Oil service BMW 325i 1994 E36 User Guide

[x] Cancel search | Manufacturer: BMW, Model Year: 1994, Model line: 325i, Model: BMW 325i 1994 E36Pages: 759

Page 31 of 759

Final

Drive

Gear

Oil

BMW

recommends

using

only

a

specially

formulatedsyn-

thetic

gear

oil

that

is

available

through

an

authorized

BMW

dealer

parts

department

.

For

additional

information

on

this

¡u-

bricant

andany

other

lubricants

that

may

be

compatible,

con-

tact

an

authorized

BMW

dealer

senrice

department

.

See

331

Final

Drive

.

Brake

Fluid

Brake

fluid

absorbs

moisture

easily,

and

moisture

in

the

fluid

affects

brake

performance

and

reliability

.

This

is

why

brake

fluid

should

be

flushed

from

the

system

every

two

years

.

When

re-

placing

or

adding

brake

fluid,

use

only

new

(luid

from

previously

unopened

containers

.

Do

not

use

brake

fluid

that

has

been

bled

from

the

system,

even

ifit

is

brand

new

.

Use

only

DOT

4

brake

fluid

.

See340

Brakes

for

more

information

.

Engine

Coolant

(Anti-freeze)

BMW

recommends

coolant

that

is

a

50/50

mixture

of

distilled

water

and

phosphate/nítrate

freeanti-freeze

containing

ethyl-

ene

glycol

.

Anti-freezeraises

the

boiling

point

and

lowersthe

freezingpoint

of

the

coolant

.

It

alsocontains

additives

that

help

prevent

cooling

system

corrosion

.

Power

Steering

Fluid

The

power

steering

fluid

is

Dexron

II]®

ATF,

or

equivalent

.

The

system

is

permanently

filled

and

does

not

have

a

drain

.

Routinely

adding

ATF

is

not

required

unlessthe

system

is

leak-

i

n

g,

WARNING

-

Be

sure

to

check

the

fluid

specifications

on

the

pow-

er

steering

reservoir

to

confirm

the

fluid

type

in-

stalled

in

the

system

.

In

some

instances,

the

power

steering

system

may

be

filled

with

an

alternative

hy-

draulic

fluid

designated

CHF

7

.1

.

MAINTENANCE

PROGRAM

020-

ENGINE

OIL

SERVICE

Engine

oil

and

fiiter,

changing

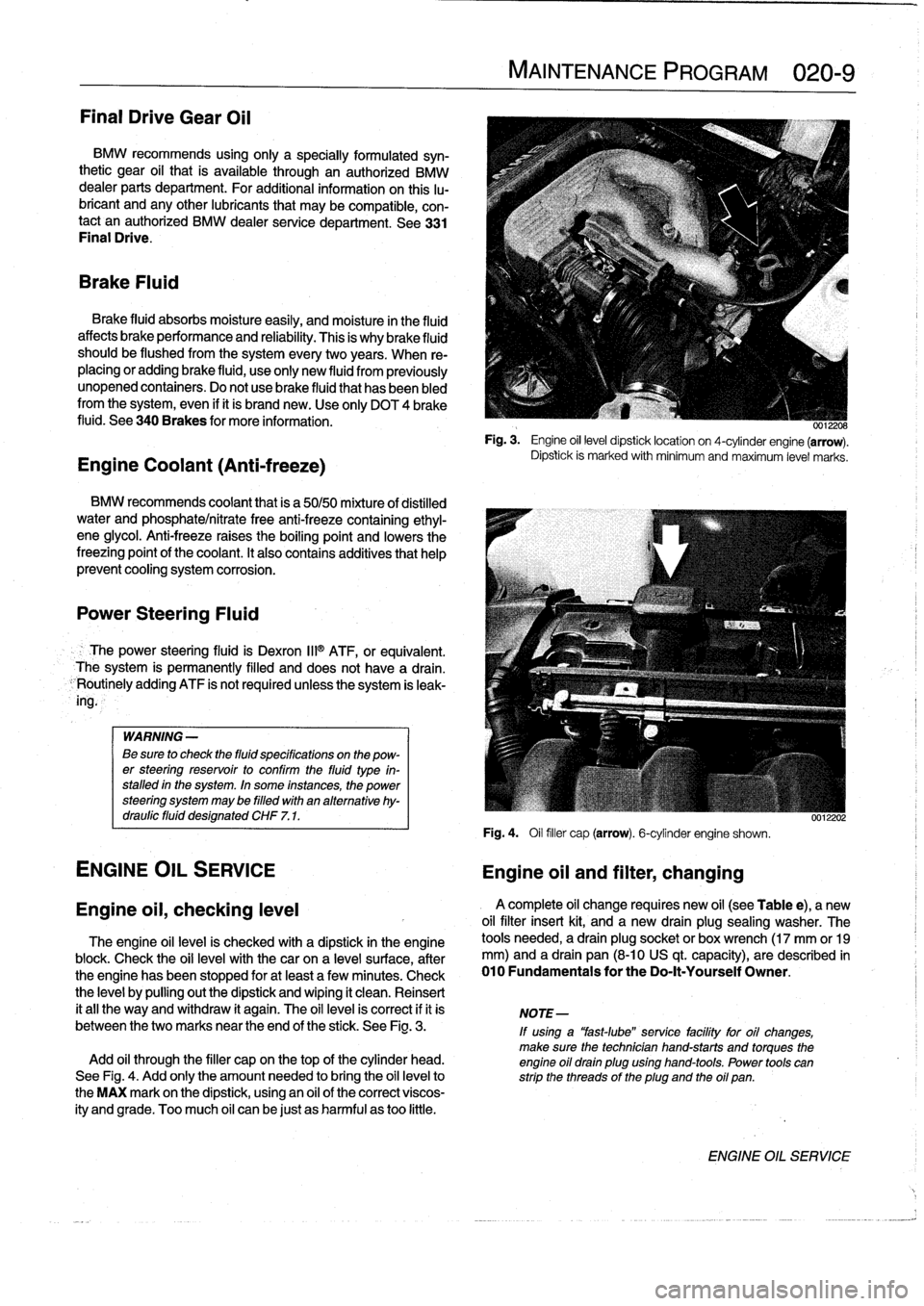

Fig

.

3

.

Engine

oil

level

dipsticklocation

on

4-cylinder

engine

(arrow)

.

Dipsfck

is

marked

with

mínimum

and

maximum

level

marks

.

Fig

.

4

.

Oil

filler

cap

(arrow)

.

6-cylinder

engine

shown

.

0012202

Engine

oii,

checking

leve¡

A

complete

oil

change

requires

new

oil

(see

Table

e),

a

new

oil

filter

insert

kit,

and

a

new

drain

plug

sealing

washer

.

The

The

engine

oil

leve]

is

checked

with

a

dipstick

in

the

engine

tools

needed,

a

drain

plug

socket

or

box

wrench

(17

mm

or19

block

.

Check

the

oii

leve¡

with

the

canon

a

level

surface,

after

mm)

and

a

drain

pan

(8-10

US

qt

.

capacity),

are

described

in

the

engine

has

been

stopped

for

atleast

a

few

minutes

.

Check

010

Fundamentals

for

the

Do-It-Yourself

Owner

.

the

leve¡

by

pulling

outthe

dipstick

and

wiping

it

clean

.

Reinsert

it

all

the

way

and

withdraw

it

again

.

The

oil

leve¡

is

correct

if

it

is

NOTE-

between

the

two

marks

near

the

end

of

the

stick

.

See

Fig

.

3

.

If

using

a

"fast-lube"

service

facility

for

oil

changes,

make

sure

the

technician

hand-starts

and

torques

the

Add

oil

through

the

filler

cap

on

thetop

of

the

cylinder

head

.

engine

oil

drain

plug

using

hand-tools

.

Power

tools

can

See

Fig

.

4

.

Add

only

the

amount

needed

to

bring

the

oil

leve¡to

strip

the

threads

of

the

plug

and

the

oil

pan

.

the

MAX

mark

on

the

dipstick,

using

an

oil

of

the

correctviscos-

ity

andgrade

.

Too

much

oil

canbe

just

as

harmful

as

too

little

.

ENGINE

OIL

SERVICE

Page 36 of 759

020-

1

4

MAINTENANCE

PROGRAM

uu11989

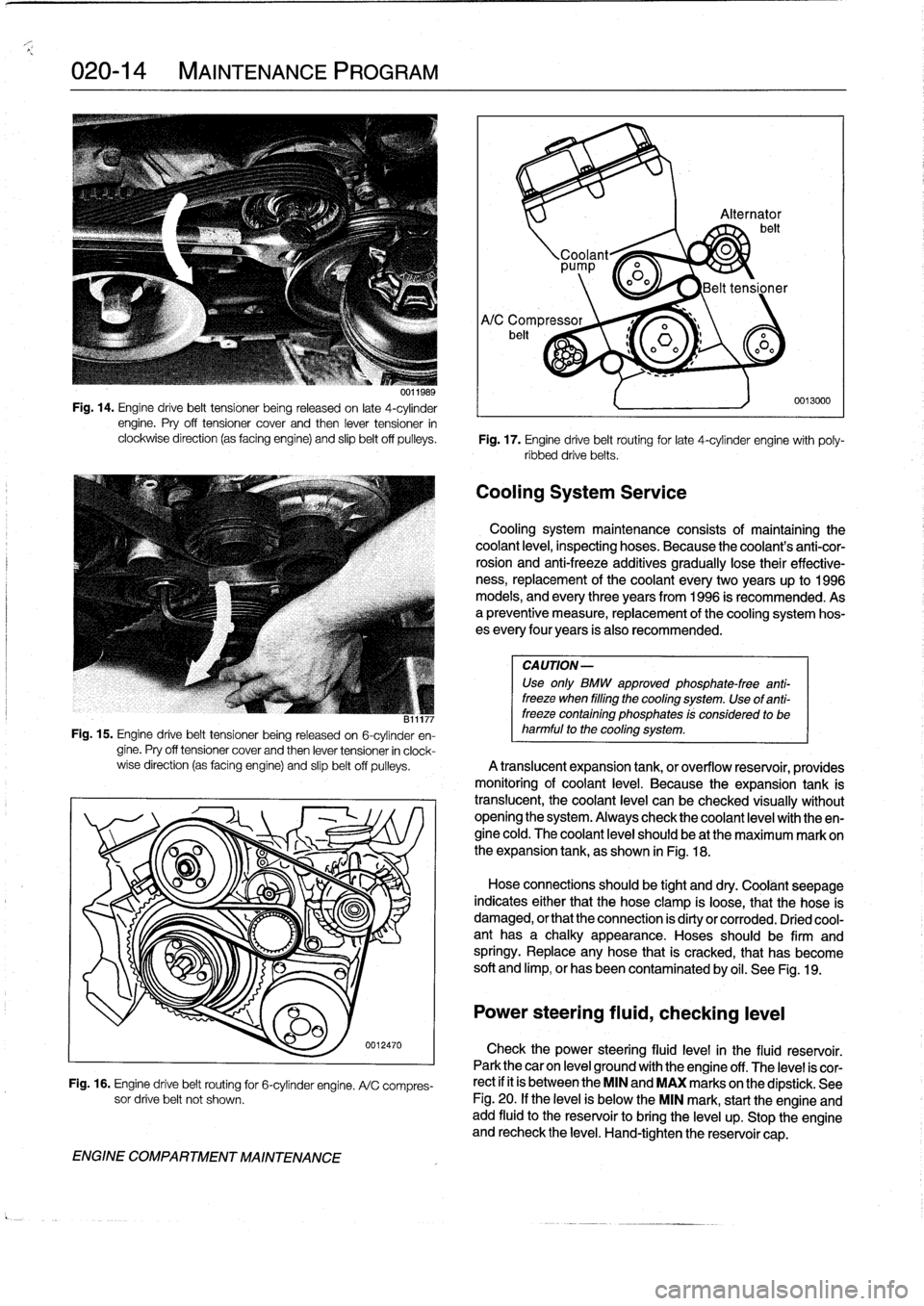

Fig

.

14

.

Engine

drive

belt

tensíoner

being

released

on

late

4-cylinder

engine

.

Pry

off

tensioner

cover

and

then

lever

tensioner

in

clockwise

direction

(as

facing

engine)

and

slip

beltoff

pulleys

.

Fig

.

17

.

Engine

drive

belt

routing

for

late

4-cylinder

engine

with

poly-

ribbed

drivebelts

.

CA

UTION-

Use

only

BMW

approved

phosphate-free

anti-

freeze

when

filling

the

cooling

system

.

Use

of

anti-

B11177

freeze

containing

phosphates

!s

considerad

to

be

Fig

.

15

.

Engine

drive

belt

tensioner

being

released

on

6-cylinder

en-

harmful

to

the

cooling

system

.

gine

.

Pry

off

tensioner

cover

and

then

lever

tensioner

in

clock-

wise

direction

(as

facing

engine)

and

slipbelt

off

pulleys

.

A

translucent

expansion

tank,

or

overflow

resenroir,

providesmonitóring

of

coolant

leve¡

.

Because

the

expansion

tank

is

translucent,

thecoolant

level

can

be

checked

visually

without

opening

the

system

.

Always

check

thecoolant

leve¡

with

theen-gine

cold

.

The

coolant

leve¡

should

be

at

the

maximum

mark

on

O

o

'~

I

the

expansion

tank,

as

shown

in

Fig

.

18

.

OO

Hose

connectionhld

b

tiht

s

soueg

an

ddry

.

Coolánt

seepage

indicates

either

that

the

hose

clamp

is

loose,

that

the

pose

is

ENGINE

COMPARTMENT

MAINTENANCE

0012470

Fig

.

16

.

Engine

drive

belt

routing

for

6-cylinder

engine

.

A/C

compres-

sor

drive

belt

not

shown

.

'92

irá

Alternator

belt

Coolant~

0

pp

o0o

Belt

tensioner

Cooling

System

Service

0013000

Cooling

system

maintenance

consists

of

maíntaining

thecoolant

leve¡,

inspecting

hoses

.

Because

the

coolant's

anti-cor-

rosion

and

anti-freeze

additives

gradually

lose

their

effective-

ness,

replacement

of

thecoolant

every

two

years

up

to

1996

models,

and

every

three

years

from

1996

is

recommended

.

Asa

preventive

measure,

replacement

of

the

cooling

system

hos-

es

every

four

years

is

also

recommended

.

damaged,

or

that

the

connection

is

dirty

or

corroded

.

Dried

cool-

ant

has

a

chalky

appearance

.

Hoses

should

be

firm

and

springy

.

Replace

any

hose

that

is

cracked,

that

has

become

soft

and

limp,

or

has

been

contaminated

by

oil

.

See

Fig

.

19

.

Power

steering

fluid,

checking

leve¡

Check

the

power

steering

fluid

level

in

the

fluid

reservoir

.

Park

thecar

on

leve¡

ground

with

the

engine

off

.

The

level

is

cor-

rect

if

it

is

between

the

MIN

and

MAX

marks

on

the

dipstick

.

See

Fig

.

20

.

If

the

leve¡

is

below

the

MIN

mark,

start

the

engine

andadd

fluid

to

the

reservoir

to

bríng

the

leve¡

up

.

Stop

the

engine

and

recheck

the

leve¡

.

Hand-tighten

the

reservoir

cap

.

Page 40 of 759

020-

1

8

MAINTENANCE

PROGRAM

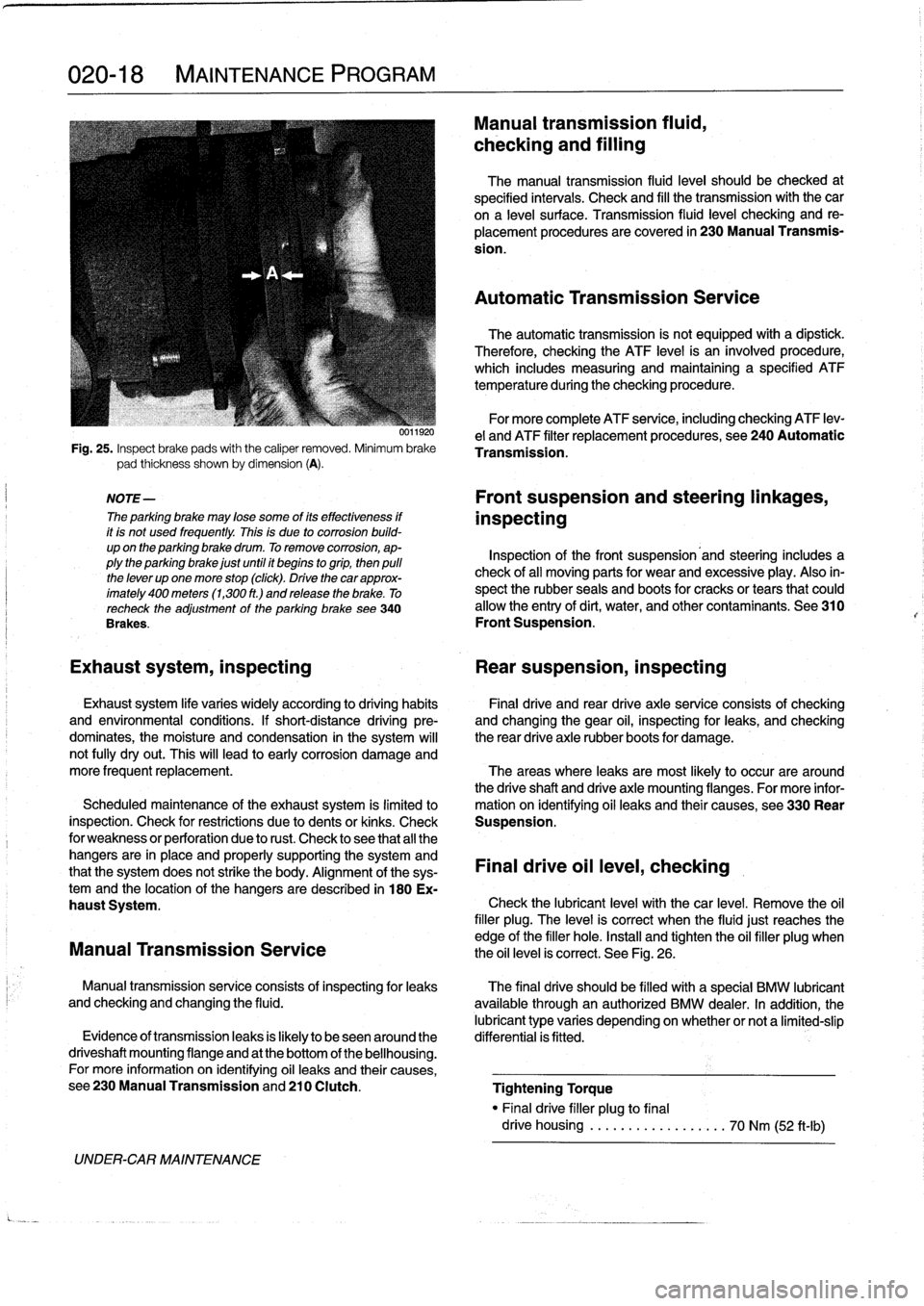

Fig

.

25

.

Inspect

brake

pads

with

the

caliper

removed

.

Minimum

brake

pad

thickness

shown

by

dimension

(A)

.

NOTE-

The

parking

brake

may

lose

some

of

its

effectiveness

if

it

is

not

used

frequently

.

This

is

due

to

corrosion

build-

up

on

the

parking

brake

drum

.

To

remove

corrosion,

ap-

plythe

parking

brake

just

until

it

begins

togrip,

then

pulí

the

lever

up

one

more

stop

(click)

.

Drive

thecar

approx-

imately

400

meters

(1,300

ft

.)

and

release

the

brake

.

To

recheck

the

adjustment

of

the

parking

brake

see340

Brakes

.

UNDER-CAR

MAINTENANCE

0011920

Manual

transmission

fluid,

checking

and

filling

The

manual

transmission

fluid

leve¡

should

be

checked

at

specified

intervals

.

Check

and

fill

the

transmission

with

the

car

ona

leve¡

surface

.

Transmission

(luid

leve¡

checking

and

re-

placement

procedures

are

covered

in

230

Manual

Transmis-

sion

.

Automatic

Transmission

Service

The

automatic

transmission

is

not

equipped

with

a

dipstíck

.

Therefore,

checking

the

ATF

level

is

an

ínvolved

procedure,

which

includes

measuring

and

maintaining

a

specified

ATF

temperature

during

the

checking

procedure

.

For

more

complete

ATF

service,

including

checking

ATF

lev-

e¡

and

ATF

filter

replacement

procedures,

see

240

Automatic

Transmission

.

Front

suspension

and

steering

linkages,

inspecting

Inspection

of

the

front

suspension'and

steering

includes

a

check

of

all

moving

parts

for

wear

and

excessive

play

.

Also

in-

spect

the

rubber

seals

and

boots

for

cracks

or

tears

that

could

allow

the

entry

of

dirt,

water,

and

other

contaminants

.

See

310

Front

Suspension

.

Exhaust

system,

inspecting

Rear

suspension,

inspecting

Exhaust

system

life

varies

widely

according

to

driving

habits

Final

drive

and

rear

drive

axle

service

consists

of

checking

and

environmental

conditions

.

If

short-distance

driving

pre-

and

changing

the

gear

oil,

inspecting

for

leaks,

and

checking

dominates,

the

moisture

and

condensation

in

the

system

will

the

rear

drive

axle

rubber

boots

for

damage

.

not

fully

dryout

.

This

will

lead

to

early

corrosion

damage

and

more

frequent

replacement

.

The

areas

where

leaks

are

most

likely

to

occur

are

around

the

driveshaft

and

drive

axle

mounting

flanges

.

For

more

infor

Scheduled

maintenance

of

the

exhaust

system

is

limitedlo

mation

on

ídentifying

oil

leaks

and

their

causes,

see330

Rear

inspection

.

Check

for

restrictions

due

to

dents

or

kinks

.

Check

Suspension

.

for

weakness

or

perforation

due

to

rust

.

Check

lo

see

that

all

the

hangers

are

in

place

and

properly

supporting

the

system

and

that

the

system

does

not

strike

the

body

.

Alignment

of

the

sys-

Final

drive

oil

leve¡,

checking

temand

the

location

of

the

hangers

aredescribed

in

180

Ex-

haust

System

.

Check

the

lubricant

leve¡

with

thecar

level

.

Remove

the

oil

filler

plug

.

The

leve¡

is

correct

when

the

fluidjust

reaches

the

edge

of

the

filler

hole

.

Install

and

tighten

the

oil

filler

plug

when

Manual

Transmission

Service

the

oil

level

is

correct

.

See

Fig

.

26

.

Manual

transmissionservice

consists

of

inspectingfor

leaks

The

final

drive

should

be

filled

with

a

special

BMW

lubricant

and

checking

and

changing

the

fluid

.

available

through

an

authorized

BMW

dealer

.

In

addition,

the

lubricant

type

varies

depending

onwhether

or

nota

limited-slip

Evidence

of

transmissionleaks

is

fkely

to

beseenaround

the

differential

is

fitted

.

driveshaft

mounting

flange

and

at

the

bottom

of

the

bellhousing

.

For

more

information

on

identifying

oil

leaks

and

their

causes,

see230ManualTransmissionand210

Clutch

.

Tightening

Torque

"

Finaldrive

filler

plug

to

final

drive

housing

..................

70

Nm

(52

ft-Ib)

Page 42 of 759

020-20

MAINTENANCE

PROGRAM

Seat

Belts

Washing

Chassis

Dirt

and

other

abrasive

particles

will

damage

seat

belt

web-

Periodic

washing

of

the

underside

of

the

car,

especially

in

bing

.

If¡t

is

necessary

to

clean

seat

belts,

use

a

mild

soap

solu-

winter,

will

help

prevent

accumulation

of

road

salt

and

rust

.

The

tion

.

Bleach

and

other

strong

cleaning

agents

may

weaken

the

besttime

to

wash

the

underside

is

just

after

the

car

has

been

belt

webbing

and

should

be

avoided

.

driven

in

wet

conditions

.

Spray

the

chassis

with

a

powerful

jet

of

water

.

Commercial

or

self-service

car

washes

may

not

be

best

WARNING-

for

this,

as

they

may

recycle

the

salt-contaminated

water

.

Do

not

clean

the

seat

belt

webbing

using

dry

clean-

ing

or

other

chemicals

.

Allow

wet

belts

to

dry

before

allowing

them

to

retract

.

Speeial

Cleaning

The

condition

of

the

belt

webbing

and

the

function

of

the

re-

tractor

mechanisms

should

be

inspected

.

See720

Seat

Belts

for

seat

belt

inspection

information

.

Exterior

Washing

The

longer

dirt

isleft

on

the

paint,

the

greater

the

risk

of

dam-

aging

the

glossy

finish,

either

by

scratching

or

by

the

chemical

effect

dirt

particles

may

have

on

the

paintedsurface

.

Do

not

wash

the

car

in

direct

sunlight

.

If

the

engine

hood

is

warm,

allow

it

to

cool

.

Beads

of

water

not

only

leavespots

when

dried

rapidly

by

the

sun

or

heat

from

the

engine,

but

also

can

act

as

small

magnifyingglasses

and

burn

spots

into

the

finish

.

Wash

thecar

with

a

mixture

of

lukewarmwater

and

a

car

wash

product

.

Rinse

using

plenty

of

clear

water

.

Wipe

the

body

dry

witha

soft

cloth

towel

or

chamois

to

prevent

water-spotting

.

Waxing

For

a

long-lasting,protective,

and

glossy

finish,

apply

a

hard

wax

after

thecar

has

been

washed

and

dried

.

Use

carnauba

or

synthetic

based

products

.

Waxing

is

not

needed

after

every

washing

.

You

can

tell

when

waxing

is

required

by

looking

at

the

finísh

when

it

is

wet

.

If

the

water

coats

the

paint

in

smooth

sheets

instead

of

forming

beads

that

rol¡

off,

a

new

coat

of

wax

is

needed

.

Wax

shouldnot

be

applied

to

black

trim

pieces,

rub-

ber,or

other

plastic

parts

.

Polishing

Use

paintpolish

only

if

the

finish

assumes

a

dull

lock

after

long

service

.

Polish

can

beused

to

remove

tar

spots

and

tar-

nish,

but

afterwards

a

coat

of

wax

should

be

applied

to

protect

the

clean

finish

.

Do

not

use

abrasive

polish

or

cleaners

on

alu-

minum

trimor

accessories

.

BODYAND

INTERIOR

MAINTENANCE

Cylinder

Head

and

Valvetrain

The

aluminum

cylinder

head

uses

chain-driven

double

overhead

camshafts

and

four

valves

per

cylinder

.

See

Fig

.

1

.

Tha

rvfinriar

hand

nmnlnve

n

ernceflnier

rineinn

fnr

nronter

Tar

spots

canbe

removed

with

a

bugand

tar

remover

.

Never

use

gasoline,

kerosene,

nail

polish

remover,

or

other

unsuitable

solvents

.

Insect

spots

also

respond

to

tar

remover

.

A

bit

of

bak-

ing

soda

dissolved

in

the

wash

water

will

facilitate

their

removal

.

This

method

can

also

beused

to

remove

spotting

from

tree

sap

.

Interior

Care

Dirt

spots

can

usually

be

removed

with

lukewarm

soapy

wa-

ter

or

a

dry

foam

cleaner

.

Use

spot

remover

for

grease

and

o¡I

spots

.

Do

not

pour

the

(quid

directly

on

the

carpetor

fabric,

but

dampen

a

clean

cloth

and

rub

carefully,starting

at

the

edge

of

the

spot

and

working

inward

.

Do

not

use

gasoline,

naptha,

or

other

flammable

substances

.

Leather

Upholstery

and

Trim

Leather

upholstery

and

trim

should

be

periodically

cleaned

using

a

slightly

damp

cotton

or

wool

cloth

.

The

idea

is

to

get

rid

of

the

dirtin

the

creases

and

pores

that

can

cause

brittleness

and

premature

aging

.

On

heavily

soiled

areas,

usea

mild

deter-

gent

(such

as

Woolite®)

or

other

specially

formulated

leather

r

cleaners

.

Use

two

tablespoons

to

one

quart

of

cold

water

.

Dry

the

trim

and

upholstery

completely

using

a

soft

cloth

.

Regular

use

of

agood

quality

leather

conditioner

will

reduce

drying

and

crackingof

the

leather

.

1

.

Camshafts

2

.

Rocker

arms

3

.

Hydraulic

valve

adjusters

(HVA)

4

.

Valve

and

conical

valve

spring

Page 48 of 759

100-6

ENGINE-GENERAL

Cylinder

compression,

checking

A

compression

tester

is

needed

to

make

a

compression

test

.

To

obtain

accurate

test

results,

the

battery

and

starter

must

be

capable

of

cranking

the

engine

at

250-300

rpm,

and

theen-

gine

should

be

at

normal

operating

temperature

.

Use

com-

pressed

air

to

clean

aroundthe

spark

plugs

before

removal

.

1

.

Disable

the

ignítion

system

by

removing

the

engine

management

system

main

relay

and

the

fuel

pump

re-

¡ay

.

See

Fig

.

6

.

WARNING

-

The

ignítion

system

produces

high

voltages

that

canbe

fatal

.

Avoid

contact

with

exposed

termínals

and

useextreme

caution

when

working

on

acar

wíth

the

ignítion

switched

on

or

the

engine

running

.

Fuel

DM

E

pump

main

re

ay

rel

ay

o

oa

ooa

.,

o00

oao

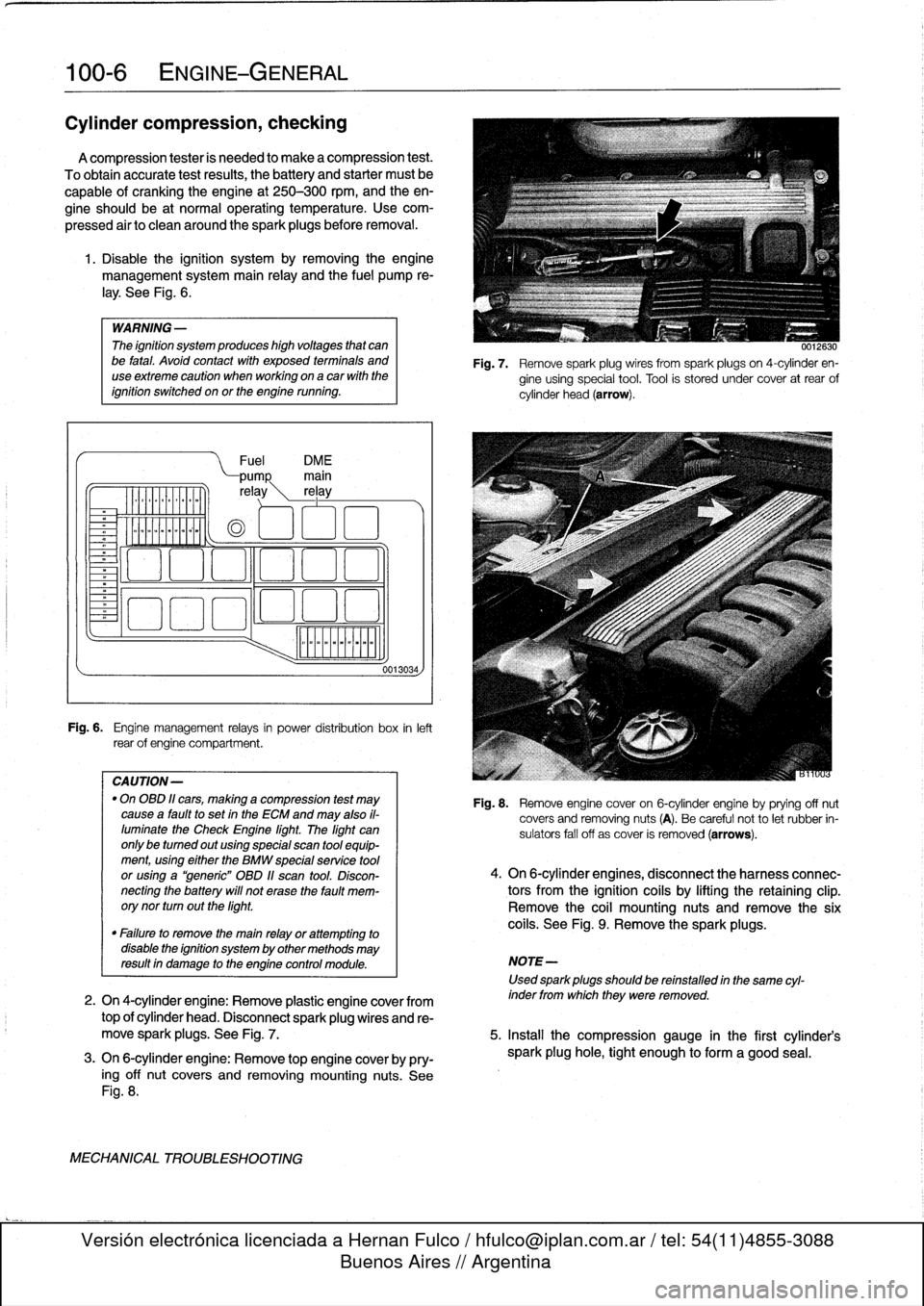

Fig

.

6

.

Engine

management

relays

in

power

distribution

box

inleft

rear

of

engine

compartment

.

CAUTION-

"

On

OBD

11

cars,

making

a

compression

test

may

causea

faultto

set

in

the

ECM

and

may

also

il-

luminate

the

Check

Engine

light

.

The

light

can

only

be

tumed

out

using

special

scan

tool

equip-

ment,using

eíther

the

BMW

specialservíce

tool

or

using

a

"generic"

OBD

11

scan

tool

.

Discon-

necting

the

battery

will

not

erase

the

fault

mem-

orynor

turn

outthe

light

.

0013034,

0012630

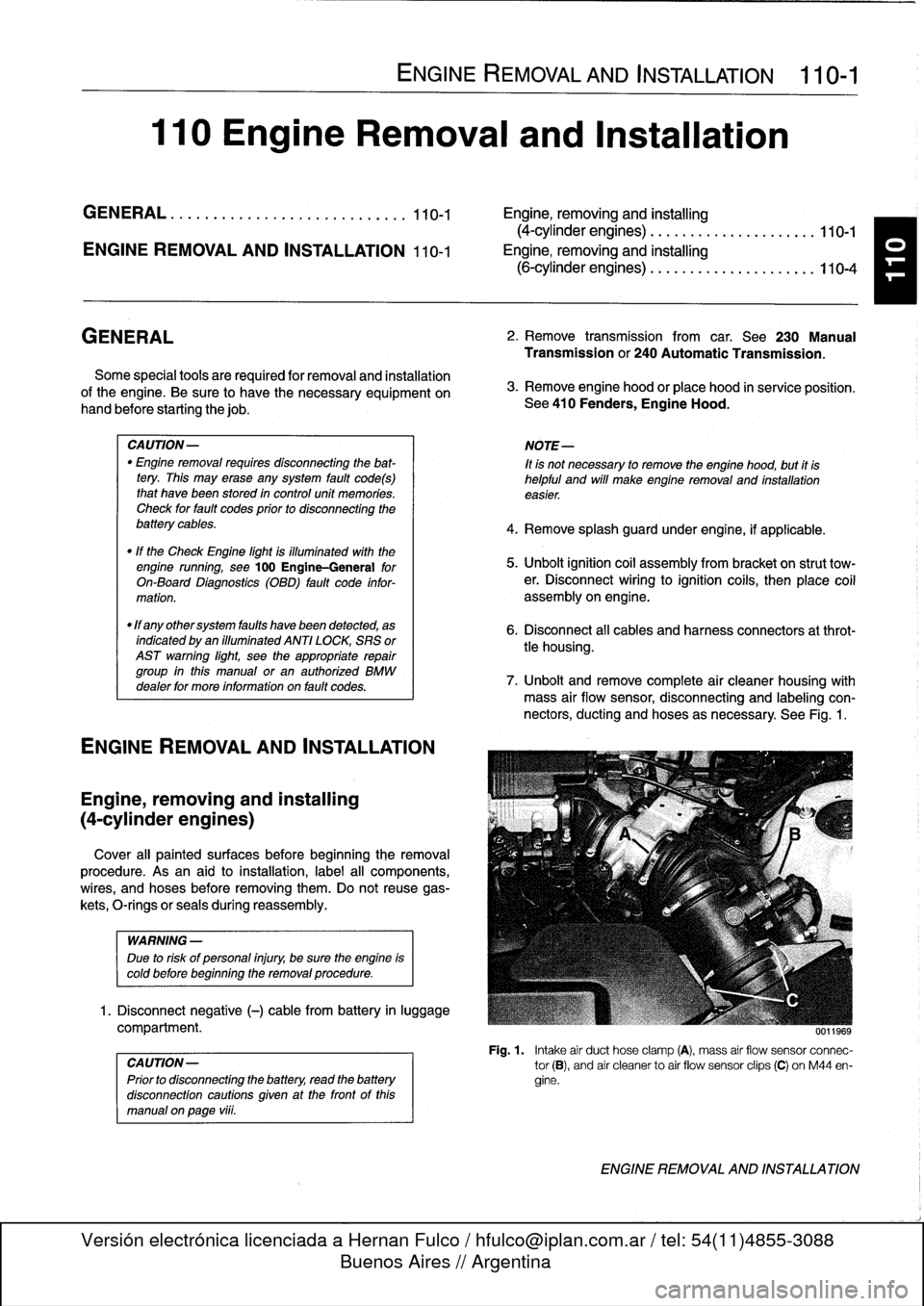

Fig

.

7

.

Remove

spark

plug

wires

from

spark

plugs

on

4-cylinder

en-

gine

using

special

tool

.

Tool

is

stored

under

cover

at

rear

of

cylinder

head

(arrow)

.

Fig

.

8

.

Remove

engine

cover

on

6-cylinder

engine

byprying

off

nut

covers

and

removing

nuts

(A)

.

Be

careful

not

to

let

rubber

in-

sulators

fall

off

as

cover

is

removed

(arrows)

.

4

.

On

6-cylinder

engines,

disconnect

the

harness

connec-

tors

from

the

ignítion

coils

by

lifting

the

retaining

clip

.

Remove

the

coil

mounting

nuts

andremove

the

six

coils

.

See

Fig

.

9

.

Remove

the

sparkplugs

.

"

Failure

to

remove

the

main

relay

or

attempting

to

disable

the

ignítion

system

by

other

methods

may

resultin

damage

to

the

engine

control

module

.

NOTE-

Used

sparkplugs

should

be

reinstalled

in

the

same

cyl-

2

.

On

4-cylinder

engine

:

Remove

plastic

engine

cover

from

inder

fromwhich

they

were

removed

.

top

of

cylinder

head

.

Disconnect

spark

plug

wires

and

re-

move

spark

plugs

.

See

Fig

.

7

.

5

.

Insta¡¡

the

compression

gauge

in

the

first

cylinder's

3

.

On

6-cylinder

engine

:

Remove

top

engine

coverby

pry-

spark

plug

hole,

tight

enough

to

form

a

good

seal

.

ing

off

nut

covers

and

removing

mounting

nuts

.

See

Fig

.

8

.

MECHANICAL

TROUBLESHOOTING

Page 59 of 759

110

Engine

Removal

and

Installation

GENERAL

.

.

.

.

.......

.

.

.

..........

.

...

110-1

Engine,

removing

and

installing

(4-cylinder

engines)

.

..

.....

..

...........

110-1

ENGINE

REMOVAL

AND

INSTALLATION

110-1

Engine,

removing

and

installing

(6-cylinder

engines)

..

...

...

..

.....

..

....

110-4

GENERAL

Some

special

tools

are

required

for

removal

and

installation

of

the

engine

.

Be

sure

to

have

the

necessary

equipment

on

hand

before

starting

thejob

.

CAUTION-

"

Engine

removal

requires

disconnecting

the

bat-

tery

.

This

may

erase

any

system

fault

code(s)

that

havebeen

stored

in

control

unit

memories

.

Check

forfault

codes

prior

to

disconnecting

the

battery

cables

.

"

If

the

Check

Engine

lightis

illuminated

with

the

engine

running,

see

100

Engine-General

for

On-Board

Diagnostics

(08D)

fault

code

infor-

mation

.

"

If

any

other

system

faults

have

been

detected,

as

indicated

by

an

illuminated

ANTI

LOCK,

SRS

or

AST

warning

light,

see

the

appropriate

repair

group

inthis

manual

or

an

authorized

BMW

dealer

for

more

information

on

fault

codes

.

ENGINE

REMOVALAND

INSTALLATION

Engine,

removing

and

installing

(4-cylinder

engines)

Cover

al¡

painted

surfaces

before

beginning

theremoval

procedure

.

Asan

aid

to

installation,

label

al¡

components,

wires,

and

hoses

before

removing

them

.

Do

not

reuse

gas-

kets,

O-rings

or

seals

during

reassembly

.

WARNING

-

Due

to

risk

of

personal

injury,

be

sure

the

engine

is

cold

before

beginning

the

removalprocedure

.

1.

Disconnect

negative

(-)

cable

from

battery

in

luggage

compartment

.

0011969

CAUTION-

Prior

to

disconnecting

the

battery,

read

the

battery

disconnection

cautions

given

at

the

front

of

this

manual

on

page

viii

.

ENGINE

REMOVAL

AND

INSTALLATION

110-1

2

.

Remove

transmission

from

car

.

See230

Manual

Transmission

or

240

Automatic

Transmission

.

3

.

Remove

enginehood

or

place

hood

in

service

positíon

.

See

410

Fenders,

Engine

Hood

.

NOTE-

tt

is

notnecessary

to

remove

the

engine

hood,

but

it

is

helpful

and

will

make

engine

removal

and

installation

easier

.

4

.

Remove

splash

guard

under

engine,

if

applicable

.

5

.

Unbolt

ignition

coil

assembly

from

bracket

on

strut

tow-er

.

Disconnect

wiring

to

ignition

cofs,

then

place

coil

assembly

on

engine

.

6

.

Disconnect

al¡

cables

and

harness

connectors

at

throt-

tle

housing

.

7

.

Unbolt

andremove

complete

air

cleaner

housing

with

mass

air

flow

sensor,

disconnecting

and

labeling

con-

nectors,

ducting

and

hoses

asnecessary

.

See

Fig

.

1

.

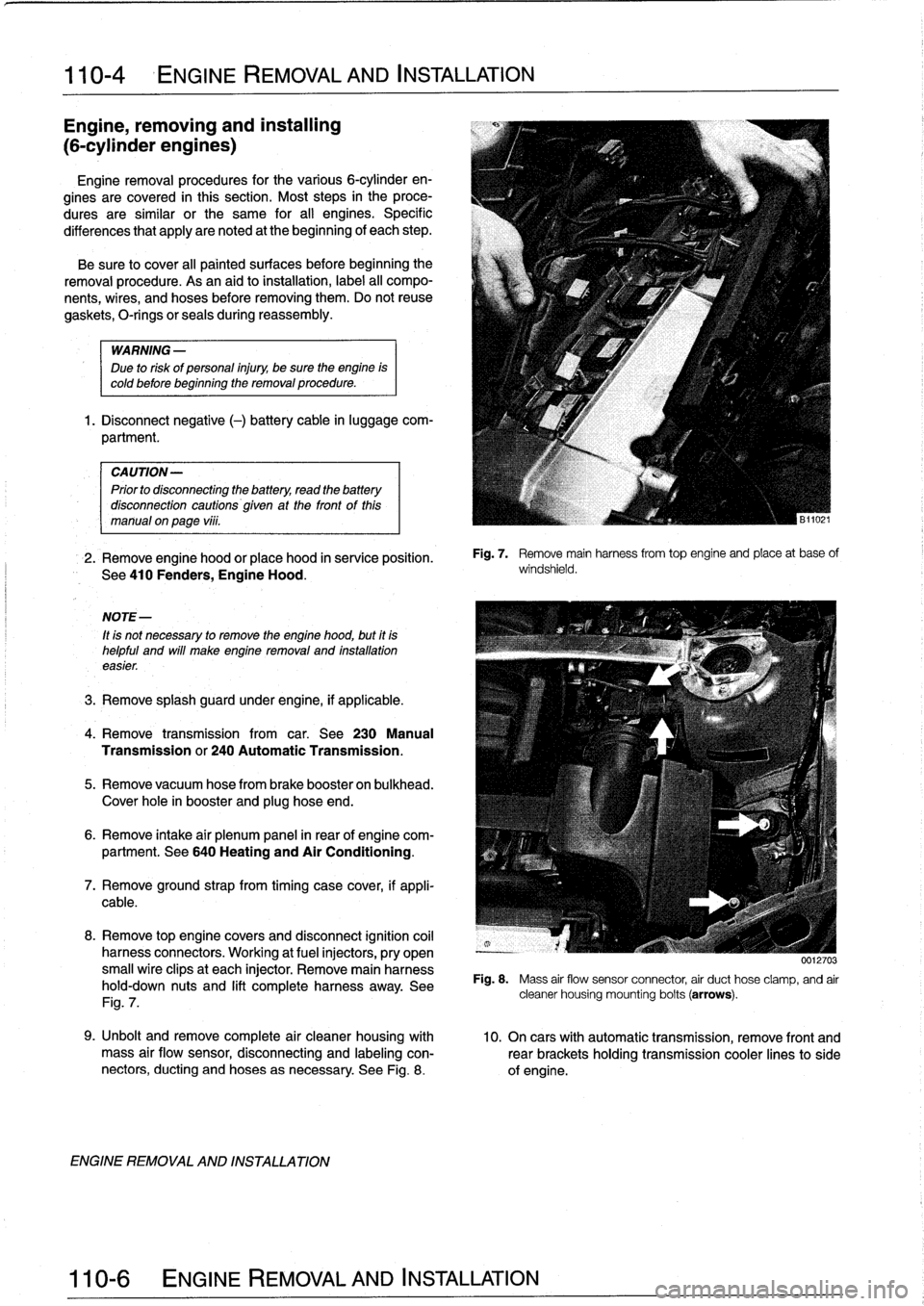

Fig

.

1

.

Intake

air

duct

hose

clamp

(A),

mass

air

flow

sensor

connec-

tor

(B),

and

air

cleanerto

air

flow

sensor

clips

(C)

on

M44

en-

gine

.

ENGINE

REMOVAL

AND

INSTALLATION

Page 62 of 759

110-

4

ENGINE

REMOVAL

AND

INSTALLATION

Engine,

removing

and

installing

(6-cylinder

engines)

Engineremoval

procedures

for

the

various

6-cylinder

en-

gines

arecovered

in

this

section

.

Most

steps

in

theproce-

dures

are

similar

or

the

same

for

al¡

engines

.

Specific

differences

that

apply

are

noted

at

the

beginning

of

each

step

.

Be

sure

to

cover

all

painted

surfaces

before

beginning

the

removal

procedure

.

As

an

aid

to

installation,

label

all

compo-

nents,wires,

and

hoses

before

removing

them

.

Do

not

reuse

gaskets,

O-rings

or

seals

during

reassembly

.

WARNING

-

Due

to

risk

of

personal

injury,

be

sure

the

engine

is

cold

before

beginning

the

removalprocedure

.

1

.

Disconnect

negative

(-)

battery

cable

in

luggage

com-

partment

.

CAUTION-

Prior

to

disconnecting

the

battery,

read

the

battery

disconnection

cautions

given

at

the

front

of

this

manual

onpage

vi¡¡

.

2

.

Remove

engine

hood

or

place

hood

in

service

position

.

See410

Fenders,

Engine

Hood

.

NOTE-

1t

is

not

necessary

to

remove

the

engine

hood,

but

it

is

helpful

and

will

make

engine

removal

and

installation

easier

.

3

.

Remove

splash

guardunder

engine,

if

applicable

.

4

.

Remove

transmission

from

car

.

See

230

Manual

Transmission

or

240Automatic

Transmission

.

5

.

Remove

vacuum

hosefrom

brake

booster

on

bulkhead

.

Cover

hole

in

booster

and

plug

hose

end

.

6

.

Remove

intake

air

plenum

panel

in

rear

of

engine

com-

partment

.

See

640

Heating

and

AirConditioning

.

7

.

Remove

ground

strap

from

timing

case

cover,

if

appli-

cable

.

8

.

Remove

top

enginecovers

and

disconnect

ignition

coil

harness

connectors

.

Working

at

fuel

injectors,

pry

open

small

wire

clipsat

each

injector

.

Remove

main

harness

hold-down

nuts

and

lift

completeharness

away

.

See

Fig

.

7

.

ENGINE

REMOVAL

AND

INSTALLATION

Fig

.

7

.

Remove

mainharnessfrom

top

engine

and

place

at

base

of

windshield

.

0012703

Fig

.

8

.

Mass

air

flow

sensor

connector

air

duct

hose

clamp,

and

air

cleaner

housing

mounting

bolts

(arrows)

.

9

.

Unbolt

andremove

complete

air

cleaner

housing

with

10

.

On

cars

with

automatic

transmission,

remove

front

and

mass

air

flow

sensor,

disconnecting

and

labeling

con-

rearbrackets

holding

transmission

cooler

linesto

side

nectors,

ducting

and

hoses

asnecessary

.

See

Fig

.

8

.

of

engine

.

Page 85 of 759

GENERAL

CYLINDER

HEAD,

DISASSEMBLY

AND

ASSEMBLY

CYLINDER

HEAD

AND

VALVETRAIN

116-1

116

Cylinder

Head

and

Valvetrai

n

GENERAL

.

.....

.

.

.

...

.

.

.

.

.

.

.

.

.

.......

116-1

Hydraulic

cam

followers,

checking

and

replacing

(M42

and

al¡

6-cylinder

engines)

.

...

.....

.

..

116-9

CYLINDER

HEAD,

Valve

guides

.

.

.

...

.

.

.

.

.

.

...

.

.

.

.

.

.

.

.

.

.

116-10

DISASSEMBLY

AND

ASSEMBLY

...

.

...

116-1

Valves

.

.

.

.

.

.

.

.

.

.

.

.

.

...

.

...

.

.

.

.

.

...

.

.

116-11

Camshafts,

removing

and

installing

(M42

engine)

....

.

....

.

.

.

.

.

.

.

.

.

.....

.

.

116-1

Valves,

leak

test

.

.

.

.

.

.

.

.

.

.

...

.

.

.

.

.

.

.

.

.

.

116-11

Camshafts,

removing

and

installing

Valve

stem

oil

seals

.

.

.

.......

.

.

.

.

.

...

.

.

116-11

(M44

engine)

.........

.

.

.

.

.

.

.

.

.

.......

116-3

Valve

seats

.

.

.

.

.

.

.

.

.

...

.

...

.

.

.

.

.

...

.

.116-12

Camshafts,

removing

and

installing

Valve

springs

.

.

.

.

.

.

.

.

...

.

...

.

.

.

.

.

.....

116-12

(6-cylinder

engine)

.....

.

.

.

.

.

.

.

.

.

.......

116-4

Valves,

removing

and

installing

........

.

....

116-6

TABLES

CYLINDER

HEAD

AND

VALVETRAIN,

a

.

Cylinder

Head

Height

........

....

.

..

..........

116-7

RECONDITIONING

.

...

.

.

.

.

.

.

.

.

.

.......

116-7

b

.

Camshaft

Specifications

.......

..

.

..

........

.116-7

Cylinder

head

...

.

.

.

...

.

.

.

.

.

.

.

.

.

....

.

..

116-7

c

.

Valve

Guide

Specifications

....

...

.

..

........

116-10

d

.

Valve

Specifications

...........

..

.

..

........

116-11

Camshaft

.

.

.

.

.

.

.

.

.

.

.

.

.

.

...

.

.

.

.

.

.......

116-7

e

.

Valve

Seat

Dimensions

.........

.

..

..

......

.116-12

Hydraulic

valve

adjusters,

checking

and

replacing

(M44

engine)

..

.

.

.

116-8

Camshafts,

removing

and

installing

(M42

engine)

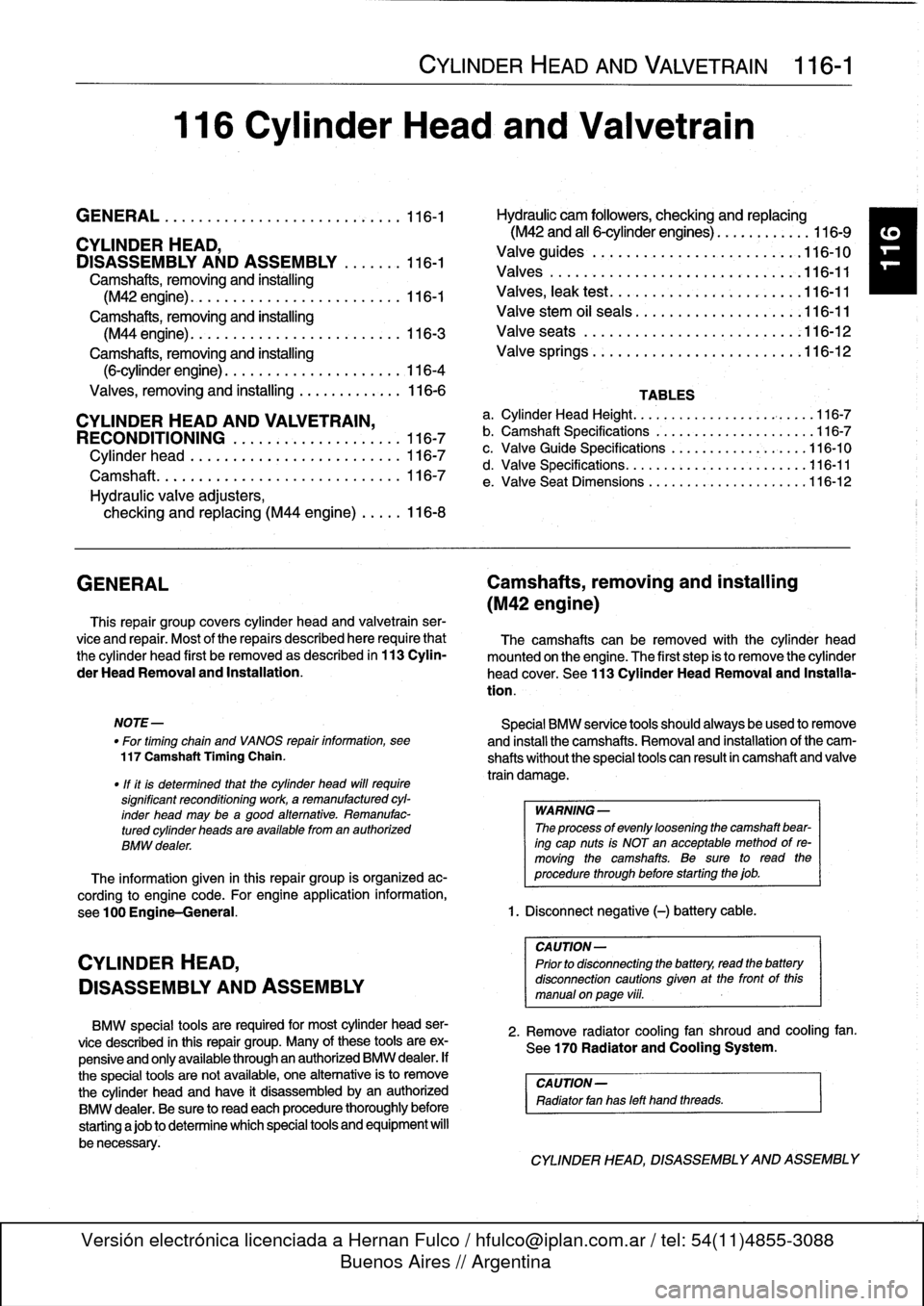

This

repair

group

covers

cylinder

head

and

valvetrain

ser-

vice

and

repair

.

Most

of

the

repairs

described

here

require

that

The

camshafts

can

be

removed

with

the

cylinder

head

the

cylinder

head

first

be

removed

as

described

in

113

Cylin-

mounted

on

the

engine

.

The

first

step

is

to

remove

the

cylinder

der

HeadRemoval

and

Installation

.

head

cover

.

See

113

Cylinder

HeadRemoval

and

Installa-

tion

.

NOTE-

Special

BMW

service

tools

should

always

be

used

to

remove

"

For

timing

chain

and

VANOS

repair

information,

see

and

install

the

camshafts

.

Removal

and

installation

of

the

cam-

117

Camshaft

Timing

Chain

.

shafts

without

the

special

tools

can

result

in

camshaft

and

valve

"

If

it

is

determined

that

the

cylinder

head

will

require

train

damage

.

significant

reconditioning

work,

a

remanufactured

cyl-

inder

head

may

bea

good

alternative

.

Remanufac-

WARNING-

tured

cylinder

heads

are

available

froman

authorized

The

process

of

evenly

loosening

the

camshaftbear

BMW

dealer

.

ing

cap

nuts

is

NOT

an

acceptable

method

of

re-

moving

the

camshafts

.

Be

sure

to

read

the

The

information

given

in

this

repair

group

is

organized

ac-

procedure

through

before

starting

the¡ob

.

cording

to

engine

code

.

For

engine

applicationinformation,

see100

Engine-General

.

1

.

Disconnect

negative

(-)

battery

cable

.

CAUTION-

Prior

to

disconnectiog

the

battery,

read

the

battery

disconnection

cautions

given

at

the

front

of

this

manualonpage

viii

.

BMW

special

tools

are

required

for

most

cylinder

head

ser-

2

.

Remove

radiator

cooling

fan

shroud

and

cooling

fan

.

vice

described

in

this

repair

group

.

Many

of

these

tools

areex-

See

170

Radiator

and

Cooling

System

.

pensive

and

only

available

through

an

authorized

BMW

dealer

.

If

the

special

tools

are

not

available,

one

altematve

is

to

remove

the

cylinder

head

and

have

it

disassembled

byan

authorized

CAUTION-

BMW

dealer

.

Be

sure

to

read

each

procedure

thoroughlybefore

Radiator

fa

n

has

left

hand

threads

.

starting

a

job

to

determinewhich

special

tools

and

equipment

will

be

necessary

.

CYLINDER

HEAD,

DISASSEMBLYANDASSEMBLY

Page 91 of 759

CYLINDER

HEAD

AND

VALVETRAIN,

RECONDITIONING

Thís

section

provides

the

specifications

and

special

recon-

ditioning

information

necessary

to

repair

the

cylinder

heads

covered

by

this

manual

.

If

machine

shop

services

are

not

readily

available,

one

al-

ternative

is

to

install

a

remanufactured

cylinder

head

froman

authorized

BMW

dealer

.

Cylinder

head

NOTE-

When

replacing

the

cylinder

headon

engines

with

re-

movablecamshaft

carriers,

be

sure

to

check

the

cam-

shaft

carrier

bearing

surfaces

for

warpage

.

4-cylinder

1

140

.0

mm

(5

.512

in)

1

139

.55

mm

(5

.494

in)

6-cylinder

1

140

.0

mm

(5

.512

in)

1

139

.7

mm

(5

.500

in)

CYLINDER

HEAD

AND

VALVETRAIN

116-

7

A

The

disassembled

cylinder

head

should

be

inspected

for

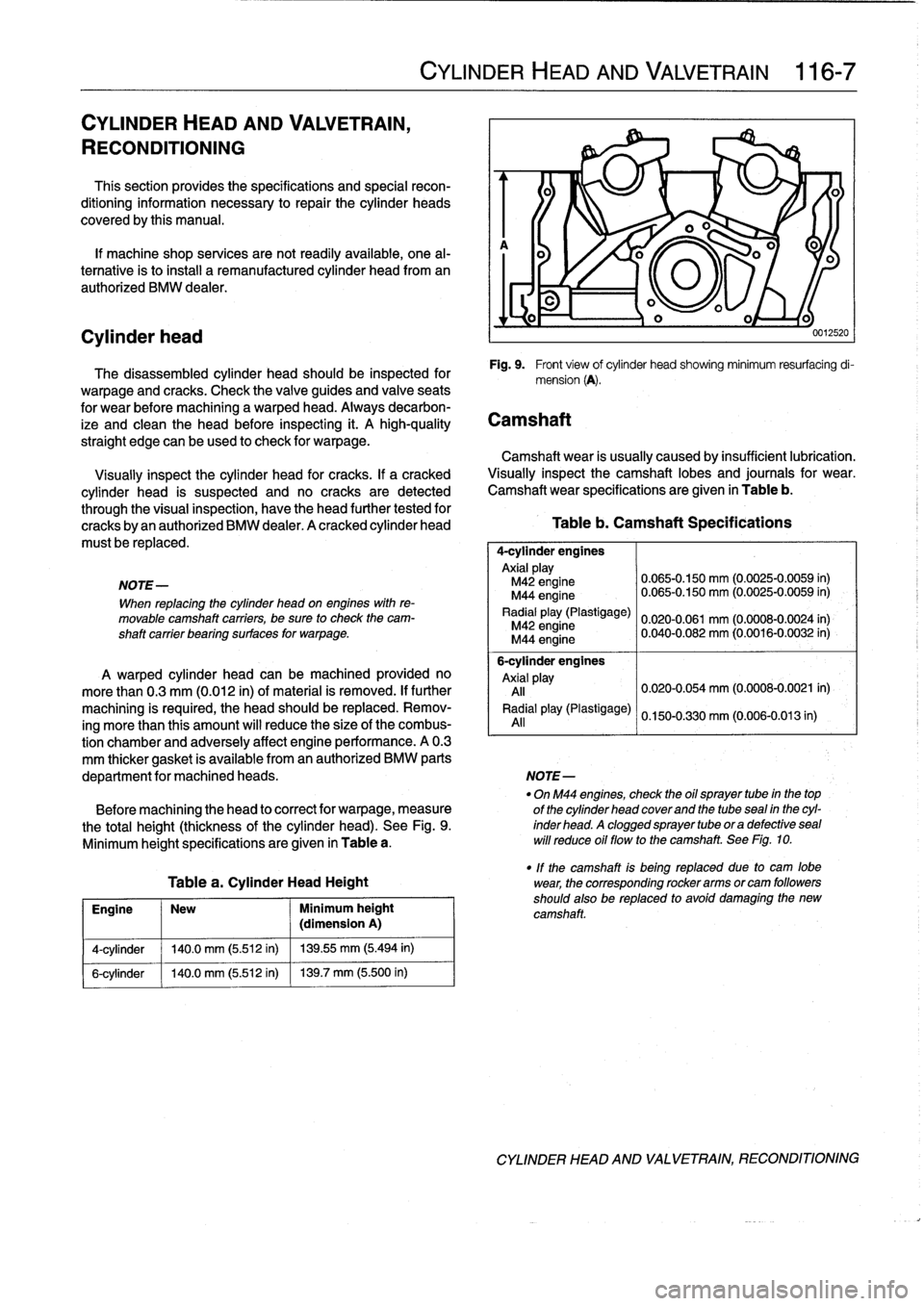

Fig

.

9

.

Front

víew

of

cylinder

head

showing

minimum

resurfacing

di-

warpage

and

cracks

.

Check

the

valve

guides

and

valveseats

mension

(A)

.

for

wear

before

machining

a

warped

head

.

Always

decarbon-

ize

and

clean

the

head

before

inspectiog

it

.

A

high-quality

Camshaft

straíght

edge

can

be

used

to

check

for

warpage

.

Camshaft

wear

is

usually

caused

by

insufficient

lubrication

.

Visually

inspect

the

cylinder

head

for

cracks

.

If

acracked

Visually

inspect

the

camshaft

lobes

and

journals

for

wear

.

cylinder

head

is

suspected

and

no

cracks

are

detected

Camshaftwear

specifications

are

given

in

Table

b

.

through

the

visual

inspection,

have

the

head

further

tested

for

cracks

byan

authorized

BMW

dealer

.

A

cracked

cylinder

head

Table

b

.

Camshaft

Specifications

must

be

replaced

.

4-cylinder

engines

Axialplay

M42

engine

0

.065-0

.150

mm

(0

.0025-0

.0059

in)

M44

engine

0

.065-0

.150

mm

(0

.0025-0

.0059

in)

Radial

play(Plastigage)

0

.020-0.061

mm

(0

.0008-0

.0024

in)

M42

engine

M44

engine

0

.040-0

.082

mm

(0

.0016-0

.0032

in)

6-cylinder

engines

A

warped

cylinder

head

can

be

machined

provided

no

Axial

pla

y

more

than

0

.3

mm

(0

.012

in)

of

material

is

removed

.

If

further

All

0

.020-0.054

mm

(0

.0008-0

.0021

in)

machining

is

required,

the

head

should

be

replaced

.

Remov-

Radial

play(Plastigage)

0

.150-0.330

mm

(0

.006-0.013

in)

ing

more

than

this

amount

will

reduce

the

size

of

the

combus-

All

tion

chamber

and

adversely

affect

engine

performance

.

A

0

.3

mm

thicker

gasket

is

available

from

an

authorized

BMW

parts

department

for

machined

heads

.

NOTE-

-

On

M44

engines,

check

the

oil

sprayer

tube

in

the

top

Before

machining

the

head

to

correct

for

warpage,

measure

of

the

cylinder

head

coverand

the

tubesea¡

in

the

cyl-

the

total

height(thicknessof

the

cylinder

head)

.

See

Fig

.

9

.

inderhead

.Acloggedsprayertubeoradefectiveseal

Minimum

height

specifications

are

given

in

Table

a

.

will

reduce

oil

flowto

the

camshaft

.

See

Fig

.

10

.

-

If

the

camshaft

is

being

replaced

due

to

cam

lobe

Table

a

.

Cylinder

Head

Height

wear,

the

corresponding

rockerarms

orcam

followers

Engine

New

Minimum

height

shouId

also

be

replaced

to

avofd

damaglng

the

new

(dimension

A)

camshaft

.

CYLINDER

HEAD

AND

VALVETRAIN,

RECONDITIONING

Page 102 of 759

117-

6

CAMSHAFT

TIMING

CHAIN

15

.

Insta¡¡

upper

timing

chaincover

:

17

.

Remove

crankshaft

locking

tool

from

transmission

bell-

"

Thoroughly

clean

profile

gasketgroove

and

all

sealing

housing

and

camshaft

locking

tool

from

rear

of

cylinder

surfaces

.

head

.

"

Applya

small

bead

ofsilicon

sealer

(3-Bond

1209®

or

equivalent)

to

upper

and

lower

joint

comers

where

18

.

Turn

engine

over

by

hand

in

direction

of

rotation

at

least

chaincover

meets

cylinder

head

.

two

full

rotations

.

Reinstall

camshaft

and

crankshaft

"

Insta¡¡

new

profile

gasket

to

groove

in

lowerchain

cover

.

locking

tools

to

check

engine

timing

.

Repeat

cam

timing

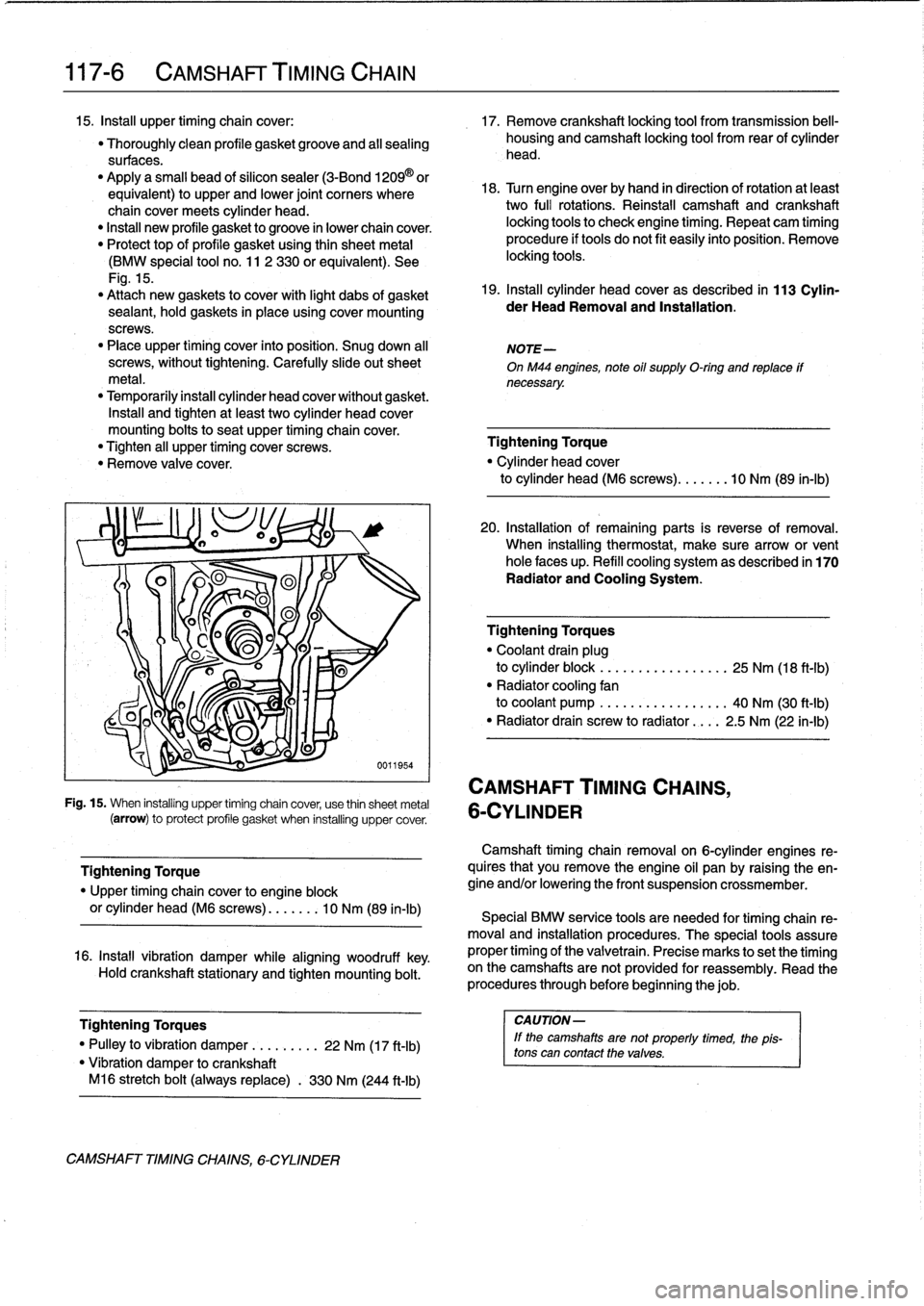

"

Protect

top

of

profile

gasket

using

thin

sheetmetal

procedure

if

tools

do

not

fit

easily

into

position

.

Remove

(BMW

special

tool

no

.

11

2

330

or

equivalent)

.

See

locking

tools

.

Fig

.

15

.

"

Attach

new

gaskets

to

cover

with

light

dabs

of

gasket

19

.

Install

cylinder

head

cover

as

described

in

113

Cylin-

sealant,

hold

gaskets

in

placeusing

cover

mounting

der

HeadRemoval

and

Installation

.

screws

.

"

Place

upper

timing

cover

into

position

.

Snug

down

al¡

NOTE-

screws,

without

tightening

.

Carefully

slide

out

sheet

OnM44

engines,

note

oil

supply

O-ring

and

replace

ff

metal

.

necessary

.

"

Temporarily

install

cylinder

head

cover

without

gasket

.

Insta¡¡

and

tighten

at

least

two

cylinder

head

cover

mounting

bolts

to

seat

upper

timing

chaincover

.

"

Tighten

all

upper

timing

cover

screws

.

Tightening

Torque

"

Remove

valve

cover

.

"

Cylinder

head

cover

to

cylinder

head

(M6

screws)

...

..

.

.

10

Nm

(89

ín-Ib)

-

CAMSHAFT

TIMING

CHAINS,

Fig

.

15

.

When

installing

upper

timing

chain

cover,

use

thin

sheetmetal

6-CYLINDER

(arrow)

to

protect

profile

gasket

when

installing

uppercover

.

Tightening

Torque

"

Upper

timing

chaincover

to

engine

block

or

cylinder

head

(M6

screws)

....

.

..

10

Nm

(89

in-lb)

16

.

Install

vibration

damper

while

aligning

woodruff

key

.

Hold

crankshaft

stationary

and

tighten

mounting

bolt

.

Tightening

Torques

I

CAUTION-

"

Pulley

to

vibration

damper

..

.

.

.

....

22

Nm

(17

ft-Ib)

lf

the

camshaftsare

not

properly

timed,

the

1

pis-

tons

can

contact

thevalves

.

"

Vibration

damper

tocrankshaft

M16

stretch

bolt

(always

replace)

.

330

Nm

(244

ft-Ib)

CAMSHAFT

TIMINGCHAINS,

6-CYLINDER

20

.

Installation

of

remaining

parts

is

reverse

of

removal

.

When

installing

thermostat,

make

sure

arrow

or

vent

hole

faces

up

.

Refill

cooling

system

as

described

in

170

Radiator

and

Cooling

System

.

Tighteníng

Torques

"

Coolant

drain

plug

to

cylinder

block

.

..

.

.

.

...

.

..

.....

25

Nm

(18

ft-Ib)

"

Radiator

cooling

fan

to

coolant

pump

.

..

.

...

...

..

.....

40

Nm

(30

ft-Ib)

"

Radiator

drain

screw

to

radiator

....

2

.5

Nm

(22

in-lb)

Camshaft

timing

chainremovalon

6-cylinder

engines

re-

quires

that

you

Rmove

the

engine

oil

pan

by

raising

the

en-

gine

and/or

lowering

the

front

suspension

crossmember

.

Special

BMW

service

tools

are

needed

for

timing

chain

re-

moval

and

installation

procedures

.

The

special

tools

assure

proper

timing

of

the

valvetrain

.

Precise

marks

to

setthe

timing

on

the

camshafts

arenot

provided

for

reassembly

.

Read

the

procedures

through

before

beginning

thejob

.