Automatic transmission fluid check BMW 325i 1994 E36 User Guide

[x] Cancel search | Manufacturer: BMW, Model Year: 1994, Model line: 325i, Model: BMW 325i 1994 E36Pages: 759

Page 221 of 759

230

Manual

Transmission

MANUAL

TRANSMISSION

230-1

GENERAL

...

.

............

.

.......

.

.

.

.

230-1

Output

shaft

sea¡,

replacing

(transmission

installed)

....

.

.....

.

.....

.230-4

TRANSMISSION

FLUID

SERVICE

.

.

.

.

.

.

.230-1

Inputshaft

sea¡,

replacing

Transmission

fluid

leve¡,

checking

...

.

...

.

.

230-2

(transmission

removed)

.

.

.

.

...

.

.

.

.....

.

230-5

Transmission

fluid,

replacing

.........

.

.

.

.

230-2

TRANSMISSION

REMOVAL

AND

TRANSMISSION

SERVICE

.

.

.....

.

.

.

.

.

.

230-2

INSTALLATION

.

.

.

.

.

.

.....

.

.

.

.

.

.

.

.....

.

230-5

Back-up

light

switch,

replacing

.

.

.

...

.

.

.

.

.

.

230-2

Transmission,

removing

and

installing

...

.

.

.

.

230-6

_

Selector

shaft

sea¡,

replacing

(transmission

installed)

.

.

.

.

.

.

.

.

.

.

.

...

.

.

230-3

TAB

a

.

Manual

Transmission

Gear

Ratios

.

.

.

.........

.230-1

GENERAL

TRANSMISSION

FLUID

SERVICE

This

repair

group

covers

external

transmission

service,

in-

The

manual

transmissions

installed

in

the

E36

models

are

cluding

removal

and

installation

of

thetransmission

unit

.

Inter-

normally

filled

with

automatic

transmission

fluid

(ATF),

al-

nal

transmission

repair

is

not

covered

.

Special

press

tools

and

though

alternative

lubricants

may

have

beenused

from

the

procedures

are

required

to

disassemble

and

service

the

inter-

factory,

depending

on

transmission

type

and

model

year

.

For

nal

geartrain

.

example,

transmissions

fitted

to

the

M3

models

are

normally

filled

with

a

"lifetime"

manual

transmission

fluid

(BMW

MTF

Manual

transmissions

used

are

based

on

engine

applica-

LT-1)

and

do

not

require

periodic

fluid

changes

.

tion

.

Consult

200

Transmission-General

for

transmission

application

information

.

Table

a

lists

gear

ratio

specifications

.

NOTE-

The

transmission

lubricant

type

can

be

found

ona

label

NOTE-

on

the

sideof

the

transmission

.

Consult

an

authorized

Do

not

rely

on

forged

casting

numbers

for

transmission

BMW

dealer

for

altemate

fluid

use

and

the

most-up-to-

code

identification

.

date

information

regarding

transmission

operating

fluids

.

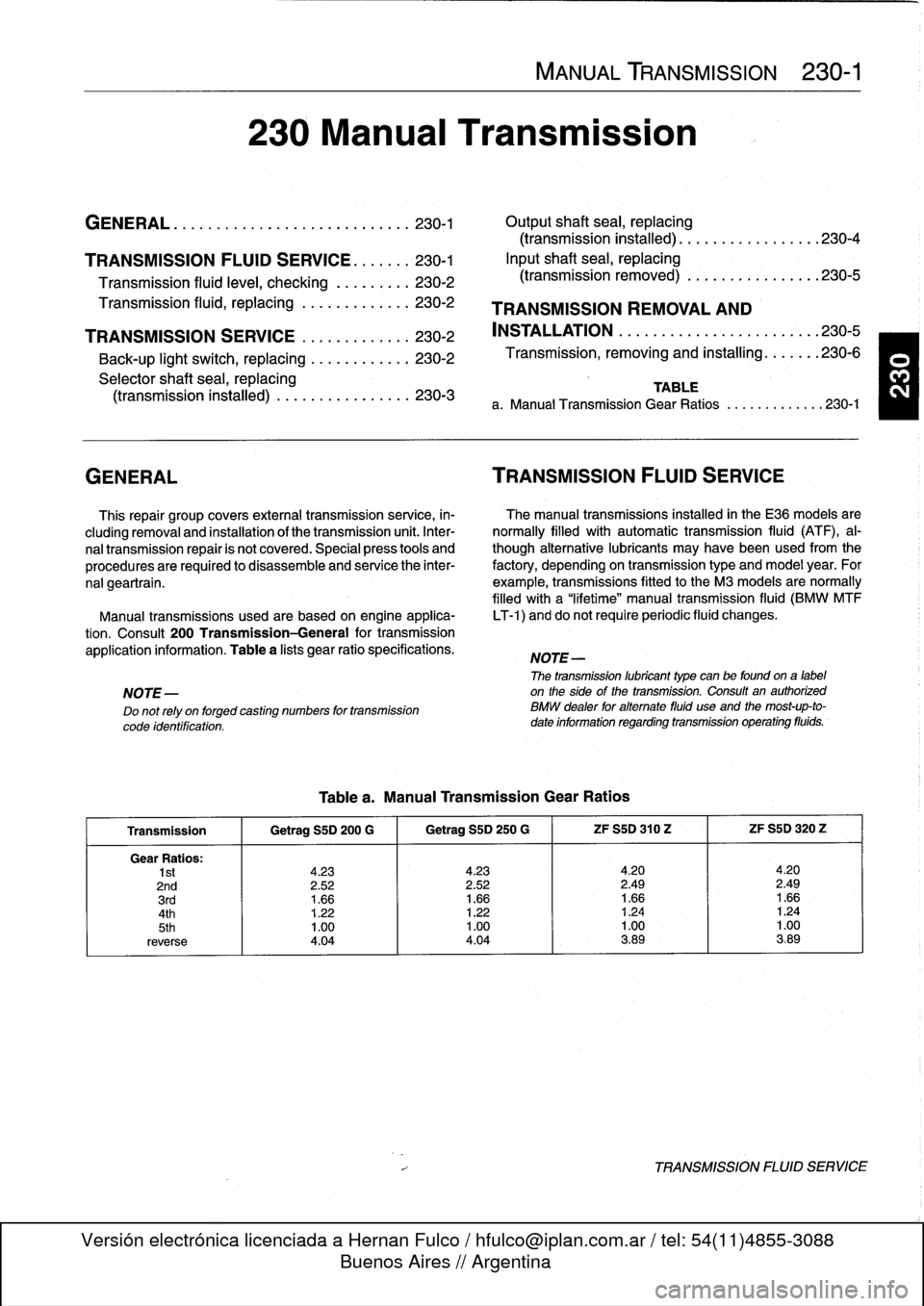

Tablea

.

Manual

Transmission

Gear

Ratios

Transmission

1

Getrag

S5D

200

G

1

Getrag

SSD

250

G

1

ZF

S5D

310

Z

1

ZF

S5D

320

Z

Gear

Ratios

:

1st

4

.23

4

.23

4

.20

4

.20

2nd

2

.52

2

.52

2

.49

2

.49

3rd

1

.66

1

.66

1

.66

1

.664th

1

.22

1

.22

1

.24

1

.24

5th

1

.00

1

.00

1

.00

1

.00

reverse

4

.04

4

.04

3

.89

3

.89

TRANSMISSION

FLUID

SERVICE

Page 229 of 759

AUTOMATIC

TRANSMISSION

240-1

240

Automatic

Transmission

GENERAL

.....

.

.

.

.

.

.

.

.

.

.

.

.

.

.........

.

240-1

TRANSMISSION

REMOVAL

AND

INSTALLATION

..................

.

.

.

.

.240-4

TRANSMISSION

SERVICE

.

.

.

.

.

.......

.

240-1

Transmission,

removing

and

installing

....

.

.

.240-4

ATF

leve¡,

checking

..

.

.

.

.

.

.

.

.

.

..........

240-1

ATF,

draining

and

filling

.

.

.

.

.

.

.

..........

240-2

TABLE

a

.

Automatic

Transmission

Gear

Ratios

.......

..

.

.

240-1

GENERAL

TRANSMISSION

SERVICE

lo

Automatic

transmissions

are

identified

by

code

letters

ATF

leve¡,

checking

foundon

a

data

plate

located

on

the

sideof

thetransmission

case,

behind

the

manual

valve

lever

.

See

200Transmis-

The

automatic

transmissions

installed

in

the

E36

models

sion-General

for

application

information

.

Forgear

ratio

spec-

are

normally

filled

with

Dexron

III

automatic

transmission

fluid

ifications,

see

Table

a

.

(ATF),

although

alternative

fluids

have

been

installed

from

the

factory,

depending

on

transmission

type

and

model

year

.

CAUTION-

Some

transmíssions

are

filled

with

a

special

BMW

"lifetime"

ATF

does

not

circulate

unless

the

engine

is

run-

automatic

transmission

fluid,

which

does

not

require

periodic

ning

.

When

towing

an

automafic

transmission

ve-

fluid

changes

.

hicle,

usea

flat-bed

truck

or

ralse

the

rear

wheels

off

the

ground

.

CAUTION-

Mixing

different

types

of

transmission

fluids

will

The

electronic

transmission

control

module

(TCM)

monitors

lead

to

transmission

failure

.

transmissionoperation

for

faults

and

alerts

the

driver

by

illumi-

nating

the

transmission

fault

indicator

on

the

instrument

pan-

el

.

On-board

diagnostic

codes

stored

in

the

TCM

mustbe

NOTE-

downloaded

and

interpreted

by

trained

technicians

using

spe-

The

transmission

lubricant

instafed

can

be

foundona

cial

BMW

diagnostic

equipment

.

type

plate

on

the

side

of

the

transmission

.

In

addition,

a

sticker

may

be

located

on

the

fluid

sump

indicatingthe

typeof

transmission

lubricant

used

.

Ifin

doubt,

con

NOTE-

sult

an

authorized

BMW

dealer

for

altemate

fluid

use

Internal

repairs

to

the

automatic

transmission

require

and

current

information

regardingtransmission

operat-

special

service

equipment

and

knowledge

.

If

it

is

deter-

ing

fluids

.

mined

thatinterna¡

service

is

required,

consult

en

au-

thorízedBMWdealerabouta

factoryreconditioned

unit

The

transmission

is

not

equipped

with

a

dipstick

.

Checking

or

a

transmission

rebuild

.

the

ATF

leve¡

requires

measuring

and

maintaining

a

specified

ATF

temperature

during

the

checking

procedure

.

The

check-

ing

temperature

is

not

fully

warm

orcold

(the

ATF

sump

should

be

approximately

warm

to

the

touch)

.

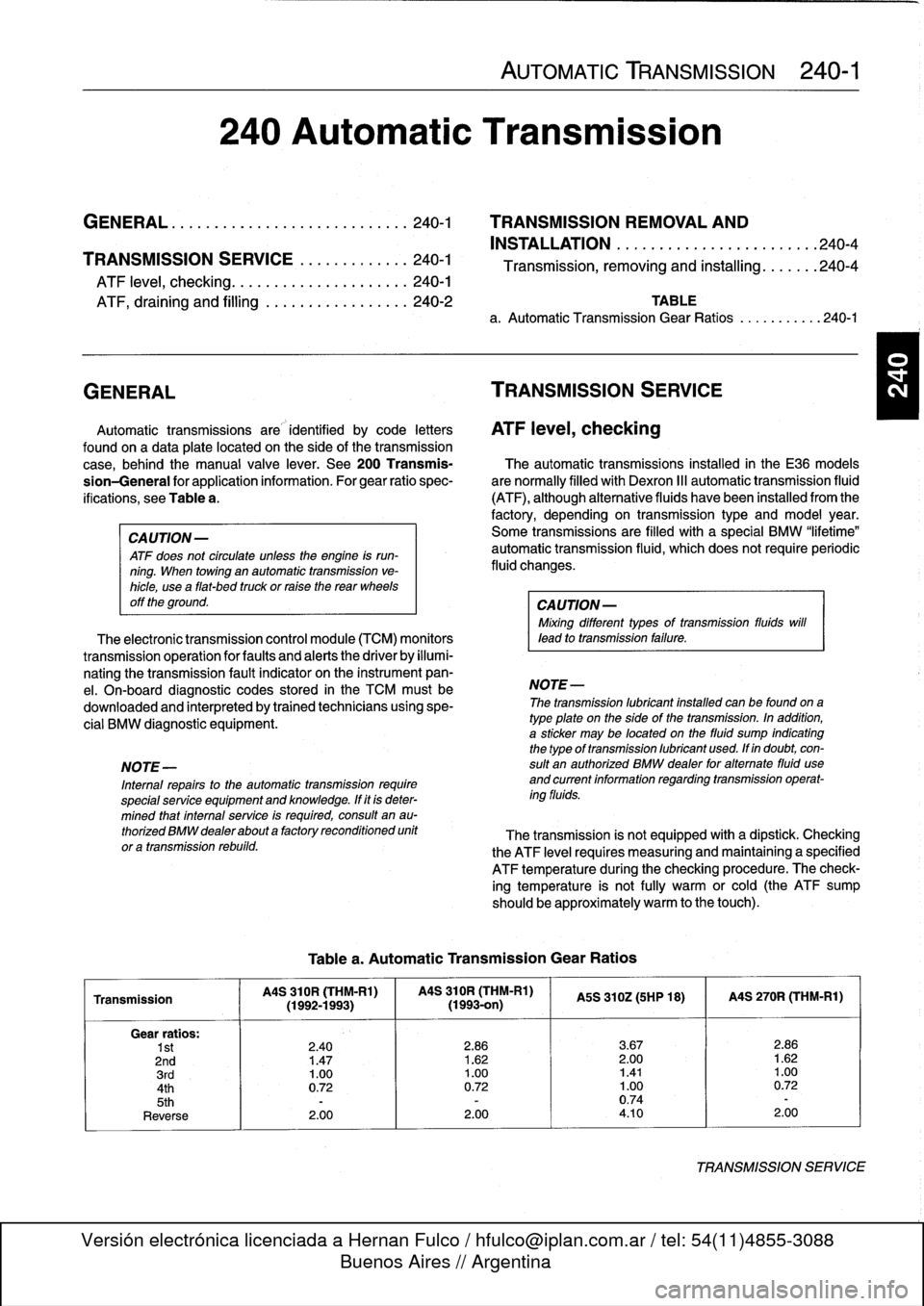

Table

a

.

Automatic

Transmission

Gear

Ratios

Transmission

MS

310R

(THM-R1)

MS

310R

(THM-Rl)

MS

310Z(5HP

18)

I

MS

270R

(THM-R1)

(1992-1993)(1993-on)

Gear

ratios

:

1st

2

.40

2

.86

3

.67

2

.86

2nd

1

.47

1

.62

2

.00

1

.62

3rd

1

.00

1

.00

1.41

1

.00

4th

0

.72

0

.72

1

.00

0

.72

5th

-

-

0

.74

-

Reverse

2

.00

2

.00

4

.10

2

.00

TRANSMISSIONSERVICE

Page 230 of 759

240-2

AUTOMATIC

TRANSMISSION

WARNING

-

If

the

appropriate

temperature

measuring

equip-

ment

is

not

available,

ATF

leve¡

checking

shouldbe

left

to

an

authorized

BMW

dealer

The

checking

pro-

cedure

should

be

done

on

a

lift

with

the

engine

run-

ning

in

neutral

.

In

addition,

the

transmission

fluid

temperature

must

be

maintained

within

a

narrow

range

duringthe

checking

procedure

.

1

.

Place

vehicle

on

a

lift

.

WARNING

-

To

lift

the

vehicle

safely,

see

010

Fundamentals

for

the

Do-it-Yourself

Owner

.

2

.

Warm

up

drivetrain

by

running

engine

until

ATF

reach-

es

specified

temperature

.

Apply

brake

and,

while

idling

engine,

shift

through

all

gears

severa¡

times

.

Turn

en-

gine

off

.

ATF

Level

Checking

"

Fluid

temperature

..

...........

30-55°C

(86-131°F)

3

.

Remove

ATF

fill

plug

.

Place

transmission

in

neutral

and

ATF,draining

and

filling

restart

engine

.

See

Fig

.

1

or

Fig

.

2

.

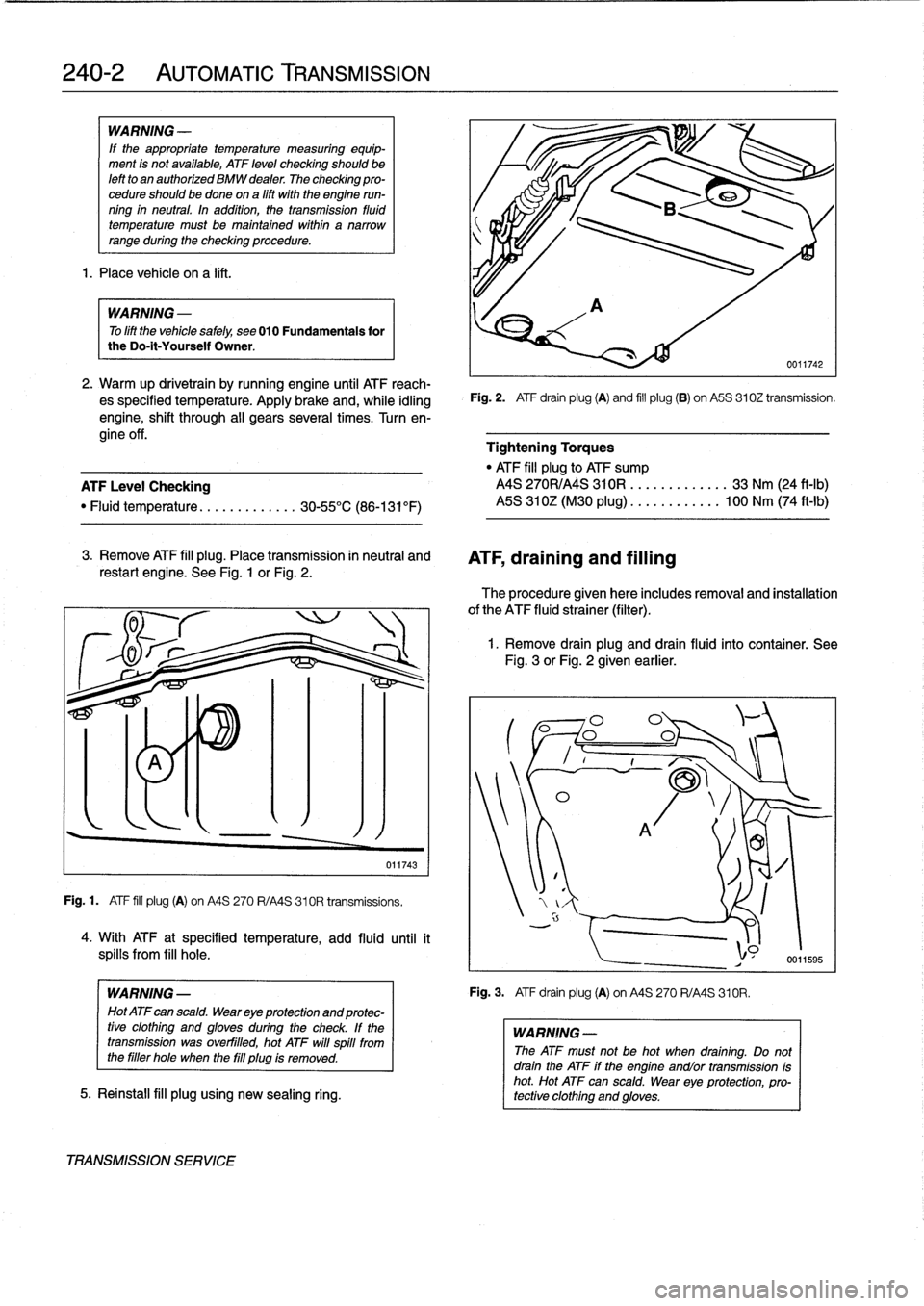

Fig

.

1

.

ATF

fill

plug

(A)

on

MS

270R/A4S310R

transmissions

.

4

.

With

ATF

at

specified

temperature,

add

(luid

until

it

spilis

from

fill

hole

.

WARNING

-

HotATFcan

scald

.

Weareye

protection

and

protec-

tive

clothing

and

gloves

duringthe

check

.

If

thetransmission

was

overfilled,

hot

ATF

will

spill

from

the

filler

hole

when

the

fill

plug

is

removed

.

5

.

Reinstall

fill

plug

using

new

sealing

ring

.

TRANSMISSION

SERVICE

011743

0011742

Fig

.

2

.

ATF

drain

plug

(A)

and

fill

plug

(B)

on

A5S

310Z

transmission

.

Tightening

Torques

"

ATF

fill

plug

to

ATF

sump

MS

270R/A4S

31

OR

.............

33

Nm

(24

ft-Ib)

MS

310Z

(M30

plug)

............

100

Nm

(74

ft-Ib)

The

procedure

given

here

includes

removal

and

installation

of

the

ATF

(luid

strainer

(filter)

.

1

.

Remove

drain

plug

and

drain

fluidinto

container

.

See

Fig

.

3

or

Fig

.

2

given

earlier

.

0~

0

/\1--Z

.IZ

~

~

A

~

"o

15/

Fig

.

3

.

ATF

drain

plug

(A)

on

A4S

270R/A4S

310R

.

WARNING

-

The

ATF

must

not

be

hot

when

draining

.

Do

not

drain

the

ATF

if

the

engineandlor

transmission

Is

hot

.

Hot

ATF

can

scald

.

Wear

eye

protection,

pro-

tective

clothing

and

gloves

.

0011595

Page 231 of 759

2

.

On

MS

270R/A4S

310R

transmissions

:

Remove

front

5

.

Installation

is

reverse

of

Rmoval

.

and

rear

oil

sump

mounting

bolts

andremove

sumps

"

Always

replace

sea¡

for

drain

plug

and

al¡

gasket(s)

andand

sump

gaskets

.

O-rings

.

"

Clean

sump

and

sump

magnet(s)

using

a

lint-free

NOTE-

cloth

.

The

MS

270

R/A4S

310

R

transmissions

may

be

fitted

"

On

MS

270R/A4S310R

transmissions

:

Use

new

bolts

with

ASE

(inch)

bolts

.

at

sump

and

tighten

bolts

in-line,

one

after

other

(do

nottighten

bolts

in

a

cross-wise

pattern)

.

3

.

On

A5S

310Z

transmission

:

Remove

oil

sump

mount-

"

On

MS

310Z

transmission,

be

sureto

instan

rounded

ing

bolts

and

brackets,

noting

position

of

brackets

.

Re-

sump

clamping

brackets

at

corners

of

sump

.

move

"

Fill

transmission

with

approved

fluid

.

sump

and

sump

gasket

.

"

Check

fluid

level

as

described

under

ATF

leve¡,

4

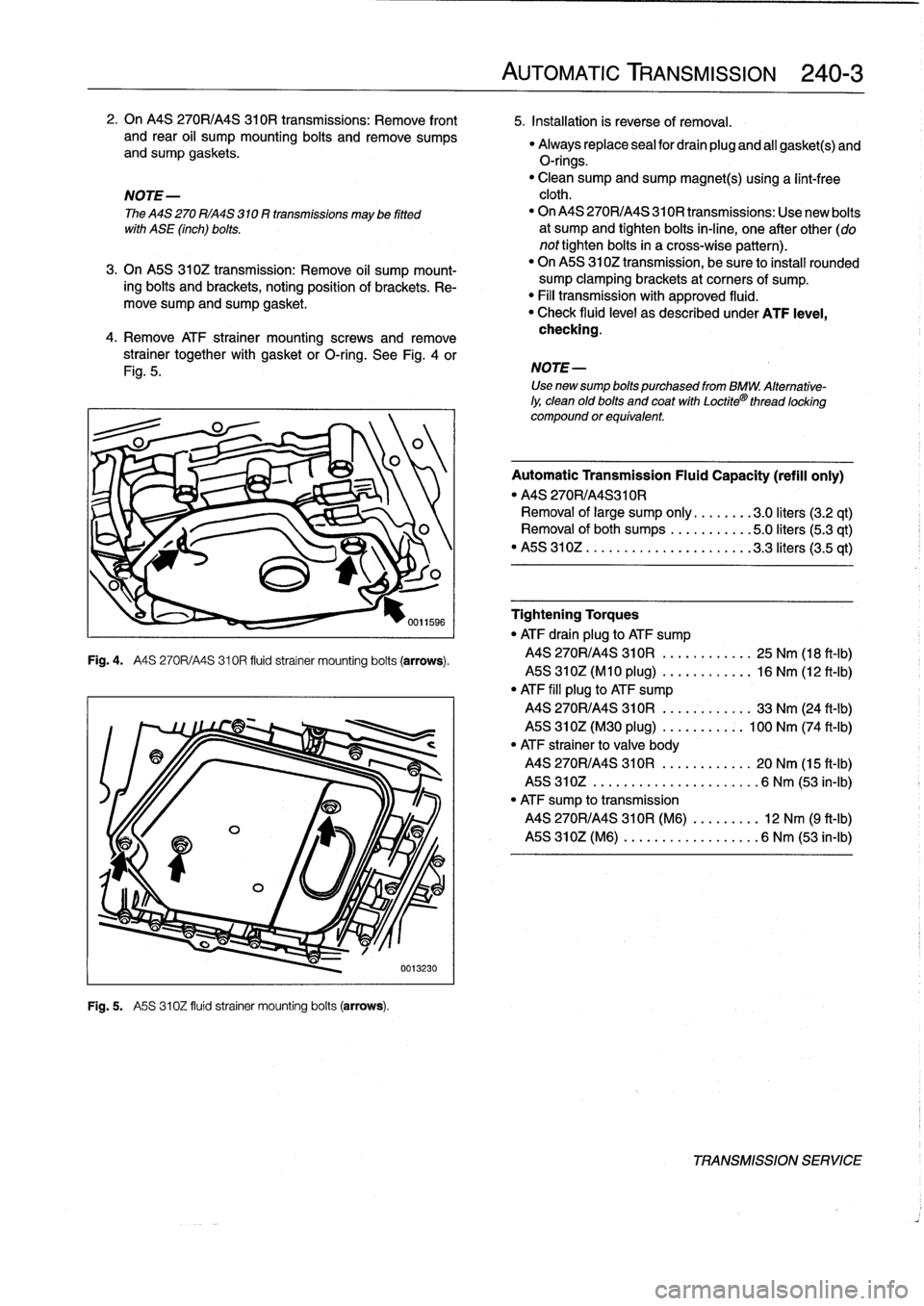

.

Remove

ATF

otra¡ner

mount¡ng

screws

and

remove

checking

.

strainer

together

with

gasket

orO-ring

.

See

Fig

.

4

or

Fig

.

5

.

Fig

.

4

.

A4S

270R/A4S310R

fluid

strainer

mounting

boits

(arrows)

.

Fig

.

5

.

A5S

310Z

fluid

strainer

mounting

boits

(arrows)

.

0013230

AUTOMATIC

TRANSMISSION

240-

3

NOTE-

Use

newsump

bolts

purchased

from

BMW

.

Alternative-

ly,

clean

old

bolts

and

coat

with

Loctite®

thread

locking

compound

or

equivalent

Automatic

Transmission

Fluid

Capacity

(refill

only)

"

MS

270R/A4S310R

Removal

of

large

sump

only

........

3

.0liters

(3.2

qt)

Removal

ofboth

sumps

...........

5

.0liters(5

.3

qt)

"

MS

310Z

..

..

..................

3

.3liters

(3.5

qt)

Tightening

Torques

"

ATF

drain

plug

to

ATF

sump

MS

270R/A4S

310R

..........

..

25

Nm

(18

ft-Ib)

MS

310Z(M10

plug)

..........

..

16

Nm

(12

ft-Ib)

"

ATF

fill

plug

to

ATF

sump

MS

270R/A4S

310R

..........

..

33

Nm

(24

ft-Ib)

MS

310Z(M30

plug)

.....

..

..

:.

100

Nm

(74

ft-Ib)

"

ATF

strainer

to

valve

body

MS

270R/A4S

310R

.....

..

.

...

.

20

Nm

(15

ft-Ib)

MS

310Z

..............

..

.

...

..

6

Nm

(53

in-lb)

"

ATF

sump

to

transmission

MS

270R/A4S

310R

(M6)

.

..

.

..

...

12

Nm

(9

ft-¡b)

MS

310Z

(M6)

..........

..

.

..

...

6

Nm

(53

in-¡b)

TRANSMISSION

SERVICE

Page 234 of 759

240-

6

AUTOMATIC

TRANSMISSION

14

.

Remove

transmission

by

pulling

back

and

down

.

Lower

jack

to

allow

transmission

to

clear

vehicle

.

Tightening

Torques

"

ATF

drain

plug

to

ATF

sump

CA

UTION-

MS

270R/A4S

310R

....

..

....

.

..

25

Nm

(18

ft-Ib)

Do

not

allow

the

torque

converter

to

fati

off

the

ASS

310Z(M10

plug)

..

..

..

.

.

..

.

..

16

Nm

(12

ft-Ib)

transmission

inputshaft

.

"

ATF

fill

plug

to

ATF

sump

MS

270R/A4S

310R

..

..

....

..

..

.

33

Nm

(24

ft-Ib)

15

.

Installation

is

reverse

of

removal,

noting

the

following

:

MS

310Z(M30

plug)

......

.

.

..

.

.

100

Nm

(74

ft-Ib)

"Blowoutofcoolerlineswithlow-pressurecompressed

"

ATF

cooler

lines

(A4S

270R/A4S

310R)

air

and

flush

coolerwith

clean

ATF

twice

before

reat-

Coupling

nuts

............

.

.

..

..

.

20

Nm

(15

ft-Ib)

taching

lines

to

transmission

.

Hollow

bolts

.........

.

.....

..

..

.

37

Nm

(28

ft-Ib)

"

Reinforcing

cross

brace

CAUTION-

to

chassis

(M10)

.............

.

..

.

42

Nm

(31

ft-Ib)

"

Wear

safety

glasses

when

working

with

com-

"

Torque

converter

pressedair

.

to

driveplate

(M10)

.........

..

.

..

45

Nm

(33

ft-Ib)

"

Transmissionsupport

crossmember

to

chassis

"

Do

not

reuse

ATF

after

flushing

.

M8

......................

22-24

Nm

(16-17

ft-1b)

M10

................

.

....

..

.

..

42

Nm

(31

ft-Ib)

"

Install

new

sealing

washers

on

hollow

bolts

.

"

Transmissíon

to

engine

(Torx-head

with

washer)

"

Insta¡¡

new

O-rings

on

transmission

cooler

lines,

where

M8

......................

..

.

..

21

Nm

(15

ft-Ib)

applicable

.

M10

.....................

..

..

.

42

Nm

(31

ft-Ib)

"

Inspect

driveplate

for

cracks

or

elongatedholes

.

Re-

M12

................

.

....

..

.

..

72

Nm

(53ft-Ib)

place

if

necessary

.

"

Check

to

be

sure

torque

converter

is

seated

correctly

in

transmission

during

final

installation

.

"

When

mounting

transmission

to

engine,

the

three

mounting

tabs

on

torque

converter

must

be

aligned

with

indentations

on

driveplate

.

Use

an

alignment

dowel

to

line

up

bolt

holes,

if

necessary

.

"

Fill

transmission

with

clean

ATF

until

oil

leve¡

is

even

with

fill

hole

.

Then

check

fluid

leve¡

as

described

ear-

lier

.

"

Adjust

gearshift

mechanism

.

See

250

Gearshift

link-

age

.

NOTE-

Torx-head

mounting

bolts

shouldalwaysbe

used

with

washers

to

prevent

difficult

removal

.

TRANSMISSION

REMOVAL

AND

INSTALLATION

Page 397 of 759

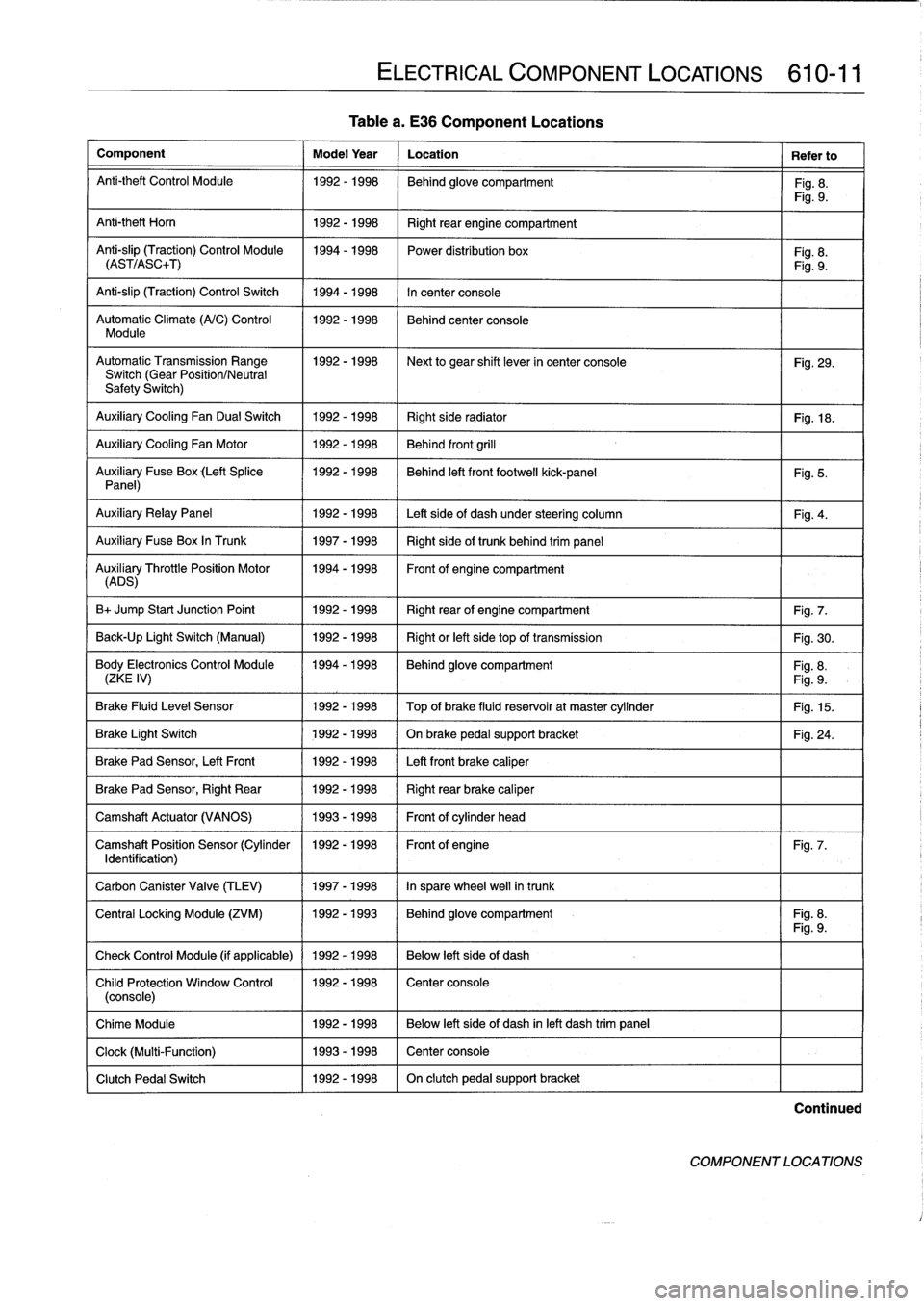

Table

a

.

E36

Component

Locations

Component

Model

Year

Location

Refer

to

Anti-theft

Control

Module

1992-1998

Behind

glove

compartment

Fig

.

8

.

Fig

.

9

.

Anti-theft

Horn

1

1992-1998

1

Right

rear

engine

compartment

Anti-slip

(Traction)

Control

Module

1994-1998

Power

distribution

box

Fig

.

8

.

(AST/ASC+T)

Fig

.

9

.

Anti-slip

(Traction)

Control

Switch

1994-1998

In

center

console

Automatic

Climate

(A/C)

Control

1992-1998

Behind

center

console

Module

AutomaticTransmission

Range

1992-1998

~

Next

to

gear

shift

lever

in

center

console

Fig

.

29

.

Switch

(Gear

Position/Neutral

Safety

Switch)

Auxiliary

Cooling

Fan

Dual

Switch

1992-1998

Right

side

radiator

1

Fig

.

18

.

Auxiliary

Cooling

Fan

Motor

1992-1998

Behind

front

grill

Auxiliary

Fuse

Box

(Left

Splice

1992-1998

I

Behind

left

front

footwell

kick-panel

Panel)

Auxiliary

RelayPanel

1

1992-1998

1

Left

side

of

dash

under

steering

column

Auxiliary

Fuse

Box

In

Trunk

1

1997-1998

1

Right

sideof

trunk

behind

trim

panel

AuADSry

ThrottlePosition

Motor

11994-1998

Front

of

engine

compartment

B+

Jump

Start

Junction

Point

1992-1998

Right

rear

of

engine

compartment

Fig

.

7

.

Back-Up

Light

Switch

(Manual)

1992-1998

Right

or

left

side

top

of

transmission

Fig

.

30

.

Body

Electronics

Control

Module

1994-1998

Behindglove

compartment

Fig

.

8

.

(ZKE

IV)

Fig

.

9

.

Brake

Fluid

Level

Sensor

1992-1998

Top

of

brake

fluid

reservoir

at

master

cylinder

Fig

.

15

.

Brake

Light

Switch

1

1992-1998

1

On

brake

pedal

supportbracket

Brake

Pad

Sensor,

Left

Front

1

1992-1998

1

Left

front

brake

caliper

Brake

Pad

Sensor,

Right

Rear

1992-1998

Right

rear

brake

caliper

Camshaft

Actuator

(VANOS)

1993-1998

Front

of

cylinder

head

Camshaft

Position

Sensor

(Cylinder

1992-1998

Front

of

engine

Identification)

Carbon

Canister

Valve

(TLEV)

1

1997-1998

1

In

sparewheel

well

in

trunk

ELECTRICAL

COMPONENT

LOCATIONS

610-11

Fig

.

5

.

Fig

.

4

.

Fig

.

24

.

Fig

.

7

.

Central

Locking

Module

(ZVM)

11992-1993

1

Behindglove

compartment

I

Fig

.

8

.

Fig

.

9

.

Check

Control

Module

(if

applicable)

1

1992

-

1998

1

Below

left

side

of

dash

Child

Protection

Window

Control

1992-1998

Center

console

(console)

Chime

Module

1992-1998

Below

left

side

of

dash

inleft

dash

trim

panel

Clock

(Multi-Function)

1993-1998

Center

console

Clutch

Pedal

Switch

1992-1998

On

clutch

pedal

support

bracket

Continued

COMPONENT

LOCATIONS

Page 750 of 759

WARNING

Your

common

sense,

good

judge-

ment,

and

general

alertness

are

cru-

cial

to

safe

and

successful

service

work

.

Before

attempting

any

work

on

your

BMW,

read

the

warnings

and

cautions

on

page

vi¡

and

the

copyright

page

at

the

front

of

the

manual

.

Review

these

warnings

and

cautions

each

time

youprepare

to

work

on

your

BMW

.

Please

also

read

any

warnings

and

cautions

that

accom-

pany

the

procedures

in

the

manual

.

A

ABS

(anti-lock

brakes)

See

Brakes

Accelerator

and

throttle

linkage

See

Maintenance

program

Air

conditioning

general

information

640-1

air

distribution

motor,

replacing

(rotary

knob)

640-10

air

distribution

motors

640-9

blower

motor,

removing/installing

640-1blower

motor

resistor

pack,

replacing

640-3

compressor,

replacing

640-12

compressor

clutch

640-13

condenser,

replacing

640-14

control

head

640-7

removing/installing

(digital

-display)

640-8

removing/installing

(rotary

knob)

640-7

control

module

removing/installing

(digital-display)

640-8

removing/installing

(rotary

knob)

640-8

evaporator,

removinglinstalling

640-17

evaporator

temperature

sensor,

replacing

640-17

expansion

valve,

removing/installing

640-16

microfilter,

replacing

640-18

receiverldrier,

replacing

640-15

sensor

fan

forinterior

temperature,

replacing

640-9

warnings

and

cautions

640-11

Air

distribution

(flap)

motor

See

Air

conditioning

See

also

Heating

Air

filter

See

Maintenanceprogram

Airbag

system

(SRS)

general

information

721-1

contact

ring,

replacing

721-3

driver

side

airbag,removing/installing

721-5

front

crash

sensor,

replacing

721-4

front

side-impact

airbag,

removing/

installing

721-7

front

side-impact

airbag

crash

sensor,

removing/installing

721-5

passenger

side

airbag,

removing/

installing

721-6

sensors

and

electronics

721-1

SRS

warning

light

and

fault

display

721-2

systems

721-1

ZAE

control

module,

replacing

721-5

Alarm

system

See

Central

locking

and

anti-theft

Alternator

See

Battery,

starter,

alternator

Anti-freeze

(Engine

coolant)

See

Maintenance

program

Anti-theft

See

Central

lockíng

and

anti-theft

AST

(Al¡

season

traction)

300-4

ATF

(Automatic

transmission

fluid)

See

Automatic

transmission

Automatic

transmission

See

alsoTransmission-general

general

information

240-1

ATF,draining

and

filling

240-2

ATF

leve¡,

checking

240-1

transmission

removaland

ínstallation

240-4

transmission,

removinglinstalling

240-4

transmission

service

240-1

Auxiliary

fan

See

Cooling

system

Axle

joint

See

Maintenance

program

B

Back-up

light

switch

See

Manual

transmission

Balljoint

See

Front

suspension

Battery

See

Battery,

starter,

alternator

Battery,

starter,

alternator

See

also

Maintenance

program

general

information

121-1

alternator,

removing/installing

(4-

cylinder

engine)

121-5

alternator,

removinglinstalling

(6-

cylinder

engine)

121-6

alternator

brushes,

inspecting/

replacing

121-7

alternator

service

121-4

batterycharging

121-4

battery

load

voltage

test

121-4

batteryopen-circuit

voltage

test

121-4

battery

service

121-3

INDEX

1

Battery,

starter,

alternator

(cont

.)

battery

testing

121-3

charging

system

quick

check121-2

charging

system

troubleshooting

121-

2

hydrometer

testing

121-3

solenoid

switch,

removinglinstalling

121-10

starter

service

121-7

starter

troubleshooting

121-7

starter,

removing/installing(4-cylinder

engine)

121-8

starter,

removing/installing(6-cylinder

engine

with

automatic

transmission)

121-9

starter,

removing/installing

(6-cylinder

engine

with

manual

transmission)

121-8

static

current

draw,

checking

121-2

voltage

regulator,

removing/installing

121-6

Bearing,

wheel

See

Front

suspension

or

Rear

suspension

Blowermotor

See

Air

conditioning

See

also

Heatíng

BMW

emblem

See

Exterior

trim,

bumpers

Body-general

general

information

400-1

body

assembly

400-1

central

body

electronics

400-4

convertible

models

400-2

coupe

models

400-2

electronic

immobilizatíon

system

400-

4

exterior

and

aerodynamics

400-2

heating

afhdair

conditioning

400-5

instruments

and

controls

400-4

interior

equipment

400-3

seats

and

seatbelts

400-3

Body

side

molding

See

Exterior

trim,

bumpers

Brake

fluid

See

Maintenance

program

Brakes

general

information

340-1

antilock

brake

system

(ABS)

340-11

inspection

340-12

wheelspeed

sensors,

replacing

340-12

bleeding

brakes

340-3

brake

booster,

removinglinstalling

340-8

brake

caliper,

removing/installing

340-6

brake

pads,

calipers,

and

rotors

340-3

brake

pads,

replacing

340-4

brake

rotor,

removing/installing

340-7

master

cylinder,

removing/installing

340-7

parking

brake

340-10

adjusting

340-10

.

cable,

replacing

340-11

shoes,

removinglinstalling

340-11

Page 754 of 759

WARNING

Your

common

sense,

good

judge-

ment,

and

general

alertness

are

cru-

cial

tosafe

and

successful

service

work

.

Before

attempting

any

work

on

your

BMW,

read

the

warnings

and

cautions

on

page

vi¡

and

the

copyright

page

at

the

frontof

the

manual

.

Review

these

warnings

and

cautions

each

time

you

prepare

to

work

on

your

BMW

.

Please

also

read

any

warnings

and

cautions

that

accom-

pany

the

procedures

in

the

manual

.

Fuel

pressure

regulator

See

Fuel

injection

Fue]

pump

general

information

160-1

electrical

tests

160-7

power

consumption,

testing

160-7

delivery

tests160-8

delivery

volume,

testing

g

160-9

electrical

circuit,

checking

160-7

fuse

and

relay

160-6

level

sender

See

pump/fuel

leve¡

sender

operating

fuel

pump

for

tests

160-6

pump/fuel

level

sender

(left

side),

removing/installing

160-6

pump/fuel

leve¡

sender

(right

side),

removing/installing

160-5

relieving

fuel

pressure

and

connecting

fue¡

pressure

gauge

160-8

Fueltank

and

lines

general

information

160-1

draining

160-2

evaporative

control

system

160-4

leve¡

senders,

testing

160-5

removing/installing

160-3

Fundamentals

for

the

do-it-yourself

owner

general

information

010-1

advice

for

the

beginner

010-4

cleanliness

010-4

electrical

testing

010-6

gaskets

and

seals

010-5

non-reusable

fasteners

010-5

planning

ahead

010-4

tightening

fasteners

010-5

wire

repairs

010-6

buying

parts

010-6

genuine

BMW

parts

010-6

information

you

need

to

know

010-7

non-returnable

parts

010-7

emergencies

010-11brake

fluid

leve¡

010-13

car

will

not

start

010-11

changinga

tire

010-11

check

enginewarning

light

010-13

dim

Iights

010-13

jump

starting

car

010-12

low

o]I

pressure

010-13

overheating

010-12

Emergencies

(cont

.)

spare

parts

kit

010-14

towing

010-13

gettingstarted

010-2

lifting

thecar

010-3

raising

car

safely

010-3

safety

010-2

working

under

car

safely

010-4

how

to

use

this

manual

010-2

warnings,

cautions

and

notes

010-2

service

010-7

tools

010-7

basic

tool

requirements010-8

BMW

specialtools

010-11

feeler

gauges

010-10

jack

stands

010-9

oil

change

equipment

010-9

torque

wrench

010-10

volt-ohm

meter

(VOM)

or

Multi-

meter010-10

Fuses

See

Electrical

component

locations

G

Gaskets

See

Fundamentals

for

the

do-it-

yourself

owner

Gearshift

See

Gearshift

linkage

Gearshift

linkagegeneral

information

250-1

automatic

shiftlock,

checking

function

250-5

automatic

transmission

gearshift

250-

3

gear

position/neutral

safety

switch,

replacing

(automatic

transmission)

250-4

gearshift

lever,

installing

(manual

transmission)

250-2

gearshift

lever,

removing

(manual

transmission)

250-1

gearshift

mechanism,

adjusting

(automatictransmission)

250-3

manual

transmission

gearshift

250-1

shift

interlock,

checking

function

(automatic

transmission)

250-6Glass

See

Door

windows

Glove

compartment

See

Interior

trim

Grille

See

Exterior

trim,

bumpers

Guibo

(flex

disc)

See

Driveshaft

Handle,

door

See

Doors

Hardtop

See

Body-general

Headlight

See

Exterior

lighting

Headlight

switch

See

Switches

and

electrical

accessoriesHeater

box

See

Heating

Heater

core

See

Heating

Heater

valve

See

Heating

Heating

general

information

640-1

air

distribution

motors

640-9

air

distribution

motor,

replacing

(rotary

knob)

640-10

blower

motor,

removing/installing

640-1blower

motor

resistor

pack,

replacing

640-3

control

head

640-7

removing/installing

(digital-display)

640-8

removing/installing

(rotary

knob)

640-7

control

module

removing/installing

(digital-display)

640-8

removing/installing

(rotary

knob)

640-8

heater

box,

removing640-4

heater

core,

replacing

640-6

heater

core

temperature

sensor,

replacing

640-7

heater

valve,

replacing

640-3

rear

window

blower

(convertible

models)

640-10

reas

window

defogger

640-10sensor

fan

forinterior

temperature,

replacing

640-9warnings

and

cautions

640-11

Hood

See

Fenders,

engine

hood

Idle

speed

See

Maintenance

program

Idle

speed

control

valve

See

Fuel

injection

Ignition

switch

See

Switches

and

electrical

accessories

INDEX

5

Page 755 of 759

6

INDEX

Ignition

system

general

information

120-1basictroubleshooting

principies

120-3camshaft

position

(CMP)

sensor

120-

6

camshaft

positíon

(CMP)

sensor,

replacing

(4-cylinder

engine)

120-6camshaft

position

(CMP)

sensor,

replacing

(6-cylinder

engines)

120-7

checking

for

spark

120-3

crankshaftposition/rpm

sensor

120-5

crankshaft

position/rpm

sensor,

testing/replacing

(front

mounted

sensor)

120-6

crankshaft

positíon/rpm

sensor,

testing

(rear

mounted

sensor)

120-6

disabling

ignition

system120-2

ignition

coil,

testing

and

replacing

(4-

cylinder

engines)

120-3

ignition

coil,

testing

and

replacing

(6-

cylinder

engines)

120-4

ignítion

firing

order

120-7

ignition

system

diagnostics

120-3

ignition

system

schematics

120-7

ignition

system

service

120-3knock

sensors,

replacing

120-7warnings

and

cautions

120-2

Inspectíon

I

and

Inspection

II

See

Maintenanceprogram

Instrumentpanel

See

interior

trim

Instruments

general

information

620-1

instrument

cluster,

removinglinstalling

620-1

instrument

cluster,

self-testing

620-1

instrument

cluster

bulbs,

replacing

620-2

multi-information

display

(MID),

620-4

multi-information

display

(MID),

removing/installing

620-4

odometer

coding

plug,

replacing

620-

2

vehicle

speed

sensor,

replacing

620-3

Intake

manifold

4-cylinder

engíne,

removing

113-3

6-cylinder

engine,

removing

113-11

See

alsoCylinder

head

removal

and

installation

Intake

air

temperaturesensor

See

Fuel

injection

Interior

trim

general

information

513-1

center

console,

removing/installing

513-1

dashboard,

removing/installing

513-3

glove

compartment,

removing/

installing

513-2

lower

left

dash

panel,

removing/

installing

513-2

J

Jump

startíng

010-12

K

Knock

sensor

See

Ignition

system

L

Leather

upholstery

See

Maíntenance

program

Leve¡

sender

See

Fuel

pump

Lubrication

system

general

information

119-1

oil

pan,

removing/installing

(4-cylinder

engines)

119-2

oil

pan,

removing/installing

(6-cylinder

engine,

1992models)119-4

oil

pan

119-2

oil

pan,

removing/installing

(6-cylinder

engine,

1993

and

later

models)

119-6

oil

pressure,

checking

119-1

oil

pressure

warningsystem,

testing

119-2

oil

pump

119-8

oil

pump,

removing/installing

(4-cylinder

engine)

119-8

oil

pump,

removing/installing

(6-cylinder

engine)

119-9

troubleshooting

119-1

M

Maíntenance

program

general

information

020-2

accelerator

and

throttle

linkage

020-13

air

filter,

replacing

020-11

automatic

transmission

fluid

020-8

automatic

transmission

service

020-18

battery,

checking

and

cleaning

020-12

battery,

replacing

020-12

BMW

service

indicator

020-2

body

and

hinges,

lubricating

020-19

brake

fluid

020-9

brake

fluid,

replacing

020-17

brake

pad/rotor

wear,

checking

020-17

brake

system,

inspecting

020-17

clutch

fluid,

checking

020-19

cooling

system

service

020-14

drive

axle

joint

boots,

inspecting

020-19

engine

coolant

(anti-freeze)

020-9

engine

drive

belts

020-13

engine

oil,

checking

leve¡

020-9

Maintenance

program

(cont

.)

engine

oil

and

filter,

changing020-9engine

oil

service

020-9

exhaust

system,

inspecting

020-18

exterior

washing020-20

final

drive

gear

oil

020-9

final

drive

oil

level,

checking

020-18

front

suspension

and

steering

linkages,

inspecting

020-18

fuel

filter,

replacing

020-16

fuel

tank

and

fuel

lines,

inspecting

020-19

¡dle

speed

020-12

inspection

I

and

inspection

11

020-2

interior

care020-20

leather

upholstery

and

trim

020-20

maintenance

tables

020-3

manual

transmission

fluid,

checking

and

filling

020-18manual

transmission

fluid

020-8

manual

transmission

service

020-18oxygensensors

020-15

parking

brake,

checking

020-17

polishing

020-20

poly-ribbed

belt,

replacing

020-13

power

steering

fluid

020-9

power

steering

fluid,

checking

leve¡

020-14

rear

suspension,

inspecting

020-18

resetting

service

indicator

020-3

seat

belts

020-20

spark

plugs,

replacing

020-11

special

cleaning

020-20

tires,

checking

inflation

pressure

020-17

tires,

rotating

020-17

v-belt,

replacing

020-13

washing

chassis

020-20waxing020-20

windshield

wiperblade

maintenance

020-19

wheels,

aligníng

020-17

Manual

transmission

See

also

Maintenance

program

See

also

Transmission-general

general

information

230-1

back-up

light

switch,

replacing

230-2

inputshaft

sea¡,

replacing

(transmission

installed)

230-5

output

shaftsea¡,

replacing

(transmission

installed)

230-4

selector

shaft

sea¡,

replacing

(transmission

installed)

230-3

transmission

fluid,

replacing

230-2

transmission

fluidlevel,

checking

230-2

transmission

fluid

service

230-1

transmission

removal

and

installation

230-5

transmission,

removing/installing

230-

6

transmission

service

230-2

Mass

air

flow

sensor

See

Fuel

Injection