suspension BMW 325i 1997 E36 Repair Manual

[x] Cancel search | Manufacturer: BMW, Model Year: 1997, Model line: 325i, Model: BMW 325i 1997 E36Pages: 759

Page 283 of 759

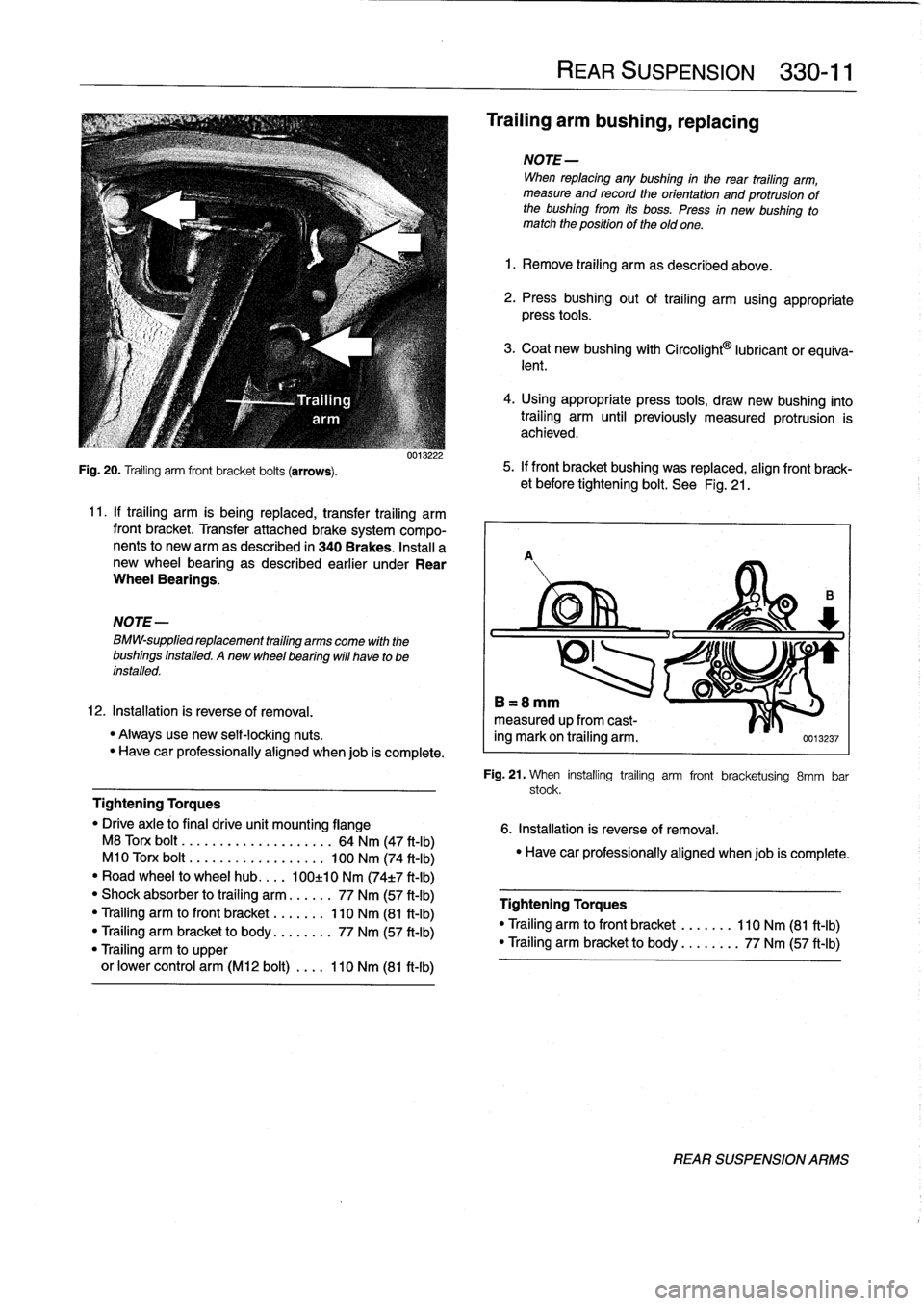

Fig

.

20

.

Trailing

arm

front

bracket

bolts

(arrows)

.

NOTE-

BMW-supplied

replacement

trailing

arms

come

with

the

bushings

installed

.

Anew

wheel

bearing

will

have

to

be

installed

.

0013222

11

.

If

trailing

arm

is

being

replaced,

transfer

trailing

arm

front

bracket

.

Transfer

attached

brake

system

compo-

nents

to

newarm

as

described

in

340Brakes

.

Insta¡¡

a

new

wheel

bearing

as

described

earlier

under

Rear

Wheel

Bearings

.

12

.

Installation

is

reverse

of

removal

.

"

Alwaysuse

new

self-locking

nuts

.

"

Have

car

professionally

aligned

when

job

is

complete

.

Tightening

Torques

"

Drive

axle

#o

final

drive

unit

mounting

flange

M8

Torx

bolt

......

.

...

.....

.

..

..

64

Nm

(47

ft-Ib)

M10

Torx

bolt

.....

...

.

....

.....

100

Nm

(74

ft-Ib)

"

Road

wheel

to

wheel

hub

.

...

100±10

Nm

(74t7

ft-Ib)

"

Shock

absorber

to

trailing

arm

......

77

Nm

(57

ft-Ib)

"

Trailing

arm

tofront

bracket

.......

110

Nm

(81

ft-Ib)

"

Trailing

arm

bracket

to

body

........

77

Nm

(57

ft-Ib)

"Trailing

arm

to

upper

or

lower

control

arm

(M12

bolt)

....

110

Nm

(81

ft-Ib)

REAR

SUSPENSION

330-

1

1

Trailing

arm

bushing,

replacing

NOTE-

When

replacing

any

bushing

in

the

rear

trailing

arm,

measure

and

recordthe

orientation

and

protrusion

of

the

bushing

from

its

boss

.

Press

in

new

bushing

to

match

the

positionof

theold

one

.

1

.

Remove

trailing

arm

as

described

above

.

2

.

Pressbushing

out

of

trailing

arm

using

appropriate

press

tools

.

3

.

Coat

new

bushing

with

Circolight

9

lubricant

or

equiva-

lent

.

4

.

Using

appropriate

press

tools,

draw

new

bushing

into

trailing

arm

until

previously

measured

protrusion

is

achieved

.

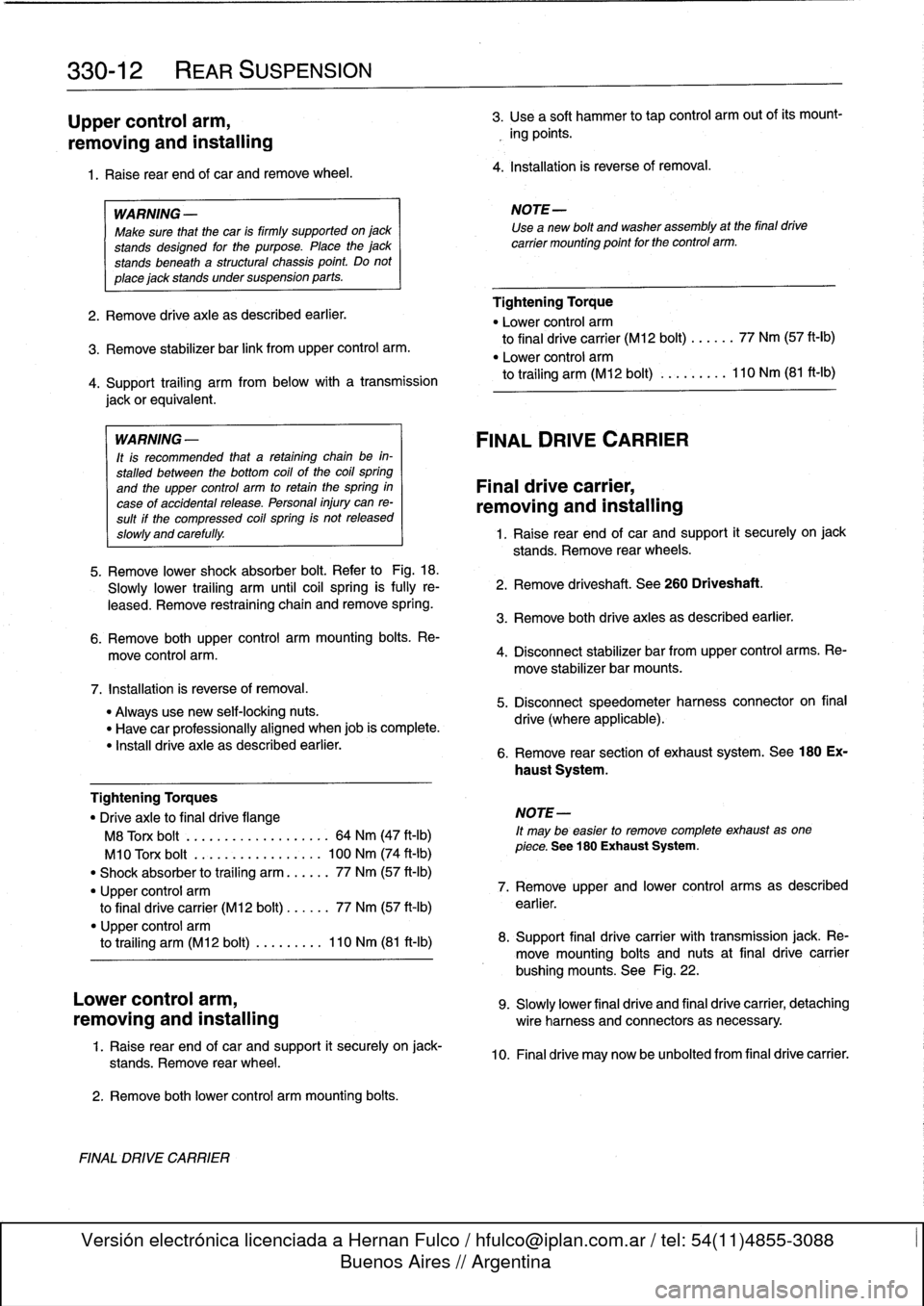

5

.

If

front

bracket

bushing

was

replaced,

alignfront

brack-

et

before

tightening

bolt

.

See

Fig

.

21

.

A

B=8mm

measured

upfrom

cast-

ing

mark

on

trailing

arm

.

0013237

Fig

.

21

.

When

installing

trailing

arm

front

bracketuising

8mm

bar

stock

.

6

.

Installation

is

reverse

of

removal

.

"

Have

car

professionally

aligned

when

job

is

complete

.

Tightening

Torques

"

Trailing

arm

tofront

bracket

.......

110

Nm

(81

ft-Ib)

"Trailing

arm

bracket

to

body

......

.

.

77

Nm

(57

ft-Ib)

REAR

SUSPENSION

ARMS

Page 284 of 759

330-

1

2

REAR

SUSPENSION

Upper

control

arm,

removing

and

installing

1.

Raise

rear

end

of

car

and

remove

wheel

.

WARNING

-

Make

sure

that

the

car

is

firmly

supportedon

jack

stands

designed

for

the

purpose

.

Place

the

jack

stands

beneatha

structural

chassis

point

.

Do

not

place

jack

stands

under

suspension

parts

.

2

.

Remove

drive

axle

as

described

earlier

.

3

.

Remove

stabilizer

bar

link

fromupper

control

arm

.

4

.

Support

trailing

arm

from

below

with

a

transmission

jackorequivalent

.

WARNING

-

It

is

recommended

that

a

retaining

chain

be

in-

stalled

between

the

bottom

coil

of

the

coil

spring

and

the

upper

control

arm

to

retain

thespring

in

case

of

accidental

release

.

Personal

injury

can

re-

sult

if

the

compressed

coil

spring

ís

not

released

slowly

and

carefully

.

5

.

Remove

lower

shock

absorber

bolt

.

Refer

to

Fig

.

18

.

Slowly

lower

trailing

arm

until

coil

spring

is

fully

re-

leased

.

Remove

restraining

chain

and

remove

spring

.

7

.

Installation

is

reverse

of

removal

.

"

Always

use

new

self-locking

nuts

.

"

Have

car

professionally

aligned

when

job

is

complete

.

"

Insta¡¡

drive

axle

as

described

earlier

.

Tightening

Torques

"

Drive

axleto

final

drive

flange

M8

Torx

bolt

..........

..

.

..

....

64

Nm

(47

ft-Ib)

M10

Torx

bolt

.........

..

..

.

...

100

Nm

(74

ft-Ib)

"

Shock

absorber

to

trailing

arm

..

..

..

77

Nm

(57

ft-Ib)

"

Upper

control

arm

to

final

drive

carrier

(M12

bolt)

...

..

.

77

Nm

(57

ft-Ib)

"

Upper

control

arm

to

trailing

arm

(M12

bolt)

.........

110

Nm

(81

ft-Ib)

Lower

control

arm,

1

.

Raise

rear

end

of

car

and

support

it

securely

on

jack-

stands

.

Remove

rear

wheel

.

2

.

Remove

both

lower

control

arm

mounting

bolts

.

FINAL

DRIVE

CARRIER

3

.

Use

a

soft

hammer

to

tap

control

arm

out

of

its

mount-

ing

points

.

4

.

Installation

is

reverse

of

removal

.

NOTE-

Use

a

new

bolt

and

washer

assembly

at

the

final

drive

carrier

mountíng

point

forthe

control

arm

.

Tightening

Torque

"

Lower

control

arm

to

final

drive

carrier

(M12

bolt)

......

77

Nm

(57

ft-Ib)

"

Lower

control

arm

to

trailing

arm

(M12

bolt)

....

..

.

..

110

Nm

(81

ft-Ib)

FINAL

DRIVE

CARRIER

Final

drive

carrier,

removing

and

installing

1

.

Raise

rear

end

of

car

and

support

it

securely

on

jack

stands

.

Remove

rear

wheels

.

2

.

Remove

driveshaft

.

See

260

Driveshaft

.

3

.

Remove

both

drive

axles

as

described

earlier

.

6

.

Remove

both

upper

control

arm

mounting

bolts

.

Re-

move

control

arm

.

4

.

Disconnect

stabilizer

bar

from

upper

control

arms

.

Re-

move

stabilizer

bar

mounts

.

5

.

Disconnect

speedometer

harness

connector

on

final

drive

(where

applicable)

.

6

.

Remove

rear

section

of

exhaust

system

.

See

180

Ex-

haust

System

.

NOTE-

It

may

be

easier

to

remove

complete

exhaust

asonepiece

.

See

180

Exhaust

System

.

7

.

Remove

upper

and

lower

control

arms

as

described

earlier

.

8

.

Support

final

drive

carrierwith

transmissíon

jack

.

Re-

move

mounting

bolts

and

nuts

at

final

drive

carrier

bushing

mounts

.

See

Fig

.

22

.

9

.

Slowly

lower

final

drive

and

final

drive

carrier,

detaching

removing

and

installing

wire

harness

and

connectors

as

necessary

.

10

.

Finaldrive

may

now

be

unbolted

from

final

drive

carrier

.

Page 287 of 759

GENERAL

......

.

.

.

.

.

.

.

.....

.

.

.

.

.

.

.

.

.

.

331-1

Final

Drive

Oil

Seals

.

.

...

.

.

.

.......

.

.

.

.

.

331-1

Finaldrive

flange

oil

sea¡,

replacing

....

.

.

.

..

331-2

FINAL

DRIVE

SERVICE

.

.....

.

.

.

.

.

.

.

.

.

.

331-1

Finaldrive

inputshaft

oil

seal,

replacing

.

.

.

.

.

331-3

Final

drive

oí¡,

draining

and

filling

.

.

.

.

.

.

.

.

.

.

331-1

Finaldrive

unit,

removíng

and

installing

.

.

.

.

.

.

331-3

GENERAL

This

repa¡r

group

covers

repair

operations

that

do

not

re-

quire

complicated

disassembly

of

the

final

drive

.

Internal

re-

pairs

and

final

drive

disassembly

are

not

covered

in

this

manual

.

FINAL

DRIVE

SERVICE

Al¡

final

drive

work

requires

some

method

of

raising

thecar

and

supporting

it

securely

while

the

work

is

performed

.

Jack

stands

and

a

floor

jack

can

easily

be

used,

but

use

extreme

caution

when

working

beneath

the

car

.

See010

Fundamen-

tais

for

the

Do-It-Yourself

Owner

.

NOTE-

Removal

of

final

drive

carrier

is

covered

in

330

Rear

Suspension

.

Final

drive

oil,

draining

and

filling

1

.

Drive

car

to

warm

final

drive

fluid

.

2

.

Raise

car

and

support

safely

.

WARNING

-

Make

sure

that

thecar

is

firmly

supported

on

jack

standsdesigned

for

the

purpose

.

Place

the

jack

standsbeneatha

structural

chassis

point

.

Do

not

place

jack

stands

under

suspension

parts

.

5

.

Fill

final

drive

with

appropriate

type

and

quantity

of

lu-

bricant

.

Insta¡¡

and

tighten

fill

plug

.

331

Final

Drive

0

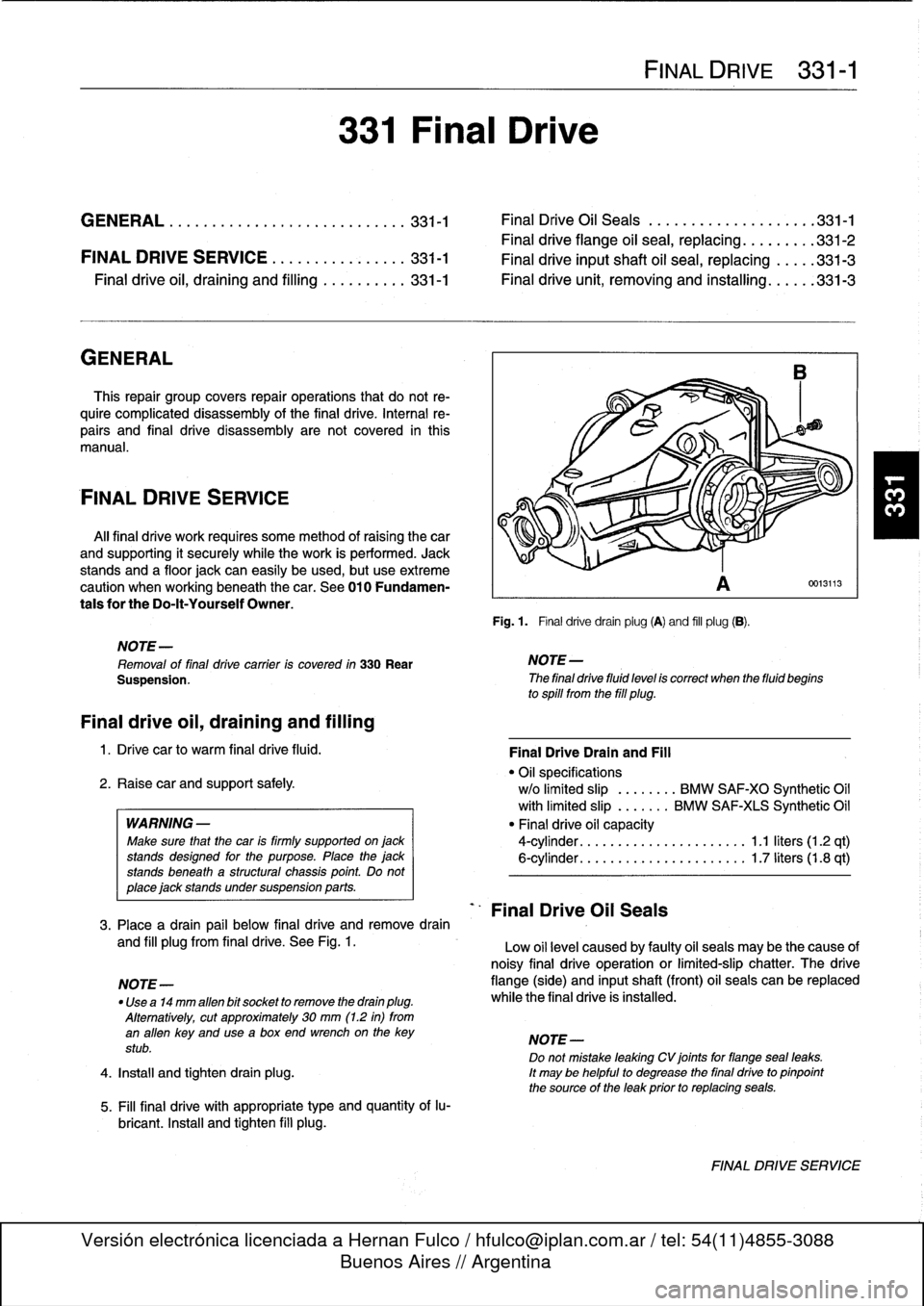

Fig

.

1

.

Final

drivedrain

plug

(A)

and

fill

plug

(B)

.

D

NOTE-

The

final

drive

fluid

level

is

correct

when

the

fluid

begins

to

spill

from

the

fill

plug

.

Final

Drive

Oil

Seals

FINAL

DRIVE

331-1

0013113

Final

DriveDrain

and

Fill

"

Oil

specifications

w/o

limited

slip

.

.......

BMW

SAF-XO

Synthetic

Oil

with

limited

slip

.

......

BMW

SAF-XIS

Synthetic

Oil

"

Final

drive

oil

capacity

4-cylinder

.

.

.

...

................

1

.1

liters

(1

.2

qt)

6-cylinder

.

.

.

...

................

1

.7liters(1.8

qt)

3

.

Place

a

drain

pail

below

final

drive

andremove

drain

and

fill

plugfrom

final

drive

.

See

Fig

.

1

.

Low

oil

level

caused

by

faulty

oil

seals

may

be

the

cause

of

noisy

final

drive

operation

or

limited-slip

chatter

.

The

drive

NOTE-

flange

(side)

and

inputshaft

(front)

oil

seals

can

be

replaced

"

Use

a14

mm

alíen

bit

socket

to

remove

the

drain

plug

.

while

the

final

drive

is

installed

.

Alternatively,

cut

approximately

30

mm

(1

.2

in)

from

an

alíen

key

and

usea

box

end

wrenchon

the

key

NOTE-

stub

.

Do

not

mistake

leaking

CV

joints

for

flangeseal

leaks

.

4

.

Install

and

tighten

drain

plug

.

It

may

be

helpful

to

degrease

the

final

drive

to

pinpoint

the

source

of

the

leak

prior

to

replacing

seals

.

FINAL

DRIVE

SERVICE

Page 288 of 759

331-2

FINAL

DRIVE

Make

sure

that

the

car

is

firm1y

supportedon

Tjack

.

.-

"

:

.-

:

.

n

-

2

.

Detach

drive

axle(s)

from

final

drive

.

See330

Rear

Suspension

.

CA

UTION-

Suspend

the

detached

drive

axlefrom

the

car

body

with

a

stiff

wire

hook

to

prevent

damage

to

the

outer

CV

joint

.

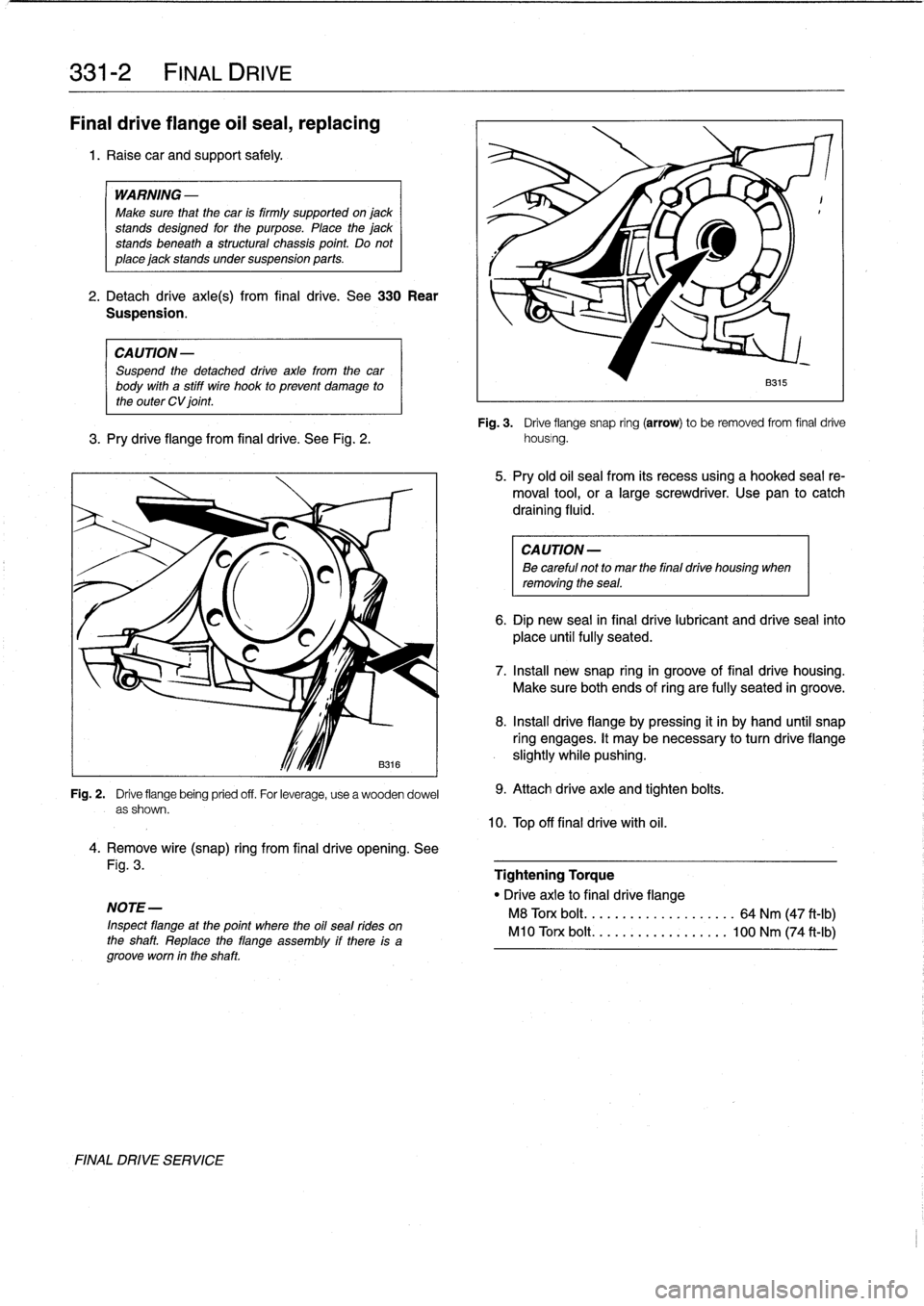

Fig

.

3

.

Drive

flange

snap

ring

(arrow)

to

be

removed

from

final

drive

3

.

Pry

drive

flange

from

final

drive

.

See

Fig

.

2

.

housing

.

Fig

.

2

.

Drive

flange

being

pried

off

.

For

leverage,

use

a

wooden

dowel

as

shown

.

4

.

Remove

wire(snap)

ring

from

final

drive

opening

.

See

Fig

.

3

.

NOTE-

Inspect

flangeat

the

point

where

the

oil

seal

rides

on

the

shaft

.

Replace

the

flange

assembly

if

there

is

agrooveworn

in

the

shaft

FINAL

DRIVE

SERVICE

9

.

Attach

drive

axle

and

tighten

bolts

.

10

.

Top

off

final

drive

with

ofl

.

B315

5

.

Pry

old

oil

sea¡

from

its

recess

using

a

hooked

seal

re-

moval

tool,

or

a

large

screwdriver

.

Use

pan

to

catch

draining

fluid

.

CA

UTION-

Be

careful

not

to

mar

the

final

drive

housing

when

removing

the

sea¡

.

6

.

Dip

new

seal

in

final

drive

lubricant

and

drive

seal

into

place

untilfully

seated

.

7

.

Insta¡¡

new

snap

ringin

groove

of

final

drive

housing

.

Make

sureboth

ends

ofring

are

fully

seated

in

groove

.

8

.

Insta¡¡

drive

flangeby

pressing

it

in

by

hand

until

snap

ring

engages

.

It

may

benecessary

to

turn

drive

flange

slightly

while

pushing

.

Tightening

Torque

"

Drive

axle

to

final

drive

flange

M8

Torx

bolt

..

..................

64

Nm

(47

ft-Ib)

M10

Torx

bolt

.

.................

100

Nm

(74

ft-Ib)

Page 289 of 759

Final

driveinputshaft

oil

sea¡,

replacing

1

.

Raise

car

and

support

safely

.

2

.

Drain

final

drive

oil

as

described

earlier

.

3

.

Remove

driveshaft

from

final

drive

inputshaft

flange

.

See

260

Driveshaft

.

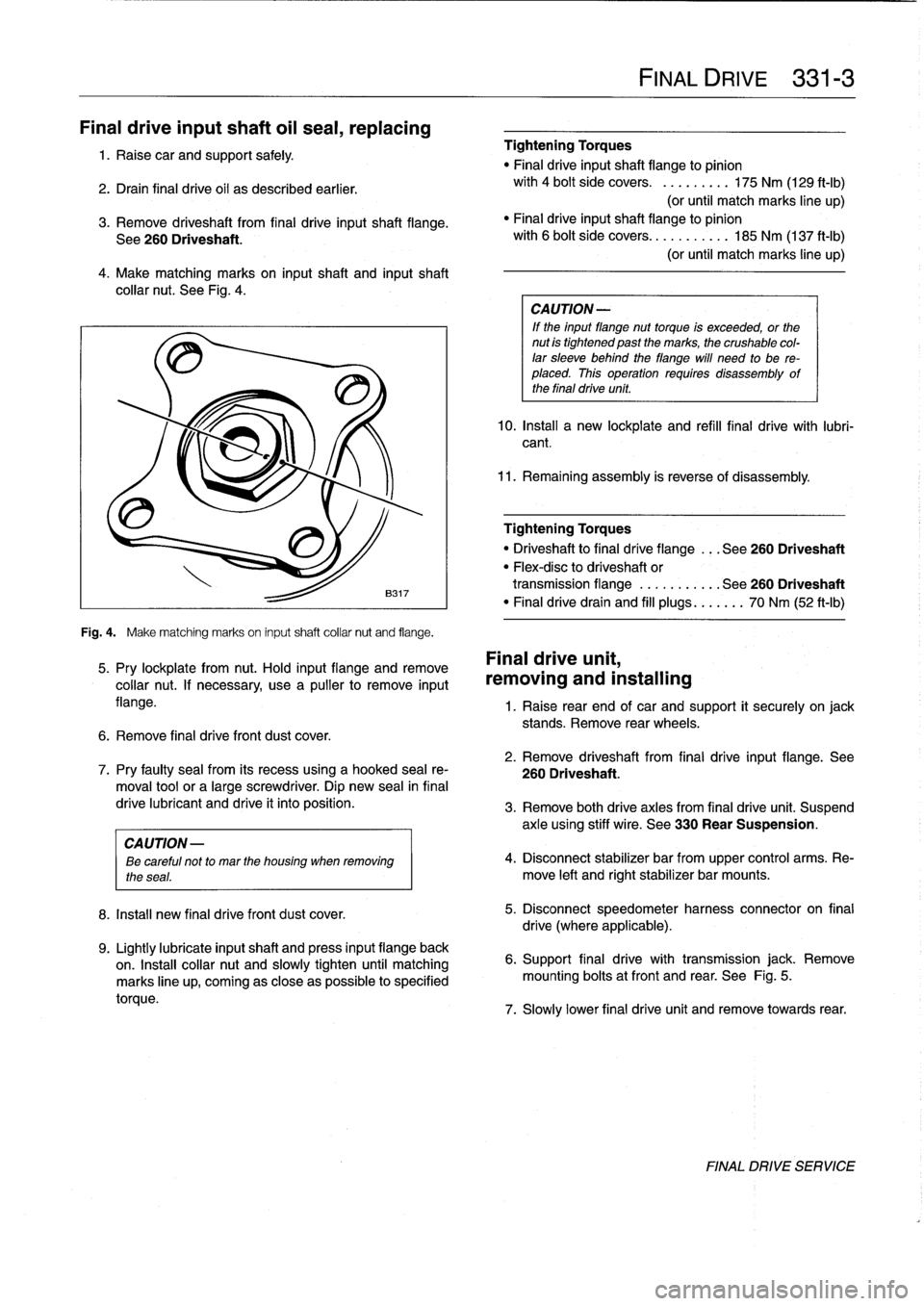

4

.

Make

matching

marks

on

input

shaft

and

inputshaft

collar

nut

.

See

Fig

.

4

.

Fig

.

4

.

Make

matching

marks

on

input

shaft

collar

nut

and

flange

.

5

.

Pry

lockplate

from

nut

.

Hold

input

flange

andremove

collar

nut

.

If

necessary,

usea

pullerto

remove

input

flange

.

6

.

Remove

final

drive

front

dust

cover

.

8

.

Install

new

final

drivefront

dust

cover

.

9

.

Lightly

lubricate

inputshaft

and

press

input

flange

back

on

.

Insta¡¡

collar

nut

and

slowly

tighten

until

matching

marks

line

up,

coming

as

close

aspossible

to

specified

torque

.

Tightening

Torques

"

Final

driveinputshaft

flange

to

pinion

with

4

bolt

side

covers

.

.........

175

Nm

(129

ft-Ib)

(or

until

match

marks

line

up)

"

Finaldriveinputshaft

flange

to

pinion

with

6

bolt

side

covers

...........

185

Nm

(137

ft-Ib)

(or

until

match

marks

line

up)

CA

UTION-

If

the

input

flange

nuttorque

is

exceeded,

or

the

nut

is

tightened

past

the

marks,

the

crushable

col-

lar

sleeve

behind

theflange

will

need

to

be

re-

placed

.

This

operation

requires

disassembly

of

the

final

drive

unit

.

10

.

Install

a

new

lockplate

and

refill

final

drive

with

lubri-

cant

.

11

.

Remaining

assembly

is

reverse

of

disassembly

.

Tightening

Torques

"

Driveshaftto

final

dríve

flange

...

See260

Driveshaft

"

Flex-disc

to

driveshaft

or

transmission

flange

...........

See260

Driveshaft

"

Finaldrivedrain

and

fill

plugs

...

.

..

.

70

Nm

(52

ft-Ib)

Final

drive

unit,

removing

and

installing

FINAL

DRIVE

331-

3

1

.

Raise

rear

end

of

car

and

support

it

securely

on

jack

stands

.

Remove

rear

wheels

.

2

.

Remove

driveshaft

from

final

drive

input

flange

.

See

7

.

Pry

faulty

sea¡

from

its

recess

using

a

hooked

sea¡

re-

260

Driveshaft

.

moval

toolor

a

large

screwdriver

.

Dip

new

sea¡

in

final

drive

lubricant

and

drive

it

into

position

.

3

.

Remove

both

drive

axles

from

final

drive

unit

.

Suspend

axle

using

stiff

wire

.

See

330

Rear

Suspension

.

CAUTION

-

ee

careful

not

to

mar

the

housing

when

removing

4

.

Disconnect

stabilizer

bar

from

upper

control

arms

.

Re-

the

seas

.

move

left

and

rightstabilizer

bar

mounts

.

5

.

Disconnect

speedometer

harness

connector

on

final

drive

(where

applicable)

.

6

.

Support

final

drive

with

transmission

jack

.

Remove

mounting

bolts

atfront

and

rear

.

See

Fig

.

5

.

7

.

Slowly

lower

final

drive

unit

and

remove

towards

rear

.

FINAL

DRIVE

SERVICE

Page 291 of 759

Brake

rotor,

removing

and

installing

.

.

.

.

.

.

.

.

340-7

MASTER

CYLINDER

............

.

.

.

.

.

.

.340-7

Master

cylinder,

removing

and

installing

.

...

.

340-7

GENERAL

TROUBLESHOOTING

WARNING

-

"

Although

semi-metallic

and

metallic

Brake

friction

materials

in

Brake

pads

or

shoes

no

longer

con-

tain

asbestos,

they

produce

dangerous

dust

.

"

Brake

fluid

is

poisonous,

highly

corrosive

and

dangerous

to

the

environment

Wear

safety

glasses

and

rubber

gloves

when

working

with

Brake

fluid

.

Do

not

siphonBrake

fluid

with

your

mouth

.

Immediately

clean

away

any

fluid

spilled

on

painted

surfaces

and

wash

with

water,

asBrake

fluid

will

remove

paint

.

"

Always

use

new

Brake

fluid

froma

fresh,

un-

opened

container

.

Brake

fluid

will

absorb

mois-

ture

from

the

air

.

This

canlead

to

corrosion

problems

in

the

brakingsystem,

and

will

also

low-

er

the

Brake

fluid's

boiling

point

.

Dispose

of

Brake

fluid

properly

.

"

Do

notreuse

self-locking

nuts,bolts

or

fasteners

.

They

are

designed

to

be

used

only

once

and

may

failif

reused

.

Always

replace

them

with

new

self-

locking

fasteners

.

BMW

E36

models

areequipped

with

vacuum

power-assist-

ed

four-wheel

disc

brakes

with

an

integral

Antilock

Brake

Sys-

tem

(ABS)

.

Single-pistoncalipers

act

on

solid

or

vented

front

rotors

and

solid

rear

rotors

.

A

brake

pad

wear

sensor

for

each

axle

indicates

when

brake

padsneed

replacement

.

The

dual

drum-type

parking

brakesystem

is

integrated

with

the

rear

brake

rotors

.

NOTE-

M3

models

havevented

directional

Brake

rotors

on

the

rearaxle

as

well

ason

the

front

.

340

Brakes

BRAKES

340-1

GENERAL

.

.

.

.

.

.

.........

.

.

.

..........

340-1

BRAKE

BOOSTER

.........

.

.

.

.

.

...

.

.

.

.

340-8

TROUBLESHOOTING

.......

.

......

.

...

340-1

Brake

booster,

removing

and

installing

....

.

.

340-8

PARKING

BRAKE

.

.....

.

...

.

.

.

.....

.

.

.

340-10

BLEEDING

BRAKES

.

.

.

.

.

.

.

.

..........

340-3

Parking

brake,adjusting

.

.

.

.

.

.

.

.

.

.

.....

.

340-10

Pressure

bleeding

brakes

Parking

brake

shoes,

removing

and

installing

.

340-11(except

cars

with

AST)

.

.

.

.

.

.

.

.

.

...

.

.

.

.

.340-3

Parking

Brake

cable,

replacing

.

.

.

.

.

.

.

.

.

.

.

.

340-11

BRAKE

PADS,

CALIPERS,

ANTILOCK

BRAKE

SYSTEM

(ABS)

.

.

.

.340-11

AND

ROTORS

..........

.

.......

.

.

.

.

.

.

.

340-3

ABS

System

Inspection

.

...

.

.......

.

.

.

..

340-12

Brake

pads,

replacing

............

.

.

.

.

.

.

.

340-4

ABS

wheel

speed

sensors,

replacing

.

.

.

.

..

340-12

Brake

caliper,

removing

and

installing

.

..

..

.

340-6

TABLES

a

.

Brake

System

Troubleshooting

.....

...

.

.

.....

.340-2

b

.

Brake

Rotor

Reconditioning

Specifications

.

.....

.340-7

Brakeperformance

is

mainly

affected

by

three

things

:

the

leve¡

and

condition

of

the

brake

fluid,

the

system's

abilíty

to

create

and

maintain

hydraulic

pressure,

and

the

condition

of

the

friction

components

.

Air

in

the

Brake

fluid

will

make

the

Brake

pedal

feel

spongy

during

braking

or

will

increase

the

Brake

pedalforce

required

to

stop

.

Fluid

contaminated

by

moisture

or

dirt

can

corrode

the

system

.

Inspect

the

Brake

fluid

inside

the

reservoir

.

Ifit

is

dirty

or

murky,

or

is

over

a

year

old,

the

fluid

should

be

replaced

.

Visually

check

the

hydraulic

system

startingat

the

master

cylinder

.

To

check

the

function

of

the

master

cylinder

hold

the

brake

pedal

down

hard

with

the

engine

running

.

The

pedal

should

feelsolid

and

stay

solid

.

If

the

pedal

slowly

falls

to

the

floor,

either

the

master

cylinder

is

leaking

internally,

or

fluid

is

leaking

externally

.

If

no

leaks

canbe

found,

the

master

cylin-

der

is

faulty

and

should

be

replaced

.

Check

all

Brake

fluid

lines

and

couplings

for

leaks,

kinks,

chafing

and

corrosion

.

Check

the

Brake

booster

by

pumping

the

Brake

pedal

ap-

proximately

10

times

with

the

engine

off

.

Hold

the

pedal

down

and

start

the

engine

.

The

pedal

should

fa¡¡

slightly

.

If

not,

check

for

any

visiblefaults

before

suspecting

a

faulty

brake

booster

.

Check

for

strong

vacuum

at

the

vacuum

hose

fitting

at

the

booster,

and

check

the

non-retum

valve

for

one-way

flow

.

Worn

or

contaminated

brake

pads

will

cause

poor

braking

performance

.

Oil-contaminated

or

glazed

pads

will

cause

stopping

distances

to

increase

.

Inspect

the

rotors

for

glazing,

discoloration

and

scoring

.

Steering

wheel

vibration

while

braking

at

speed

is

often

caused

by

warped

rotors,

but

can

also

be

caused

byworn

suspension

components

.

TROUBLESHOOTING

Page 292 of 759

340-2

BRAKES

When

troubleshooting,

keep

in

mind

that

tire

inflation,

wear

and

temperature

can

affect

braking

and

suspension

.

See310

Front

Suspension

for

more

information

on

front

suspension

parts

inspection

.

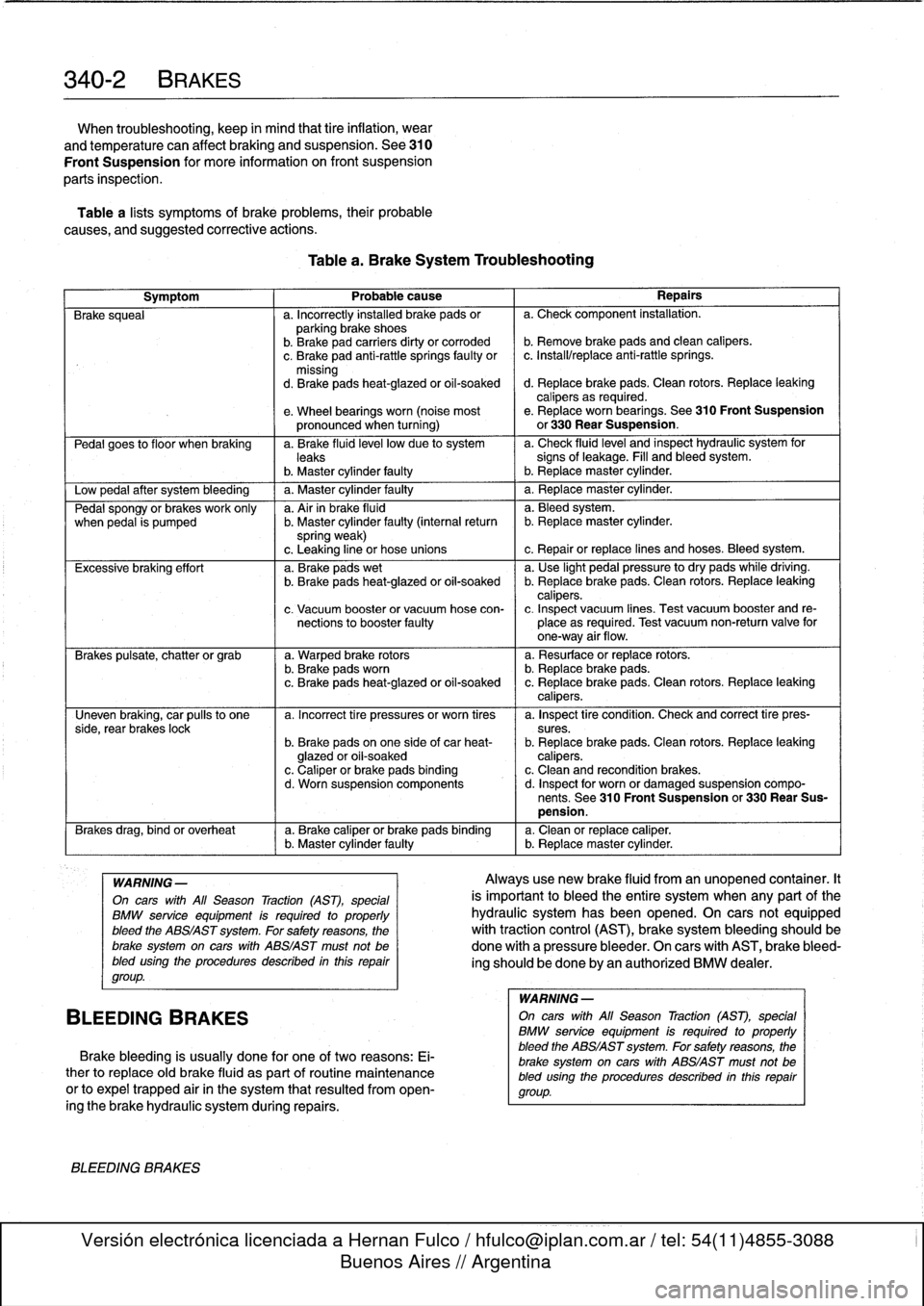

Table

a

lists

symptoms

of

brake

problems,

their

probable

causes,

and

suggested

corrective

actions

.

Table

a

.

Brake

System

Troubleshooting

Symptom

1

Probable

cause

1

Repairs

Brake

squeal

a

.

Incorrectly

installed

brake

pads

or

a

.

Check

component

installation

.

parking

brake

shoes

b

.

Brakepad

carriers

dirty

or

corroded

b

.

Remove

brake

pads

and

clean

calipers

.

c

.

Brake

pad

anti-rattle

springs

faulty

or

c

.

Install/replace

anti-rattle

springs

.

missing

d

.

Brakepads

heat-glazed

or

oil-soaked

d

.

Replace

brake

pads

.

Clean

rotors

.

Replace

leaking

calipers

as

required

.

e

.

Wheel

bearings

worn

(noise

most

e

.

Replace

worn

bearings

.

See310

Front

Suspension

pronounced

when

turning)

or

330

Rear

Suspension

.

Pedal

goes

to

f

loor

when

braking

a

.

Brake

fluid

leve¡

low

due

to

system

a

.

Check

fluidlevel

and

inspect

hydraulic

system

for

leaks

signs

of

leakage

.

Fill

and

bleed

system

.

b

.

Master

cylinder

faulty

I

b

.

Replacemaster

cylinder

.

Low

pedal

after

system

bleeding

1

a

.

Master

cylinder

faulty

1

a

.

Replace

master

cylinder

.

Pedal

spongy

or

brakes

work

only

a

.

Air

in

brake

fluid

a

.

Bleedsystem

.

when

pedal

is

pumped

b

.

Master

cylinder

faulty

(interna¡

return

b

.

Replacemaster

cylinder

.

spring

weak)

c

.

Leaking

line

or

hose

unions

c

.

Repair

or

replace

lines

and

hoses

.

Bleed

system

.

Excessive

braking

effort

a

.

Brake

pads

wet

a

.

Use

light

pedal

pressure

to

dry

pads

while

driving

.

b

.

Brake

pads

heat-glazed

oroil-soaked

b

.

Replace

brake

pads

.

Clean

rotors

.

Replace

leaking

calipers

.

c

.

Vacuum

booster

or

vacuum

hose

con-

c

.

Inspect

vacuum

lines

.

Test

vacuum

booster

and

re

nections

to

booster

faulty

place

as

required

.

Test

vacuum

non-return

valve

for

one-way

air

flow

.

Brakes

pulsate,

chatter

or

grab

a

.

Warped

brake

rotors

a

.

Resurface

or

replace

rotors

.

b

.

Brake

padsworn

b

.

Replace

brake

pads

.

c

.

Brake

pads

heat-glazed

or

oil-soaked

c

.

Replace

brake

pads

.

Clean

rotors

.

Replace

leaking

calipers

.

Uneven

braking,

car

pulís

to

one

a

.

Incorrect

tire

pressures

or

worn

tires

a

.

Inspect

tire

condition

.

Check

and

correct

tire

pres-

side,

rear

brakes

lock

sures

.

b

.

Brake

pads

on

one

side

of

car

heat-

b

.

Replace

brake

pads

.

Clean

rotors

.

Replace

leaking

glazed

or

oil-soaked

calipers

.

c

.

Caliper

or

brake

pads

binding

c

.

Clean

and

recondition

brakes

.

d

.

Worn

suspension

components

d

.

Inspect

for

worn

or

damaged

suspension

compo-

nents

.

See

310

Front

Suspension

or

330

Rear

Sus-

pension

.

Brakes

drag,

bind

or

overheat

a

.

Brake

caliper

or

brake

pads

binding

a

.

Clean

or

replace

caliper

.(

b

.

Master

cylinder

faulty

b

.

Replacemaster

cylinder

.

WARNING

-

On

cars

with

All

Season

Traction

(AST),

special

BMW

service

equipment

is

required

to

properly

bleed

the

ABS/AST

system

.

For

safety

reasons,

the

brake

system

on

carswith

ABS/AST

must

not

be

bled

using

the

procedures

described

inthis

repair

group

.

BLEEDING

BRAKES

Brake

bleeding

is

usually

done

for

one

of

two

reasons

:

Ei-

ther

to

replace

oíd

brake

fluid

as

part

of

routine

maintenance

or

to

expel

trapped

air

in

the

system

that

resulted

from

open-

ingthe

brake

hydraulic

system

during

repairs

.

BLEEDING

BRAKES

Alwaysuse

new

brake

fluid

from

an

unopened

container

.It

is

important

to

bleed

the

entire

system

when

any

part

of

the

hydraulic

system

has

been

opened

.

On

cars

not

equipped

with

traction

control

(AST),

brake

system

bleeding

should

be

done

with

a

pressure

bleeder

.

On

cars

with

AST,

brake

bleed-

ing

should

be

done

by

an

authorized

BMW

dealer

.

WARNING

-

On

cars

with

All

Season

Traction

(AST),

special

BMW

service

equipment

is

requíred

to

properly

bleed

the

ABS/AST

system

.

For

safetyreasons,

the

brake

system

on

carswith

ABS/AST

must

not

be

bled

using

the

procedures

described

inthís

repair

group

.

Page 293 of 759

When

bleeding

the

brakes,

startat

the

wheel

farthest

from

4

.

Close

bleeder

screw

and

release

brake

pedal

.

Refill

the

master

cylinder

and

progress

in

the

following

order

:

brake

fluid

reservoir

and

proceed

to

rear

left

wheel

.

"

right

rear

brake

5

.

Proceed

with

the

remaining

wheels

using

the

order

list-

"

left

rear

brake

ed

earlier

.

"

rightfront

brake

"

left

front

brake

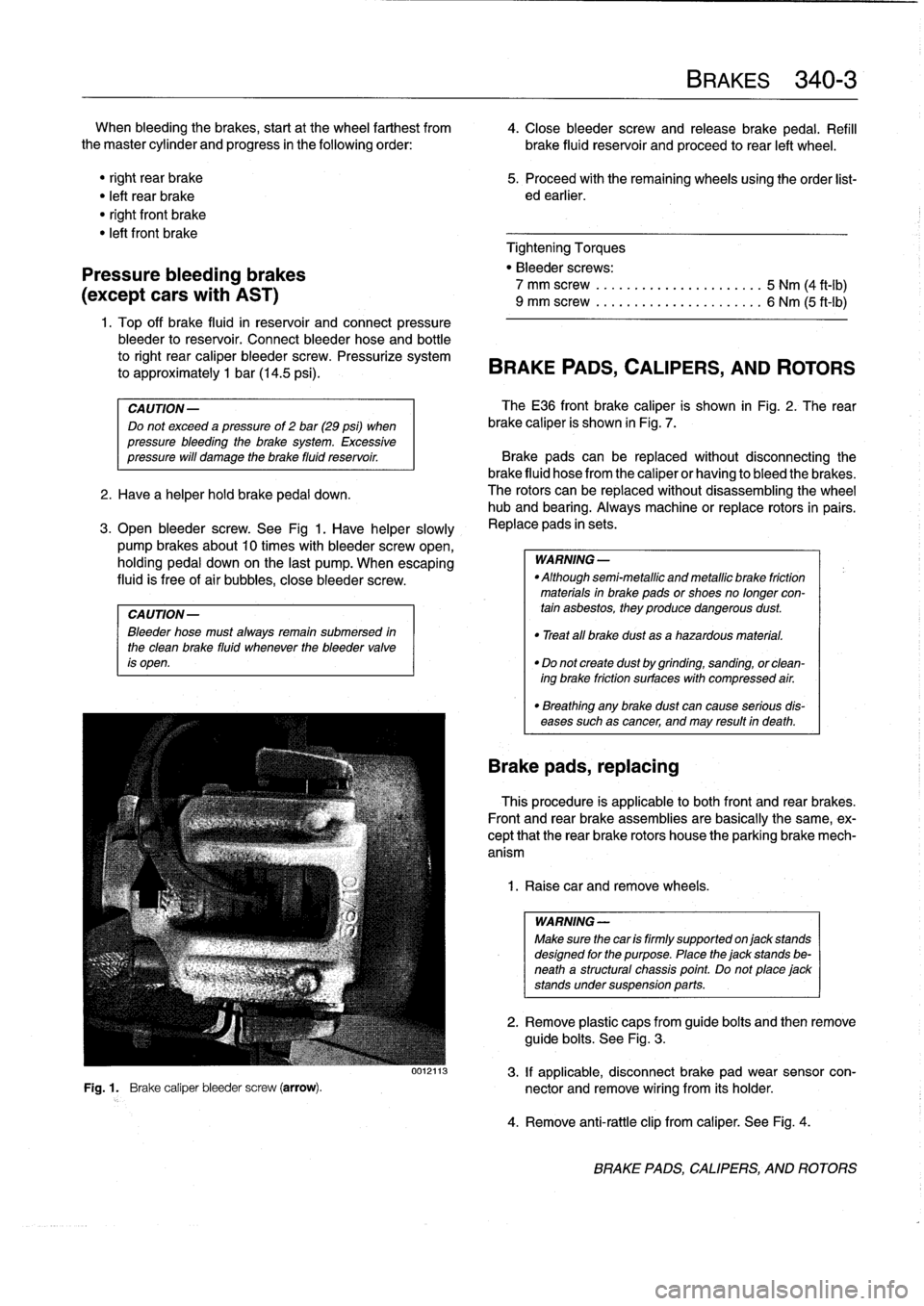

Pressure

bleeding

brakes

(except

carswith

AST)

1

.

Top

off

brake

fluid

in

reservoir

and

connect

pressure

bleeder

to

reservoir

.

Connect

bleeder

hose

and

bottle

to

right

rearcaliper

bleeder

screw

.

Pressurize

system

to

approximately

1

bar

(14

.5

psi)

.

BRAKES

340-

3

Tightening

Torques

"

Bleeder

screws

:

7

mm

screw

..........

..

.

.

.

.

......

5

Nm

(4

ft-Ib)

9

mm

screw

..........

..

.

..

.......

6

Nm

(5

ft-Ib)

BRAKE

PADS,

CALIPERS,

AND

ROTORS

CAUTION-

TheE36

front

brake

caliper

is

shown

in

Fig

.

2

.

The

rear

Do

not

exceed

a

pressure

of

2

bar

(29

psi)

when

brake

caliper

is

shown

in

Fig

.

7

.

pressure

bleeding

the

brake

system

.

Excessive

pressure

will

damage

the

brake

fluid

reservoir

.

Brake

pads

canbe

replaced

without

disconnecting

the

brake

fluid

hose

from

the

caliper

or

having

to

bleed

the

brakes

.

2

.

Have

a

helperhold

brake

pedal

down

.

The

rotors

can

be

replaced

without

disassembling

the

wheel

huband

bearing

.

Always

machine

or

replace

rotors

in

parts

.

3

.

Open

bleeder

screw

.

See

Fig

1

.

Have

helper

slowly

,

Replace

pads

in

sets

.

pump

brakes

about10

times

with

bleeder

screw

open,

holding

pedal

down

on

the

last

pump

.

When

escaping

WARNING-

fluid

is

free

of

air

bubbles,

close

bleeder

screw

.

"

Althoughsemi-metallicandmetallicbrake

friction

materials

in

brake

pads

or

shoes

no

longer

con

CAUTION-

tain

asbestos,

they

produce

dangerous

dust

.

Bleeder

hose

must

alwaysremain

submersed

in

"

Treat

all

brake

dust

asa

hazardous

material

.

the

clean

brake

fluid

whenever

the

bleeder

valve

is

open

.

"

Do

not

create

dust

by

grinding,

sanding,

orclean-

ing

brake

friction

surfaces

with

compressed

air

.

"

Breathing

any

brake

dust

can

cause

serious

dis-

eases

such

as

cancer,

and

may

result

in

death

.

Brake

pads,

replacing

This

procedure

is

applicable

lo

both

front

and

rear

brakes

.

Front

and

rear

brake

assemblies

are

basically

the

same,

ex-

cept

that

the

rear

brake

rotors

house

the

parking

brake

mech-

anism

1

.

Raise

car

andremove

wheels

.

WARNING

-

Make

sure

thecar

is

firmly

supported

onjack

stands

designed

for

the

purpose

.

Place

the

jack

stands

be-

neath

a

structural

chassis

point

.

Do

not

place

jack

stands

undersuspension

parts

.

2

.

Remove

plastic

caps

from

guide

bolts

and

then

remove

guide

bolts

.

See

Fig

.

3

.

0012113

3

.

If

applicable,

disconnect

brake

pad

wear

sensor

con-

Fig

.

1

.

Brake

caliper

bleeder

screw

(arrow)

.

nector

and

remove

wiring

from

its

holder

.

4

.

Remove

anti-rattle

clip

from

caliper

.

See

Fig

.

4

.

BRAKE

PADS,

CALIPERS,

AND

ROTORS

Page 300 of 759

340-

1

0

BRAKES

PARKING

BRAKE

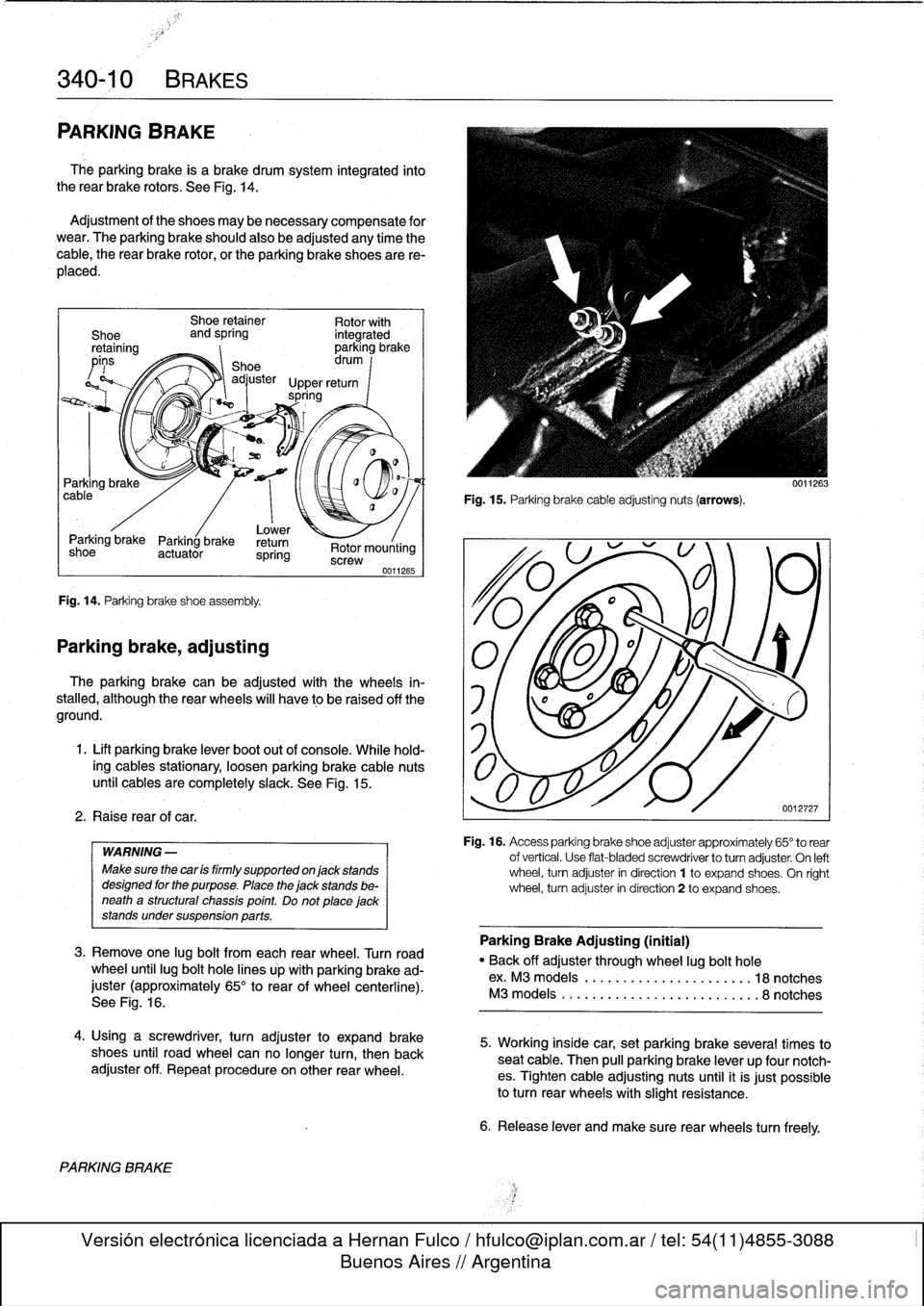

The

parking

brake

is

a

brake

drum

system

integrated

into

the

rear

brake

rotors

.

See

Fig

.

14

.

Adjustment

of

the

shoes

may

benecessary

compensate

for

wear

.

The

parking

brake

should

also

be

adjusted

any

time

the

cable,

the

rear

brake

rotor,

or

the

parking

brake

shoes

are

re-

placed

.

Lower

Parking

brake

Parking

brake

retum

shoe

actuator

spring

Fig

.

14

.

Parking

brake

shoeassembly

.

Parking

brake,

adjusting

2

.

Raise

rearof

car

.

PARKING

BRAKE

Shoe

retainer

Rotor

with

and

spring

integrated

parking

brake

Shoe

drum

I

adjuster

Upper

return

spring

-í

<~

:

:

Rotor

mounting

screw

WARNING

-

Make

sure

the

car

is

firmly

supported

on

jack

stands

designed

for

the

purpose

.

Place

the

jack

stands

be-

neatha

structural

chassis

point

.

Do

not

placejack

stands

undersuspension

parts

.

0011265

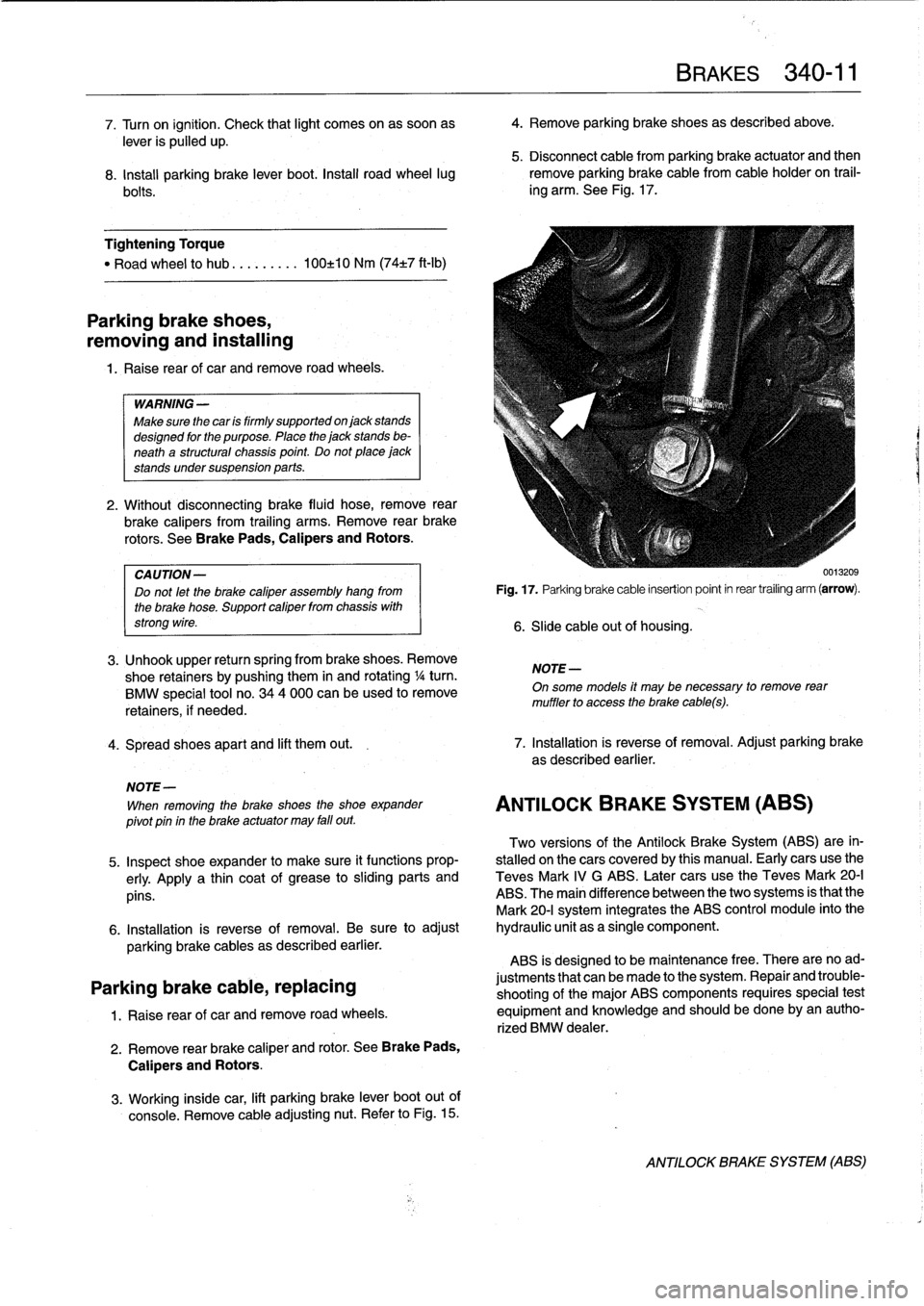

3

.

Remove

one

lug

bolt

from

each

rear

wheel

.

Turnroad

wheel

until

lug

bolt

hole

lines

úp

with

parking

brake

ad-

juster

(approximately

65°

to

rear

of

wheel

centerline)

.

See

Fig

.

16

.

4

.

Usinga

screwdriver,

turn

adjusterto

expand

brake

shoes

until

road

wheel

canno

longer

turn,

then

back

adjuster

off

.

Repeatprocedureon

other

rear

wheel

.

Fig

.

15

.

Parking

brake

cable

adjustingnuts

(arrows)

.

The

parking

brake

can

be

adjusted

with

the

wheels

in-

stalled,

although

the

rear

wheels

will

have

to

be

raised

off

the

1

f

l

i\

aground

.

1

.

Lift

parking

brake

lever

boot

out

of

console

.

While

hold-

ing

cables

stationary,

loosen

parking

brake

cable

nuts

until

cablesare

completely

slack

.

See

Fig

.

15

.

0011263

0012727

Fig

.

16

.

Access

parking

brake

shoe

adjuster

approxímately

65°

to

rear

of

vertical

.

Use

flat-bladed

screwdriver

to

turnadjuster

.

On

left

wheel,

turn

adjuster

in

direction

1

to

expand

shoes

.

On

ríght

wheel,

turn

adjuster

in

direction

2

to

expand

shoes

.

Parking

Brake

Adjusting

(initial)

"

Back

off

adjuster

through

wheel

lug

bolt

hole

ex

.

M3

models

.........

..

...

...

.

...

.

18notches

M3

models

............

.

.....

..

..

..

.

.

8notches

5

.

Working

inside

car,

set

parking

brake

several

times

to

seat

cable

.

Then

pull

parking

brake

lever

up

four

notch-

es

.

Tighten

cable

adjusting

nuts

until

it

is

just

possible

to

turnrear

wheels

with

slight

resistance

.

6

.

Release

lever

and

make

sure

rear

wheels

turn

freely

.

Page 301 of 759

7

.

Turn

on

ignition

.

Check

that

light

comes

on

as

soonas

4

.

Remove

parkíng

brake

shoes

as

described

above

.

lever

is

pulled

up

.

5

.

Disconnect

cable

from

parking

brake

actuator

and

then

8

.

Install

parking

brake

lever

boot

.

Install

road

wheel

lug

remove

parking

brakecable

from

cable

holder

on

trail-

bolts

.

ing

arm

.

See

Fig

.

17

.

Tightening

Torque

"

Road

wheel

to

hub

.

..

......

100±10

Nm

(74±7

ft-Ib)

Parking

brake

shoes,

removing

and

installing

1.

Raise

rear

of

car

andremove

road

wheels

.

WARNING

-

Make

sure

the

car

is

firmly

supportedon

jack

stands

designed

for

the

purpose

.

Place

the

jack

stands

be-

neath

a

structural

chassis

point

.

Do

not

place

jack

stands

undersuspension

parts

.

2

.

Without

disconnecting

brake

fluid

hose,

remove

rear

brake

calipers

from

trailing

arms

.

Remove

rear

brake

rotors

.

See

Brake

Pads,

Calipers

and

Rotors

.

CA

UTION-

Do

not

let

the

brake

caliper

assembly

hang

from

the

brake

hose

.

Support

caliper

from

chassis

with

strong

wire

.

3

.

Unhook

upper

return

spring

from

brake

shoes

.

Remove

shoe

retainers

bypushing

them

in

and

rotating

1

/4turn

.

BMW

special

tool

no

.

344

000

can

beused

to

remove

retainers,

if

needed

.

4

.

Spread

shoes

apart

and

lift

them

out

.

7

.

Installation

is

reverse

of

removal

.

Adjust

parking

brake

as

described

earlier

.

NOTE-

When

removing

the

brake

shoes

the

shoe

expander

pivot

pin

in

the

brake

actuator

may

fall

out

.

Two

versions

of

the

Antilock

Brake

System

(ABS)

are

in-

5

.

Inspect

shoe

expander

to

make

sure

it

functions

prop-

stalled

onthe

cars

coveredby

this

manual

.

Early

cars

use

the

erly

.

Apply

a

thin

coat

of

grease

tosliding

parts

and

Teves

Mark

IV

G

ABS

.

Later

cars

use

the

Teves

Mark

20-I

pins

.

ABS

.

The

main

difference

between

the

two

systems

is

that

the

Mark

20-I

system

integrates

the

ABS

control

module

into

the

6

.

Installation

is

reverse

of

removal

.

Be

sure

to

adjust

hydraulic

unit

as

a

single

component

.

parking

brake

cables

as

described

earlier

.

ABS

is

designed

to

be

maintenance

free

.

There

are

noad

Parking

brake

cable,

replacing

justments

that

canbe

made

to

the

system

.

Repair

and

trouble-

shooting

of

the

major

ABS

components

requires

special

test

1

.

Raise

rear

of

car

and

remove

road

wheels

.

equipment

and

knowiedge

and

should

be

done

by

an

autho-

rized

BMW

dealer

.

2

.

Remove

rear

brake

caliper

and

rotor

.

See

Brake

Pads,

Calipers

and

Rotors

.

3

.

Working

inside

car,

lift

parking

brake

lever

boot

out

of

console

.

Remove

cable

adjusting

nut

.

Refer

to

Fig

.

15

.

Fig

.

17

.

Parking

brake

cable

insertion

point

in

rear

trailing

arm

(arrow)

.

6

.

Slide

cable

out

of

housing

.

NOTE

-

BRAKES

340-

1

1

On

some

models

it

may

be

necessary

to

remove

rear

muffler

to

access

the

brake

cabes)

.

ANTILOCK

BRAKE

SYSTEM

(ABS)

0013209

ANTILOCK

BRAKE

SYSTEM

(ABS)