electric system BMW 325i 1992 E36 Repair Manual

[x] Cancel search | Manufacturer: BMW, Model Year: 1992, Model line: 325i, Model: BMW 325i 1992 E36Pages: 759

Page 306 of 759

400-

4

BODY-GENERAL

INTERIOR

EQUIPMENT

E36

interiors

have

a

unique

character,

with

a

combínation

of

sporty

features

and

innovative

design

.

Al¡

body

versions

were

made

in

a

wide

choice

of

interior

and

exterior

colors

.

New

colors

with

matching

leather

and/or

fabric

upholstery

were

in-

troduced

for

each

model

year,

including

light-alloy

wheels

in

new

designs

.

Driving

comfort

is

enhanced

by

power

steering,

tilt

steering

wheel

(optional),

height-adjustable

front

seats,

and

electrical-

ly

adjustable

and

heated

rear-view

mirrors

.

Inside

thecar

there

are

reading

lights

at

four

seating

positions

.

Seats

and

Seat

Belts

NOTE-

Theseat

base

usedon

cars

with

pyrotechnic

seatbelt

Anatom¡cal

ly-correct

seats

are

constructed

from

polyure-

tensioners

is

not

interchangeable

with

the

earlier

seat

thane

foam

containing

areas

or

"zones"

of

different

firmness

.

base

.

The

seat

bases

have

steel

springs

for

added

support

and

strength

.

The

power

seats

are

provided

with

conveniently

lo-

Instruments

and

Controls

cated

switches

along

the

outside

edge

of

the

seat

.

Heated

seats

are

an

option

in

all

models

.

See

520

Seats

for

more

de-

Everything

in

the

interior

passenger

compartment

essential

tails

.

to

the

driver

is

logically

grouped

and

easy

to

reach

.

Al¡

instru-

ments

and

controls

havebeen

arranged

ergonomically

and

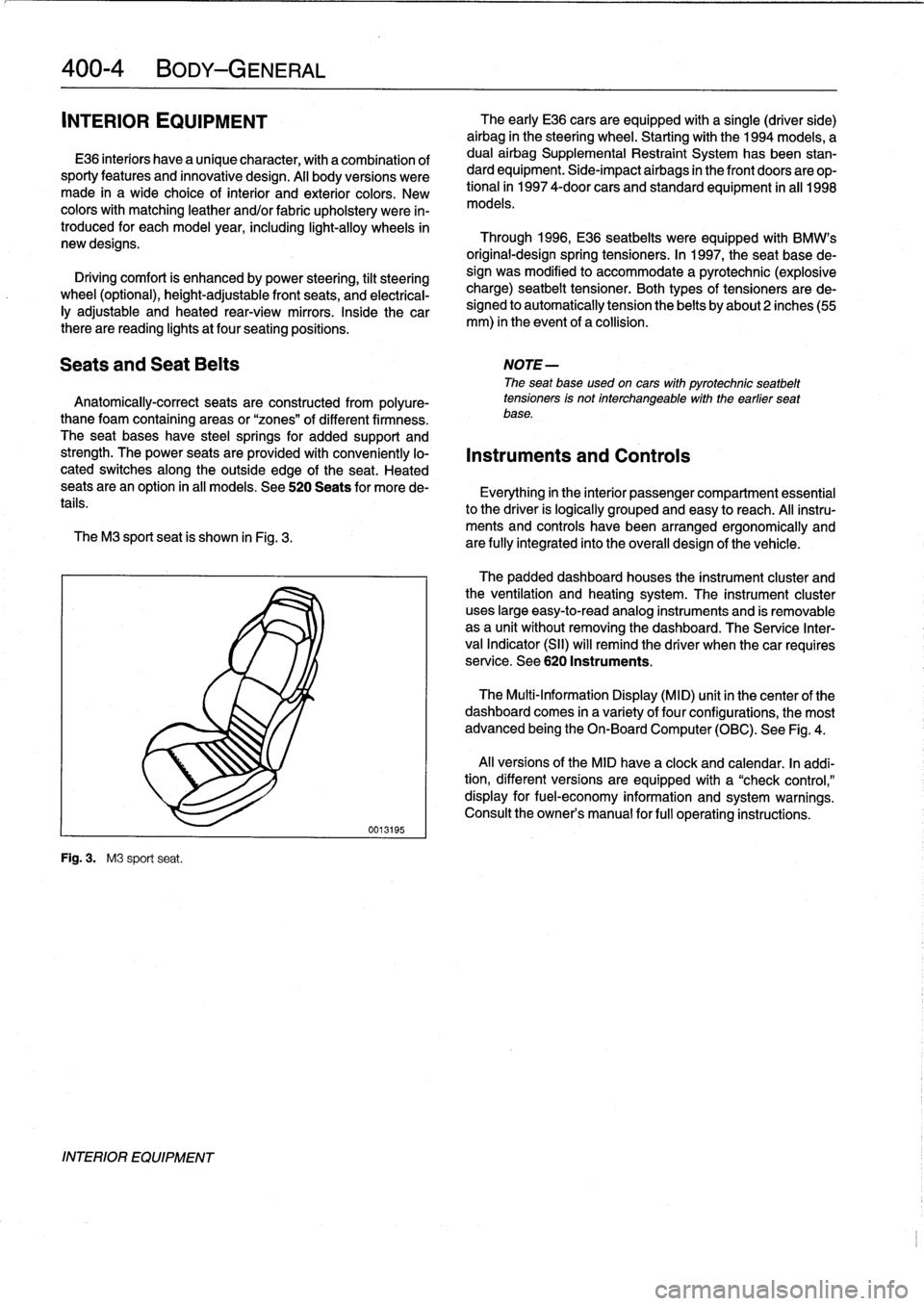

The

M3

sport

seat

is

shown

in

Fig

.

3

.

are

fully

integrated

into

the

overall

design

of

the

vehicle

.

Fig

.

3

.

M3

sport

seat

.

INTERIOR

EQUIPMENT

0013195

The

early

E36

cars

areequipped

with

a

single

(driver

side)

airbag

in

the

steering

wheel

.

Startingwith

the

1994

models,

a

dual

airbag

Supplemental

Restraint

System

has

been

stan-

dard

equipment

.

Side-impact

airbags

in

the

front

doors

are

op-

tional

in

1997

4-door

cars

and

standard

equipment

in

all

1998

models

.

Through

1996,

E36

seatbelts

were

equipped

with

BMW's

original-designspring

tensioners

.

In

1997,

the

seat

base

de-

sign

was

modified

to

accommodate

a

pyrotechnic

(explosive

charge)

seatbelt

tensioner

.

Both

types

of

tensioners

arede-

signed

to

automatically

tension

the

belts

by

about2

inches(55

mm)

in

the

event

of

a

collision

.

The

padded

dashboard

houses

the

instrument

cluster

and

the

ventilation

and

heating

system

.

The

instrument

cluster

uses

large

easy-to-read

analog

instruments

and

is

removable

as

a

unit

without

removing

the

dashboard

.

The

Service

Inter-

val

Indicator

(SII)

will

remind

the

driver

when

thecar

requires

service

.

See

620

Instruments

.

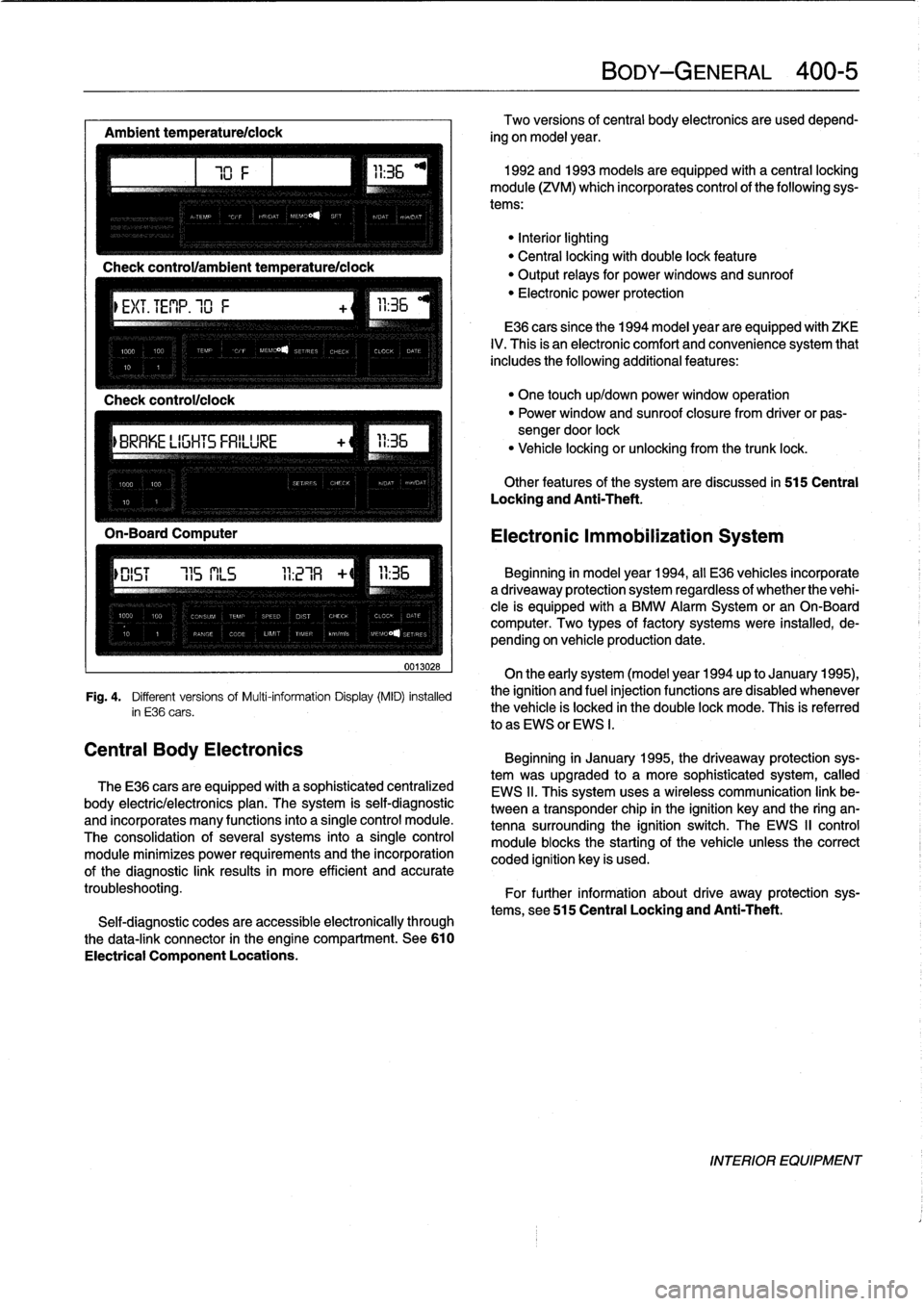

The

Multi-Information

Display

(MID)

unit

in

thecenter

of

the

dashboard

comes

in

a

variety

of

four

configurations,

the

most

advanced

being

the

On-Board

Computer

(OBC)

.

See

Fig

.

4

.

Al¡

versions

of

the

MID

have

a

clock

and

calendar

.

In

addi-

tion,

different

versions

areequipped

with

a

"check

control,"

display

for

fuel-economy

information

and

system

warnings

.

Consult

the

owner's

manual

for

fui¡

operating

instructions

.

Page 307 of 759

Ambient

temperaturelclock

MÍM

Aa

.Mi}rm

-Mil"

IMua~naa~u~itacar

"

za

.~

Central

Body

Electronics

0013028

Fig

.

4

.

Different

versionsof

Multi-information

Display(MID)

installed

in

E36

cars

.

The

E36

cars

are

equipped

with

a

sophisticated

centralized

body

electric/electronics

plan

.

The

system

is

self-diagnostic

and

incorporates

many

functions

into

a

single

control

module

.

The

consolidation

of

several

systems

into

a

single

control

module

minimizes

power

requirements

and

the

incorporation

of

the

diagnostic

link

results

in

more

efficient

and

accurate

troubleshooting

.

Self-diagnostic

codes

are

accessible

electronically

through

the

data-link

connector

in

the

engine

compartment

.

See610

Electrical

Component

Locations

.

BODY-GENERAL

400-

5

Two

versions

of

central

body

electronics

are

used

depend-

ing

on

model

year

.

1992

and

1993

models

are

equipped

with

a

central

locking

module

(ZVM)

which

incorporates

control

of

the

following

sys-

tems

:

"Interiorlighting

"

Central

locking

with

double

lock

feature

"

Output

relays

for

powerwindows

and

sunroof

"

Electronic

power

protection

E36

cars

since

the

1994

model

year

are

equipped

with

ZKE

IV

.

This

is

an

electronic

comfort

and

convenience

system

that

includes

the

following

additional

features

:

"

One

touch

up/down

power

window

operation

"

Power

window

and

sunroof

closure

from

driver

or

pas-

sengerdoor

lock

"

Vehicle

locking

or

unlocking

from

the

trunk

lock

.

Other

features

of

the

system

are

discussed

in

515

Central

Locking

and

Anti-Theft

.

Electronic

Immobilization

System

Beginning

in

model

year

1994,

all

E36

vehicles

incorporate

adriveaway

protection

system

regardless

of

whether

the

vehi-

cle

is

equipped

with

a

BMW

Alarm

System

or

an

On-Board

computer

.

Two

types

of

factory

systems

were

installed,

de-

pending

on

vehicle

production

date

.

On

the

early

system

(model

year

1994

up

to

January

1995),

the

ignition

and

fuel

injection

functions

are

disabled

whenever

the

vehicle

is

locked

in

the

double

lock

mode

.

This

is

referred

lo

as

EWS

or

EWS

I

.

Beginning

in

January

1995,

the

driveaway

protection

sys-

tem

was

upgraded

to

a

more

sophisticated

system,

called

EWS

II

.

This

system

uses

a

wireless

communication

link

be-

tween

a

transponder

chip

in

the

ignition

keyand

the

ring

an-

tenna

surrounding

the

ignition

switch

.

The

EWS

II

control

module

blocksthe

starting

of

the

vehicle

unlessthe

correct

coded

ignition

key

is

used

.

For

further

information

about

drive

away

protection

sys-

tems,

see

515

Central

Locking

and

Anti-Theft

.

INTERIOR

EQUIPMENT

Page 312 of 759

410-4

FENDERS,

ENGINE

HOOD

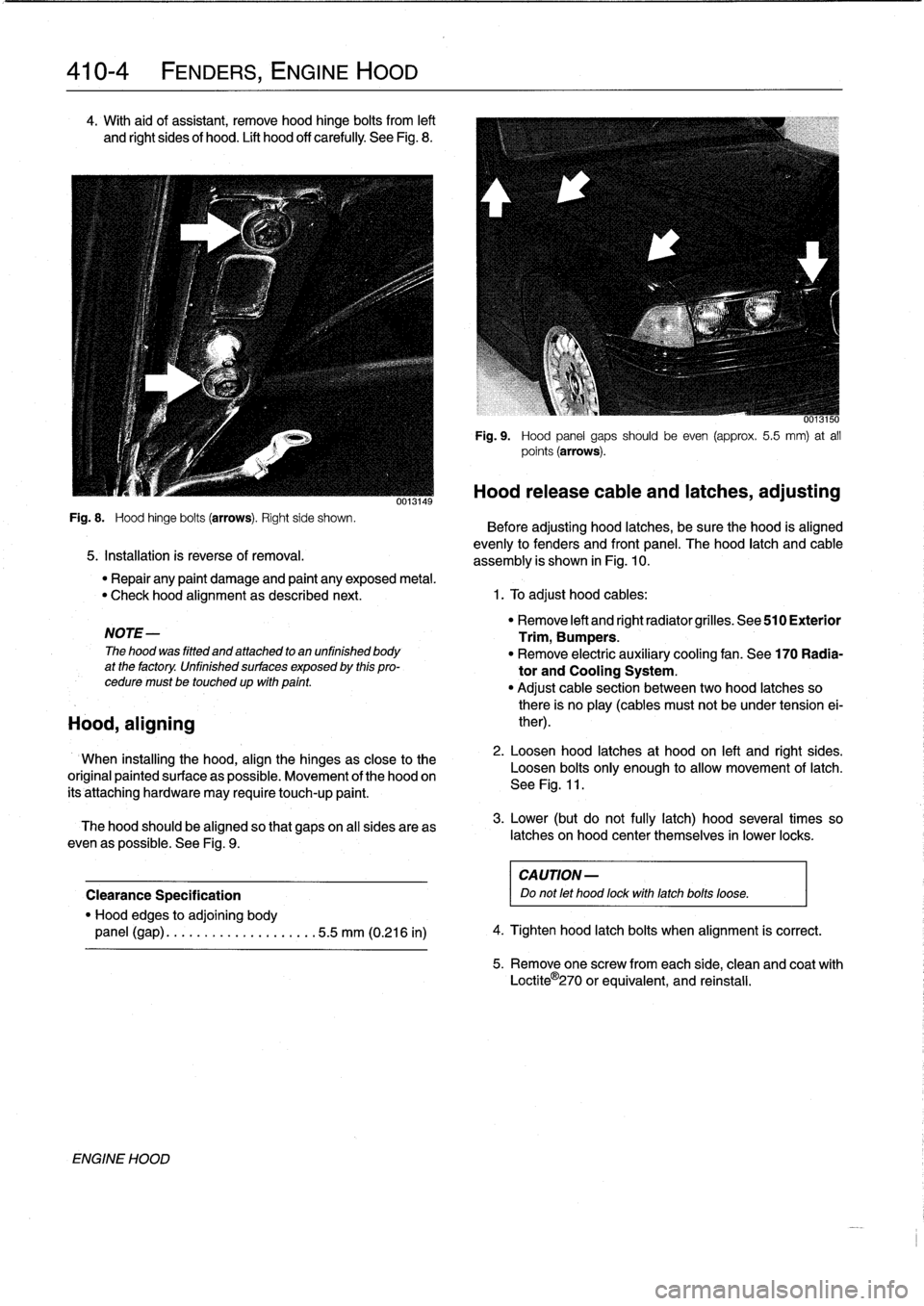

4

.

With

aid

of

assistant,

remove

hood

hinge

bolts

from

left

and

Rght

sides

of

hood

.

Lift

hood

off

carefully

See

Fig

.

8

.

Fig

.

8

.

Hood

hinge

bolts

(arrows)

.

Right

side

shown

.

5

.

Installation

is

reverse

of

removal

.

NOTE-

The

hood

was

fitted

and

attached

to

an

unfinished

body

at

the

factory

.

Unfinished

surfaces

exposed

by

this

pro-

cedure

must

betouchedup

wfth

pafnt

.

Hood,

aligning

ENGINE

HOOD

0013149

6013150

Fig

.

9

.

Hood

panel

gaps

should

be

even

(approx

.

5

.5

mm)

at

all

points

(arrows)

.

Hood

release

cable

and

latches,

adjusting

Before

adjusting

hood

latches,

be

sure

the

hood

is

aligned

evenly

to

fenders

and

front

panel

.

The

hood

latch

and

cable

assembly

is

shown

in

Fig

.

10

.

"

Repair

any

paint

damage

and

paint

any

exposed

metal

.

"

Check

hood

alignment

as

described

next

.

1

.

To

adjust

hood

cables

:

When

installing

the

hood,

align

the

hinges

as

close

to

the

original

paintedsurface

as

possible

.

Movement

of

the

hood

on

its'attaching

hardware

may

require

touch-up

paint

.

The

hood

should

be

aligned

so

that

gapson

all

sides

areas

even

as

possible

.

See

Fig

.

9

.

Clearance

Specification

"

Hood

edges

to

adjoining

body

panel

(gap)

........

..

..

..

.....

.5

.5

mm

(0.216

in)

"

Remove

left

and

right

radiator

grilles

.

See

510

Exterior

Trim,

Bumpers

.

"

Remove

electric

auxíliary

cooling

fan

.

See

170

Radia-

tor

and

Cooling

System

.

"

Adjust

cable

section

between

two

hood

latches

so

there

is

no

play

(cables

must

not

be

under

tension

ei-

ther)

.

2

.

Loosen

hood

latches

at

hood

on

left

and

right

sides

.

Loosen

bolts

only

enough

to

allow

movement

of

latch

.

See

Fig

.

11

.

3

.

Lower

(but

do

not

fully

latch)

hood

severa¡

times

so

latches

on

hood

center

themselves

in

lower

locks

.

CA

UTION-

Do

not

let

hood

fockwith

latchbolts

loose

.

4

.

Tighten

hood

latch

bolts

when

alignment

is

correct

.

5

.

Remove

one

screw

fromeach

side,

clean

and

coat

with

Loctite

O

270

or

equivalent,

and

reinstall

.

Page 346 of 759

513-2

INTERIOR

TRim

DASHBOARD

Dashboard

removal

is

a

complex

operation,

involving

dis-

connection

and

dismantling

of

a

number

of

electrical

and

dash

structural

components

.

The

BMW

E36

is

equipped

with

SRS

airbags

mounted

in

the

steering

wheel,

in

the

dashboard

(1994

and

later)

on

the

passenger

side,

and

in

the

front

doors(1997

and

later)

.

Air-

bags

units

are

pyrotechnic

devices

and

should

be

treated

with

extreme

caution

.

Improper

handling

of

the

airbags

could

cause

serious

injury

.

WARNING

-

"

The

BMW

Supplemental

Restraint

System

(SRS)

is

complex

and

special

precautions

must

be

ob-

served

when

servicing

.

Serious

injury

may

result

if

system

service

is

attempted

by

persons

unfa-

miliar

with

the

BMW

SRS

and

its

approved

ser-vice

procedures

.

BMW

specifies

that

all

inspection

and

service

shouldbe

performed

byan

authorized

BMW

dealer

.

"

Beforeperforming

any

work

involving

the

steering

wheel

or

interior

trim

in

the

vicinity

of

the

airbags,

disconnect

the

negative

()

battery

cable

.

See

721

Airbag

System

(SRS)

.

"

SRS

contains

aback-up

power

supply

within

the

SRS

control

module

.

A

10

minute

díscharge

peri-

od

should

be

allowed

after

the

battery

cable

has

been

disconnected

.

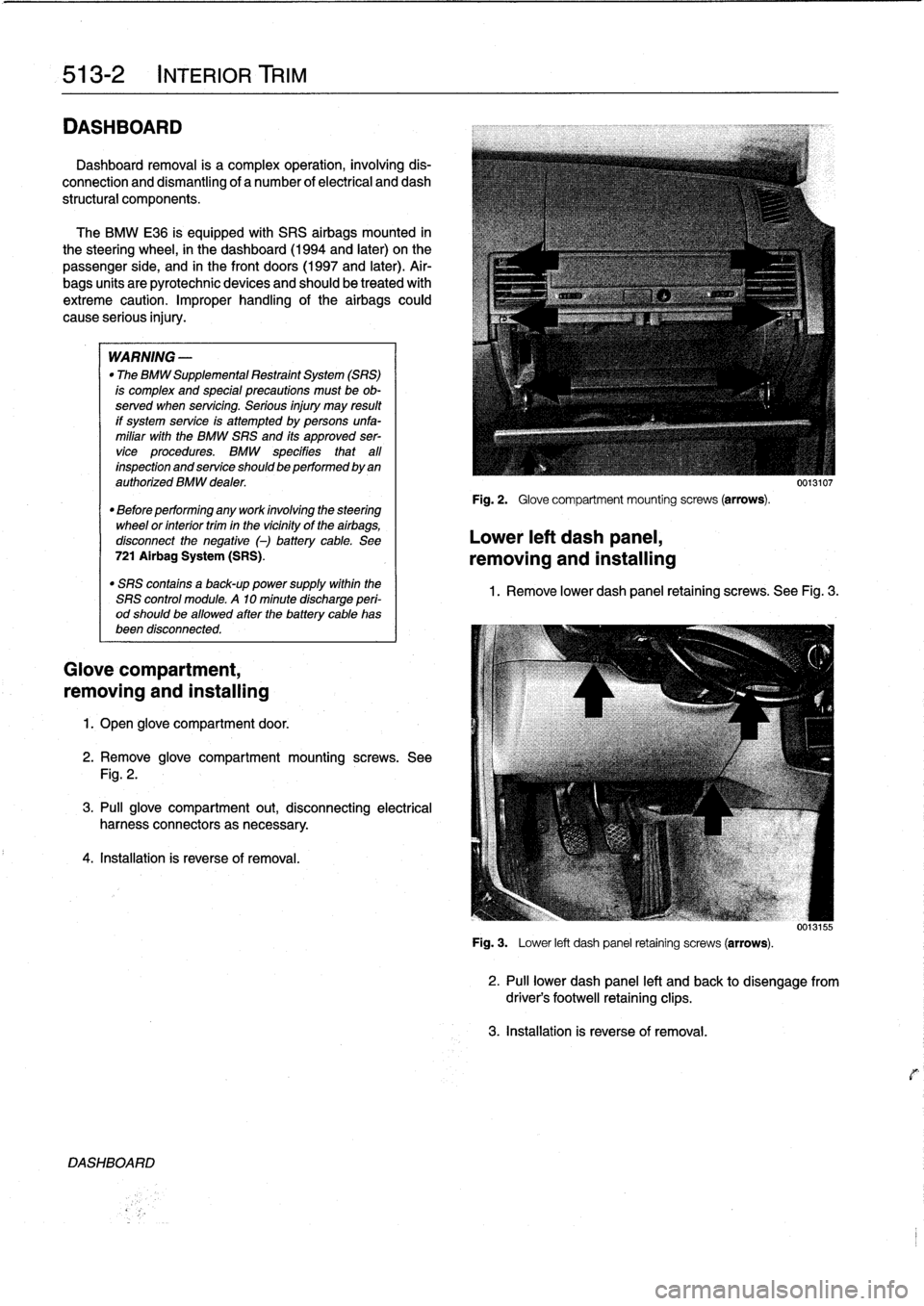

Glove

compartment,

removing

and

installing

1.

Open

glove

compartment

door

.

2

.

Remove

glove

compartment

mounting

screws

.

See

Fig

.

2

.

3

.

Pull

glove

compartment

out,

disconnecting

electrical

harness

connectors

as

necessary

.

4

.

Installation

is

reverse

of

removal

.

DASH80ARD

Fig

.

2

.

Glove

compartment

mounting

screws

(arrows)

.

Lower

left

dash

panel,

removing

and

installing

0013107

1

.

Remove

lower

dash

panel

retaining

screws

.

See

Fig

.

3

.

0013155

Fig

.

3

.

Lower

left

dash

panel

retaining

screws

(arrows)

.

2

.

Pull

lower

dash

panel

left

and

back

to

disengagefrom

driver's

footwell

retaining

clips

.

3

.

Installation

is

reverse

of

removal

.

Page 347 of 759

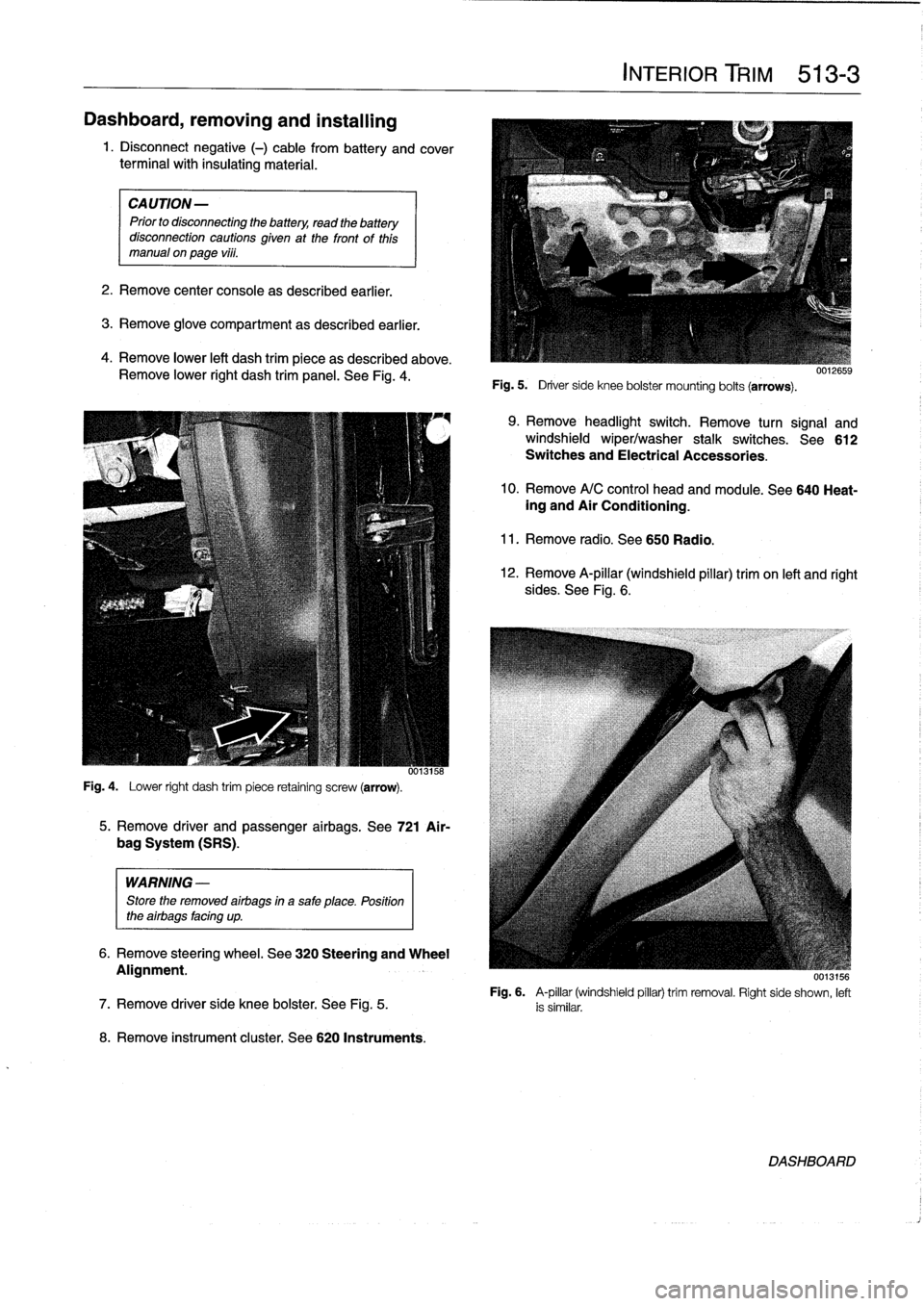

Dashboard,

removing

and

installing

1

.

Disconnect

negative

(-)

cable

from

battery

and

cover

terminal

with

insulating

material

.

CAUTION-

Prior

to

disconnectiog

the

battery,

read

the

battery

disconnection

cautionsgiven

at

the

front

of

this

manual

onpage

vi¡¡

.

2

.

Remove

center

console

as

described

earlier

.

3

.

Remove

glove

compartment

as

described

earlier

.

4

.

Remove

lower

left

dash

trim

piece

as

described

above

.

Remove

lower

right

dash

trim

panel

.

See

Fig

.

4

.

Fig

.

4

.

Lower

right

dash

trim

piece

retaining

screw

(arrow)

.

WARNING

-

Store

the

removed

airbags

in

a

safe

place

.

Position

the

airbags

facing

up

.

8

.

Remove

instrument

cluster

.

See

620

Instruments

.

5

.

Remove

driver

and

passenger

airbags

.

See

721

Air-

bag

System

(SRS)

.

6

.

Remove

steering

wheel

.

See

320

Steering

and

Wheel

Alignment

.

INTERIOR

TRIM

513-

3

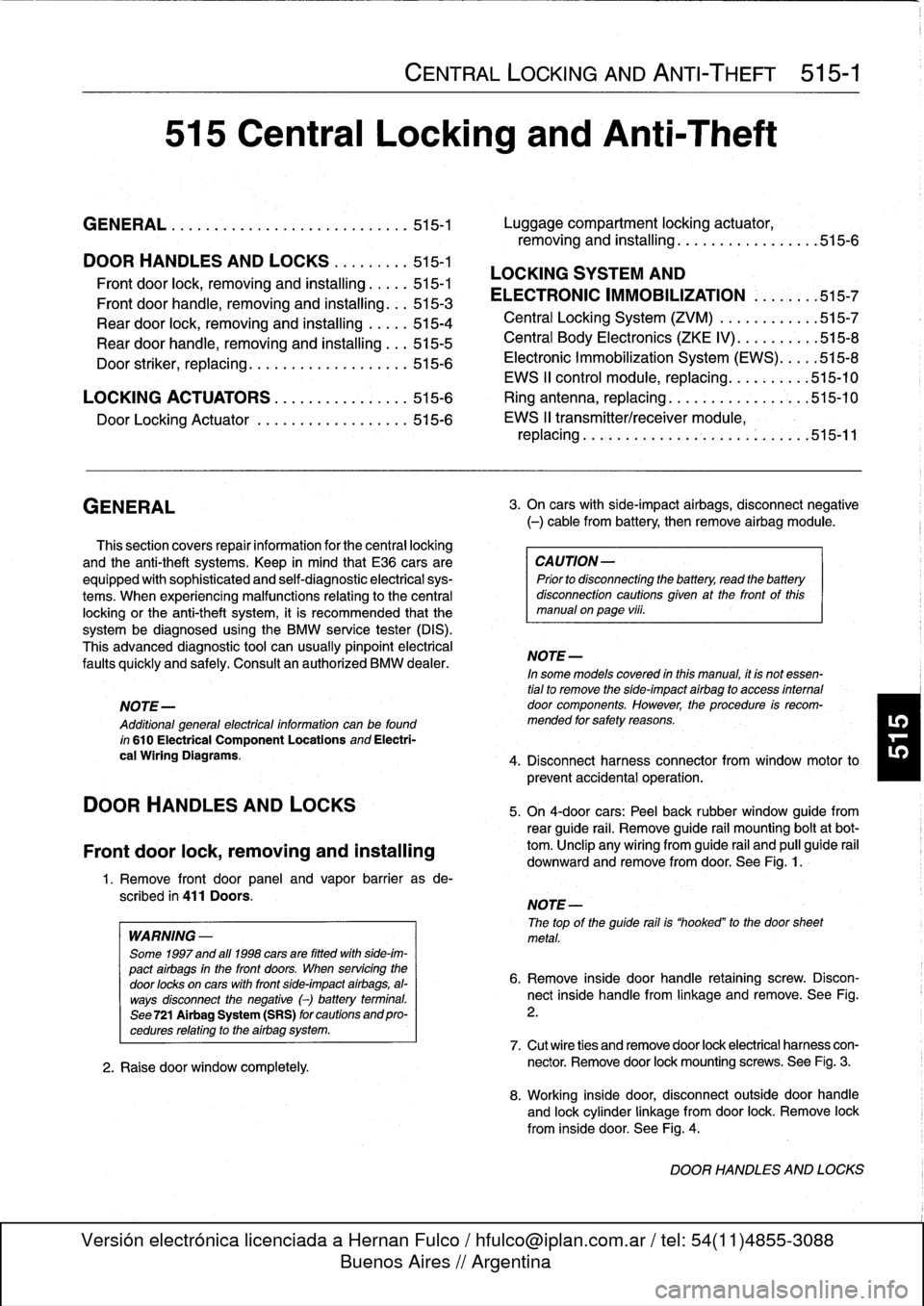

Fig

.

5

.

Driver

side

knee

bolster

mounting

bolts

(arrows)

.

9

.

Remove

headlight

switch

.

Remove

turn

signal

and

windshield

wiper/washer

stalk

switches

.

See612

Switches

and

Electrical

Accessories

.

10

.

Remove

A/C

control

head

and

module

.

See

640

Heat-ing

and

Air

Conditioning

.

11

.

Remove

radio

.

See650

Radio

.

12

.

Remove

A-pillar

(windshield

pillar)

trim

on

left

and

right

sides

.

See

Fig

.

6

.

UU13156

Fig

.

6

.

A-pillar

(windshield

pillar)

trim

removal

.

Right

side

shown,

left

7

.

Remove

driver

side

knee

bolster

.

See

Fig

.

5

.

is

similar

.

DASHBOARD

Page 349 of 759

515

Central

Locking

and

Anti-Theft

GENERAL

.....

.

.

.

.

.

.

.

..:

.

.

.

......

.

.

.

.

515-1

Luggage

compartment

locking

actuator,

removing

and

installing

.

.

.

.

.

...........

.

515-6

DOOR

HANDLES

AND

LOCKS

.........

515-1

LOCKING

SYSTEM

AND

Front

door

lock,

removing

and

installing

....

.515-1

ELECTRONIC

IMMOBILIZATION

......

.515-7

Front

door

handle,

removing

and

installing

...

515-3

Rear

door

lock,

removing

and

installing

.....

515-4

Central

Locking

System(ZVM)

.

.

.

.

.......

.

515-7

Rear

door

handle,

removing

and

installing

...

515-5

Central

Body

Electronics

(ZKE

IV)

.

.

.......

.515-8

Electronic

Immobilization

System

(EWS)

.

.

.

.

.515-8

Door

striker,

rep

lacing

.

.

.

.

.

.

.

.

.

..........

515-6

EWS

II

control

module,

re

lacin

515-10

LOCKING

ACTUATORS

.

.

.

.

.

.

..........

515-6

Ring

antenna,

replacing

.

.

.

.

.

.

.

.

.

.

...

.

.

.

.

515-10

Door

Locking

Actuator

.

.

.

.

.

.

.

.

..........

515-6

EWS

II

transmitter/receiver

module,

replacing

...........

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

515-11

GENERAL

This

section

covers

repair

information

for

the

central

locking

and

the

anti-theft

systems

.

Keep

in

mind

that

E36

cars

are

CA

UTION-

equipped

with

sophisticated

and

self-diagnostic

electrical

sys-

Prior

to

disconnecting

the

battery,

read

the

battery

tems

.

When

experiencing

malfunctions

relatinglo

the

central

disconnection

cautions

given

at

the

front

of

this

locking

or

the

anti-theft

system,

it

is

recommended

that

the

manual

onpage

vi¡¡

.

systembe

diagnosed

using

the

BMW

service

tester

(DIS)

.

This

advanced

diagnostic

tool

can

usually

pinpoint

electrical

NOTE-

faults

quickly

and

safely

.

Consult

an

authorized

BMW

dealer

.

In

some

models

covered

inthis

manual,

it

is

not

essen-

tial

to

remove

the

side-impact

airbag

to

access

intemal

NOTE-

door

components

.

However,

the

procedure

is

recom-

Additional

general

electrical

information

can

be

found

mended

for

safely

reasons

.

i

n

610

Electrical

Component

Locations

and

Electri-

cal

Wiring

Diagrams

.

4

.

Disconnect

harnessconnector

from

window

motor

to

DOOR

HANDLES

AND

LOCKS

Front

door

lock,

removing

and

installing

1

.

Remove

front

door

panel

and

vapor

barrier

asde-

scribed

in

411

Doors

.

WARNING

-

Some

1997

and

all

1998

cars

are

fitted

with

side-im-

pact

airbags

in

the

front

doors

.

When

servicing

the

door

locks

on

cars

with

front

side-impact

airbags,

al-

ways

disconnect

the

negative

(-)

battery

terminal

.

See721

Airbag

System

(SRS)

forcautions

andpro-

cedures

relating

to

the

airbag

system

.

2

.

Raise

door

window

completely

CENTRAL

LOCKING

AND

ANTI-THEFT

515-1

3

.

On

cars

with

side-impact

airbags,

disconnect

negative

(-)

cable

from

battery,

then

remove

airbag

module

.

prevent

accidental

operation

.

5

.

On

4-door

cars

:

Peel

back

rubber

window

guide

from

reas

guide

rail

:

Remove

guide

rail

mounting

boltat

bot-

tom

.

Unclip

any

wiring

from

guide

rail

and

pull

guide

rail

downward

and

remove

from

door

.

See

Fig

.

1

.

NOTE

-

The

top

of

the

guide

rail

is

"hooked"

to

the

doorsheet

metal

.

6

.

Remove

inside

door

handle

retaining

screw

.

Discon-

nect

inside

handle

from

linkage

and

remove

.

See

Fig

.

2

.

7

.

Cut

wire

ties

and

remove

door

lock

electrical

harness

con-

nector

.

Remove

door

lock

mounting

screws

.

See

Fig

.

3

.

8

.

Working

inside

door,

disconnect

outside

door

handle

and

lockcylinder

linkage

from

door

lock

.

Remove

lock

from

inside

door

.

See

Fig

.

4

.

DOOR

HANDLES

AND

LOCKS

Page 351 of 759

![BMW 325i 1992 E36 Repair Manual

Front

door

handle,

removing

and

installing

1

.

Closedoor

window

completely

.

2

.

Remove

front

door

panel

and

vapor

barrier

asde-

scribed

in

411

Doors

.

WARNING

-

Some

1997

and

al]

1998

cars

are

f BMW 325i 1992 E36 Repair Manual

Front

door

handle,

removing

and

installing

1

.

Closedoor

window

completely

.

2

.

Remove

front

door

panel

and

vapor

barrier

asde-

scribed

in

411

Doors

.

WARNING

-

Some

1997

and

al]

1998

cars

are

f](/img/1/2800/w960_2800-350.png)

Front

door

handle,

removing

and

installing

1

.

Closedoor

window

completely

.

2

.

Remove

front

door

panel

and

vapor

barrier

asde-

scribed

in

411

Doors

.

WARNING

-

Some

1997

and

al]

1998

cars

are

fitted

with

side-im-

pact

airbags

in

the

front

doors

.

When

servicing

the

door

handles

on

cars

with

front

side-impact

airbags,

always

disconnect

the

negative

(-)

battery

terminal

.

See

721

Airbag

System

(SRS)

for

cautions

and

pro-

cedures

relatíng

to

the

airbag

system

.

3

.

On

carswíth

side-impact

airbags,

disconnect

negative

(-)

cable

from

battery,

then

remove

airbag

module

.

CAUTION-

Prior

to

disconnecting

the

battery,

read

the

battery

disconnection

cautions

given

at

the

front

of

thís

manual

onpage

vi¡¡

.

NOTE-

In

some

models

covered

inthis

manual,

it

is

not

essen-

tial

to

remove

the

side-impact

airbag

to

access

internal

door

components

.

However,

the

procedure

is

recom-

mended

for

safety

reasons

.

4

.

Remove

door

lock

as

described

earlier

.

5

.

Remove

window

as

described

in

512

Door

Windows

.

CA

UTION-

On

models

with

side-impact

airbags,

removinglin-

stalling

the

front

window

requires

that

the

battery

cable

bereconnected

wíth

the

side-impact

airbag

disconnected

.

This

will

seta

fault

code

in

the

SRS

control

module,

turn

on

the

SRS

warning

light,

and

disable

the

SRS

system

until

the

fault

memo-

ry

is

cleared

usíng

special

SRS

test

equipment

.

6

.

Pry

out

access

plug

in

end

of

door

.

Use

screwdriver

through

access

hole

to

slide

exteriortrim

locking

plate

into

released

position

.

See

Fig

.

5

.

Remove

doorhandle

exterior

trim

piece

.

7

.

Working

inside

door,

remove

locking

clip

for

doorhan-

dle

retaining

pin

and

push

pin

out

.

8

.

Working

inside

door,

disconnect

electrical

harness

con-

nector

at

door

handle

.

Twist

plastic

connector

bracket

to

remove

from

door

handle

.

CENTRAL

LOCKING

AND

ANTI-THEFT

515-

3

0011681

Fig

.

5

.

Insert

screwdriver

into

access

hole

and

push

lockingplate

forward

(arrow)

to

release

exterior

handle

trim

.

uu11682

Fig

.

6

.

Door

handle

retaining

pin(A)

and

lock

collar

nut

(B)

.

Door

handle

trim

shown

removed

.

10

.

Remove

door

handle

fromdoor

by

angling

out

of

door

cavity

.

Removed

door

handle

assembly

is

shown

in

Fig

.

7

.

0012684

Fig

.

7

.

Door

handle

harnessconnector

(A)

;

retaining

pin

Iocking

clip

9

.

Working

at

door

exterior,

remove

handle

collar

nut

(B)

;

exterior

trim

Iocking

plate

(C)

.

Handleassembly

shown

re-

while

supporting

handle

.

See

Fig

.

6

.

moved

from

door

.

DOOR

HANDLES

AND

LOCKS

Page 355 of 759

002262

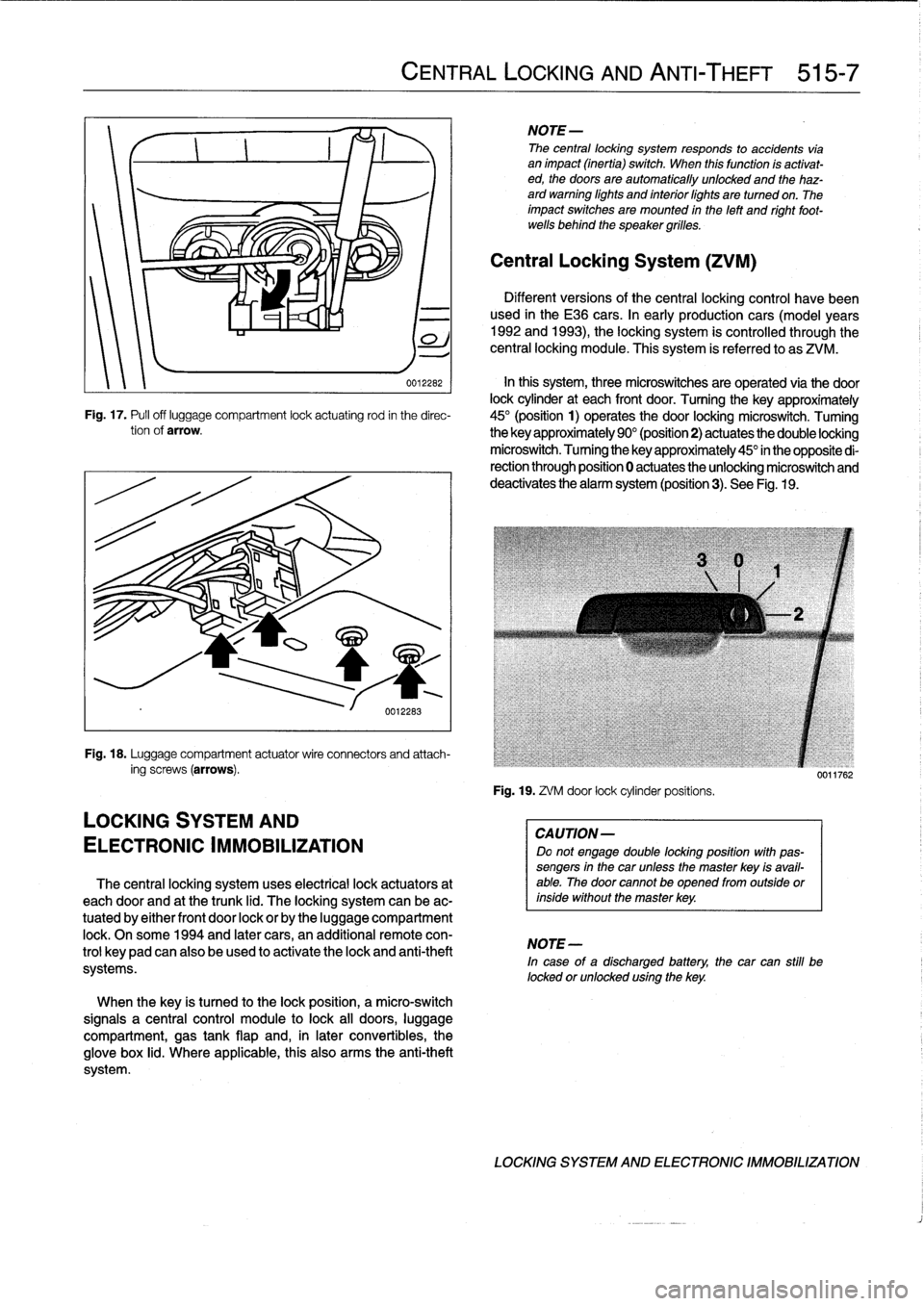

In

this

system,

three

microswitches

are

operated

via

the

door

lock

cylinder

at

each

front

door

.

Turning

the

key

approximately

Fig

.

17

.

Pufl

off

luggage

compartment

lock

actuating

rod

in

the

direc-

45°

(position

1)

operates

the

door

locking

microswitch

.

Tuming

tionof

arrow

.

the

key

approximately

90°

(position2)

actuates

the

double

locking

microswitch

.

Tuming

the

key

approximately

45°

in

the

opposite

di-

rection

through

position

0

actuates

the

unlocking

microswitch

and

deactivates

the

alarm

system

(position3)

.

See

Fig

.

19

.

Fig

.

18

.

Luggage

compartment

actuatorwire

connectors

and

attach-

ing

screws

(arrows)

.

LOCKING

SYSTEM

AND

ELECTRONIC

IMMOBILIZATION

The

central

locking

system

uses

electrical

lock

actuators

at

each

door

and

at

the

trunk

lid

.

The

locking

system

can

be

ac-

tuated

by

either

front

door

lock

or

by

the

luggage

compartment

lock

.

Onsome

1994

and

later

cars,

an

additional

remote

con-

trol

keypadcan

also

be

used

to

activate

the

lock

and

anti-theft

systems

.

When

the

key

is

tuned

to

the

lock

position,

a

micro-switch

signals

a

central

control

module

to

lock

all

doors,

luggage

compartment,

gas

tank

flap

and,

in

later

convertibles,

the

glove

box

lid

.

Where

applicable,

this

also

arms

the

anti-theft

system

.

CENTRAL

LOCKING

AND

ANTI-THEFT

515-7

NOTE-

The

central

locking

system

responds

to

accidents

vía

animpact

(inertia)

switch

.

When

this

function

ís

activat-

ed,

the

doors

are

automatically

unlocked

and

the

haz-

ard

warning

lights

and

interiorlights

are

turned

on

.

The

impact

switches

are

mounted

in

the

left

and

right

foot-

wells

behind

the

speaker

grilles

.

Central

Locking

System

(ZVM)

Different

versions

of

the

central

locking

control

havebeen

used

in

the

E36

cars

.

In

early

production

cars

(model

years

1992

and

1993),

the

locking

system

is

controlled

through

the

central

locking

module

.

This

system

is

referred

to

as

ZVM

.

Fig

.

19

.

ZVM

door

lock

cylinderpositíons

.

CAUTION-

Do

not

engage

double

locking

position

with

pas-

sengers

in

the

car

unless

the

master

key

isavail-

able

.

The

door

cannotbe

opened

from

outside

orinside

without

the

master

key

.

NOTE-

In

case

of

a

discharged

battery,

the

car

can

still

be

locked

orunlocked

using

the

key

.

0011762

LOCKING

SYSTEM

AND

ELECTRONIC

IMMOBILIZATION

Page 371 of 759

GENERAL

.

...

.

.

.

......

.

.

.

.

.

.

.

.

.

......

541-1

Visor

Latch

Plate

.....

.

....

.

.

.

.

.

...

.

...

.541-4

Visor

Latch

..

.

............

.

.

.

..........

541-4

MANUAL

CONVERTIBLE

TOP

.

.

.

.

...

.

..

541-1

Visor

Latch

Motor

...

.......

.

.

.

..

........

541-5

Visor

Latch

Plate

.

.

......

.

.

.

...

.

.

.

.

.

.

.

..

541-1

Convertible

top

and

frame,

replacing

........

541-5

VisorLatch

.

.

.

.

.

.

.

.

..........

.

.....

.

.

.541-1

Convertible

top

drive

motor,

replacing

......

541-7

Convertible

Top

Lid

Release

Mechanism

.

.

.

.

541-2

Convertible

Top

Emergency

Operation

.....

.541-7

Convertible

top

and

frame,

replacing

....

.

.

.

541-2

Convertible

Top

Lid

.

.

.

.

...........

.

.....

541-9

POWER

CONVERTIBLE

TOP

.

.

.

.

....

.

.

.

541-2

ROLLOVER

PROTECTION

SYSTEM

..

.

.

541-9

FrontLatching

Mechanism

.

.

.

.

.

.

.

.

......

.

541-4

GENERAL

The

convertible

top

comes

in

three

versions

:

a

manually

op-erated

top,

a

semi-automatic

power

top

and

a

fully

automatic

power

top

.

NOTE-

The

convertible

top

control

module

(CVM)

is

located

behind

the

left

rearside

trim

panel

.

For

the

location

of

other

convertible

top

electric

components

see610

Electrical

Component

Locations

.

The

rear

window

in

the

convertible

models

is

made

of

a

strong,

flexible

vínyl

which

is

available

separately

.

Replace-

ment

of

the

rear

window

is

not

covered

in

this

manual

.

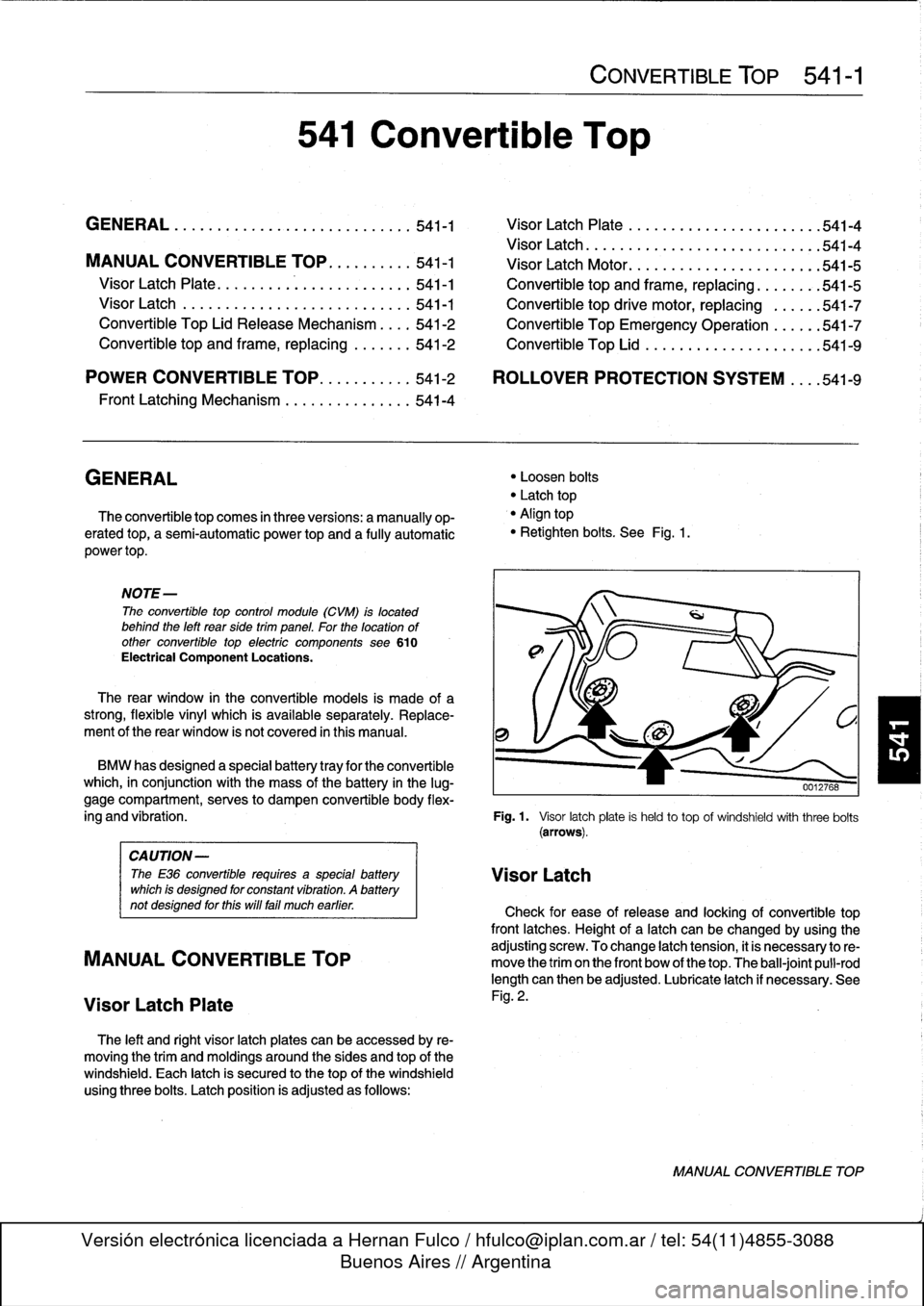

The

left

and

right

visor

latch

plates

can

be

accessed

by

re-

moving

the

trim

and

moldings

around

the

sides

and

top

of

the

windshield

.

Each

latch

is

secured

to

thetop

of

the

windshield

usingthree

bolts

.

Latch

position

is

adjusted

as

follows

:

541

Convertible

Top

CONVERTIBLE

TOP

541-1

"

Loosen

bolts

"

Latch

top

"

Align

top

"

Retighten

bolts

.

See

Fig

.

1

.

BMW

has

designed

a

specialbattery

tray

for

the

convertible

which,

in

conjunction

with

the

mass

of

the

battery

in

the

lug-

gage

compartment,

serves

to

dampen

convertible

body

flex

ing

and

vibration

.

Fig

.

1.

Visor

latchplate

is

held

to

top

of

windshieldwith

three

bolts

(arrows)

.

CAUTION-

The

E36

convertible

requires

a

specialbattery

VisorLatch

which

is

designed

for

constant

vibration

.

A

battery

not

designed

forthis

will

fa¡¡

much

earlier

.

Check

for

ease

of

release

and

locking

of

convertible

top

front

latches

.

Height

of

a

latch

can

be

changed

by

using

the

adjusting

screw

.

To

change

latch

tension,

it

is

necessary

to

re-

MANUAL

CONVERTIBLE

TOP

move

the

trim

on

the

front

bow

of

thetop

.

The

ball-joint

pull-rod

length

can

then

be

adjusted

.

Lubricate

latch

if

necessary

.

See

Visor

Latch

Plate

Fig

.

2

.

MANUAL

CONVERTIBLE

TOP

Page 377 of 759

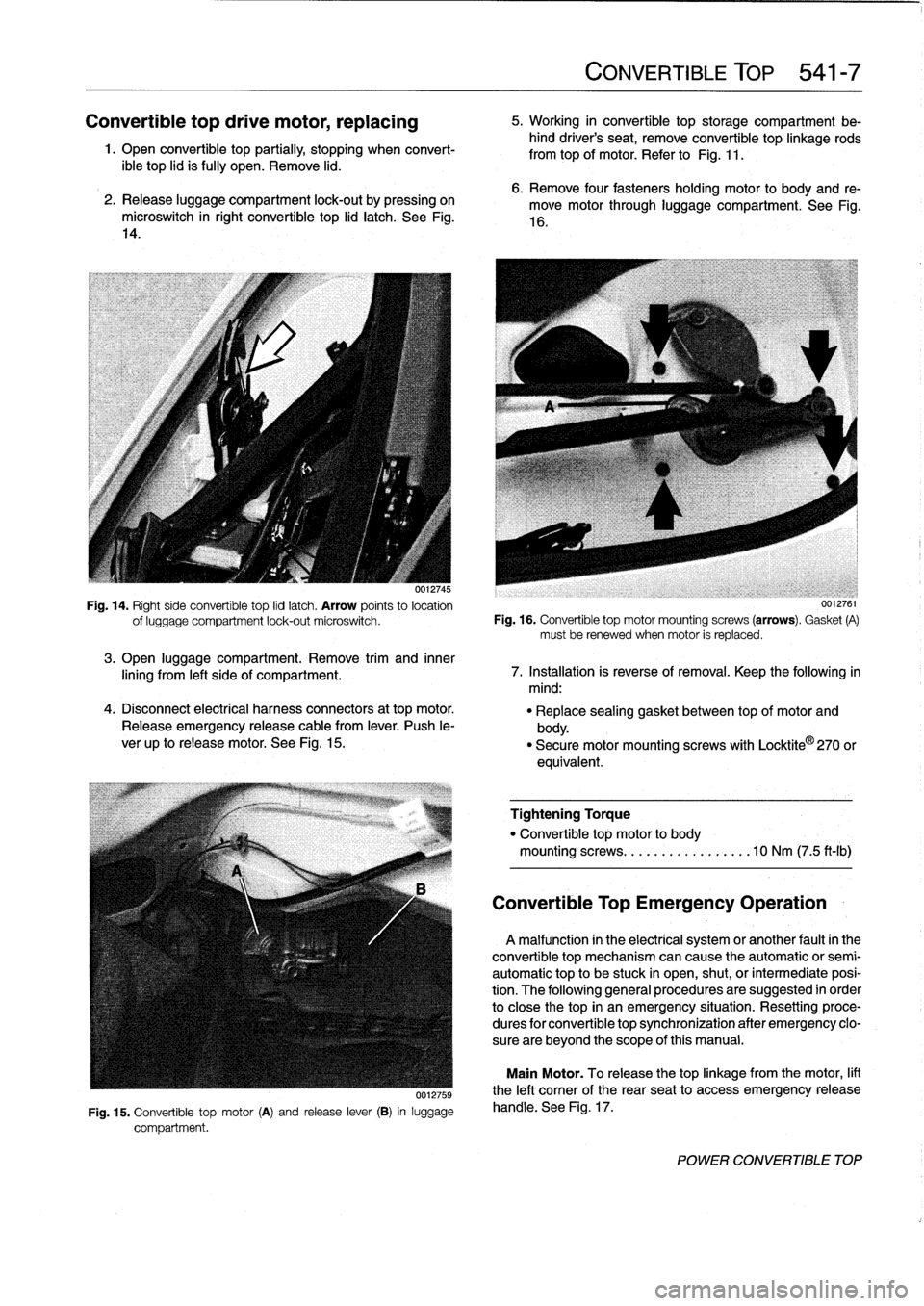

Convertible

top

drive

motor,

replacing

5

.

Working

in

convertible

top

storage

compartment

be-

hind

driver's

seat,

remove

convertible

top

linkage

rods

1

.

Open

convertible

top

partially,

stopping

when

convert-

from

top

of

motor

.

Refer

to

Fig

.

11

.

ible

top

lid

is

fully

upen

.

Remove

lid

.

2

.

Release

luggage

compartment

lock-out

by

pressing

on

microswitch

in

right

convertible

top

lid

latch

.

See

Fig

.

14

.

0012745

Fig

.

14

.

Rightside

convertible

top

lid

latch

.

Arrow

points

to

location

of

luggage

compartment

lock-out

microswitch

.

3

.

Open

luggage

compartment

.

Remove

trim

and

inner

lining

from

left

side

of

compartment

.

4

.

Disconnect

electrical

harness

connectors

at

top

motor

.

Release

emergency

release

cable

from

lever

.

Push

le-

ver

up

to

release

motor

.

See

Fig

.

15

.

uu12759

Fig

.

15

.

Convertible

top

motor

(A)

and

release

lever

(B)

in

luggage

compartment

.

CONVERTIBLE

TOP

541-

7

6

.

Remove

four

fastenersholding

motor

to

body

and

re-

move

motor

through

luggage

compartment

.

See

Fig

.

16

.

0012761

Fig

.

16

.

Convertible

top

motor

mountingscrews

(arrows)

.

Gasket

(A)

mustbe

renewed

when

motor

is

replaced

.

7

.

Installation

is

reverse

of

removal

.

Keep

the

following

in

mind

:

"

Replace

sealing

gasket

between

top

of

motor

and

body

.

"

Securemotormountingscrews

with

Locktite

®

270

or

equivalent

.

Tightening

Torque

"

Convertible

top

motor

to

body

mountingscrews

...

...

.

.

.........

10

Nm

(7

.5

ft-Ib)

Convertible

Top

Emergency

Operation

A

malfunction

in

the

electrical

system

or

another

fault

in

the

convertible

top

mechanism

can

cause

the

automatic

or

semi-

automatic

top

to

be

stuck

in

open,

shut,

or

intermediate

posi-

tion

.

The

following

general

procedures

are

suggested

in

order

to

close

the

top

in

an

emergency

situation

.

Resetting

proce-

dures

for

convertible

top

synchronization

after

emergency

clo-

sure

are

beyond

the

scope

of

this

manual

.

Main

Motor

.

To

release

thetop

linkage

from

the

motor,

lift

the

left

comer

of

the

rearseat

to

access

emergency

release

handle

.

See

Fig

.

17

.

POWER

CONVERTIBLE

TOP