temp BMW 325i 1994 E36 Manual PDF

[x] Cancel search | Manufacturer: BMW, Model Year: 1994, Model line: 325i, Model: BMW 325i 1994 E36Pages: 759

Page 274 of 759

330-2

REAR

SUSPENSION

Table

a

.

Rear

RideHeight

Specifications

Wheel

size

318,323,

325,

M3

modeis

328

modeis

17inch

std

.

suspension

546

mm

(21.69

in)

sport

suspension

~

535

mm

(21.06

in)

1

540

mm

(21

.26

in)

Maximum

variation

between

sides

:

10

mm

(0

.4in)

Maximum

deviation

from

specifications

:

10

mm

(0

.4in)

SHOCK

ABSORBERS

AND

SPRINGS

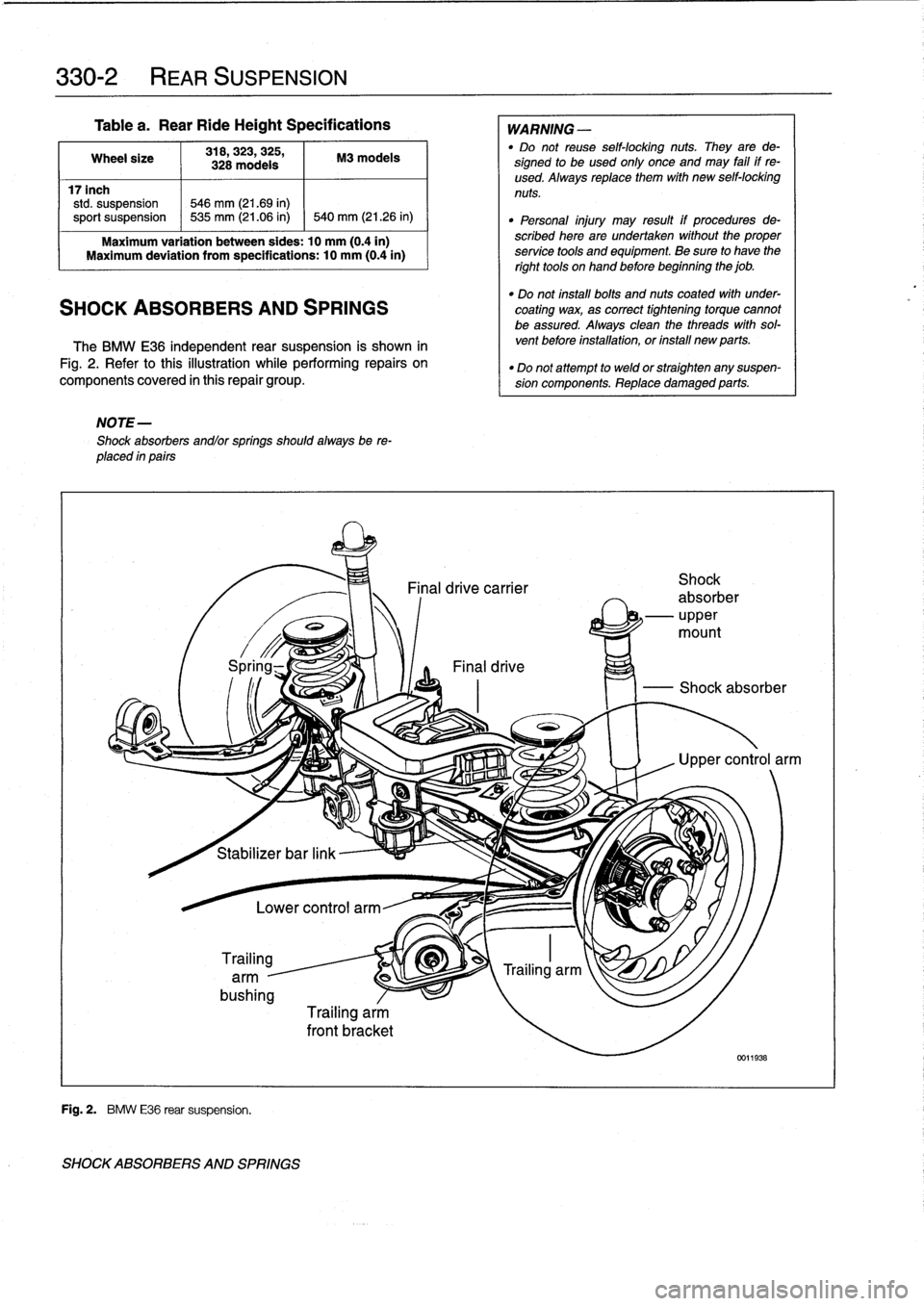

The

BMW

E36

independent

rear

suspension

is

shown

in

Fig

.

2

.

Refer

tothis

illustration

while

performing

repairs

on

components

covered

in

this

repair

group

.

NOTE-

Shock

absorbers

andlor

springs

shouldalways

be

re-

placed

in

pairs

i

Stabilizer

bar

link

Trailing

arm

-

bushing

Fig

.

2

.

BMW

E36

rear

suspension

.

SHOCK

ABSORBERS

AND

SPRINGS

Lower

control

arm

Trailing

arm

front

bracket

WARNING

-

"

Do

not

reuse

self-locking

nuts

.

They

arede-

signed

to

beused

only

once

and

may

fail

if

re-

used

.

Always

replace

them

with

new

self-locking

nuts

.

"

Personal

injury

may

result

if

procedures

de-

scribed

here

are

undertaken

without

the

proper

service

tools

and

equipment

.

Be

sure

to

have

the

right

tools

onhand

before

beginning

the

job

.

"

Do

not

install

bolts

and

nuts

coated

with

under-

coating

wax,

as

correct

tightening

torque

cannot

be

assured

.

Always

clean

the

threads

with

sol-

vent

before

installation,

or

ínstall

new

parts

.

"

Do

not

attempt

to

weld

or

straighten

any

suspen-

sion

components

.

Replace

damaged

parts

.

Page 281 of 759

9

.

Packeach

CV

joint

and

rubber

boot

with

specified

REAR

SUSPENSION

ARMS

amount

of

lubricant

supplied

.

Apply

adhesive

to

large

end

of

boot

and

mount

it

on

joint

.

Secure

boot

with

clamps

.

The

trailing

arms,

control

arms

and

their

mountingbushings

Apply

sealer

to

inner

CV

joint

dust

cover

and

instan

.

control

the

position

of

the

rear

wheels

.

A

damaged

suspen-

sion

arm

or

worn

bushings

will

change

the

rear

wheel

align

NOTE-

ment

and

may

adversely

affect

handling

and

stability

.

"

Before

installing

each

small

boot

clamp

be

sure

to

"burp"

the

boot

by

flexing

the

CV

joint

as

far

overas

it

WARNING

will

go

.

A

small

screw-driver

inserted

between

the

Do

notattempt

to

straighten

a

damaged

suspension

boot

and

the

axle-shaft

will

help

the

process

.

arm

.

Bending

or

heating

may

weaken

the

original

"

BMW

recommends

Bostil101513

or

EppleC4851

ad-

part

.

If

the

suspension

arm

shows

any

signs

of

hesive,

and

Epple®39

or

Curil©T

sealer

damage

or

excessive

corrosion,

it

must

be

re-

placed

.

CV

Joint

Lubricant

Capacity

"

Wheel

hub

end

ex

.

M3

..

..

.

....

.

.............

80

gram

(2.8

oz

.)

M3

..

...

.

..

.................

100

gram

(3

.5

oz

.)

"

Finaldrive

end

.................

85

gram

(3

.0

oz

.)

10

.

Install

drive

axle

as

described

earlier

.

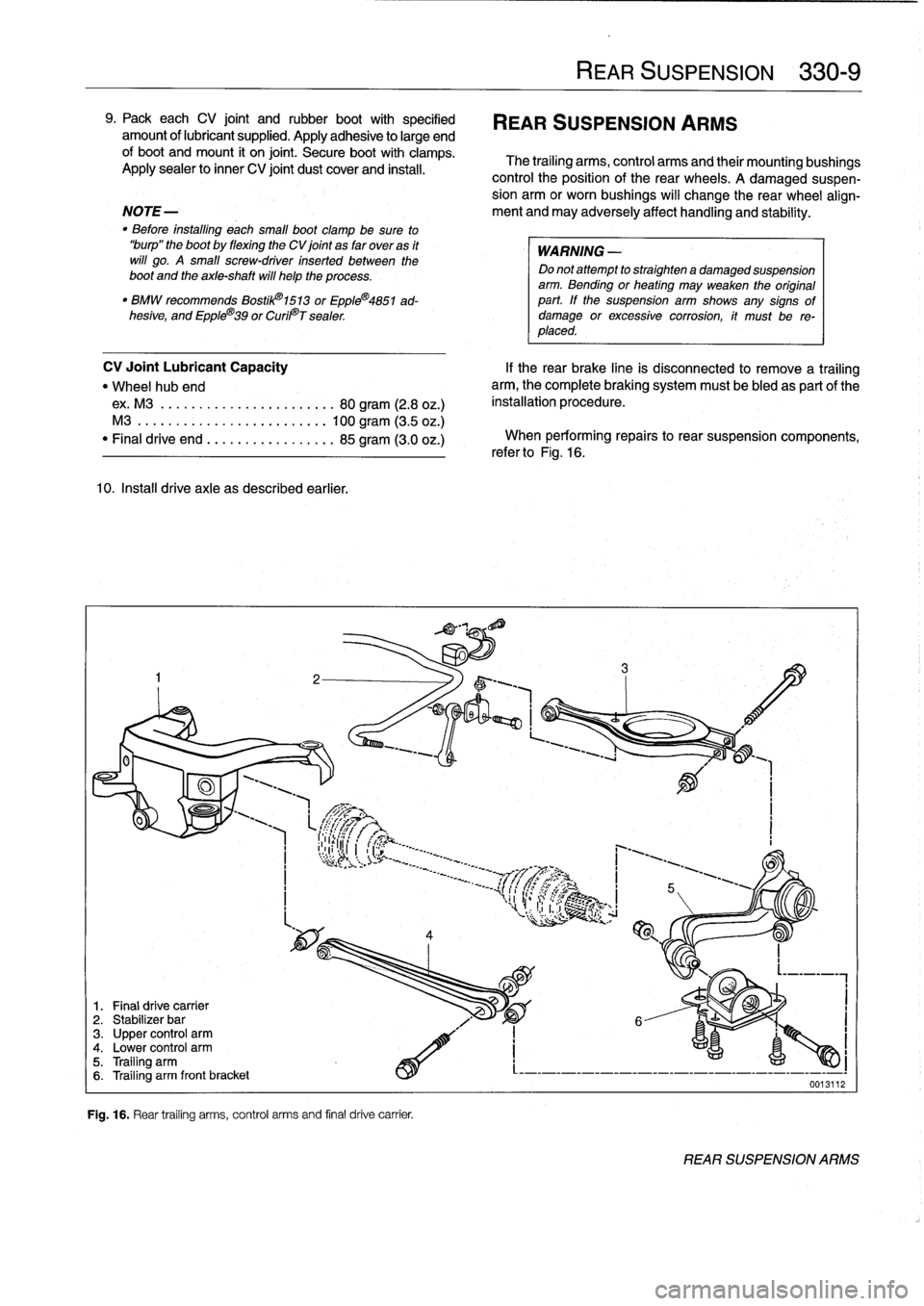

1

.

Final

drive

carrier

2

.

Stabilizer

bar

3

.

Upper

control

arm4

.

Lower

control

arm5

.

Trailing

arm6

.

Trailing

arm

front

bracket

Fig

.

16

.

Rear

trailing

arms,

control

arms

and

final

drive

carrier

.

If

the

rear

brake

cine

is

disconnected

to

remove

a

trailing

arm,

the

complete

braking

system

must

be

bled

as

partof

the

installation

procedure

.

When

performing

repairs

to

rear

suspension

components,

refer

to

Fig

.

16

.

REAR

SUSPENSION

330-

9

0013112

REAR

SUSPENSION

ARMS

Page 292 of 759

340-2

BRAKES

When

troubleshooting,

keep

in

mind

that

tire

inflation,

wear

and

temperature

can

affect

braking

and

suspension

.

See310

Front

Suspension

for

more

information

on

front

suspension

parts

inspection

.

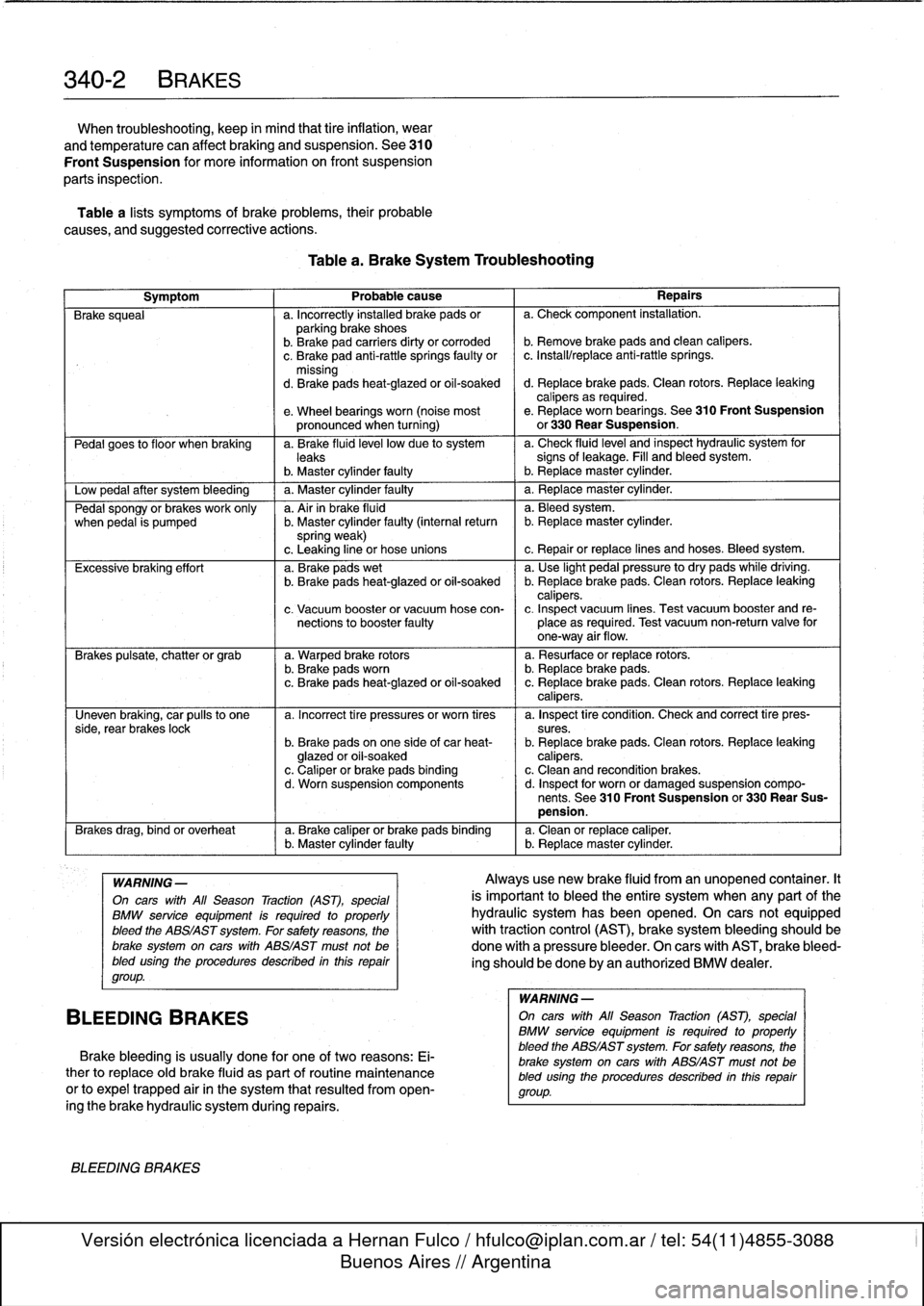

Table

a

lists

symptoms

of

brake

problems,

their

probable

causes,

and

suggested

corrective

actions

.

Table

a

.

Brake

System

Troubleshooting

Symptom

1

Probable

cause

1

Repairs

Brake

squeal

a

.

Incorrectly

installed

brake

pads

or

a

.

Check

component

installation

.

parking

brake

shoes

b

.

Brakepad

carriers

dirty

or

corroded

b

.

Remove

brake

pads

and

clean

calipers

.

c

.

Brake

pad

anti-rattle

springs

faulty

or

c

.

Install/replace

anti-rattle

springs

.

missing

d

.

Brakepads

heat-glazed

or

oil-soaked

d

.

Replace

brake

pads

.

Clean

rotors

.

Replace

leaking

calipers

as

required

.

e

.

Wheel

bearings

worn

(noise

most

e

.

Replace

worn

bearings

.

See310

Front

Suspension

pronounced

when

turning)

or

330

Rear

Suspension

.

Pedal

goes

to

f

loor

when

braking

a

.

Brake

fluid

leve¡

low

due

to

system

a

.

Check

fluidlevel

and

inspect

hydraulic

system

for

leaks

signs

of

leakage

.

Fill

and

bleed

system

.

b

.

Master

cylinder

faulty

I

b

.

Replacemaster

cylinder

.

Low

pedal

after

system

bleeding

1

a

.

Master

cylinder

faulty

1

a

.

Replace

master

cylinder

.

Pedal

spongy

or

brakes

work

only

a

.

Air

in

brake

fluid

a

.

Bleedsystem

.

when

pedal

is

pumped

b

.

Master

cylinder

faulty

(interna¡

return

b

.

Replacemaster

cylinder

.

spring

weak)

c

.

Leaking

line

or

hose

unions

c

.

Repair

or

replace

lines

and

hoses

.

Bleed

system

.

Excessive

braking

effort

a

.

Brake

pads

wet

a

.

Use

light

pedal

pressure

to

dry

pads

while

driving

.

b

.

Brake

pads

heat-glazed

oroil-soaked

b

.

Replace

brake

pads

.

Clean

rotors

.

Replace

leaking

calipers

.

c

.

Vacuum

booster

or

vacuum

hose

con-

c

.

Inspect

vacuum

lines

.

Test

vacuum

booster

and

re

nections

to

booster

faulty

place

as

required

.

Test

vacuum

non-return

valve

for

one-way

air

flow

.

Brakes

pulsate,

chatter

or

grab

a

.

Warped

brake

rotors

a

.

Resurface

or

replace

rotors

.

b

.

Brake

padsworn

b

.

Replace

brake

pads

.

c

.

Brake

pads

heat-glazed

or

oil-soaked

c

.

Replace

brake

pads

.

Clean

rotors

.

Replace

leaking

calipers

.

Uneven

braking,

car

pulís

to

one

a

.

Incorrect

tire

pressures

or

worn

tires

a

.

Inspect

tire

condition

.

Check

and

correct

tire

pres-

side,

rear

brakes

lock

sures

.

b

.

Brake

pads

on

one

side

of

car

heat-

b

.

Replace

brake

pads

.

Clean

rotors

.

Replace

leaking

glazed

or

oil-soaked

calipers

.

c

.

Caliper

or

brake

pads

binding

c

.

Clean

and

recondition

brakes

.

d

.

Worn

suspension

components

d

.

Inspect

for

worn

or

damaged

suspension

compo-

nents

.

See

310

Front

Suspension

or

330

Rear

Sus-

pension

.

Brakes

drag,

bind

or

overheat

a

.

Brake

caliper

or

brake

pads

binding

a

.

Clean

or

replace

caliper

.(

b

.

Master

cylinder

faulty

b

.

Replacemaster

cylinder

.

WARNING

-

On

cars

with

All

Season

Traction

(AST),

special

BMW

service

equipment

is

required

to

properly

bleed

the

ABS/AST

system

.

For

safety

reasons,

the

brake

system

on

carswith

ABS/AST

must

not

be

bled

using

the

procedures

described

inthis

repair

group

.

BLEEDING

BRAKES

Brake

bleeding

is

usually

done

for

one

of

two

reasons

:

Ei-

ther

to

replace

oíd

brake

fluid

as

part

of

routine

maintenance

or

to

expel

trapped

air

in

the

system

that

resulted

from

open-

ingthe

brake

hydraulic

system

during

repairs

.

BLEEDING

BRAKES

Alwaysuse

new

brake

fluid

from

an

unopened

container

.It

is

important

to

bleed

the

entire

system

when

any

part

of

the

hydraulic

system

has

been

opened

.

On

cars

not

equipped

with

traction

control

(AST),

brake

system

bleeding

should

be

done

with

a

pressure

bleeder

.

On

cars

with

AST,

brake

bleed-

ing

should

be

done

by

an

authorized

BMW

dealer

.

WARNING

-

On

cars

with

All

Season

Traction

(AST),

special

BMW

service

equipment

is

requíred

to

properly

bleed

the

ABS/AST

system

.

For

safetyreasons,

the

brake

system

on

carswith

ABS/AST

must

not

be

bled

using

the

procedures

described

inthís

repair

group

.

Page 307 of 759

Ambient

temperaturelclock

MÍM

Aa

.Mi}rm

-Mil"

IMua~naa~u~itacar

"

za

.~

Central

Body

Electronics

0013028

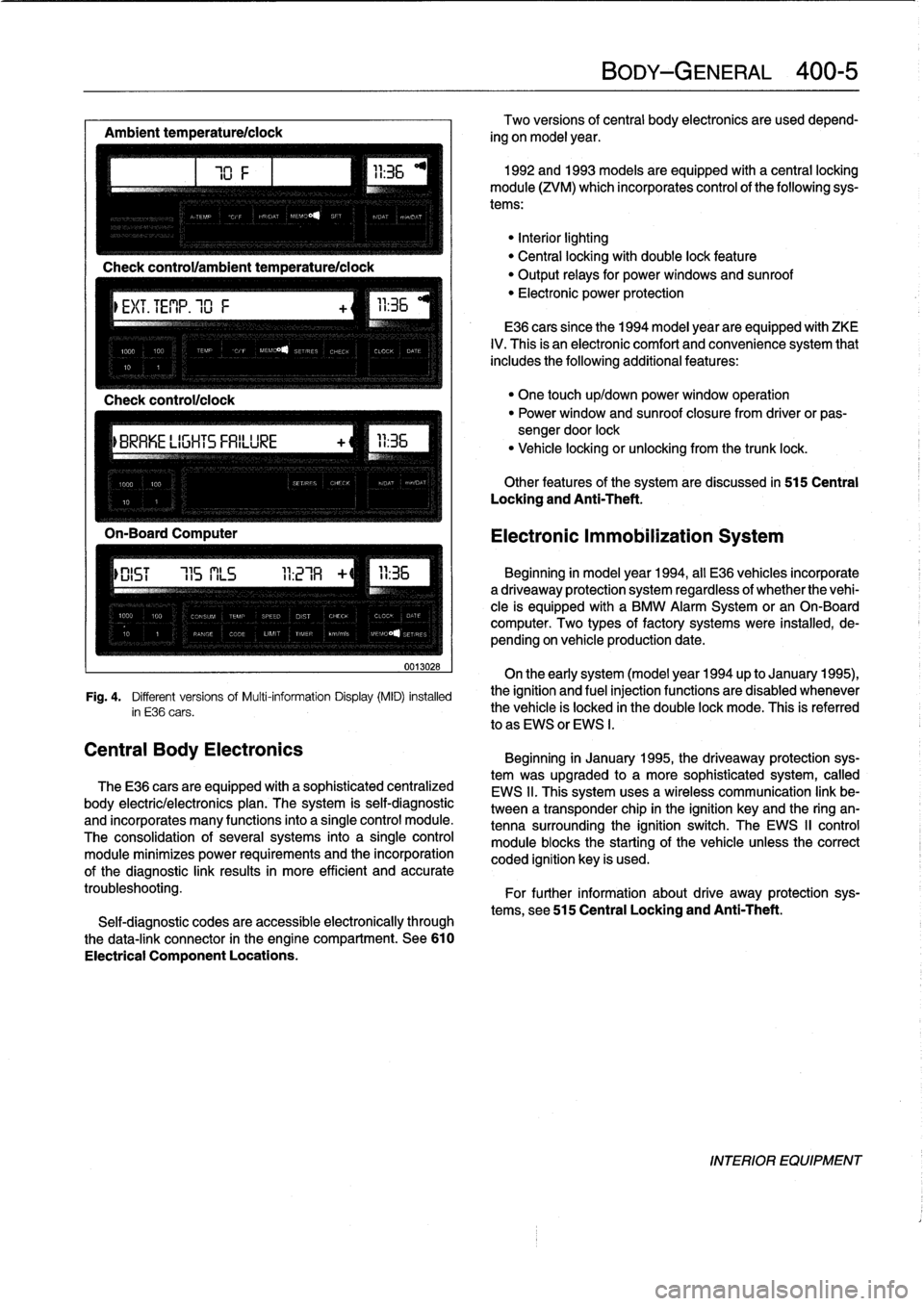

Fig

.

4

.

Different

versionsof

Multi-information

Display(MID)

installed

in

E36

cars

.

The

E36

cars

are

equipped

with

a

sophisticated

centralized

body

electric/electronics

plan

.

The

system

is

self-diagnostic

and

incorporates

many

functions

into

a

single

control

module

.

The

consolidation

of

several

systems

into

a

single

control

module

minimizes

power

requirements

and

the

incorporation

of

the

diagnostic

link

results

in

more

efficient

and

accurate

troubleshooting

.

Self-diagnostic

codes

are

accessible

electronically

through

the

data-link

connector

in

the

engine

compartment

.

See610

Electrical

Component

Locations

.

BODY-GENERAL

400-

5

Two

versions

of

central

body

electronics

are

used

depend-

ing

on

model

year

.

1992

and

1993

models

are

equipped

with

a

central

locking

module

(ZVM)

which

incorporates

control

of

the

following

sys-

tems

:

"Interiorlighting

"

Central

locking

with

double

lock

feature

"

Output

relays

for

powerwindows

and

sunroof

"

Electronic

power

protection

E36

cars

since

the

1994

model

year

are

equipped

with

ZKE

IV

.

This

is

an

electronic

comfort

and

convenience

system

that

includes

the

following

additional

features

:

"

One

touch

up/down

power

window

operation

"

Power

window

and

sunroof

closure

from

driver

or

pas-

sengerdoor

lock

"

Vehicle

locking

or

unlocking

from

the

trunk

lock

.

Other

features

of

the

system

are

discussed

in

515

Central

Locking

and

Anti-Theft

.

Electronic

Immobilization

System

Beginning

in

model

year

1994,

all

E36

vehicles

incorporate

adriveaway

protection

system

regardless

of

whether

the

vehi-

cle

is

equipped

with

a

BMW

Alarm

System

or

an

On-Board

computer

.

Two

types

of

factory

systems

were

installed,

de-

pending

on

vehicle

production

date

.

On

the

early

system

(model

year

1994

up

to

January

1995),

the

ignition

and

fuel

injection

functions

are

disabled

whenever

the

vehicle

is

locked

in

the

double

lock

mode

.

This

is

referred

lo

as

EWS

or

EWS

I

.

Beginning

in

January

1995,

the

driveaway

protection

sys-

tem

was

upgraded

to

a

more

sophisticated

system,

called

EWS

II

.

This

system

uses

a

wireless

communication

link

be-

tween

a

transponder

chip

in

the

ignition

keyand

the

ring

an-

tenna

surrounding

the

ignition

switch

.

The

EWS

II

control

module

blocksthe

starting

of

the

vehicle

unlessthe

correct

coded

ignition

key

is

used

.

For

further

information

about

drive

away

protection

sys-

tems,

see

515

Central

Locking

and

Anti-Theft

.

INTERIOR

EQUIPMENT

Page 323 of 759

GENERAL

.

.

.

.

.

.

.

.

.

...

.

..

.

...

.

.........

510-1

Front

bumper

impact

absorber,

replacing

....

510-4

Rear

bumper,

removing

and

installing

.....

.510-4

OUTSIDE

REAR

VIEW

MIRRORS

.

...

.

.....

510-1

Rear

bumper

impact

absorber,

replacing

...

.

510-6

Outside

mirrorglass,

replacing

.

.

.........

510-1

Bumper

height,

adjusting

...

.

...

.

...

.

.

.

.

.

510-6

Outside

mirror

housing,

removing

and

installing

....

.

.....

.

.

.

.

.

.

510-1

EXTERIOR

TRIM

...

.

.

.

.

.

.

.

.

.

.

.

...

.

.

.

.

.

510-6

Outside

mirror,

removing

and

installing

.

.

.

.

.

510-2

BMW

embiem,

removing

and

installing

.

.

.

.

.

.

510-7

Body

side

molding,

replacing

.

.

.

.

.

.

.

.

.

.

.

.

.

510-7

BUMPERS

.

.

.

.

.

....

.

.....

.

.....

.

.

.

.

.

.

510-3

Radiator

grille,

removing

and

installing

.

.

.

.

.

.510-7

Front

bumper,

removing

and

installing

.

.

.

.

.

.

510-3

Front

panel,

removing

and

installing

...

.

.

.

.

.

510-7

GENERAL

510

Exterior

Trim,

Bumpers

This

repair

group

includes

repair

information

for

the

outside

rear

view

mirror,

front

and

rear

bumpers,

and

the

easily

re-

movable

exterior

trim

parts

.

OUTSIDE

REAR

VIEW

MIRRORS

The

remove

controlled

mirrors

come

in

two

styles

:

heated

and

unheated

.

Many

of

the

mirror

components

are

separately

available

from

an

authorized

BMW

dealer,

including

the

glass

and

outside

plastic

housing

.

Outside

mirror

glass,

replacing

CAUTION-

Mirror

shouldbe

ator

above

room

temperature

before

removal

.

Otherwise,

small

plastic

parts

or

glass

will

break

.

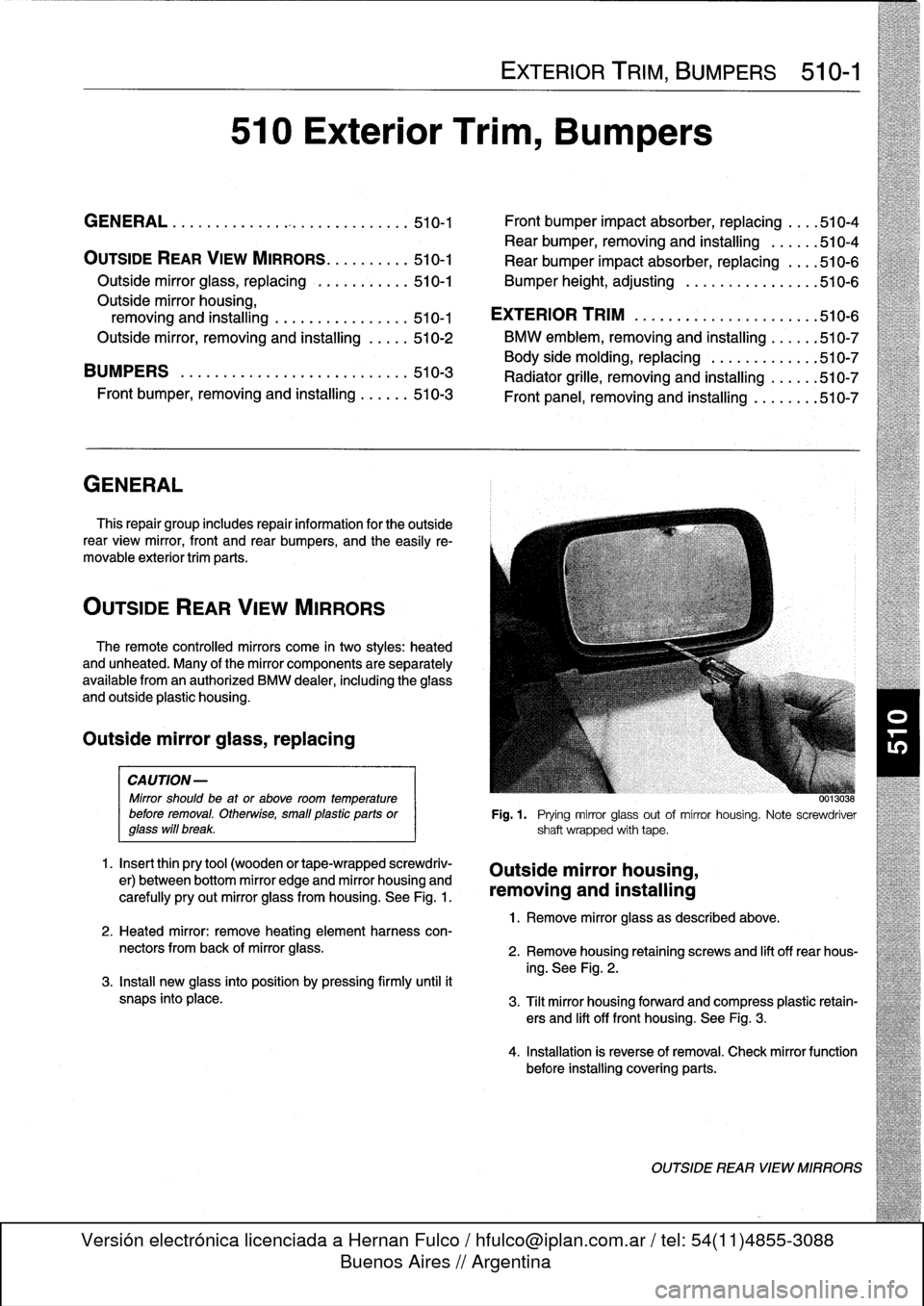

1

.

Insert

thin

pry

tool

(wooden

or

tape-wrapped

screwdriv-

er)

between

bottom

mirror

edge

and

mirror

housing

and

carefully

pry

out

mirror

glass

from

housing

.

See

Fig

.

1

.

2

.

Heated

mirror

:

remove

heating

element

harness

con-

nectors

from

back

of

mirror

glass

.

3

.

Install

new

glass

into

position

by

pressing

firmly

until

it

snaps

into

place

.

EXTERIOR

TRIM,

BUMPERS

510-1

00130

..

Fig

.1

.

Prying

mirror

glass

out

of

mirror

housing

.

Note

screwdriver

shaft

wrapped

with

tape

.

Outside

mirror

housing,

removing

and

installing

1

.

Remove

mirror

glass

as

described

above

.

2

.

Remove

housing

retaining

screws

and

lift

off

rear

hous-

ing

.

See

Fig

.

2

.

3

.

Tilt

mirror

housing

forward

and

compress

plastic

retain-

ers

and

lift

off

front

housing

.

See

Fig

.

3

.

4

.

Installation

is

reverse

of

removal

.

Check

mirror

function

before

installing

covering

parts

.

OUTSIDE

REAR

VIEW

MIRRORS

Page 326 of 759

510-4

EXTERIOR

TRIM,

BUMPERS

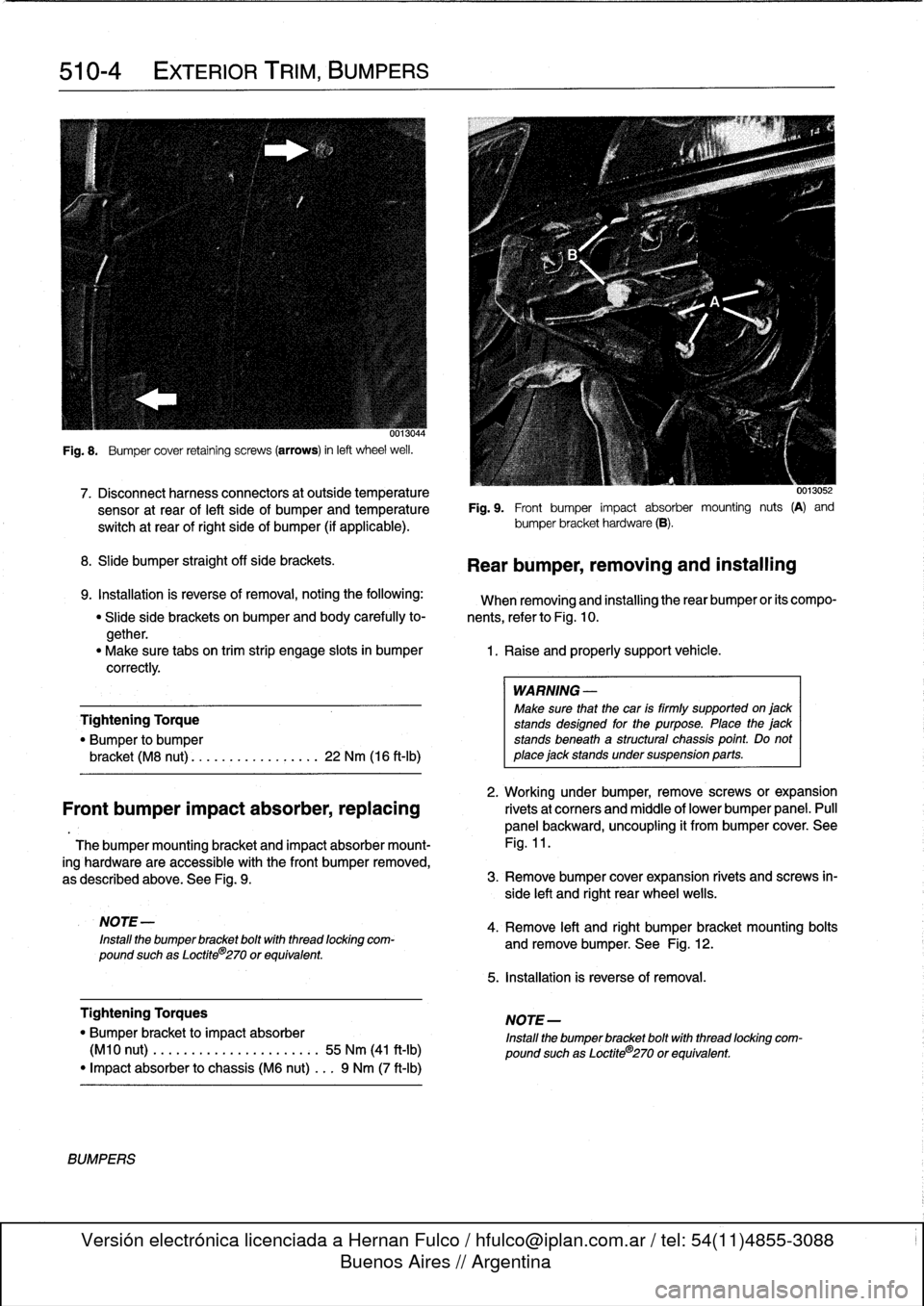

Fig

.

8

.

Bumper

cover

retaining

screws

(arrows)

in

left

wheel

weil

.

7

.

Disconnect

harnessconnectors

at

outside

temperature

0013052

sensor

at

rear

of

left

side

of

bumperand

temperatura

Fig

.

9

.

Front

bumper

impact

absorber

mounting

nuts

(A)

and

switch

at

rear

of

right

side

of

bumper

(if

applicable)

.

bumper

bracket

hardware

(B)

.

8

.

Slide

bumper

straight

off

sida

brackets

.

9

.

Installation

is

reverse

of

removal,

notingthe

following

:

When

removing

and

installing

therear

bumper

or

its

compo-

"

Slide

side

brackets

on

bumper

and

body

carefully

to-

nents,

referto

Fig

.

10

.

gether

.

"

Make

sure

tabs

on

trim

strip

engage

slots

in

bumper

1

.

Raise

and

properly

support

vehicle

.

correctly

.

Tightening

Torque

"

Bumper

to

bumper

bracket

(M8

nut)

............

...

.

.

22

Nm

(16

ft-Ib)

2

.

Working

under

bumper,

remove

screws

or

expansion

Front

bumper

impact

absorber,replacing

rivetsat

corners

and

middle

of

lower

bumper

panel

.

Pull

panel

backward,

uncoupling

it

from

bumper

cover

.

See

Thebumper

mounting

bracket

and

impact

absorber

mount-

Fig

.

11

.

ing

hardware

are

accessible

with

the

Font

bumper

removed,

as

described

above

.

See

Fig

.

9

.

3

.

Remove

bumper

cover

expansion

rivets

and

screws

in-

side

left

and

right

rear

wheel

wells

.

NOTE

-

Install

the

bumper

bracket

boltwith

thread

locking

com-

pound

suchas

Loctite

8

270

or

equivalent

.

Tightening

Torques

"

Bumper

bracket

to

impact

absorber

(M10

nut)

.

..

.

...

.............:.

55

Nm

(41

ft-Ib)

"

Impact

absorber

to

chassis

(M6

nut)

...

9

Nm

(7

ft-Ib)

BUMPERS

Rear

bumper,

removing

and

installing

WARNING

-

Make

sure

that

the

car

is

firmly

supported

on

jack

stands

designad

for

the

purpose

.

Place

the

jack

stands

beneath

a

structural

chassis

point

.

Do

not

place

jack

stands

under

suspension

parts

.

4

.

Remove

left

and

right

bumper

bracket

mounting

bolts

and

remove

bumper

.

See

Fig

.

12

.

5

.

Installation

is

reverse

of

removal

.

NOTE-

Install

the

bumper

bracket

bolt

with

thread

locking

com-

pound

suchas

Loctite®270

or

equivalent

.

Page 334 of 759

512-

4

DOOR

WINDOWS

7

.

Push

regulator

stop

tightly

against

window

regulator

4

.

Lower

door

window

about

12

in

.

(300

mm)

.

Remove

sector

and

tighten

nut

.

window

lifting

arm

retaining

clip

from

window

slide

.

Re-

o

Check

for

tight,

even

fit

at

top

of

window

frame

.

fer

to

Fig

.

2

.

"

If

necessary,temporarily

reconnect

negative

(-)

cable

to

battery

and

raise

window

so

it

is

pressing

uniformly

WARNING-

against

toprubber

sea¡

before

final

tightening

.

Once

the

window

is

lowered,

dísconnect

harness

connector

from

power

window

motor

to

prevent

ac-

8

.

Reinitialize

front

window

motorsas

described

earlier

.

cidental

operation

of

the

window

.

Tightening

Torques

"

Regulator

stop

to

window

regulator

....

9

Nm

(7

ft-Ib)

"

Window

regulator

bracket

to

door

.....

9

Nm

(7

ft-Ib)

Rear

door

window,

removing

and

installing

(4-door

models)

1

.

Remove

rear

door

panel

and

vapor

barrier

.

See

411

7

.

Remove

window

glass

from

above

.

Doors

.

2

.

Pul¡

out

rubber

guide

at

front

of

window

frame

.

Remove

three

screws

and

pul¡

off

exteriortrim

cover

.

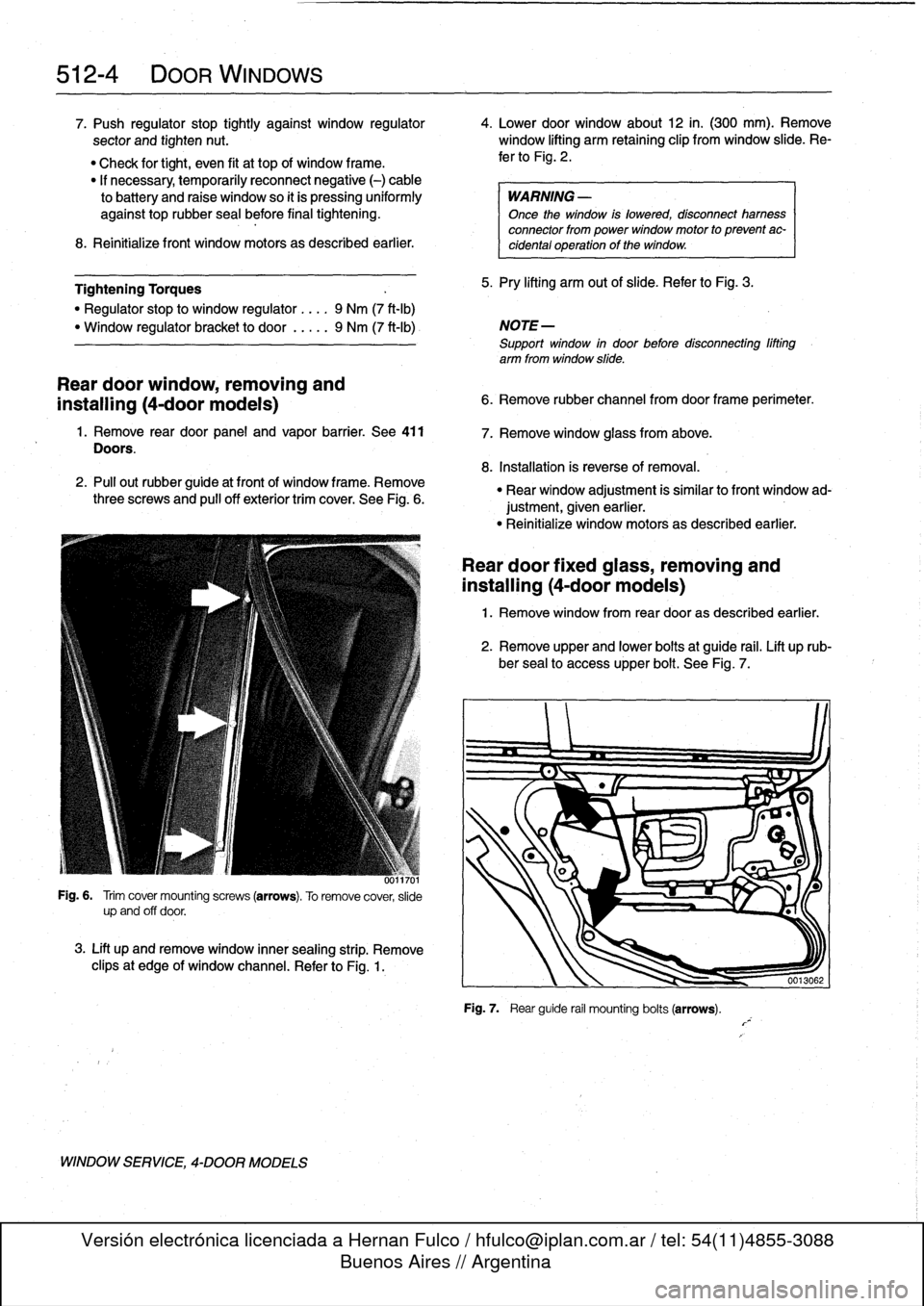

See

Fig

.

6

.

UJ117U1

Fig

.

6

.

Trim

covermounting

screws

(arrows)

.

To

remove

cover,

slide

upand

off

door

.

3

.

Lift

up

andremovewindow

inner

sealing

strip

.

Remove

clipsat

edge

of

window

channel

.

Refer

to

Fig

.

1

.

WINDOW

SERVICE,

4-DOOR

MODELS

5

.

Pry

lifting

arm

out

of

slide

.

Refer

to

Fig

.

3

.

NOTE

-

Support

window

in

door

before

disconnecting

lifting

arm

from

window

slide

.

6

.

Remove

rubber

channelfromdoorframe

perimeter

.

8

.

Installation

is

reverse

of

removal

.

"

Rear

window

adjustment

is

similar

to

front

window

ad-

justment,given

earlier

.

"

Reinitialize

window

motorsas

described

earlier

.

Rear

door

fixed

glass,

removing

and

installing

(4-door

models)

1

.

Remove

window

from

rear

dooras

described

earlier

.

2

.

Remove

upper

and

lower

bolts

at

guide

rail

.

Lift

up

rub-

ber

sea¡

to

accessupper

bolt

.

See

Fig

.

7

.

Fig

.

7

.

Rear

guide

rail

mounting

bolts

(arrows)

.

Page 335 of 759

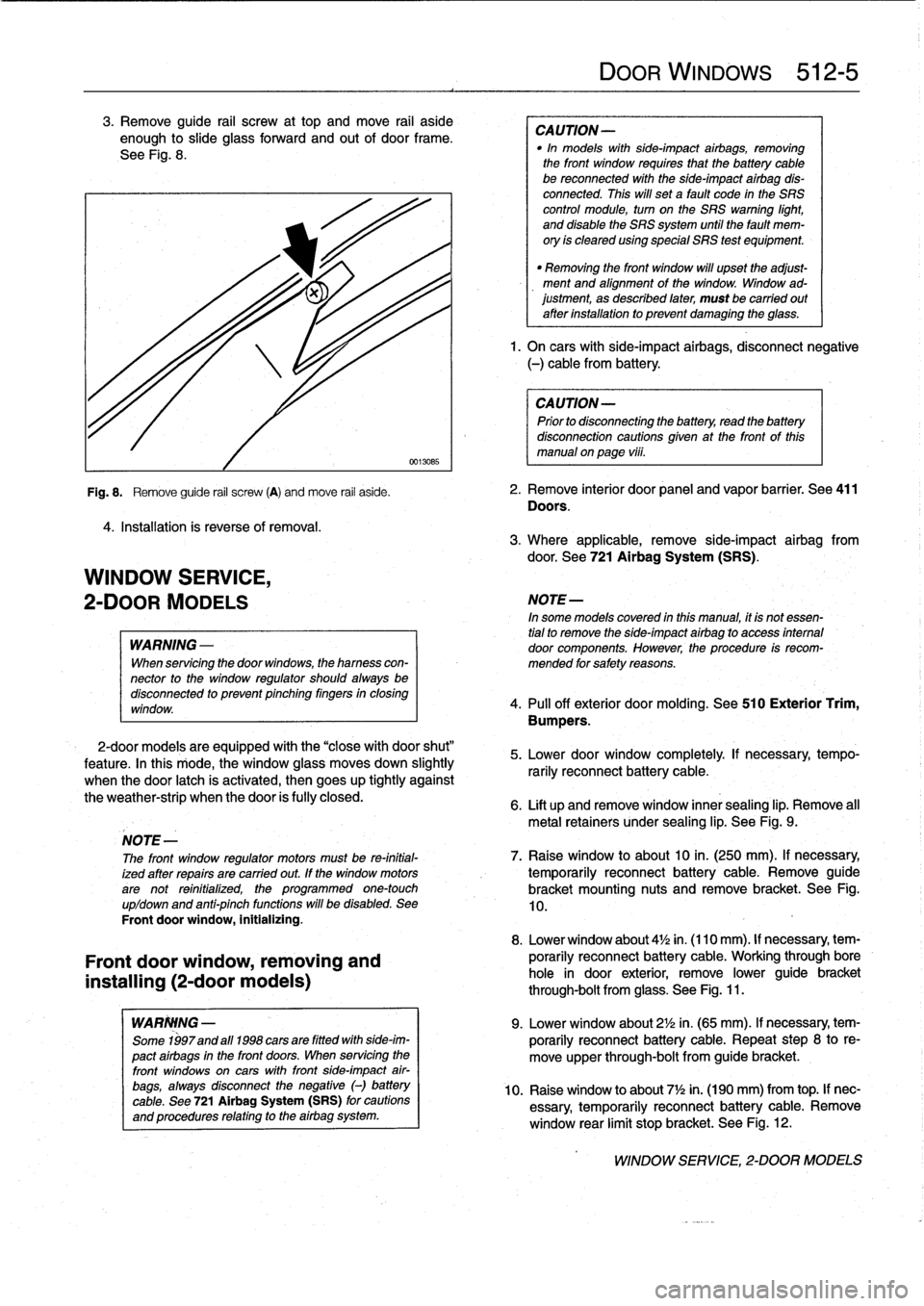

3

.

Remove

guide

rail

screw

at

top

and

move

rail

aside

enough

to

slide

glass

forward

and

out

of

door

frame

.

See

Fig

.

8

.

4

.

Installation

is

reverse

of

removal

.

WINDOW

SERVICE,

2-DOOR

MODELS

WARNING

-

When

servicing

the

door

windows,

the

hamess

con-

nector

to

the

window

regulator

shouldalwaysbe

disconnectod

to

prevent

pinching

fingers

in

closing

window

.

2-door

models

are

equipped

with

the

"close

with

door

shut"

feature

.

In

this

rriode,

the

window

glass

moves

down

slightly

when

the

door

latch

is

activated,

then

goes

up

tightly

against

the

weather-strip

when

the

door

is

fully

closed

.

Front

door

window,

removing

and

installing

(2-door

models)

WARIWNG

-

Some

1997and

a111998

cars

are

fitted

with

side-im-

pact

airbags

in

the

front

doors

.

When

servicing

the

front

windows

on

cars

with

front

side-impact

air-

bags,

always

disconnect

the

negative

(-)

battery

cable

.

See

721

Airbag

System(SRS)

for

cautions

and

procedures

relating

to

the

airbag

system

.

DOOR

WINDOWs

512-

5

CAUTION-

"In

models

with

side-impact

airbags,

removing

the

front

window

requires

fhat

the

battery

cable

be

reconnected

with

the

side-impact

airbag

dis-

connected

.

This

will

set

a

fault

code

in

the

SRS

control

module,

turn

on

the

SRS

warning

light,

and

disable

the

SRS

system

until

the

fault

mem-

ory

is

cleared

using

special

SRS

test

equipment

.

"

Removing

the

front

window

will

upset

the

adjust-

ment

and

alignment

of

the

window

.

Window

ad-justment,

as

described

later,

must

be

carried

out

after

installation

to

prevent

damaging

the

glass

.

1.

On

carswith

side-impact

airbags,

disconnect

negative

(-)

cable

from

battery

.

CAUTION-

Prior

to

disconnectiog

the

battery,

read

the

battery

disconnection

cautions

given

at

the

front

of

this

manual

on

page

viii

.

Fig

.

8

.

Remove

guide

rail

screw

(A)

and

move

rail

aside

.

2

.

Remove

interior

door

panel

and

vapor

barrier

.

See

411

Doors

.

3

.

Where

applicable,

remove

side-impact

airbag

from

door

.

See

721

Airbag

System

(SRS)

.

NOTE-

In

some

models

covered

in

this

manual,

it

is

notessen-

tial

to

remove

the

side-impact

airbag

lo

access

intemal

door

components

.

However,

the

procedure

is

recom-

mended

for

safety

reasons

.

4

.

Pull

off

exterior

doormolding

.

See

510

Exterior

Trim,

Bumpers

.

5

.

Lower

door

window

completely

If

necessary,

tempo-

rarily

reconnect

battery

cable

.

6

.

Lift

up

and

remove

window

innersealing

lip

.

Remove

all

metal

retainers

under

sealing

lip

.

See

Fig

.

9

.

NOTE

-

The

front

window

regulator

motors

must

be

re-initial-

7

.

Raise

window

to

about10

in

.

(250

mm)

.

If

necessary,

ized

after

repairs

are

carried

out

.

If

the

window

motors

temporarily

reconnect

battery

cable

.

Remove

guide

arenot

reinitialized,

the

programmed

one-touch

bracket

mounting

nuts

and

remove

bracket

.

See

Fig

.

up/down

and

anti-pinch

functions

will

be

disabled

.

See

10,

Front

doorwindow,

initializing

.

8

.

Lower

window

about

4'/2

in

.

(110mm)

.

If

necessary,

tem-

porarily

reconnect

batterycable

.

Working

through

bore

hole

in

door

exterior,

remove

lower

guide

bracket

through-bolt

from

glass

.

See

Fig

.

11

.

9

.

Lower

window

about

2'/2

in

.

(65

mm)

.

If

necessary,

tem-

porarily

reconnect

battery

cable

.

Repeat

step

8

to

re-

move

upper

through-bolt

from

guide

bracket

.

10

.

Raise

window

to

about

7

1

/2in

.

(190

mm)

from

top

.

If

nec-

essary,

temporarily

reconnect

batterycable

.

Remove

window

rear

limit

stop

bracket

.

See

Fig

.

12

.

WINDOW

SERVICE,

2-DOOR

MODELS

Page 336 of 759

512-

6

DOORWINDOWS

0013061

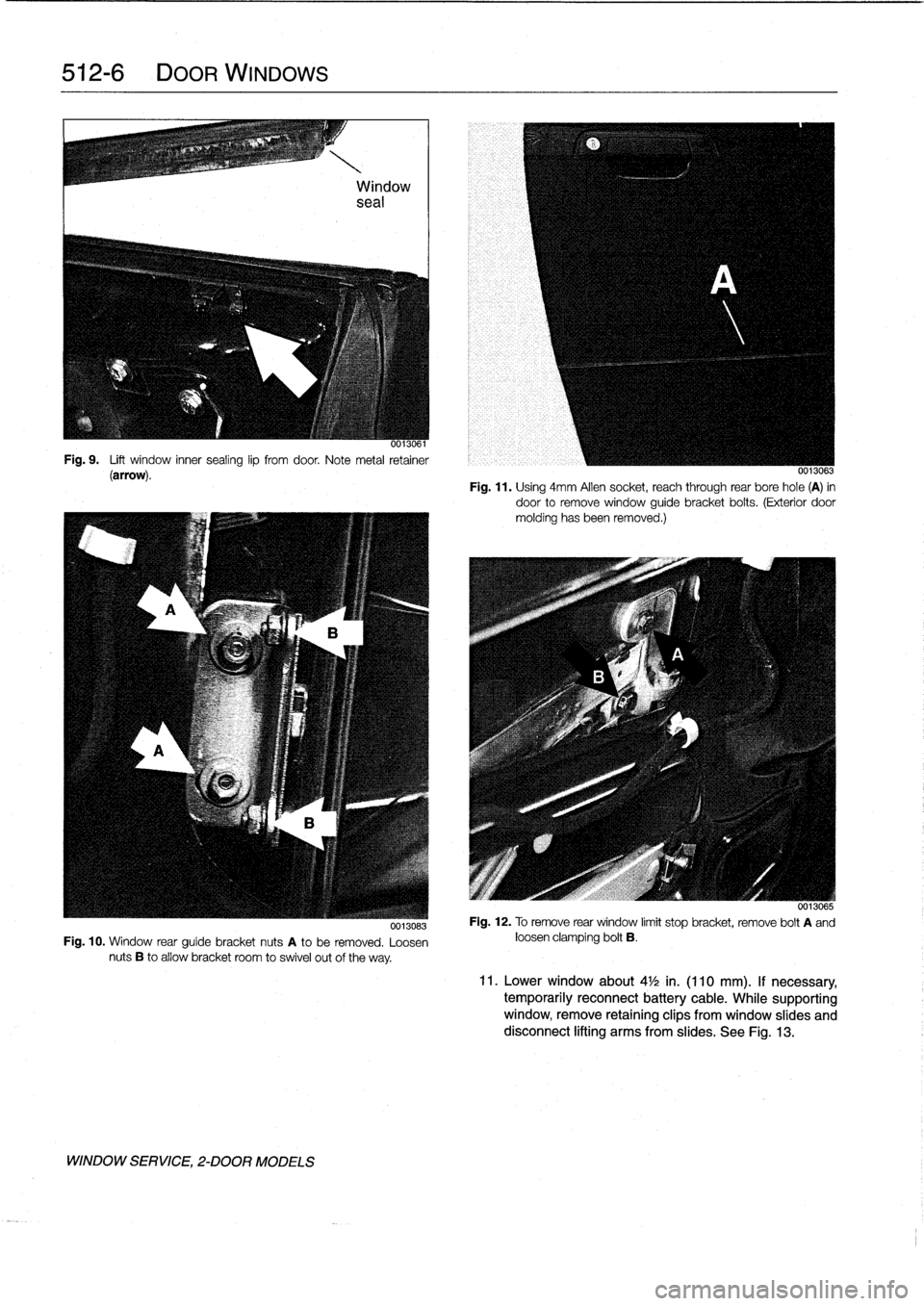

Fig

.

9

.

Lift

window

inner

sealing

lip

fromdoor

.

Note

metal

retainer

(arrow)

.

0013083

Fig

.

10

.

Window

rear

guíde

bracket

nuts

A

to

be

removed

.

Loosen

nuts

B

to

allow

bracket

room

to

swivel

out

of

the

way

.

WINDOW

SERVICE,

2-DOOR

MODELS

0013063

Fig

.

11

.

Using

4mm

Allen

socket,

reach

through

rear

bore

hole

(A)

in

door

to

remove

window

guide

bracket

boits

.

(Exterior

door

molding

hasbeen

removed

.)

0013065

Fig

.

12

.

Toremove

rear

window

limit

stop

bracket,

remove

bolt

A

and

loosen

clamping

bolt

B

.

11

.

Lower

window

about

4

1

/2

in

.

(110

mm)

.

If

necessary,

temporarily

reconnect

battery

cable

.

While

supporting

window,

remove

retaining

clips

from

window

slides

and

disconnect

lifting

arms

from

slides

.

See

Fig

.

13

.

Page 339 of 759

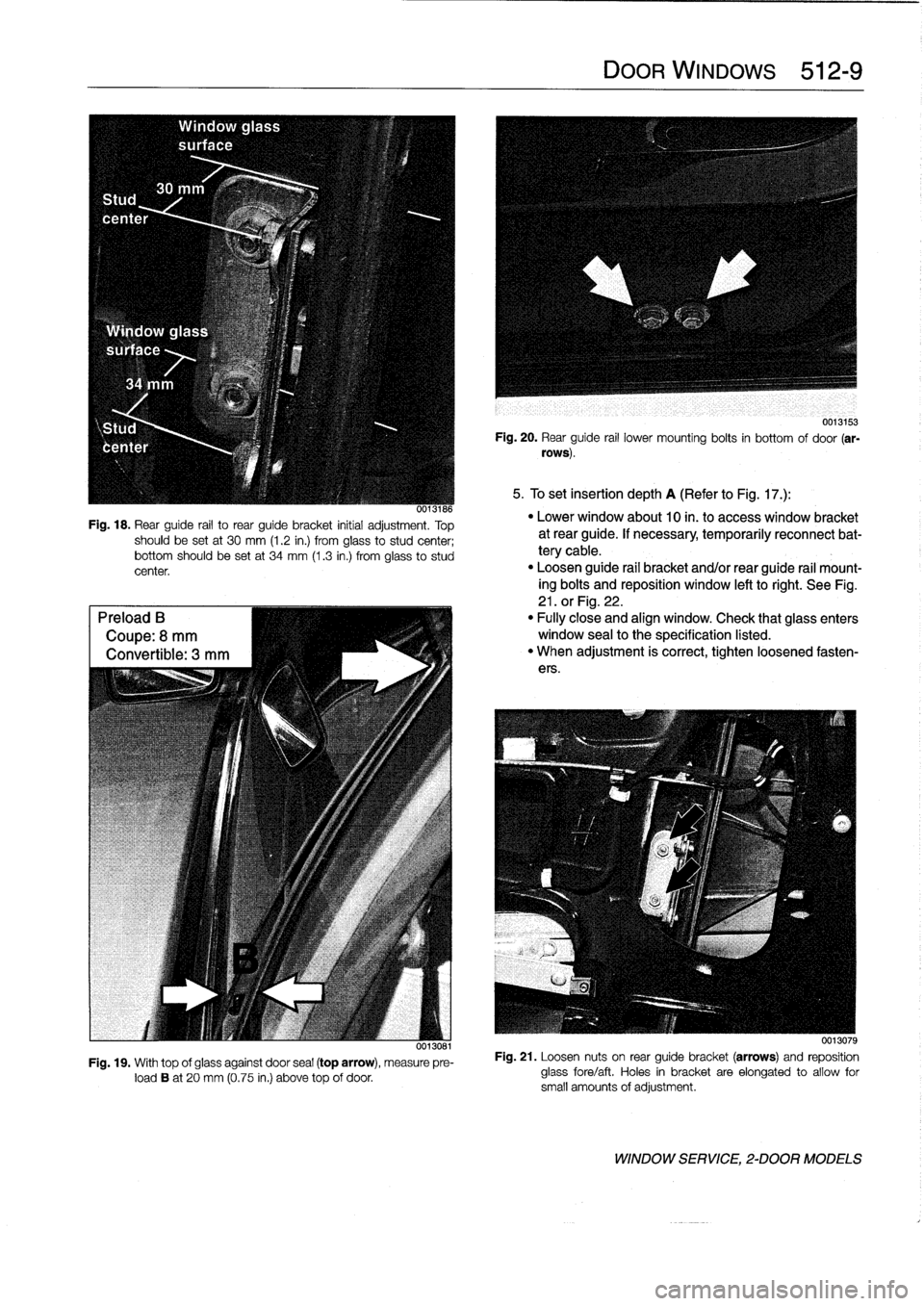

5tud

center

Window

glass

surface

Fig

.

18

.

Rear

guide

rail

to

rear

guide

bracket

initial

adjustment

.

Top

should

be

setat

30

mm

(1

.2

in

.)

from

glass

to

studcenter

;

bottom

should

be

set

at

34

mm

(1

.3

in

.)

from

glass

to

stud

center

.

Preload

B

Coupe

:

8

mm

Convertible

:

3

mm

0013081

Fig

.

19

.

With

top

of

glassagainst

door

sea¡(top

arrow),

measure

pre-load

B

at

20

mm

(0

.75

in

.)

above

top

of

door

.

DOOR

WINDOWS

512-

9

0013153

Fig

.

20

.

Rear

guide

rail

lower

mounting

bolts

in

bottom

of

door

(ar-

rows)

.

5

.

To

set

insertion

depth

A

(Referto

Fig

.

17

.)

:

"

Lowerwindow

about

10

in

.

t

o

access

window

bracket

at

rear

guide

.

If

necessary,

temporarily

reconnect

bat-

tery

cable

.

"

Loosen

guide

rail

bracket

and/or

rear

guide

rail

mount-

ing

bolts

and

reposition

window

left

to

right

.

See

Fig

.

21

.

orFig

.

22

.

"

Fully

close

and

align

window

.

Check

that

glass

enters

window

sea¡

to

the

specification

listed

.

"

When

adjustment

is

correct,

tighten

loosened

fasten-

ers

.

0013079

Fig

.

21

.

Loosen

nuts

on

rear

guide

bracket

(arrows)

and

reposition

glass

fore/aft

.

Holes

in

bracket

areelongated

to

allow

for

small

amounts

of

adjustment

.

WINDOW

SERVICE,

2-DOOR

MODELS