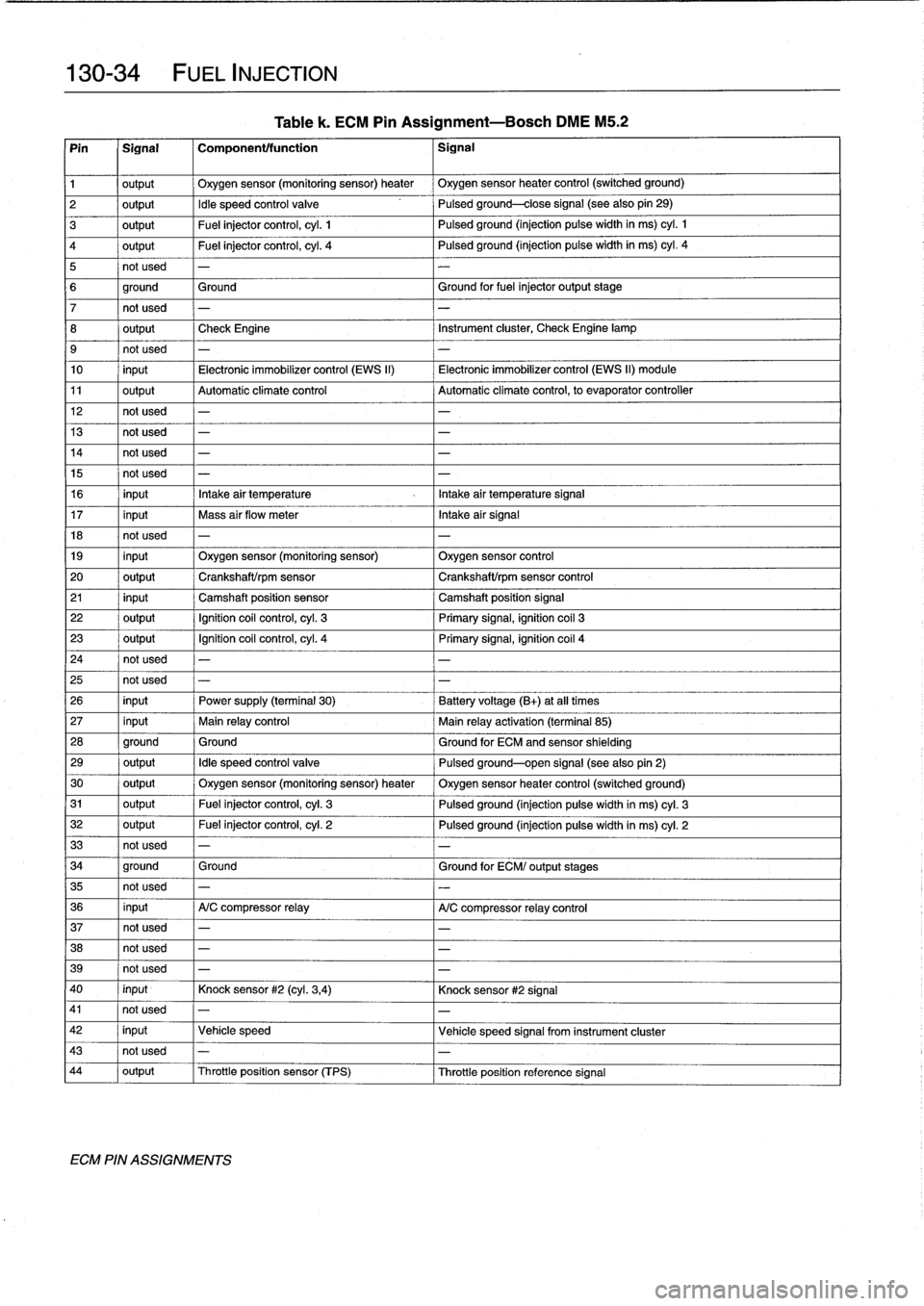

Page 180 of 759

130-

34

FUEL

INJECTION

Pin

i

Signal

1

Component/function

1

Signal

1

output

Oxygen

sensor

(monitoring

sensor)heater

Oxygen

sensor

heater

control

(switched

ground)

2

output

Idle

speed

control

valve

Pulsed

ground-close

signal

(see

also

pin

29)

3

output

Fuel

injector

control,

cyl

.

1

Pulsed

ground

(injection

pulsewidth

in

ms)

cyl

.

1

4

output

Fuel

injector

control,

cyl

.

4

Pulsed

ground

(injection

pulse

width

in

ms)

cyl

.

4

5

not

used

-

-

6

ground

Ground

Ground

for

fuel

injector

output

stage

7

not

used

-

8

1

output

1

Check

Engine

1

Instrument

cluster,

Check

Engine

lamp

9

not

used

-

-

10

input

Electronic

immobilizer

control

(EWS

II)

Electronic

immobilizer

control

(EWS

II)

module

11

output

Automatic

climate

control

Automatic

climate

control,

to

evaporator

controlier

12

not

used

-

-

13

not

used

-

-

14

not

used

-

-

15

not

used

-

-

16

input

Intake

air

temperature

Intake

air

temperature

Signal

17

input

Mass

air

flow

meter

Intake

air

signal

18

not

used

-

-

19

input

Oxygen

sensor

(monitoring

sensor)

Oxygen

sensor

control

20

output

Crankshaft/rpm

sensor

Crankshaft/rpm

sensor

control

21

input

Camshaft

position

sensor

Camshaft

position

signal

22

output

Ignition

coil

control,

cyl

.

3

Primary

signal,

ignitioncoil

3

23

output

Ignition

coil

control,

cyl

.

4

Primary

signal,

ignitioncoil

4

24

not

used

-

-

25

not

used

-

-

26

input

Power

supply

(terminal

30)

Battery

voltage

(B+)

at

al¡

times

27

input

Main

relay

control

Main

relay

activation

(terminal

85)

28

ground

Ground

Ground

for

ECM

and

sensor

shielding

29

output

Idle

speed

control

valve

Pulsed

ground-open

signal

(seealsopin

2)

30

output

Oxygen

sensor

(monitoring

sensor)

heater

Oxygen

sensor

heater

control

(switched

ground)

31

output

Fuel

injectorcontrol,

cyl

.

3

Pulsed

ground

(injection

pulsewidth

in

ms)

cyl

.

3

32

output

Fuel

injector

control,

cyl

.

2

Pulsed

ground

(injection

pulsewidth

in

ms)

cyl

.

2

33

I

not

used

40

input

Knock

sensor

#2

(cyl

.

3,4)

Knock

sensor

#2

signal

41

not

used

-

-

42

input

Vehicle

speed

Vehicle

speed

signal

from

instrument

cluster

43

not

used

-

-

44

output

Throttleposition

sensor

(TPS)

Throttleposition

reference

signal

ECM

PIN

ASSIGNMENTS

Table

k

.

ECM

Pin

Assignment-Bosch

DME

M5

.2

34

ground

Ground

Ground

for

ECM/

output

stages

35

not

used

-

-

36

input

A/C

compressor

relay

A/C

compressor

relay

control

37

not

used

-

-

38

not

used

-

-

39

not

used

-

-

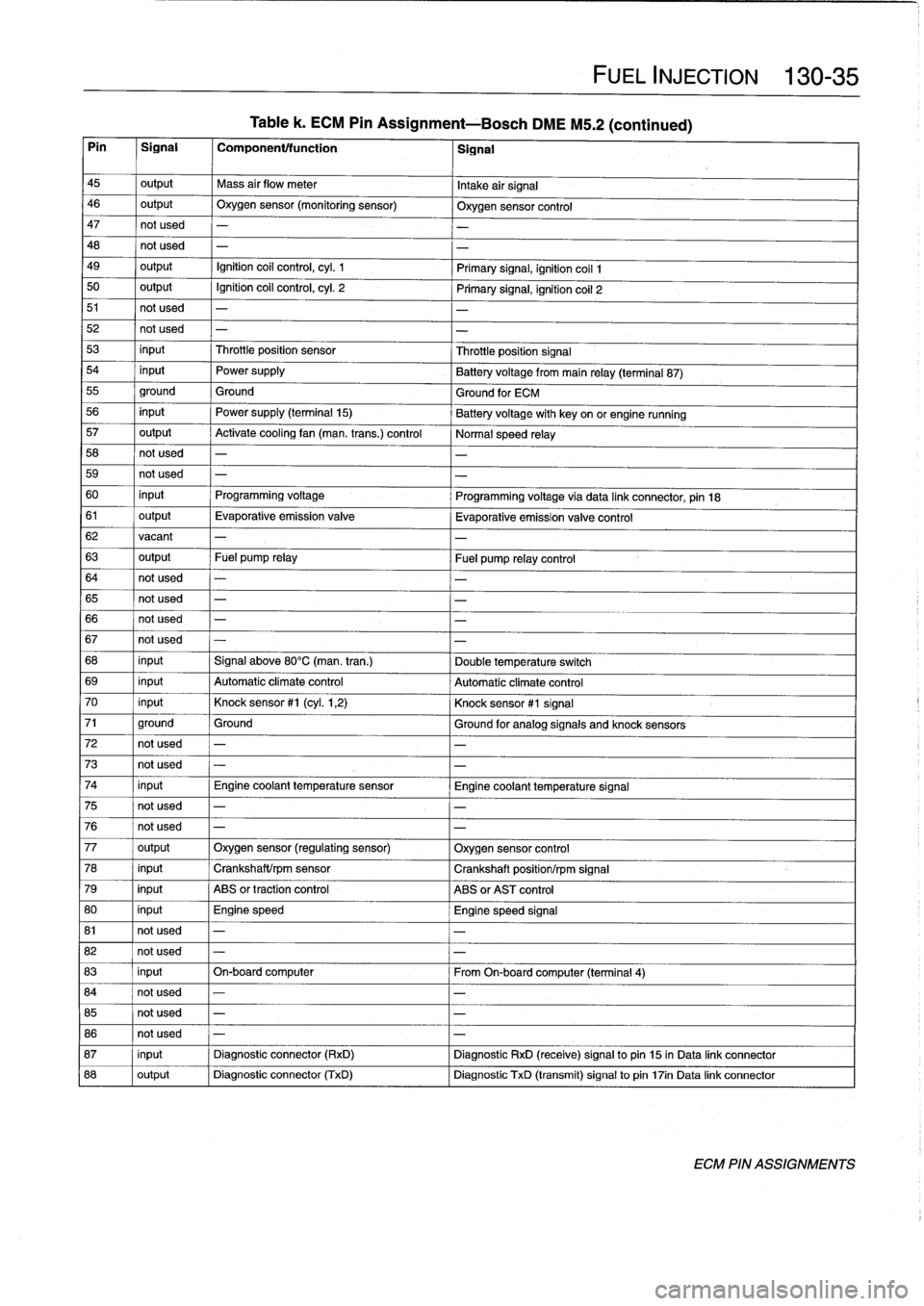

Page 181 of 759

Table

k

.

ECM

Pin

Assignment-Bosch

DME

M5

.2

(continued)

Pin

I

Signal

1

Componentltunction

1

Signal

45

I

output

I

Mass

air

flow

meter

I

Intake

airSignal

46

output

Oxygen

sensor

(monitoring

sensor)

Oxygen

sensor

control

47

not

used

-

48

not

used

-

49

output

Ignition

coil

control,

cyl

.

1

Primary

signal,

ignition

coil

1

50

output

Ignition

coil

control,

cyl

.

2

Primary

signal,

ignition

coil

2

51

not

used

-

52

not

used

-

53

input

Throttleposition

sensor

Throttleposition

Signal

54

input

Power

supply

Batteryvoltage

from

main

relay

(terminal

87)

55

ground

Ground

Ground

for

ECM

56

input

Power

supply

(terminal

15)

Battery

voltage

with

key

on

or

engine

running

57

output

Activate

cooling

fan

(man

.

trans

.)

control

Normal

speed

relay

58

not

used

-

-

59

not

used

-

-

60

input

Programming

voltage

Programming

voltage

via

data

link

connector,

pin

18

61

output

Evaporative

emissionvalve

Evaporative

emission

valve

control

62

vacant

-

-

63

output

Fuel

pump

relay

Fuel

pump

relay

control

64

not

used

-

65

not

used

-

-

66

not

used

-

-

67

not

used

-

-

68

input

Signal

above

80°C(man

.

tran

.)

Double

temperature

switch

69

input

Automatic

climate

control

Automatíc

climate

control

70

input

Knock

sensor

#1

(cyl

.

1,2)

Knock

sensor

#1

Signal

71

ground

Ground

Ground

for

analog

signals

and

knock

sensors

72

not

used

-

-

73

not

used

-

-

74

input

Engine

coolant

temperature

sensor

Engine

coolant

temperatura

Signal

75

not

used

-

-

76

not

used

-

-

77

output

Oxygen

sensor

(regulating

sensor)

Oxygen

sensor

control

78

input

Crankshaft/rpm

sensor

Crankshaft

position/rpmSignal

79

input

ABS

or

traction

control

ABS

or

AST

control

80

input

Engine

speed

Engine

speed

Signal

81

not

used

-

-

82

not

used

-

-

FUEL

INJECTION

130-

3

5

83

input

On-board

computar

From

On-boardcomputer

(terminal

4)

84

not

used

-

-

85

not

used

-

-

86

not

used

-

-

87

input

Diagnostic

connector

(RxD)

Diagnostic

RxD

(receive)signal

to

pin

15

in

Data

link

connector

88

output

I

Diagnostic

connector

(TxD)

Diagnostic

TxD

(transmit)

signal

to

pin

17in

Data

link

connector

ECM

PIN

ASSIGNMENTS

Page 182 of 759

130-

3

6

FUEL

INJECTION

Pin

1

Signal

1

Componentffunction

1

Signal

1

output

Ignition

coil

control,

cyl

.

2

Primary

signal,

ignition

coil

2

2

output

Ignition

coil

control,

cyl

.

4

Primary

signal,

ignitioncoil

4

3

output

Ignition

coil

control,

cyl

.

6

Primary

signal,

ignition

coil

6

4

ground

Ground

Ground

5

output

Fuel

injectorcontrol,

cyl

.

2

Pulsed

ground

(injection

pulse

width

in

ms)

cyl

.

2

6

output

Fuel

injectorcontrol,

cyl

.

1

Pulsed

ground

(injection

pulse

width

in

ms)

cyl

.

1

7

output

Mass

air

flow

meter

Mass

air

meter

signal

8

input

Mass

air

flow

meter

Mass

air

meter

signal

9

output

Instrument

cluster

Fuel

consumption

signal

10

output

Engine

coolant

temperature

(ECT)

sensor

ECT

signal

11

output

Fueltankpressure

sensor

Fueltankpressure

sensor

control

12

input

Throttleposition

sensor

(TPS)

Throttleposition

signal

13

-

14

input

Intake

air

temperature

(IAT)

sensor

Intake

air

temperature

signal

15

Traction

control

AST

module

16

input

Automatic

climate

control

Automatic

climate

control

17

18

input

Electronic

immobilizer

control

(EWS

II)

Electronic

immobilizer

control

(EWS

II)

module

19

Automatic

climate

control

Automatic

climate

control

20

-

Instrument

cluster

Instrument

cluster

21

output

Camshaft

actuator

(VANOS

solenoid)

control

Camshaft

actuator

(VANOS

solenoid),

switched

ground

22

output

Fuel

injectorcontrol,

cyl

.

3

Pulsed

ground

(injection

pulse

width

in

ms)

cyl

.

3

23

Fuel

injectorcontrol,

cyl

.

6

Pulsed

ground

(injection

pulse

width

in

ms)

cyl

.

6

24

Fuel

injectorcontrol,

cyl

.

4

Pulsed

ground

(injection

pulse

width

in

ms)

cyl

.

4

25

output

Oxygen

sensor

heater

control

Oxygen

sensor

heater

ground

26

input

Power

supply

(terminal

30)

Battery

voltage(B+)

at

all

times

27

output

Idle

speed

control

valve

Pulsed

ground-open

signal

(see

also

pin

53)

28

ground

Ground

Ground

29

output

Ignition

coil

control,

cyl

.

1

Primary

signal,

ignition

coíl

1

30

output

Ignition

coil

control,

cyl

.

3

Primary

signal,

ignition

coil

3

31

output

Ignition

coil

control,

cyl

.

5

Primary

signal,

ignition

coil

5

32

ground

Ground

Ground

33

output

Fuel

injector

control,

cyl

.

5

Pulsedground

(injection

pulsewidth

in

ms)

cyl

.

5

34

ground

Ground

Ground

35

output

Secondary

air

injection

Secondary

air

injection

pump

relay

control

36

output

Engine

speed

output

Engine

speed

signal

37

-

38

ground

Knock

sensor

Shielding

for

knock

sensors

39

output

Intake

air

temperature

sensor

(IAT

Sensor)

Voltagesupply

to

IAT

sensor

and

ECT

sensorEngine

coolant

temperature

(ECT)

sensor

40

output

Crankshaft

position

sensor

(Hall

effect)

Crankshaft

position

sensor

control

41

ground

Camshaft

position

(CMP)

sensor

Shielding

for

CMP

sensor

42

output

Throttle

position

sensor

(TPS)

TPS

ground

43

input

Camshaft

position/rpm

sensor

Camshaft

position/rpm

sensor

control

44

output

Throttle

position

sensor

(TPS)

Voltagesupply

to

TPS

(5

VDC)

45

Traction

control

AST

module

46

-

Instrument

cluster

Instrument

cluster

ECM

PIN

ASSIGNMENTS

Table

I.

ECM

Pin

Assignment-Siemens

DME

MS

41

.1

Page 185 of 759

160

Fuel

Tank

and

Fuel

Pump

GENERAL

.

.

.

.

.

.

...........

.

....

.

.

.

.

.

.

160-1

Operating

fuel

pump

for

tests

.

.

.

.

.

.

.......

.160-6

Fuel

Pump

Electrical

Tests

.

.

.

.

.

.

.

...

.

.

.

.

.

160-7

FUEL

TANK

AND

LINES

..

.

.

.

..........

160-2

Fuel

pump

electrical

circuit,

testing.

...

.

.

.

.

.

160-7

Fuel

tank,

draining

..

.

.

.

.

.

.

.

.

.

..........

160-2

Fuel

pump

power

consumption,

testing

.

.

.

.

.

.

160-7

Fuel

tank,

removing

and

installing

.........

160-3

Fuel

Delivery

Tests

....

.

.

.

...

.

.....

.

.

.

..

160-8

Fuel

Tank

Evaporative

Control

System

.....

160-4

Relieving

fuel

pressure

and

connecting

fuel

pressure

gauge

..

.

...........

.

.

.

..

160-8

FUEL

LEVEL

SENDERS

.

.

.

.

.

.......

.

.

.

160-4

System

pressure,

testing

.................

160-9

Fuel

level

senders,

testing

.

.

.

.

.

.......

.

.

.

160-5

Fuel

delivery

volume,

testing

.............

160-10

Fuel

leve¡

sender

and

fuel

pump

(right

side),

emoving

and

installing

.

.

.

.

.

.

160-5

TABLES

Fuel

leve¡

sender

(left

side),

a

.

FuelLeve¡

Sender

Resistances

...........

.

.

..

.160-5

removing

and

installing

.........

.

.

.

.

.

.

.

160-6

b

.

Fuel

Pump

Current

...

.................

..

...

160-8

c

.

Fuel

Pressure

Specifications

..............

.

..

160-10

FUEL

PUMP

.

.

.

................

.

.

.

.

.

.

.

160-6

d

.

Fuel

Pump

Delivery

Specifications

.........

.

..

160-10

Fuel

Pump

Fuse

and

Relay

.

.

.

....

.

.

.

.

.

.

.

160-6

GENERAL

This

repair

group

covers

service

information

specifically

for

The

cautions

and

warnings

on

this

page

should

beob

the

fuel

supply

system

.

Information

on

the

fue¡

injection

sys-

served

when

servicing

the

fuel

system

.

tem

is

covered

in

130

Fuel

Injection

.

NOTE-

Fue¡

filter

replacement

is

covered

in

020

Maintenance

Program

.

WARNING

-

"

The

fuel

system

is

designed

to

retain

pressure

even

when

the

ignition

isoff

.

When

working

with

the

fuel

system,

loosen

the

fuel

lines

slowly

toal-

low

residual

fuel

pressure

to

dissipate

gradually

.

Avoid

spraying

fuel

.

"

Before

beginning

any

work

on

the

fuel

system,

place

a

tire

extinguisher

in

the

vicinity

of

the

work

area

.

"

Fuel

is

highly

flammable

.

When

working

around

fuel,

do

not

disconnect

any

wires

that

could

cause

electrical

sparks

.

Do

not

smoke

or

work

near

heaters

or

other

tire

hazards

.

"

Always

unscrew

the

fuel

tank

cap

to

release

pres-

sure

in

the

tank

before

working

on

the

tank

or

fines

.

"

Do

not

use

a

work

light

near

any

fuel

.

Fuel

may

spray

onto

the

hot

bulb

causing

a

tire

.

"

Make

sure

the

work

area

is

properly

ventifated

.

FUEL

TANK

AND

FUEL

PUMP

160-1

CAUTION-

"

Prior

to

disconnecting

the

battery,

read

the

bat-tery

disconnection

cautions

given

at

the

front

of

this

manual

onpage

viü

.

"

Before

making

any

electrical

tests

with

the

ignition

tumed

on,

disable

the

ignition

system

as

de-

scribed

in

120

Ignition

System

.

Be

sure

the

bat-tery

is

disconnected

when

replacing

components

.

"

To

prevent

damage

to

the

ignition

system

or

the

electronic

fuel

system

components,

including

the

control

unit,

aiways

connect

and

disconnect

wires

and

test

equipment

with

the

ignition

off

.

"

Cleanliness

is

essential

when

working

with

the

fuel

system

.

Thoroughly

clean

the

fuel

fine

unionsbefore

disconnecting

any

of

the

fines

.

"

Use

only

clean

tools

.

Keep

removed

parts

clean

and

sealed

or

covered

with

a

clean,

lint-free

cloth,

especially

if

completion

of

the

repair

is

delayed

.

"

Do

not

move

the

car

while

the

fuel

system

is

open

.

"

Avoid

using

high

pressure

compressed

air

to

blow

out

fines

and

componente

.

High

pressure

can

rupture

infernal

seals

and

gaskets

.

"

Always

replace

seals

and

O-rings

.

GENERAL

Page 190 of 759

160-

6

FUEL

TANK

AND

FUEL

PUMP

Fig

.

7

.

Fuel

sender

and

pump

assembly

.

To

operate

the

fuel

pump

for

testing

purposes

without

hav-

Fuel

leve¡

sender

(left

side),

ing

to

runthe

engine,

the

fuel

pump

relay

can

be

bypassed

to

removing

and

installing

powerthe

pump

directly

.

The

procedure

for

removing

and

replacing

the

left

side

fuel

To

runthe

fuel

pump,

remove

the

relay

and

connect

the

leve¡

sender

is

similar

tothat

used

for

the

right

side

.

There

is

socket

for

relayterminal

30

to

the

socket

for

relay

terminal

no

.

no

fuel

pump

on

the

left

side

.

87

with

afused

jumper

wire

.

Relay

terminal

identification

is

shown

in

Fig

.

9

.

After

completing

the

tests,

remove

the

jumper

wire

.

FUEL

PUMP

The

electric

fuel

pump

ís

mounted

in

the

fuel

tank

in

tandem

with

the

right

side

fuelleve¡

sender

.

The

fuel

pump

delivers

fuel

at

high

pressure

to

the

fuel

injection

system

.

A

pressure

regulator

maintains

system

pressure

.

The

quantity

of

fuel

sup-

plied

exceeds

demand,

so

excess

fuel

retums

to

the

fuel

tank

via

a

retum

líne

.

See

130

Fuel

Injection

for

more

information

on

system

pressure

and

the

fuel

pressure

regulator

.

NOTE

-

Fuel

pump

removalprocedures

are

given

earlier

under

Fuel

leve¡

sender

(right

side)

and

fuel

pump,

remov-

íng

and

installing

.

Fuel

Pump

Fuse

and

Relay

The

fuel

pump

is

operated

by

a

fuel

pump

relay

located

ín

the

power

distribution

box

.

The

fuel

pump

circuit

is

protected

by

fuse

no

.

18

located

in

the

power

distribution

box

.

See

Fig

8

.

FUEL

PUMP

0013142

Fuel

DM

E

PUMP

main

re

ay

rel

ay

0

aoo

o

~a

aao

ó

Fig

.

8

.

Fuel

pump

relay

location

in

power

distribution

box

.

The

DME

engine

control

module

(ECM)

and

the

DME

main

relay

supply

power

to

the

coi¡

sideof

the

fuel

pump

relay

.

Dur-

ing

starting,

the

fuel

pump

runs

as

long

as

the

ignition

switch

is

in

the

start

position

and

continues

to

run

oncethe

engine

starts

.

If

an

electrical

system

fault

interrupts

power

to

the

fuel

pump,

the

engine

will

notrun

.

Operating

fuel

pump

for

tests

CA

UTION-

Relay

locations

may

vary

.

Use

care

when

identify-

ing

relays

and

when

troubleshooting

the

electrical

system

at

the

fuselrelay

panel

.

The

fuel

pump

re-

¡ay

is

a

four

pin

relay

and

has

a

1.5

mm

2

red

wireat

terminal

30

in

the

relay

socket,

lf

in

doubt,

con-

sult

an

authorized

BMW

dealer

.

NOTE-

Thejumper

wire

shouldbe

1.5

mm2

(14

ga

.)

and

in-

clude

en

in-fine

fuse

holder

with

a16

amp

fuse

.

To

avoid

fuselrelay

panel

damage

fromrepeated

connect-

íng

and

disconnecting,

also

include

a

toggleswitch

.

A

heavy-duty

jumper,

BMW

tool

no

.

613

050,

fs

also

available

from

en

authorized

BMW

dealer

.

0013034,

If

the

pump

does

notrun

with

the

jumper

installed,

the

fault

could

be

in

the

fuel

pump

or

the

wiring

to

the

pump

.

Check

the

pump

and

its

wiring

as

described

below

.

Page 198 of 759

170-

4

RADIATOR

AND

COOLING

SYSTEM

A

quick

testat

the

coolant

temperature

gauge

sender

can

The

auxiliary

cooling

fan

comes

on

when

coolant

tempera

determine

if

the

gauge

is

functioning

correctly

.

ture

exceeds

a

predetermined

leve¡

or

whenever

the

air

condi-

tioning

is

on

.

A

dual-range

temperature

switch

for

cooling

fan

lf

the

gauge

needie

remains

at

the

rest

position

with

theen-

control

is

mounted

on

the

right

side

of

the

radiator

.

See

Fig

.

3

.

gine

warm,

remove

the

harness

connector

from

the

sender

and

jumper

the

correct

terminals

in

the

connector

to

simulate

a

high

engine

temperature

.

See

Table

a

.

Turn

the

ignition

on

.

If

the

gauge

needle

moves

upward,

the

sender

is

faulty

.

If

the

gauge

does

not

respond,

the

wiring

to

the

gauge

is

broken

(open

circuit)

or

the

gauge

itselfis

faulty

.

WARNING

-

1996

and

laten

models

are

OBD

11

compliant

.

Dis-

connecting

electrical

connectors

wíth

the

ignition

turned

on

may

set

fault

codes

in

the

ECM

.

It

is

rec-

ommended

that

you

leave

the

diagnosis

of

faults

in

the

coolant

temperature

sensorsystem

to

the

BMW

dealer

service

department

which

has

specialized

OBD

11

scan

tool

equipment

.

If

the

gauge

needle

reads

too

high

when

the

engine

is

cold,

remove

the

harness

connector

from

the

sender

.

Turn

the

igni-

tion

on

.

lf

the

gauge

needle

position

does

not

change,

the

wir-

ing

or

the

gauge

is

shorted

to

ground

.

If

the

gauge

needle

drops,

the

sender

is

faulty

and

should

be

replaced

.

When

re-

placing

a

faulty

coolant

temperature

sender,

the

gasket

ring

on

the

sender

should

also

be

replaced

.

Tightening

Torque

"

Temperature

gauge

sender

to

engine

18

Nm

(13

ft-Ib)

Cooling

fan,

testing

NOTE-

OnM44

engines

with

manual

transmission,

the

primary

electric

cooling

fan

is

mounted

on

the

engine

side

of

the

radiator

and

is

controlled

by

the

engine

control

module

(ECM)

.

Troubleshooting

thiscircuit

should

be

left

to

an

authorized

BMW

dealer

with

the

proper

diagnostic

equipment

An

otherwise

sound

cooling

system

may

still

overheat,

par-

ticularly

with

prolonged

idling,

due

to

a

failure

of

the

coolíng

fan(s)

.

The

belt-driven

cooling

fan

is

controlled

by

a

temperature

dependent

viscous

clutch

.

A

failed

fan

clutch

may

affect

air

flow

through

the

radiator

resulting

in

overheating

orpossibly

overcooling

.

Speed

Low

sp

High

s

With

the

engine

off,

check

thefan

clutch

by

spinning

thefan

.

eed

The

fan

should

spin

on

the

clutch

with

some

resistance

.

peed

Check

for

signs

of

leaking

fluid

from

the

clutch

.

If

thefan

free-

wheels

with

no

resistance,

cannot

be

tu

rned

by

hand,

or

there

are

signs

of

oil

leakage,

the

clutch

should

be

replaced

.

TROUBLESHOOTING

Fig

.

3

.

Radiatorcooling

fan

temperature

switch

(arrow)

.

WARNING

-

"

Use

caution

when

testing

the

electric

cooling

fan(s)

and

coolant

temperature

switch

.

Keep

hands

and

wires

clear

of

thefan

blades

.

The

cool-

ing

fan(s)

can

run

any

time

the

ignition

is

ON

.

"

For

greatest

safety,

coolíng

fan

and

coolant

tem-perature

switch

tests

shouldbe

performed

on

acoldengine

with

the

air

conditioning

off

.

Table

b

.

Auxiliary

Cooling

Fan

Switching

Temperatures

Switching

temperature

196°F(91°C)

210°F(99°C)

0012506

If

a

faulty

thermostat,

trapped

air,

or

a

restriction

in

the

sys-

tem

is

not

allowing

the

coolant

to

circulate

through

the

radia-

tor,

the

temperature

switch

will

not

close

and

the

auxiliary

cooling

fan

will

not

run

.

Before

making

the

tests

described

be-

low,

make

sure

the

thermostat

is

operating

correctly

as

de-

scribed

earlier

.

The

normal

switching

temperatures

for

the

dual

-speed

switch

are

listed

in

Table

b

.

Page 199 of 759

NOTE-

Some

cars

covered

by

this

manual

may

have

an

alter-

nate

cooling

fan

switchwith

switching

temperatures

of

176%190W

(80%88°C)

.

When

replacing

the

switch

check

theswitching

specifications,

whichshouldbe

stamped

on

the

switch

body

.

1

.

If

coolant

is

circulating

at

normal

operating

tempera-

ture,

but

auxiliary

cooling

fan

does

not

run,

disconnect

connector

from

radiator

temperature

switch

and

make

tests

listed

in

Table

c

.

Table

c

.

Auxiliary

Cooling

Fan

Temperature

Switch

Tests

Wires

jumpered

Test

Test

resuits

conditions

Black/green

(terminal2)

and

Ignition

ON

Fan

runs

on

brown

(terminal

1)

low

speed

Black/gray

(terminal

3)

and

Ignition

ON

Fan

runson

brown

(terminal

I

1)

high

speed

2

.

If

fan

runs

only

when

powered

directly

by

jumpered

connector

and

hot

coolant

is

circulating

through

radia-

tor,

radiator

temperature

switch

is

most

likelyfaulty

.

Use

a

new

sealing

ring

when

replacing

switch

Tightening

Torque

"

Temperature

switch

to

radiator

......

15

Nm

(11

ft-Ib)

3

.

If

auxiliary

fan

does

notrun

when

powered

directly,

check

for

battery

voltage

at

temperature

switch

connec-

tor

(black/green

wire)

with

ignition

on

.

If

battery

voltage

is

not

present,

check

fuses

.

See

610

Electrical

Com-

ponent

Locations

.

RADIATOR

AND

COOLING

SYSTEM

170-

5

~r~nmm

a

00

0

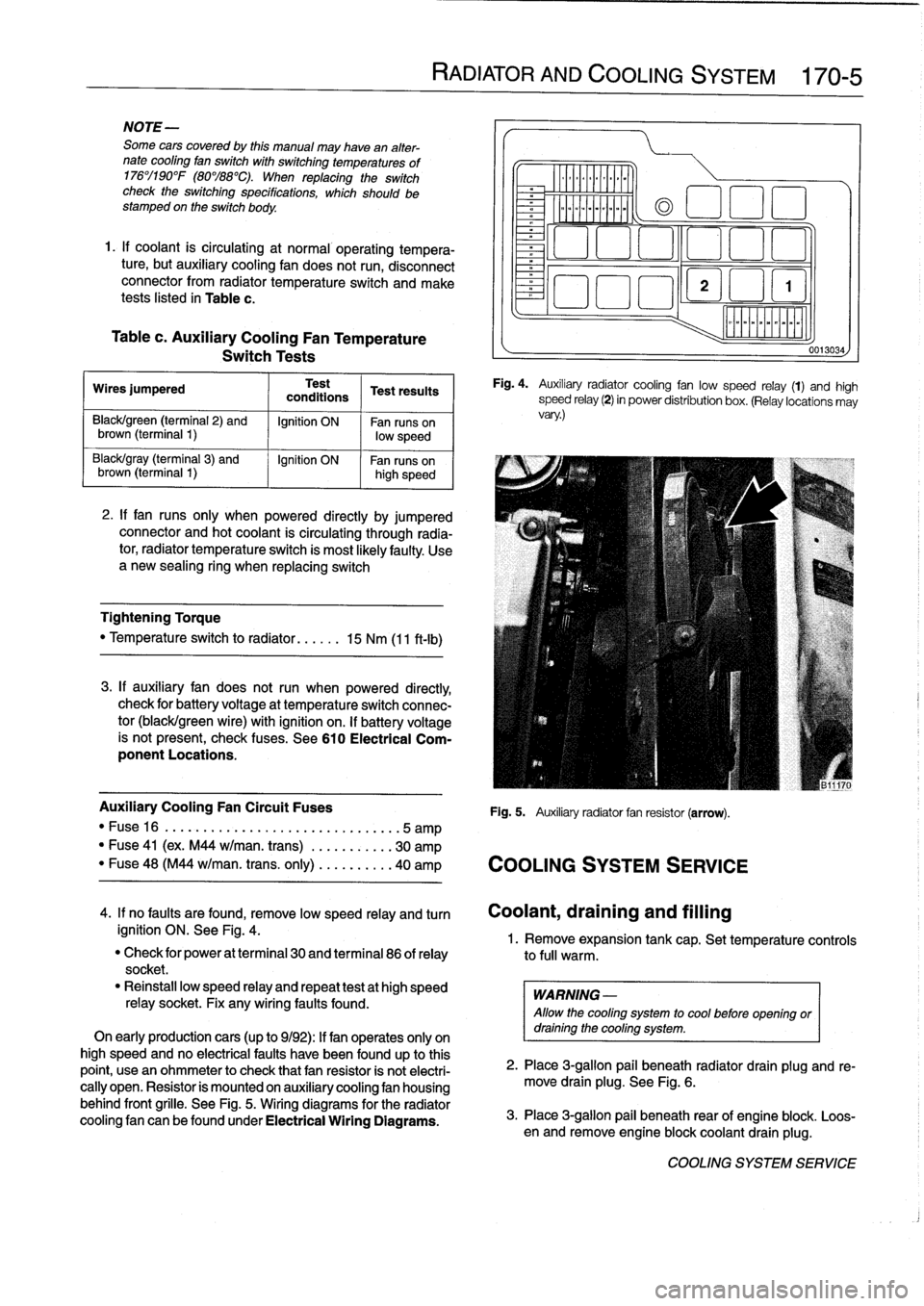

Fig

.

4

.

Auxiliary

radiator

cooling

fan

low

speed

relay

(1)

and

high

speed

relay

(2)

in

power

distribution

box

.

(Relay

locations

may

vary

.)

Auxiliary

Cooling

Fan

Circuit

Fuses

Fig

.

5

.

Auxiliary

radiator

fan

resistor

(arrow)

.

"

Fuse16

.

...................

..

..

...

...

.5

amp

"

Fuse

41

(ex

.

M44

w/man

.

trans)

.

..

.

..

.....

30

amp

"

Fuse

48

(M44

w/man

.

trans

.

only)

..

.

..

.....

40

amp

COOLING

SYSTEM

SERVICE

0013034

4

.

If

no

faults

are

found,

remove

low

speed

relay

and

turn

Coolant,draining

and

filling

ignition

ON

.

See

Fig

.

4

.

1

.

Remove

expansion

tank

cap

.

Set

temperature

controls

"

Check

for

power

at

terminal

30

and

terminal

86

of

relay

to

full

warm

.

socket

.

"

Reinstall

low

speed

relay

and

repeat

testat

high

speed

WARNING

-

relay

socket

.

Fix

any

wiring

faults

found

.

Allow

the

cooling

system

to

cool

before

openlng

or

On

early

productioncars

(up

to

9/92)

:

If

fan

operates

only

on

draining

the

cooling

system

.

high

speed

and

no

electrical

faults

have

been

foundup

to

this

point,

usean

ohmmeter

to

check

that

fan

resistor

is

not

electri-

2

.

Place

3

ra

allo

ug

.

beneath

radiator

drain

plug

and

re-

cally

open

.

Resistor

is

mounted

on

auxiliary

cooling

fan

housing

move

drain

plg

.

See

Fig

.

6

.

behind

front

grille

.

See

Fig

.

5

.

Wiring

diagrams

for

the

radiator

cooling

fan

canbefoundunder

Electrical

Wiring

Diagrams

.

3

.

Place

3-g

pail

beneath

rear

of

engine

blo

.

Loos-

en

and

re

mlon

ove

engine

blockcoolant

drain

plug

k

.

COOLING

SYSTEM

SERVICE

Page 200 of 759

170-6

RADIATOR

AND

COOLING

SYSTEM

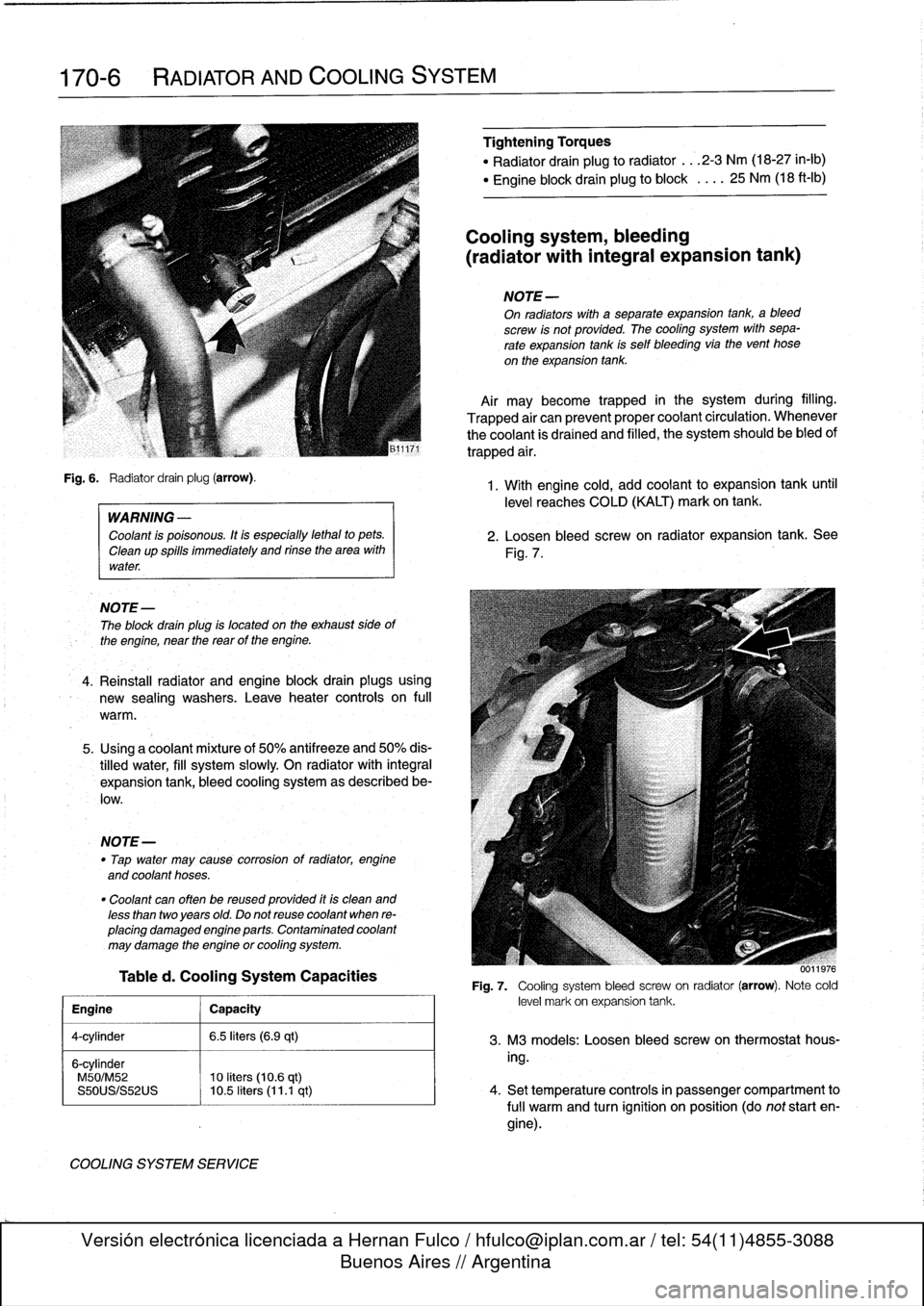

Fig

.

6

.

Radiator

drain

plug

(arrow)

.

WARNING

-

Coolant

is

poisonous

.

Itis

especially

lethal

to

pets

.

Cleanup

spills

immediately

and

rinse

the

area

with

water

.

NOTE

-

The

block

drain

plug

is

located

on

the

exhaust

side

of

the

engine,

near

the

reas

of

the

engine

.

4

.

Reinstall

radiator

and

engine

block

drain

plugsusing

new

sealing

washers

.

Leave

heater

controis

on

full

warm

.

5

.

Using

a

coolantmixture

of

50%

antifreeze

and

50%

dis-

tilled

water,

fill

system

slowly

On

radiator

with

integral

expansion

tank,

bleed

cooling

system

as

described

be-

low

.

NOTE-

"

Tap

water

may

cause

corrosion

of

radiator,

engine

and

coolant

hoses

.

"

Coolant

can

often

be

reused

provided

itis

clean

and

less

than

twoyears

old

.

Do

not

reuse

coolant

when

re-

placing

damaged

engine

parts

.

Contaminated

coolant

may

damage

the

engine

or

cooling

system

.

Tabled

.

Cooling

System

Capacities

Engine

j

Capacity

4-cylinder

1

6

.5

liters

(6.9

qt)

6-cylinder

M50/M52

10

liters

(10

.6

qt)

S50US/S52US

10

.5

liters

(11

.1

qt)

COOLING

SYSTEM

SERVICE

Tightehing

Torques

"

Radiator

drain

plug

to

radiator

...

2-3

Nm

(18-27

in-lb)

"

Engine

block

drain

plug

to

block

.

.

..

25

Nm

(18

ft-Ib)

Cooling

system,

bleeding

(radiator

with

integral

expansion

tank)

NOTE

-

On

radiators

with

a

separate

expansion

tank,

ableed

screw

is

not

provided

.

The

cooling

system

with

sepa-

rate

expansion

tank

is

self

bleeding

via

the

vent

hose

on

the

expansion

tank

.

Air

maybecome

trapped

in

the

system

during

filling

.

Trapped

air

can

prevent

proper

coolant

circulation

.

Whenever

the

coolant

is

drained

and

filled,

the

system

should

be

bled

of

trapped

air

.

1

.

With

engine

cold,

add

coolant

to

expansion

tank

until

level

reaches

COLD

(KALT)

mark

on

tank

.

2

.

Loosen

bleed

screw

on

radiator

expansion

tank

.

See

Fig

.

7

.

0011976

Fig

.

7

.

Cooling

system

bleed

screwon

radiator

(arrow)

.

Note

cold

level

mark

on

expansion

tank

.

3

.

M3

models

:

Loosen

bleed

screw

on

thermostathous-

ing

.

4

.

Set

temperature

controls

in

passenger

compartment

to

fui¡

warm

and

turn

ignition

on

position

(do

not

start

en-

gine)

.