engine mount BMW 328i 1997 E36 Workshop Manual

[x] Cancel search | Manufacturer: BMW, Model Year: 1997, Model line: 328i, Model: BMW 328i 1997 E36Pages: 759

Page 450 of 759

640-4

HEATING

AND

AIR

CONDITIONING

Heater

box,

removing

and

installing

The

heater

box,

located

underneath

thecenter

of

the

dash-

board,

houses

theheater

core,

the

A/C

evaporator,

and

asso-

ciated

sensors

and

actuators

.

Removal

of

theheater

box

requires

that

the

A/C

refrigerant

be

discharged

.

CAUTION-

"

Removing

the

heater

box

requires

evacuating

the

AIC

system

.

DO

NOT

attempt

this

procedure

without

proper

tools

and

training

.

"

Any

person

who

services

a

motor

vehicle

air

con-

ditioner

must,

by

law,

be

properly

trained

and

cer-

tified,

and

use

approved

refrigerant

recycling

equipment

.

Technicians

must

complete

an

EPA-

approved

recycling

course

to

be

certified

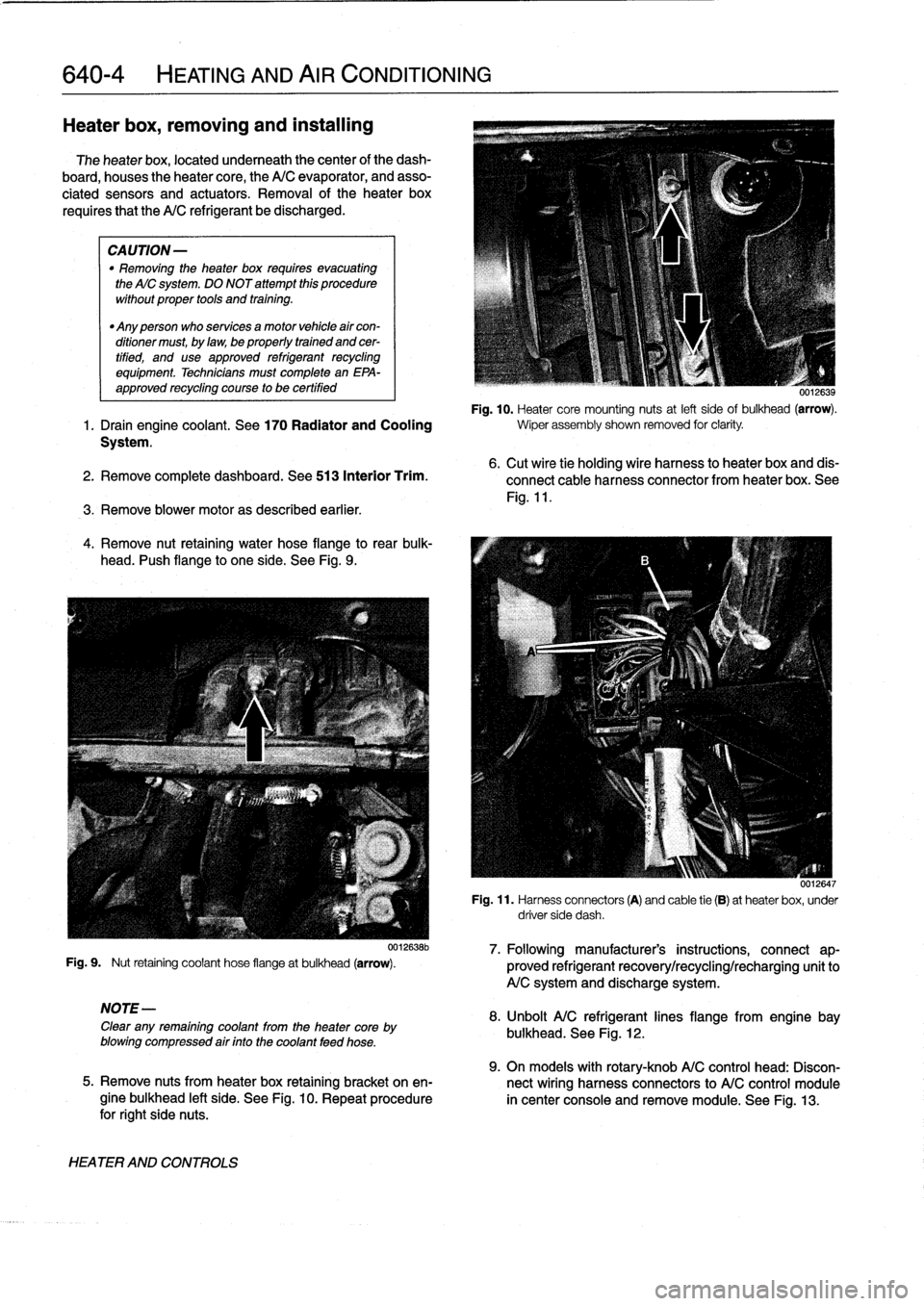

UU12639

Fig

.

10

.

Heater

core

mounting

nuts

at

left

sideof

bulkhead

(arrow)

.

1

.

Drain

engine

coolant

.

See

170

Radiator

and

Cooling

wiper

assembly

shown

removed

for

clarity

.

System

.

2

.

Remove

complete

dashboard

.

See513

Interior

Trim

.

3

.

Remove

blower

motoras

described

earlier

.

4

.

Remove

nut

retaining

water

hose

flange

to

rear

bulk-

head

.

I'ush

flange

to

one

side

.

See

Fig

.

9

.

Fig

.

9

.

Nut

retaining

coolant

hose

flangeat

bulkhead

(arrow)

.

NOTE-

Clear

any

remaining

coolant

from

the

heater

core

by

blowing

compressed

air

finto

the

coolant

feed

hose

.

HEATER

AND

CONTROLS

0012638b

6

.

Cut

wire

tie

holding

wire

harness

to

heater

box

and

dis-

connect

cable

harness

connector

from

heater

box

.

See

Fig

.

11

.

0012647

Fig

.

11

.

Harness

connectors

(A)

and

cable

tie

(B)

at

heaterbox,

under

driver

side

dash

.

7

.

Followingmanufacturer's

instructions,

connect

ap-

proved

refrigerant

recovery/recycling/recharging

unitto

A/C

system

and

discharge

system

.

8

.

Unbolt

A/C

refrigerantlines

flange

from

engine

bay

bulkhead

.

See

Fig

.

12

.

9

.

On

models

with

rotary-knob

A/C

control

head

:

Discon-

5

.

Remove

nuts

from

heater

box

retaining

bracket

on

en-

nect

wiring

harness

connectors

to

A/C

control

module

gine

bulkhead

left

side

.

See

Fig

.

10

.

Repeat

procedure

in

center

console

and

remove

module

.

See

Fig

.

13

.

for

right

side

nuts

.

Page 456 of 759

640-10

HEATING

AND

AIR

CONDITIONING

i

El

Radio

Antenna

Rear

.

,

si,-

Left

side

I

d

1

.

Rear

vents

2

.

Fresh

air

3

.

Face-level

vents

4

.

Recirculation

5

.

Footwell

vents

0013017

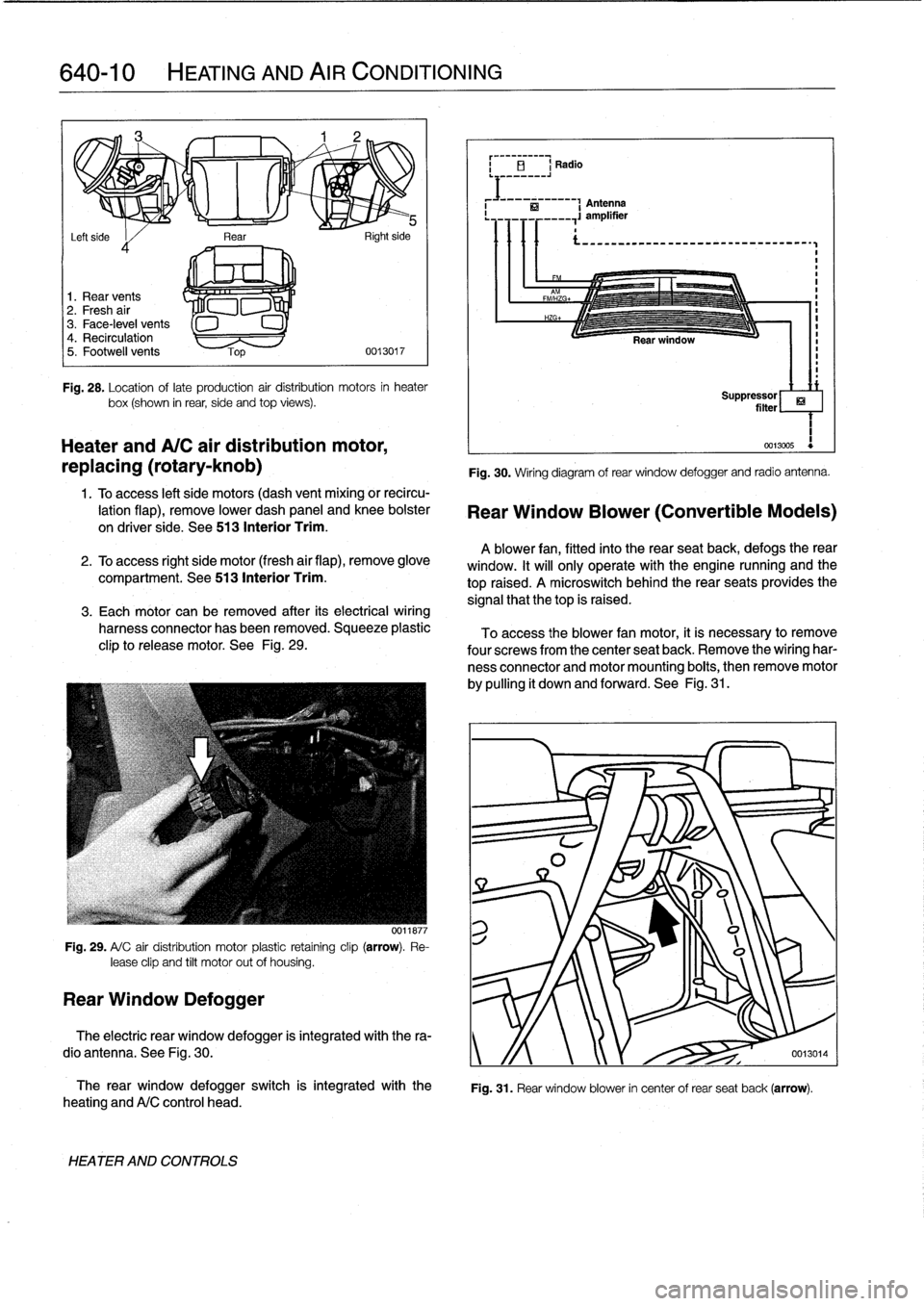

Fig

.

28

.

Location

oflate

production

air

distribution

motors

in

heater

box(shown

in

rear,

side

and

top

views)

.

Heater

andA/C

air

distribution

motor,

replacing

(rotary-knob)

1

.

Toaccess

left

side

motors

(dash

vent

mixing

or

recircu-

lation

flap),

remove

lower

dash

panel

and

knee

bolster

on

driver

side

.

See

513

Interior

Trim

.

2

.

To

access

right

side

motor

(fresh

air

flap),

remove

glove

compartment

.

See513

Interior

Trim

.

3

.

Each

motor

can

be

removed

after

its

electrical

wiring

harness

connector

has

been

removed

.

Squeeze

plastic

clip

to

release

motor

.

See

Fig

.

29

.

Fig

.

29

.

A/

C

air

distribution

motor

plastic

retaíning

clip

(arrow)

.

Re-

lease

clip

and

tilt

motor

out

of

housing

.

Rear

Window

Defogger

0011877

The

rear

window

defogger

switch

is

integrated

with

the

heating

andA/C

control

head

.

HEATER

AND

CONTROLS

Fig

.

30

.

Wiring

diagram

of

rear

window

defogger

and

radio

antenna

.

Rear

Window

Blower

(Convertible

Models)

A

blower

fan,

fitted

into

the

rear

seatback,

defogs

therear

window

.

It

will

only

operate

with

the

engine

nunning

and

the

top

raised

.

A

microswitch

behindthe

rear

seats

provides

the

signal

that

thetop

is

raised

.

To

access

the

blower

fan

motor,

it

is

necessary

to

remove

four

screwsfrom

the

center

seat

back

.

Remove

the

wiring

har-

ness

connector

and

motor

mounting

boits,

then

remove

motor

by

pulling

it

down

and

forward

.

See

Fig

.

31

.

ri

Suppressor

filter

1

0013005

Fig

.

31

.

Rear

window

blower

in

center

of

rear

seat

back

(arrow)

.

The

electric

rear

window

defogger

is

integrated

with

the

ra-

dio

antenna

.

See

Fig

.

30

.

y

/f

0013014

Page 459 of 759

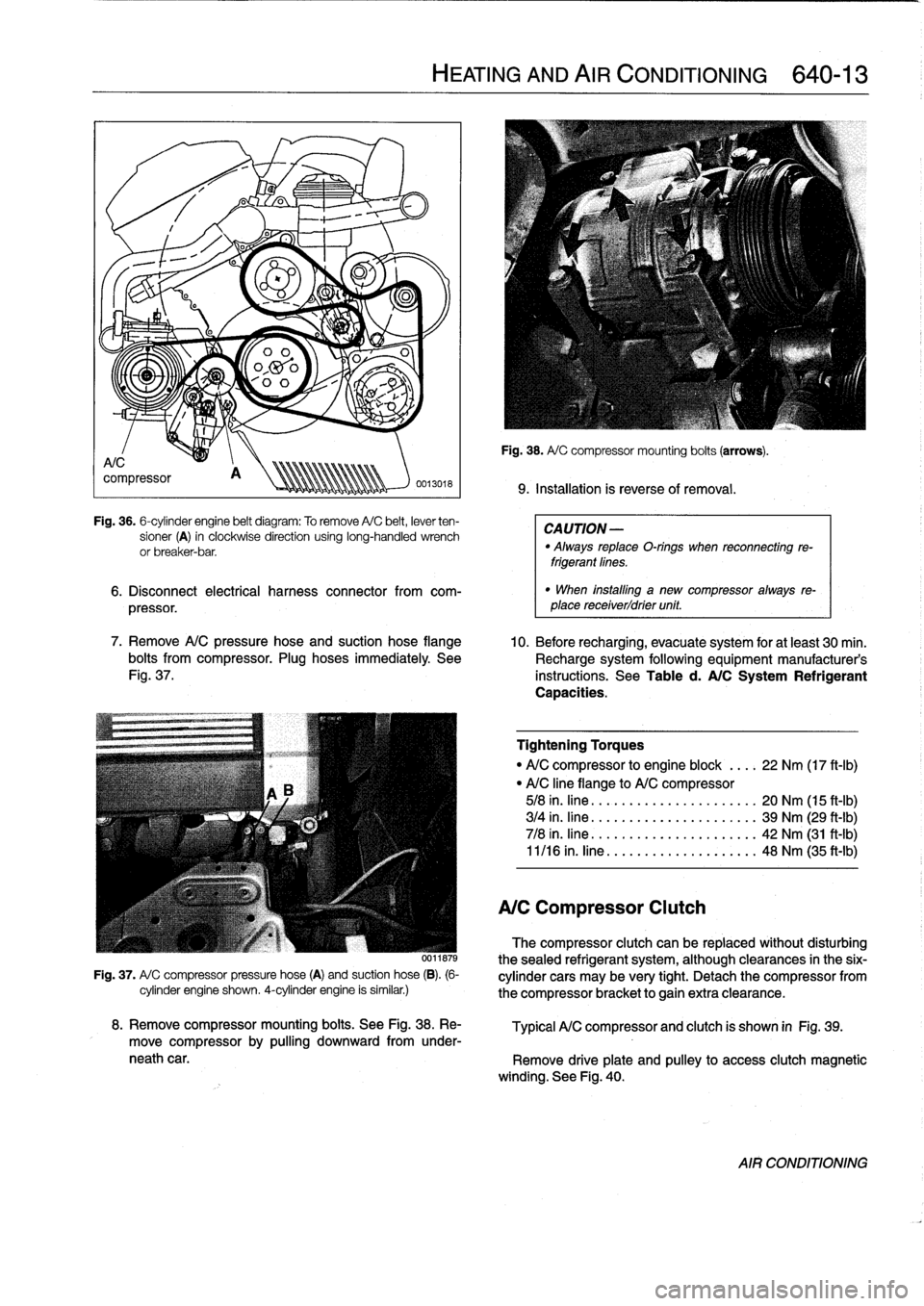

Fig

.

36

.

6-cylinder

engine

belt

diagram

:

To

remove

A/C

belt,

lever

ten-

sioner

(A)

in

clockwise

direction

using

long-handled

wrench

or

breaker-bar

.

6

.

Disconnect

electrical

harness

connector

from

com-

pressor

.

7

.

Remove

A/C

pressure

hose

and

suction

hose

flange

10

.

Before

recharging,

evacuate

system

for

at

least

30

min

.

bolts

from

compressor

.

Plug

hoses

immediately

See

Recharge

system

following

equipment

manufacturer's

Fig

.

37

.

instructions

.

See

Table

d

.

A/C

System

Refrigerant

Capacities

.

0011879

Fig

.

37

.

A/

C

compressor

pressure

hose

(A)

and

suction

hose

(B)

.

(6-

cylinder

engine

shown

.

4-cylinder

engine

is

similar

.)

HEATING

AND

AIR

CONDITIONING

640-

1

3

Fig

.

38

.

A/

C

compressor

mounting

boits

(arrows)

.

9

.

Installation

is

reverseof

removal

.

CAUTION

-

"

Always

replaceO-rings

when

reconnecting

re-

frigerantfines

.

"

When

installlng

a

new

compressor

always

re-

place

receiverldrier

unit

.

Tightening

Torques

"

A/C

compressor

to

engine

block

....

22

Nm

(17

ft-Ib)

"

A/C

line

flange

to

A/C

compressor

5/8

in

.

fine

.

......

.....

....

.

.....

20

Nm

(15

ft-Ib)

3/4

in

.

fine

.......

.....

..........

39

Nm

(29

ft-Ib)

7/8

in

.

fine

...

....

.....

..........

42

Nm

(31

ft-Ib)

11/16

in

.

fine

.....

..

..

..

...

.

.....

48

Nm

(35

ft-Ib)

A/C

Compressor

Clutch

The

compressor

clutch

can

be

replaced

without

disturbing

thesealed

refrigerant

system,

although

clearances

in

the

six-

cylinder

cars

may

be

very

tight

.

Detach

the

compressor

from

the

compressor

bracket

togain

extra

clearance

.

8

.

Remove

compressor

mounting

boits

.

See

Fig

.

38

.

Re-

Typical

A/C

compressor

and

clutch

is

shown

in

Fig

.

39

.

move

compressor

by

pulling

downward

from

under-

neath

car

.

Remove

driveplate

and

pulley

to

access

clutch

magnetic

winding

.

See

Fig

.

40

.

AIR

CONDITIONING

Page 461 of 759

Fig

.

42

.

Upper

A/C

condensermounting

bolts

(arrows)

.

8

.

Before

recharging,

evacuate

system

for

at

least

30

min

.

Recharge

system

following

equipment

manufacturer's

instructions

.

See

Table

d

.

A/C

System

Refrigerant

Capacities

.

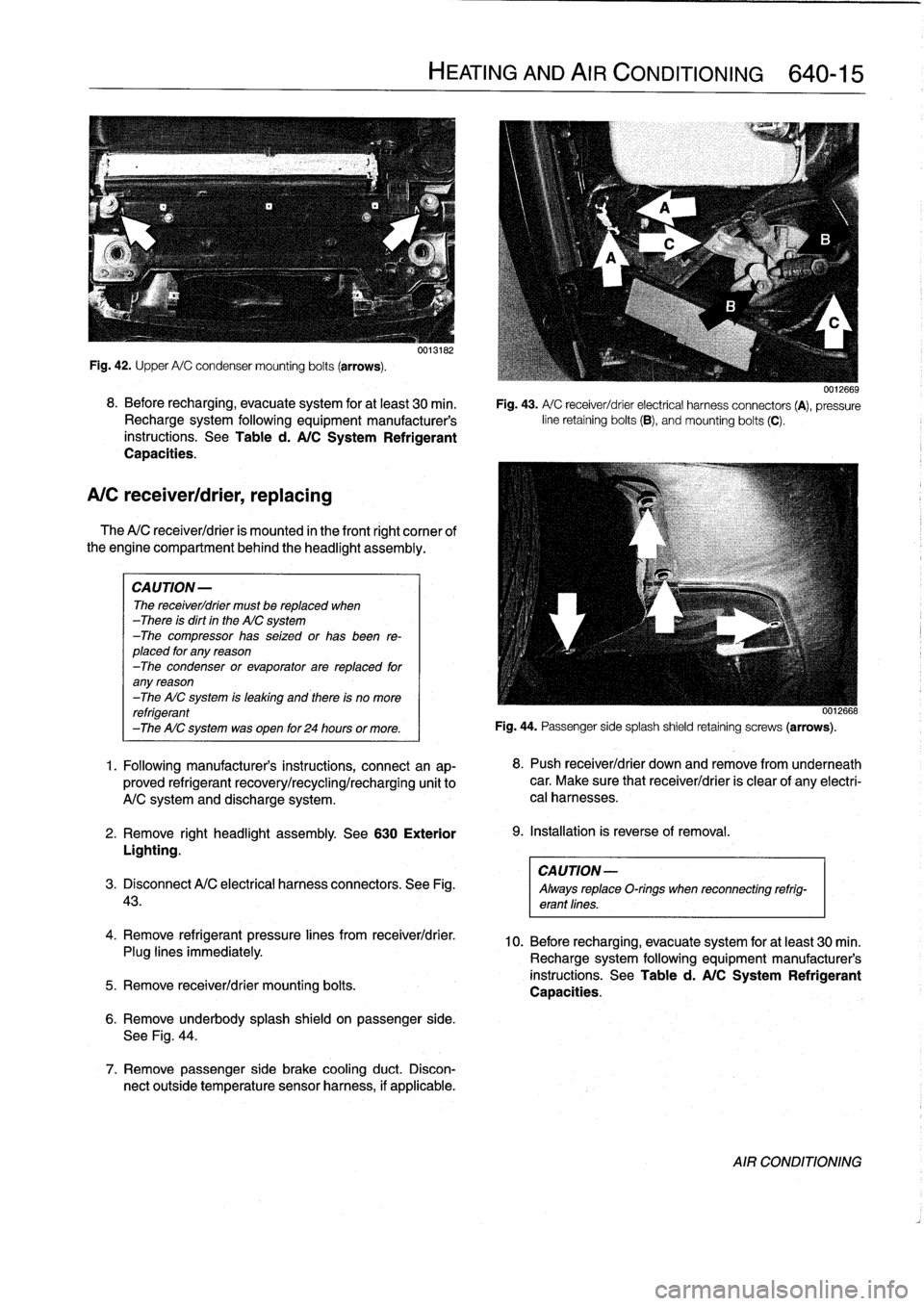

A/C

receiver/drier,

replacing

The

A/C

receiver/drier

is

mounted

in

the

front

right

cornee

of

the

engine

compartment

behind

the

headlight

assembly

.

CAUTION-

The

receiver/drier

must

be

replaced

when

-There

is

dirt

in

the

AIC

system

-The

compressor

has

seized

or

has

been

re-

placed

for

any

reason

-The

condenser

or

evaporator

are

replaced

for

any

reason

-The

AIC

system

is

leaking

and

there

is

no

more

refrigerant

-The

AIC

system

was

open

for

24

hours

or

more

.

1

.

Following

manufacturer's

instructions,

connectan

ap-

proved

refrigerant

recovery/recycling/recharging

unit

to

A/C

system

and

discharge

system

.

2

.

Remove

right

headlight

assembly

.

See

630

Exterior

Lighting

.

CAUTION-

3

.

Disconnect

A/C

electrical

harness

connectors

.

See

Fig

.

Always

replaceO-rings

when

reconnecting

refrig-

43

.

erant

lines

.

4

.

Remove

refrigerant

pressure

lines

from

receiver/drier

.

Plug

lines

immediately

.

5

.

Remove

receiver/drier

mounting

bolts

.

0013182

6

.

Remove

underbody

splash

shield

on

passenger

side

.

See

Fig

.

44

.

7

.

Remove

passenger

side

brake

cooling

duct

.

Discon-

nect

outside

temperature

sensor

harness,

if

applicable

.

HEATING

AND

AIR

CONDITIONING

640-15

0012669

Fig

.

43

.

A/

C

receiver/drier

electrical

harness

connectors

(A),

pressure

line

retaining

bolts

(B),

andmounting

bolts

(C)

.

0012668

Fig

.

44

.

Passenger

sidesplash

shield

retaining

screws

(arrows)

.

8

.

Push

receiver/drier

down

andremove

from

underneath

car

.

Make

sure

that

receiver/drier

is

clear

of

any

electri-

cal

harnesses

.

9

.

Installation

is

reverse

of

removal

.

10

.

Before

recharging,

evacuate

system

for

at

least

30

min

.

Recharge

system

following

equipment

manufacturer's

instructions

.

See

Table

d

.

A/C

System

Refrigerant

Capacities

.

AIR

CONDITIONING

Page 480 of 759

721-

4

AIRBAG

SYSTEM

(SRS)

CAUTION-

A

new

contact

ring

is

held

in

center

position

with

a

screw

.

This

locking

device

must

be

removed

after

contact

ring

is

installed

on

steering

wheel

.

See

Fig

.

4

.

Latercars

(1994

on)

:

"

Connect

ground

lead

at

contact

ring

.

"

When

installing

a

new

contact

ring

from

BMW,

remove

locking

pin

after

installing

contact

ring

to

steering

wheel

.

See

Fig

.

5

.

Airbag

crash

sensor,

replacing

Fig

.

5

.

Airbag

contact

ring

locking

pin

(arrows),

as

installed

on

new

replacement

part

from

BMW

(later

production

cars)

.

Contact

ring

mountíng

screws

shown

at

A

.

CAUTION-

Anew

contact

ring

is

held

in

center

position

with

a

screw

or

pin

.

This

locking

device

mustbe

removed

after

contact

ring

is

installed

on

steering

wheel

.

See

Fig

.

5

.

The

airbag

system

in

cars

produced

through

1993

uses

two

crash

sensors

mounted

in

the

engine

compartment

on

the

left

and

right

wheel

arches

.

The

sensors

are

identified

by

their

or-

ange

color

.

WARNING

-

If

en

airbag

is

deployed,

both

sensors

must

be

re-

placed

.

1

.

Disconnect

negative

(-)

cable

from

battery

and

cover

negative

terminal

with

insulating

material

.

CAUTION-

Prior

to

disconnectiog

the

battery,

read

the

battery

disconnection

cautíons

given

at

the

front

of

thls

manual

on

page

viii

.

AIRBAG

SENSORS

AND

ELECTRONICS

2

.

Remove

lower

steering

column

trim

mounting

screw

and

remove

lower

trim

.

See

Fig

.

6

.

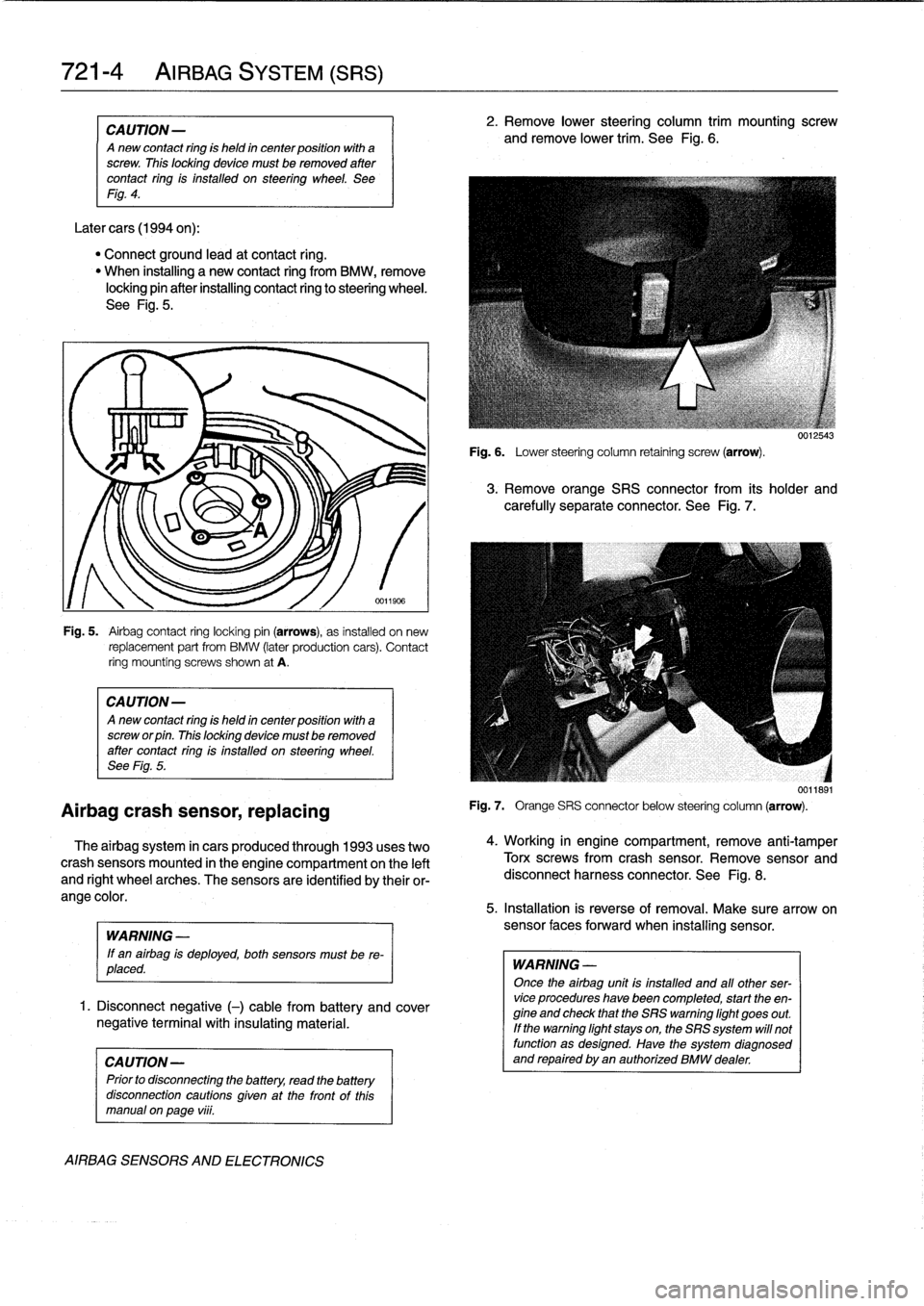

Fig

.

6

.

Lower

steering

column

retaining

screw

(arrow)

.

3

.

Remove

orange

SRS

connector

from

its

holder

and

carefully

separate

connector

.

See

Fig

.

7

.

Fig

.

7

.

Orange

SRS

connector

below

steering

column

(arrow)

.

4

.

Working

in

engine

compartment,

remove

anti-tamper

Torx

screwsfrom

crash

sensor

.

Remove

sensor

and

disconnect

harness

connector

.

See

Fig

.

8

.

5

.

Installation

is

reverse

of

removal

.

Make

sure

arrow

on

sensor

faces

forward

when

installing

sensor

.

WARNING

-

Once

the

airbag

unit

is

installed

and

all

other

ser-vice

procedures

have

been

completed,

start

the

en-

gine

and

check

that

the

SRS

warning

light

goes

out

.

If

the

warning

light

stays

on,the

SRS

system

will

not

function

as

designed

.

Have

the

system

diagnosed

and

repaired

byen

authorized

BMW

dealer

.

0012543

0011891

Page 482 of 759

721-

6

AIRBAG

SYSTEM

(SRS)

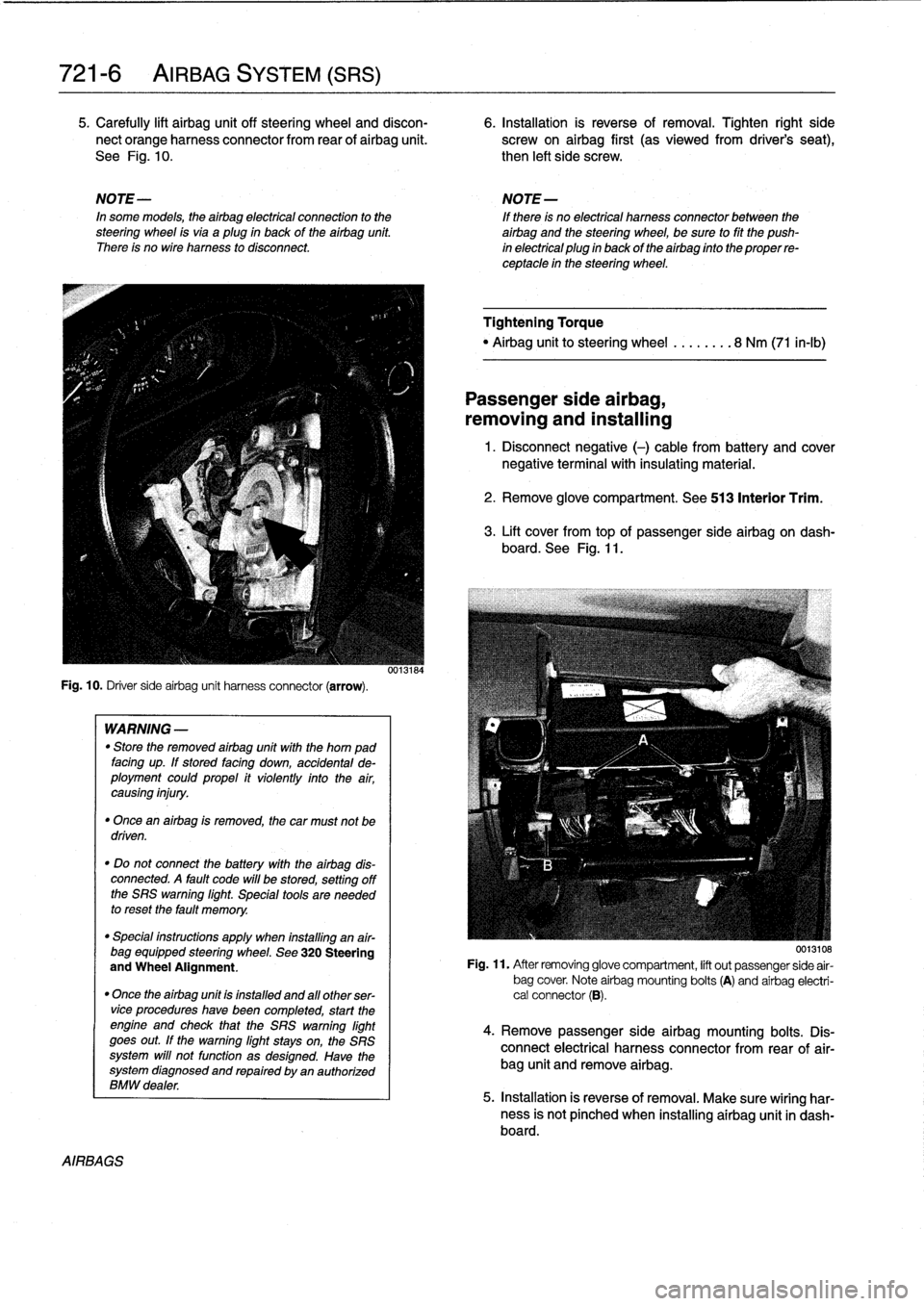

5

.

Carefully

lift

airbag

unit

off

steering

wheel

and

discon-

6

.

Installation

is

reverse

of

removal

.

Tighten

right

side

nect

orange

harness

connector

from

rear

of

airbag

unit

.

screw

on

airbag

first

(as

viewedfrom

driver's

seat),

See

Fig

.

10

.

then

left

side

screw

.

NOTE-

NOTE-

In

some

models,

theairbag

electrical

connection

to

the

If

there

is

no

electrical

harness

connector

between

the

steering

wheel

isvia

aplug

in

back

of

the

airbag

unit

.

airbag

and

the

steering

wheel,

be

sure

to

fit

the

push

There

is

no

wire

harness

to

disconnect

.

in

electrical

plug

in

back

of

the

airbag

finto

the

proper

re-

ceptacle

in

the

steering

wheel

.

Fig

.

10

.

Driver

sideairbag

unit

harness

connector

(arrow)

.

AIRBAGS

WARNING

-

"

Store

the

removed

airbag

unit

with

the

horn

pad

facing

up

.

If

stored

facing

down,

accidental

de-

ployment

couldpropel

it

violently

into

the

air,

causing

injury

.

"

Once

an

airbag

is

removed,

the

car

must

not

be

driven

.

"

Do

not

connect

the

battery

with

the

airbag

dis-

connected

.

A

fault

code

will

be

stored,

setting

off

the

SRS

warning

light

.

Special

tools

are

needed

to

reset

the

fault

memory

.

"

Special

instructions

apply

when

installing

an

air-

bag

equipped

steering

wheel

.

See

320

Steering

and

Wheel

Alignment

.

"

Once

the

airbag

unit

is

installnd

and

all

other

ser-vice

procedureshave

been

completed,

start

the

engíne

and

check

that

the

SRS

warning

light

goes

out

.

If

the

warning

light

stays

on,

the

SRS

system

will

not

function

as

designed

.

Have

the

system

diagnosed

and

repaired

by

an

authorized

BMW

dealer

.

0013184

Tightening

Torque

"

Airbag

unitto

steering

wheel

........

8

Nm

(71

in-lb)

Passenger

side

airbag,

removing

and

installing

1

.

Disconnect

negative

(-)

cable

from

battery

and

cover

negative

terminal

with

insulating

material

.

2

.

Remove

glove

compartment

.

See

513

Interior

Trim

.

3

.

Lift

cover

from

topof

passenger

sideairbag

on

dash-

board

.

See

Fig

.

11

.

0013108

Fig

.

11

.

After

removing

glove

compartment,

lift

out

passenger

side

air-

bag

cover

.

Note

airbag

mounting

bolts

(A)

and

airbag

electri-

cal

connector

(B)

.

4

.

Remove

passenger

sideairbag

mounting

bolts

.

Dis-

connect

electrical

harness

connector

from

rear

of

air-

bag

unit

and

remove

airbag

.

5

.

Installation

is

reverse

of

removal

.

Make

sure

wiring

har-

ness

is

not

pínched

when

installing

airbag

unit

in

dash-board

.

Page 486 of 759

ELE--2

ELECTRICAL

WIRING

DIAGRAMS

FUSE

LINK

64766

I-i

I

-

i

a

1

I

_

ZJ

I

I

I

I

I

I.

4

2

GRN/VIO

I_I

!

___I

I_I

1

D>

6

END

INECONTROL

ENGINECONTROL

TRANSMISSION

CONTROL

DATALINK

MODULE

MODULE

RELAY

MODULE

(EGS)

CONNECTOR

I

I

I

I

5

(F18

--_______________________________________________

O19~

N

RIBUON

BOX

I

FUSE

II

15A

o~___________________________________________________Q~____-aft

TO

FUSE

F5

C

RED

(DIAGRAM

6

OF

7)

FUELPUMP

I

(DIAGRAM60F7)

C'

RED

\

L------r>

(DIAGRAM60F7)

I

LOW

F

I

FRONT

HIGH

BEAM

FOGJ

BEAM

I

I

LIGHT

I

I

LIGHT

I

j

/

I

LIGHT

RELAY

I

RELAY

li

SJ

RELAY

1992

1993W/TRUNK

MOUNTEDBATTERV

1993W/ENGINE

COMPARTMENTMOUNTEDBATTERV

1993W/TRUNK

1993W/ENGINE

1992

1992

WI

ENGINE

W/TRUNK

BATTERY

MOUNTEDBATTERV

¢)

MOUNTED

BATTERY

MOUN

O

TEDBATT

I

ERV

¢I¢I

MOUNTEDBATTERV

TOFUSEF40

<

,.k

RED

(DIAGRAM

6

OF

7)

I

I

(DIAGRAM

3

OF

7)

TO

FUSEF3

E

RED

(DIAGRAMfiOF7)

"

.

1k

I

(DIAGRAM

6OF7)

>I

mJ~CANADA

RED

BNUMPSTART

JUNCTION

POINT

REO

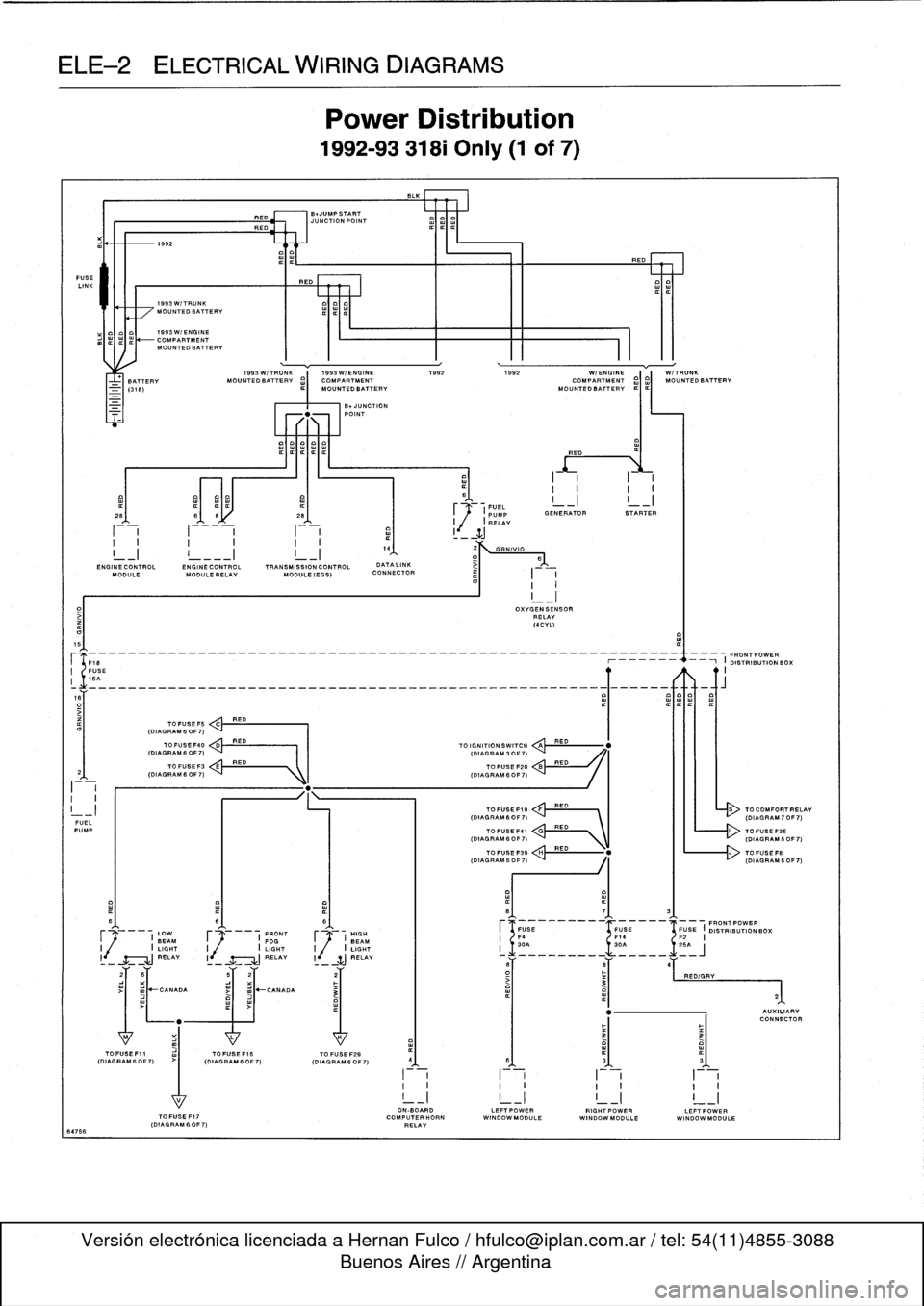

Power

Distribution

1992-93

318i

Only

(1

of

7)

-UNCTION

POINT

TOFUSEF15

TO

FUSE

F29

(DIAGRAM60F7)

(OIAGRAM6OF7)

I

~1

.

FUEL

_I

I

_I

~

(PUMP

GENERATOR

STARTER

I

,(

I

RELAY

TO

IGNITION

SWITCH

QA

TOFUSE

F20

TOFUSEF19

FRED

(DIAGRAM6OF7)

`

I

III

-

(DIAGRAM70F7)

OXVGENSENSOR

RELAY

(4CVL)

RED

RED

RED

ON-BOARD

LEFTPOWERRIGHTPOWERLEFTPOWER

TOFUSEF17

COMPUTERHORN

WINDOWMODULE

WINDOWMODULE

WINDOW

MODULE

(DIAGRAM

60F

7)

RELAY

TO

COMFORTRELAV

Page 493 of 759

ELE

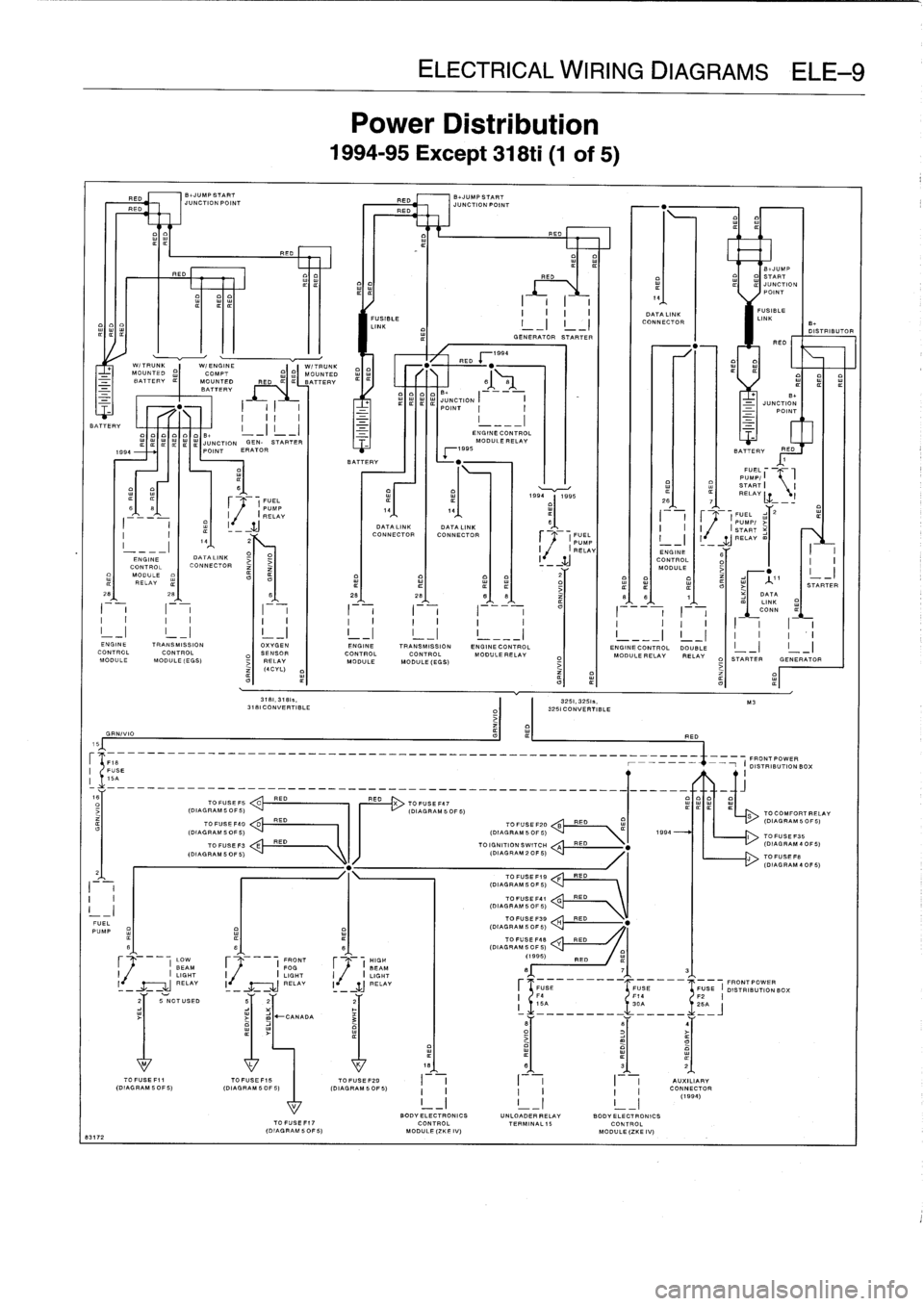

Power

E

1994-95

Exc

JMPSTART

B+JUMP

START

C710NPOINT

RED

JUNC710NPOIN7

RED

REO

.,

.

..

Fil

-----------

FUSIBLE

I

-

I

I

-I

CONNECTOR

I

LINK

B

LINK

m

D

¢

GENERATOR

STARTER

RED

x1994

W/TRUNK

W/ENGINE

W/TRUNK

RED

+

.

-

MOUNTED

MOUNTED

I~

BATTERY

MOUNTED

RED

BATTERY

61

81

w

_¢

BATTERY

o

B+

.

.'S

.

JS

_

JUONCINT

TION

I

I

B+_

I

I

I

P

I

I

-

JUNCTION

_

POINT

BATTERY

I

II

-

-_-

I

-

0

ENGINECON7ROL

¢

JUNCTION

GEN-

STARTER

MODULERELAY

1994

POINT

ERATOR

x1995

BATTERY

REO

Iffm

BATTERY

+

"

1

o

FUEL'w

PUMP/

I

B

w

w

START

I

I

mm

O

0

~

~

Y

¢¢ww

r'

19941995

RELAY

¢

Lz

(

PUMP

2

2fi

7

¢

¢

I

R

r

ELAY

14

14

r

2

'

8

I

1

(

P/

M

i

II

w

-

yJ

DATA

LINK

DATA

LINK

I

I

I~

SPT

U

ART

I

CONNECTOR

CONNECTOR

FUEL

I

I

14

22

PUMP

-_I

_--

IJRELAYm

_--I

O

I

RELAY

ENGINE

I

ENGINE

DATALINK

CONTROLCONTROL

CONNECTOR

-

MODULEj

MODULE

2

RELAY

-

S'

28

B

28

28

BB

86

1

DATA

LI

NK

II

I2

I

I

I

I

I

I

_

__

__

__

m

C.

NN

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

¢

I__I

I__I

!

_I

!

_I

!

_I

!

___I

!

___I

!

_I

I

I

ENGINETRANSMISSION

OXYGEN

ENGINE

TRANSMISSION

ENGINECONTROL

ENGINECONTROL

DOUBLE

CONTROL

CONTROL

SENSOR

CONTROL

CONTROL

MODULERELAY

MODULE

BELAY

RELAY

MODULE

MODULE

(EGB)

RELAY

MODULE

MODULE(EGS)

O

STARTER

GENERAT

(4CYL)

3181,37815,

3251,3251

.,

M3

3181

CONVERTIBLE

3251

CONVERTIBLE

GRN/VIO

RED

15

P1B

FRONT

POWER

USE

-1

I

DISTRIBUTION

BOX

-

-

-

---

--

-

---

-

-

-

-

-

-

-

-

-

---

--

-

---

-

---

-

-

-

-

-

-

-

-

-

-

-

-

----

-

-

-

-

-

-

-

-

-----

---

g

TO

FUSE

15

C

RED

RED

X

TO

FUSEF47

-

1.20

(DIAGRAM50F5)

(DIAGRAMSOF5)

S

TOCOMFORTR

TO

FUSEF40

0

RED

TO

TUBEF20

B

RED

(DIAGRAMSOF

(D(AGRAM

5

0F

5)

(DIAGRAM

5

0F

5)

R

1994

I

TO

'

.BE

P

.1

70

FUSE

F3

E

RED

TO

IGNITION

SWITCH

A

RED

"

(DIAGSAM4OF

(DIAGRAM5OF5)

ID

IAGRAM2OF5)

J

70

FUSE

FB

(DIAG

RAM

4

OF

2

TO

FUSEFI9

F

RED

I

I

(DIAGRAMSOF5)

I

I

TO

FUSE-

G

RED

I

-

I

(DIAGRAMSORS)

TOFUSEF39

RED

FUEL

PUMP

(DIAGRAMSOFS)

H

fi

6

g

(DIAGRAMSOFSTOFUSE

'48

I

Y

RED

(1

O

I

FRONT

HIGH

99

5)

RED

¢BEAM

FOG

I

BEAM

8

7

3

(

LIGHT

I

(

LIGHT

I

(

LIGHT

RELAY

I

j~(

RELAY

I~

~j

RELAY

r

FUBE

FUSE

FUSE

I

FRONTPOWER

OISTRIBUTIONBCX

2

I

F4

14

F25

NOTUSED

5

2

2

5

S

2

_

CANADA

3

v

8

B

4

M

L

K

18

8

3

2

TOFUSEF11

TOFUSEFIS

TOFUSEF29

I

I

I

I

AUXILIARY

(OIAGRAMSOFS)

(DIAGRAM

5DF5/

(DIAGRAM

SOBS)

I

I

I

I

I

I

CONNECTOR

V

I

_I

_

I

-I

(19)

BODY

ELECTRONICS

UNLO

I

ADERRELAY

BODY

EI

LCTRDNCS

TOFUSEFI7

CONTROL

TERMINAL15

CONTROL

IDIAGRAM50F5(

MODUL

.(ZKEIV)

MODULE(ZKEIV)

83172

-

Page 498 of 759

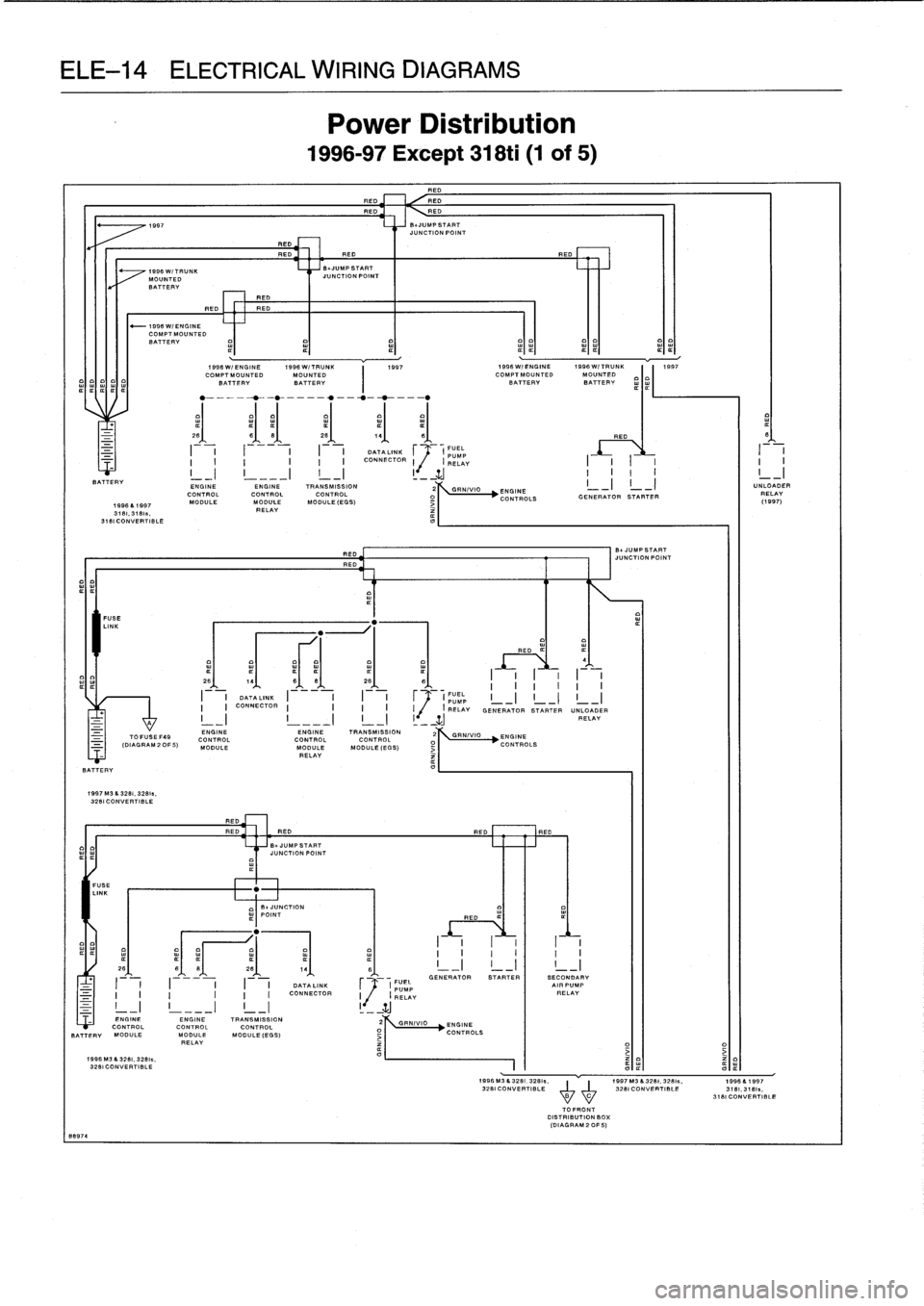

ELE-14

ELECTRICAL

WIRING

DIAGRAMS

BATTERY

FUSE

LINK

REDRED

RED

RED

RED

1997

S

.JUMPSTART

JUNCTION

POINT

1996W/TRUNK

MOUNTED

BATTERY

----

1998W/ENGINE

¢

¢

¢

¢¢COMPTMOUNTED

BATTERY

1996&1997

3181,3181

.,

3181

CONVERTIBLE

b

~

_

I

ENGINETO

FUSE

F49

CONTROL

(DIAGRAM

2OF5)

MODULE

BATTERY

1997M3

&328i.32811,3281

CONVERTIBLE

f

FUSE

LINK

1996

M3

&3281

.

3281

..

3281

CONY

ERTIBLE

1996

W/ENGINE

1996

W/TRUNK

1997

1996

W/ENGINE

1996

WITRUNK

COMPTMOUNTED

MOUNTED

COMPTMOUNTED

MOUNTEDC

BATTERY

BATTERY

BATTERY

BATTERY

REDREDRED

MP

START

JUNCTION

POINT

Power

Distribution

1996-97

Except

318ti

(1

of

5)

RED

RED

RED

I

I

T=

BtJUMPSTART

JU

NCTION

POINT

_RED

RED

0

I

I

I

I

I

I

DATA

LINK

r

(

(FUEL

I

I

I

I

I

I

I

I

CONNECTOR

(

(

Pump

RELAY

I

I

I

I

II

I

I

I

I

I

I

Zj

I

I

I

I

I

I

ENGINE

ENGINETRANSMISSION

I

-I

I

_I

UNLOADER

2//

\\GRN/VI

O

ENGINE

CONTROL

CONTROL

CONTROL

/

~

RELAY

MODULE

MODULE

MODULE(EGS)

I

"

CONTROLS

GENERATOR

STARTER

(1997)

RELAY

W

W

W

RED

8r.1

28

6

1

I

I

I

I

__

____

__

I

IIII

I

I

I

DATALINK

I

I

I

I

r

_~

_I

FUEL

I

-

I

I

-

I

I

-

I

I

CONNECTOR

I

I

I

I

I

I

ENGINE

TRANSMISSION

2

GRNIV

CONTROL

CONTROL

MODULE

MODULE(EGS)RELAY

i

ENGINE

ENGINE

TRANSMISSION

CONTROLCONTROLCONTROL

02

GRN/VIO

BATTERY

MODULE

MODULE

MOD

ULE(EGS)

_

RELAY

ENGINE

CONTROLS

ENGINE

CONTROLS

RED

[EH]RED

2I

POINT

CTION

RED

¢I

I

I

II

I

-

,

I

I

I

I

I

I

261

61

.1

281

1

,

11

61

I

-I

!

_I

I

i

_I

m

FUEL

GENERATOR

STARTER

SECONDARY

I

I

I

I

I

I

DATALINK

r

/y

(

PUMP

I

AI-

PUMP

I

I

I

I

I

I

CONNECTOR

I

f

(RELAY

RELAY

zJ

TOFRONT

DISTRIBUTION

BOX

(DIAGRAM

20F

5)

1997

B+

JUMP

START

JUNCTION

POINT

1996M3&3281,32811

.

1997M3&3281,3281

.,

1898&1997

3281

CONVERTIBLE

3281CONVERTIBLF

3181.3181x,BC

3181CONVERTIBLE

Page 547 of 759

SPIN

HOT

IN

RUN

RED

F

-

i

B4

JUMP

START

ANDSTART

RED

I

JUNCTION

POINT

r

F28

1

DISTRIBUTION

BOX

I

FUSE

FUSIBLE

LINK

RED

0

.1

O

BATTERY

BRNI

1

88171

88158

2

41

3251

&

325is

BLK/YEL

GIN

I

SIN

I

11

BLK/YEL

I

G202

DATA

LINK

CONNECTOR

BLK/

BLK/

GRN

GRN

8

10

I

I

I

I

I

I

I

I

_I

I

_ION-BOARD

WIPER/WASHER

COMPUTER

MODULE

(CANADA)

RED

X7183

W/

ENGINE

I

RED

I

J

BATTERY

DATA

LI

NK

CONNECTOR

BLK/YEL

BLK/

BLK/

GRN(

GRN

ELECTRICAL

WIRING

DIAGRAMS

ELE-63

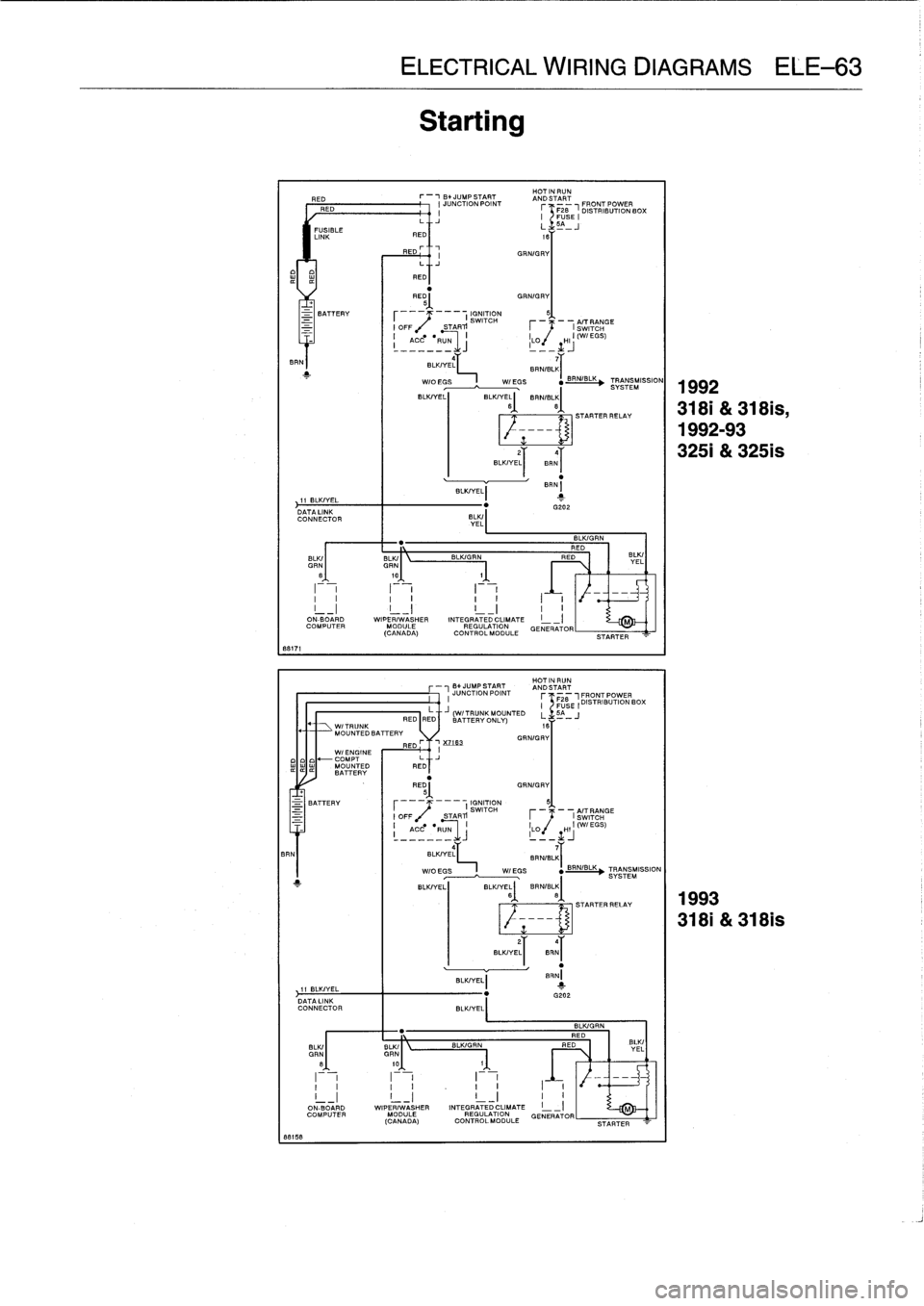

Starting

RED

GRN/GRY

LJ

RED

RED

GRN/GRYI

1,

5

IGNITIONSt

I

SWITCH

A/TRANCE

I

OFF

STARTI

I

SWITCH

-

ACC=RUN

iLO

~HJ(

W/EGS

)I

j

'

BLK/YEL

BRN/BLK

W/O

W/EGS

I

BRN/BLKio

TRANSMISSION

SYSTEM

1992

EGS

"

~

BLK/YELI

BLK/VE6~

BRN/BLK

STARTERRELAY

3181

&

318is,

1992-93

BLK/

VEL

BLKIGRN

RED

BLK/GRN

RED

I

-

I

I

I

INTEGRATEDCLIMATE

REGULATION

GENERATOR

CONTROLMODULE

RED

GRN/GRY

J5

STARTER

HOT

IN

RUN

r

--

)

B

.

JUMP

START

AND

777

S

RRR

TART

---

III

JUNCTION

POINT

r

F28

1FRONTPOWER

~

J

I

FUSE

DISTRIBUTION

BOX

DISTRIBUTION

D

-

(W/TRUNK

MOUNTED

L

5A

-

J

111

BATTERY

ONLY)B

u~~~

,,,

-/TRUNK

1I

MOUNTED

BATTERY

=

BATTERY

(

IGNITION

5),

SWITCH

A/TRANGE

__

(OFF

STAITI

I

SWITCH

-

ACC-RUN

J

iW

Y

HJ

(W/EGS)

4

7

BLK/YEL~

SINAILK

WIOEGS

III

BOB

"

BRNI

TRANSMISSION

SYSTEM

BLK/YEL

^

BLKIYE

B

LI

RN/

.Let

STARTERRELAY

2T4T

BLK/YELI

BRNI

BLK/YELI

It

BLK/YEL

1_

G202

BLKIGRN

RED

BLK/GRN

RED

8

l

I

I

0j,

1j,

I

I

I

_I

I

I

I

~

1I

I

_I

II

ON-BOARD

WIPER/WASHER

INTEGRATEDCLIMATE

I

-)

COMPUTER

MODULE

REGULATION

GENERATOR

(CANADA)

CONTR

.

LMODULE

BLK/

YEL

BLK/

YEL

1993

3181

&

318is