battery BMW 325i 1998 E36 Owners Manual

[x] Cancel search | Manufacturer: BMW, Model Year: 1998, Model line: 325i, Model: BMW 325i 1998 E36Pages: 759

Page 267 of 759

320

Steering

and

Wheel

Alignment

GENERAL

...

.

.

.

...

.

....

.

.

.

.

.

.

.

.

.

...

.

.

320-1

Outer

tie

rod

end,

replacing

.

...

.

.

.

.

.

.

.

...

.

320-4

Tie

rod,

replacing

.

.

.

.

.

.

.

.......

.

.

.

.

.

...

.

320-5

STEERING

WHEEL

320-1

Steering

wheel,

removing

and

installing

.....

320-1

WHEEL

ALIGNMENT

.

.

.

.........

.

.....

.320-5

POWER

STEERING

SYSTEM

.

.

.

.

.

.

.....

320-2

Front

Toe-in

and

Toe

Difference

Angle

.

.

...

.

320-6

Power

steering

pump,

Rear

Toe-in

.

.

.

.

.

.

.

...

.

................

320-6

removing

and

installing

..

.

.

.

.

.

.

.

.

.

.....

320-2

Wheel

Alignment

Specifications

.....

.

......

320-6

Power

steering

system,

bleeding

and

filling

.

.

320-3

STEERING

GEAR

.

.

.

.

...

.

.

.

.

.

.

.

.

.

.....

320-3

Steering

gear

rack,

removing

and

installing

.

...

.

..

.

..

..

..

.

..

.

320-3

GENERAL

STEERING

WHEEL

This

repair

group

covers

servicing

of

the

mechanical

and

The

BMW

E36

is

equipped

with

an

SRS

airbag

mounted

in

hydraulic

components

of

the

steering

system,

including

wheel

the

steering

wheel

.

Improper

handling

of

the

airbag

could

alignment

information

.

cause

serious

injury

.

The

airbag

is

an

explosivedevice

and

should

be

treated

with

extreme

caution

.

Always

follow

the

air-

The

variable-assist

power

steering

system

consistsof

an

bag

removal

procedure

as

outlined

in

721

Airbag

System

engine-driven

hydraulic

pump,

a

rack-and-pinion

steering

(SRS)

.

gear

assembly

with

an

integral

hydraulic

control

valve,

and

connecting

linkage

to

the

road

wheels

.

WARNING-

"

The

BMW

Supplemental

Restraint

System

(SRS)

At

lowspeeds,

maximum

power

assist

is

provided

to

ease

is

complex

and

special

precautions

must

be

ob-

parking

and

city

driving

.

At

high

speeds,

assist

is

reduced

to

served

when

servicing

.

Serious

injury

may

result

ensure

stability

.

The

power

steering

system

varies

assist

if

system

service

is

attempted

by

persons

unfa-

based

on

engine

speed

.

miliar

with

the

BMW

SRS

and

its

approved

ser-

vice

procedures

.

BMW

specifies

that

all

ING-

inspection

and

service

shouldbe

performed

by

WARN

an

authorized

BMW

dealer

.

"

Do

not

reuse

self-locking

nuts

.

They

are

de-signed

to

beused

only

once

and

may

failif

re-

"

BMW

Supplemental

Restraint

Systems

(SRS)

used

.

Always

replace

them

with

new

locking

nuts

.

are

equipped

with

a

back-up

power

supply

inside

the

SRS

control

module

.

A

10minute

waiting

"

Do

not

ínstall

bolts

and

nuts

coated

with

under-

shouldbe

observed

after

the

battery

cable

has

coating

wax,

as

correct

tightening

torque

cannot

been

disconnected

.

This

will

allow

the

reserve

be

assured

.

Always

clean

the

threads

with

sol-

power

supply

to

discharge

.

vent

before

installation,

or

install

new

parts

.

"

Do

not

attempt

to

weldor

straighten

any

steering

components

.

Always

replace

damaged

parts

.

NOTE-

For

information

on

steering

column-mounted

switches

and

the

ignition

lock,

see

612

Switches

and

Electrical

Accessories

.

STEERING

AND

WHEEL

ALIGNMENT

320-1

Caster

and

Camber

.

.

.

.

.

...........

.

....

320-5

TABLES

a

.

Front

Wheel

Alignment

Specifications

.

...

.......

320-6

b

.

Rear

Wheel

Alignment

Specifications

.

...

.......

320-6

Steering

wheel,

removing

and

installing

1

.

Center

steering

wheel

.

Make

sure

front

wheelsare

pointed

straight

ahead

.

2

.

Disconnect

negative

(-)

cable

from

battery

and

cover

terminal

with

insulating

material

.

CAUTION-

Prior

to

disconnectiog

the

battery,

read

the

battery

disconnection

cautions

given

at

the

front

of

this

manual

on

page

viii

.

STEERING

WHEEL

Page 269 of 759

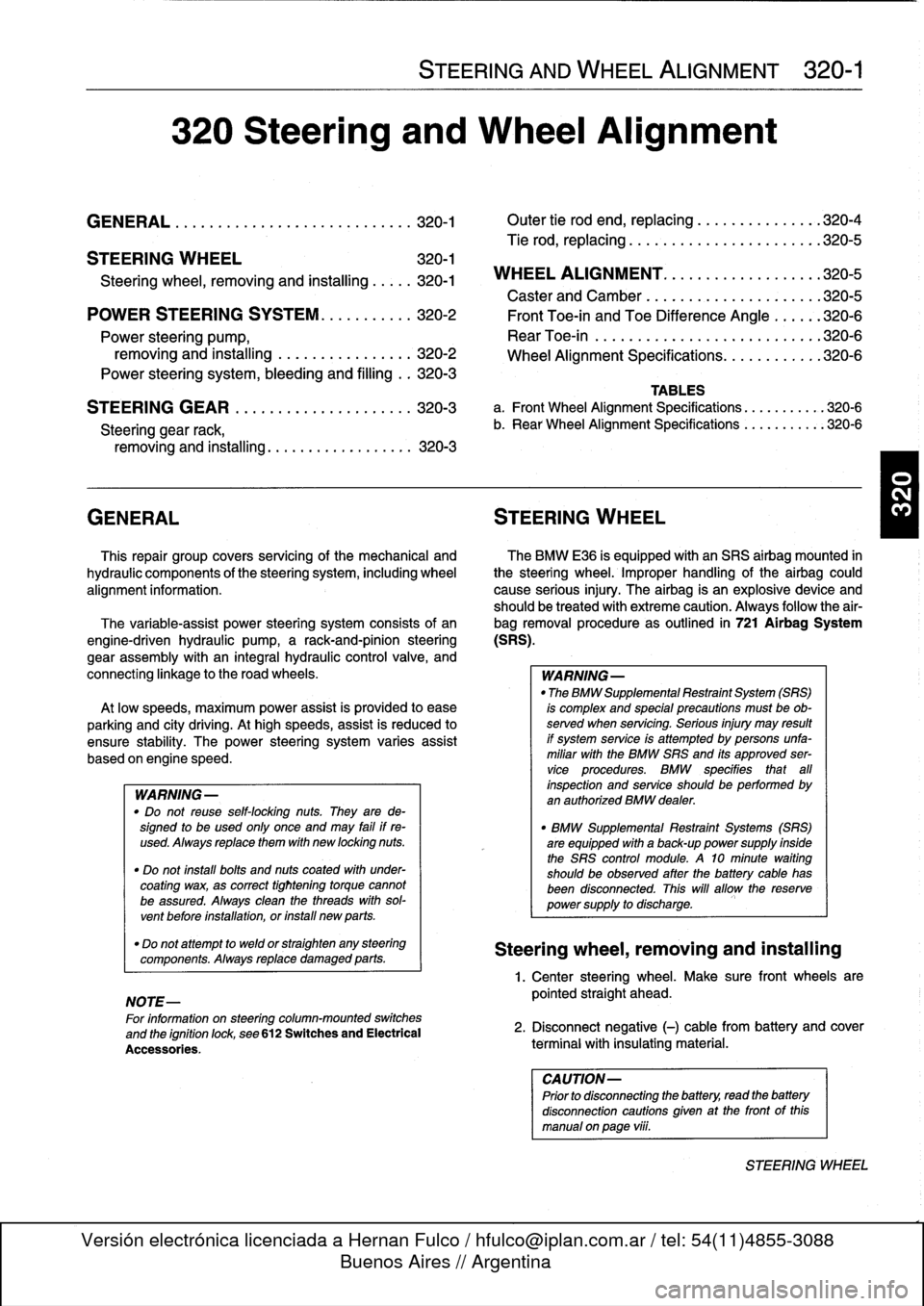

Fig

.

3

.

Power

steering

pump

and

pulley

mounting

bolts

.

6

.

Installation

is

reverse

of

removal,

noting

the

following

:

"

Make

sure

al¡

thread

bores,

bolts,

nuts,

fluid

couplings

and

mating

surfaces

are

clean,

and

that

inside

surface

of

multi-ribbed-belt

is

free

of

grease

and

dirt

.

"

Use

new

sealing

washers

when

reattaching

power

steering

pressure

lines

.

"

Make

sure

hoses

have

adequate

clearance

from

chas-

sis

.

Do

not

over-torque

banjo

bolts

.

"

Fill

and

bleed

power

steering

system

as

described

be-

low

.

Power

steering

system,

bleeding

and

filling

1

.

Wíth

engine

off,

fill

power

steering

fluid

reservoir

with

clean

fluid

.

Fill

levelto

MAX

mark

on

dipstick

.

STEERING

AND

WHEEL

ALIGNMENT

320-

3

STEERING

GEAR

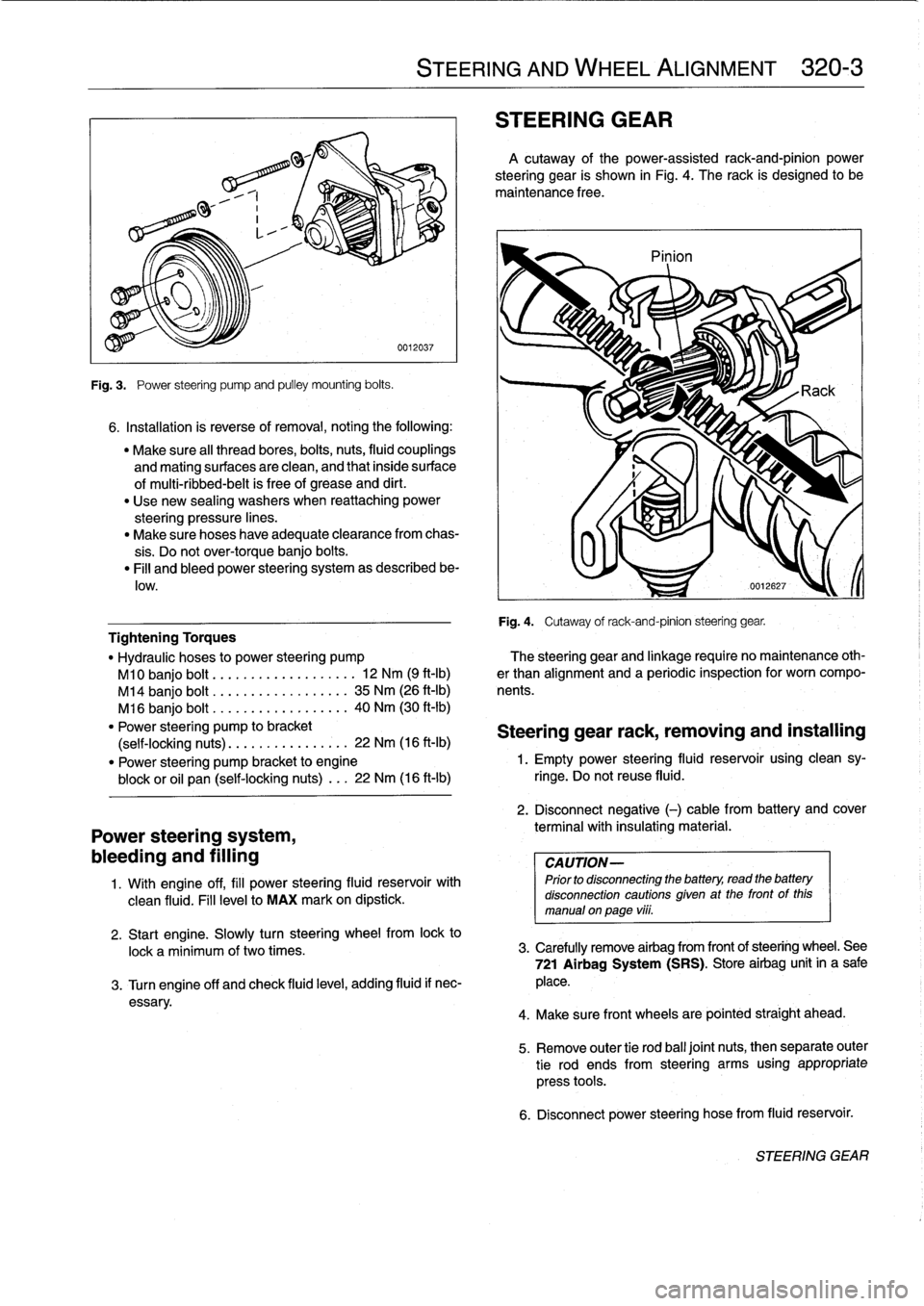

A

cutaway

of

the

power-assisted

rack-and-pinion

power

steering

gear

is

shown

in

Fig

.

4

.

The

rack

is

designed

to

be

maintenance

free

.

Pinion

Fig

.

4

.

Cutaway

of

rack-and-pinion

steering

gear

.

Tightening

Torques

"

Hydraulic

hoses

to

power

steering

pump

?he

steering

gear

and

linkage

require

no

maintenance

oth-

M10

banjo

bolt

.........

..

.

...

...

.

12

Nm

(9

ft-Ib)

er

than

alignment

and

a

periodic

inspection

for

worn

compo

M14

banjo

bolt

..............

..

..

35

Nm

(26

ft-Ib)

nents

.

M16

banjo

bolt

..............

...

.

40

Nm

(30

ft-Ib)

"

Power

steering

pump

to

bracket

Steering

gear

rack,

removing

and

installing

(self-locking

nuts)

.............

..

.

22

Nm

(16

ft-Ib)

"

Power

steering

pump

bracket

to

engine

1

.

Empty

power

steering

fluid

reservoir

using

clean

sy-

block

or

oil

pan

(self-locking

nuts)

...

22

Nm

(16

ft-lb)

ringe

.

Do

not

reuse

fluid

.

2

.

Disconnect

negative

(-)

cable

from

battery

and

cover

terminal

with

insulating

material

.

CAUTION-

Prior

to

disconnectiog

the

battery,

read

the

battery

disconnection

cautions

given

at

the

front

of

this

manual

on

page

viii

.

2

.

Start

engine

.

Slowly

turn

steering

wheelfrom

lock

to

lock

a

minimum

of

two

times

.

3

.

Carefully

remove

airbag

from

frontof

steering

wheel

.

See

721

Airbag

System

(SRS)

.

Store

airbag

unit

in

a

sale

3

.

Turn

engine

off

and

check

fluid

leve¡,

adding

fluid

if

nec-

place

.

essary

.

4

.

Make

sure

front

wheelsare

pointed

straight

ahead

.

5

.

Remove

outer

tie

rod

ball

joínt

nuts,

thenseparate

outer

tie

rod

ends

from

steering

arms

using

appropriate

press

tools

.

6

.

Disconnect

power

steering

hose

from

fluid

reservoir

.

STEERING

GEAR

Page 298 of 759

340-

8

BRAKES

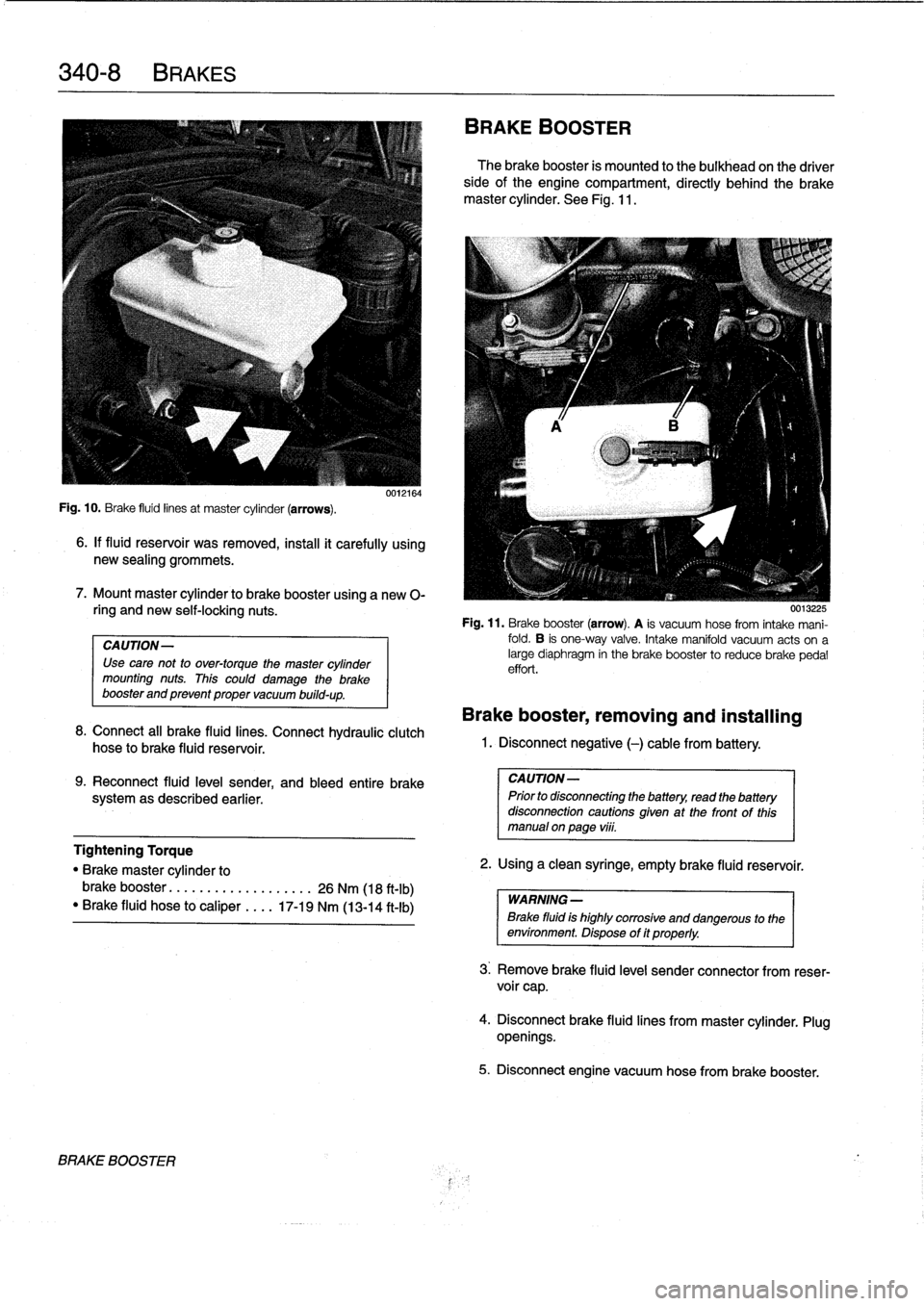

Fig

.

10

.

Brake

fluid

linesat

master

cylinder

(arrows)

.

6

.

If

fluid

reservoir

was

removed,

install

it

carefully

using

new

sealing

grommets

.

7

.

Mount

master

cylinder

to

brake

booster

using

a

new

0-

ring

and

new

self-locking

nuts

.

CAUTION-

Use

cave

not

to

over-torque

the

master

cylinder

mounting

nuts

.

This

could

damage

the

brake

booster

and

prevent

proper

vacuum

build-up

.

0012164

8

.

Connect

all

brake

fluid

lines

.

Connect

hydraulic

clutch

hose

to

brake

fluid

reservoir

.

9

.

Reconnect

fluid

leve¡

sender,

and

bleed

entire

brake

systemas

described

earlier

.

BRAKE

BOOSTER

BRAKE

BOOSTER

The

brake

booster

is

mounted

to

the

bulkhead

on

the

driver

sideofthe

engine

compartment,

directly

behind

the

brake

master

cylinder

.

See

Fig

.

11

.

0015225

Fig

.

11

.

Brake

booster

(arrow)

.

A

is

vacuum

hose

from

intake

mani-

fold

.

B

is

one-way

valve

.

Intake

manifold

vacuum

acts

ona

large

diaphragm

in

the

brake

booster

to

reducebrake

pedal

effort

.

Brake

booster,

removing

and

installing

1

.

Disconnect

negative

(-)

cable

from

battery

.

CAUTION-

Prior

to

disconnecting

the

battery,

read

the

battery

disconnection

cautions

given

at

the

front

of

this

manual

onpage

vi¡¡

.

Tightening

Torque

"

Brake

master

cylinder

to

2

.

Using

a

clean

syringe,

empty

brake

(luid

reservoir

.

brake

booster

.....

..

.

..

.........

26

Nm

(18

ft-Ib)

WARNING-

"

Brake

fluid

hose

to

caliper

....

17-19

Nm

(13-14

ft-Ib)

Brake

fluid

is

highly

corroslve

and

dangerous

to

the

environment

.

Dispose

of

it

properly

.

3

.

Remove

brake

fluid

level

sender

connector

from

reser-

voir

cap

.

4

.

Disconnectbrake

fluid

lines

from

master

cylinder

.

Plug

openings

.

5

.

Disconnect

engine

vacuum

hose

from

brake

booster

.

Page 303 of 759

GENERAL

.

....

.

.

.

.

.

.......

.

.

.

.

.

...

.

.

.

400-1

INTERIOR

EQUIPMENT

......

.

.

.

.......

400-4

Seats

and

Seatbelts

.

.

.

.

.

.

.....

.

.

.

.

.

..

.

..

400-4

BODY

ASSEMBLY

.

.

.

.

.

.....

.

.

.

.

.

.

.

.

.

.

.400-2

Instruments

and

Controls

.

..

....

.

.

.

.

.

.

.

...

400-4

Exterior

and

Aerodynamics

....

.

.

.

.

.

.

.

.

.

.

.

400-2

Central

Body

Electronics

.......

.

.

.

...

.

...

400-5

Coupe

Models

..

.

.

.

.

.

.......

.

.

.

.

.

.

.

.

.

..

400-3

Electronic

Immobilization

System

.

.

.

...

.

...

400-5

Convertible

Models

.

.

.

.

.

.

.

.....

.

.

.

.

.

.

.

..

400-3

Heating

and

Air

Conditioning

.

...

.

.

.

.

.

.

.

...

400-6

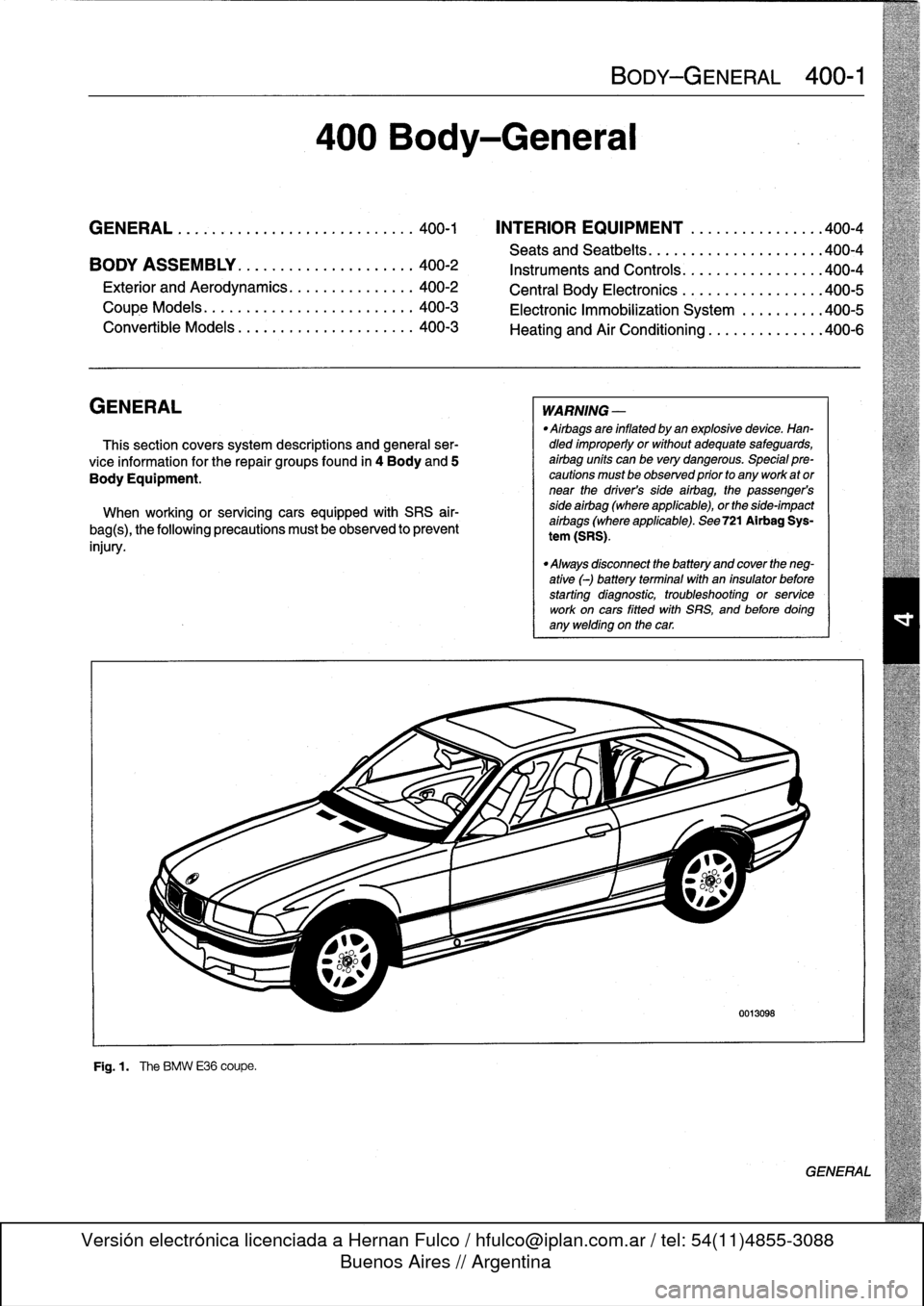

GENERAL

This

section

covers

system

descriptions

and

general

ser-

vice

information

for

the

repair

groupsfound

in

4

Body

and

5

Body

Equipment

.

When

working

or

servicing

cars

equipped

with

SRS

air-

bag(s),

the

following

precautions

must

be

observed

to

prevent

injury

.

F19

.1

.

The

BMW

E36

coupe

.

400

Body-General

BODY-GENERAL

400-1

WARNING

-

"

Airbags

are

inflated

by

an

explosivedevice

.

Han-dled

improperly

or

without

adequate

safeguards,

airbag

units

can

be

very

dangerous

.

Special

pre-cautions

must

be

observed

prior

to

any

work

ator

near

the

driver's

side

airbag,

the

passenger's

side

airbag

(where

applicable),

or

the

side-impact

aírbags

(where

applicable)

.

See

721

Airbag

Sys-

tem

(SRS)

.

"

Always

disconnect

the

battery

and

cover

the

neg-

ative

(-)

battery

terminalwith

an

insulator

before

starting

diagnostic,

troubleshooting

or

service

work

oncars

fitted

with

SRS,

and

before

doíng

any

welding

on

the

car

.

0013098

GENERAL

Page 305 of 759

TheE36

convertible

is

an

all-season

vehicle

with

a

high

lev-

e¡offunctionality,

excellent

interior

comfort,

and

acoustic

re-

finement

.

Interior

materials

and

colors,

the

soft

top

and

the

light-alloy

wheelshave

been

carefully

matched

.

Various

versions

of

manual

and

automatic

soft

tops

have

been

used,

with

the

fully

automatic

convertible

roof

being

in-

stalled

beginning

in

the

1997

model

year

.

A

hard-top

in

body

color

with

heated

rear

window

is

avail-

ableas

an

option

for

the

cold

season

.

BODY-GENERAL

400-

3

Coupe

Models

The

convertible

body

structure

includes

many

passive

safe-

ty

refinements

over

its

fixed-top

counterparts

.

Some

of

the

en-

TheE36

coupe

is

similar

to

the4-door

sedan,

but

has

a

hancements

include

:

more

stretched

and

sleeker

appearance

.

Thus,

with

the

same

wheelbase

and

identicallength,

it

looks

different

but

still

famil-

"

More

rígíd

underbody

.

iar

.

"

Transverse

seat

members

.

"

Reinforced

windshield

frame

with

bonded

windshield,

The

2-door

variant

differs

from

the

4-door

sedan

by

a

3

.12

and

tubular

door

reinforcements

.

inch

(8

cm)

longer

front

end,

a

flatter

hood

line

with

air

slits,

"

Rollover

protection

system,

which

is

tripped

into

position

and

a

roof

almost

1

.2

inches

(3

cm)

shorter

.

Additional

differ-

in

a

fraction

of

second

.

This

is

available

as

optional

ences

include

wider

doors

with

frameless

Windows,

glass-

equipment

(standard

on

the

1998

328iC)

and

may

be

fit-

covered

door-posts

(B-pillars)

and

a

shorter

and

lower

lug-

ted

to

earlier

convertible

models

.

With

this

feature,

two

gage

compartment

lid

.

bars

fully

independent

of

each

other

come

up

behind

each

rear-seat

backrest

when

the

vehicle

is

in

danger

of

Convertible

Models

turning

over

.

A

convertible

body

normally

flexes

and

vibrates,

transfer-

ring

oscillations

to

the

luggage

compartment

.

In

the

E36

con-

vertible,

BMW

utilizes

a

special

battery

in

the

luggage

compartment,

in

conjunction

with

a

unique

battery

tray,

asa

vibration

dampening

system

to

counteract

thisoscillation

.

CAUTION

-

The

E36

convertible

requires

a

specialbattery

which

is

designed

for

constant

vibration

.

Information

for

the

convertible

top

and

its

related

mecha-

nisms

can

be

found

541

Convertible

Top

.

BODYASSEMBLY

Page 315 of 759

GENERAL

This

repair

group

covers

front

and

rear

door

repair

informa-

tion,

including

removal

and

installationof

the

interior

doorpan-

els

.

DOORS

WARNING

-

Late

M3

moddis

havealuminum

doors

.

Use

extra

care

in

handling

aluminum

parts

in

order

to

avoid

damage

from

gouging

or

corrosión

.

NOTE-

"

For

information

on

the

power

door

windows

and

door

glass

replacement,

sea512Door

Windows

.

"

Forinformation

on

the

power

door

locking

system,

see

515

Central

Locking

and

Anti-Theft

.

WARNING

-

Some

1997

and

all

1998

cars

are

fitted

with

side-im-

pact

airbags

in

the

front

doors

.

When

servicing

doors

on

cars

with

front

side-impact

airbags,

always

dis-

connect

the

negative

(-)

battery

terminal

.

See

721

Airbag

System

(SRS)

for

cautions

and

procedures

relating

to

the

airbag

system

.

Front

orrear

door,

removing

and

installing

1

.

If

workingon

front

door

with

side-impact

airbag,

discon-

nect

negative

(-)

battery

cable

.

CAUTION

-

Prior

to

disconnectiog

the

battery,

read

the

battery

disconnection

cautions

given

at

the

front

of

this

manual

on

page

vüi

.

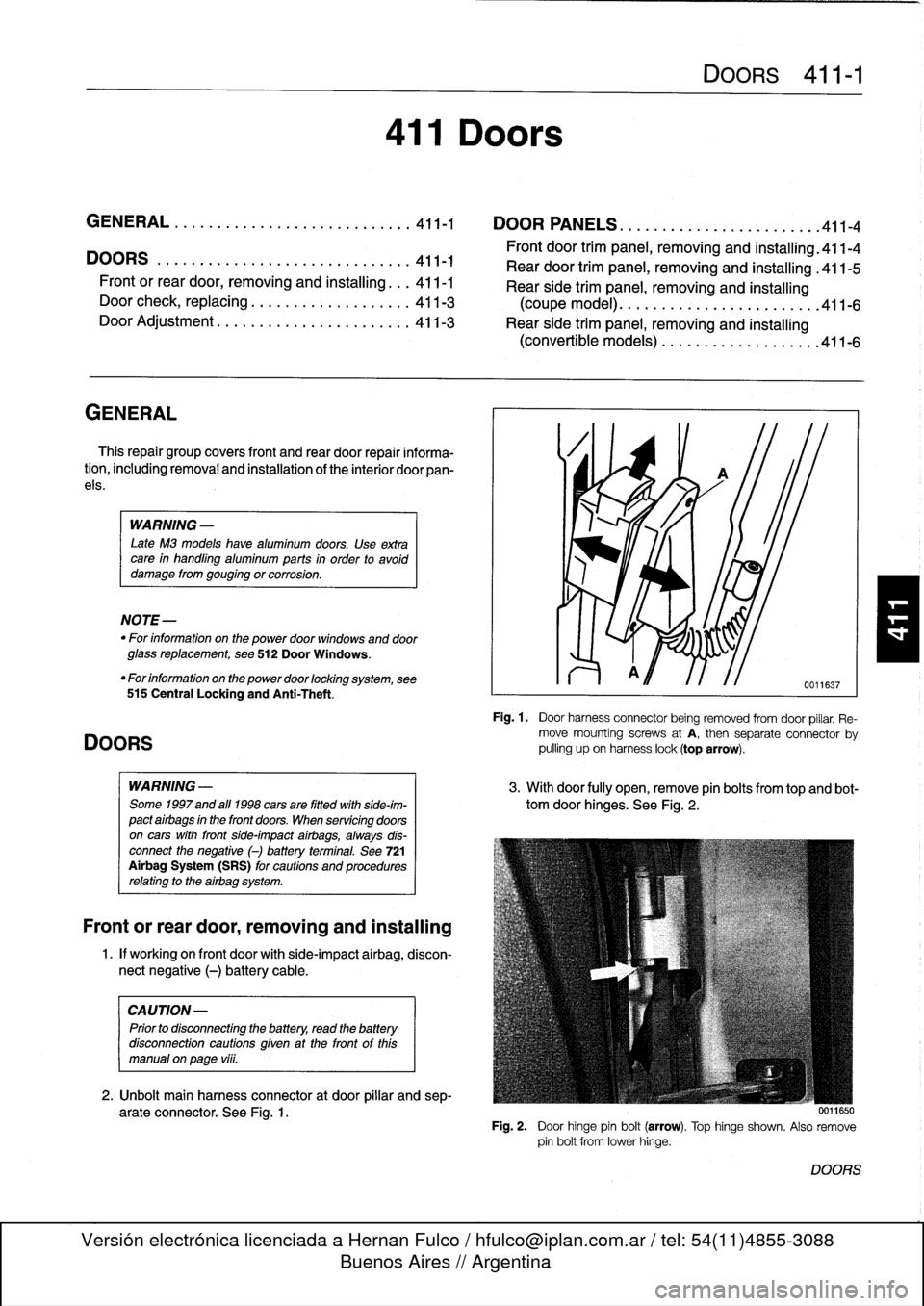

2

.

Unbolt

main

harness

connector

at

door

pillar

and

sep-

arate

connector

.

See

Fig

.

1

.

411

Doors

GENERAL

.............

.

.

.

.

.

.

.

.

.

.

.

.

.

..

411-1

DOOR

PANELS

.

.

.

.

.

.

.

...

.

.

.

.

.

.

.

.

.

...

.

.

411-4

Front

door

trim

panel,

removing

and

installing

.411-4

DOORS

..

.

.

.

.

.

.

.

.

.

...

.

.......

.

....

.

.

.

411-1

Rear

door

trim

panel,

removing

and

installing

.411-5

Front

or

reardoor,

removing

and

installing

..

.

411-1

Rear

side

trim

panel,

removing

and

installing

Door

check,

replacing

.

.

.

.

.

.

.

.

.

.

.

.

.......

411-3

(coupemodel)

.

.

.

.

.

.

....

.

.............

411-6

Door

Adjustment

.......

.

.

.

.

.

.

.

.

.

.

.

.....

411-3

Rear

side

trim

panel,

removing

and

installing

(convertible

models)

.

...

.

.

.

.

.

.

.

.

.

.

.

...

.

411-6

DOORS

411-1

Fig

.

1

.

Door

harness

connector

being

removed

fromdoor

pillar

.

Re-

move

mountingscrews

atA,

then

separate

connector

by

pulling

upon

harness

lock(top

arrow)

.

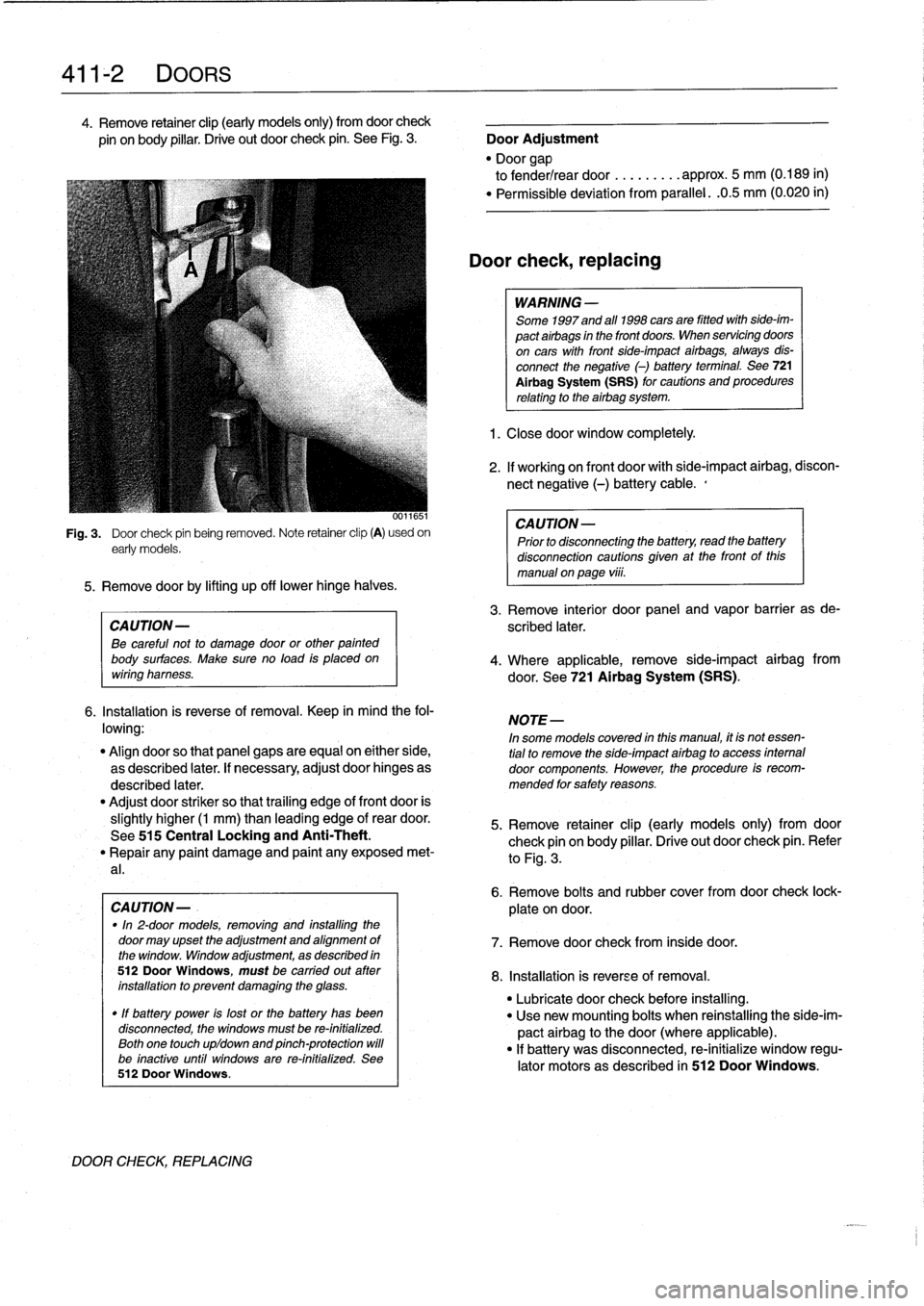

3

.

Withdoor

fully

open,

remove

pin

bolts

from

top

and

bot-

tom

door

hinges

.

See

Fig

.

2

.

0011650

Fig

.

2

.

Door

hinge

pin

bolt

(arrow)

.

Top

hinge

shown

.

Also

remove

pin

bolt

from

lowerhinge

.

DOORS

Page 316 of 759

411-2

DOORS

4

.

Remove

retainer

clip

(early

models

only)

from

doorcheck

pin

onbody

pillar

.

Drive

out

door

check

pin

.

See

Fig

.

3

.

Door

Adjustment

"

Door

gap

to

fender/rear

door

.........

approx

.

5

mm

(0

.189

in)

"

Permíssible

deviation

from

parallel

.

.0

.5

mm

(0

.020

in)

0011651

Fig

.

3

.

Door

check

pin

being

removed

.

Note

retainer

clip

(A)

usedon

early

models

.

5

.

Remove

doorby

lifting

up

off

lowerhinge

halves

.

CAUTION-

Be

careful

not

to

damage

door

or

other

painted

body

surfaces

.

Make

sure

no

load

is

placedon

wiring

harness

.

6

.

Installation

is

reverse

of

removal

.

Keep

in

mind

the

fol-

lowing

:

"

Align

doorso

that

panel

gaps

are

equal

on

either

side,

as

described

later

.

If

necessary,

adjust

door

hinges

as

described

later

.

"

Adjust

door

striker

so

that

trailing

edge

of

front

door

is

slightly

higher

(1

mm)

than

leading

edge

of

rear

door

.

See

515

Central

Locking

and

Anti-Theft

.

"

Repair

any

paint

damage

and

paínt

any

exposed

met-

al

.

CAUTION-

.

"In

2-door

models,

removing

and

installing

the

door

may

upset

the

adjustment

and

alignment

of

the

window

.

Window

adjustment,

as

described

in

512DoorWindows,

must

be

carried

out

ater

installation

to

prevent

damaging

the

glass

.

"

If

battery

power

is

lost

or

the

battery

has

been

disconnected,

the

windows

must

be

re-initialized

.

Both

one

touch

upldown

and

pinch-protection

will

be

inactive

until

windows

are

re-initialized

.

See

512

Door

Windows

.

DOOR

CHECK,

REPLACING

Door

check,replacing

WARNING

-

Some

1997

and

all

1998

cars

are

fitted

with

side-im-

pact

airbags

in

the

front

doors

.

When

servicing

doors

on

cars

with

front

side-impact

airbags,

always

dis-

connect

the

negative

(-)

battery

terminal

.

See

721

Al

rbag

System

(SRS)

for

cautions

and

procedures

relating

to

the

airbag

system

.

1

.

Closedoor

window

completely

.

2

.

If

working

on

front

door

with

side-impact

airbag,

discon-

nect

negative

(-)

battery

cable

.,

CAUTION-

Prior

to

disconnectiog

the

battery,

read

the

battery

disconnection

cautions

gíven

at

the

front

of

this

manual

on

page

viii

.

3

.

Remove

interior

door

panel

and

vapor

barrier

as

de-

scribed

later

.

4

.

Where

applicable,

remove

side-impact

airbag

from

door

.

See

721

Airbag

System

(SRS)

.

NOTE-

In

some

models

covered

inthis

manual,

ít

is

not

essen-

tial

to

remove

the

side-ímpact

airbag

to

access

internal

door

components

.

However,

the

procedure

is

recom-

mended

for

safety

reasons

.

5

.

Remove

retainer

clip

(early

models

only)

from

door

check

pin

on

body

pillar

.

Drive

out

door

check

pin

.

Refer

to

Fig

.

3

.

6

.

Remove

bolts

and

rubber

cover

fromdoor

check

lock-

plate

ondoor

.

7

.

Remove

door

check

from

inside

door

.

8

.

Installation

is

reverse

of

removal

.

"

Lubricate

door

check

before

installing

.

"

Use

new

mounting

bolts

when

reinstalling

the

side-im-

pact

airbag

to

thedoor(where

applicable)

.

"

If

battery

was

disconnected,

re-initialize

window

regu-

lator

motors

as

described

in

512

Door

Windows

.

Page 317 of 759

Door

Hinge

Adjustment

If

the

installed

door

is

uneven

or

out

of

parallel,

shims

can

be

used

to

correct

its

position

.

The

shims

are

placedbehind

the

hinge

plate

and

are

available

in

two

different

thicknesses

(0

.5

mm

and

1

.0

mm)

.

See

Fig

.

4

.

Tightening

Torque

"

Door

hinge

to

door

.............

..

21

Nm

(15

.5

ft-I

b)

"

Door

striker

to

door

...........

...

25

Nm

(18

ft-Ib)

DOOR

PANELS

0

l

o

0013102

Fig

.

4

.

Door

hinge

and

door

check

components

.

Front

and

rear

doors

are

similar

.

WARNING

-

Some

1997

and

all

1998

cars

are

fitted

with

side-im-

pact

airbags

in

the

front

doors

.

When

servicing

doors

on

cars

with

front

side-impact

airbags,

always

dis-

connect

the

negative

()

battery

terminal

.

See

721

Airbag

System

(SRS)

for

cautions

and

procedures

relating

to

the

airbag

system

.

Front

door

trimpanel,

removing

and

in-

stalling

1

.

On

cars

with

side-impact

airbags,

disconnect

negative

(-)

battery

cable

.

CAUTION

-

Prior

to

disconnecting

the

battery,

read

the

battery

disconnection

cautions

given

at

the

front

of

this

manual

on

page

viii

.

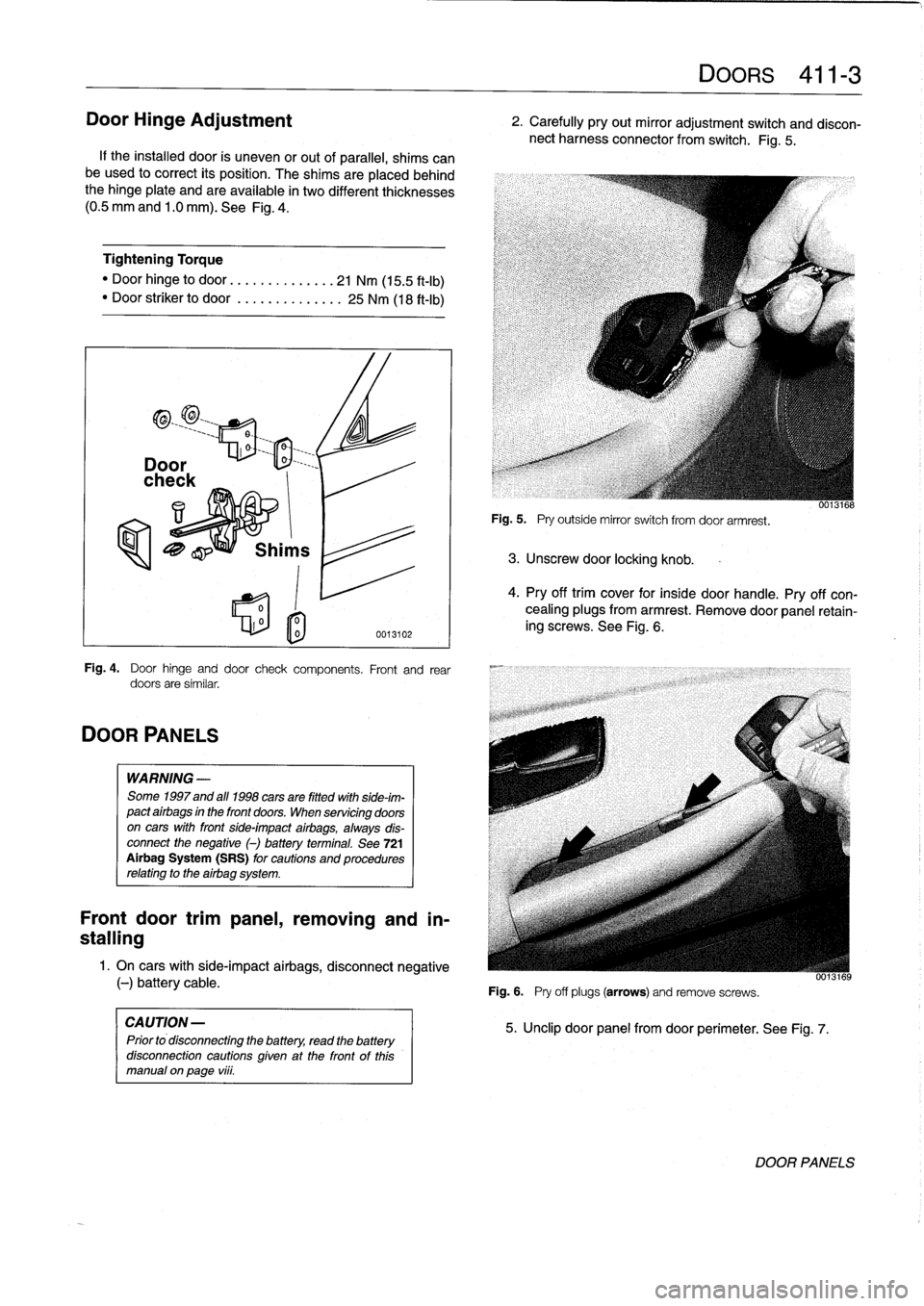

Fig

.

5

.

Pry

outside

mirror

switch

from

door

armrest

.

3

.

Unscrew

door

locking

knob

.

Fig

.

6

.

Pry

off

plugs

(arrows)

and

remove

screws

.

DOORS

411-

3

2

.

Carefully

pry

out

mirror

adjustment

switch

and

discon-

nect

harness

connector

from

switch

.

Fig

.

5

.

5

.

Unclip

door

panel

from

door

perimeter

.

See

Fig

.

7

.

0013168

4

.

Pry

off

trim

cover

for

insíde

door

handle

.

Pry

off

con-

cealing

plugs

from

armrest

.

Remove

door

panel

retain-

ing

screws

.

See

Fig

.

6

.

UU13169

DOOR

PANELS

Page 318 of 759

411-

4

DOORS

6

.

Disconnect

radio

speaker

harness

connector

.

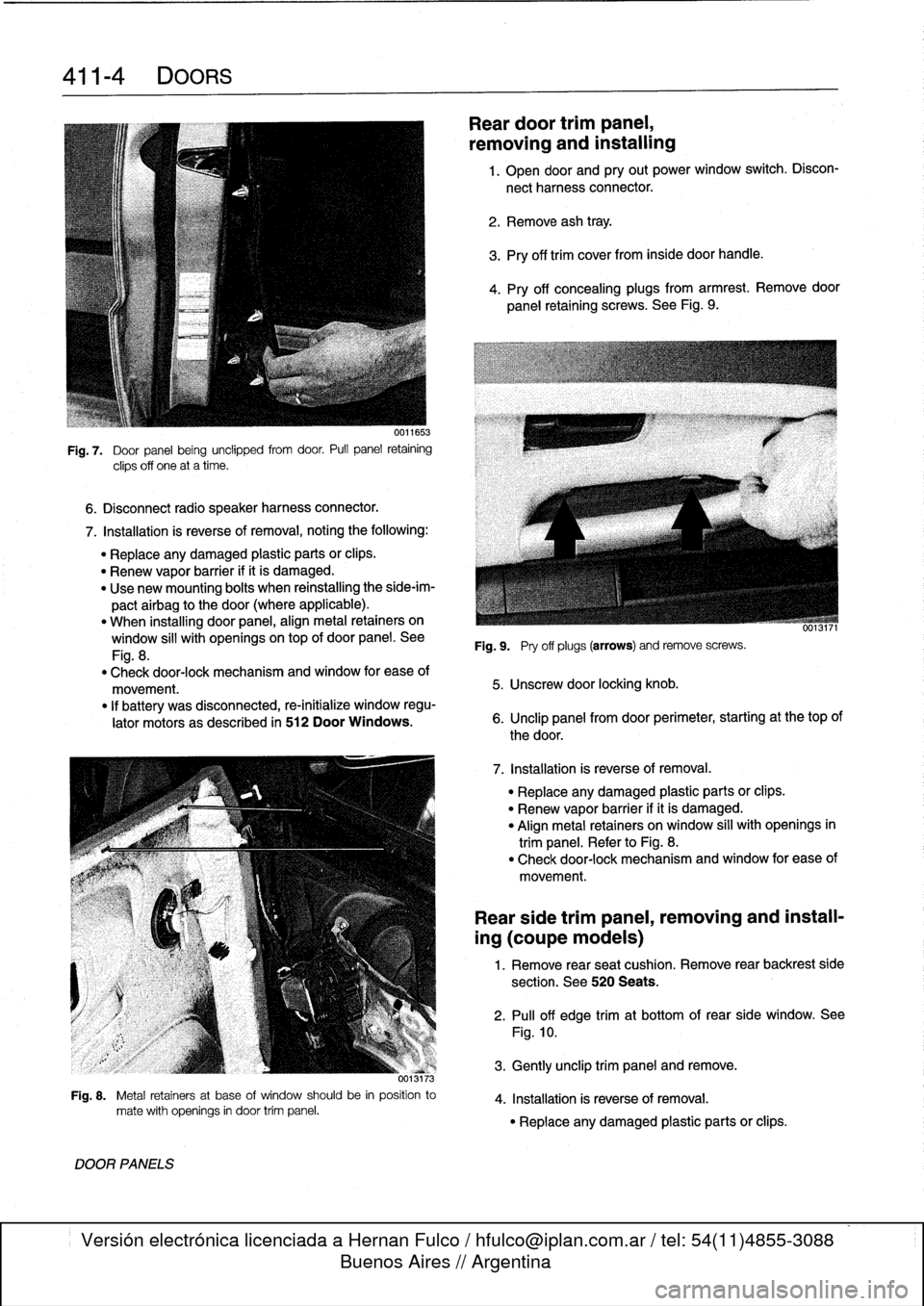

Fig

.

7

.

Door

panel

being

unclipped

from

door

.

Pull

panel

retaining

clips

off

one

at

a

time

.

7

.

Installation

is

reverse

of

removal,

noting

the

following

:

"

Replace

any

damaged

plastic

parts

orclips

.

"

Renew

vapor

barrier

ifit

is

damaged

.

"

Use

new

mounting

bolts

when

reinstalling

the

side-im-

pactairbag

to

the

door

(where

applicable)

.

"

When

installing

door

panel,

align

metal

retainers

on

window

sill

with

openingsontop

of

door

panel

.

See

Fig

.

8

.

"

Check

door-lock

mechanism

and

window

for

ease

of

movement

.

"

If

battery

was

disconnected,

re-initialize

window

regu-

lator

motors

as

described

in

512

Door

Windows

.

373

Fig

.

8

.

Metal

retainers

at

base

of

window

should

be

in

position

to

mate

with

openings

in

door

trim

panel

.

DOOR

PANELS

Reardoor

trimpanel,

removing

and

installing

1

.

Open

door

and

pry

out

power

window

switch

.

Discon-

nect

harness

connector

.

2

.

Remove

ash

tray

.

3

.

Pry

off

trim

cover

from

inside

door

handle

.

4

.

Pry

off

concealing

plugs

from

armrest

.

Remove

door

panel

retaining

screws

.

See

Fig

.

9

.

Fig

.

9

.

Pry

off

plugs

(arrows)

andremove

screws

.

5

.

Unscrew

door

locking

knob

.

6

.

Unclip

panel

from

door

perimeter,

starting

at

thetop

of

the

door

.

7

.

Installation

is

reverse

of

removal

.

"

Replace

any

damaged

plastic

parts

or

clips

.

"

Renew

vapor

barrier

ifit

is

damaged

.

"

Align

metal

retainers

on

window

sill

with

openings

in

trim

panel

.

Refer

to

Fig

.

8

.

"

Check

door-lock

mechanism

and

window

for

ease

of

movement

.

Rear

side

trim

panel,

removing

and

install-

ing

(coupe

models)

1

.

Remove

rear

seat

cushion

.

Remove

rear

backrest

side

section

.

See

520

Seats

.

2

.

Pull

off

edge

trimat

bottom

of

rear

side

window

.

See

Fig

.

10

.

3

.

Gently

unclip

trim

panel

andremove

.

4

.

Installation

is

reverse

of

removal

.

"

Replace

any

damaged

plastic

parts

or

clips

.

Page 328 of 759

510-

6

EXTERIOR

TRIM,

BUMPERS

Rear

bumper

impact

absorber,replacing

1

.

Remove

bumperas

described

above

.

2

.

Remove

luggage

compartment

floor

covering

.

Fig

.

13

.

Luggage

compartment

floor

panel

fasteners

(arrows)

.

(Left

side

shown

.

Righf

side

is

similar)

5

.

Installation

ís

reverse

of

removal

.

Bumper

height,

adjusting

Tightening

Torques

"

Bumper

bracket

to

impact

absorber

(M10

bolt)

.

............

.

...

..

..

.

42

Nm

(31

ft-lb)

"

Impact

absorber

to

chassis

(M8

nut)

.

.

..........

.

......

.

.

.

.

22

Nm

(16

ft-Ib)

The

adjustment

procedure

given

below

applies

to

either

the

frontor

rear

bumper

.

A

14mm

allen

socket

is

needed

to

make

the

adjustment

.

1

.

Raise

and

properly

support

vehicle

.

WARNING

-

Make

sure

that

the

car

is

firmly

supported

on

jack

stands

designed

for

the

purpose

.

Place

the

jack

stands

beneath

a

structural

chassis

point

.

Do

not

place

jack

stands

under

suspension

parts

.

2

.

Front

bumper

:

"

Remove

bumper

as

described

earlier

.

"

Remove

bumper

bracket

bolt

.

Refer

to

Fig

.

9

.

EXTERIOR

TRIM

3

.

Rear

bumper

:

"

Remove

lower

bumper

panel

as

described

in

Rear

bumper,

removing

and

installing

.

"

Remove

bumper

bracket

mounting

bolt

at

impact

ab-

sorber

.

3

.

Right

side

:

Remove

battery

and

battery

tray

.

4

.

Using

a

12-inch

extension

and

a

l4mm

Allen

socket,

turn

adjusting

collar

clockwise

or

counterclockwise

as

4

.

Remove

fasteners

from

left

or

right

luggage

compart-

needed

to

change

height

of

adjusting

collar

.

See

Fig

.

ment

floor

panels

and

lift

out

panel

.

See

Fig

.

13

.

Impact

14

.

absorber

mounting

nuts

can

now

be

accessed

.

~4

EXTERIOR

TRIM

Ratchet

extension

Adjusting

collar

Impact

absorber,

14

mm

Allen

Socket

Ratchet

0012073

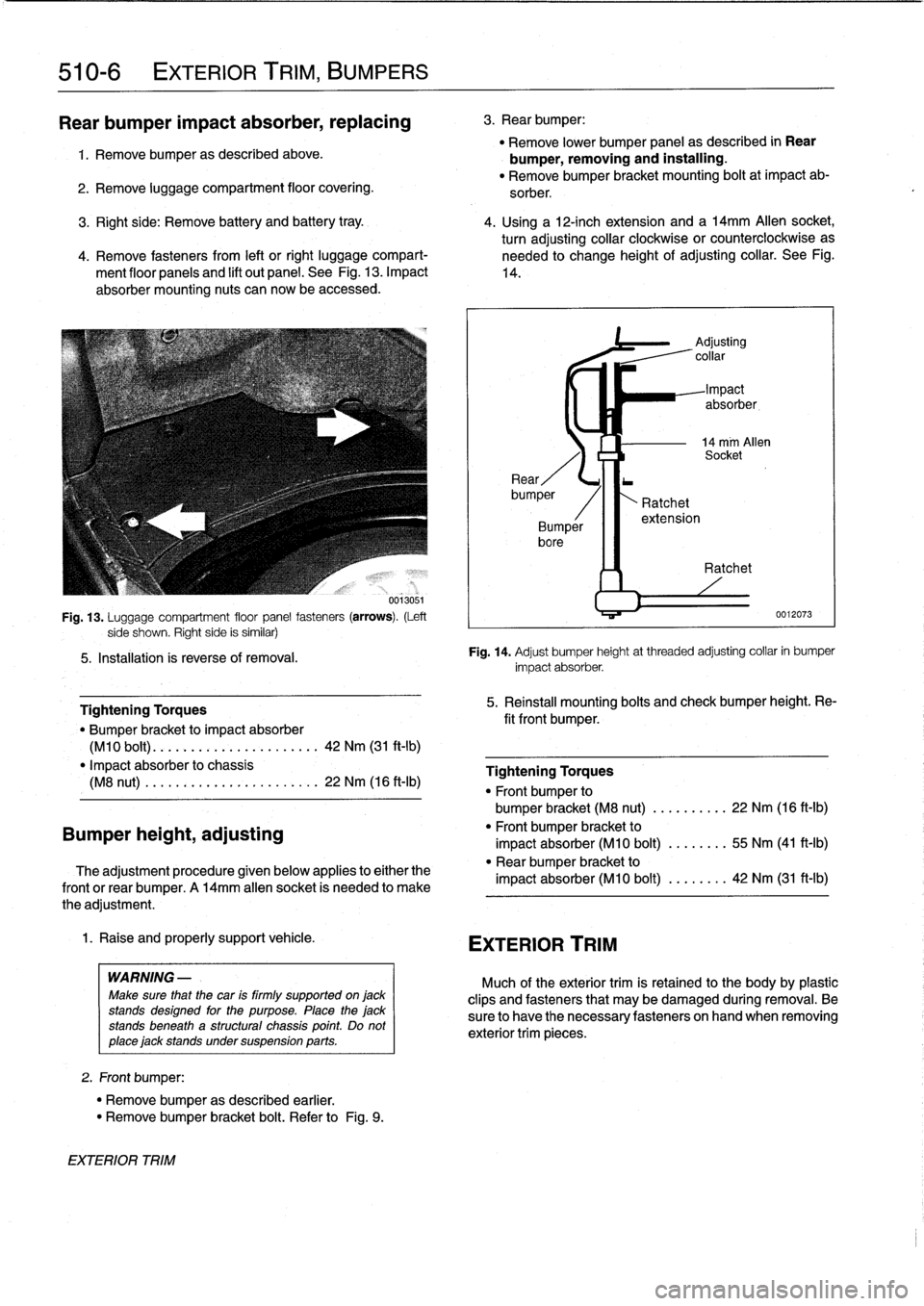

Fig

.

14

.

Adjust

bumper

height

at

threaded

adjusting

collar

in

bumper

impact

absorber

.

5

.

Reinstall

mounting

bolts

and

check

bumper

height

.

Re-

fit

front

bumper

.

Tightening

Torques

"

Front

bumper

to

bumper

bracket

(M8

nut)

......

.

..

.

22

Nm

(16

ft-Ib)

"

Front

bumper

bracket

to

impact

absorber

(M10

bolt)

........

55

Nm

(41

ft-Ib)

"

Rear

bumper

bracket

to

impact

absorber

(M10

bolt)

........

42

Nm

(31

ft-Ib)

Much

of

the

exteriortrim

is

retained

to

the

body

by

plasticclips

and

fasteners

that

may

be

damaged

during

removal

.

Be

sure

to

have

the

necessary

fasteners

onhand

when

removing

exterior

trim

pieces

.