Rear window BMW 325i 1992 E36 Owner's Manual

[x] Cancel search | Manufacturer: BMW, Model Year: 1992, Model line: 325i, Model: BMW 325i 1992 E36Pages: 759

Page 345 of 759

GENERAL

This

repair

group

covers

interior

trim

removal

and

installa-

tion

procedures

.

Forremoval

and

installation

of

interior

switches,

including

interior

lighting

equipment,

see

612

Switches

and

Electrical

Accessories

.

Most

of

the

interior

trim

and

finish

paneis

are

clipped

or

screwed

into

place

.

Many

of

the

trim

retaining

clips

arede-

signed

to

be

used

only

once

.

When

removing

trim

that

is

held

in

place

with

clips,

it

is

a

good

idea

lo

have

spareson

hand

be-

fore

beginningthejob

.

CENTER

CONSOLE

The

front

section

center

console

houses

the

Multi-Informa-

tion

Display

(MID)

module,the

front

ashtray

and

cigarette

lighter

;

shifter

lever,

power

window

switches

and

the

hazard

warning

switch

.

The

rear

center

console

section

houses

the

ashtray(s)

and

covers

the

emergency

brakecable

ends

.

Center

console,

removing

and

installing

1

.

Disconnect

negative

(-)

cable

from

battery

and

cover

terminal

with

insulating

material

.

CA

UTION-

Prior

to

disconnectiog

the

battery,

read

the

battery

disconnection

cautionsgiven

at

the

front

of

this

manual

onpage

viii

.

2

.

Remove

shifter

boot

or

selectorlever

cover

.

See250

Gearshift

t-inkage

.

3

.

Remove

rear

ashtray

retaining

screws

totake

out

ash-

tray

.

Remove

rear

console

retaining

screwunder

ash-

tray

.

513

Interior

Tri

m

INTERIORTRIM

513-1

GENERAL

..

.

.....

.

.

.

.

.

.

.

.

.

.

.

......

.

.

.

513-1

DASHBOARD

.....

.

.

.

.

.

.

.

.

.

.

.

.

.

.

...

.

:

.

.513-2

Glove

compartment,removing

and

installing

.

.513-2

CENTER

CONSOLE

.

.

.

.

.

.

.

.

.

.

.........

513-1

Lower

left

dash

panel,

Center

console,

removing

and

installing

.....

513-1

removing

and

installing

.

.

.

.

.

.

.

.

.

.

.....

.

.

513-2

Dashboard,removing

and

installing

.

.

.

.

...

.

.513-3

4

.

Remove

Multi-Information

Display

module

.

See620

In-

struments

.

5

.

Remove

hazardwarning

switch

and

power

window

switches

bypushing

up

and

out

from

below

.

6

.

Remove

lower

left

dashboard

panel

and

glove

compart-

ment

as

described

later

in

this

repair

group

.

7

.

Remove

retaining

screwunder

hazard

light

switch

.

Pull

rear

console

back

and

remove

retaining

nut

at

back

of

front

console

.

See

Fig

.

1

.

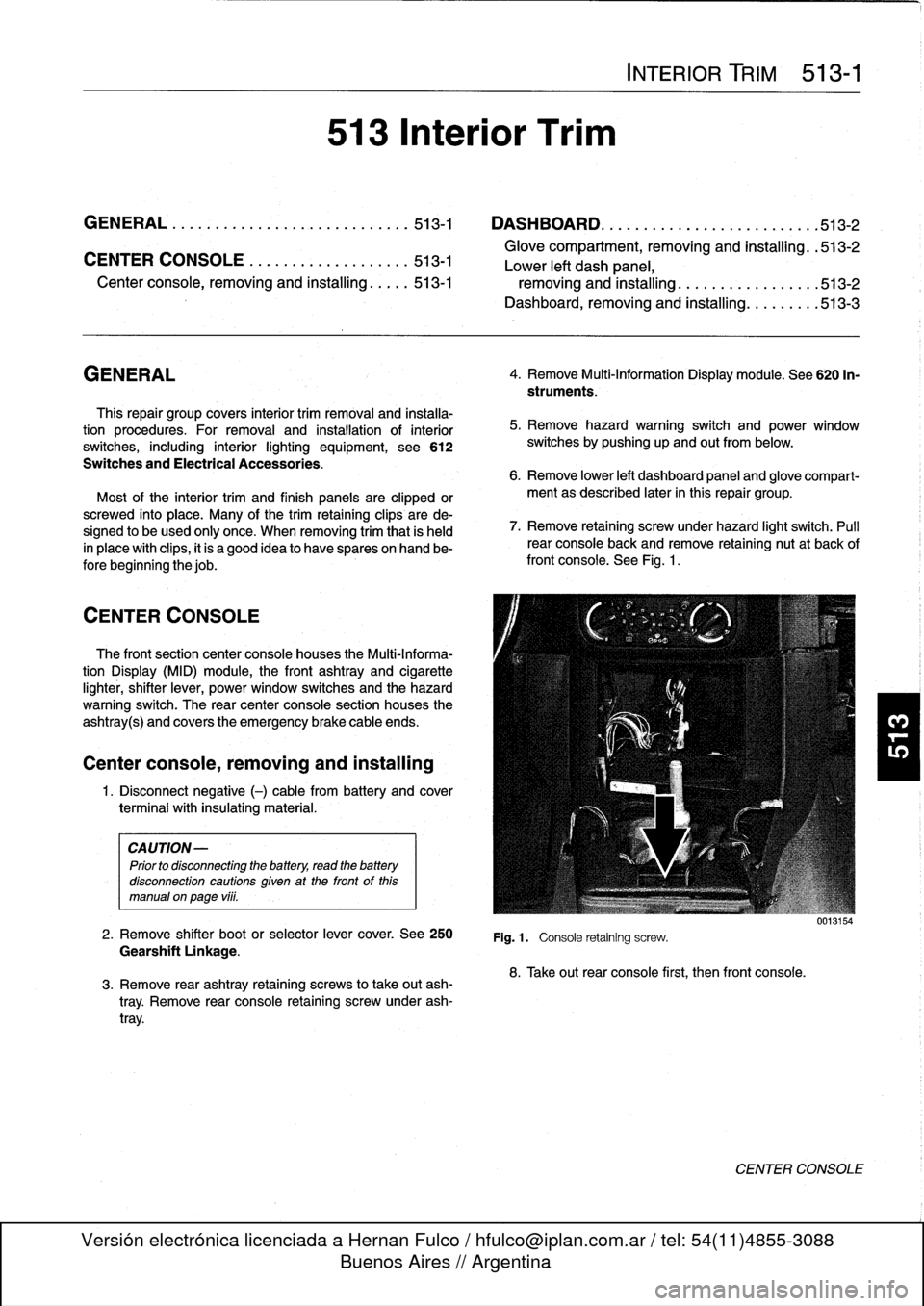

Fig

.1.

Console

retaining

screw

.

8

.

Take

out

rear

console

first,

then

front

console

.

0013154

CENTER

CONSOLE

Page 349 of 759

515

Central

Locking

and

Anti-Theft

GENERAL

.....

.

.

.

.

.

.

.

..:

.

.

.

......

.

.

.

.

515-1

Luggage

compartment

locking

actuator,

removing

and

installing

.

.

.

.

.

...........

.

515-6

DOOR

HANDLES

AND

LOCKS

.........

515-1

LOCKING

SYSTEM

AND

Front

door

lock,

removing

and

installing

....

.515-1

ELECTRONIC

IMMOBILIZATION

......

.515-7

Front

door

handle,

removing

and

installing

...

515-3

Rear

door

lock,

removing

and

installing

.....

515-4

Central

Locking

System(ZVM)

.

.

.

.

.......

.

515-7

Rear

door

handle,

removing

and

installing

...

515-5

Central

Body

Electronics

(ZKE

IV)

.

.

.......

.515-8

Electronic

Immobilization

System

(EWS)

.

.

.

.

.515-8

Door

striker,

rep

lacing

.

.

.

.

.

.

.

.

.

..........

515-6

EWS

II

control

module,

re

lacin

515-10

LOCKING

ACTUATORS

.

.

.

.

.

.

..........

515-6

Ring

antenna,

replacing

.

.

.

.

.

.

.

.

.

.

...

.

.

.

.

515-10

Door

Locking

Actuator

.

.

.

.

.

.

.

.

..........

515-6

EWS

II

transmitter/receiver

module,

replacing

...........

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

515-11

GENERAL

This

section

covers

repair

information

for

the

central

locking

and

the

anti-theft

systems

.

Keep

in

mind

that

E36

cars

are

CA

UTION-

equipped

with

sophisticated

and

self-diagnostic

electrical

sys-

Prior

to

disconnecting

the

battery,

read

the

battery

tems

.

When

experiencing

malfunctions

relatinglo

the

central

disconnection

cautions

given

at

the

front

of

this

locking

or

the

anti-theft

system,

it

is

recommended

that

the

manual

onpage

vi¡¡

.

systembe

diagnosed

using

the

BMW

service

tester

(DIS)

.

This

advanced

diagnostic

tool

can

usually

pinpoint

electrical

NOTE-

faults

quickly

and

safely

.

Consult

an

authorized

BMW

dealer

.

In

some

models

covered

inthis

manual,

it

is

not

essen-

tial

to

remove

the

side-impact

airbag

to

access

intemal

NOTE-

door

components

.

However,

the

procedure

is

recom-

Additional

general

electrical

information

can

be

found

mended

for

safely

reasons

.

i

n

610

Electrical

Component

Locations

and

Electri-

cal

Wiring

Diagrams

.

4

.

Disconnect

harnessconnector

from

window

motor

to

DOOR

HANDLES

AND

LOCKS

Front

door

lock,

removing

and

installing

1

.

Remove

front

door

panel

and

vapor

barrier

asde-

scribed

in

411

Doors

.

WARNING

-

Some

1997

and

all

1998

cars

are

fitted

with

side-im-

pact

airbags

in

the

front

doors

.

When

servicing

the

door

locks

on

cars

with

front

side-impact

airbags,

al-

ways

disconnect

the

negative

(-)

battery

terminal

.

See721

Airbag

System

(SRS)

forcautions

andpro-

cedures

relating

to

the

airbag

system

.

2

.

Raise

door

window

completely

CENTRAL

LOCKING

AND

ANTI-THEFT

515-1

3

.

On

cars

with

side-impact

airbags,

disconnect

negative

(-)

cable

from

battery,

then

remove

airbag

module

.

prevent

accidental

operation

.

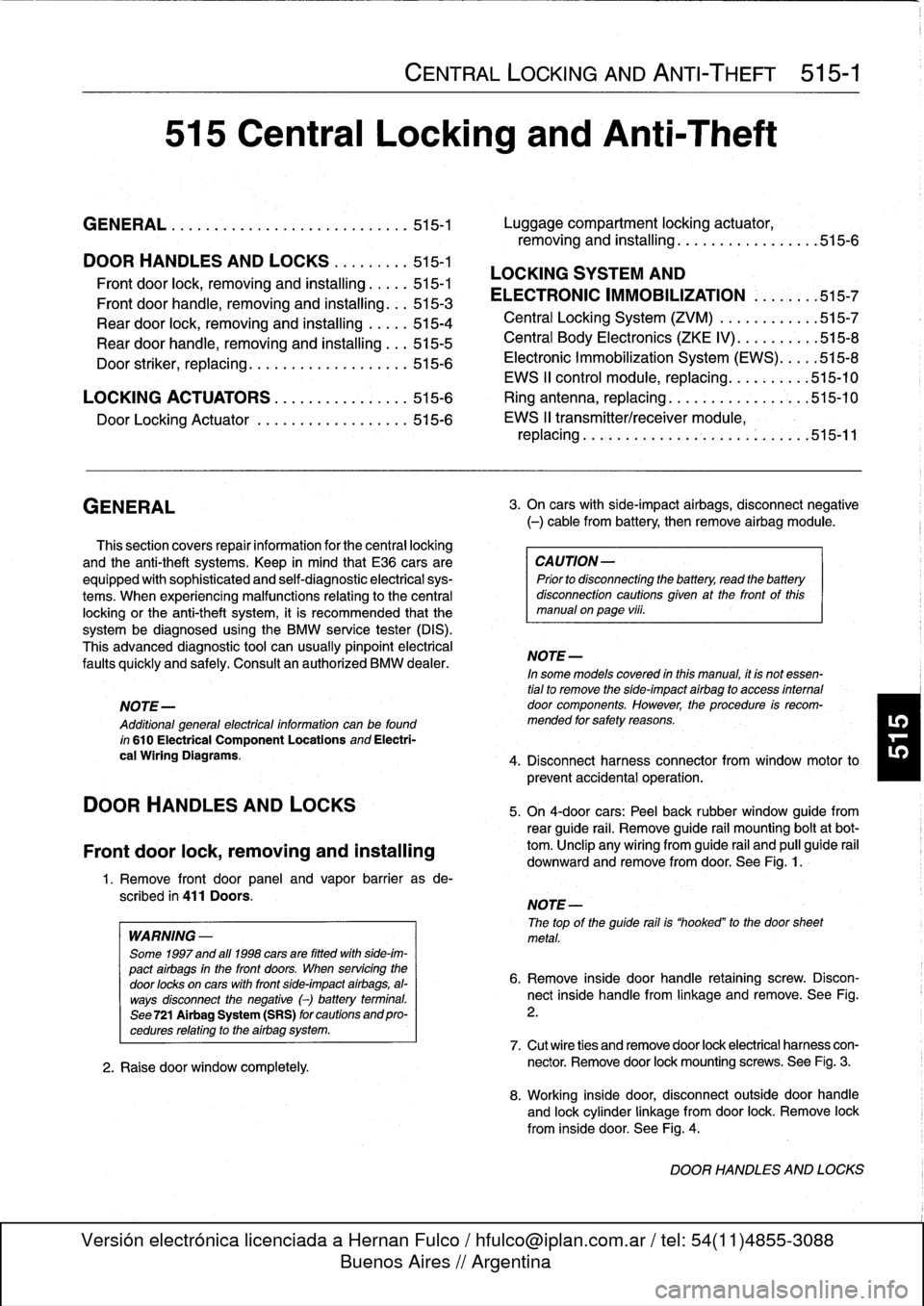

5

.

On

4-door

cars

:

Peel

back

rubber

window

guide

from

reas

guide

rail

:

Remove

guide

rail

mounting

boltat

bot-

tom

.

Unclip

any

wiring

from

guide

rail

and

pull

guide

rail

downward

and

remove

from

door

.

See

Fig

.

1

.

NOTE

-

The

top

of

the

guide

rail

is

"hooked"

to

the

doorsheet

metal

.

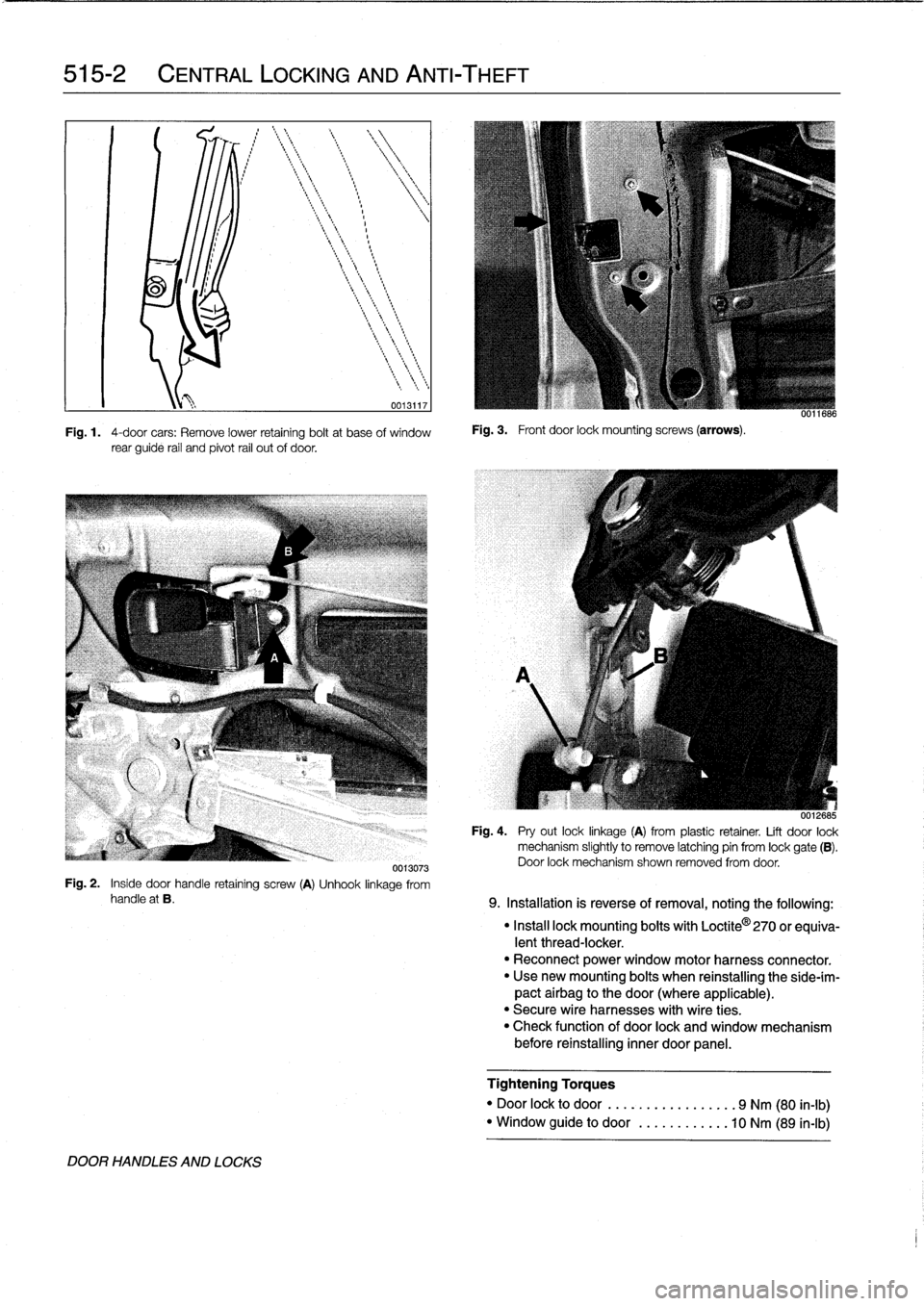

6

.

Remove

inside

door

handle

retaining

screw

.

Discon-

nect

inside

handle

from

linkage

and

remove

.

See

Fig

.

2

.

7

.

Cut

wire

ties

and

remove

door

lock

electrical

harness

con-

nector

.

Remove

door

lock

mounting

screws

.

See

Fig

.

3

.

8

.

Working

inside

door,

disconnect

outside

door

handle

and

lockcylinder

linkage

from

door

lock

.

Remove

lock

from

inside

door

.

See

Fig

.

4

.

DOOR

HANDLES

AND

LOCKS

Page 350 of 759

515-2

CENTRAL

LOCKING

AND

ANTI-THEFT

0013117

Fig

.

1

.

4-door

cars

:

Remove

lower

retaining

boltat

base

of

window

rear

guide

rail

and

pivot

rail

out

of

door

.

Fig

.

3

.

Front

door

lock

mounting

screws

(arrows)

.

uu11686

0012685

Fig

.

4

.

Pry

out

locklinkage

(A)

from

plastic

retainer

.

Lift

door

lock

mechanism

slightly

to

Rmove

latching

pin

from

lock

gate

(B)

.

Door

lock

mechanism

shown

removed

from

door

.

0013073

Fig

.

2

.

Inside

door

handle

retaining

screw

(A)

Unhook

linkage

from

handle

at

B

.

9

.

Installation

is

reverse

of

removal,

noting

the

following

:

DOOR

HANDLES

AND

LOCKS

"

Install

lock

mounting

bolts

with

Loctite

0

270

or

equiva-

lent

thread-locker

.

"

Reconnect

power

window

motor

harness

connector

.

"

Usenew

mounting

bolts

when

reinstalling

the

side-ím-

pact

airbag

to

the

door

(where

applicable)

.

"

Secure

wire

harnesses

with

wire

ties

.

"

Check

function

of

door

lock

and

window

mechanism

before

reinstalling

inner

door

panel

.

Tightening

Torques

"

Door

lock

to

door

......

.

..........

9

Nm

(80

in-lb)

"

Window

guide

to

door

........

.

...

10

Nm

(89

in-lb)

Page 352 of 759

515-4

CENTRAL

LOCKING

AND

ANTI-THEFT

11

.

Installation

is

reverse

of

removal

.

Keep

in

mind

the

fol-

4

.

Remove

screws

mounting

bottom

of

window

rear

track

lowing

:

to

door

.

See

Fig

.

9

.

"

Make

sure

rubber

seal

for

handle

is

correctly

posi-

tionedbefore

tightening

mounting

fasteners

.

"

Install

exteriortrim

piece

and

then

use

a

hooked

tool

to

pull

locking

plate

into

locked

position

.

Make

sure

door

handle

trim

contacts

body

evenly

before

locking

trim

in

place

.

"

Use

new

mounting

bolts

when

reinstalling

the

side-im-

pactairbag

to

the

door(where

applicable)

.

Reset

SRS

warning

light

and

clear

SRS

fault

memory

using

spe-

cial

test

equipment

.

See

721

Airbag

System

(SRS)

.

"

Reconnect

al¡

harness

connectors

(including

power

window

motor)before

installing

door

panel

.

"

Secure

wire

harnesses

withwire

ties

.

"

Adjust

and

reinitialize

windows

.

See

512

Door

Win-

dows

.

Tightening

Torque

"

Collar

nut

to

doorhandle

..........

10

Nm

(89

in-lb)

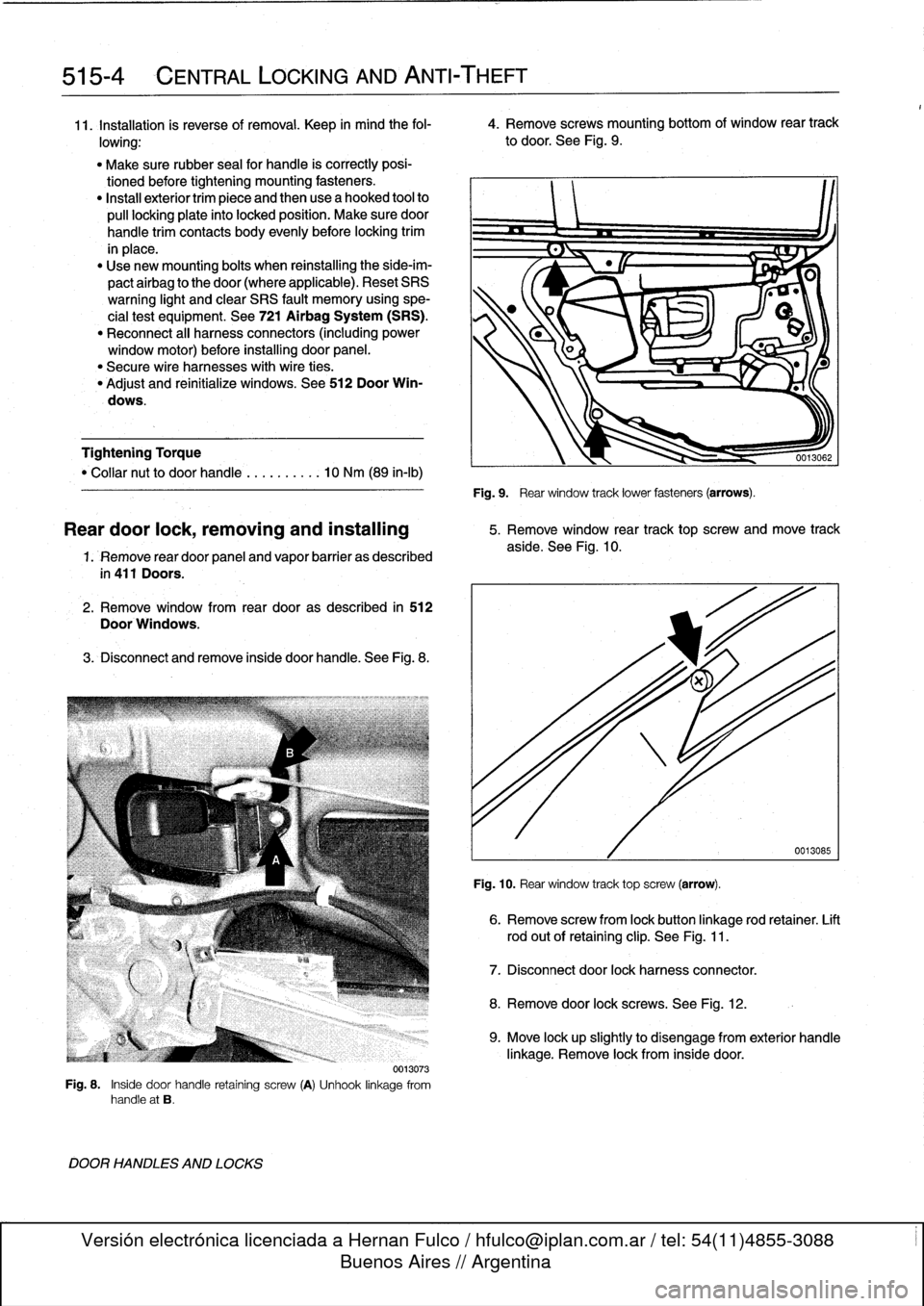

1.

Remove

rear

door

panel

and

vapor

barrier

as

described

in

411

Doors

.

2

.

Remove

window

from

rear

dooras

described

in

512

Door

Windows

.

3

.

Disconnect

andremove

inside

door

handle

.

See

Fig

.

8

.

0013073

Fig

.

8

.

Inside

door

handle

retaining

screw

(A)

Unhook

linkage

from

handle

at

B

.

DOOR

HANDLES

AND

LOCKS

Fig

.

9

.

Rear

window

track

lower

fasteners

(arrows)

.

Reardoor

lock,

removing

and

installing

5

.

Remove

window

rear

track

top

screw

and

move

track

aside

.

See

Fig

.

10

.

Fig

.

10

.

Rear

window

track

top

screw

(arrow)

.

6

.

Remove

screw

from

lock

button

linkage

rod

retainer

.

Lift

rod

out

of

retaining

clip

.

See

Fig

.

11

.

7

.

Disconnect

door

lock

harnessconnector

.

8

.

Remove

door

lock

screws

.

See

Fig

.

12

.

0013085

9

.

Move

lock

upslightly

to

disengage

from

exterior

handle

linkage

.

Remove

lock

from

inside

door

.

Page 353 of 759

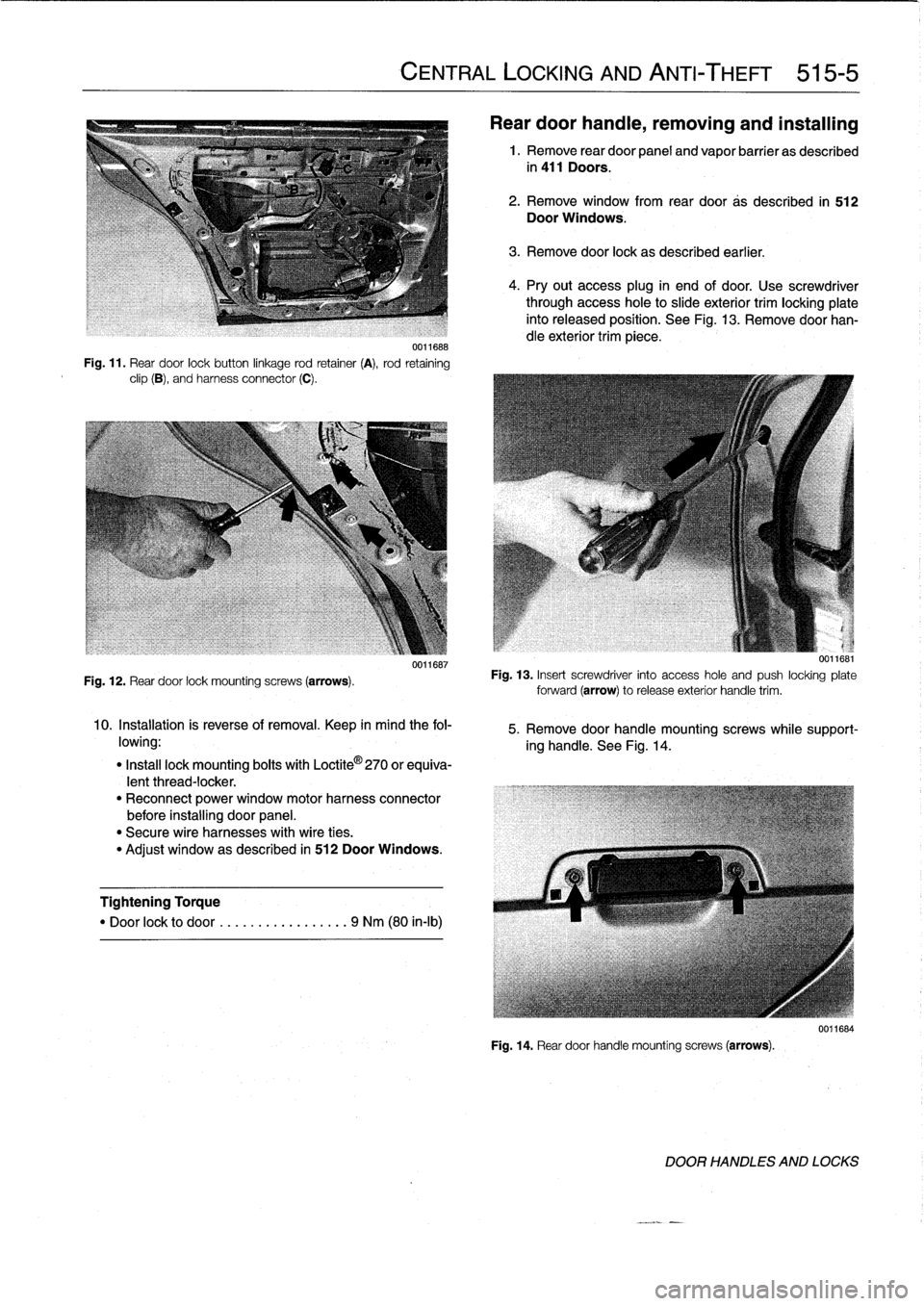

0011688

Fig

.

11

.

Rear

door

lockbutton

linkage

rod

retainer

(A),

rod

retaining

clip

(B),

and

harness

connector

(C)

.

Fig

.

12

.

Rear

door

lock

mounting

screws

(arrows)

.

0011687

10

.

Installation

is

reverse

of

removal

.

Keep

in

mind

the

fol-

lowing

:

"

Insta¡¡

lock

mounting

boits

with

Loctite

©

270

or

equiva-

lentthread-locker

.

"

Reconnect

power

window

motorharness

connector

before

installing

door

panel

.

"

Secure

wire

harnesses

with

wire

ties

.

"

Adjust

window

as

described

in

512

Door

Windows

.

Tightening

Torque

"

Door

lock

to

door

.

...

.

..

..........

9

Nm

(80

in-lb)

CENTRAL

LOCKING

AND

ANTI-THEFT

515-5

Rear

door

handie,

removing

and

installing

1

.

Remove

rear

door

panel

and

vapor

barrier

as

described

in

411

Doors

.

2

.

Remove

window

from

rear

door

as

described

in

512

Door

Windows

.

3

.

Remove

door

lock

as

described

earlier

.

4

.

Pry

out

access

plug

in

end

of

door

.

Use

screwdriver

through

access

hole

to

slide

exterior

trim

locking

plate

into

released

position

.

See

Fig

.

13

.

Remove

doorhan-

dle

exterior

trim

piece

.

u

.]lbbl

Fig

.

13

.

Insert

screwdriver

into

access

hole

and

push

locking

plate

forward

(arrow)torelease

exterior

handle

trim

.

5

.

Remove

door

handle

mountingscrews

while

support-

ing

handle

.

See

Fig

.

14

.

Fig

.

14

.

Reardoor

handle

mounting

screws

(arrows)

.

0011684

DOOR

HANDLES

AND

LOCKS

Page 354 of 759

515-6

CENTRAL

LOCKING

AND

ANTI-THEFT

6

.

Remove

door

handle

assembly

from

inside

door

.

7

.

Installation

is

reverse

of

removal

.

Keep

in

mindthe

fol-

lowing

:

"

Make

sure

rubber

seal

for

handle

is

correctly

posi-

tionedbefore

tightening

mounting

fasteners

.

"

Install

exterior

trim

piece

and

then

use

a

hooked

toolto

pull

locking

plate

into

locked

position

.

Make

sure

door

handle

trim

contacts

body

evenly

before

lockingtrim

in

place

.

"

Reconnect

all

harness

connectors

(including

power

window

motor)before

installing

door

panel

.

"

Secure

wire

harnesses

withwire

ties

.

"

Adjust

windowas

described

in

512

Door

Windows

.

Tightening

Torque

"

Rear

door

handle

mounting

screws

..

10

Nm

(89

in-lb)

NOTE

If

the

striker

backup

plate

fafls

into

the

body

cavlty,

it

can

be

retrieved

after

removing

the

inside

trim

from

the

B-pillar

(door-post

pillar)

.

Tightening

Torque

"

Striker

plate

to

body

pillar

..........

28

Nm

(20

ft-lb)

LOCKING

ACTUATORS

Door

Locking

Actuator

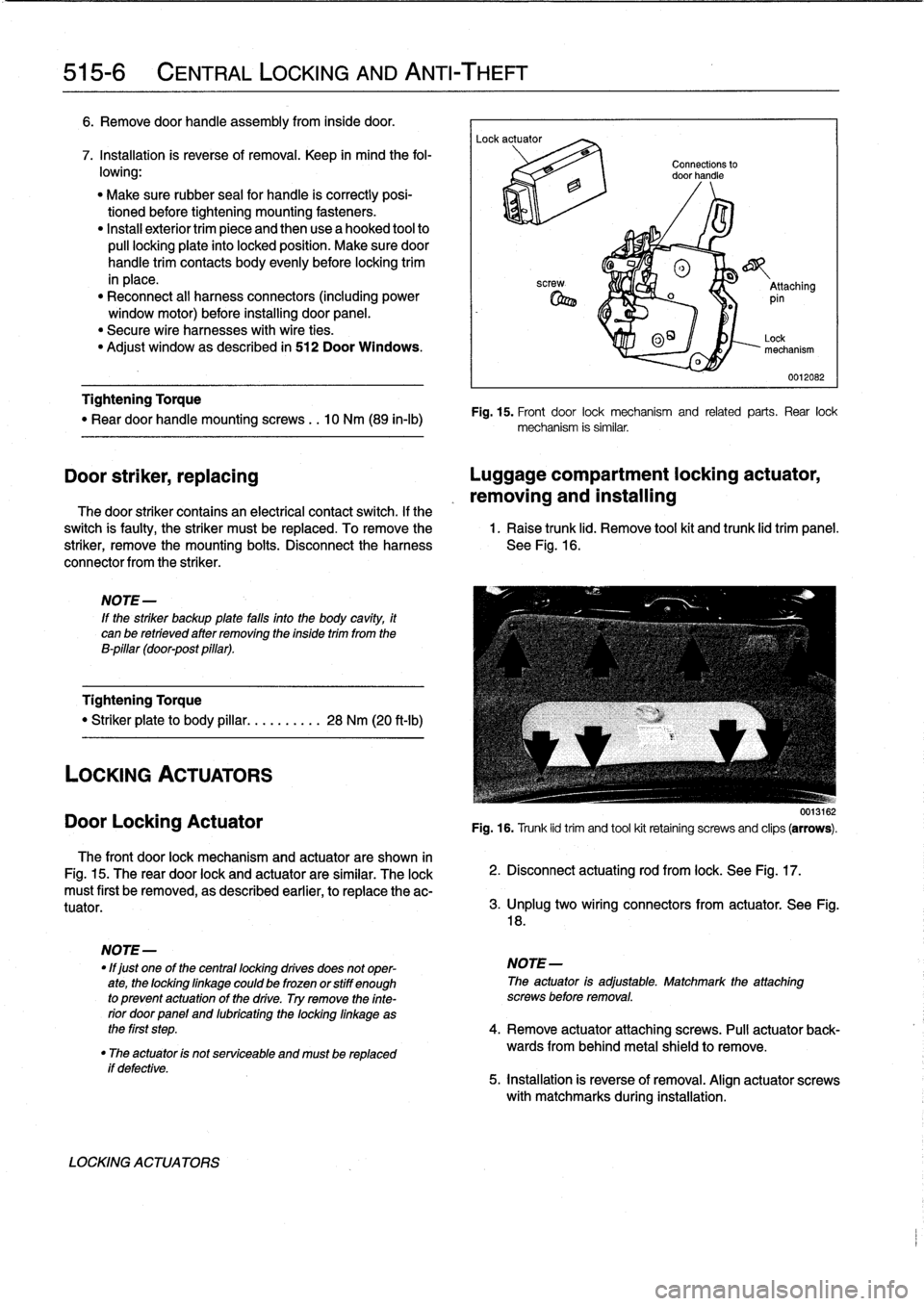

The

front

door

lock

mechanism

and

actuator

are

shown

in

Fig

.

15

.

The

rear

door

lock

and

actuator

are

similar

.

The

lock

must

first

be

removed,

as

described

earlier,

to

replace

the

ac-

tuator

.

if

defective

.

LOCKING

ACTUATORS

Connections

to

door

handle

®

o

_

Attaching

pin

0

O~

Lock

mechanism

0012082

Fig

.

15

.

Front

door

lock

mechanism

and

related

parts

.

Rear

lock

mechanism

is

similar

.

Door

striker,

replacing

Luggage

compartment

locking

actuator,

removing

and

installing

The

door

striker

contains

an

electrical

contact

switch

.

If

the

switch

is

faulty,

the

striker

must

be

replaced

.

To

remove

the

1

.

Raise

trunk

lid

.

Remove

tool

kit

and

trunk

lid

trim

panel

.

striker,

remove

the

mounting

bolts

.

Disconnect

the

harness

See

Fig

.

16

.

connector

from

the

striker

.

0013162

Fig

.

16

.

Trunk

lid

trim

and

tool

kit

retainíng

screws

and

clips

(arrows)

.

2

.

Disconnect

actuating

rod

from

lock

.

See

Fig

.

17

.

3

.

lJnplug

two

wíring

connectors

from

actuator

.

See

Fig

.

18

.

NOTE

-

"

lf

just

one

of

the

centrallocking

drives

does

not

oper-

NOTE-

ate,

the

lockinglinkage

could

be

frozen

orstiff

enough

The

actuator

is

adjustable

.

Matchmark

the

attaching

to

prevent

actuatonof

the

drive

.

Try

remove

the

finte-

screws

before

removal

.

rior

doorpanel

and

lubricating

the

locking

linkage

as

the

first

step

.

4

.

Remove

actuator

attaching

screws

.

Pull

actuator

back-

"

The

actuator

is

not

serviceable

and

mustbe

replaced

wards

from

behind

metal

shield

to

remove

.

5

.

installation

is

reverse

of

removal

.

Align

actuator

screws

with

matchmarks

during

installation

.

Page 371 of 759

GENERAL

.

...

.

.

.

......

.

.

.

.

.

.

.

.

.

......

541-1

Visor

Latch

Plate

.....

.

....

.

.

.

.

.

...

.

...

.541-4

Visor

Latch

..

.

............

.

.

.

..........

541-4

MANUAL

CONVERTIBLE

TOP

.

.

.

.

...

.

..

541-1

Visor

Latch

Motor

...

.......

.

.

.

..

........

541-5

Visor

Latch

Plate

.

.

......

.

.

.

...

.

.

.

.

.

.

.

..

541-1

Convertible

top

and

frame,

replacing

........

541-5

VisorLatch

.

.

.

.

.

.

.

.

..........

.

.....

.

.

.541-1

Convertible

top

drive

motor,

replacing

......

541-7

Convertible

Top

Lid

Release

Mechanism

.

.

.

.

541-2

Convertible

Top

Emergency

Operation

.....

.541-7

Convertible

top

and

frame,

replacing

....

.

.

.

541-2

Convertible

Top

Lid

.

.

.

.

...........

.

.....

541-9

POWER

CONVERTIBLE

TOP

.

.

.

.

....

.

.

.

541-2

ROLLOVER

PROTECTION

SYSTEM

..

.

.

541-9

FrontLatching

Mechanism

.

.

.

.

.

.

.

.

......

.

541-4

GENERAL

The

convertible

top

comes

in

three

versions

:

a

manually

op-erated

top,

a

semi-automatic

power

top

and

a

fully

automatic

power

top

.

NOTE-

The

convertible

top

control

module

(CVM)

is

located

behind

the

left

rearside

trim

panel

.

For

the

location

of

other

convertible

top

electric

components

see610

Electrical

Component

Locations

.

The

rear

window

in

the

convertible

models

is

made

of

a

strong,

flexible

vínyl

which

is

available

separately

.

Replace-

ment

of

the

rear

window

is

not

covered

in

this

manual

.

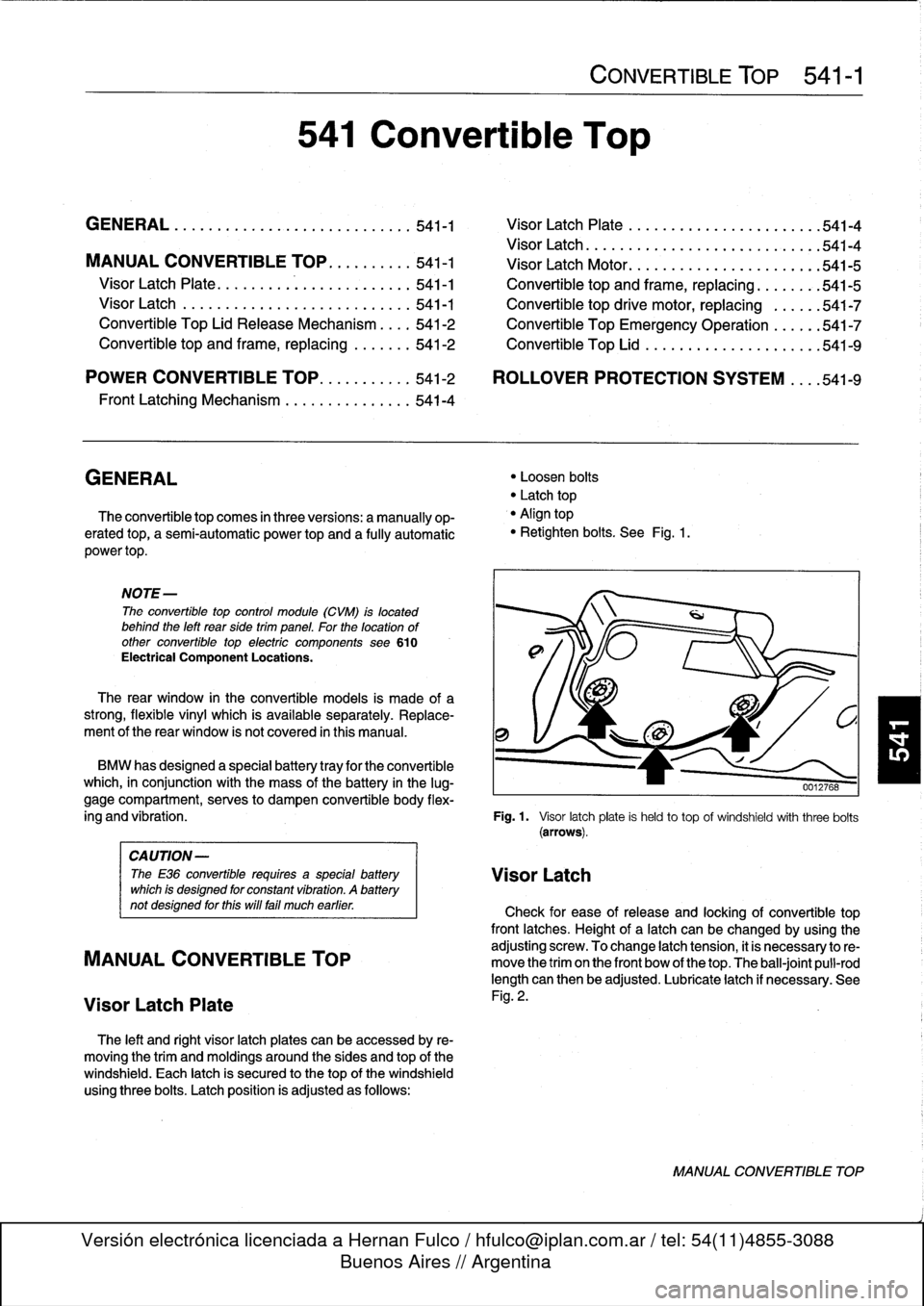

The

left

and

right

visor

latch

plates

can

be

accessed

by

re-

moving

the

trim

and

moldings

around

the

sides

and

top

of

the

windshield

.

Each

latch

is

secured

to

thetop

of

the

windshield

usingthree

bolts

.

Latch

position

is

adjusted

as

follows

:

541

Convertible

Top

CONVERTIBLE

TOP

541-1

"

Loosen

bolts

"

Latch

top

"

Align

top

"

Retighten

bolts

.

See

Fig

.

1

.

BMW

has

designed

a

specialbattery

tray

for

the

convertible

which,

in

conjunction

with

the

mass

of

the

battery

in

the

lug-

gage

compartment,

serves

to

dampen

convertible

body

flex

ing

and

vibration

.

Fig

.

1.

Visor

latchplate

is

held

to

top

of

windshieldwith

three

bolts

(arrows)

.

CAUTION-

The

E36

convertible

requires

a

specialbattery

VisorLatch

which

is

designed

for

constant

vibration

.

A

battery

not

designed

forthis

will

fa¡¡

much

earlier

.

Check

for

ease

of

release

and

locking

of

convertible

top

front

latches

.

Height

of

a

latch

can

be

changed

by

using

the

adjusting

screw

.

To

change

latch

tension,

it

is

necessary

to

re-

MANUAL

CONVERTIBLE

TOP

move

the

trim

on

the

front

bow

of

thetop

.

The

ball-joint

pull-rod

length

can

then

be

adjusted

.

Lubricate

latch

if

necessary

.

See

Visor

Latch

Plate

Fig

.

2

.

MANUAL

CONVERTIBLE

TOP

Page 379 of 759

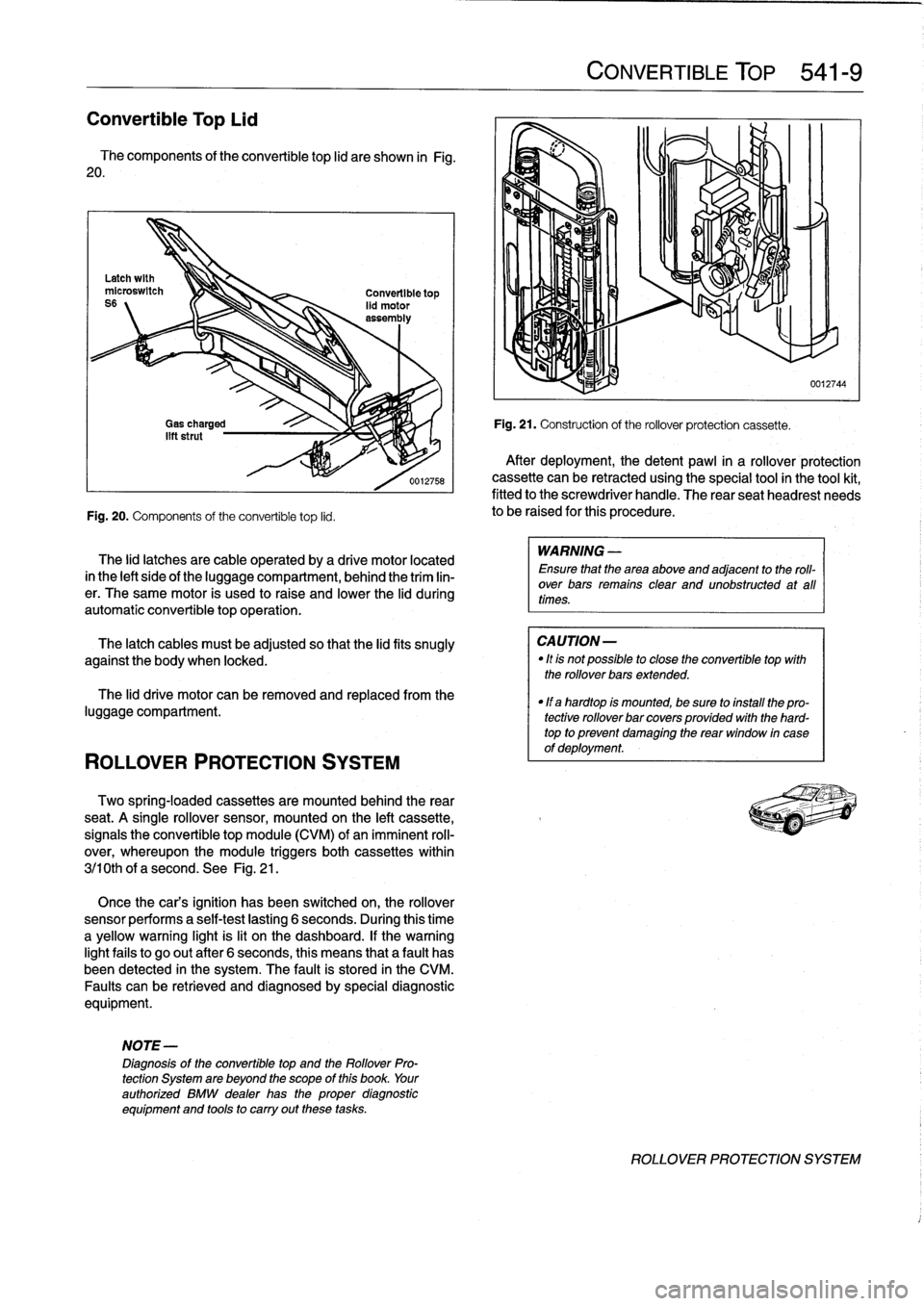

Convertible

Top

Lid

The

components

of

the

convertible

top

lid

are

shown

in

Fig

.

20

.

Fig

.

20

.

Components

of

the

convertible

top

lid

.

ROLLOVER

PROTECTION

SYSTEM

The

lid

latches

are

cable

operated

by

a

drive

motor

located

in

the

left

sideof

the

luggagecompartment,

behind

the

trim

lin-

er

.

The

same

motor

is

used

to

raise

and

lower

the

lid

during

automatic

convertible

topoperation

.

The

latch

cables

must

be

adjusted

so

that

the

lidfits

snugly

against

the

body

when

locked

.

The

lid

drive

motor

can

be

removed

and

replaced

from

the

luggage

compartment

.

Two

spring-locaed

cassettes

are

mounted

behind

the

rear

seat

.

A

single

rollover

sensor,

mounted

on

the

left

cassette,

signals

the

convertible

top

module

(CVM)

of

animminent

roll-

over,

whereupon

the

module

triggers

both

cassettes

within

3j10th

of

a

second

.

See

Fig

.

21

.

Once

the

cars

ignition

has

been

switched

on,

the

rollover

sensor

performs

a

self-test

lasting

6

seconds

.

During

this

time

a

yellow

warning

light

is

lit

on

the

dashboard

.

If

thewarning

lightfails

to

go

out

after

6

seconds,

this

means

that

a

fault

has

been

detected

in

the

system

.

The

fault

is

stored

in

the

CM

Faults

canbe

retrieved

and

diagnosedby

special

diagnostic

equipment

.

NOTE-

Diagnosis

of

the

convertible

top

and

the

Rollover

Pro-

tection

System

are

beyond

the

scope

of

this

book

.

Your

authorized

BMW

dealer

has

the

proper

diagnostic

equipment

and

tools

to

carry

out

these

tasks

.

CONVERTIBLE

TOP

541-

9

Fig

.

21

.

Construction

of

the

rollover

protection

cassette

.

After

deployment,

thedetent

pawl

in

a

rollover

protection

cassette

can

be

retracted

using

the

special

tool

in

the

tool

kit,

fitted

to

the

screwdriver

handle

.

The

rear

seatheadrest

needs

to

be

raised

for

this

procedure

.

WARNING

-

Ensure

that

the

area

above

and

adjacent

to

the

roll-

over

bars

remains

clear

and

unobstructed

at

all

times

.

CAUTION-

"

Itis

not

possible

to

close

the

convertible

top

with

the

rollover

bars

extended

.

"

If

a

hardtop

is

mounted,

be

sure

to

install

the

pro-

tective

rollover

bar

covers

provided

with

the

hard-

top

to

prevent

damaglng

the

rear

window

in

case

of

deployment

.

0012744

ROLLOVER

PROTECTION

SYSTEM

Page 390 of 759

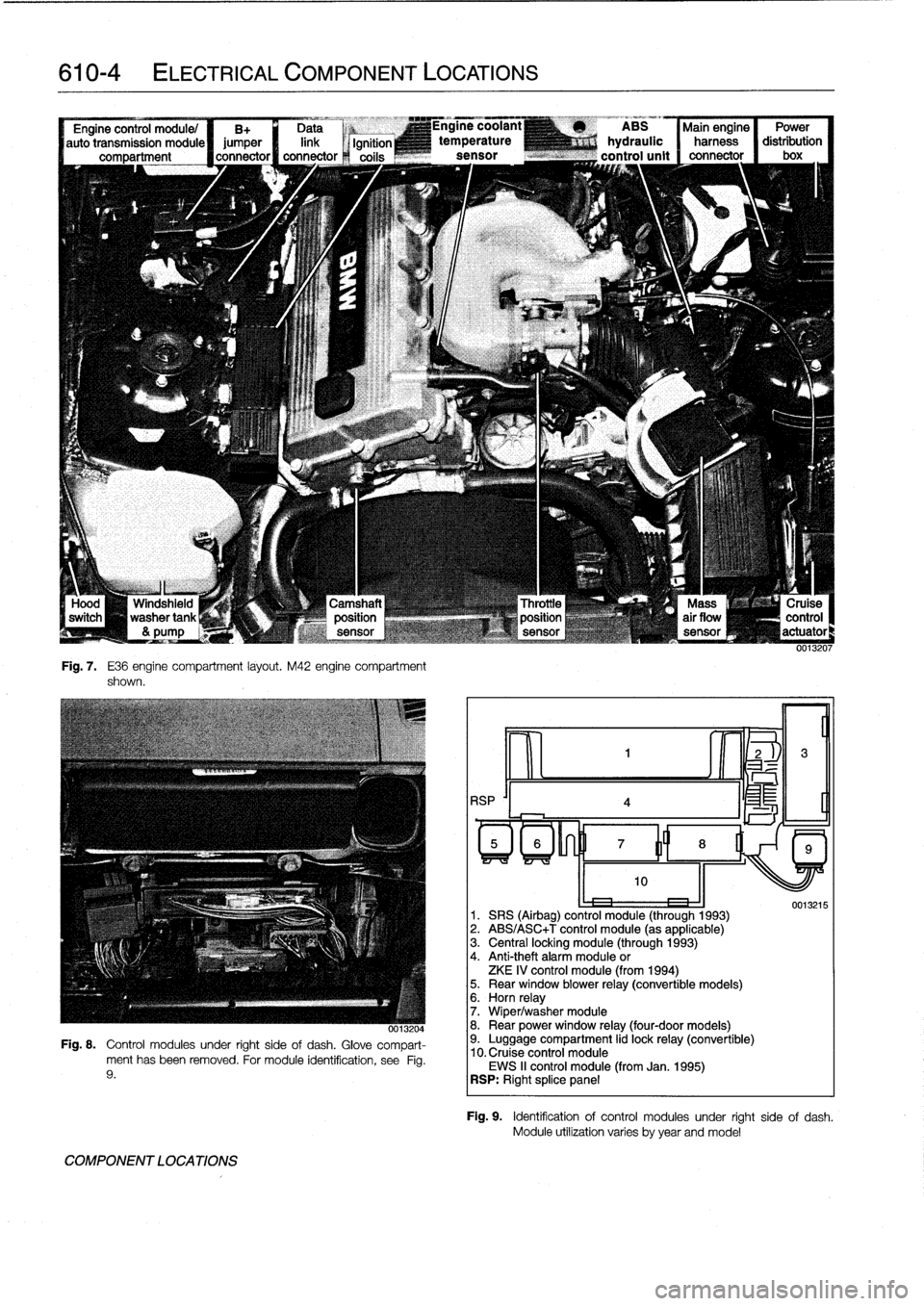

610-4

ELECTRICAL

COMPONENT

LOCATIONS

--J

L

Windshield

washertank

&

pump

Fig

.

7

.

E36

engine

compartment

layout

.

M42

engine

compartment

shown

.

-,x

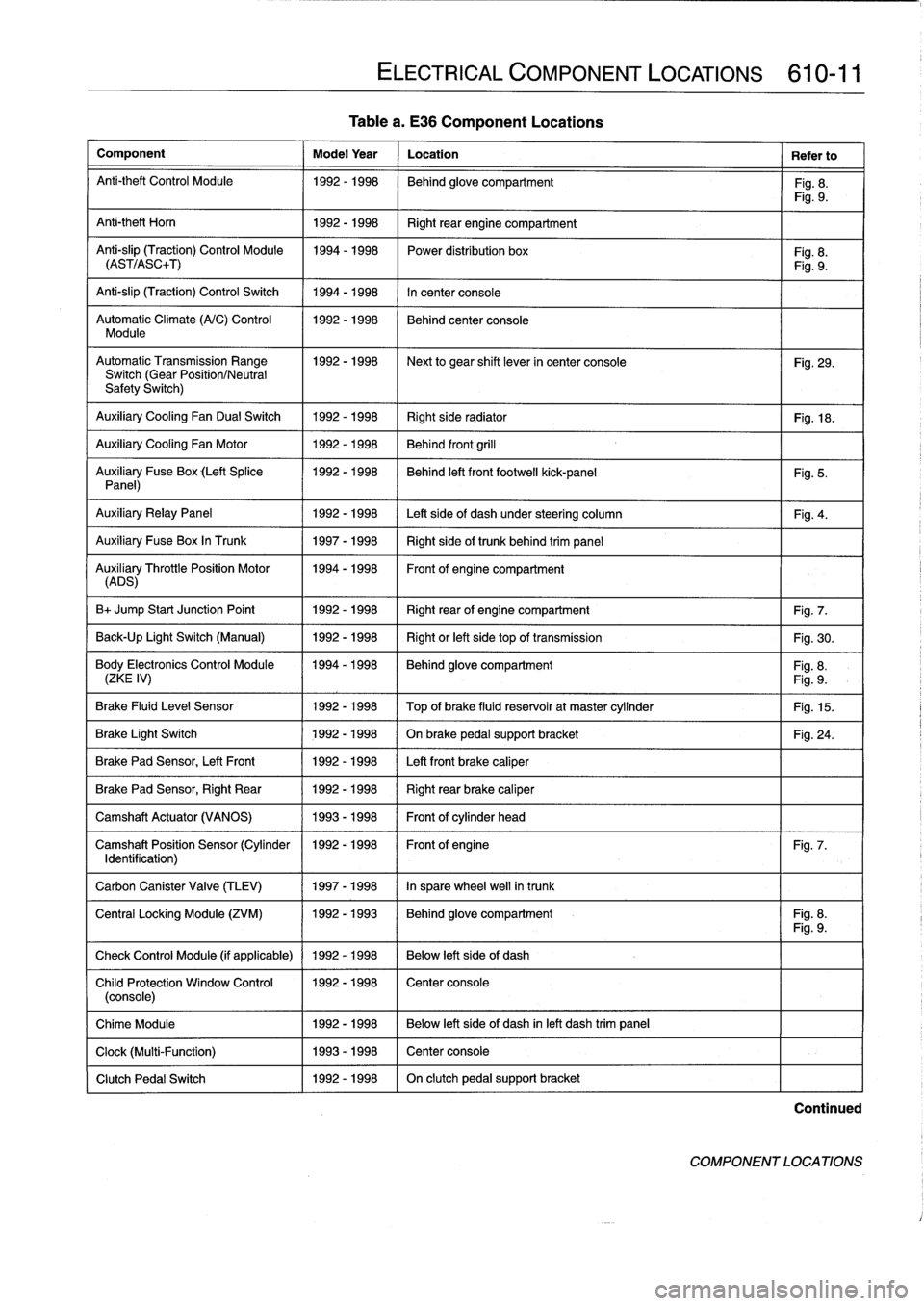

0013204

Fig

.

8

.

Control

modules

under

right

sideof

dash

.

Glove

compart-

ment

has

been

removed

.

For

module

identification,

see

Fig

.

9

.

COMPONENT

LOCATIONS

RSP

'I

4

ABS

Main

engine

Power

hydraulic

harness

distribution

control

unit

connector

I

box

oe

1

.

SRS

(Airbag)

control

module

(through

1993)

2

.

ABS/ASC+T

control

module

(as

applicable)

3

.

Central

locking

module

(through

1993)

4

.

Anti-theft

alarm

module

or

ZKE

IV

control

module

(from

1994)5

.

Rear

window

blower

relay

(convertible

models)6

.

Horn

relay

7

.

Wiper/washer

module

8

.

Rear

power

window

relay

(four-door

models)9

.

Luggage

compartment

lid

lock

relay

(convertible)

10

.

Cruise

control

module

EWS

II

control

module

(from

Jan

.

1995)

RSP

:

Right

splice

panel

0013215

Fig

.

9

.

Identificationof

control

modules

under

right

side

of

dash

.

Module

utilízation

varies

byyear

andmodel

Page 397 of 759

Table

a

.

E36

Component

Locations

Component

Model

Year

Location

Refer

to

Anti-theft

Control

Module

1992-1998

Behind

glove

compartment

Fig

.

8

.

Fig

.

9

.

Anti-theft

Horn

1

1992-1998

1

Right

rear

engine

compartment

Anti-slip

(Traction)

Control

Module

1994-1998

Power

distribution

box

Fig

.

8

.

(AST/ASC+T)

Fig

.

9

.

Anti-slip

(Traction)

Control

Switch

1994-1998

In

center

console

Automatic

Climate

(A/C)

Control

1992-1998

Behind

center

console

Module

AutomaticTransmission

Range

1992-1998

~

Next

to

gear

shift

lever

in

center

console

Fig

.

29

.

Switch

(Gear

Position/Neutral

Safety

Switch)

Auxiliary

Cooling

Fan

Dual

Switch

1992-1998

Right

side

radiator

1

Fig

.

18

.

Auxiliary

Cooling

Fan

Motor

1992-1998

Behind

front

grill

Auxiliary

Fuse

Box

(Left

Splice

1992-1998

I

Behind

left

front

footwell

kick-panel

Panel)

Auxiliary

RelayPanel

1

1992-1998

1

Left

side

of

dash

under

steering

column

Auxiliary

Fuse

Box

In

Trunk

1

1997-1998

1

Right

sideof

trunk

behind

trim

panel

AuADSry

ThrottlePosition

Motor

11994-1998

Front

of

engine

compartment

B+

Jump

Start

Junction

Point

1992-1998

Right

rear

of

engine

compartment

Fig

.

7

.

Back-Up

Light

Switch

(Manual)

1992-1998

Right

or

left

side

top

of

transmission

Fig

.

30

.

Body

Electronics

Control

Module

1994-1998

Behindglove

compartment

Fig

.

8

.

(ZKE

IV)

Fig

.

9

.

Brake

Fluid

Level

Sensor

1992-1998

Top

of

brake

fluid

reservoir

at

master

cylinder

Fig

.

15

.

Brake

Light

Switch

1

1992-1998

1

On

brake

pedal

supportbracket

Brake

Pad

Sensor,

Left

Front

1

1992-1998

1

Left

front

brake

caliper

Brake

Pad

Sensor,

Right

Rear

1992-1998

Right

rear

brake

caliper

Camshaft

Actuator

(VANOS)

1993-1998

Front

of

cylinder

head

Camshaft

Position

Sensor

(Cylinder

1992-1998

Front

of

engine

Identification)

Carbon

Canister

Valve

(TLEV)

1

1997-1998

1

In

sparewheel

well

in

trunk

ELECTRICAL

COMPONENT

LOCATIONS

610-11

Fig

.

5

.

Fig

.

4

.

Fig

.

24

.

Fig

.

7

.

Central

Locking

Module

(ZVM)

11992-1993

1

Behindglove

compartment

I

Fig

.

8

.

Fig

.

9

.

Check

Control

Module

(if

applicable)

1

1992

-

1998

1

Below

left

side

of

dash

Child

Protection

Window

Control

1992-1998

Center

console

(console)

Chime

Module

1992-1998

Below

left

side

of

dash

inleft

dash

trim

panel

Clock

(Multi-Function)

1993-1998

Center

console

Clutch

Pedal

Switch

1992-1998

On

clutch

pedal

support

bracket

Continued

COMPONENT

LOCATIONS