Fuel pump wiring BMW 325i 1994 E36 User Guide

[x] Cancel search | Manufacturer: BMW, Model Year: 1994, Model line: 325i, Model: BMW 325i 1994 E36Pages: 759

Page 157 of 759

3

.

Observe

fuel

pressure

gauge

after

20

minutes

.

The

pressure

shouldnot

drop

off

more

than

0

.5

bar

from

system

pressure

listed

in

Tablec

.

4

.

When

finished

testing,

disconnect

pressure

gauge

and

reconnect

fuel

line

.

If

the

fuel

system

does

not

maintain

pressure,

check

visual-

¡y

for

leaks

in

fuel

lines

orat

unions

.

Leaks

can

also

be

due

to

a

leaking

injector

or

a

faulty

fuel

pump

check

valve

.

Check

the

pump

check

valve

by

repeating

the

test,

butbefore

turning

the

fuel

pump

off,

pinch

off

theretum

line

at

the

fuel

rail

.

If

the

pressure

is

now

maintained,

the

fault

is

most

likely

the

fuel

pump

check

valva

.

Tabla

c

.

Fuel

Pressure

Specifications

Engine

1

Fuel

pressure

4-cytinder

1

3

.0

t

0

.2

bar

(43

.5

t

2

.9psi)

6-cytinder

M50/S50US

engine

3

.0

t

0

.2

bar

(43

.5

±2

.9psi)

M52/S52US

engine

3

.5

f

0

.2

bar

(51

t

2.9psi)

Fuel

pressure

regulator

response

to

engine

load,

testing

1

.

With

fuel

pressure

gauge

connected,

reinstallfuel

pump

relay

.

Start

engine

and

allow

it

to

idle

.

NOTE-

The

fuel

pressure

should

be

lower

by0

.4-0.7

bar

from

the

specifications

listed

in

Table

c

.

Engine

vacuum

act-

ing

on

the

fuel

pressure

regulator

diaphragm

reduces

the

fuel

pressure

.

2

.

With

engine

idling,

remove

vacuum

hose

from

regula-

tor

.

Pressure

should

increase

.

3

.

Reconnecthose

and

check

that

pressure

decreases

.

4

.

When

finished

testing,

disconnect

pressure

gauge

and

reconnect

fuelline

.

Tighten

hose

clamp

.

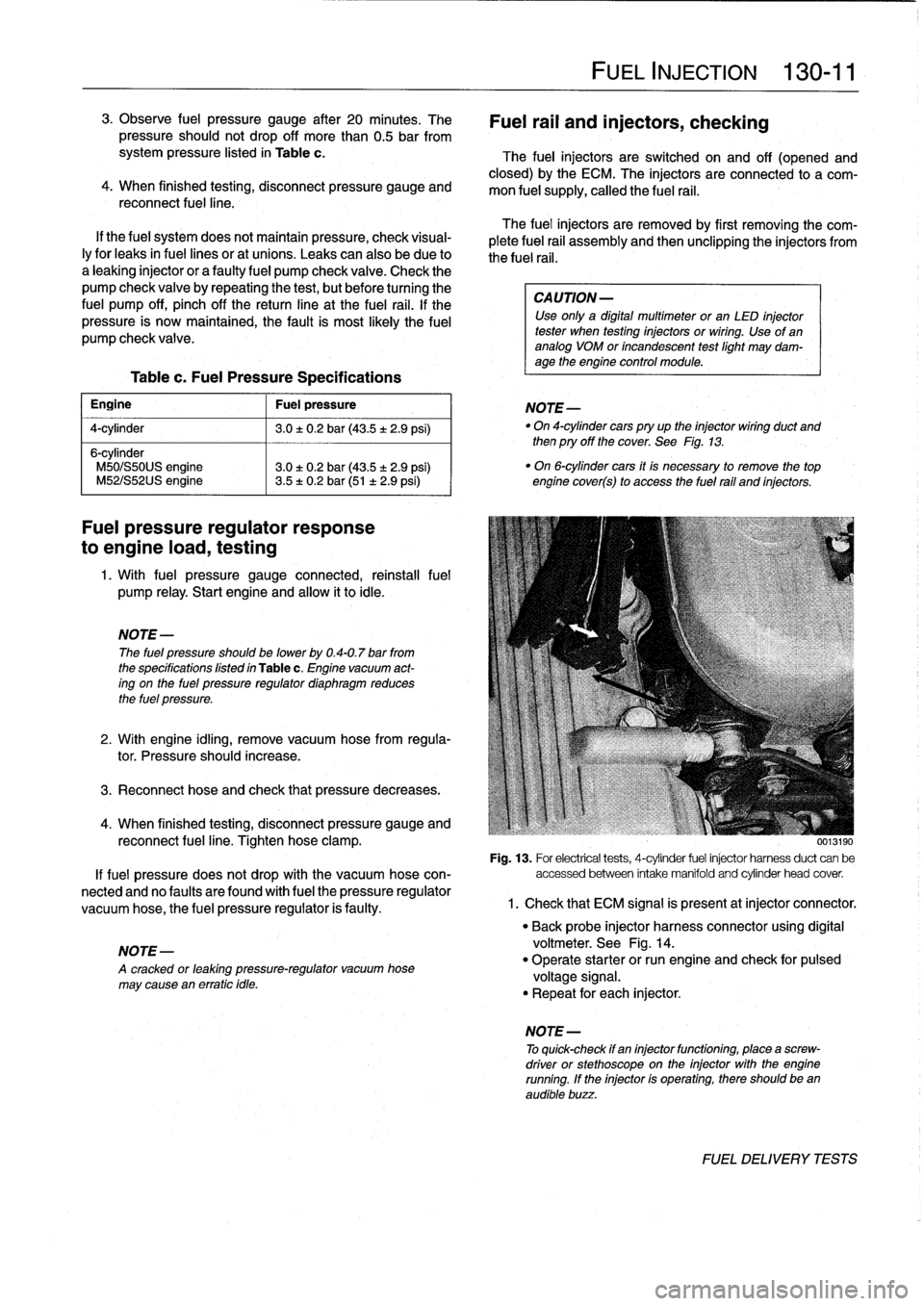

0013190

Fig

.

13

.

For

electrical

tests,

4-cytinder

fuel

injector

harnessduct

can

be

If

fuel

pressure

does

not

drop

with

the

vacuum

hose

con-

accessed

between

intake

manifold

and

cytinder

head

cover

.

nected

and

no

faulty

are

found

with

fuel

the

pressure

regulator

vacuum

hose,

the

fuel

pressure

regulator

is

faulty

.

1

.

Check

that

ECM

signal

is

present

atinjector

connector

.

NOTE-

A

cracked

or

leaktng

pressure-regulator

vacuum

hose

may

cause

en

erratic

tdle

.

FUEL

INJECTION

130-

11

Fuel

rail

and

injectors,

checking

The

fuel

injectors

are

switched

on

and

off

(opened

and

closed)

by

the

ECM

.

The

injectors

are

connected

to

a

com-

mon

fuel

supply,

callad

the

fuel

rail

.

The

fuel

injectors

are

removed

by

first

removing

the

com-

plete

fuel

rail

assembly

and

then

unclipping

the

injectors

from

the

fuel

rail

.

CA

UTION-

Use

only

a

digital

multimeter

or

an

LED

injector

tester

when

testing

injectors

or

wiring

.

Use

of

ananalog

VOM

or

incandescent

testlight

may

dam-

age

the

engine

control

module

.

NOTE-

"

On

4-cytindercars

pry

up

the

injector

wiring

duct

and

then

pry

off

the

cover

.

See

Fig

.

13

.

"

On

6-cytinder

cars

it

is

necessary

to

remove

the

top

engine

cover(s)

to

access

the

fuel

rail

and

injectors

.

"

Back

probe

injector

harness

connector

using

digital

voltmeter

.

See

Fig

.

14

.

"

Operate

starter

or

run

engine

and

check

for

pulsad

voltage

signal

.

"

Repeat

for

each

injector

.

NOTE

-

To

quick-check

if

en

injectorfunctioning,

place

a

screw-

driver

or

stethoscope

on

the

injector

with

the

engine

running

.

If

the

injector

is

operating,there

should

been

audible

buzz

.

FUEL

DELIVERYTESTS

Page 160 of 759

130-

1

4

FUEL

INJECTION

NOTE-

Be

sure

to

retrieve

thrust

washer

behind

fuel

pressure

regulator

on

6-cylinder

engine

.

4

.

Installation

is

reverse

of

removal

.

Replace

O-rings

.

Fuel

pressure

regulator,

replacing

(under

car

mount)

WARNING

-

Fuel

will

be

discharged

.

Do

not

disconnect

any

wires

that

could

cause

electrical

sparks

.

Do

not

smoke

or

work

near

heaters

or

other

fire

hazards

.

Keep

an

approved

tire

extinguisher

handy

.

On

late

4-

and

6-cylinder

cars,

the

fuel

pressure

regulator

is

mounted

beneath

the

left

sideof

the

car,

under

a

protective

cover

.

See

Fig

.

20

.

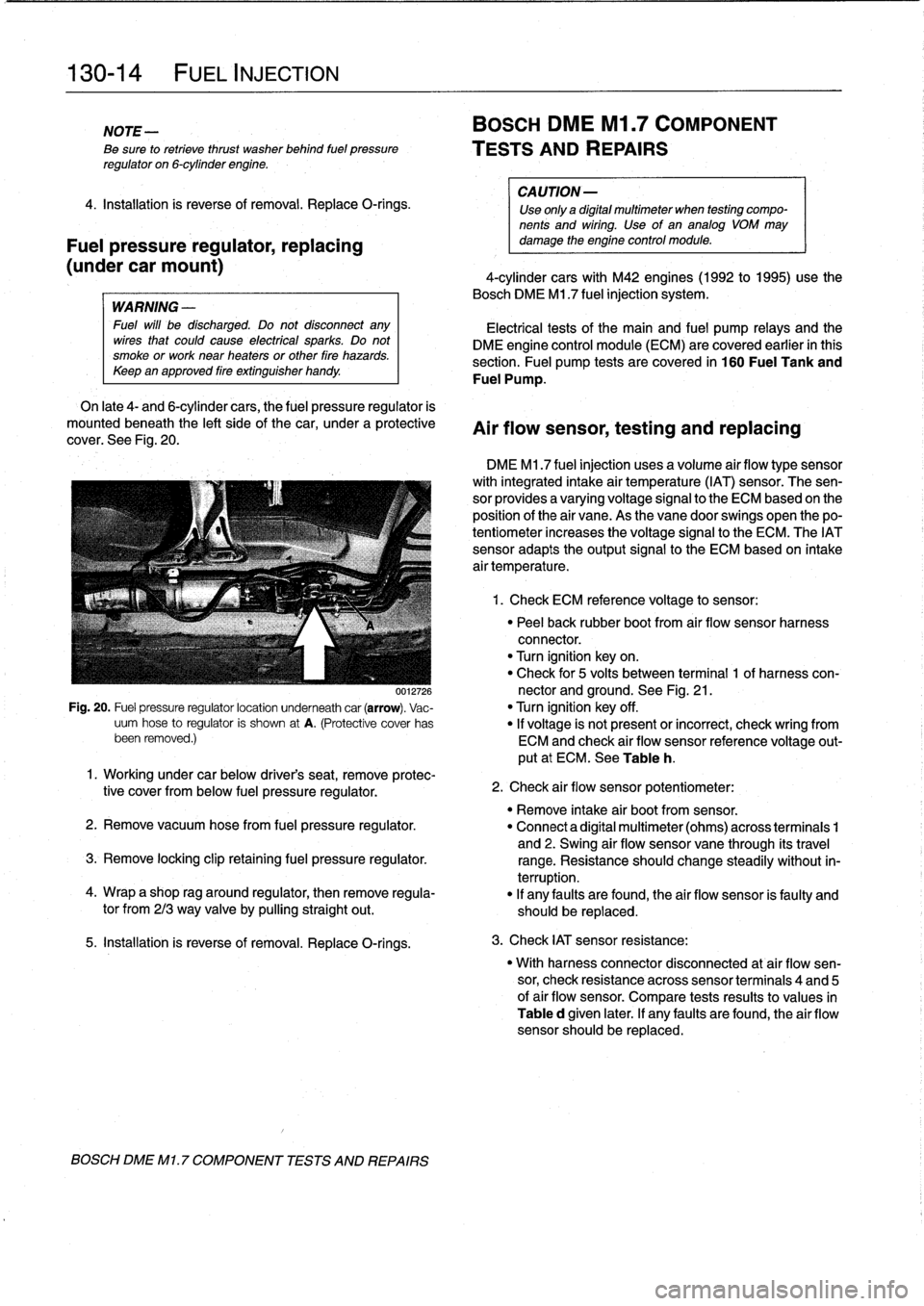

0012726

Fig

.

20

.

Fuel

pressure

regulatorlocation

underneath

car

(arrow)

.

Vac-

uum

hose

to

regulator

is

shown

at

A

.

(Protective

cover

has

been

removed

.)

5

.

Installation

is

reverse

of

removal

.

Replace

O-rings

.

BOSCH

DME

Ml

.

7

COMPONENT

TESTS

AND

REPAIRS

BOSCH

DME

Ml

.7

COMPONENT

TESTS

AND

REPAIRS

CA

UTION-

Use

only

a

digital

multimeter

when

testing

compo-

nents

and

wiring

.

Use

of

an

analog

VOM

may

damage

the

engine

control

module

.

4-cylinder

cars

with

M42

engines(1992

to

1995)use

the

Bosch

DME

M1

.7

fuel

injection

system

.

Electrical

tests

of

the

main

and

fuel

pump

relays

and

the

DME

engine

control

module

(ECM)

are

covered

earlier

in

this

section

.

Fuel

pump

tests

arecovered

in

160

Fuel

Tank

and

Fuel

Pump

.

Air

flow

sensor,

testing

and

replacing

DME

M1

.7

fuel

injection

uses

a

volume

air

flow

type

sensor

with

integrated

intake

air

temperature

(IAT)

sensor

.

The

sen-

sor

provides

a

varyingvoltage

signal

to

the

ECM

based

on

the

position

of

the

air

vane

.

As

the

vane

doorswings

open

thepo-

tentiometer

increases

the

voltage

signal

to

the

ECM

.

The

IATsensor

adapts

theoutput

signal

to

the

ECM

based

on

intake

air

temperature

.

1

.

Check

ECM

reference

voltage

to

sensor

:

"

Peel

back

rubber

boot

from

air

flow

sensor

harness

connector

.

"

Turn

ignition

keyon

.

"

Check

for

5

volts

between

terminal

1

of

harness

con-

nector

and

ground

.

See

Fig

.

21

.

"

Turn

ignition

key

off

.

"

If

voltage

is

not

present

or

incorrect,

check

wring

from

ECM

and

check

air

flow

sensor

reference

voltage

out-

put

at

ECM

.

See

Table

h

.

1

.

Working

under

car

below

driver's

seat,

remove

protec-

tive

cover

from

below

fuel

pressure

regulator

.

"

Remove

intake

air

bootfrom

sensor

.

2

.

Remove

vacuum

hosefrom

fuel

pressure

regulator

.

"

Connect

a

digital

multimeter

(ohms)

across

terminais

1

and

2

.

Swing

air

flow

sensor

vane

through

its

travel

3

.

Remove

locking

clip

retaining

fuel

pressure

regulator

.

range

.

Resistance

should

change

steadily

without

in-

terruption

.

4

.

Wrap

a

shop

rag

around

regulator,

then

remove

regula-

"

If

any

faults

are

found,

the

air

flow

sensor

is

faulty

and

tor

from

213

way

valve

by

pullingstraight

out

.

should

be

replaced

.

2

.

Check

air

flow

sensor

potentiometer

:

3

.

Check

IAT

sensor

resistance

:

"

With

harness

connector

disconnected

at

air

flow

sen-

sor,

check

resistance

across

sensor

terminais

4

and

5

of

air

flow

sensor

.

Compare

tests

results

to

values

in

Table

d

given

later

.

If

any

faults

are

found,

the

air

flow

sensor

should

be

replaced

.

Page 163 of 759

BOSCH

DME

MM

AND

M33

.1

COMPONENT

TESTS

AND

REPAIRS

Consult

Table

a

for

engine

application

information

for

the

Bosch

DME

3

.1

and

3

.3.1

systems

.

The

DME

3

.1

and

DME

3

.3

.1

systems

are

similar

in

opera-

tion,

with

knock

control

and

VANOS

operation

being

the

key

differences

.

DME

3

.1

engines

arenot

equipped

with

VANOS

or

knock

detectors,

while

the

DM

E3

.3

.1

system

is

.

CA

UTION-

Use

onty

a

digital

multimeter

when

testing

wiring

.

Use

of

an

analog

VOM

may

damage

the

engine

control

module

.

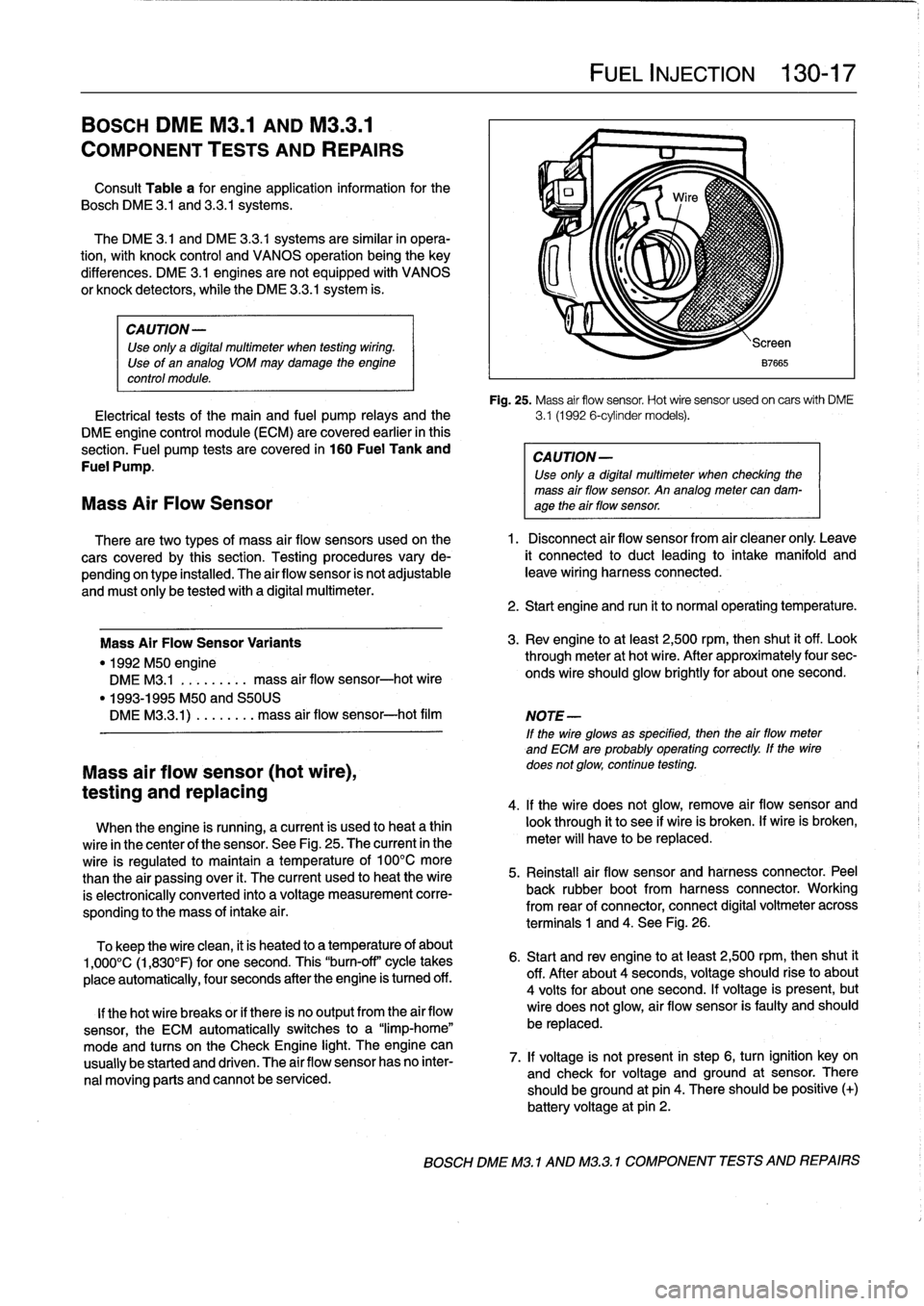

Fig

.

25

.

Mass

air

flow

sensor

.

Hot

wire

sensor

usedon

carswith

DME

Electrical

tests

of

the

main

and

fuel

pump

relays

and

the

3

.1

(1992

6-cylinder

models)

.

DME

engine

control

module

(ECM)

are

covered

earlier

in

this

section

.

Fuel

pump

tests

are

covered

in

160

Fuel

Tank

and

CAUTION-

Fuel

Pump

.

Use

only

a

digital

multimeter

when

checking

the

mass

air

flow

sensor

.

An

analog

meter

can

dam-

Mass

Air

Flow

Sensor

age

theair

flow

sensor

.

There

are

two

types

of

mass

air

flow

sensors

used

onthe

1

.

Disconnect

air

flow

sensor

from

air

cleaner

only

.

Leave

cars

covered

by

this

section

.

Testing

procedures

vary

de-

it

connected

to

duct

leading

to

intake

manifold

and

pending

on

type

installed

.

The

airflow

sensor

is

not

adjustable

leave

wiring

harness

connected

.

and

must

only

be

tested

with

a

digital

multimeter

.

Mass

Air

FlowSensor

Variants

"

1992

M50

engine

DME

M3

.1

.

.

.

.

...

..

mass

air

flow

sensor-hot

wire

"

1993-1995

M50

and

S50US

DMEM33

.1)

.

...

...

.

mass

air

flow

sensor-hot

film

Mass

air

flow

sensor

(hot

wire),

testing

and

replacing

When

the

engine

is

running,

a

current

is

used

to

heat

a

thin

wire

in

the

center

of

the

sensor

.

See

Fig

.

25

.

The

current

in

the

wire

is

regulated

to

maintain

a

temperature

of

100°C

more

than

the

air

passing

over

it

.

The

current

used

to

heat

the

wire

is

electronically

conneced

into

a

voltage

measurement

corre-

sponding

to

the

mass

of

intake

a¡

r

.

To

keep

the

wire

clean,

it

is

heated

to

a

temperature

of

about

1,000°C

(1,830°F)

for

one

second

.

This

"burn-off"

cycle

takes

place

automatically,

four

seconds

after

the

engine

is

tumed

off

.

lf

thehot

wire

breaks

or

if

there

is

no

output

from

the

air

flow

sensor,

the

ECM

automatically

switches

to

a

"limp-home"

mode

and

tucos

on

the

Check

Engine

light

.

The

engine

can

usually

be

started

and

driven

.

The

air

flow

sensor

has

no

inter-

nal

moving

parts

and

cannot

be

serviced

.

FUEL

INJECTION

130-

1

7

2

.

Start

engine

and

run

it

to

normal

operating

temperature

.

3

.

Rev

engine

toat

least

2,500

rpm,then

shut

it

off

.

Look

through

meter

at

hot

wire

.

After

approximately

four

sec-

onds

wire

should

glow

brightly

for

about

one

second

.

NOTE

-

If

the

wire

glowsas

specified,

then

the

airflow

meter

and

ECM

are

probably

operating

correctly

.

lf

the

wire

does

not

glow,

continue

testing

.

4

.

lf

the

wire

does

not

glow,

remove

air

flow

sensor

and

look

through

it

to

see

if

wire

is

broken

.

lf

wire

is

broken,

meter

will

have

to

be

replaced

.

5

.

Reinstall

air

flow

sensor

and

harness

connector

.

Peel

back

rubber

bootfrom

harness

connector

.

Working

from

rear

of

connector,

connect

digital

voltmeter

across

terminals

1

and

4

.

See

Fig

.

26

.

6

.

Start

and

rev

engine

toat

least

2,500

rpm,thenshut

it

off

.

After

about

4

seconds,

voltage

should

riseto

about

4

volts

for

about

one

second

.

lf

voltage

is

present,

but

wire

does

not

glow,

air

flow

sensor

is

faulty

and

should

be

replaced

.

7

.

lf

voltage

is

not

present

in

step

6,

turn

ignition

key

on

and

check

for

voltage

and

ground

at

sensor

.

There

should

beground

at

pin

4

.

There

should

be

positive

(+)

battery

voltage

at

pin

2

.

BOSCH

DME

M3

.1

AND

M32

.1

COMPONENT

TESTS

AND

REPAIRS

Page 190 of 759

160-

6

FUEL

TANK

AND

FUEL

PUMP

Fig

.

7

.

Fuel

sender

and

pump

assembly

.

To

operate

the

fuel

pump

for

testing

purposes

without

hav-

Fuel

leve¡

sender

(left

side),

ing

to

runthe

engine,

the

fuel

pump

relay

can

be

bypassed

to

removing

and

installing

powerthe

pump

directly

.

The

procedure

for

removing

and

replacing

the

left

side

fuel

To

runthe

fuel

pump,

remove

the

relay

and

connect

the

leve¡

sender

is

similar

tothat

used

for

the

right

side

.

There

is

socket

for

relayterminal

30

to

the

socket

for

relay

terminal

no

.

no

fuel

pump

on

the

left

side

.

87

with

afused

jumper

wire

.

Relay

terminal

identification

is

shown

in

Fig

.

9

.

After

completing

the

tests,

remove

the

jumper

wire

.

FUEL

PUMP

The

electric

fuel

pump

ís

mounted

in

the

fuel

tank

in

tandem

with

the

right

side

fuelleve¡

sender

.

The

fuel

pump

delivers

fuel

at

high

pressure

to

the

fuel

injection

system

.

A

pressure

regulator

maintains

system

pressure

.

The

quantity

of

fuel

sup-

plied

exceeds

demand,

so

excess

fuel

retums

to

the

fuel

tank

via

a

retum

líne

.

See

130

Fuel

Injection

for

more

information

on

system

pressure

and

the

fuel

pressure

regulator

.

NOTE

-

Fuel

pump

removalprocedures

are

given

earlier

under

Fuel

leve¡

sender

(right

side)

and

fuel

pump,

remov-

íng

and

installing

.

Fuel

Pump

Fuse

and

Relay

The

fuel

pump

is

operated

by

a

fuel

pump

relay

located

ín

the

power

distribution

box

.

The

fuel

pump

circuit

is

protected

by

fuse

no

.

18

located

in

the

power

distribution

box

.

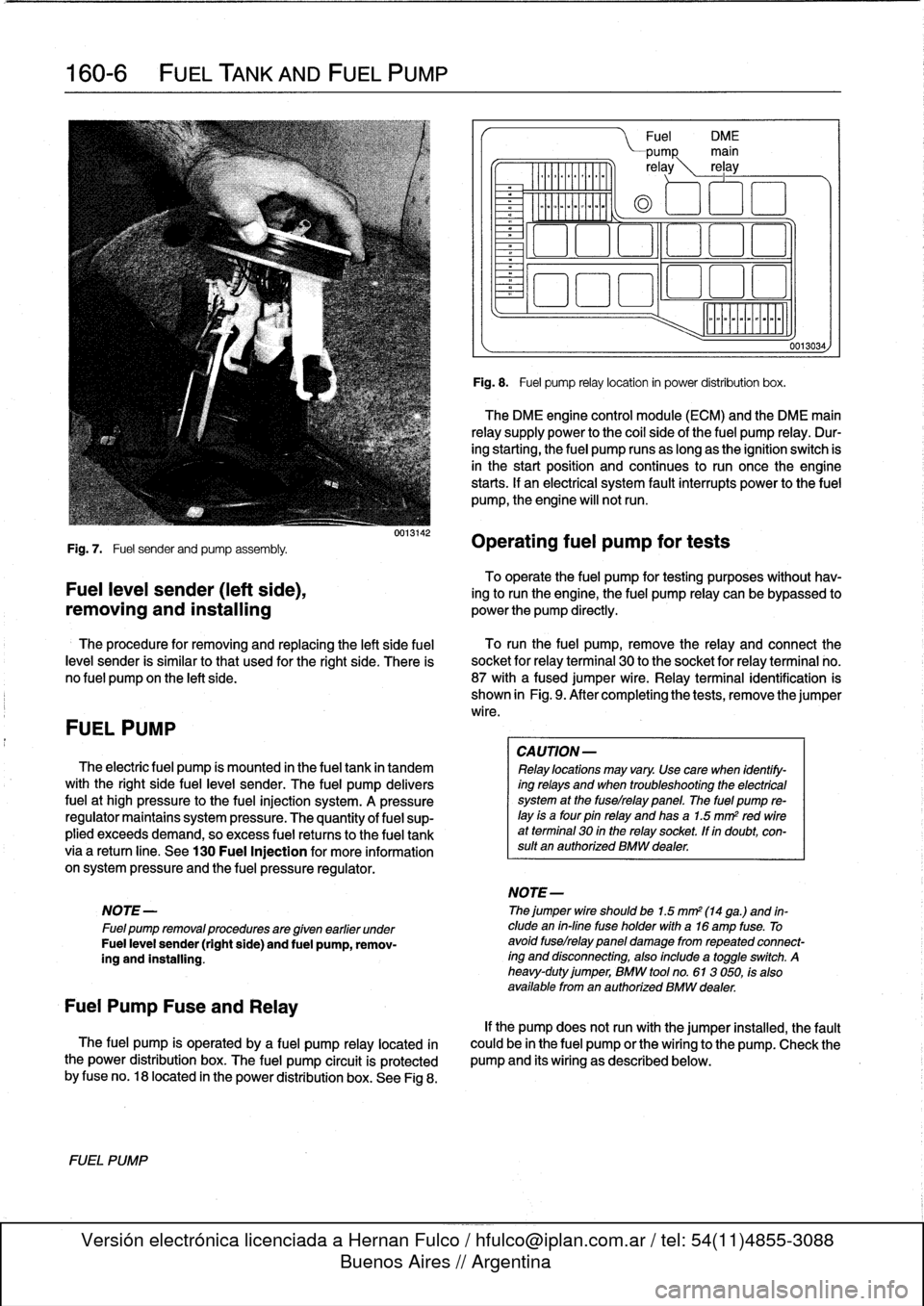

See

Fig

8

.

FUEL

PUMP

0013142

Fuel

DM

E

PUMP

main

re

ay

rel

ay

0

aoo

o

~a

aao

ó

Fig

.

8

.

Fuel

pump

relay

location

in

power

distribution

box

.

The

DME

engine

control

module

(ECM)

and

the

DME

main

relay

supply

power

to

the

coi¡

sideof

the

fuel

pump

relay

.

Dur-

ing

starting,

the

fuel

pump

runs

as

long

as

the

ignition

switch

is

in

the

start

position

and

continues

to

run

oncethe

engine

starts

.

If

an

electrical

system

fault

interrupts

power

to

the

fuel

pump,

the

engine

will

notrun

.

Operating

fuel

pump

for

tests

CA

UTION-

Relay

locations

may

vary

.

Use

care

when

identify-

ing

relays

and

when

troubleshooting

the

electrical

system

at

the

fuselrelay

panel

.

The

fuel

pump

re-

¡ay

is

a

four

pin

relay

and

has

a

1.5

mm

2

red

wireat

terminal

30

in

the

relay

socket,

lf

in

doubt,

con-

sult

an

authorized

BMW

dealer

.

NOTE-

Thejumper

wire

shouldbe

1.5

mm2

(14

ga

.)

and

in-

clude

en

in-fine

fuse

holder

with

a16

amp

fuse

.

To

avoid

fuselrelay

panel

damage

fromrepeated

connect-

íng

and

disconnecting,

also

include

a

toggleswitch

.

A

heavy-duty

jumper,

BMW

tool

no

.

613

050,

fs

also

available

from

en

authorized

BMW

dealer

.

0013034,

If

the

pump

does

notrun

with

the

jumper

installed,

the

fault

could

be

in

the

fuel

pump

or

the

wiring

to

the

pump

.

Check

the

pump

and

its

wiring

as

described

below

.

Page 191 of 759

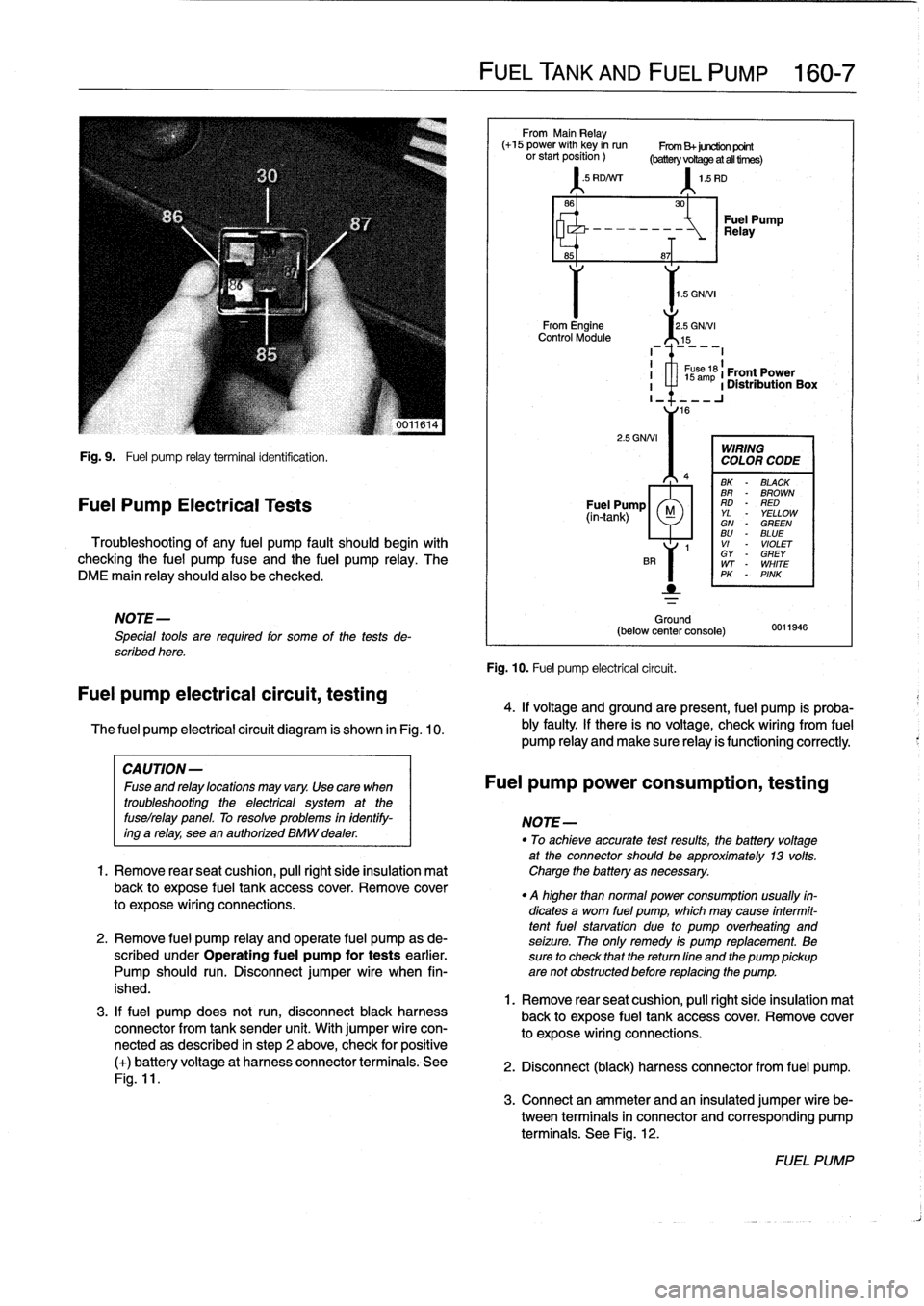

Fig

.

9

.

Fuel

pump

relay

terminal

identification

.

Fuel

Pump

Electrical

Tests

Troubleshooting

of

any

fuel

pump

fault

should

begin

with

checking

the

fuel

pump

fuse

and

the

fuel

pump

relay

.

The

DME

main

relay

should

also

be

checked

.

NOTE-

Special

tools

are

requíred

for

some

of

the

tests

de-

scribed

here

.

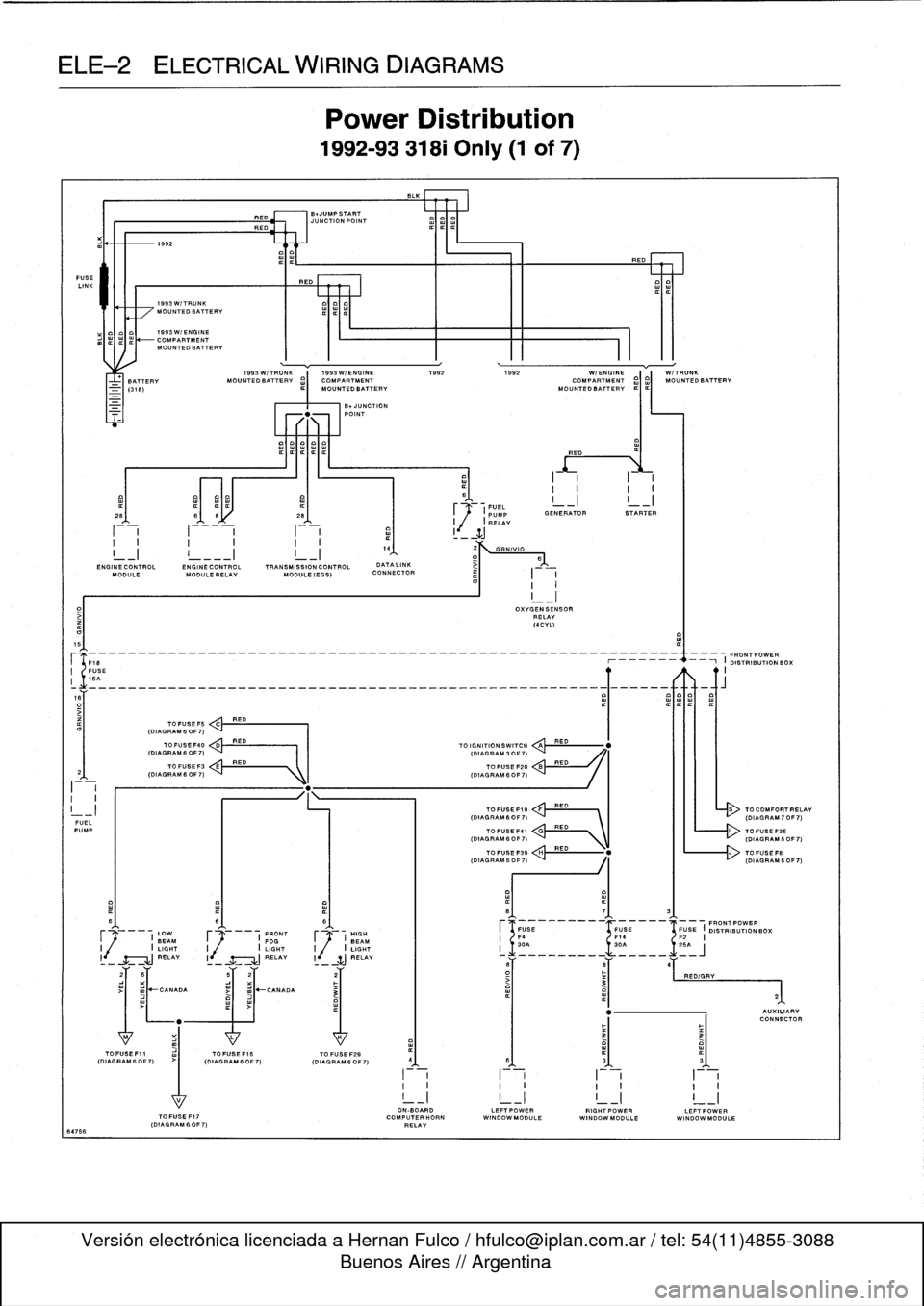

Fuel

pump

electrical

circuit,

testing

The

fuel

pump

electrical

circuit

diagram

is

shown

in

Fig

.

10

.

3

.

If

fuel

pump

does

not

run,

disconnect

black

harness

connector

from

tank

sender

unit

.

With

jumper

wire

con-

nectedas

described

in

step

2

above,

check

for

positive

(+)

batteryvoltage

at

harness

connector

terminals

.

See

Fig

.

11

.

FUEL

TANK

AND

FUEL

PUMP

160-

7

From

Main

Relay

(+15

power

with

key

in

run

From

B+juretion

point

orstartposition)

(batteryvoRageatalltirnes)

'

.5

RD/Nrr

1

.5

RD

1

.5

GNNI

From

Engine

2

.5

GNNI

Control

Module

15

2

.5

GNNI

Ground

(below

center

console)

Fig

.

10

.

Fuel

pump

electrical

circuit

.

30

-~

Relay

Fuel

Pump

8~T

I

1

s

ám

61

Front

Power

I

a

1

Distribution

Box

I_

16

WIRING

COLOR

CODE

BK

-

BLACK

BR

-

BROWN

Fuel

Pump

RD

-

RED

(in-tank)

M

YL

YELLOWGN

-

GREENBU

-

BLUE

1

VI

-

VIOLET

GY

-

GREY

WT

-

WHITE

PK

-

PINK

0011946

4

.

If

voltage

and

groundare

present,

fuel

pump

is

proba-

bly

faulty

.

If

there

is

no

voltage,

check

wiring

From

fuel

pump

Reay

and

make

sure

Reay

is

functioning

correctly

.

CAUTION-

Fuseandrelaylocationsmayvary

.

Usecara

when

Fuel

pump

power

consumption,

testing

troubleshooting

the

electrical

system

at

the

fuselrelay

panel

.

To

resolve

problems

in

identify-

NOTE-

ing

a

relay,

see

en

authorízed

BMW

dealer

.

"

To

achieveaccurate

testresults,

fhe

battery

voltage

at

the

connector

should

be

approximately

13

volts

.

1.

Remove

rearseat

cushion,

pull

right

side

insulation

mat

Charge

the

battery

asnecessary

.

back

to

expose

fuel

tank

accesscover

.

Remove

cover

.

q

higher

than

normal

power

consumption

usually

fin-

to

expose

wiring

connections

.

dicates

a

worn

fuel

pump,

which

may

cause

intermit-

tentfuel

starvation

due

lo

pump

overheating

and

2

.

Remove

fuel

pump

relay

and

opérate

fuel

pump

as

de-

seizure

.

The

only

remedy

is

pump

replacement

.

Be

scribed

under

Operating

fuel

pump

for

tests

earlier

.

sure

to

check

that

thereturn

fine

and

the

pump

pickup

Pump

should

run

.

Disconnect

jumper

wire

when

fin-

are

not

obstructed

before

replacing

the

pump

.

ished

.

1

.

Remove

rear

seat

cushion,

pull

right

side

insulation

mal

back

to

expose

fuel

tank

accesscover

.

Remove

cover

to

expose

wiring

connections

.

2

.

Disconnect

(black)

harness

connector

from

fuel

pump

.

3

.

Connect

an

ammeter

and

an

insulated

jumper

wire

be-

tween

terminals

in

connector

and

corresponding

pump

terminals

.

See

Fig

.

12

.

FUEL

PUMP

Page 486 of 759

ELE--2

ELECTRICAL

WIRING

DIAGRAMS

FUSE

LINK

64766

I-i

I

-

i

a

1

I

_

ZJ

I

I

I

I

I

I.

4

2

GRN/VIO

I_I

!

___I

I_I

1

D>

6

END

INECONTROL

ENGINECONTROL

TRANSMISSION

CONTROL

DATALINK

MODULE

MODULE

RELAY

MODULE

(EGS)

CONNECTOR

I

I

I

I

5

(F18

--_______________________________________________

O19~

N

RIBUON

BOX

I

FUSE

II

15A

o~___________________________________________________Q~____-aft

TO

FUSE

F5

C

RED

(DIAGRAM

6

OF

7)

FUELPUMP

I

(DIAGRAM60F7)

C'

RED

\

L------r>

(DIAGRAM60F7)

I

LOW

F

I

FRONT

HIGH

BEAM

FOGJ

BEAM

I

I

LIGHT

I

I

LIGHT

I

j

/

I

LIGHT

RELAY

I

RELAY

li

SJ

RELAY

1992

1993W/TRUNK

MOUNTEDBATTERV

1993W/ENGINE

COMPARTMENTMOUNTEDBATTERV

1993W/TRUNK

1993W/ENGINE

1992

1992

WI

ENGINE

W/TRUNK

BATTERY

MOUNTEDBATTERV

¢)

MOUNTED

BATTERY

MOUN

O

TEDBATT

I

ERV

¢I¢I

MOUNTEDBATTERV

TOFUSEF40

<

,.k

RED

(DIAGRAM

6

OF

7)

I

I

(DIAGRAM

3

OF

7)

TO

FUSEF3

E

RED

(DIAGRAMfiOF7)

"

.

1k

I

(DIAGRAM

6OF7)

>I

mJ~CANADA

RED

BNUMPSTART

JUNCTION

POINT

REO

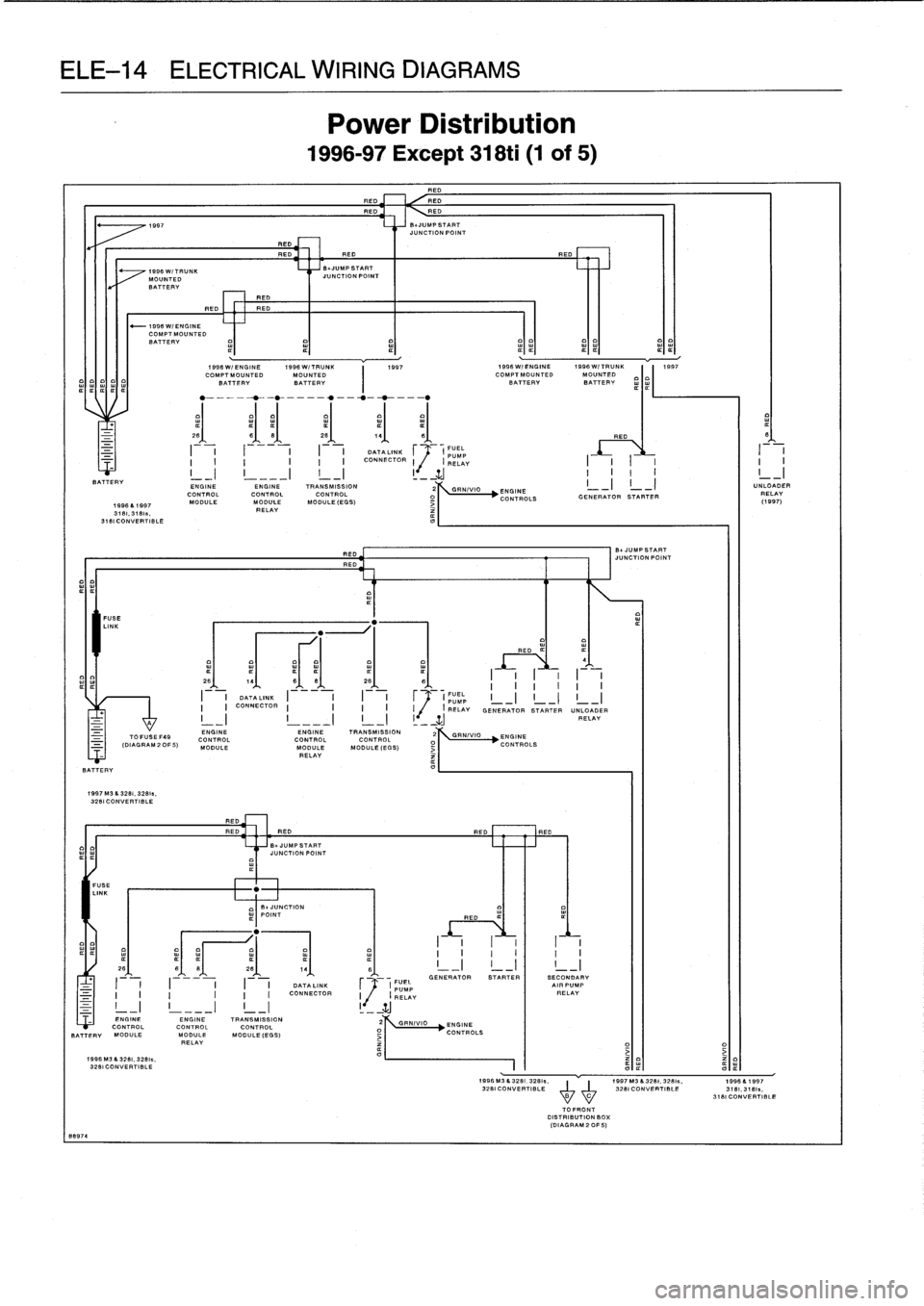

Power

Distribution

1992-93

318i

Only

(1

of

7)

-UNCTION

POINT

TOFUSEF15

TO

FUSE

F29

(DIAGRAM60F7)

(OIAGRAM6OF7)

I

~1

.

FUEL

_I

I

_I

~

(PUMP

GENERATOR

STARTER

I

,(

I

RELAY

TO

IGNITION

SWITCH

QA

TOFUSE

F20

TOFUSEF19

FRED

(DIAGRAM6OF7)

`

I

III

-

(DIAGRAM70F7)

OXVGENSENSOR

RELAY

(4CVL)

RED

RED

RED

ON-BOARD

LEFTPOWERRIGHTPOWERLEFTPOWER

TOFUSEF17

COMPUTERHORN

WINDOWMODULE

WINDOWMODULE

WINDOW

MODULE

(DIAGRAM

60F

7)

RELAY

TO

COMFORTRELAV

Page 498 of 759

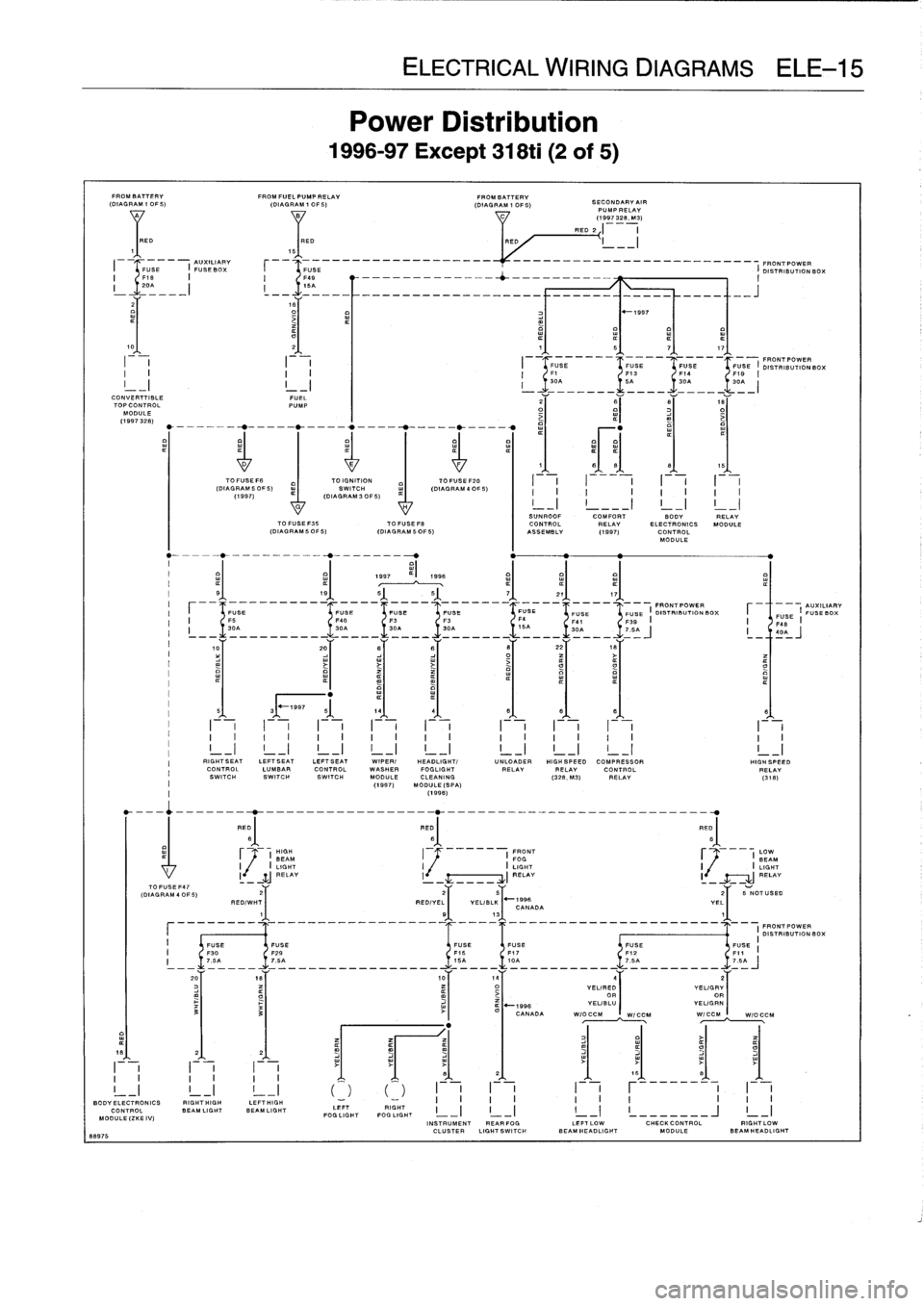

ELE-14

ELECTRICAL

WIRING

DIAGRAMS

BATTERY

FUSE

LINK

REDRED

RED

RED

RED

1997

S

.JUMPSTART

JUNCTION

POINT

1996W/TRUNK

MOUNTED

BATTERY

----

1998W/ENGINE

¢

¢

¢

¢¢COMPTMOUNTED

BATTERY

1996&1997

3181,3181

.,

3181

CONVERTIBLE

b

~

_

I

ENGINETO

FUSE

F49

CONTROL

(DIAGRAM

2OF5)

MODULE

BATTERY

1997M3

&328i.32811,3281

CONVERTIBLE

f

FUSE

LINK

1996

M3

&3281

.

3281

..

3281

CONY

ERTIBLE

1996

W/ENGINE

1996

W/TRUNK

1997

1996

W/ENGINE

1996

WITRUNK

COMPTMOUNTED

MOUNTED

COMPTMOUNTED

MOUNTEDC

BATTERY

BATTERY

BATTERY

BATTERY

REDREDRED

MP

START

JUNCTION

POINT

Power

Distribution

1996-97

Except

318ti

(1

of

5)

RED

RED

RED

I

I

T=

BtJUMPSTART

JU

NCTION

POINT

_RED

RED

0

I

I

I

I

I

I

DATA

LINK

r

(

(FUEL

I

I

I

I

I

I

I

I

CONNECTOR

(

(

Pump

RELAY

I

I

I

I

II

I

I

I

I

I

I

Zj

I

I

I

I

I

I

ENGINE

ENGINETRANSMISSION

I

-I

I

_I

UNLOADER

2//

\\GRN/VI

O

ENGINE

CONTROL

CONTROL

CONTROL

/

~

RELAY

MODULE

MODULE

MODULE(EGS)

I

"

CONTROLS

GENERATOR

STARTER

(1997)

RELAY

W

W

W

RED

8r.1

28

6

1

I

I

I

I

__

____

__

I

IIII

I

I

I

DATALINK

I

I

I

I

r

_~

_I

FUEL

I

-

I

I

-

I

I

-

I

I

CONNECTOR

I

I

I

I

I

I

ENGINE

TRANSMISSION

2

GRNIV

CONTROL

CONTROL

MODULE

MODULE(EGS)RELAY

i

ENGINE

ENGINE

TRANSMISSION

CONTROLCONTROLCONTROL

02

GRN/VIO

BATTERY

MODULE

MODULE

MOD

ULE(EGS)

_

RELAY

ENGINE

CONTROLS

ENGINE

CONTROLS

RED

[EH]RED

2I

POINT

CTION

RED

¢I

I

I

II

I

-

,

I

I

I

I

I

I

261

61

.1

281

1

,

11

61

I

-I

!

_I

I

i

_I

m

FUEL

GENERATOR

STARTER

SECONDARY

I

I

I

I

I

I

DATALINK

r

/y

(

PUMP

I

AI-

PUMP

I

I

I

I

I

I

CONNECTOR

I

f

(RELAY

RELAY

zJ

TOFRONT

DISTRIBUTION

BOX

(DIAGRAM

20F

5)

1997

B+

JUMP

START

JUNCTION

POINT

1996M3&3281,32811

.

1997M3&3281,3281

.,

1898&1997

3281

CONVERTIBLE

3281CONVERTIBLF

3181.3181x,BC

3181CONVERTIBLE

Page 499 of 759

FROM

BATTERY

FROMFUEL

PUMP

RELAY

FROM

BATTERY

(DIAGRAM

1OF5)

(DIAGRAM

10F5)

(DIAGRAM

1OF5)

SECONDARY

AIR

PUMP

RELAY

C

(1997

328,

M3)

RED

2

I

I

T

.E

.

RED

RED

I

-

I

,1

,5

8

J~

AUXILIARY

FRONTPOWER

I

FUSE

I

FUSEBOX

F

FUSE

I

DISTRIBUTION

BOX

I

F78

I

I

F49

--------_

-

---------_

I

I

20A

-

I

I

15A

_____

_-____________-___

______

_____

____

2

1S

~--,997

10

2

;

5

7

17

.1c

FRONTPOWER

I

I

I

I

FUSE

FUSE

FUSE

FUSE

I

DISTRIBUTIONBOX

I

II

I

F1

F13

F74

F19

I

_I

_

I

_I

I

30A5

A___

30A

-

I

CONVERTTIBLE

PUP,

28818

TOPCONTROL

PUMP

MODULE

O

O>

¢I

o

(1997328)

t

$

1

fi~e~

B

,

s

TO

FUSE

FS

TO

IGNITION

TO

FUSE

F20

(DIAGRAMSOF5)

SWITCH

(DIAGRAM

30F5)

(DIAGRAM

40F5)

(1997)

I

I

I

I

I

I

II

-I

I

---

I

I

-I

I

-

1

7

v

SUNROOF

COMFORT

SOOY

RELAY

TOFUSEF35

TOFUSEFS

CONTROL

RELAY

ELECTRONICS

MODULE

(DIAGRAM50F5)(DIAGRAM5OFS)

ASSEMBLY

(1997)

CONTROLMODULE

-__---__-4-----_--

"

-

1

__

____-____

1

9

__

_

_

5

l

7

_~I_

______

___

_

9

5

7

2,

,7

1

r

FRONTPOWER

r

I

-

AUXILIARY

I

FUSE

FUSE

FUSE

FUSE

USE

FUSE

FUSE-1

DISTRIBUTION

BOX

I

FUSE

I

FUSE

BOX

I

F5

F40

F3

FUSE

4

F61

F39

I

I

F68

I

I

I

__

3_A_____-___

303-A

-__

30A

530A

___

_5_j

I

40=,

I

10

20

fi

68

22

18

O_

I

w

W

III

5

3

~,997

II

I

i

I

i

I

5

l

i

.

1'

4

i

1

4

1

1

8

i

1

6

1

1

8

8

i

1

i

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I_I

!

_I

!

_I

L-1

I

!

_I

!

_I

_I

RIGHTSEAT

LEFTSEAT

LEFT

SEAT

WIPERI

HEADLIGHT/

UNLOADER

HIGHBPEED

COMPRESSOR

HIGH

SPEED

CONTROL

LUMBAR

CONTROL

WASHER

FOGLIGHT

RELAY

RELAY

CONTROL

RELAY

SWITCH

SWITCH

SWITCH

MODULE

CLEANING

(328,M3)

RELAY

(318)

(1997)

MODULE(SPA)

I

(1998)

--

----------

-----------------III

-

-------____-__--------

REDS

RE

-

RED

-t

t

HIGH

~F

FRONT

LOW

BEAM

I

/

J

I

FOG

I

BEAM

~

I

LIGHT

I

(

I

LIGHT

I

I

LIGHT

I_'

-

_

_ZJ

RELAY

If

t-~

I

RELAY

I

RELAY

TOFUSEF47

(DIAGRAM

40F5)

_

RED/WH

;

RED/YEL

L

VEL/B17

1998

VE'

SNOTUSEO

CANADA

_

____

IFRONT

,

GWER

DISTRIBUTION

BOX

I

FUSE

FUSE

FUSE

FUSE

FUSE

FUSE

I

F-O---_

f2-_-_____________

P7_F17

F12

]

FIl

-

7

.SA

7.SA

15A

tOA---------

7

.SA-------

7

.5=~

2.

18

10

to

4

2

_

VEL/RED

YEL/GRY~

m

O

OR

OR

h

r

~,99fi

VEL/BLU

YELIGRN

3

B

CANADA

W/OCCM

W/CCMW/CCMW/OCCM

18

2

2

I

I

I

I

I

I

'

e

z

r

>

1s

B

>

I

BODVELECTRONICS

RIGHTHIGH

LEFTHIGH

'~

IIII

I

II

I

II

CONTROL

BEAM

LIGHT

BEAM

LIGHT

EDQLIGHT

FO

.

LIGHT

I

-I

I

_I

I

_I

I

__

_~

I

_I

MODULE(ZKEIV)

_

__--

INSTRUMENT

REARFOG

LEFT

LOW

CHECK

CONTROL

RIGHT

LOW

CLUSTER

LIGHTSWITCH

BEAM

HEADLIGHT

MODULE

BEAM

HEADLIGHT

88975

ELECTRICAL

WIRING

DIAGRAMS

ELE-15

Power

Distribution

1996-97

Except

318ti

(2

of

5)

Page 503 of 759

10437

0

FUSE

LINK

80A

BATTERY

FUSE

LINK

BOA

4

26

-

AUXILIARY

I

FUSE

I

FUSE

BOX

I

(,

F4.

I

I

Z

2CA

27X19564

_RED

RED

_

REDRED

51X

10016

61X

10816

I

-

1

I

-

1

I

I

I

1

_I

LI

CONVERTIBLE

TOPCONTROLMODULE

ELECTRICAL

WIRING

DIAGRAMS

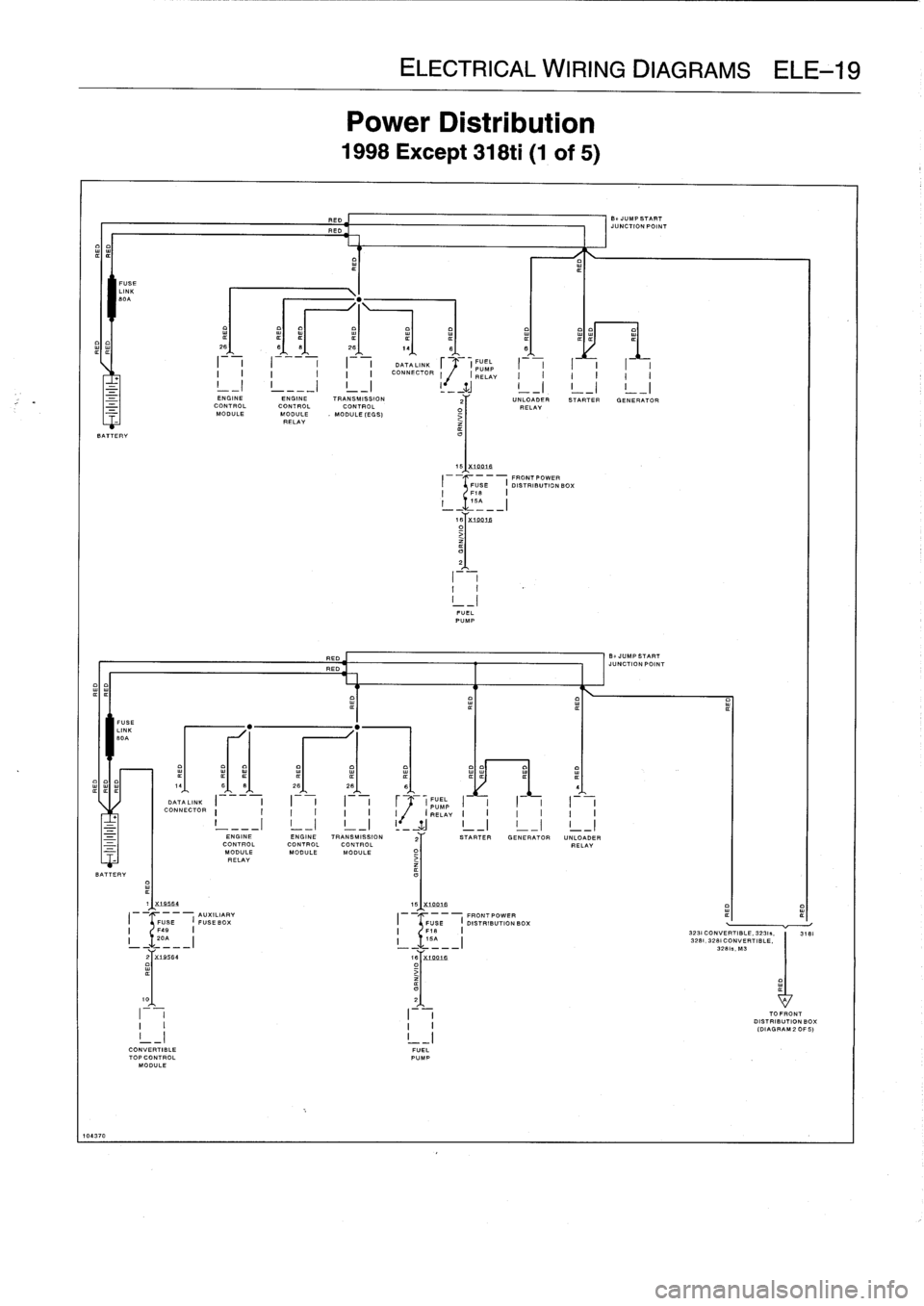

ELE-19

Power

Distribution

1998Except

318ti

(1

of

5)

FUEL

PUMP

161

X111010

FUEL

PUMP

15~X

1DD16

-

FRONT

POWER

I

USE

I

DISTRIBUTION

BOX

I

FIB

II

T15A

14j

,

61BI

261

261

6~

4I

DATA

LINK

I

I

I

I

I

I

r

(

FUEL

I

I

I

I

Pmp

I

CONNECTOR

I

1

I

I

I

I

I

f

(RELAY

I

I

I

II

___I

!

_I

!

_I

!

f

_

zJ

!

_

I

!

_I

!

_I

ENGINE

ENGINE

TRANSMISSION

21

STARTER

GENERATOR

UNLOAD-

-

CONTROLCONTROL

CONTROL

RELAY

-

MODULEMODULE

MODULE

O

RELAY

BtJUMPSTART

JUNCTION

POINT

I

I

I

I

I

I

DATALINK

r

FUEL

I

I

I

I

I

I

CONNECTOR

(

(RELAY

PUMP

1

1

I

I

I

I

_I

!

___I

!

_I

I

(((

_

sJ

!

_I

!

_I

!

_I

ENGINEENGINE

TRANSMISSION

UNLOAD-

STARTER

GENERATORCONTROL

CONTROLCONTROL

O

RELAY

MODULE

MODULE

_

MODULE(EGS)RELAY

BtJUMPSTART

JUNCTION

POINT

FRONTPOWER

¢

¢

I

FUSE

I

DISTRIBUTIONBOX

_

"

I

F'A

I

3231CONVERTIBLE,

3231.

.

I

3181

1

8

=

--

I

3281,

3281C

ONVERTIBLE,

-

32815

.

M3

TOFRONT

DISTRIBUTION

BOX

(DIAGRAM

2

OF

5)

Page 508 of 759

ELE-24

ELECTRICAL

WIRING

DIAGRAMS

I

-

II

I

8887

1

FUSIBLE

LINK

BATTERY

GRNIVIO

r

__

_

_

_

_

.-

__

_

_

_

-_

_

_

_

_

-

-

-

_

__

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

___________

_

___.

r

_

-

_

-

I

FRONTPOWER

F18

JF2

X2

DIS7RIBUTION80X

FUSE

FUSE

~

.

------------------

I

15A

15A

_____________-_________

3

___________

_____________

T

4

v

RED

I

(NOTUSED)

LOW

I

FRONT

I

FI

F

FOG

I

GHT

I

I

L

GHT

I

f--i

(

RELAY

RELAY

'

f

II'

RED

2fi1

281

8181

B1

I

I

I

I

w

I

I

r

(

F

U

EM

L

I

I

I

I

PUP

I

I

I

I

I

I

I

I

RELAY

I

I

I

I

ENGINE

CONTROL

TRANSMISSION

CONTROL

DATA

LINK

ENGINECONTROL

2

GENERATOR

STARTER

MODULE

MODULE

(EGS)

CONNECTOR

MODULERELAY

O

TOFUSE

F5

RED

TO

IGNITION

SWITCH

RED

(DIAGRAMSOF5)

H

(DIAGRAM20F5)

-

14

TO

FUSEF40

RED

TOFUSEF20

RED

RED

TO

FUSE

F8

(DIAGRAMSOF5)

Q

Q

(DIAGRAM20F5)

B

E

(DIAGRAM40F5)

TOFUSEF3

RED

(DIAGRAM

5

OF

5)

5

NOTUSED

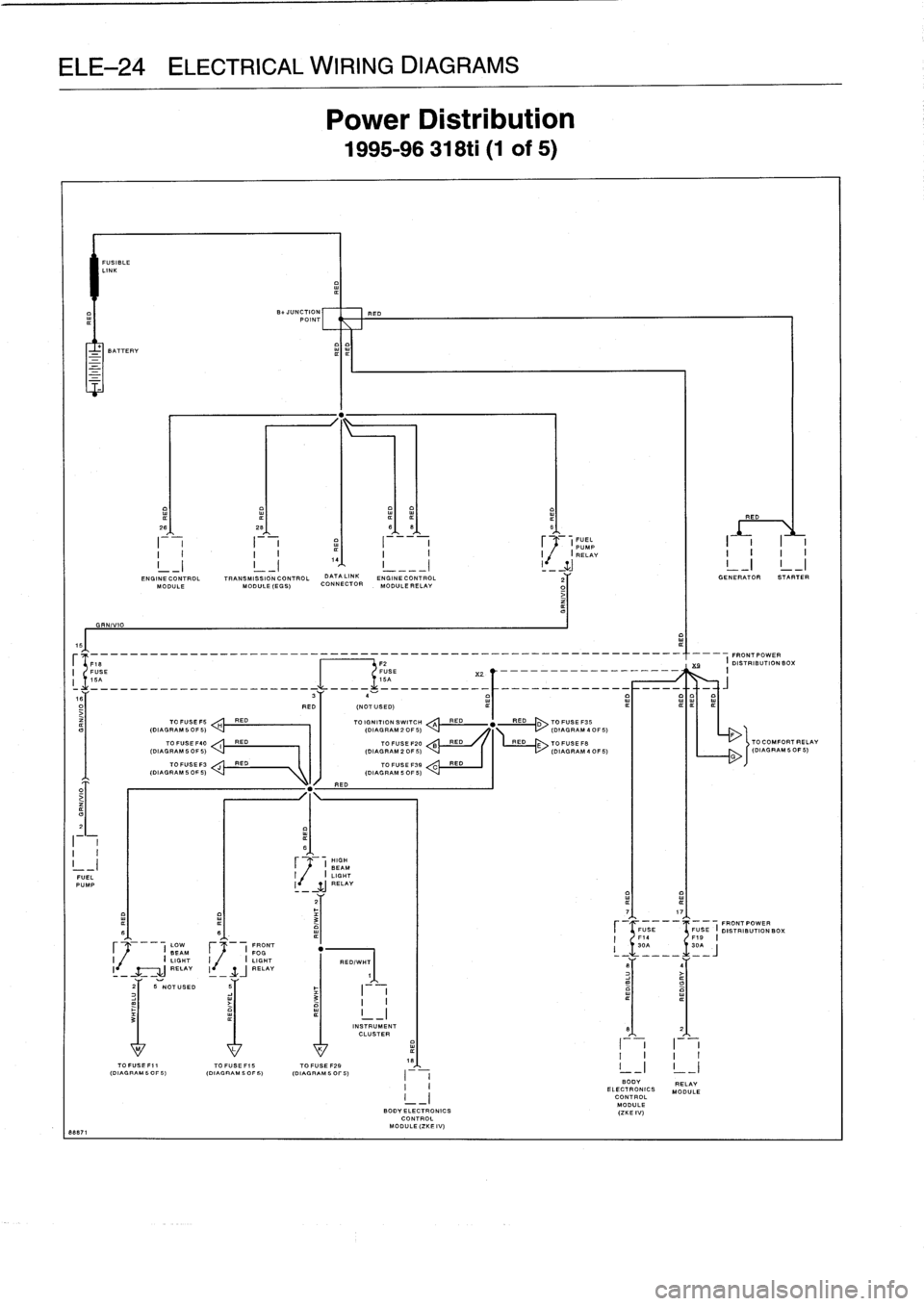

Power

Distribution

1995-96

318ti

(1

of

5)

BiJUNCTION

REO

POINT

I

-1

~

I

15IGH

EAM

FUEL

I

;

I

LIGHT

PUMP

-

~j

RELAY

2

3

TO

FUSE

FII

TO

FUSE

FiS

TOFUSE

F29

(DIAGRAM5OF5)

(DIAGRAM

5OF5)

(DIAGRAM

5OF5)

RED/WHT

TOFUSEF39

CRED

(DIAGRAM

50F5)

INSTRUMENT

CLUSTER

BODYELECTRONICS

CONTROL

MODULE

(ZKEIV)

BODY

RELAY

ELECTRONICS

MODULE

CONTROL

MODULE

(ZKEIV)

D

TO

COMFORT

RELAY

D

(DIAGRAMSOF5)

G