Hood BMW 328i 1997 E36 User Guide

[x] Cancel search | Manufacturer: BMW, Model Year: 1997, Model line: 328i, Model: BMW 328i 1997 E36Pages: 759

Page 304 of 759

400-2

BODY-GENERAL

4-door

Sedan

Coupe

-

saas3

.7""

351

/

37

.3

O

I

x

`-193

267

o

oa

'3281

model

"M3

model

Convertible

BODYASSEMBLY

55

ass

.e

iss

""

-

66

.9

-

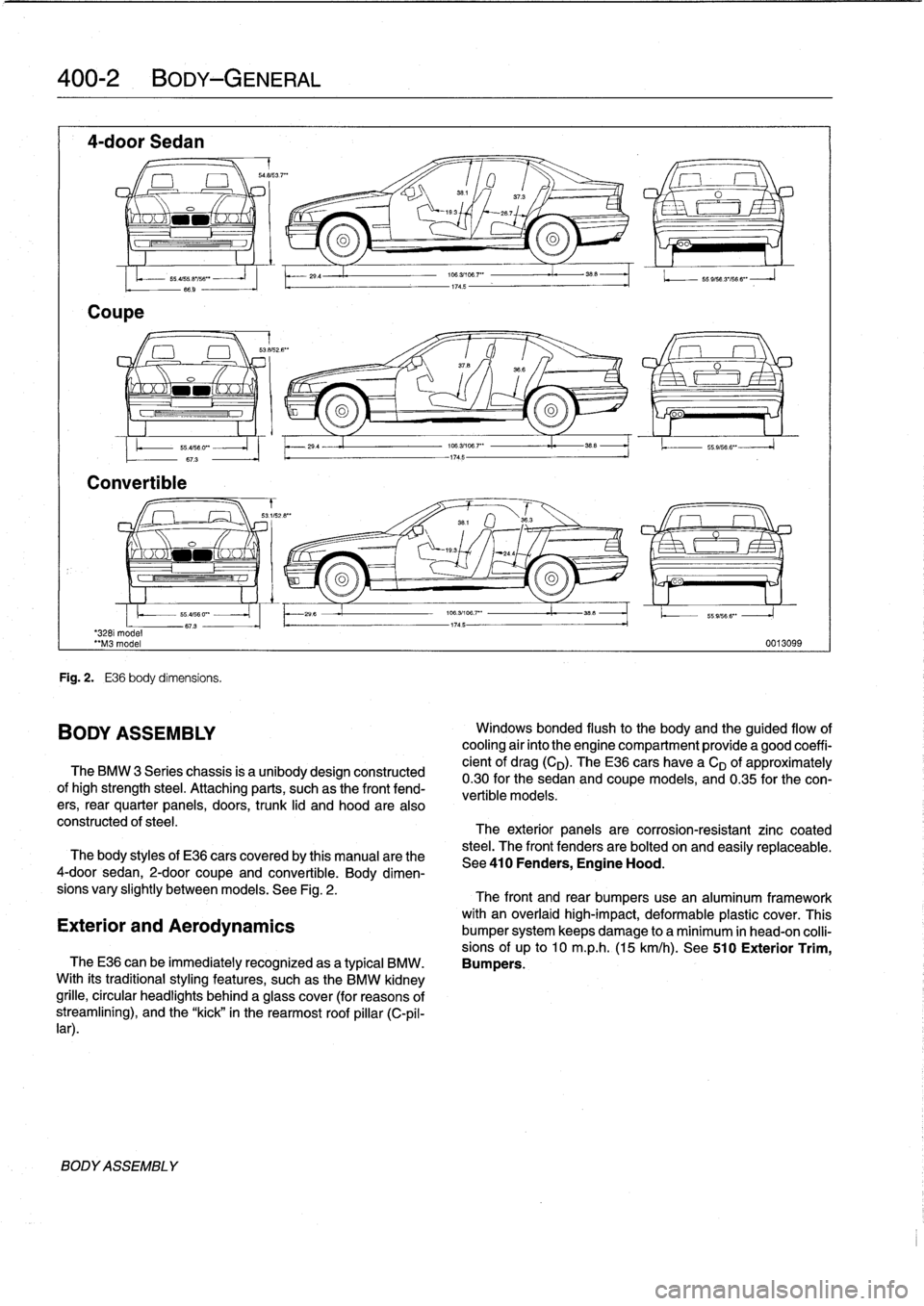

Fig

.

2

.

E36

body

dimensíons

.

BODY

ASSEMBLY

29

.4

29

4

The

BMW

3

Series

chassis

is

a

unibodydesign

constructed

ofhigh

strength

steel

.

Attaching

parts,

suchas

the

front

fend-

ers,

rear

quarter

panels,

doors,

trunk

lid

and

hood

are

also

constructed

of

steel

.

706

.31108

.7"

I

38

.5

174

.5

174

.5

O

oo

196

.3/106

.7'

"

35_5

1.

.

55

.9,566

".

106

.3/196

.7""

i.

358

-1745-

55

9/56

3'/56

6"

-

J

0013099

Windows

bonded

flush

to

the

body

and

the

guided

flow

of

cooling

air

into

the

engine

compartment

provide

a

good

coeffi-

cient

of

drag(CD)

.

TheE36

cars

have

a

CD

of

approximately

0

.30for

the

sedan

and

coupe

models,

and

0

.35

for

the

con-

vertible

models

:

The

exterior

panels

are

corrosion-resistant

zinc

coated

steel

.

The

front

fenders

are

bolted

on

and

easily

replaceabie

.

The

body

styles

of

E36

cars

coveredby

this

manual

arethe

See410

Fenders,

Engine

Hood

.

4-door

sedan,

2-door

coupe

and

convertible

.

Body

dimen-

sions

vary

slightly

betweenmodels

.

See

Fig

.

2

.

The

front

and

rear

bumpers

use

an

aluminum

framework

with

an

overlaid

high-impact,

deformable

plastic

cover

.

This

Exterior

and

Aerodynamics

bumper

system

keeps

damage

to

a

minimum

in

head-on

colli-

sions

of

up

to

10

m

.p

.h

.

(15

km/h)

.

See

510

Exterior

Trim,

TheE36

can

be

immediatelyrecognized

asa

typical

BMW

.

Bumpers

.

With

its

traditionalstyling

features,

suchas

the

BMW

kidney

grille,

circular

headlights

behind

a

glass

cover

(for

reasons

of

streamliníng),

and

the

"kick"

in

the

rearmost

roof

pillar

(C-pil-

lar)

.

Page 305 of 759

TheE36

convertible

is

an

all-season

vehicle

with

a

high

lev-

e¡offunctionality,

excellent

interior

comfort,

and

acoustic

re-

finement

.

Interior

materials

and

colors,

the

soft

top

and

the

light-alloy

wheelshave

been

carefully

matched

.

Various

versions

of

manual

and

automatic

soft

tops

have

been

used,

with

the

fully

automatic

convertible

roof

being

in-

stalled

beginning

in

the

1997

model

year

.

A

hard-top

in

body

color

with

heated

rear

window

is

avail-

ableas

an

option

for

the

cold

season

.

BODY-GENERAL

400-

3

Coupe

Models

The

convertible

body

structure

includes

many

passive

safe-

ty

refinements

over

its

fixed-top

counterparts

.

Some

of

the

en-

TheE36

coupe

is

similar

to

the4-door

sedan,

but

has

a

hancements

include

:

more

stretched

and

sleeker

appearance

.

Thus,

with

the

same

wheelbase

and

identicallength,

it

looks

different

but

still

famil-

"

More

rígíd

underbody

.

iar

.

"

Transverse

seat

members

.

"

Reinforced

windshield

frame

with

bonded

windshield,

The

2-door

variant

differs

from

the

4-door

sedan

by

a

3

.12

and

tubular

door

reinforcements

.

inch

(8

cm)

longer

front

end,

a

flatter

hood

line

with

air

slits,

"

Rollover

protection

system,

which

is

tripped

into

position

and

a

roof

almost

1

.2

inches

(3

cm)

shorter

.

Additional

differ-

in

a

fraction

of

second

.

This

is

available

as

optional

ences

include

wider

doors

with

frameless

Windows,

glass-

equipment

(standard

on

the

1998

328iC)

and

may

be

fit-

covered

door-posts

(B-pillars)

and

a

shorter

and

lower

lug-

ted

to

earlier

convertible

models

.

With

this

feature,

two

gage

compartment

lid

.

bars

fully

independent

of

each

other

come

up

behind

each

rear-seat

backrest

when

the

vehicle

is

in

danger

of

Convertible

Models

turning

over

.

A

convertible

body

normally

flexes

and

vibrates,

transfer-

ring

oscillations

to

the

luggage

compartment

.

In

the

E36

con-

vertible,

BMW

utilizes

a

special

battery

in

the

luggage

compartment,

in

conjunction

with

a

unique

battery

tray,

asa

vibration

dampening

system

to

counteract

thisoscillation

.

CAUTION

-

The

E36

convertible

requires

a

specialbattery

which

is

designed

for

constant

vibration

.

Information

for

the

convertible

top

and

its

related

mecha-

nisms

can

be

found

541

Convertible

Top

.

BODYASSEMBLY

Page 308 of 759

400-

6

BODY-GENERAL

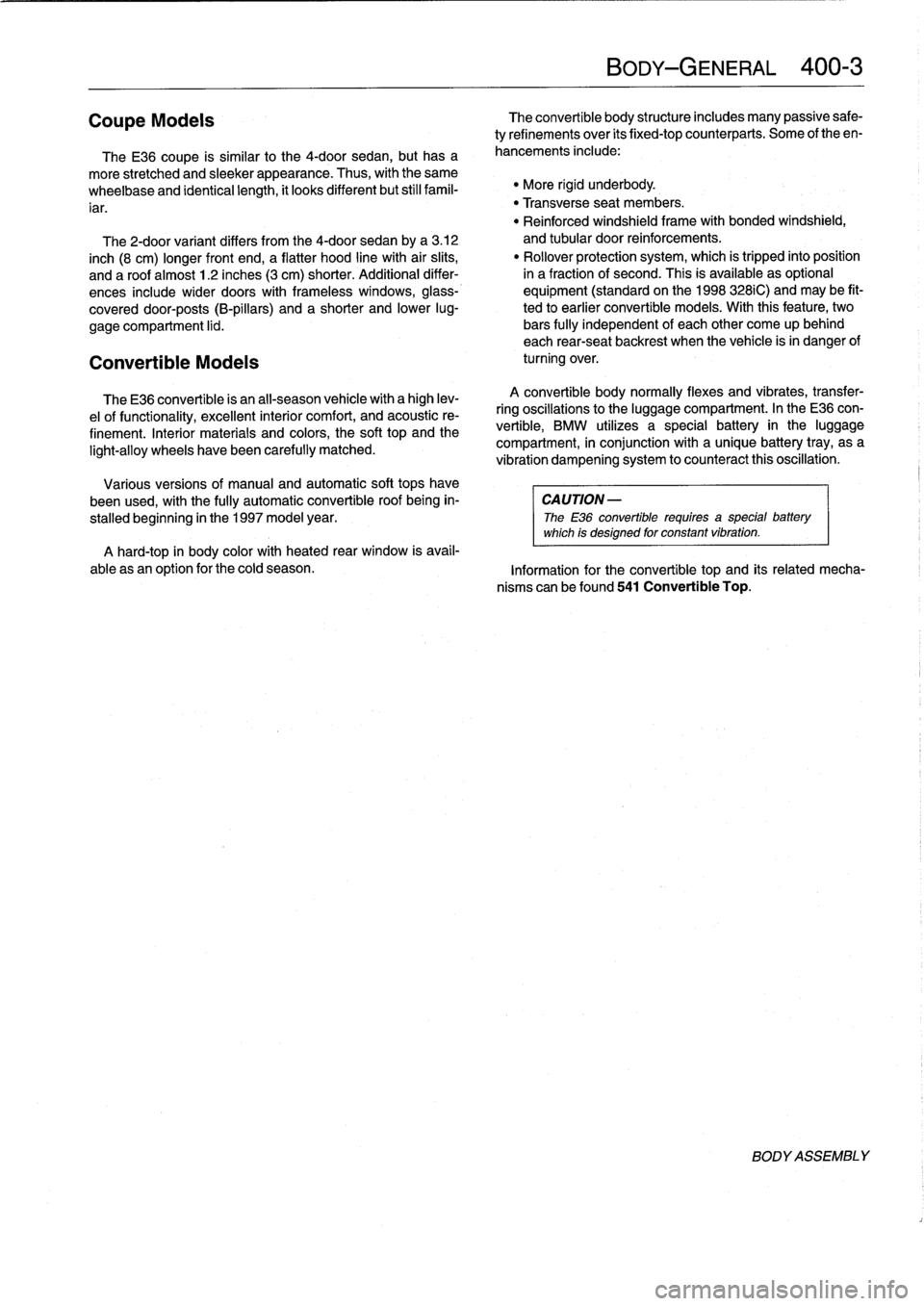

Heating

and

Air

Conditioning

The

electronically

controlled

heating

and

air

conditioning

systemusesan

extra

large,

infinitely

variable

radial

blower

motor

for

good

distribution

of

air

.

Fresh

air

enters

through

the

grille

below

the

engine

hood

and

finto

the

passenger

compart-

ment

via

the

dashboard

and

footwell

vents

.

See

Fig

.

5

.

Repair

information

for

the

heating

and

air

conditioning

sys-

tem

is

covered

in

640

Heating

and

Air

Conditioning

.

Fig

.

5

.

Heating

and

air

conditioning

ventilation

plan

.

INTERIOR

EQUIPMENT

Page 309 of 759

GENERAL

This

repair

group

covers

replacement

of

the

front

fenders

and

removal

and

installation

of

the

engine

hood

.

NOTE-

The

body

is

painted

at

the

factoryafter

assembly

.

Re-

alignment

of

body

panels

may

expose

unpainted

metal

.

Paint

all

exposed

metal

once

the

work

fs

complete

.

FRONT

FENDERS

Front

fender,

removing

and

installing

1

.

Raise

hood

.

Raise

and

safely

support

front

of

vehicle

.

WARNING

-

"

When

raising

thecar

using

a

floor

jack

or

a

hy-

draulic

lift,

carefully

position

the

jack

pad

to

pre-

vent

damaging

thecar

body

.

A

suitable

liner

(wood,

rubber,

etc

.)

should

be

placed

between

the

jack

and

the

car

to

prevent

body

damage

.

"

Watch

the

jack

closely

.

Make

sure

it

stays

stable

and

does

not

shift

or

tilt

.

As

the

car

is

raised,

the

car

may

roll

slightly

and

the

jack

may

shift

.

2

.

Remove

front

wheel

.

Remove

inner

plastic

liner

from

wheel

well

.

3

.

Remove

front

bumper

.

See510

Exterior

Trim,

Bumpers

.

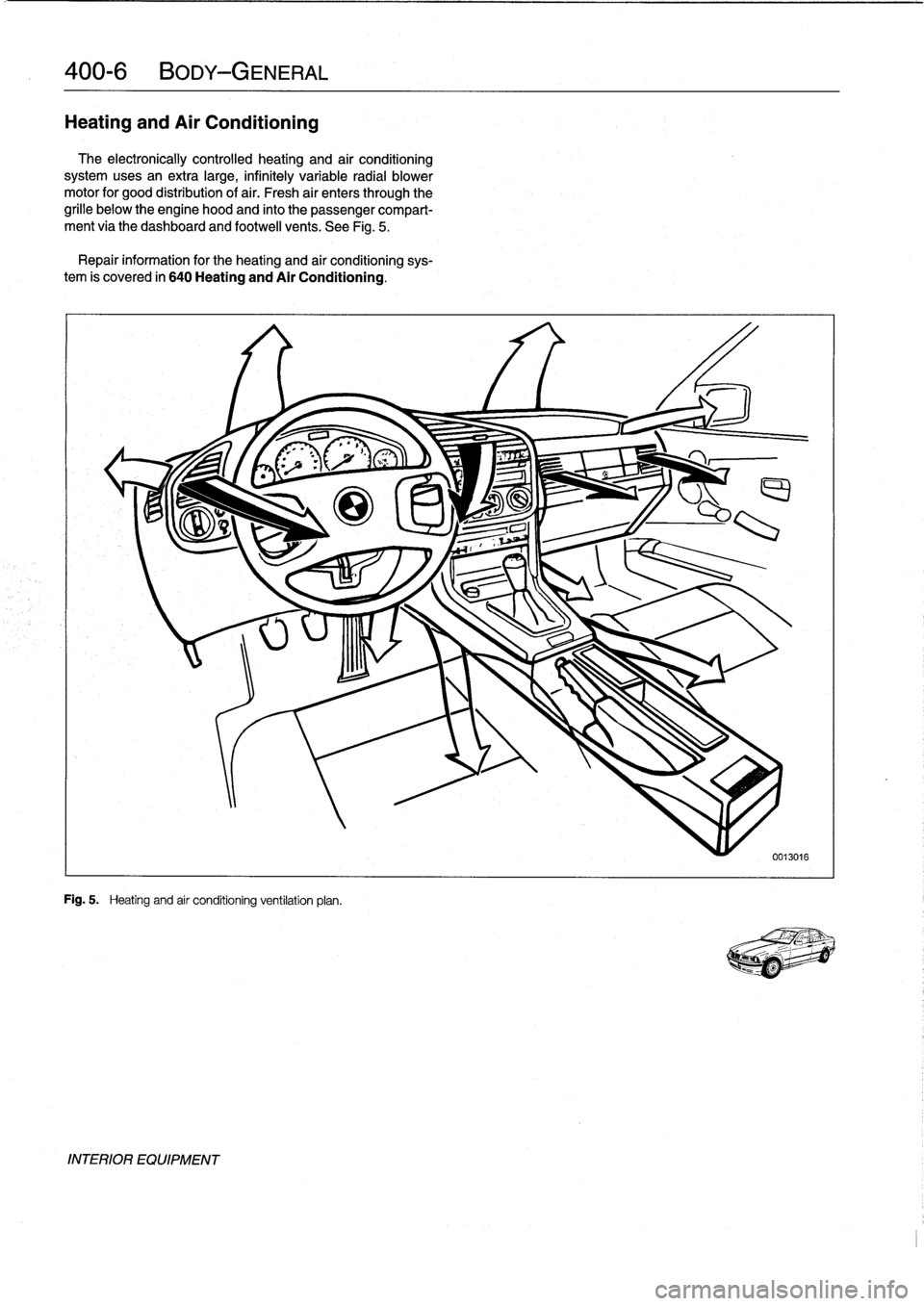

4

.

Working

atfront

corner

of

fender,

remove

front

grille

panel

bolts

(2

bolts

at

left

and

right)

.

See

Fig

.

1

.

FENDERS,

ENGINE

HOOD

410-1

410

Fenders,

Engine

Hood

GENERAL

...............

.

.

.

.

.

.

.

.

.

.

.

..

410-1

ENGINE

HOOD

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

...

.

.410-3

Hood,

raising

to

service

position

.

.

.

.

.

.

.

.

...

410-3

FRONTFENDERS

........

.

.

.

.

.

.

.

.

.

.

.

.

.410-1

Hood,

removin

and

installin

410-3

Front

Pender,

removing

and

installing

.

.

.

....

410-1

Hood,

aligning

...

.

.

.

.

.

.

.

.....

.

.

.

.

.

.

.

...

410-4

Hood

release

cable

and

latches,

adjusting

...

410-4

001

.145

Fig

.

1

.

Front

grille

panel

to

front

fender

retaining

bolts

(arrows)

.

Front

bumpershown

removed

.

5

.

Remove

front

turn

signalliens

assembly

from

applica-

ble

front

corner

.

Carefully

pryout

side

directional

from

fender

(later

cars

only)

.

See

630

Exterior

Lighting

.

6

.

Remove

fender

attaching

bolts

atfront

underside

of

fender

.

See

Fig

.

2

.

7

.

Remove

bolts

along

top

edge

of

fender

:

See

Fig

.

3

.

8

.

Open

front

door

and

remove

fender

mounting

bolts

in

door

jamb

.

See

Fig

.

4

.

9

.

Carefully

remove

fender

from

body

.

FRONTFENDERS

Page 310 of 759

410-2

FENDERS,

ENGINE

HOOD

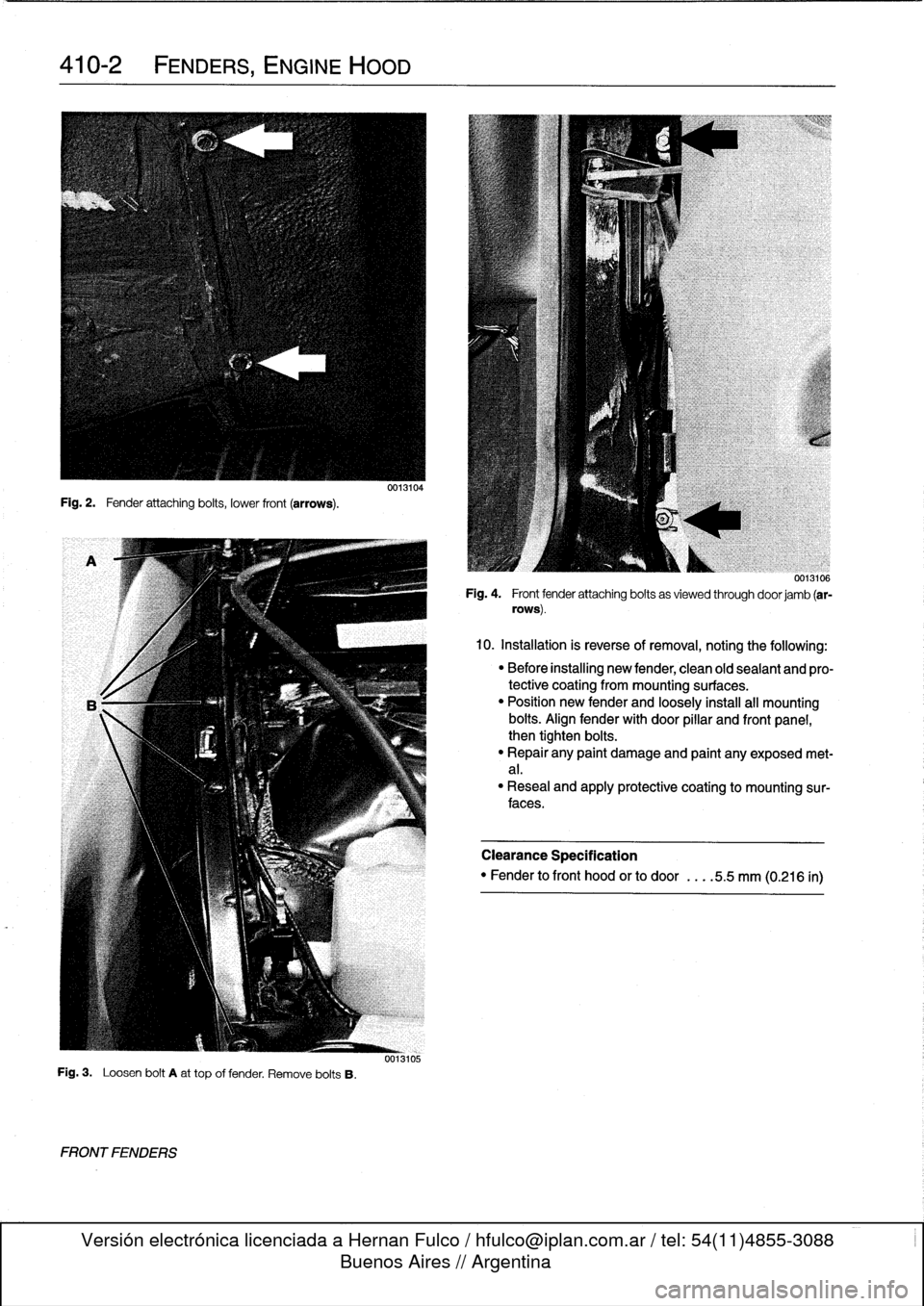

Fig

.

2

.

Fender

attaching

bolts,

lower

front

(arrows)

.

Fig

.

3

.

Loosen

bolt

A

at

top

offender

.

Remove

bolts

B

.

FRONTFENDERS

0013104

0013105

0013106

Fig

.

4

.

Front

fender

attaching

bolts

as

viewed

through

doorjamb

(ar-

rows)

.

10

.

Installation

is

reverse

of

removal,

noting

the

following

:

"

Before

installing

new

fender,

clean

old

sealant

and

pro-

tective

coating

from

mounting

surfaces

.

"

Position

new

fender

and

loosely

install

all

mounting

bous

.

Align

fender

with

door

pillar

and

front

panel,

then

tighten

bolts

.

"

Repair

any

paint

damage

and

paint

any

exposed

met-

al

.

"

Reseal

and

apply

protective

coating

to

mounting

sur-

faces

.

Clearance

Specification

"

Fender

to

front

hood

or

to

door

.

...

5

.5

mm

(0

.216

ín)

Page 311 of 759

ENGINE

HOOD

Hood,

raising

to

service

position

CA

UTION-

Do

not

switch

on

the

windshield

wipers

wlth

the

engine

hood

raised

.

As

a

precaution,

remove

the

wiper

motor

fuse

.

See

610

Electrical

Compo-

nent

Locations

.

1

.

4-door

models

:

Open

hood

fully

.

Remove

bolt

from

hood

hinge

behind

hood

supports

(left

and

right)

.

Raise

hood

to

service

position

.

See

Fig

.

5

.

2

.

2-door

models

:

Open

hood

fully

.

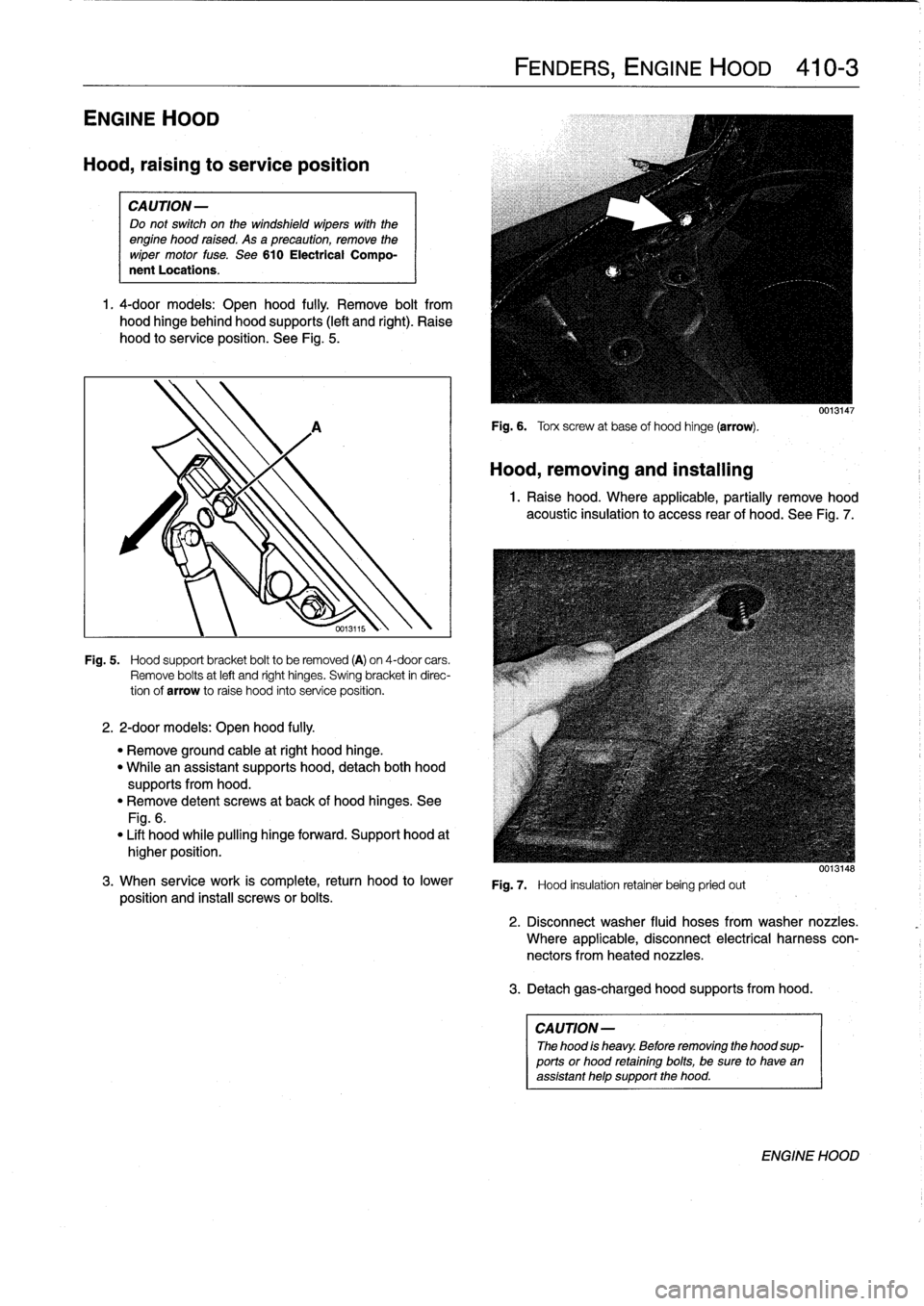

Fig

.

5

.

Hood

support

bracket

boltto

be

removed

(A)

on

4-door

cars

.

Remove

bolts

at

left

and

right

hinges

.

Swing

bracket

in

direc-

tion

of

arrow

to

raise

hood

into

service

position

.

"

Remove

ground

cable

atright

hood

hinge

.

"

Whilean

assistant

supports

hood,

detach

both

hood

supportsfrom

hood

.

"

Remove

detent

screws

at

back

of

hood

hinges

.

See

Fig

.

6

.

"

Lift

hood

while

pulling

hinge

forward

.

Support

hood

at

higher

position

.

3

.

When

service

work

is

complete,

return

hood

to

lower

position

and

instaf

screws

or

bolts

.

FENDERS,

ENGINE

HOOD

410-

3

Fig

.

6

.

Torx

screw

at

base

of

hood

hinge

(arrow)

.

Hood,

removing

and

installing

0013147

1

.

Raise

hood

.

Where

applicable,

partially

remove

hood

acoustic

insulation

to

access

rear

of

hood

.

See

Fig

.

7

.

Fig

.

7

.

Hood

insulation

retainer

being

pried

out

3

.

Detachgas-charged

hood

supportsfrom

hood

.

CAUTION

-

The

hood

is

heavy

.

Before

removing

the

hood

sup-

ports

or

hood

retainingbolts,

be

sure

to

have

an

assistant

help

support

the

hood

.

0013148

2

.

Disconnect

washer

fluid

hoses

from

washer

nozzles

.

Where

applicable,

disconnect

electrical

harness

con-

nectors

fromheated

nozzles

.

ENGINE

HOOD

Page 312 of 759

410-4

FENDERS,

ENGINE

HOOD

4

.

With

aid

of

assistant,

remove

hood

hinge

bolts

from

left

and

Rght

sides

of

hood

.

Lift

hood

off

carefully

See

Fig

.

8

.

Fig

.

8

.

Hood

hinge

bolts

(arrows)

.

Right

side

shown

.

5

.

Installation

is

reverse

of

removal

.

NOTE-

The

hood

was

fitted

and

attached

to

an

unfinished

body

at

the

factory

.

Unfinished

surfaces

exposed

by

this

pro-

cedure

must

betouchedup

wfth

pafnt

.

Hood,

aligning

ENGINE

HOOD

0013149

6013150

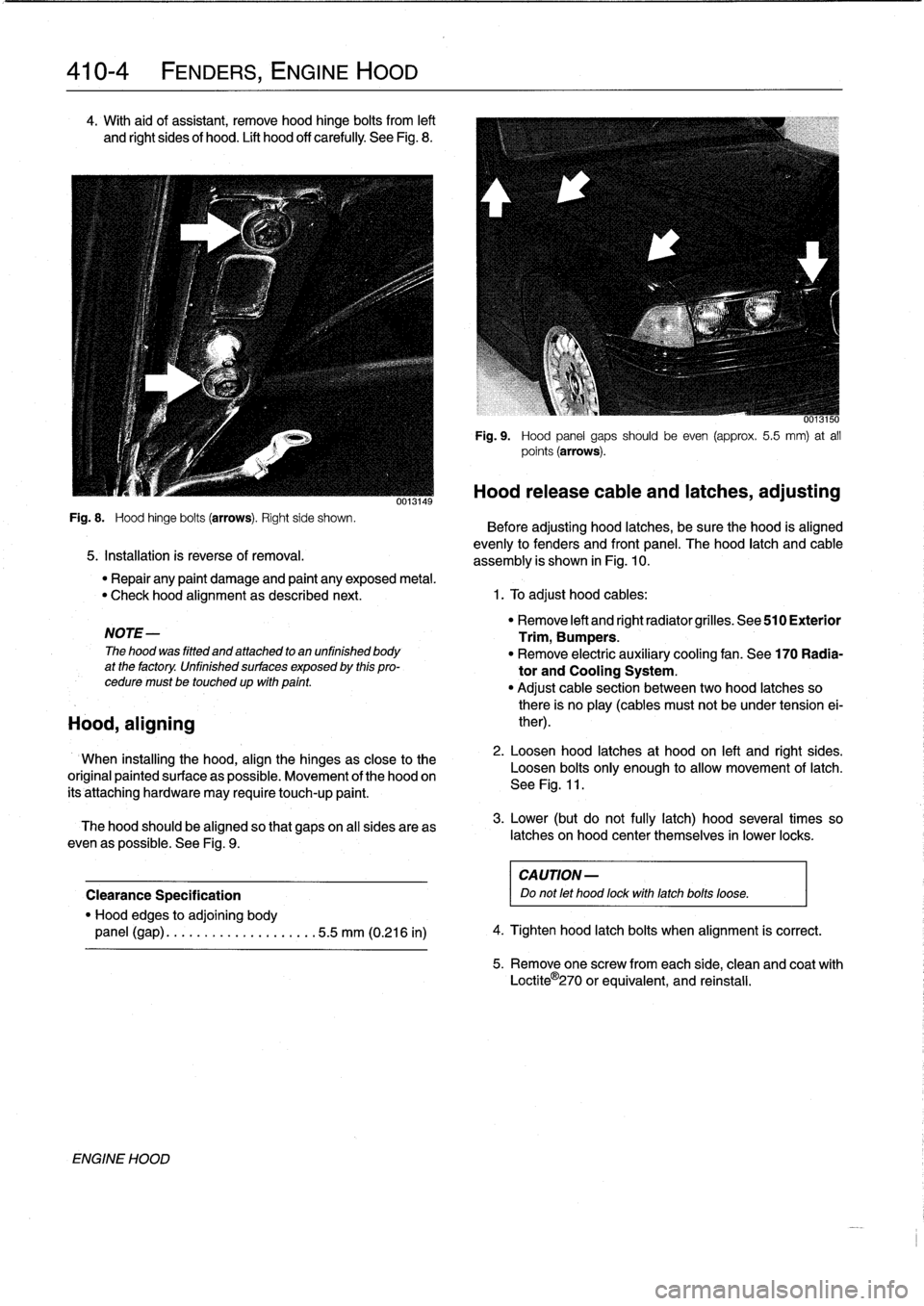

Fig

.

9

.

Hood

panel

gaps

should

be

even

(approx

.

5

.5

mm)

at

all

points

(arrows)

.

Hood

release

cable

and

latches,

adjusting

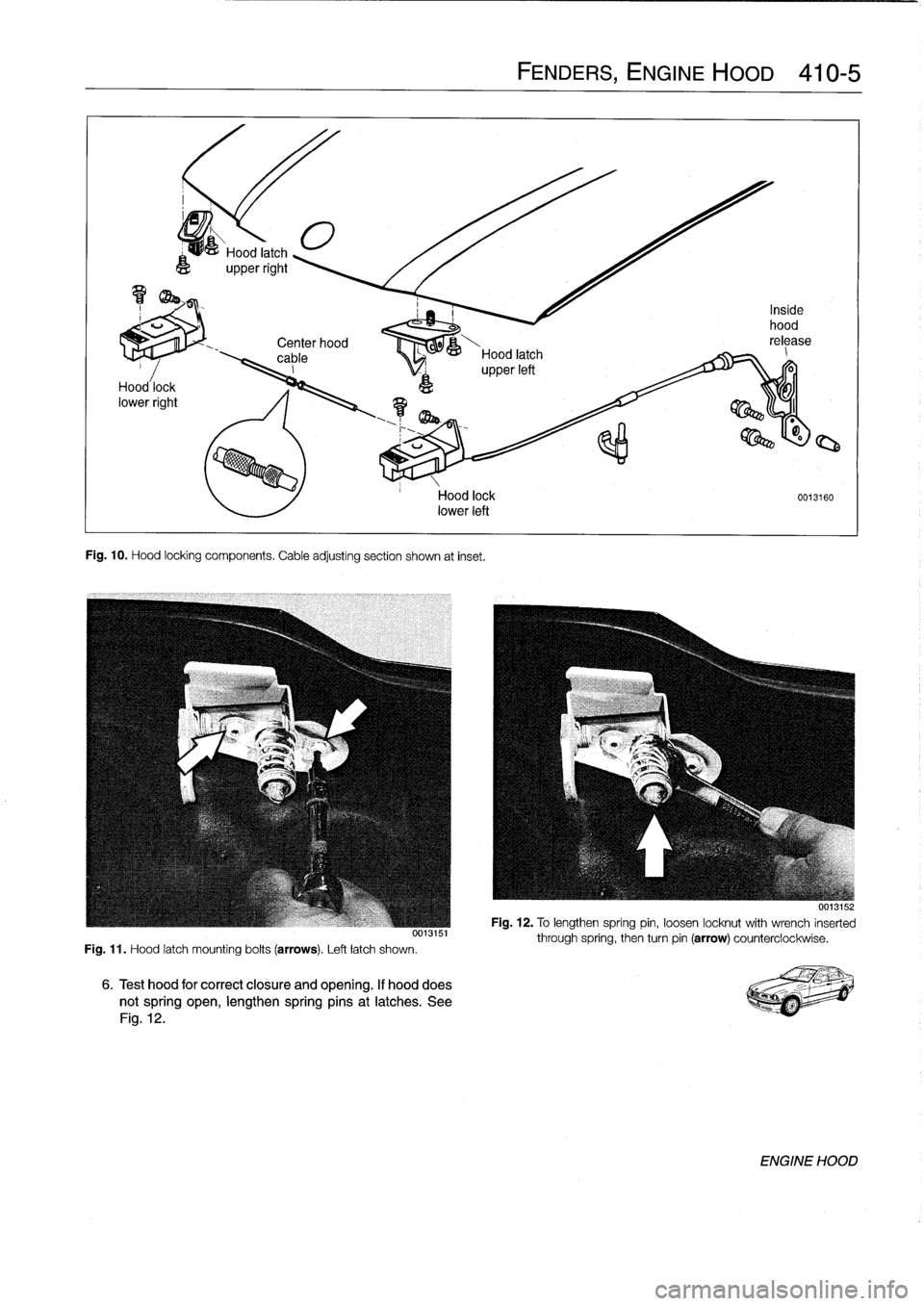

Before

adjusting

hood

latches,

be

sure

the

hood

is

aligned

evenly

to

fenders

and

front

panel

.

The

hood

latch

and

cable

assembly

is

shown

in

Fig

.

10

.

"

Repair

any

paint

damage

and

paint

any

exposed

metal

.

"

Check

hood

alignment

as

described

next

.

1

.

To

adjust

hood

cables

:

When

installing

the

hood,

align

the

hinges

as

close

to

the

original

paintedsurface

as

possible

.

Movement

of

the

hood

on

its'attaching

hardware

may

require

touch-up

paint

.

The

hood

should

be

aligned

so

that

gapson

all

sides

areas

even

as

possible

.

See

Fig

.

9

.

Clearance

Specification

"

Hood

edges

to

adjoining

body

panel

(gap)

........

..

..

..

.....

.5

.5

mm

(0.216

in)

"

Remove

left

and

right

radiator

grilles

.

See

510

Exterior

Trim,

Bumpers

.

"

Remove

electric

auxíliary

cooling

fan

.

See

170

Radia-

tor

and

Cooling

System

.

"

Adjust

cable

section

between

two

hood

latches

so

there

is

no

play

(cables

must

not

be

under

tension

ei-

ther)

.

2

.

Loosen

hood

latches

at

hood

on

left

and

right

sides

.

Loosen

bolts

only

enough

to

allow

movement

of

latch

.

See

Fig

.

11

.

3

.

Lower

(but

do

not

fully

latch)

hood

severa¡

times

so

latches

on

hood

center

themselves

in

lower

locks

.

CA

UTION-

Do

not

let

hood

fockwith

latchbolts

loose

.

4

.

Tighten

hood

latch

bolts

when

alignment

is

correct

.

5

.

Remove

one

screw

fromeach

side,

clean

and

coat

with

Loctite

O

270

or

equivalent,

and

reinstall

.

Page 313 of 759

Center

hood

,

00--&---

cable

Hood

latch

_

I

upperleft

Fig

.

10

.

Hood

locking

components

.

Cable

adjusting

section

shown

at

inset

.

Fig

.

11

.

Hood

latch

mounting

bolts

(arrows)

.

Left

latch

shown

.

Hood

lock

0013160

lower

left

6

.

Test

hood

for

correct

closure

and

opening

.

If

hooddoes

notspring

open,

lengthen

springpins

at

latches

.

See

Fig

.

12

.

FENDERS,

ENGINE

HOOD

410-5

001aio

Fig

.

12

.

To

lengthen

spring

pin,

loosen

locknut

with

wrench

inserted

through

spring,

then

turn

pin

(arrow)

counterclockwise

.

ENGINE

HOOD

Page 329 of 759

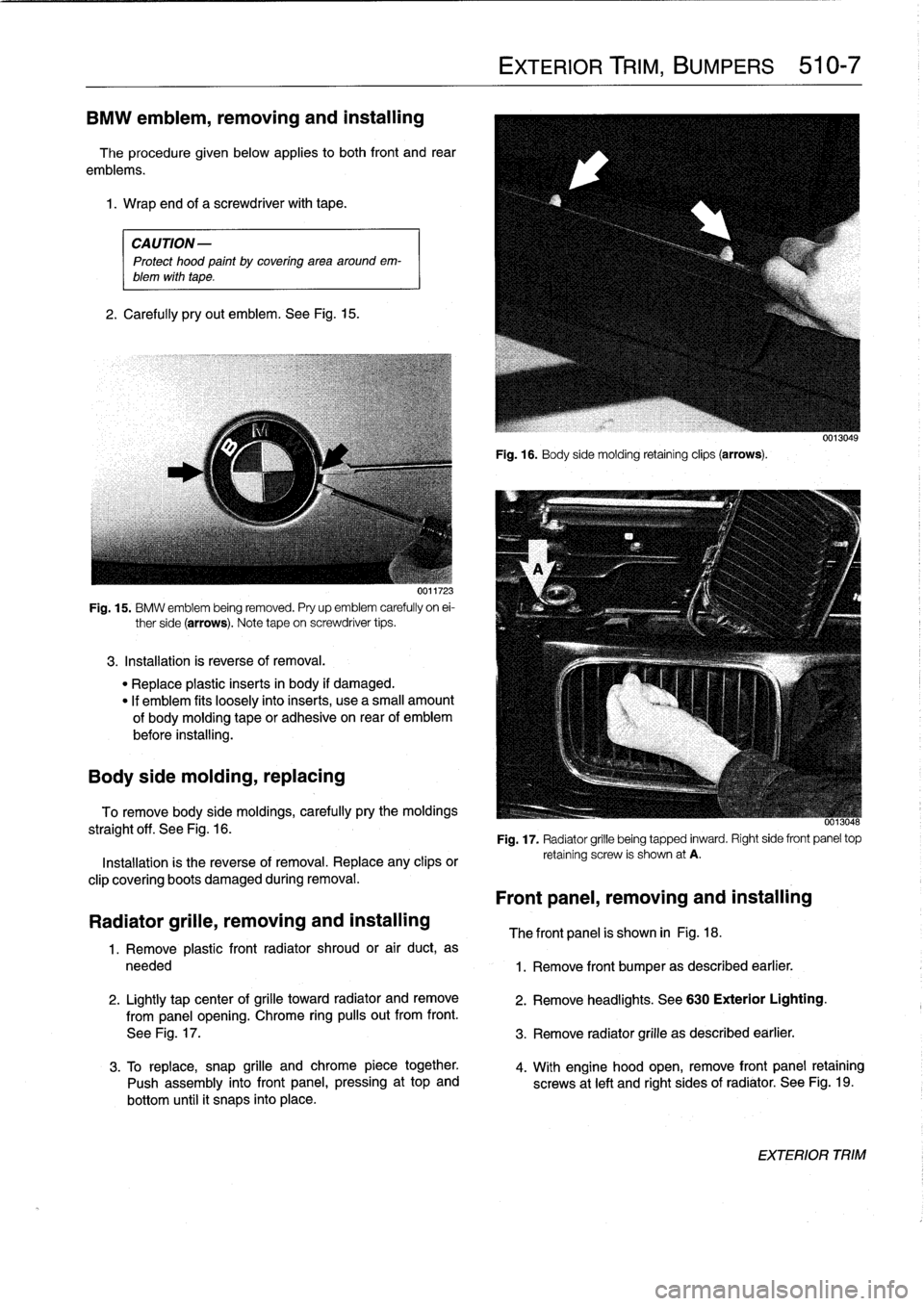

BMW

emblem,

removing

and

installing

The

procedure

given

below

applies

to

both

front

and

rear

emblems

.

1

.

Wrap

and

of

a

screwdriver

with

tape

.

CAUTION-

Protect

hood

paint

by

coveringarea

aroundem-

blem

with

tape

.

2

.

Carefully

pryout

emblem

.

See

Fig

.

15

.

UVI1'¿.

Fig

.

15

.

BMW

emblem

being

removed

.

Pry

up

emblem

carefully

on

ei-

ther

side

(arrows)

.

Note

tape

on

screwdriver

tips

.

3

.

Installation

is

reverse

of

removal

.

"

Replace

plastic

inserts

in

body

if

damaged

.

"

If

emblem

fits

loosely

intoinserts,

use

a

small

amount

of

bodymoldingtape

or

adhesiva

on

rear

of

emblem

before

installing

.

Body

side

molding,

replacing

To

remove

body

side

moldings,

carefully

pry

the

moldings

straight

off

.

See

Fig

.

16

.

Installation

is

the

reverse

of

removal

.

Replace

any

clips

or

clip

covering

boots

damaged

during

removal

.

Radiator

grille,

removing

and

installing

1

.

Remove

plastic

front

radiator

shroud

or

air

duct,

as

needed

2

.

Lightly

tap

center

of

grilla

toward

radiator

andremove

from

panel

opening

.

Chrome

ring

pulís

out

from

front

.

See

Fig

.

17

.

3

.

To

replace,

snap

grille

andchrome

piece

together

.

Push

assembly

into

front

panel,

pressing

at

top

and

bottom

until

it

snaps

into

place

.

EXTERIOR

TRIM,

BUMPERS

510-7

Fig

.

16

.

Body

sida

molding

retainingclips

(arrows)

.

-

0013048

Fig

.

17

.

Radiator

grille

being

tapped

inward

.

Right

side

front

panel

top

retaining

screw

is

shown

at

A

.

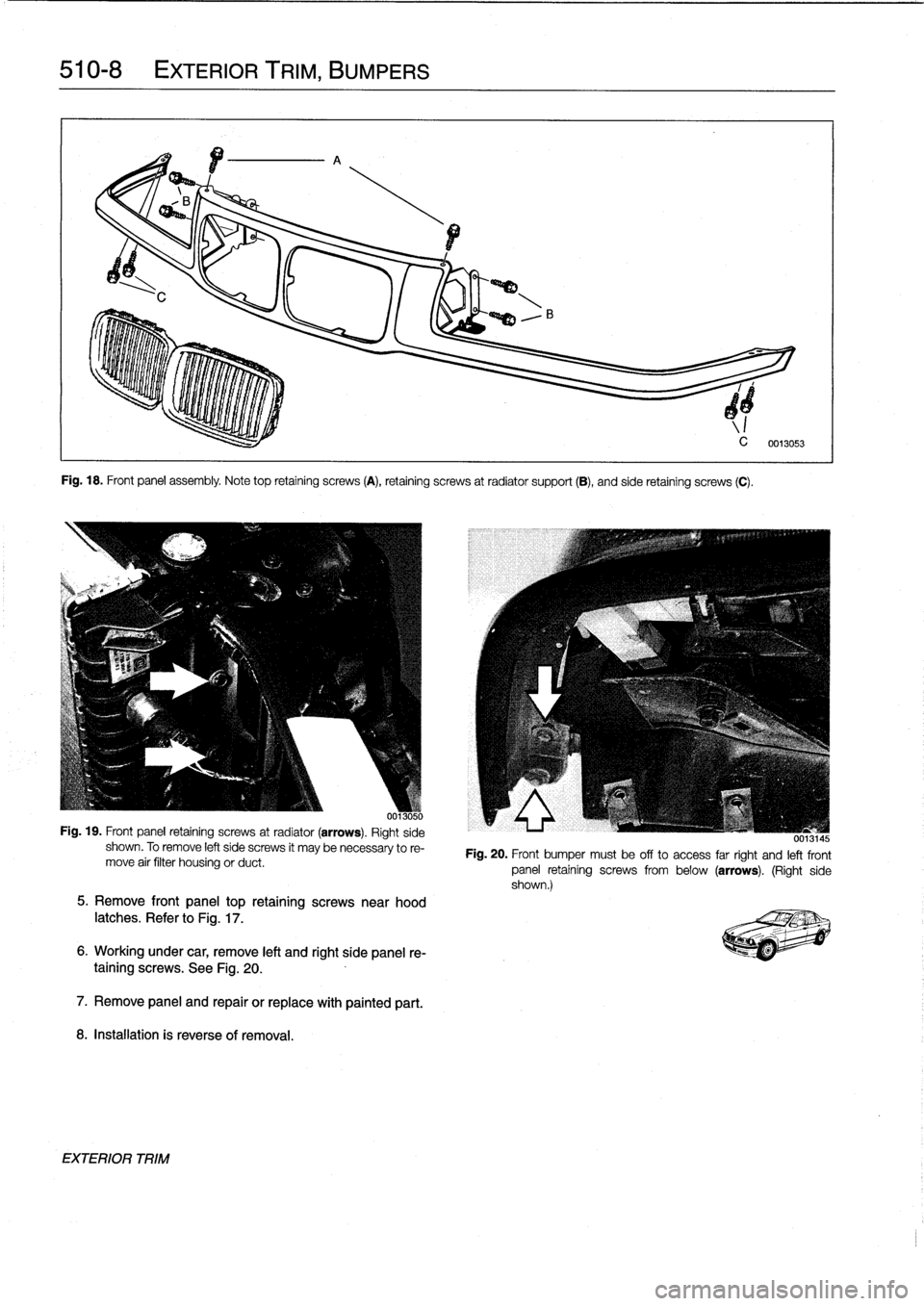

Front

panel,

removing

and

installing

The

front

panel

is

shown

in

Fig

.

18

.

1

.

Remove

front

bumper

as

described

earlier

.

2

.

Remove

headlights

.

See

630

Exterior

Lighting

.

3

.

Remove

radiator

grille

as

described

earlier

.

4

.

With

engine

hood

open,

remove

front

panel

retaining

screws

at

left

and

right

sides

of

radiator

.

See

Fig

.

19

.

EXTERIOR

TRIM

Page 330 of 759

510-

8

EXTERIOR

TRIM,

BUMPERS

Fig

.

18

.

Front

panel

assembly

.

Note

top

retaining

screws

(A),

retaining

screws

at

radiator

support

(B),

and

side

retaining

screws

(C)

.

00130~,

u

Fig

.

19

.

Front

panel

retaining

screws

at

radiator

(arrows)

.

Right

side

shown

.

To

remove

left

side

screws

it

may

be

necessary

tore-

move

airfilter

housing

or

duct

.

5

.

Remove

front

paneltop

retaining

screws

near

hood

latches

.

Refer

to

Fig

.

17

.

6

.

Working

under

car,

remove

left

and

right

side

panel

re-

taining

screws

.

See

Fig

.

20

.

7

.

Remove

panel

and

repair

orreplace

with

painted

part

.

8

.

Installation

is

reverseof

removal

.

EXTERIOR

TRIM

0013145

Fig

.

20

.

Front

bumper

mustbe

off

to

access

far

right

and

left

front

panel

retaining

screws

from

below

(arrows)

.

(Right

side

shown

.)