engine BMW 325XI 2001 Workshop Manual

[x] Cancel search | Manufacturer: BMW, Model Year: 2001, Model line: 325XI, Model: BMW 325XI 2001Pages: 211, PDF Size: 2.1 MB

Page 169 of 211

169n

IndexDataTechnologyRepairsCar careControlsOverview

BatteryBattery careThe battery is absolutely maintenance-

free, that is, the original electrolyte will

normally last for the service life of the

battery under moderate climatic condi-

tions.

For all questions that regard the

battery, please consult your BMW

center. Since the battery is mainte-

nance-free, the following is for your

information only.

please comply with the corresponding

precautions whenever you work with or

near the battery.

Before handling the battery,

please read the following infor-

mation.

Wear eye protection. Do not

allow particles containing

battery acid or lead to come into

contact with your eyes, your skin, or

your clothing.

Battery acid is extremely corro-

sive. Wear eye protection and

protective gloves. Do not tip the

battery. Battery acid can leak from the

ventilation openings.

Do not allow children access to

batteries and battery acid.

Never allow sparks or open

flame in the vicinity of the

battery. Avoid sparks from elec-

trical cables or electrical equipment.

Turn the key to position 0 in the

steering lock when disconnecting or

connecting the battery. Do not short-

circuit the battery terminals. This

creates a risk of injury from high-energy

sparks.

A highly explosive gas is gener-

ated when the battery is charged.

If battery acid is splashed into

your eyes, immediately rinse

them with clear water for

15 minutes. Consult a physician imme-

diately. If your skin or clothing are

splashed by acid, rinse immediately

with ample clear water. If battery acid is

accidentally swallowed, consult a

physician immediately.

In order to protect the battery

case from ultraviolet radiation,

do not place it in direct sunlight.

A discharged battery can freeze. Store

the battery in areas where temperature

remains above freezing.

Removal and installation

Do not disconnect the battery

when the engine is running. If you

do so, the ensuing voltage surge will

damage the vehicle's onboard elec-

tronics.

Do not make any modifications in the

wires to the positive terminal. If you do

so, the protective function of the safety

battery terminal is no longer ensured.

Repair and disposal must be performed

by trained technicians only.<

When removing the battery, disconnect

the cable on the negative terminal first,

then the cable on the positive terminal.

Loosen the center adjusting screw on

the battery retaining strap (use the

screwdriver included with the onboard

tool kit) and disconnect the strap.

When installing a battery, connect the

positive terminal first, then connect the

negative terminal.

When installing a battery, be sure

that it is mounted properly and

that the retaining bracket is installed

with the center adjustment screw. If this

is not done, the battery will not be

adequately secured in case of an acci-

dent.<

Page 170 of 211

170n

Battery FusesCharging the battery Charge the battery in the vehicle only

when the engine is not running.

Before doing any work on the elec-

trical system, be sure to unclamp

the cable from the battery's negative

terminal. Failure to do so can result in

short-circuits, a fire or personal injury.<

If the vehicle is to be parked longer than

four weeks, disconnect the battery from

the vehicle's electrical system by

disconnecting the negative terminal

cable and then recharge using a suit-

able charging device.

If you intend to store your vehicle for

longer than twelve weeks: remove the

battery, charge it and store it in a cool

(but frost-and dust-free) room. Every

three months and before reinstalling the

battery, have it recharged. If it is not

recharged, it will not be serviceable.

Every time the battery is discharged,

especially over extended periods, its

service life is reduced.

Return used batteries to a recy-

cling center or your BMW center.

Maintain the battery in an upright posi-

tion for transport and storage. Secure

the battery to prevent it from tilting

during transport.<

Storage periods during which the

battery is disconnected are not

taken into consideration by the Service

Interval Display for changing the brake

fluid.

For this reason, be sure that the brake

fluid is changed every two years,

regardless of the information displayed.

Read and comply with the information

on page 143 covering this subject.<

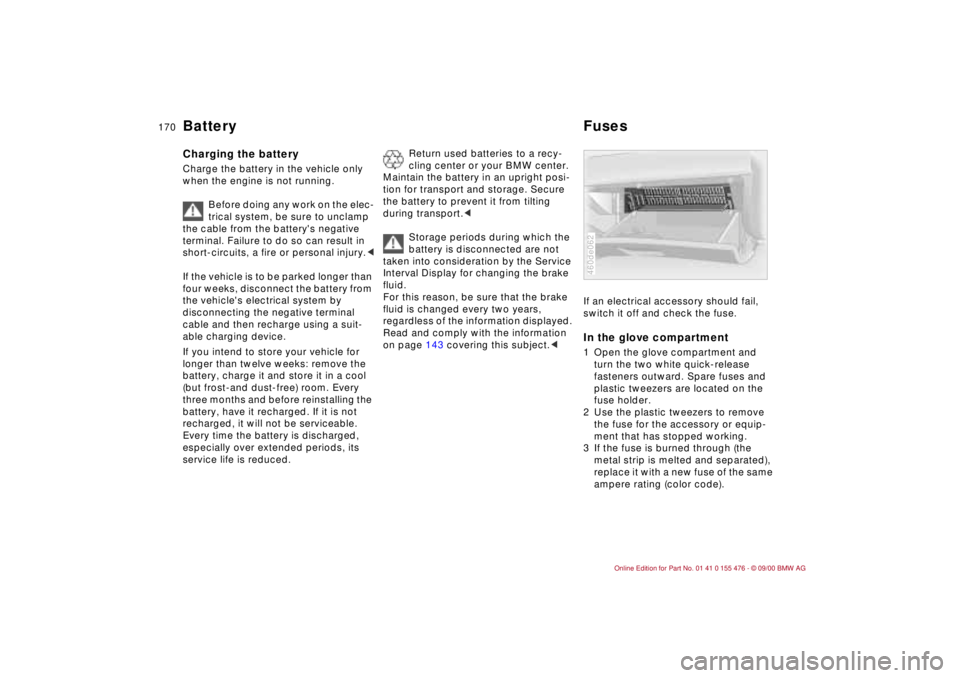

If an electrical accessory should fail,

switch it off and check the fuse. In the glove compartment1 Open the glove compartment and

turn the two white quick-release

fasteners outward. Spare fuses and

plastic tweezers are located on the

fuse holder.

2 Use the plastic tweezers to remove

the fuse for the accessory or equip-

ment that has stopped working.

3 If the fuse is burned through (the

metal strip is melted and separated),

replace it with a new fuse of the same

ampere rating (color code).460de062

Page 173 of 211

173n

IndexDataTechnologyRepairsCar careControlsOverview

Do not use spray starter fluids.

If the battery is discharged, the engine

can be started with the use of two

jumper cables and the battery of

another vehicle. Use only jumper cables

with fully insulated grips on the terminal

clamps.

Do not touch the parts conducting

electrical current while the engine

is running. Failure to comply with this

creates a risk of fatal injury.<

Carefully comply with the following

instructions to avoid personal injury or

damage to one or both vehicles:

1 Be sure that the battery on the

support vehicle is also rated at

12 volts, and that the capacities of

the two batteries (Ah) are roughly

comparable (printed on casing)

2 Leave the discharged battery

connected to the vehicle's electrical

system

3 Make sure that there is no contact

between the bodywork of the two

vehicles Ð this creates a risk of short

circuits

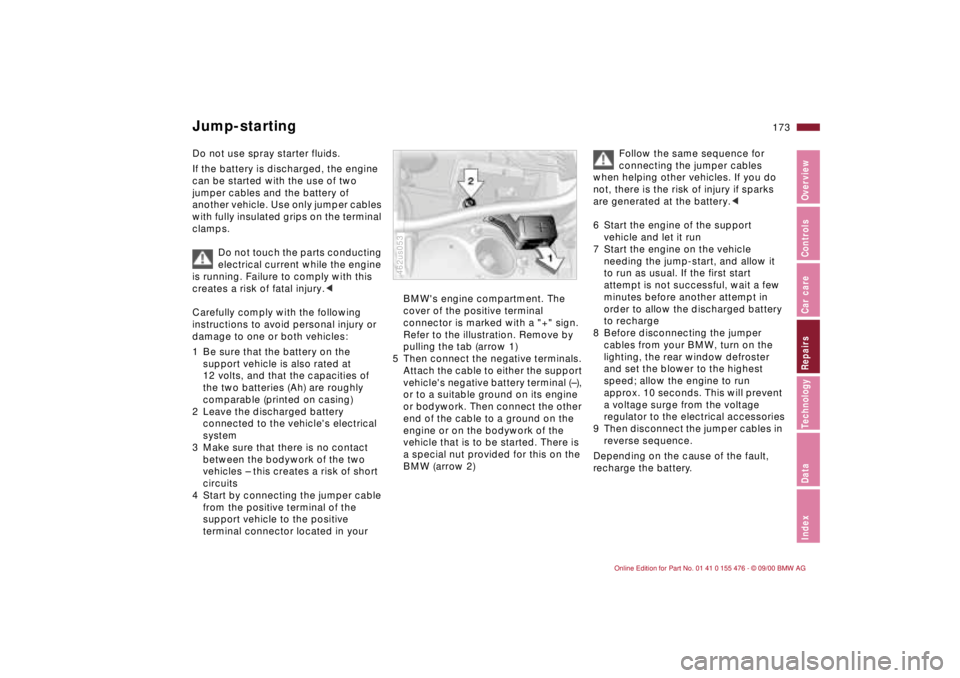

4 Start by connecting the jumper cable

from the positive terminal of the

support vehicle to the positive

terminal connector located in your

BMW's engine compartment. The

cover of the positive terminal

connector is marked with a "+" sign.

Refer to the illustration. Remove by

pulling the tab (arrow 1)

5 Then connect the negative terminals.

Attach the cable to either the support

vehicle's negative battery terminal (Ð),

or to a suitable ground on its engine

or bodywork. Then connect the other

end of the cable to a ground on the

engine or on the bodywork of the

vehicle that is to be started. There is

a special nut provided for this on the

BMW (arrow 2)462us053

Follow the same sequence for

connecting the jumper cables

when helping other vehicles. If you do

not, there is the risk of injury if sparks

are generated at the battery.<

6 Start the engine of the support

vehicle and let it run

7 Start the engine on the vehicle

needing the jump-start, and allow it

to run as usual. If the first start

attempt is not successful, wait a few

minutes before another attempt in

order to allow the discharged battery

to recharge

8 Before disconnecting the jumper

cables from your BMW, turn on the

lighting, the rear window defroster

and set the blower to the highest

speed; allow the engine to run

approx. 10 seconds. This will prevent

a voltage surge from the voltage

regulator to the electrical accessories

9 Then disconnect the jumper cables in

reverse sequence.

Depending on the cause of the fault,

recharge the battery.

Jump-starting

Page 175 of 211

175n

IndexDataTechnologyRepairsCar careControlsOverview

Towing the vehicleBMW 325xi, 330xi: towing the

vehicle with one raised axle only 1 Place the gearshift lever or selector

lever in "Neutral"

2 Switching off the engine

3 Towing speed:

Max. 30 mph (50 km/h)

4 Towing distance:

Max. 95 miles (150 km)

Remove the rear driveshaft for

towing over longer distances with

the front axle lifted; remove the front

driveshaft for towing over longer

distances with the rear axle lifted.

Failure to comply with this will result in

damage to the transfer box.<

Page 178 of 211

178n

On vehicles with an automatic trans-

mission, the ATC (Adaptive Transmis-

sion Control) uses a number of factors

to calculate the gear which provides the

maximum efficiency. In this process, it

considers your individual driving style

as well as current driving conditions.

ATC recognizes your personal driving

style from the positions and movements

of the accelerator pedal, deceleration

when braking, and lateral acceleration

through curves. Based on different shift

characteristics Ð from comfort-oriented

to performance-oriented Ð ATC will

select the appropriate gear.

460us173

In order to include driving conditions in

its calculations, ATC registers curves

and both uphill and downhill gradients.

For example, if you maintain speed

through a curve, the transmission does

not shift up. On uphill gradients, it shifts

up only when the engine speed

increases in order to make more effi-

cient use of power reserves. On down-

hill gradients, ATC shifts down when

the speed of the vehicle increases and

the driver must apply the brakes.

ATC

*

Page 180 of 211

180n

ASC+T/DSC

*

Highly sensitive sensors monitor the

number of revolutions of the wheels.

When equipped with DSC, they also

monitor steering angle, lateral accelera-

tion, brake pressure and the movement

of the vehicle around its vertical axis.

If differences in the wheel speeds occur,

ASC+T counteracts the danger of

wheelspin by reducing engine torque; if

necessary, ASC will also respond by

applying the brakes to the rear wheels.

In addition, DSC permanently monitors

the vehicle's current operating condition

and compares it with an ideal condition

that is calculated from the sensor's

signals. If deviations from this occur

(understeering or oversteering, for

instance), DSC can stabilize the vehicle

in fractions of a second by reducing

engine output and with the assistance of

braking intervention at individual

wheels. As a result, dangerous skids can

be prevented even as they are just

beginning, but only within the laws of

physics.

You may need some time to become

accustomed to this system's interven-

tion. However, it provides optimum

drive force and driving stability.

The braking intervention may be

accompanied by sounds specific to the

system.

Page 182 of 211

182n

Four-wheel driveThe transmission of power to the four

drive wheels is provided permanently

through a transfer box. The distribution

of torque between the front and rear

axles is 38% to 62%.

Traditional differential locks at the front

and rear axles and in the transfer box

are not required. Their function is taken

over by automatic braking intervention

at all four wheels. These traction inter-

ventions are governed by Automatic

Differential Brake (ADB-X), a sub-func-

tion of DSC.

If a wheel tends to slip, it is braked

automatically by ADB-X until it once

again gains traction, and drive force

can be transmitted to that wheel. In

addition, the drive force is distributed to

the remaining wheels during this 530us133

system intervention. Engine output is

also reduced if necessary.

When the DSC is deactivated, the

ADB-X traction intervention is set for

the maximum drive force. However, the

engine intervention and the stability

controls are no longer available. For

this reason, DSC should only be deacti-

vated in the exceptional circumstances

described on page 84.

The BMW 325xi and 330xi are not

intended for off-road operation. But the

permanent four-wheel drive provides a

high degree of driving stability and trac-

tion on all road conditions and surfaces.

It supports you in critical driving condi-

tions, e.g. in extreme winter conditions

or on loose road surfaces.

Page 187 of 211

187n

IndexDataTechnologyRepairsCar careControlsOverview

Self-diagnostics All of the important electrical and elec-

tronic systems in the vehicle are tested

regularly and automatically Ð the driver

does not have to perform any extra

operations or adjustments.

The indicator lamps also come on

briefly after the ignition has been turned

on.

While you are driving, the functional

status of the actuator motors (for the

windshield wipers, power windows,

seats, sliding/tilt sunroof, etc.) is

constantly analyzed by current

measurements in their relays.460de177

In the same manner, the electrical

resistance of the airbag ignition genera-

tors and all of the remaining airbag

components is measured at all times.

Any fault in this system would be

detected immediately by a current fluc-

tuation that would necessarily accom-

pany it. The fault would be indicated

immediately by the airbag warning

lamp.

Even after you shut off the engine, the

overall functional status of your vehicle

is monitored. For example, all of the

flaps of the heating and ventilation

system travel to the nearest limit posi-

tion. This ensures that the defrost func-

tion is always available even if a

malfunction in the air conditioner

system/automatic climate control

should occur while the vehicle is

parked overnight, for instance.

A calibration cycle runs every tenth time

the engine is shut off. During this cycle,

the actuator motors of all the heating

and ventilation flaps travel to their limit

stops in both directions. The limit posi-

tions and the return travel paths are

checked in this manner in order to

ensure that appropriate adjustments for

the operating elements can be made at

any time.You will hear the sounds of the air flaps

as the air conditioning system/auto-

matic climate control carry out their

self-diagnostic functions after the igni-

tion has been turned off. All of the other

self-diagnostics functions operate

silently in the background.

Any possible faults detected during

these self-diagnostics can be read out

by your BMW center during the next

regularly-scheduled maintenance and

corrected with a minimum of time.

Page 191 of 211

Overview

Controls and features

Operation, care

and maintenance

Technical data

Index Advanced technology

191n

IndexDataTechnologyRepairsCar careControlsOverview

Engine data192

Dimensions193

Weights194

Capacities195

Electrical system196

V-belts196

Data

Owner service procedures

Page 192 of 211

192n

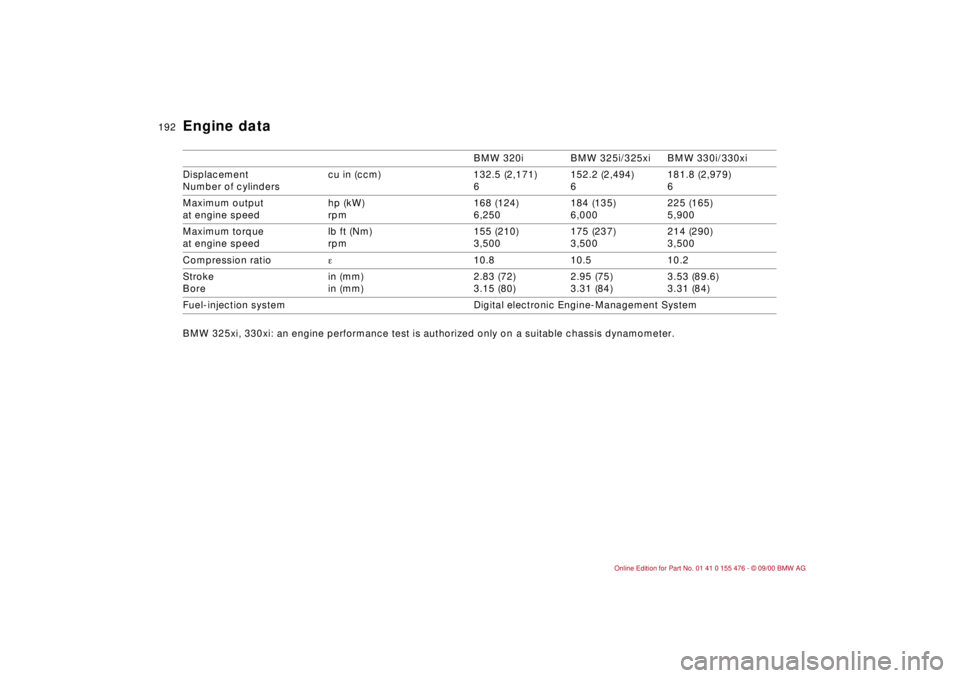

BMW 320i BMW 325i/325xi BMW 330i/330xi

Displacement

Number of cylinders cu in (ccm) 132.5 (2,171)

6152.2 (2,494)

6181.8 (2,979)

6

Maximum output

at engine speed hp (kW)

rpm168 (124)

6,250184 (135)

6,000225 (165)

5,900

Maximum torque

at engine speedlb ft (Nm)

rpm155 (210)

3,500175 (237)

3,500214 (290)

3,500

Compression ratioe

10.8 10.5 10.2

Stroke

Borein (mm)

in (mm)2.83 (72)

3.15 (80)2.95 (75)

3.31 (84)3.53 (89.6)

3.31 (84)

Fuel-injection system Digital electronic Engine-Management System

BMW 325xi, 330xi: an engine performance test is authorized only on a suitable chassis dynamometer.

Engine data