Drive fluid BMW 325i 1994 E36 Owner's Guide

[x] Cancel search | Manufacturer: BMW, Model Year: 1994, Model line: 325i, Model: BMW 325i 1994 E36Pages: 759

Page 287 of 759

GENERAL

......

.

.

.

.

.

.

.

.....

.

.

.

.

.

.

.

.

.

.

331-1

Final

Drive

Oil

Seals

.

.

...

.

.

.

.......

.

.

.

.

.

331-1

Finaldrive

flange

oil

sea¡,

replacing

....

.

.

.

..

331-2

FINAL

DRIVE

SERVICE

.

.....

.

.

.

.

.

.

.

.

.

.

331-1

Finaldrive

inputshaft

oil

seal,

replacing

.

.

.

.

.

331-3

Final

drive

oí¡,

draining

and

filling

.

.

.

.

.

.

.

.

.

.

331-1

Finaldrive

unit,

removíng

and

installing

.

.

.

.

.

.

331-3

GENERAL

This

repa¡r

group

covers

repair

operations

that

do

not

re-

quire

complicated

disassembly

of

the

final

drive

.

Internal

re-

pairs

and

final

drive

disassembly

are

not

covered

in

this

manual

.

FINAL

DRIVE

SERVICE

Al¡

final

drive

work

requires

some

method

of

raising

thecar

and

supporting

it

securely

while

the

work

is

performed

.

Jack

stands

and

a

floor

jack

can

easily

be

used,

but

use

extreme

caution

when

working

beneath

the

car

.

See010

Fundamen-

tais

for

the

Do-It-Yourself

Owner

.

NOTE-

Removal

of

final

drive

carrier

is

covered

in

330

Rear

Suspension

.

Final

drive

oil,

draining

and

filling

1

.

Drive

car

to

warm

final

drive

fluid

.

2

.

Raise

car

and

support

safely

.

WARNING

-

Make

sure

that

thecar

is

firmly

supported

on

jack

standsdesigned

for

the

purpose

.

Place

the

jack

standsbeneatha

structural

chassis

point

.

Do

not

place

jack

stands

under

suspension

parts

.

5

.

Fill

final

drive

with

appropriate

type

and

quantity

of

lu-

bricant

.

Insta¡¡

and

tighten

fill

plug

.

331

Final

Drive

0

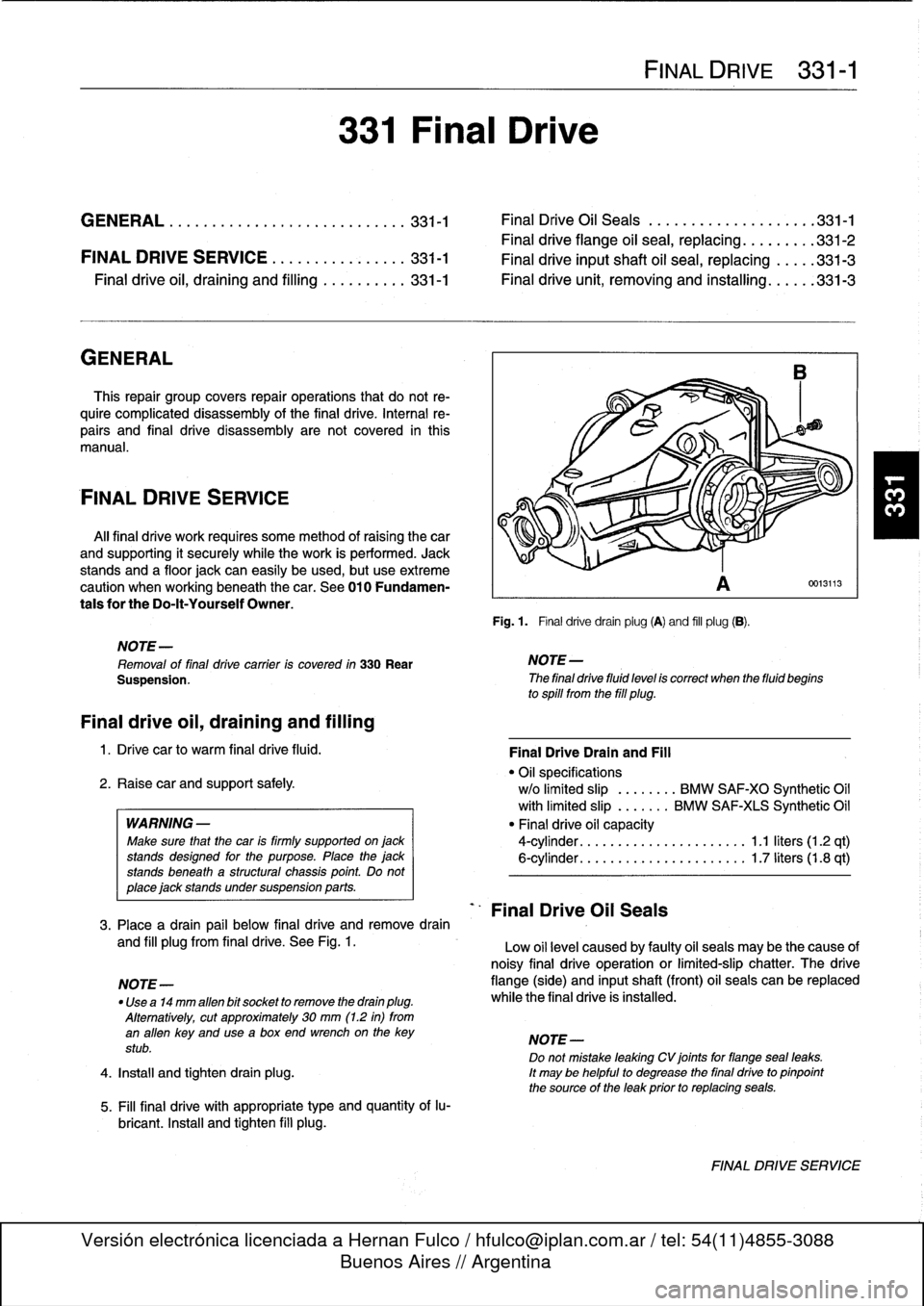

Fig

.

1

.

Final

drivedrain

plug

(A)

and

fill

plug

(B)

.

D

NOTE-

The

final

drive

fluid

level

is

correct

when

the

fluid

begins

to

spill

from

the

fill

plug

.

Final

Drive

Oil

Seals

FINAL

DRIVE

331-1

0013113

Final

DriveDrain

and

Fill

"

Oil

specifications

w/o

limited

slip

.

.......

BMW

SAF-XO

Synthetic

Oil

with

limited

slip

.

......

BMW

SAF-XIS

Synthetic

Oil

"

Final

drive

oil

capacity

4-cylinder

.

.

.

...

................

1

.1

liters

(1

.2

qt)

6-cylinder

.

.

.

...

................

1

.7liters(1.8

qt)

3

.

Place

a

drain

pail

below

final

drive

andremove

drain

and

fill

plugfrom

final

drive

.

See

Fig

.

1

.

Low

oil

level

caused

by

faulty

oil

seals

may

be

the

cause

of

noisy

final

drive

operation

or

limited-slip

chatter

.

The

drive

NOTE-

flange

(side)

and

inputshaft

(front)

oil

seals

can

be

replaced

"

Use

a14

mm

alíen

bit

socket

to

remove

the

drain

plug

.

while

the

final

drive

is

installed

.

Alternatively,

cut

approximately

30

mm

(1

.2

in)

from

an

alíen

key

and

usea

box

end

wrenchon

the

key

NOTE-

stub

.

Do

not

mistake

leaking

CV

joints

for

flangeseal

leaks

.

4

.

Install

and

tighten

drain

plug

.

It

may

be

helpful

to

degrease

the

final

drive

to

pinpoint

the

source

of

the

leak

prior

to

replacing

seals

.

FINAL

DRIVE

SERVICE

Page 288 of 759

331-2

FINAL

DRIVE

Make

sure

that

the

car

is

firm1y

supportedon

Tjack

.

.-

"

:

.-

:

.

n

-

2

.

Detach

drive

axle(s)

from

final

drive

.

See330

Rear

Suspension

.

CA

UTION-

Suspend

the

detached

drive

axlefrom

the

car

body

with

a

stiff

wire

hook

to

prevent

damage

to

the

outer

CV

joint

.

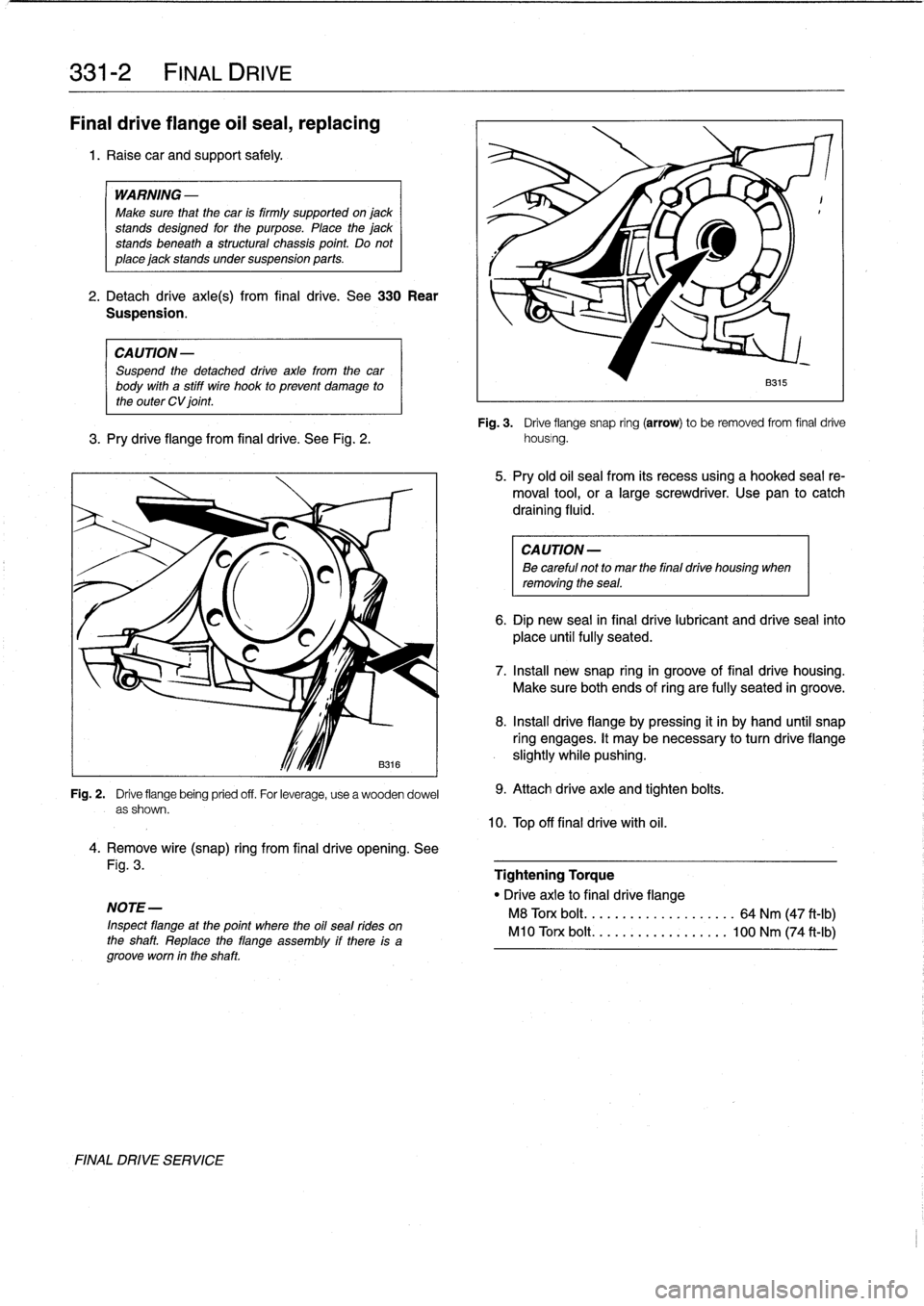

Fig

.

3

.

Drive

flange

snap

ring

(arrow)

to

be

removed

from

final

drive

3

.

Pry

drive

flange

from

final

drive

.

See

Fig

.

2

.

housing

.

Fig

.

2

.

Drive

flange

being

pried

off

.

For

leverage,

use

a

wooden

dowel

as

shown

.

4

.

Remove

wire(snap)

ring

from

final

drive

opening

.

See

Fig

.

3

.

NOTE-

Inspect

flangeat

the

point

where

the

oil

seal

rides

on

the

shaft

.

Replace

the

flange

assembly

if

there

is

agrooveworn

in

the

shaft

FINAL

DRIVE

SERVICE

9

.

Attach

drive

axle

and

tighten

bolts

.

10

.

Top

off

final

drive

with

ofl

.

B315

5

.

Pry

old

oil

sea¡

from

its

recess

using

a

hooked

seal

re-

moval

tool,

or

a

large

screwdriver

.

Use

pan

to

catch

draining

fluid

.

CA

UTION-

Be

careful

not

to

mar

the

final

drive

housing

when

removing

the

sea¡

.

6

.

Dip

new

seal

in

final

drive

lubricant

and

drive

seal

into

place

untilfully

seated

.

7

.

Insta¡¡

new

snap

ringin

groove

of

final

drive

housing

.

Make

sureboth

ends

ofring

are

fully

seated

in

groove

.

8

.

Insta¡¡

drive

flangeby

pressing

it

in

by

hand

until

snap

ring

engages

.

It

may

benecessary

to

turn

drive

flange

slightly

while

pushing

.

Tightening

Torque

"

Drive

axle

to

final

drive

flange

M8

Torx

bolt

..

..................

64

Nm

(47

ft-Ib)

M10

Torx

bolt

.

.................

100

Nm

(74

ft-Ib)

Page 297 of 759

Brake

rotor,

removing

and

installing

Brake

rotors

shouldalways

be

replaced

in

pairs

.

Fig

.

9

.

Brake

rotor

mounting

screw

(arrow)

.

3

.

Inspect

rotor

for

excessive

grooving,

cracks,

and

warp-

ing

.

Check

rotor

thickness

.

See

Table

b

.

4

.

Installation

is

reverse

of

removal

.

"

Clean

rotor

with

brakecleaner

before

installing

.

"

If

brake

fluid

hose

veas

removed

or

loosened,

brake

systemmustbe

bled

as

described

aboveunder

Bleeding

Brakes

.

BRAKES

340-

7

5

.

Once

brake

assembly

is

instalind,

depress

brakepedal

several

times

to

adjust

caliper

and

pads

.

"

Pedal

should

feel

firm

and

be

at

proper

height

.

"

Check

fluid

leve¡

.

Top

up

if

necessary

.

NOTE-

M3

models

use

directional

brake

rotors

and

mustbe

in-

NOTE-

stalled

on

the

proper

side

.

Part

numbes

are

cast

finto

When

installing

new

rear

brake

rotors,

the

parking

therotors

.

A

part

that

ends

in

an

odd

number

is

a

left

brakeshouldbe

adjusted

.

See

Parking

Brake

.

rotor

.

One

that

ends

in

an

even

number

is

a

right

rotor

.

1.

Remove

caliper

as

described-above

and

hang

from

Tightening

Torques

chassis

using

stiff

wire

.

"

Brake

rotor

to

wheel

hub

..........

16

Nm

(12

ft-Ib)

"

Front

brake

caliper

to

steering

arm

...

110

Nm

(81

ft-Ib)

NOTE-

"

Rear

brake

caliper

to

traíling

arm

....

67

Nm

(50

ft-Ib)

Do

notloosen

caliper

brake

hose

.

"

Road

wheel

to

hub

...

..

.

100

±

10

Nm

(74

t

7

ft-Ib)

2

.

Remove

mountingscrew

holding

rotor

to

wheel

hub

.

,

See

Fig

.

9

.

Table

b

.

Brake

Rotor

Reconditioning

Specificati*M`

Front

Rear

Vented

rotor

wear

limit

(min

.

thickness)

20

.4

mm

(0

.803

in.)

Solid

rotor

wear

limit

(min

.

thickness)

8

.4

mm

(0.331

in

.)

M3

models

wear

limit

(min

.

thickness)

26

.4mm

(0

.977

in

.)

18

.4

mm

(0

.723

in

.)

Axial

runout

(max

.)

rotor

removed

0

.05

mm

(0

.002

in

.)

0

.05

mm

(0

.002

in

.)

rotor

installed

0

.20

mm

(0

.008

in

.)

0

.20

mm

(0

.008

in

.)

CAUTION-

M3

brake

rotors

must

not

be

machined

.

MASTER

CYLINDER

The

brake

master

cylinder

is

mounted

to

the

front

of

the

vac-

uum

booster

on

the

driver

side

bulkhead

.

Master

cylinder,

removing

and

installing

1

.

Using

a

clean

syringe,

empty

brake

fluid

reservoir

.

WARNING

-

Brake

fluid

is

highly

corrosive

and

dangerous

to

the

environment

.

Dispose

of

it

properly

.

NOTE-

On

original

equipment

rotors,

the

mínimum

allowable

2

.

Disconnect

brake

fluid

leve¡

sender

connector

from

fluid

thickness

is

stamped

on

the

rotor

hub

.

Measure

the

rotor

reservoi

r

cap

.

brakingsurface

with

a

micrometer

at

eight

to

ten

different

points

and

use

the

smallest

measurement

recorded

.

3

.

Disconnect

brake

fluid

lines

frommaster

cylinder

.

See

Fig

.

10

.

Disconnect

hydraulic

clutch

system

supply

line

.

4

.

Unscrew

mounting

nuts

and

remove

master

cylinder

from

brake

booster

.

5

.

Make

sure

all

nuts,

fluid

couplings,

thread

bores,

and

mating

surfaces

are

clean

.

MASTER

CYLINDER

Page 298 of 759

340-

8

BRAKES

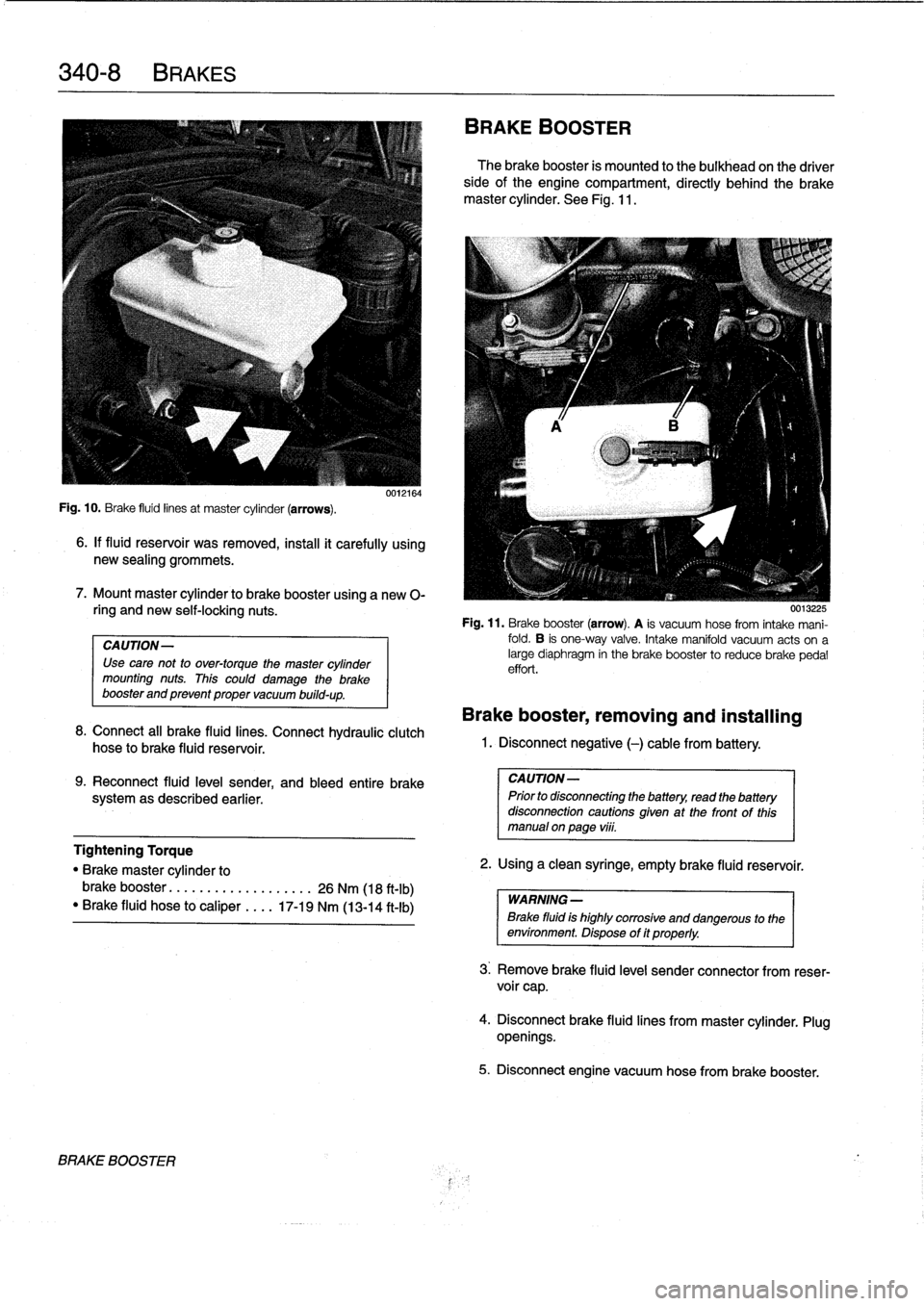

Fig

.

10

.

Brake

fluid

linesat

master

cylinder

(arrows)

.

6

.

If

fluid

reservoir

was

removed,

install

it

carefully

using

new

sealing

grommets

.

7

.

Mount

master

cylinder

to

brake

booster

using

a

new

0-

ring

and

new

self-locking

nuts

.

CAUTION-

Use

cave

not

to

over-torque

the

master

cylinder

mounting

nuts

.

This

could

damage

the

brake

booster

and

prevent

proper

vacuum

build-up

.

0012164

8

.

Connect

all

brake

fluid

lines

.

Connect

hydraulic

clutch

hose

to

brake

fluid

reservoir

.

9

.

Reconnect

fluid

leve¡

sender,

and

bleed

entire

brake

systemas

described

earlier

.

BRAKE

BOOSTER

BRAKE

BOOSTER

The

brake

booster

is

mounted

to

the

bulkhead

on

the

driver

sideofthe

engine

compartment,

directly

behind

the

brake

master

cylinder

.

See

Fig

.

11

.

0015225

Fig

.

11

.

Brake

booster

(arrow)

.

A

is

vacuum

hose

from

intake

mani-

fold

.

B

is

one-way

valve

.

Intake

manifold

vacuum

acts

ona

large

diaphragm

in

the

brake

booster

to

reducebrake

pedal

effort

.

Brake

booster,

removing

and

installing

1

.

Disconnect

negative

(-)

cable

from

battery

.

CAUTION-

Prior

to

disconnecting

the

battery,

read

the

battery

disconnection

cautions

given

at

the

front

of

this

manual

onpage

vi¡¡

.

Tightening

Torque

"

Brake

master

cylinder

to

2

.

Using

a

clean

syringe,

empty

brake

(luid

reservoir

.

brake

booster

.....

..

.

..

.........

26

Nm

(18

ft-Ib)

WARNING-

"

Brake

fluid

hose

to

caliper

....

17-19

Nm

(13-14

ft-Ib)

Brake

fluid

is

highly

corroslve

and

dangerous

to

the

environment

.

Dispose

of

it

properly

.

3

.

Remove

brake

fluid

level

sender

connector

from

reser-

voir

cap

.

4

.

Disconnectbrake

fluid

lines

from

master

cylinder

.

Plug

openings

.

5

.

Disconnect

engine

vacuum

hose

from

brake

booster

.

Page 404 of 759

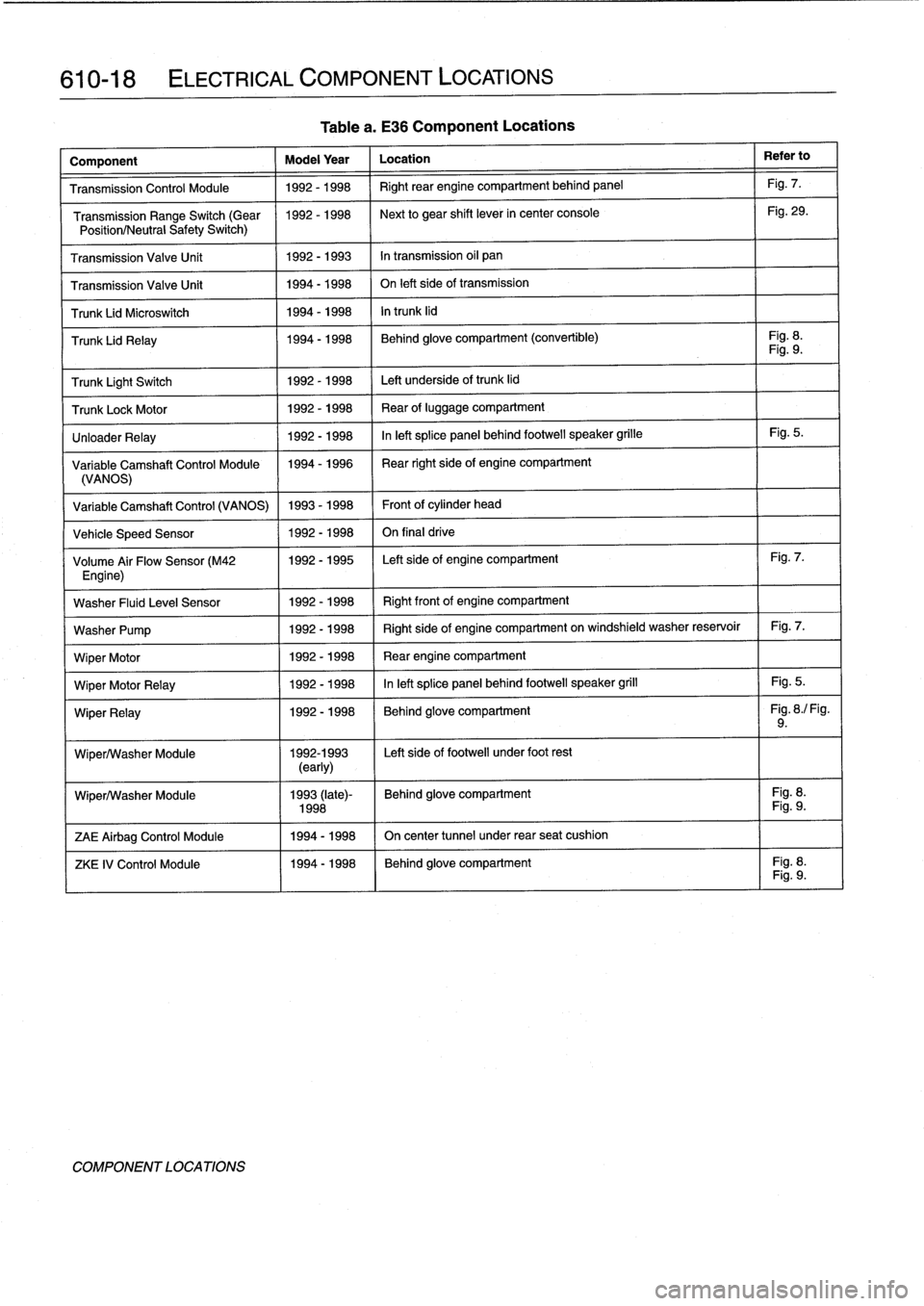

610-18

ELECTRICAL

COMPONENT

LOCATIONS

Tablea

.

E36

Component

Locations

Component

Model

Year

Location

Refer

to

Transmission

Control

Module

1992-1998

Right

rear

engine

compartment

behíndpanel

Fig

.

7

.

Transmission

Range

Switch

(Gear

1992-1998

Next

to

gear

shift

lever

in

center

console

Fig

.

29

.

Position/Neutra

l

Safety

Switch)

Transmission

Valve

Unít

1992-1993

In

transmission

oil

pan

Transmission

Valve

Unit

1994-1998

On

left

side

of

transmission

Trunk

Lid

Microswitch

1994-1998

In

trunk

lid

Trunk

Lid

Relay

1994-1998

Behind

glove

compartment

(convertible)

Fig

.

8

.

Fig

.

9

.

Trunk

Light

Switch

1992-1998

Left

underside

of

trunk

lid

TrunkLockMotor

1992-1998

Rear

of

luggage

compartment

UnloaderRelay

1992-1998

Inleft

splice

panel

behind

footwell

speaker

grille

Fig

.

5

.

Variable

Camshaft

Control

Module

1994-1996

I

Rear

right

side

of

engine

compartment

(VANOS)

Variable

Camshaft

Control

(VANOS)

1993-1998

Front

ofcylinder

head

Veh¡cle

Speed

Sensor

1992-1998

On

final

drive

Volume

Air

Flow

Sensor

(M42

1992-1995

Left

side

of

engine

compartment

Fig

.

7

.

Engine)

Washer

Fluid

Leve¡

Sensor

1992-1998

Right

frontof

engine

compartment

Washer

Pump

1992-1998

Right

side

of

engine

compartment

on

windshield

washer

reservoir

Fig

.

7

.

Wiper

Motor

1992-1998

Rear

engine

compartment

Wiper

Motor

Relay

1992-1998

Inleft

splice

panel

behind

footwell

speaker

grill

Fig

.

5

.

Wiper

Relay

1992-1998

(

Behind

glove

compartment

I

Fig

.

8

./

Fig

.

9

.

Wiper/Washer

Module

1992-1993

Left

side

of

footwell

under

foot

rest

(early)

Wiper/Washer

Module

1993

(late)-

Behind

glove

compartment

Fig

.

8

.

1998

1

Fig

.

9

.

ZAE

Airbag

Control

Module

1

1994-1998

1

On

center

tunnel

under

rear

seat

cushion

ZKE

IV

Control

Module

1994-1998

I

Behind

glove

compartment

Fig

.

8

.I

Fig

.

9

.

COMPONENT

LOCATIONS

Page 524 of 759

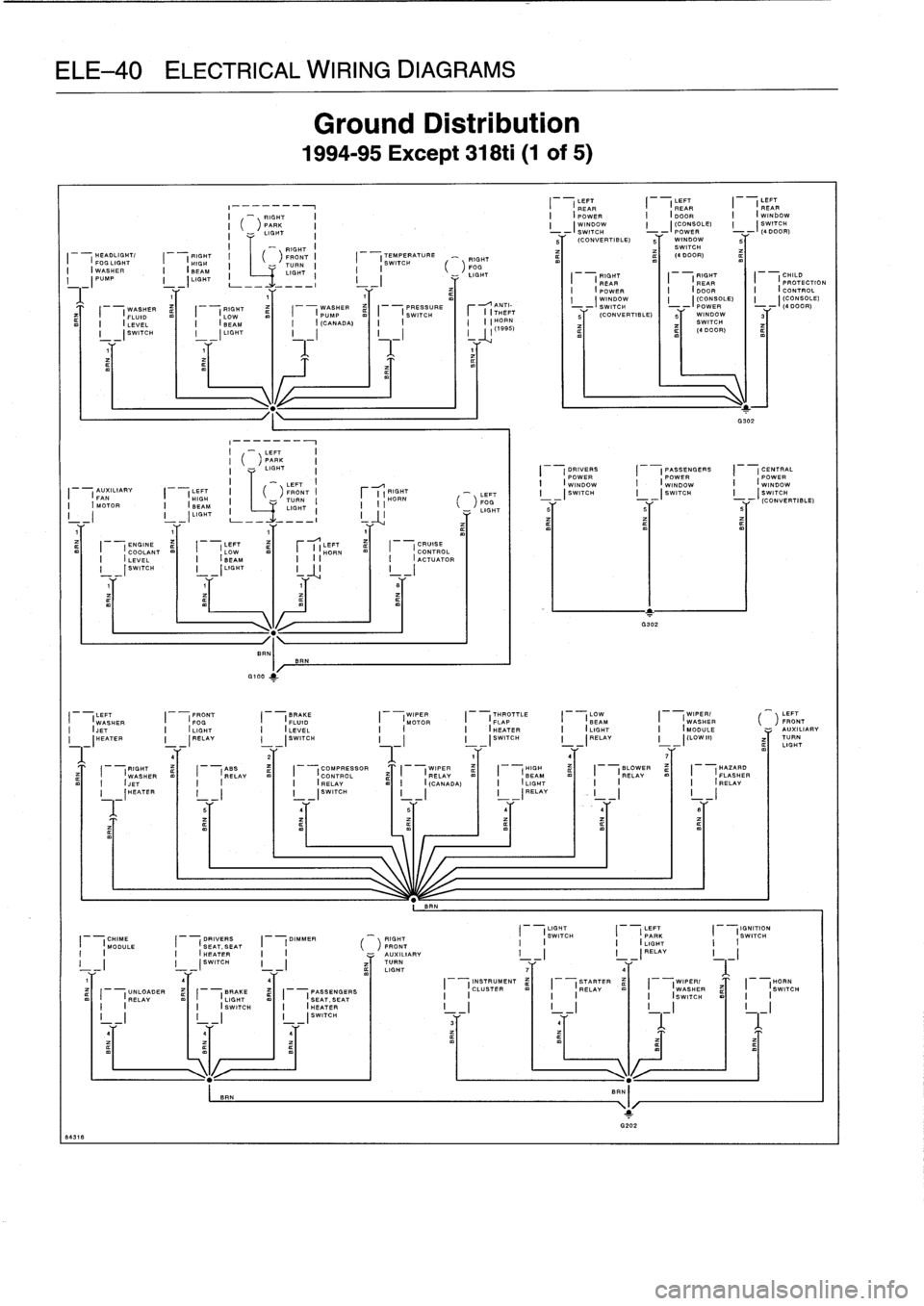

ELE-40

ELECTRICAL

WIRING

DIAGRAMS

RIGHTHEADLIGHT/

RIGHT

I

FRONT

I

FOG

LIGHT

I

HIGH

I

TURN

I

I

WASHER

I

I

BEAM

LIGHT

I

(PUMP

I

(LIGHT

,

L-

1

1

1

I

(POWER

I

(DOOR

I

]CONTROL

_

_

_-1

WINDOW

I

(

(CONSOLE)

I

(

(CONSOLE)

WASHER

RIGHT

WASHER

PRESSURE

m

ANTI-

--

SWITCH

--

POWER

--

(L

DOOR)

I

(FLUID

I

LOW

I

(PUMP

I

SWITCH

(-

IITHEFT

S

(CONVERTIBLE)

S

SWWINDOW

ITCH

3

I

(LEVEL

I

(BEAM

I

I(CANADA)

m

II

I

IIHORN

WSWITCH

I

SWITCH

I

(

LIGHT

I

I

I

I

I

(1995)

(4

DOOR)

I7

IT

~

~T

I

(

)

PARK

I

-

LIGHT

I

I

'DRIVERS

(

(PASSENGERS

I

(CENTRAL

LEFT

,

JI

I

(WINDOW

I(

POWER

]

(POWER

AUXILIARY

LEFT

I

FRONT

I

RIGHT

WINDOW

WINDOW

I

,

_

_

_

FAN

I

(

HIGH

(-

TURN

I

-

(

HORN

LEFT

I

(

SWITCH

I

(SWITCH

I

(

SWITCH

I

(

MOTOR

LIGHT

I--

I

LIGHT

LIGHT

¢~

¢~

¢~

(CONVERTIBLE)

I

I,

-I

I

-(

---

-

84318

ENGINE

LEFT

LEFT

CRUISE

I

I

I

rII

I

I

COOLANT

m

LOW

HORN

CONTROL

I

(LEVEL

I

(BEAM

I

II

I

(ACTUATOR

I

_I

SWITCH

I

-

(LIGHT

I

I_

-I

1

1

1

8

BRN

LEFT

LEFT

LEFT

I

I

I

I

I

I

REAR

REAR

REAR

RIGHT

I

I

(

POWER

I

(

DOOR

I

(

WINDOW

I

PARK

I

I

(WINDOW

I

((CONSOLE)

I

SWITCH

I

l,

LIGHT

I

--

SWITCH

--

POWER

-

r

-

(6

DOOR)

(CONVERTIBLE(

/A

BF.

T

BRN

Ground

Distribution

1994-95

Except

318ti

(1

of

5)

I

(TEMPERATURE

-

RIGHT

I

SWITCH

)FOG

51

¢1

WINDOW

SWITCH

(C

DOOR)

I

I

REAAT

I

,

FEAR'

I

,

PCHILD

ROTECTION

LEFT

FRONT

BRAKE

WIPER

THROTTLE

OW

WIPER/

LEFT

I

,

WASHER

I

(

FOG

I

(

FLUID

I

(

MOTOR

I

(FLAP

I

(LBEAM

I

(

WASHER

(

)

FRONT

I

(JET

I

[LIGHT

I

(LEVEL

I

I

I

(HEATER

I

(LIGHT

I

MODULE

_

AUXILIARY

_

_

_

(HEATER

I

-(RELAY

I

_(

SWITCH

I

I

I

SWITCH

I

-

IRELAY

I

(LOW

11)

TURN

LIGHT

_

a

_

2

1

s

RIGHT

ASS

COMPRESSOR

t

WIPER

HIGH

BLOWER

HAZARD

I

WASHER

I

RELAY

I

]CONTROL

I

RELAY

I

(BEAM

II

RELAY

I

(FLASHER

I

(JET

II

I

IRELAY

I

((CANADA)

m

I

,LIGHT

II

I

IRELAY

I

(HEATER

i

v

I

I

v

(SWITCH

I

v

I

I

v

IRELAV

I

v

I

,

v

I

BR

I

LIGHT

LEFT

IGNITION

CHIME

DRIVERS

DIMMER

RIGHT

,SWITCH

I(

PARK

I

SWITCH

I

MODULE

I

SEAT

.

BEAT

I

,

(

)

FRONT

I

I

I

(LIGHT

]

II

_

_I

,

,

HEATER

I

I

-

AUXILIARY

I

-I

I

-I

RELAY

I

I

I

-I

I

-I

SWITCH

I

-I

TURN

LIGHT

7

91

6

6

INSTRUMENT

STARTER

WIPER/

HORN

UNLOADER

BRAKE

PASSENGERS

,

CLUSTER

I

,RELAY

I

WASHER

I

,

SWITCH

I

,RELAY

I

LIGHT

I

,SEAT,SEAT

II

I

I

I

SWITCH

I

II

I

I

(

SWITCH

I

(

HEATER

I

I

I

I

I

I

I

I

"T

I

I

^T

I

I

°T

SWITCH

3

`

T

T

BRN

G302

-

I

-

.

LIGHT

-

1_

G302

Page 534 of 759

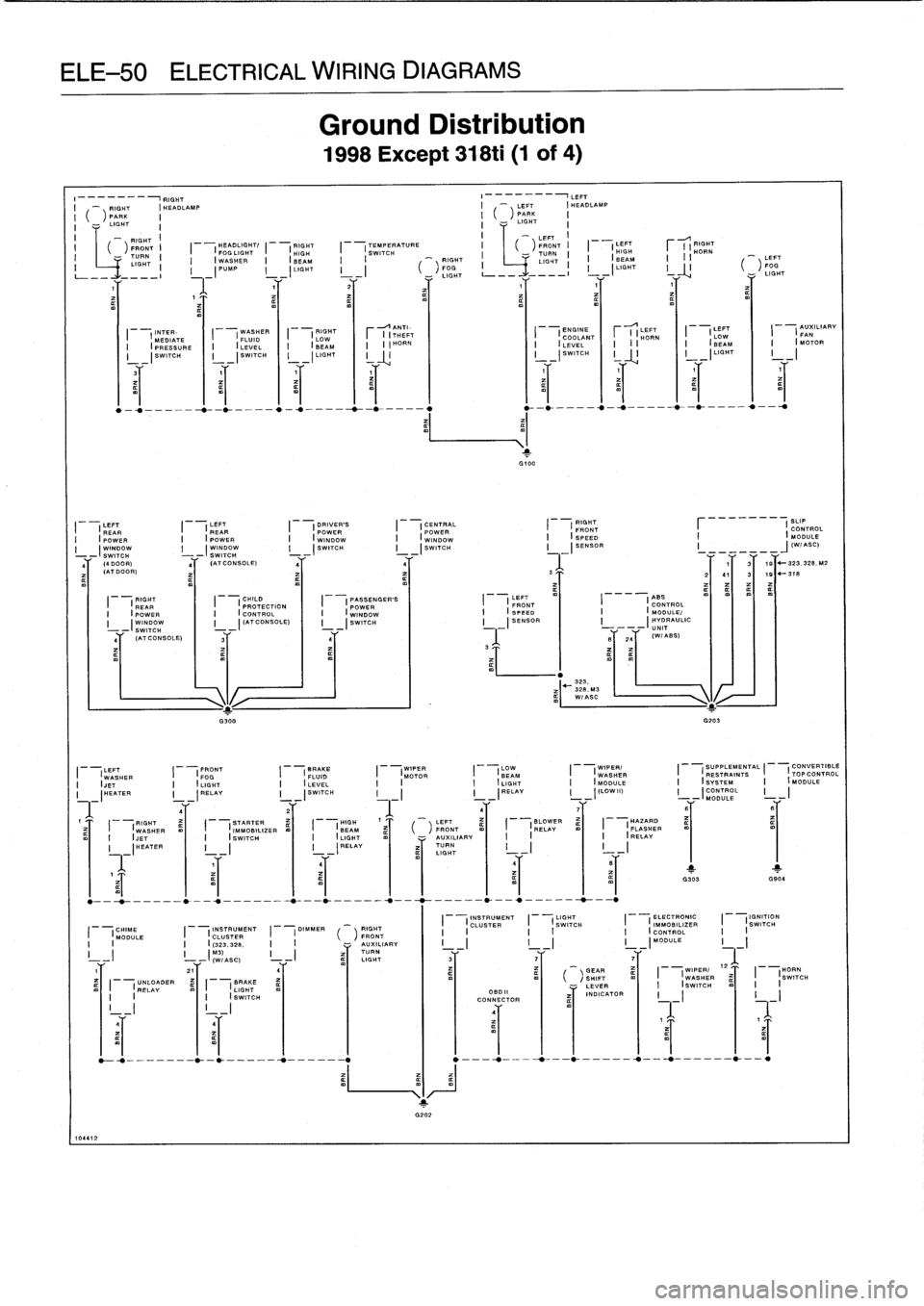

ELE-50

ELECTRICAL

WIRING

DIAGRAMS

I-

____RIGHT

~LEFT

I

RIGHT

(HEADLAMP

I

LEFT

,HEADLAMP

i

(

)

PARK

I

I

(

)

PARK

i

I

-

LIGHT

I

I

Y

LIGHT

I

LEFT

LEFT

DRIVER'S

CENTRAL

RIGHT

SLIP

I

REAR

I

REAR

I

(

POWER

I(

POWER

I

(

FRONT

CONTROL

I

POWER

I

,POWER

I

(WINDOW

I

(WINDOW

I

(SPEED

I

(MODULE

_

_,

WINDOW

I

_,

WINDOW

I

(

SWITCH

I

(

SWITCH

I

(

SENSOR

I

-

-

j

(WIASC)

SWITCH

SWITCH

``

77''q

(4AD00R)

0

(ATCONSOLE)

4

q

T

1

1I

I

3T

/

19T

/

-323

.328

.

M2

(AT

DOOR/

Z

3

7`

21

011

31

19/x"

318

10441

2

-

RIGHT

I

I

_

1--HEADLIGHT/

III

I

(

)FRONT

(

HIGH

I

IHORN

WASHE

HT

HIGH

SWITCH

TURN

II

,

R

I

(

BEAM

,

"-'

RIGHT

LIGHT

I

,

BEAM

I

,I

LEFT

LIGHT

I

I

(

PUMP

LIGHT_

I_

_

I

(

)

FOG

I

I

I

(

LIGHT

(

)FOG

--

_

I

T

LIGHT

L---

-I

LIGHT

1

2

1

1

1

T

I

INTER-

'

WASHER

I

RIGHT

I

MEDIATE

I

FLUID

I

LOW

IPRESSURE

I

I

LEVEL

I

I

(BEAM

I

-

,SWITCH

II

-

,SWITCH

I

J

-

(LIGHT

Ground

Distribution

1998Except

318ti

(1

of

4)

~

ANTI-

II

THEFT

I

I'

HORN

I

I

ENGINE

LEFT

I

COOLANTHORN

I

(

LEVEL

I

,

I

I

_I

SWITCH

I

¢t

¢~

LEFT

I

ABS

FRONT

I

CONTROL

I

I

SPEED

I

I

MODULE/

I

_

_I

SENSOR

I

I

HYDRAULIC

UNIT

(ATCONSOLE)

3'f

I

qT

2

(WIASS)

1

T

RIGHT

CHILD

I

I

REAR

I

I

PROTECTION

I

POWER

I

(CONTROL

I

,WINDOW

I

_I

(AT

CONSOLE)

--

SWITCH

G300

II

PASSENGER'S

POWER

I

I

WINDOW

I

_I

SWITCH

I

323,

1-

328,

M3

WIASC

I

I

LEFT

LO

W

I

(BEAM

I

-

(LIGHT

G203

LEFT

FRONT

BRAKE

WIPER

LOW

WIPER,

SUPPLEMENTAL

CONVERTIBLE

IWgSHER

I

FOG

,

FLUID

I

(

MOTOR

I(

BEAM

I

(WASHER

I

(

RESTRAINTS

I

ITOPCONTROL

I

,JET

I

(LIGHT

I

(LEVEL

I

I

,

(LIGHT

I

(MODULE

I

IBYSTEM

I

(MODULE

I

(HEATER__

I_

__IRELAV

I

-(SWITCH

I

I

I

-IRELAV

I

-

I(LOWIU

I

_IMODULEL

-

q

2

_

q

_

l

1

_

I

pIGHT

(STARTER

(HIGH

1

LEFT

(BLOWER

I

IHA2ARD

I

WASHER

I

IMMOBILIZER

m

I

BEAM

(

FRONT

(

RELAY

FLASHER

JET

I

SWITCH

,

,LIGHT

"'

AUXILIARY

II

I

IRELAV

I

-

,HEATER

TURN

I

-

I

I

-IRELAV

dl

IGHT

J

.

G904

INSTRUMENT

LIGHT

ELECTRONIC

IGNITION

CHIME

INSTRUMENT

DIMMER

RIGHT

I

(

CLUSTER

I

(

SWITCH

I

IIMMOaILIZER__

I(

SWITCH

I

I

MODULE

(CLUSTER

I

,

)

FRONT

I

I

I

I

I

CONTROL

I

I

II(323,328,

I

I

AUXILIARY

I

I

I

I

I

MODULE

iII

-

_

-I

I

-

-

-I

ff

TURN

(WIASC)

LIGHT

3T

7T

7

'WIPER/

12

,HORN

I

WASHER

I

--

SWITCH

,SWITCH

I

III

m

I

_I

UNLAY

OADER

I

BRAKE

I

(

REL

m

I

(

LIGHT

I

_I

I

I

SWITCH

I

_I

!

ogoHCONNECTOR

GEAR(

)

SHIFT

LEVER

INDICATOR

AU%ILIARV

I

FAN

I

I

MOTOR

Page 650 of 759

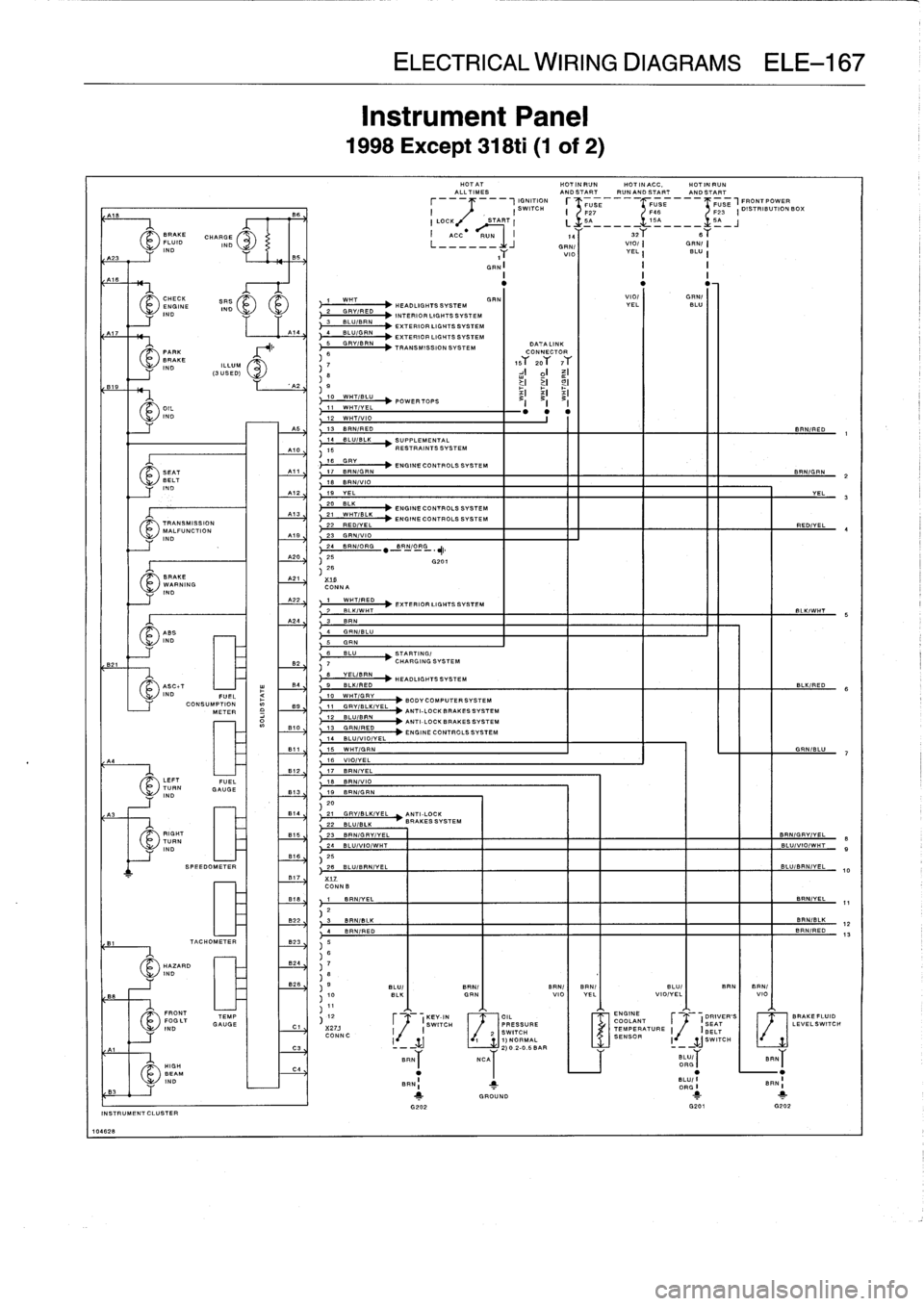

HK

ENGINE

W

STEM

IN.

2

GRV/RED

S(

)

INTERIOR

LIGHT

ICNDEC

S

SYSTEM

~3

-

BLU/BRN

EXTERIOR

LIGHTS

SYSTEM

A14

4

BLU/GRN

j~

EXTERIOR

LIGHTS

SYSTEM

5

GRVIBRN

~~

TRANSMISSION

SYSTEM

67

INSTRUMENT

CLUSTER

10462

8

ELECTRICAL

WIRING

DIAGRAMS

ELE-167

Instrument

Panel

1998

Except

318ti

(1

of2)

11

WHT/VEL

12

WHT/VIO

13

BRN/RED

14

BLUIBLK

I

SUPPLEMENTAL

1

RESTRAINTS

SYSTEM

ifi

GRV

17

BRN/GR

18

BRNIVIO

19

YEL

HOTAT

HOTINRUN

HOTINACC,

HOTINRUN

ALLTIMEE

ANDSTART

RUNAND

START

ANDSTART

IGNITION

r

FUSE

FUSE

FUSE

1

FRONTPOWER

SWITCH

I

DISTRIBUTION

BOX

I

I

I

~

F27

~F46

~

F23

I

LOCK

_START

I

L

SA

----

15A

---

EA

-

J

I

ACC

*

RUN

I

1

1

.'f

32Y

BY

L------IJ

GRNII

viol

I

GRNII

VEL

I

BILL

I

ENGINE

CONTROLS

SYSTEM

GRN

DATA

LINK

CONNECTOR15Y

20Y

7Y

j

G

I

QI

viol

GF

.1

VEL

BILL

1

VIO

GRNI

I

I

I

I

I

BLU/

BFN

BRN/

VID/VEL

I

I

I'D

ENGINE

DRIVER'S

BRAKE

FLUID

COOLANT

~~

I

SEAT

I

LEVELSWITCH

TEMPERATURE

I

]BELT

Ij

SJSWITCH

I

BLUR

BRNI

DR

.

BILL//

1

ORGI

SPIN

BRNIRED

BRN/GRN

YEL

RED/VEL

2

10

WHT/GRV

89-

l11

GRV

0

BODY

COMPUTER

SYSTEMSVSTEM

J

-

I

ANTI-LOCK

BRAKESSYSTEM

12

BLU/BPN

ANTI-

LOCK

BRAKESSYSTEM

13

GRNIREO

1~ENGINE

CONTROLS

SYSTEM

14

BLU/VIO/VEL

15

WHTIGRN

GRNIBLU

71

16

VIO/VEL

I

812

17

BRN/VEL

18

BRN/VIO

B73

19

BRN/GRN

20

B14

21

GRV/BLK/VELANTI-LOCK

22

BLD

i

IBLK

BRAKESSVSTEM

B16

23

BRN/GRV/VEL

BRNIGRY/VEL

B

24

BLU/VIO/WHT

BLUIVIOIWH7

9

Page 652 of 759

83364

L

J

23

GRN/VIO

-

BLK/WHT

8

24

BRN/ORG

BRNISLK

9

A22

,

25

I

-

BLK/RED

10

26

SPEEDOMETER

B18

CONNA

-

ENGINE

CONTROLS

SYSTEM

(1997

ONLY)

1

WHT/RED

I

'

,,II

I

WHT/GRN

G

REDUI

II

11

VIOIYEL

B4

/

2

BLK/WHT

123

BRN

1

1

11111111

BRN/YEL

13

B77

;

4

GRN/BLU

~ITI

II

IIIIII

BRN/VIO

14

TACHOMETER

818

6

BLU

STARTING/

7

CHARGINGSYSTEM

BRN/YEL

15

A20

6

YEL/8RN

HEADLIGHTSSVSTEM

9

BLK/REO

10

11

GRY/BLK/YEL

ANTI-LOCK

BRAKESSYSTEM

21

12

BLU/BRN

ANTI-LOCK

BRAKESSYSTEM

(1997ONLY)

13

GRN/RED

Cl

14

BLU/VIO/YEL

BLU/VIO/YEL

2LI

\

.I

i

B

L

N

.

II

~

15

WHT/GRN

BRN

16

VIO/YEL

-

-

I

DRIVER'S

SEAT

BELT

SWITCH

j

17

BRNIYEL

.BRN

G203

18

BRN/VIO

GRY/BLK/YEL

BRN

19

BRNIGRN

1997

ANTI-LOCK

W/pqC~

W

j_

p20220

pqy

ONLY

BRAKES

pqy/BLKIVEL

21

(OR

BRN)

SYSTEM

(

r

OR

22

BLU/BLK

23

BRN/GRV/YEL

B

RN/GRY/YEL

.

16

2425

BRN/REO

17

823

.1

28

CONN.

BRN

12

I

I

III

III

_

1

BRN/YEL

BLU/

I

BRN

I

BRN

2

BL

[

BRN/B

I

I

I

IGNITION

3

LK

4

SRN

/RED

,

,SWITCH

G202

5

YEL/WHT

INSTRUMENT

CLUSTER

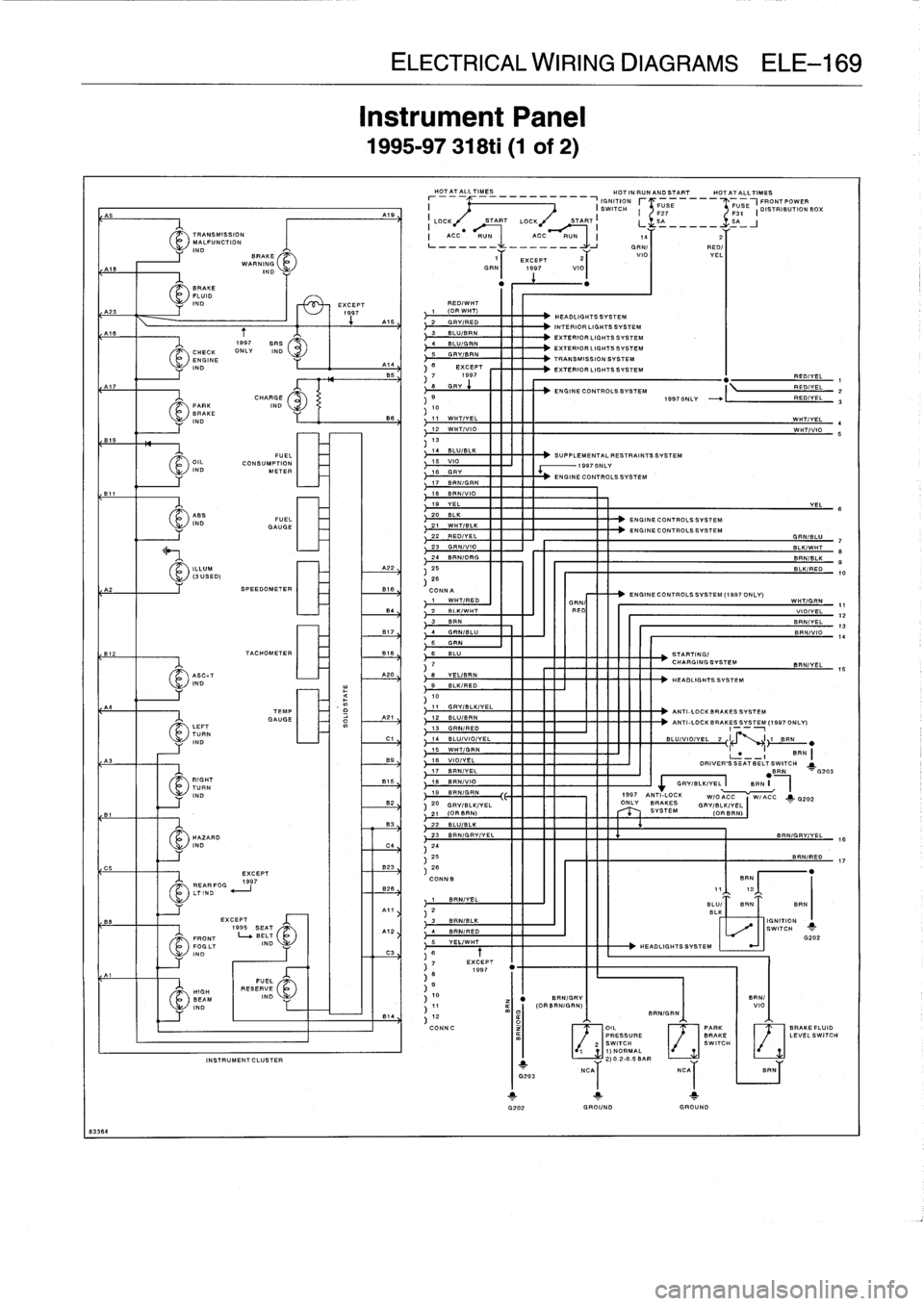

Instrument

Panel

1995-97

318ti

(1

of

2)

ELECTRICAL

WIRING

DIAGRAMS

ELE-169

HOTATALLTIMES

HOTINRUNANDSTART

HOTATALLTIMES

-~

IGNITION

RRONTPOWER

I

(

SWITCH

r

G27

E

q31

E

I

DISTRIBUTION

BOX

LOCK

START

LOCK

START

i

L

5A

-----

SA_

J

I

ACCRUNACC

RUN

I

14

2

GN/)

REO/

10

EXCEPT

GRN

1997

VIO

V

Y

EL

RED/WHT

1

(ORWHT)

2

GRV/RED

3

BLU/BRN

4

SLUIGRN

5

GAY/BAN

B

EXCEPT

7

1997

8GRY

RED/YEL

ENGINE

CONTROLS

SYSTEM

RED/YEL

1997ONLY

-

"

I

RED/YEL

1011

WHT/YEL

WHTIVEL

4

12

WHT/VIO

WHT/VIO

5

1314

BLU/BLK

SUPPLEMENTAIL

RESTRAINTSSYSTEM

15

V10

ECONTROLS

NGINECOTROLSSYSTEM

17

8RN/GRN

18

BAN/VI0

19

YEL

YEL

B

20

BLK

21

WHT/BLK

ENGINECONTROLSSYSTEM

ENGINECONTROLSSYSTEM

22

RED/YEL

GRN/BLU

7

7

EXCEPT

8

1997

9

10I

V

RN/

I

/

I

B

RNGR

NI

m

I

BRN/GRN

11

(OR

B(N/G

N)81

vio

4

,

12

O

CONNC

I

3I

OIL

PARK

IBRAKEFLUID

LEVEL

SWITCH

/j

/~

PRESSURE

BRAKE

LEVELWITCH

2

SWITCH

V~

SWITCH

7

1)NORMAL

2)

0

.2--BAR

j

G202

HEADLIGHTS

SYSTEM

INTERIORLIGHTS

SYSTEM

EXTERIOR

LIGHTS

SYSTEM

EXTERIOR

LIGHTS

SYSTEM

TRANSMISSION

SYSTEM

EXTERIOR

LIGHTS

SYSTEM

HEADLIGHTS

SYSTEM

.1L

j

GROUND

GROUND

NCAI

NCAI

I

BRN

Page 654 of 759

N

A

IDBS

H

FUEL

B12

CONSUMPTIONMETER

ASC

.T

IND

10458

0

SRS

IND

INSTRUMENT

CLUSTER

I

OF

.,1

WHT

GRN

VIO/

r

I

BLU

YEL

2

GRHEADLIGHTSSYSTEM

INTERIOR

LIGHTS

SYSTEM

SS

BLUIBRN

EXTERIORLIGHTSSYSTEM

~I

9

BLU/GRN

,

EXTERIORLIGHTS

SYSTEM

,SUPPLEMENTAL

15

RESTRAINTS

SYSTEM

16

GRV

~~

ENGINE

CONTROLS

SVSTEM

17

BRN/GRN

18

BRN/VIO

19

YEL

20

BILK

ENGINE

CONTROLS

SYSTEM

21

12

BLU/BRN

~--*

gNTI-LOCK

BRAKESSYSTEM

13

GRNIRED

ENGINECONTROLS

SYSTEM

10

BLU/VIO/V

EL

15~HT/GRN

17

1

B

RNI

El

}

~WEL

18~

BN/VIO

19

FNIGR

N2021

GRV/BLK/YEL

~

ANTI-LOCKBRAKES

22

BLU/BLK

SYSTEM

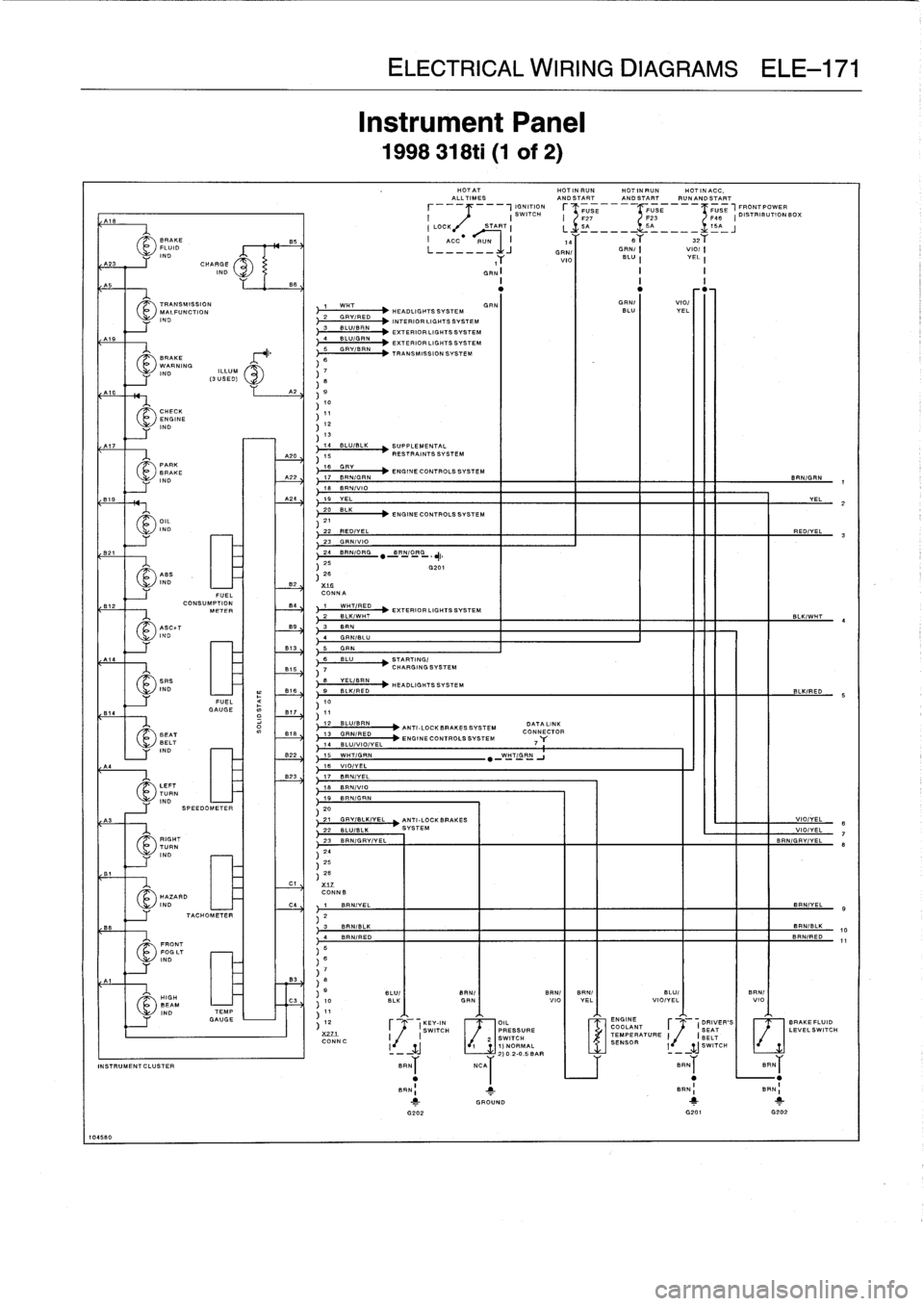

Instrument

Panel

1998

318ti

(1

of

2)

ELECTRICAL

WIRING

DIAGRAMS

ELE-171

HOTAT

HOTINRUN

HOTINRUN

HOTINACC,

ALLTIMES

ANDSTARTANDSTART

RUNANDSTART

r

---

,

IGNITION

r

FUSE

USE

USE

1

FRONTPOWER

SWITCH

F27

F23

F4B

DISTRIBUTION

BOX

~

I

LOCK/

START

I

L

=A

----

5=

----

15=

J

I

ACC

*

8U"

By

212Y

L------

j

ORN/

GFN/

I

VI01

I

1

VIO

BLU

I

YEL'

DATA

LINK

CONNECTOR

7

Y

"=W=

TIGR

_J

BV

O

/I

B

YEL

I

VIOBYEL

I

I

B

V10

I

`

s

jSWITCH

I

L

1

,

BRNI

GRNI

BRN

BRN

BRN/YEL

BRNIBLK

BRN/RED

ENGINE

DRIVER'S

BRAKEFLUID

COOLANT

1~

I

SEAT

I

LEVELSWITCH

TEMPERATURE

I

(BELT

78

10