alignment BMW 328i 1997 E36 Owner's Manual

[x] Cancel search | Manufacturer: BMW, Model Year: 1997, Model line: 328i, Model: BMW 328i 1997 E36Pages: 759

Page 269 of 759

Fig

.

3

.

Power

steering

pump

and

pulley

mounting

bolts

.

6

.

Installation

is

reverse

of

removal,

noting

the

following

:

"

Make

sure

al¡

thread

bores,

bolts,

nuts,

fluid

couplings

and

mating

surfaces

are

clean,

and

that

inside

surface

of

multi-ribbed-belt

is

free

of

grease

and

dirt

.

"

Use

new

sealing

washers

when

reattaching

power

steering

pressure

lines

.

"

Make

sure

hoses

have

adequate

clearance

from

chas-

sis

.

Do

not

over-torque

banjo

bolts

.

"

Fill

and

bleed

power

steering

system

as

described

be-

low

.

Power

steering

system,

bleeding

and

filling

1

.

Wíth

engine

off,

fill

power

steering

fluid

reservoir

with

clean

fluid

.

Fill

levelto

MAX

mark

on

dipstick

.

STEERING

AND

WHEEL

ALIGNMENT

320-

3

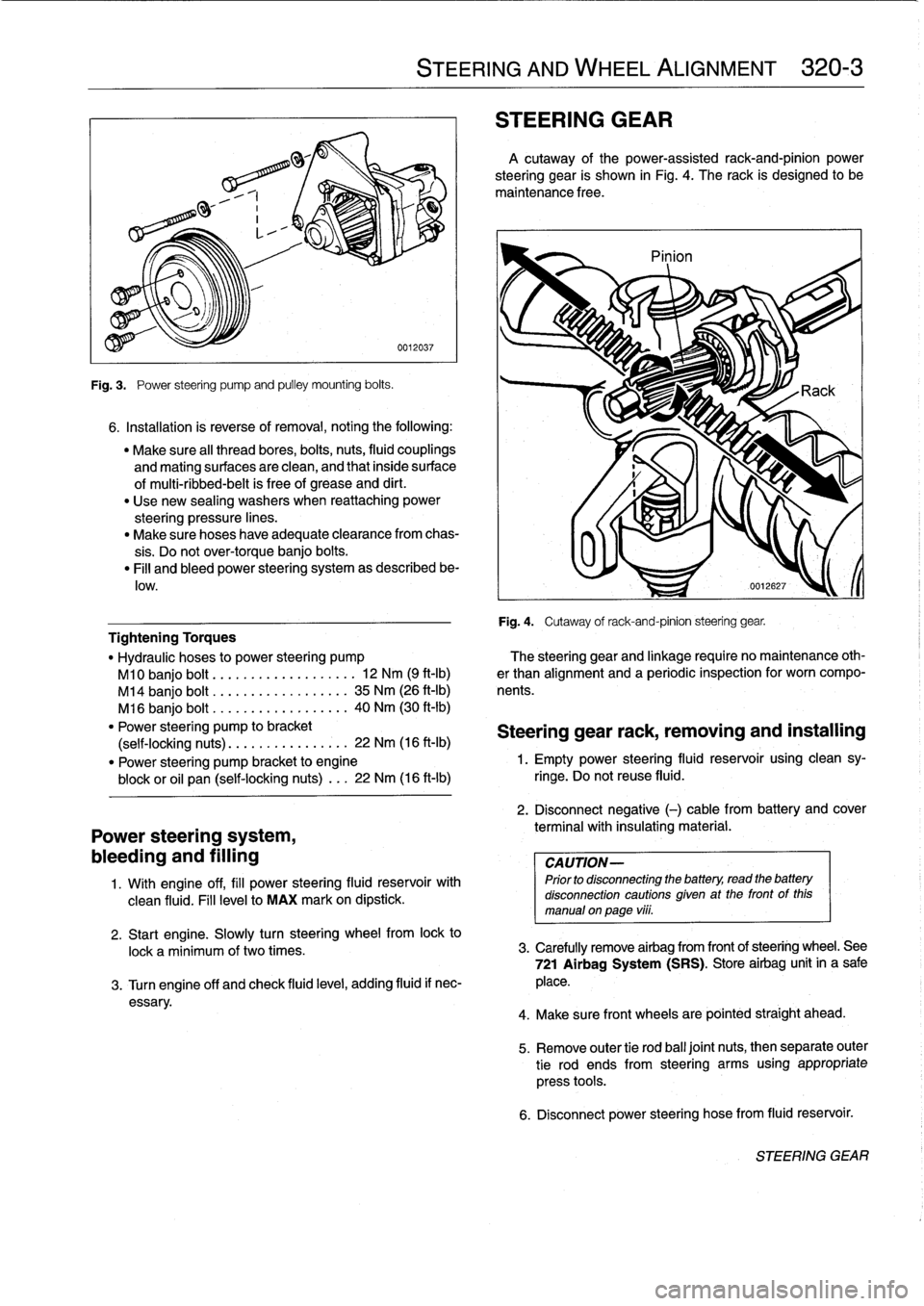

STEERING

GEAR

A

cutaway

of

the

power-assisted

rack-and-pinion

power

steering

gear

is

shown

in

Fig

.

4

.

The

rack

is

designed

to

be

maintenance

free

.

Pinion

Fig

.

4

.

Cutaway

of

rack-and-pinion

steering

gear

.

Tightening

Torques

"

Hydraulic

hoses

to

power

steering

pump

?he

steering

gear

and

linkage

require

no

maintenance

oth-

M10

banjo

bolt

.........

..

.

...

...

.

12

Nm

(9

ft-Ib)

er

than

alignment

and

a

periodic

inspection

for

worn

compo

M14

banjo

bolt

..............

..

..

35

Nm

(26

ft-Ib)

nents

.

M16

banjo

bolt

..............

...

.

40

Nm

(30

ft-Ib)

"

Power

steering

pump

to

bracket

Steering

gear

rack,

removing

and

installing

(self-locking

nuts)

.............

..

.

22

Nm

(16

ft-Ib)

"

Power

steering

pump

bracket

to

engine

1

.

Empty

power

steering

fluid

reservoir

using

clean

sy-

block

or

oil

pan

(self-locking

nuts)

...

22

Nm

(16

ft-lb)

ringe

.

Do

not

reuse

fluid

.

2

.

Disconnect

negative

(-)

cable

from

battery

and

cover

terminal

with

insulating

material

.

CAUTION-

Prior

to

disconnectiog

the

battery,

read

the

battery

disconnection

cautions

given

at

the

front

of

this

manual

on

page

viii

.

2

.

Start

engine

.

Slowly

turn

steering

wheelfrom

lock

to

lock

a

minimum

of

two

times

.

3

.

Carefully

remove

airbag

from

frontof

steering

wheel

.

See

721

Airbag

System

(SRS)

.

Store

airbag

unit

in

a

sale

3

.

Turn

engine

off

and

check

fluid

leve¡,

adding

fluid

if

nec-

place

.

essary

.

4

.

Make

sure

front

wheelsare

pointed

straight

ahead

.

5

.

Remove

outer

tie

rod

ball

joínt

nuts,

thenseparate

outer

tie

rod

ends

from

steering

arms

using

appropriate

press

tools

.

6

.

Disconnect

power

steering

hose

from

fluid

reservoir

.

STEERING

GEAR

Page 270 of 759

320-

4

STEERING

AND

WHEEL

ALIGNMENT

7

.

Remove

fluidline

banjo

bolt

from

steering

gear

.

See

9

.

Remove

steering

gearmounting

bolts

.

See

Fig

.

7

.

Re

Fig

.

5

.

move

steering

gear

from

subframe

crossmember

by

pulling

it

forward

.

CAUTION-

Plug

the

openings

in

the

pump

and

hoseends

to

prevent

dirt

from

entering

the

hydraulic

system

.

NOTE-

It

may

be

necessary

to

remove

other

components

to

gain

access

to

the

steering

gear

.

"

Make

sure

al¡

thread

bores,

bolts,

nuts,

splines

and

mating

surfaces

are

clean

.

Use

new

self-locking

nuts

wherever

applicable

.

"

Use

marks

made

during

removal

to

reassemble

steer-

ing

column

universal

jointto

steering

stub

shaft

.

Make

sure

wheels

are

straight

ahead

.

"

Use

a

new

sealing

washer

on

banjo

fitting

.

Do

not

over-

Fig

.

5

.

Fluid

hoses

and

banjo

bolts

at

steering

gear

(arrows)

.

torque

banjo

bolt

.

"

Install

airbag

to

the

steering

wheel

as

described

in

721

Airbag

System

(SRS)

.

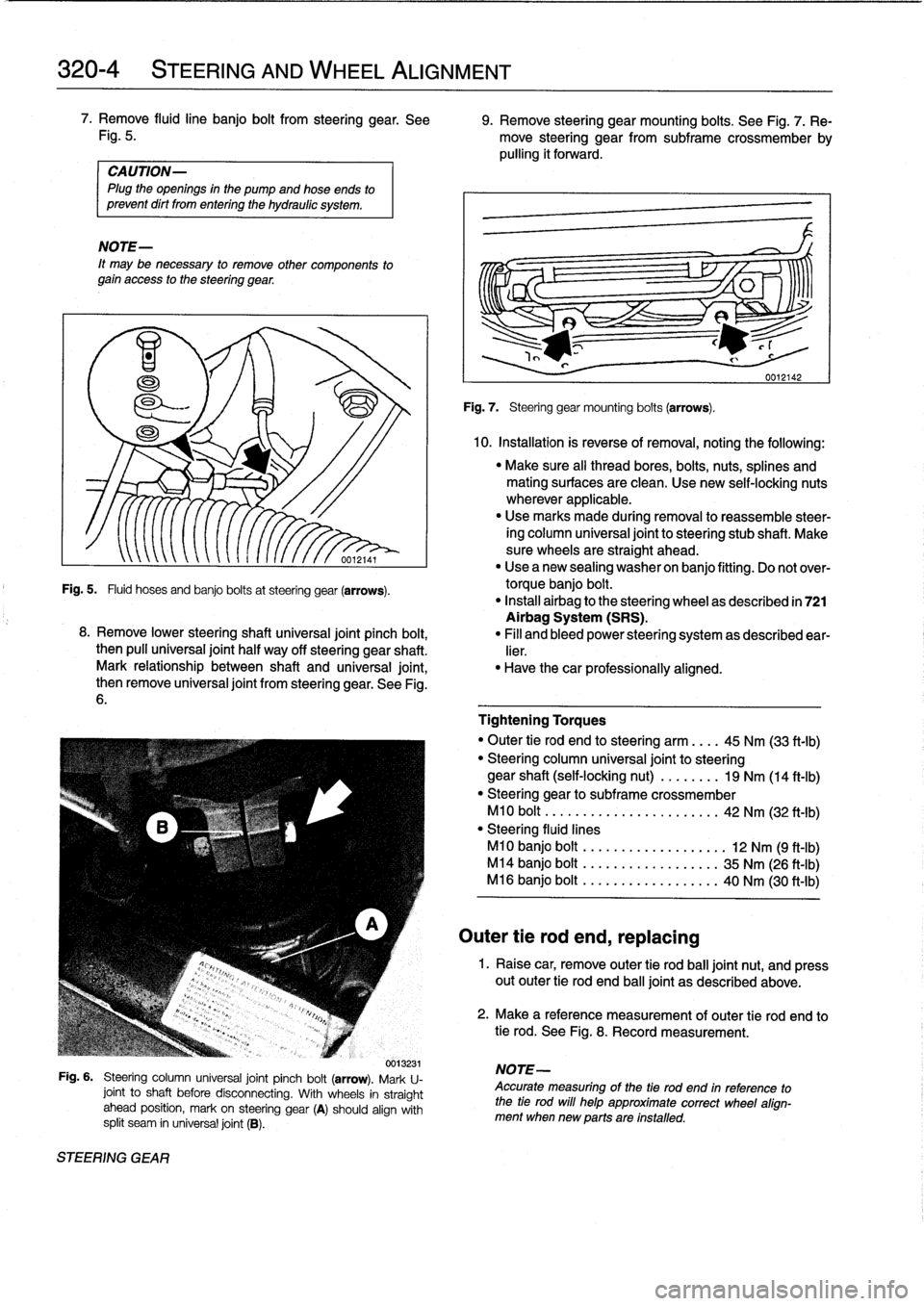

8

.

Remove

lower

steeringshaft

universal

joint

pinch

bolt,

"

Fill

and

bleed

power

steering

system

as

described

ear-

then

pull

universal

joint

half

way

off

steering

gear

shaft

.

lier

.

Mark

relationship

between

shaft

and

universal

joint,

"

Have

thecar

professionally

aligned

.

then

remove

universal

joint

from

steering

gear

.

See

Fig

.

6

.

0013231

Fig

.

6

.

Steering

column

universal

joint

pinch

bolt

(arrow)

.

Mark

U-

joint

to

shaft

before

disconnecting

.

With

wheels

in

straight

ahead

position,

mark

on

steering

gear

(A)

should

align

with

split

seam

in

universal

joint

(B)

.

STEERING

GEAR

Fig

.

7

.

Steering

gear

mounting

bolts

(arrows)

.

Outer

tie

rod

end,

replacing

10

.

Installation

is

reverse

of

removal,

noting

the

following

:

Tightening

Torques

"

Outer

tie

rod

end

to

steering

arm

.

.

..

45

Nm

(33

ft-Ib)

"

Steering

column

universal

joint

to

steering

gear

shaft

(self-locking

nut)

....

..

..

19

Nm

(14

ft-Ib)

"

Steering

gear

to

subframe

crossmember

M10

bolt

..............

.

...

.....

42

Nm

(32

ft-Ib)

"

Steering

fluíd

lines

M10

banjo

bolt

..

..

..

........

.....

12

Nm

(9

ft-Ib)

M14

banjo

bolt

..

..

..

...

..

...

....

35

Nm

(26

ft-lb)

M16

banjo

bolt

..

.......

..

..

.....

40

Nm

(30

ft-Ib)

1

.

Raise

car,

remove

outer

tie

rod

ball

joint

nut,

and

press

out

outer

tie

rod

end

ball

joint

as

described

above

.

2

.

Make

a

reference

measurement

of

outer

tie

rod

end

to

tie

rod

.

See

Fig

.

8

.

Record

measurement

.

NOTE-

Accurate

measuring

of

the

tie

rod

end

in

reference

to

the

tie

rod

will

help

approximate

correct

wheel

align-

mentwhen

new

parts

are

installed

.

Page 271 of 759

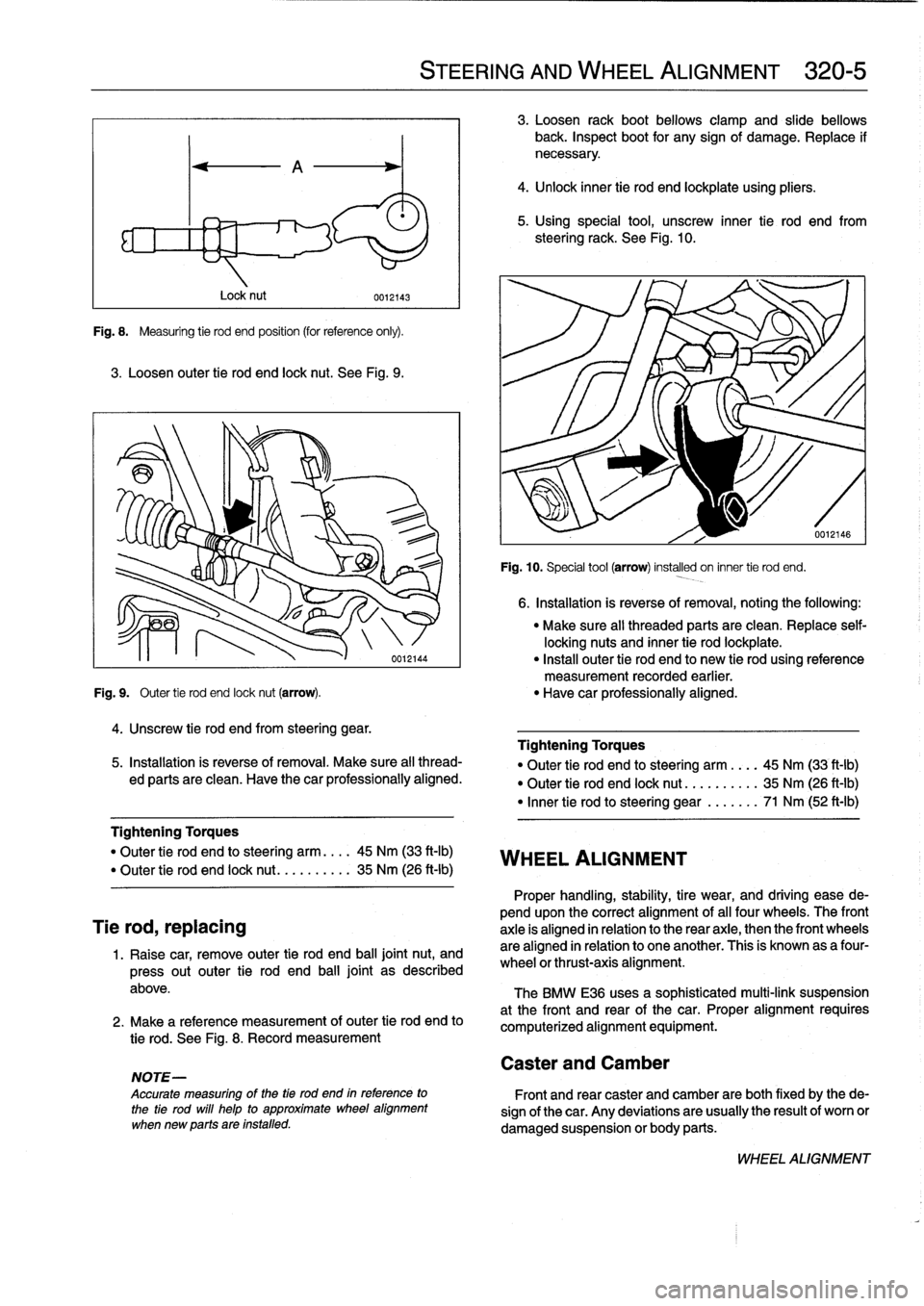

Fig

.

8

.

Measuring

tie

rod

end

position

(for

reference

only)

.

3

.

Loosen

outer

tie

rod

end

lock

nut

.

See

Fig

.

9

.

Lock

nut

4

.

Unscrew

tie

rod

end

from

steering

gear

.

0012143

"

Make

sure

all

threaded

parts

are

clean

.

Replace

self-

locking

nuts

and

inner

tie

rod

lockplate

.

"

Install

outer

tie

rod

end

to

new

tie

rod

using

reference

measurement

recorded

earlier

.

Fig

.

9

.

Outer

tie

rod

end

lock

nut

(arrow)

.

"

Have

car

professionally

aligned

.

5

.

Installation

is

reverse

of

removal

.

Make

sure

all

thread-

ed

parts

are

clean

.

Have

thecar

professionally

aligned

.

Tightening

Torques

"

Outer

tie

rod

end

losteering

arm

....

45

Nm

(33

ft-Ib)

"

Outer

tie

rod

end

lock

nut

..

.......

.

35

Nm

(26

ft-Ib)

Tie

rod,

replacing

1

.

Raise

car,

remove

outer

tie

rod

end

ball

jointnut,

and

press

out

outer

tie

rod

end

ball

joint

as

described

above

.

2

.

Make

a

reference

measurement

of

outer

tie

rod

end

to

tie

rod

.

See

Fig

.

8

.

Record

measurement

NOTE-

Accurate

measuring

of

the

tía

rod

end

in

reference

to

the

tie

rod

will

help

to

approximate

wheel

alignment

when

new

parts

are

installed

.

STEERING

AND

WHEEL

ALIGNMENT

320-

5

3

.

Loosen

rack

boot

bellows

clamp

and

slide

bellows

back

.

Inspect

boot

for

any

signof

damage

.

Replace

if

necessary

.

4

.

Unlock

inner

tie

rod

end

lockplate

using

pliers

.

5

.

Using

special

tool,

unscrew

inner

tie

rod

end

from

steeringrack

.

See

Fig

.

10

.

WHEEL

ALIGNMENT

Caster

and

Camber

Fig

.

10

.

Special

tool

(arrow)

installed

on

inner

tie

rod

end

.

6

.

Installation

is

reverse

of

removal,

noting

the

following

:

Tightening

Torques

"

Outer

tie

rod

end

to

steering

arm

..

.

.

45

Nm

(33

ft-Ib)

"

Outer

tie

rod

end

lock

nut

..........

35

Nm

(26

ft-Ib)

"

Inner

tie

rod

to

steering

gear

.......

71

Nm

(52

ft-Ib)

Proper

handling,

stability,

tire

wear,

and

driving

ease

de-

pendupon

the

correct

alignment

of

al¡

four

wheels

.

The

front

axle

is

aligned

in

relation

to

the

rear

axie,

then

the

front

wheels

are

aligned

in

relation

to

one

another

.

This

is

known

as

a

four-

wheel

or

thrust-axis

alignment

.

The

BMW

E36

uses

a

sophisticated

multi-link

suspension

at

the

front

and

rear

of

the

car

.

Proper

alignment

requires

computerized

alignment

equipment

.

Front

and

rear

caster

and

Camber

are

both

fixed

by

the

de-

sign

of

the

car

.

Any

deviations

are

usually

the

result

of

worn

or

damaged

suspension

or

body

parts

.

WHEEL

ALIGNMENT

Page 272 of 759

320-

6

STEERING

AND

WHEEL

ALIGNMENT

Front

Toe-in

andToe

Difference

Angle

Wheel

Alignment

Specifications

Toe-in

is

the

difference

in

the

distance

between

the

front

of

Alignment

specificationsfor

the

E36

are

listed

in

Table

a

the

front

wheels

and

the

rear

of

the

front

wheels

.

It

is

adjusted

and

Table

b

.

The

specifications

only

apply

under

the

following

by

altering

the

length

of

the

outer

tie

rods

.

conditions

:

Toe-in

adjustments

should

only

be

made

on

alignment

equipment

with

the

car

in

normalloaded

position

as

described

below

under

Wheel

Alignment

Specifications

.

Toe

difference

angledetermines

the

progressively

different

pathstaken

by

the

front

wheelsas

the

car

is

turning

.

It

is

fixed

by

the

steering

gear,

but

depends

on

accurate

setting

of

the

toe-in

.

Rear

Toe-in

There

is

no

provision

for

routinerear

wheel

toe-in

adjust-

ment

.

If

any

alignment

angles

deviate

from

specifications,

carefully

inspect

the

rear

trailing

arms,

rear

suspension

sub-

frame

and

al¡

associated

bushings

and

flexible

mounts

for

wear

or

damage

.

After

replacing

any

parts

that

appear

worn

or

damaged,

re-check

thetoe

measurements

.

WHEEL

ALIGNMENT

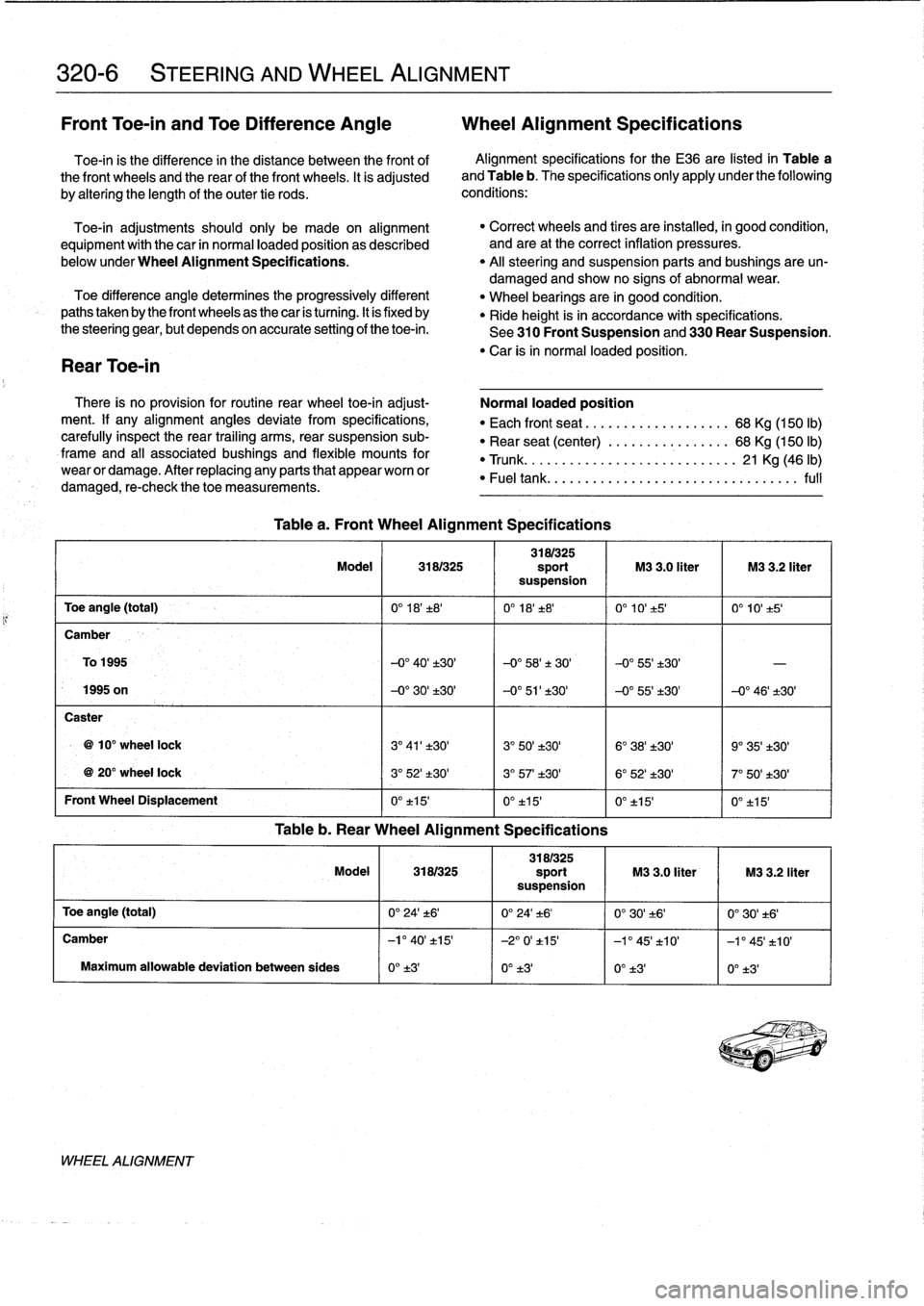

Table

a

.

Front

Wheel

Alignment

Specifications

"

Correct

wheels

and

tires

are

installed,

in

good

condition,

and

are

at

the

correct

inflation

pressures

.

"

Al¡

steering

and

suspension

parts

and

bushings

areun-

damaged

and

show

no

signs

of

abnormal

wear

.

"

Wheel

bearings

are

in

good

condition

.

"

Ride

height

is

in

accordance

with

specifications

.

See

310

Front

Suspension

and330

Rear

suspension

.

"

Car

isin

normal

loaded

position

.

Normal

loaded

position

"

Each

front

seat

.....:.............

68

Kg

(150

lb)

"

Rear

seat

(center)

................

68

Kg

(150

lb)

"

Trunk

.

.

.

..

.......................

21

Kg

(46

lb)

"

Fueltank

.

........................

...

.

..

..

full

3181325

Model

3181325

sport

M3

3

.0

liter

M3

3

.2

liter

suspension

Toe

angle

(total)

0°

18'±8'

0°

18'±8'

0°

10'

±5'

0°

10't5'

Camber

To

1995

-0°

40'±30'

-0°

58'±

30'

-0°55'±30'

-

1995

on

-0°

30'

±30'

-0°

51'±30'

-0°55'±30'

-0°

46'±30'

Caster

10°

wheel

lock

3°

41'±30'

3°

50'±30'

6°

38'±30'

9°

35'±30'

20°

wheel

lock

3°

52'±30'

3°

57'

t30'

6°

52'±30'

7°

50'±30'

Front

Wheel

Displacement

0°

t15'

0°t15'

0°

±15

0°

±15'

Table

b

.

Rear

Wheel

Alignment

Specifications

3181325

Model

3181325

sport

M3

3

.0

liter

M3

3

.2

liter

suspension

Toe

angle

(total)

0°

24't6'

0°

24'±6'

0'30'

.-t6'

0°

30't6'

Camber

-l'

40'

t15'

-2°

0'

t15'

-1

°

45'

t10'

-1'45'±10'

Maximum

allowabledeviation

between

sides

0°

±3'

0°

±3'

0°

t3'

0°

t3'

Page 309 of 759

GENERAL

This

repair

group

covers

replacement

of

the

front

fenders

and

removal

and

installation

of

the

engine

hood

.

NOTE-

The

body

is

painted

at

the

factoryafter

assembly

.

Re-

alignment

of

body

panels

may

expose

unpainted

metal

.

Paint

all

exposed

metal

once

the

work

fs

complete

.

FRONT

FENDERS

Front

fender,

removing

and

installing

1

.

Raise

hood

.

Raise

and

safely

support

front

of

vehicle

.

WARNING

-

"

When

raising

thecar

using

a

floor

jack

or

a

hy-

draulic

lift,

carefully

position

the

jack

pad

to

pre-

vent

damaging

thecar

body

.

A

suitable

liner

(wood,

rubber,

etc

.)

should

be

placed

between

the

jack

and

the

car

to

prevent

body

damage

.

"

Watch

the

jack

closely

.

Make

sure

it

stays

stable

and

does

not

shift

or

tilt

.

As

the

car

is

raised,

the

car

may

roll

slightly

and

the

jack

may

shift

.

2

.

Remove

front

wheel

.

Remove

inner

plastic

liner

from

wheel

well

.

3

.

Remove

front

bumper

.

See510

Exterior

Trim,

Bumpers

.

4

.

Working

atfront

corner

of

fender,

remove

front

grille

panel

bolts

(2

bolts

at

left

and

right)

.

See

Fig

.

1

.

FENDERS,

ENGINE

HOOD

410-1

410

Fenders,

Engine

Hood

GENERAL

...............

.

.

.

.

.

.

.

.

.

.

.

..

410-1

ENGINE

HOOD

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

...

.

.410-3

Hood,

raising

to

service

position

.

.

.

.

.

.

.

.

...

410-3

FRONTFENDERS

........

.

.

.

.

.

.

.

.

.

.

.

.

.410-1

Hood,

removin

and

installin

410-3

Front

Pender,

removing

and

installing

.

.

.

....

410-1

Hood,

aligning

...

.

.

.

.

.

.

.

.....

.

.

.

.

.

.

.

...

410-4

Hood

release

cable

and

latches,

adjusting

...

410-4

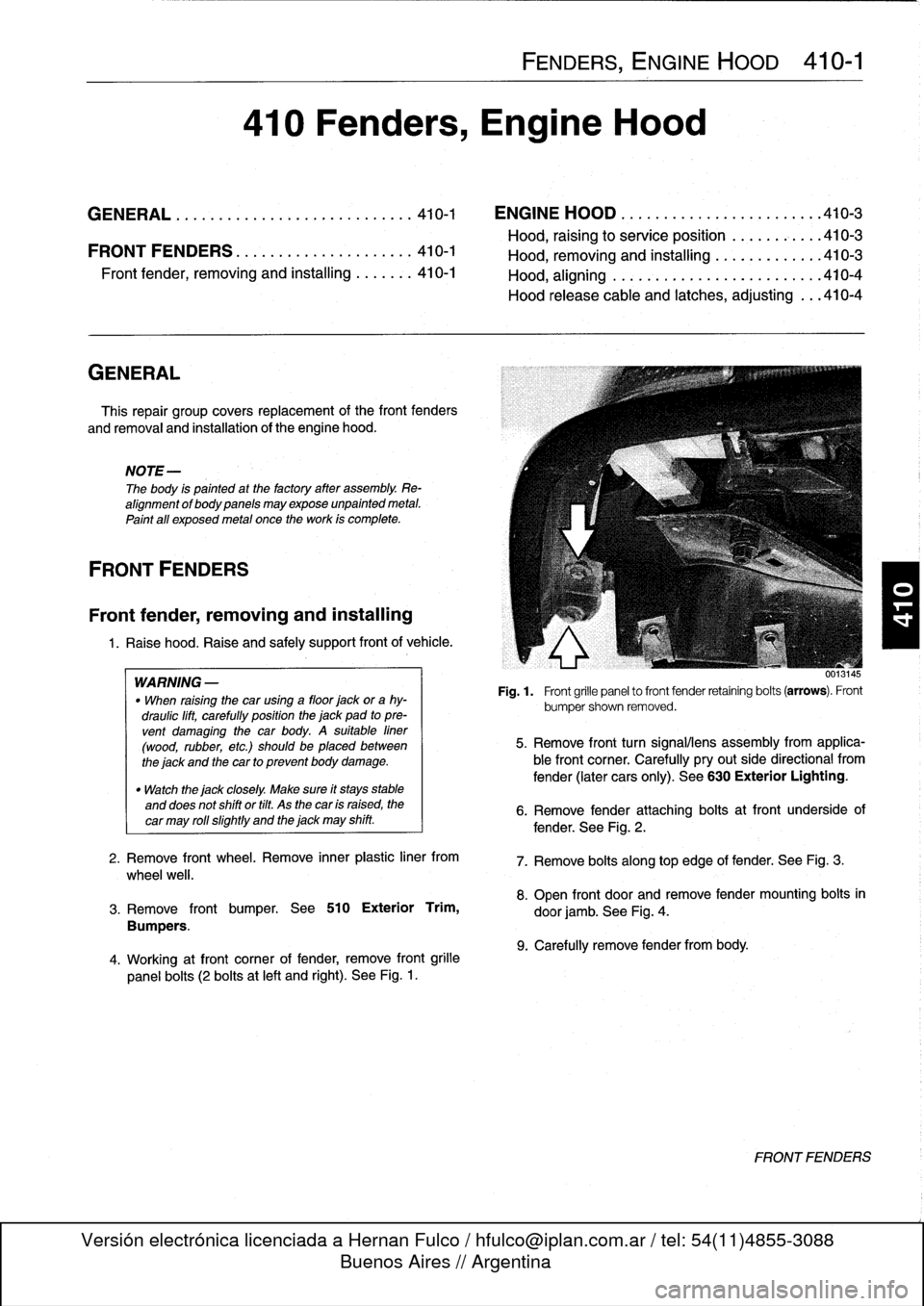

001

.145

Fig

.

1

.

Front

grille

panel

to

front

fender

retaining

bolts

(arrows)

.

Front

bumpershown

removed

.

5

.

Remove

front

turn

signalliens

assembly

from

applica-

ble

front

corner

.

Carefully

pryout

side

directional

from

fender

(later

cars

only)

.

See

630

Exterior

Lighting

.

6

.

Remove

fender

attaching

bolts

atfront

underside

of

fender

.

See

Fig

.

2

.

7

.

Remove

bolts

along

top

edge

of

fender

:

See

Fig

.

3

.

8

.

Open

front

door

and

remove

fender

mounting

bolts

in

door

jamb

.

See

Fig

.

4

.

9

.

Carefully

remove

fender

from

body

.

FRONTFENDERS

Page 312 of 759

410-4

FENDERS,

ENGINE

HOOD

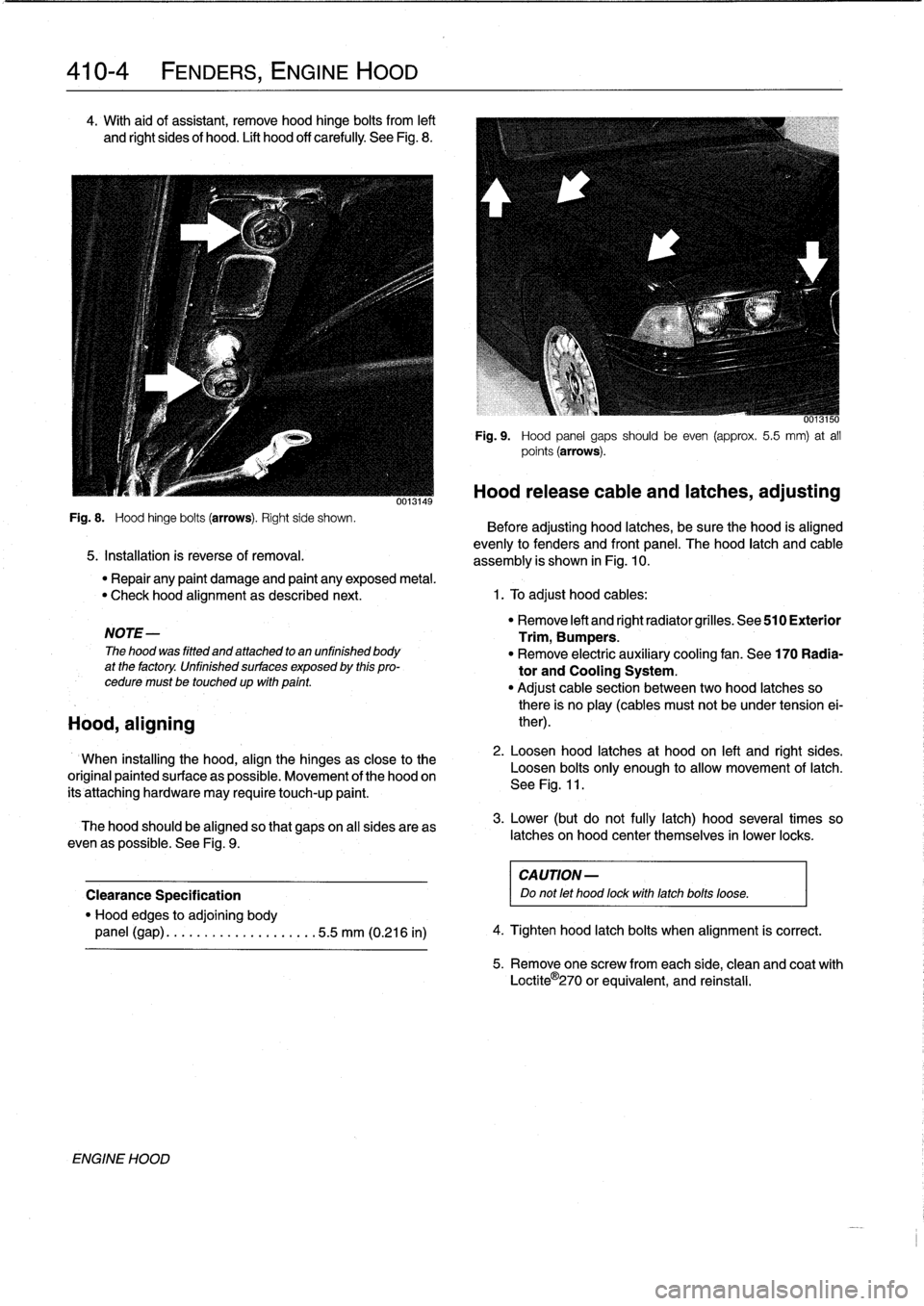

4

.

With

aid

of

assistant,

remove

hood

hinge

bolts

from

left

and

Rght

sides

of

hood

.

Lift

hood

off

carefully

See

Fig

.

8

.

Fig

.

8

.

Hood

hinge

bolts

(arrows)

.

Right

side

shown

.

5

.

Installation

is

reverse

of

removal

.

NOTE-

The

hood

was

fitted

and

attached

to

an

unfinished

body

at

the

factory

.

Unfinished

surfaces

exposed

by

this

pro-

cedure

must

betouchedup

wfth

pafnt

.

Hood,

aligning

ENGINE

HOOD

0013149

6013150

Fig

.

9

.

Hood

panel

gaps

should

be

even

(approx

.

5

.5

mm)

at

all

points

(arrows)

.

Hood

release

cable

and

latches,

adjusting

Before

adjusting

hood

latches,

be

sure

the

hood

is

aligned

evenly

to

fenders

and

front

panel

.

The

hood

latch

and

cable

assembly

is

shown

in

Fig

.

10

.

"

Repair

any

paint

damage

and

paint

any

exposed

metal

.

"

Check

hood

alignment

as

described

next

.

1

.

To

adjust

hood

cables

:

When

installing

the

hood,

align

the

hinges

as

close

to

the

original

paintedsurface

as

possible

.

Movement

of

the

hood

on

its'attaching

hardware

may

require

touch-up

paint

.

The

hood

should

be

aligned

so

that

gapson

all

sides

areas

even

as

possible

.

See

Fig

.

9

.

Clearance

Specification

"

Hood

edges

to

adjoining

body

panel

(gap)

........

..

..

..

.....

.5

.5

mm

(0.216

in)

"

Remove

left

and

right

radiator

grilles

.

See

510

Exterior

Trim,

Bumpers

.

"

Remove

electric

auxíliary

cooling

fan

.

See

170

Radia-

tor

and

Cooling

System

.

"

Adjust

cable

section

between

two

hood

latches

so

there

is

no

play

(cables

must

not

be

under

tension

ei-

ther)

.

2

.

Loosen

hood

latches

at

hood

on

left

and

right

sides

.

Loosen

bolts

only

enough

to

allow

movement

of

latch

.

See

Fig

.

11

.

3

.

Lower

(but

do

not

fully

latch)

hood

severa¡

times

so

latches

on

hood

center

themselves

in

lower

locks

.

CA

UTION-

Do

not

let

hood

fockwith

latchbolts

loose

.

4

.

Tighten

hood

latch

bolts

when

alignment

is

correct

.

5

.

Remove

one

screw

fromeach

side,

clean

and

coat

with

Loctite

O

270

or

equivalent,

and

reinstall

.

Page 316 of 759

411-2

DOORS

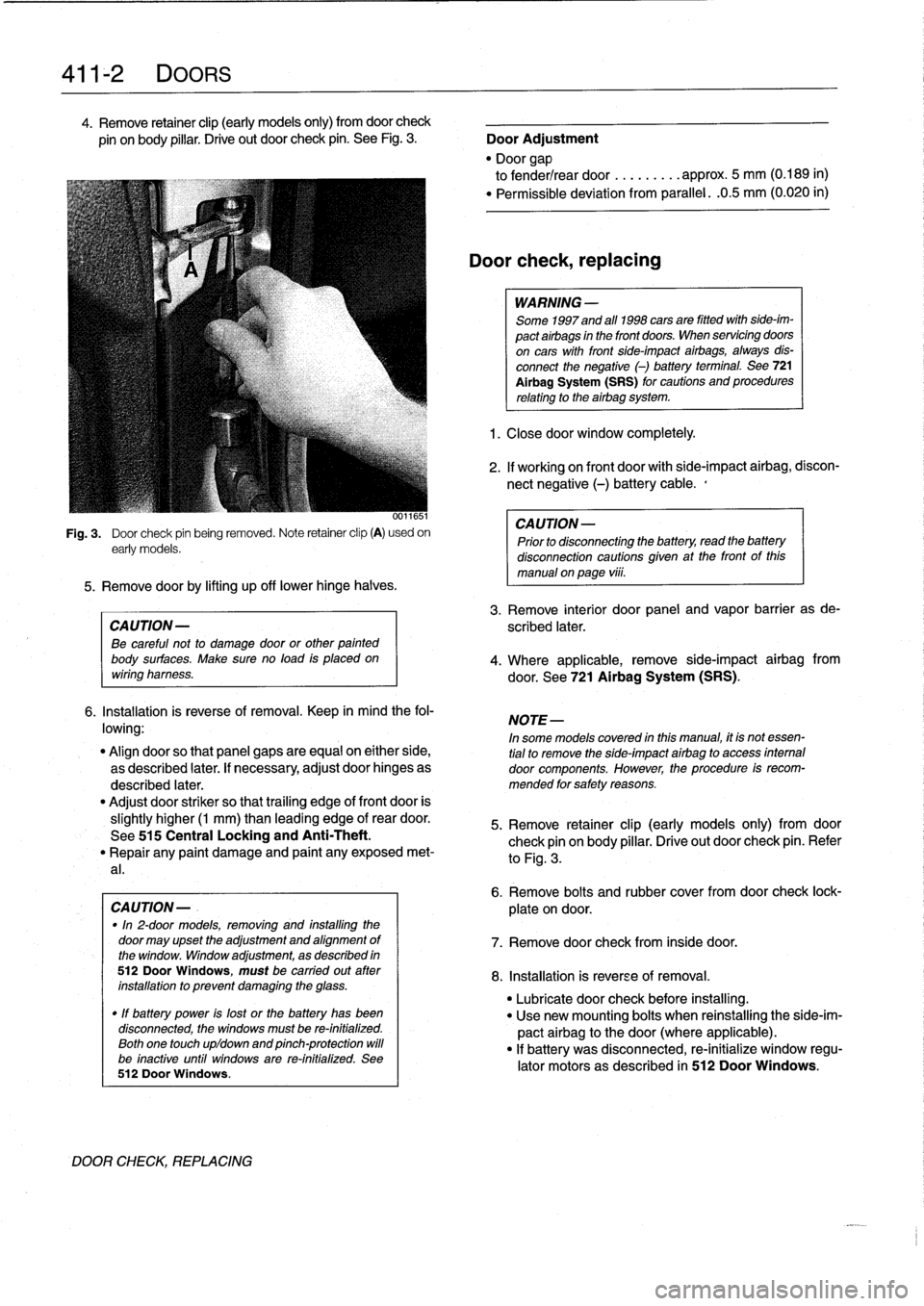

4

.

Remove

retainer

clip

(early

models

only)

from

doorcheck

pin

onbody

pillar

.

Drive

out

door

check

pin

.

See

Fig

.

3

.

Door

Adjustment

"

Door

gap

to

fender/rear

door

.........

approx

.

5

mm

(0

.189

in)

"

Permíssible

deviation

from

parallel

.

.0

.5

mm

(0

.020

in)

0011651

Fig

.

3

.

Door

check

pin

being

removed

.

Note

retainer

clip

(A)

usedon

early

models

.

5

.

Remove

doorby

lifting

up

off

lowerhinge

halves

.

CAUTION-

Be

careful

not

to

damage

door

or

other

painted

body

surfaces

.

Make

sure

no

load

is

placedon

wiring

harness

.

6

.

Installation

is

reverse

of

removal

.

Keep

in

mind

the

fol-

lowing

:

"

Align

doorso

that

panel

gaps

are

equal

on

either

side,

as

described

later

.

If

necessary,

adjust

door

hinges

as

described

later

.

"

Adjust

door

striker

so

that

trailing

edge

of

front

door

is

slightly

higher

(1

mm)

than

leading

edge

of

rear

door

.

See

515

Central

Locking

and

Anti-Theft

.

"

Repair

any

paint

damage

and

paínt

any

exposed

met-

al

.

CAUTION-

.

"In

2-door

models,

removing

and

installing

the

door

may

upset

the

adjustment

and

alignment

of

the

window

.

Window

adjustment,

as

described

in

512DoorWindows,

must

be

carried

out

ater

installation

to

prevent

damaging

the

glass

.

"

If

battery

power

is

lost

or

the

battery

has

been

disconnected,

the

windows

must

be

re-initialized

.

Both

one

touch

upldown

and

pinch-protection

will

be

inactive

until

windows

are

re-initialized

.

See

512

Door

Windows

.

DOOR

CHECK,

REPLACING

Door

check,replacing

WARNING

-

Some

1997

and

all

1998

cars

are

fitted

with

side-im-

pact

airbags

in

the

front

doors

.

When

servicing

doors

on

cars

with

front

side-impact

airbags,

always

dis-

connect

the

negative

(-)

battery

terminal

.

See

721

Al

rbag

System

(SRS)

for

cautions

and

procedures

relating

to

the

airbag

system

.

1

.

Closedoor

window

completely

.

2

.

If

working

on

front

door

with

side-impact

airbag,

discon-

nect

negative

(-)

battery

cable

.,

CAUTION-

Prior

to

disconnectiog

the

battery,

read

the

battery

disconnection

cautions

gíven

at

the

front

of

this

manual

on

page

viii

.

3

.

Remove

interior

door

panel

and

vapor

barrier

as

de-

scribed

later

.

4

.

Where

applicable,

remove

side-impact

airbag

from

door

.

See

721

Airbag

System

(SRS)

.

NOTE-

In

some

models

covered

inthis

manual,

ít

is

not

essen-

tial

to

remove

the

side-ímpact

airbag

to

access

internal

door

components

.

However,

the

procedure

is

recom-

mended

for

safety

reasons

.

5

.

Remove

retainer

clip

(early

models

only)

from

door

check

pin

on

body

pillar

.

Drive

out

door

check

pin

.

Refer

to

Fig

.

3

.

6

.

Remove

bolts

and

rubber

cover

fromdoor

check

lock-

plate

ondoor

.

7

.

Remove

door

check

from

inside

door

.

8

.

Installation

is

reverse

of

removal

.

"

Lubricate

door

check

before

installing

.

"

Use

new

mounting

bolts

when

reinstalling

the

side-im-

pact

airbag

to

thedoor(where

applicable)

.

"

If

battery

was

disconnected,

re-initialize

window

regu-

lator

motors

as

described

in

512

Door

Windows

.

Page 321 of 759

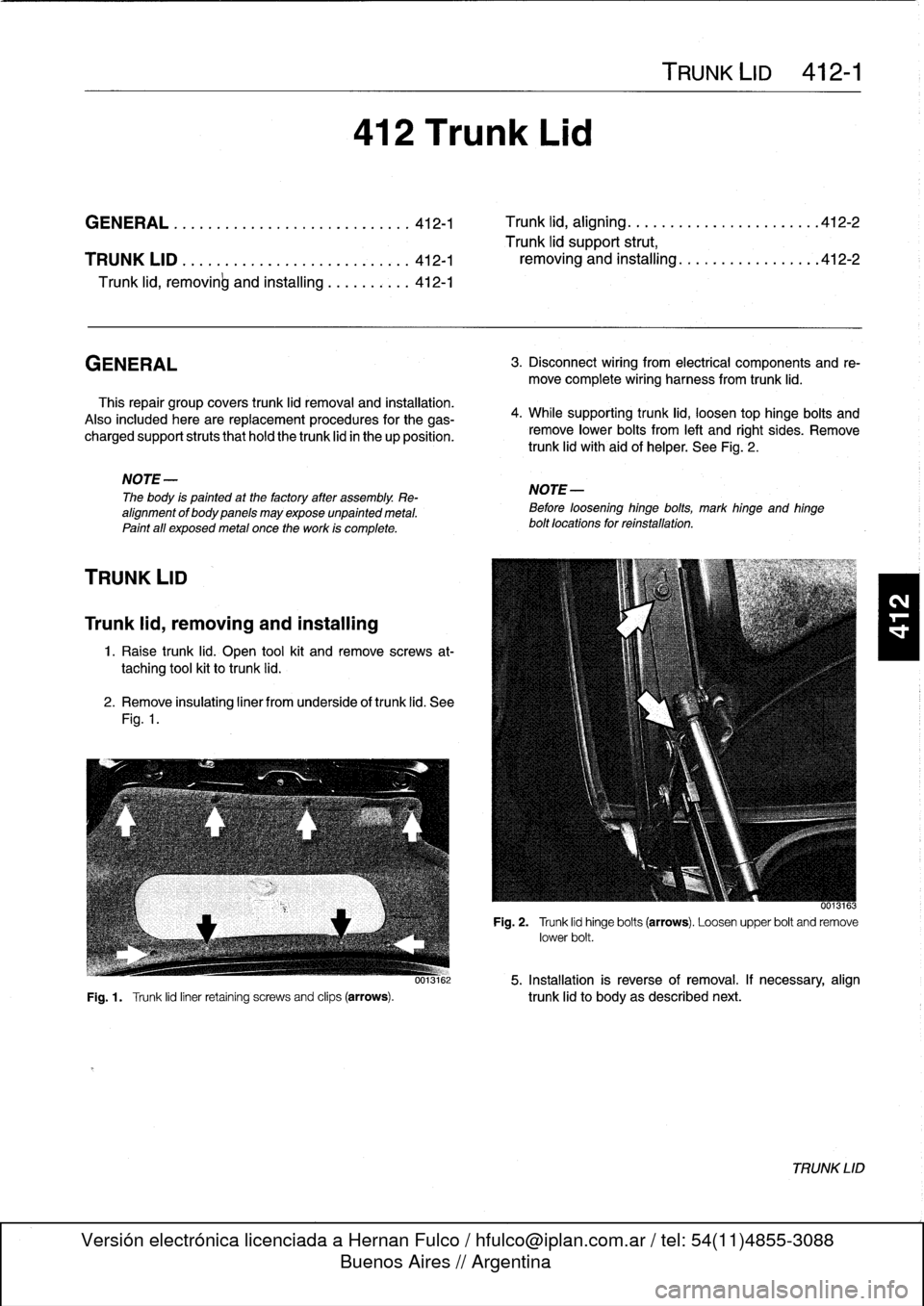

GENERAL

This

repair

group

covers

trunk

lid

removal

and

installation

.

Also

inciuded

here

arereplacement

procedures

for

the

gas-

charged

support

struts

that

hold

the

trunk

lid

in

the

up

position

.

NOTE

-

The

body

ís

painted

at

the

factory

after

assembly

.

Re-

alignment

of

body

panels

may

expose

unpainted

metal

.

Paint

all

exposed

metal

once

the

work

is

complete

.

TRUNK

LID

Trunk

lid,

removing

and

installing

1

.

Raise

trunk

lid

.

Open

tool

kit

and

remove

screws

at-

taching

tool

kit

lo

trunk

lid

.

2

.

Remove

insulating

liner

from

underside

of

trunk

lid

.

See

Fig

.

1

.

412

Trunk

Lid

TRUNK

LID

412-1

GENERAL

............

.

...

.

.....

.

...

.

.

412-1

Trunk

lid,

aligning

.

.

.

.

.

.....

.

...

.

.

.

.

.

.

.

..

412-2

Trunk

lid

support

strut,

TRUNK

LID

.

.

.

............

.

.

.

...

.

.

.

.

.

.

412-1

removing

and

installing

..

.

.

.

.

.

.

.

.

.

...

.

.

.

412-2

Trunk

lid,

removinb

and

installing

......

.

.

.

.

412-1

3

.

Disconnect

wiring

from

electrical

components

and

re-

move

complete

wiring

harness

from

trunk

lid

.

4

.

While

supporting

trunk

lid,

loosen

top

hinge

bolts

and

remove

lower

bolts

from

left

and

right

sides

.

Remove

trunk

lid

with`aid

of

helper

.

See

Fig

.

2

.

NOTE-

Before

loosening

hinge

bolts,

mark

hinge

and

hinge

bolt

locations

for

reínstallation

.

0013163

Fig

.

2

.

Trunk

lid

hinge

bolts

(arrows)

.

Loosen

upper

bolt

and

remove

lower

bolt

.

0013162

5

.

Installation

is

reverse

of

removal

.

If

necessary,

align

Fig

.

1

.

Trunk

lid

liner

retaining

screws

and

clips

(arrows)

.

trunk

lid

to

body

as

described

next

.

TRUNK

LID

Page 335 of 759

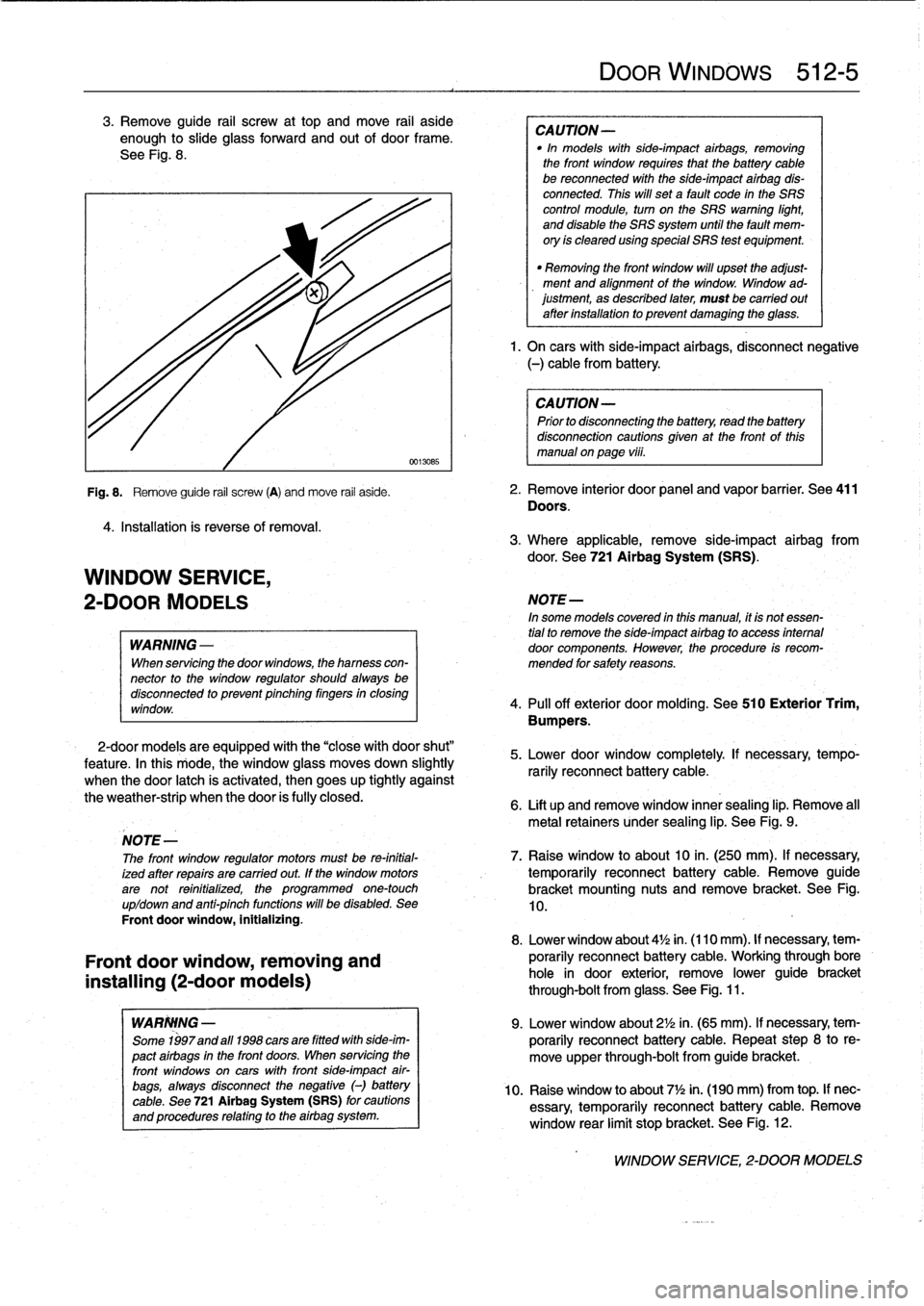

3

.

Remove

guide

rail

screw

at

top

and

move

rail

aside

enough

to

slide

glass

forward

and

out

of

door

frame

.

See

Fig

.

8

.

4

.

Installation

is

reverse

of

removal

.

WINDOW

SERVICE,

2-DOOR

MODELS

WARNING

-

When

servicing

the

door

windows,

the

hamess

con-

nector

to

the

window

regulator

shouldalwaysbe

disconnectod

to

prevent

pinching

fingers

in

closing

window

.

2-door

models

are

equipped

with

the

"close

with

door

shut"

feature

.

In

this

rriode,

the

window

glass

moves

down

slightly

when

the

door

latch

is

activated,

then

goes

up

tightly

against

the

weather-strip

when

the

door

is

fully

closed

.

Front

door

window,

removing

and

installing

(2-door

models)

WARIWNG

-

Some

1997and

a111998

cars

are

fitted

with

side-im-

pact

airbags

in

the

front

doors

.

When

servicing

the

front

windows

on

cars

with

front

side-impact

air-

bags,

always

disconnect

the

negative

(-)

battery

cable

.

See

721

Airbag

System(SRS)

for

cautions

and

procedures

relating

to

the

airbag

system

.

DOOR

WINDOWs

512-

5

CAUTION-

"In

models

with

side-impact

airbags,

removing

the

front

window

requires

fhat

the

battery

cable

be

reconnected

with

the

side-impact

airbag

dis-

connected

.

This

will

set

a

fault

code

in

the

SRS

control

module,

turn

on

the

SRS

warning

light,

and

disable

the

SRS

system

until

the

fault

mem-

ory

is

cleared

using

special

SRS

test

equipment

.

"

Removing

the

front

window

will

upset

the

adjust-

ment

and

alignment

of

the

window

.

Window

ad-justment,

as

described

later,

must

be

carried

out

after

installation

to

prevent

damaging

the

glass

.

1.

On

carswith

side-impact

airbags,

disconnect

negative

(-)

cable

from

battery

.

CAUTION-

Prior

to

disconnectiog

the

battery,

read

the

battery

disconnection

cautions

given

at

the

front

of

this

manual

on

page

viii

.

Fig

.

8

.

Remove

guide

rail

screw

(A)

and

move

rail

aside

.

2

.

Remove

interior

door

panel

and

vapor

barrier

.

See

411

Doors

.

3

.

Where

applicable,

remove

side-impact

airbag

from

door

.

See

721

Airbag

System

(SRS)

.

NOTE-

In

some

models

covered

in

this

manual,

it

is

notessen-

tial

to

remove

the

side-impact

airbag

lo

access

intemal

door

components

.

However,

the

procedure

is

recom-

mended

for

safety

reasons

.

4

.

Pull

off

exterior

doormolding

.

See

510

Exterior

Trim,

Bumpers

.

5

.

Lower

door

window

completely

If

necessary,

tempo-

rarily

reconnect

battery

cable

.

6

.

Lift

up

and

remove

window

innersealing

lip

.

Remove

all

metal

retainers

under

sealing

lip

.

See

Fig

.

9

.

NOTE

-

The

front

window

regulator

motors

must

be

re-initial-

7

.

Raise

window

to

about10

in

.

(250

mm)

.

If

necessary,

ized

after

repairs

are

carried

out

.

If

the

window

motors

temporarily

reconnect

battery

cable

.

Remove

guide

arenot

reinitialized,

the

programmed

one-touch

bracket

mounting

nuts

and

remove

bracket

.

See

Fig

.

up/down

and

anti-pinch

functions

will

be

disabled

.

See

10,

Front

doorwindow,

initializing

.

8

.

Lower

window

about

4'/2

in

.

(110mm)

.

If

necessary,

tem-

porarily

reconnect

batterycable

.

Working

through

bore

hole

in

door

exterior,

remove

lower

guide

bracket

through-bolt

from

glass

.

See

Fig

.

11

.

9

.

Lower

window

about

2'/2

in

.

(65

mm)

.

If

necessary,

tem-

porarily

reconnect

battery

cable

.

Repeat

step

8

to

re-

move

upper

through-bolt

from

guide

bracket

.

10

.

Raise

window

to

about

7

1

/2in

.

(190

mm)

from

top

.

If

nec-

essary,

temporarily

reconnect

batterycable

.

Remove

window

rear

limit

stop

bracket

.

See

Fig

.

12

.

WINDOW

SERVICE,

2-DOOR

MODELS

Page 347 of 759

Dashboard,

removing

and

installing

1

.

Disconnect

negative

(-)

cable

from

battery

and

cover

terminal

with

insulating

material

.

CAUTION-

Prior

to

disconnectiog

the

battery,

read

the

battery

disconnection

cautionsgiven

at

the

front

of

this

manual

onpage

vi¡¡

.

2

.

Remove

center

console

as

described

earlier

.

3

.

Remove

glove

compartment

as

described

earlier

.

4

.

Remove

lower

left

dash

trim

piece

as

described

above

.

Remove

lower

right

dash

trim

panel

.

See

Fig

.

4

.

Fig

.

4

.

Lower

right

dash

trim

piece

retaining

screw

(arrow)

.

WARNING

-

Store

the

removed

airbags

in

a

safe

place

.

Position

the

airbags

facing

up

.

8

.

Remove

instrument

cluster

.

See

620

Instruments

.

5

.

Remove

driver

and

passenger

airbags

.

See

721

Air-

bag

System

(SRS)

.

6

.

Remove

steering

wheel

.

See

320

Steering

and

Wheel

Alignment

.

INTERIOR

TRIM

513-

3

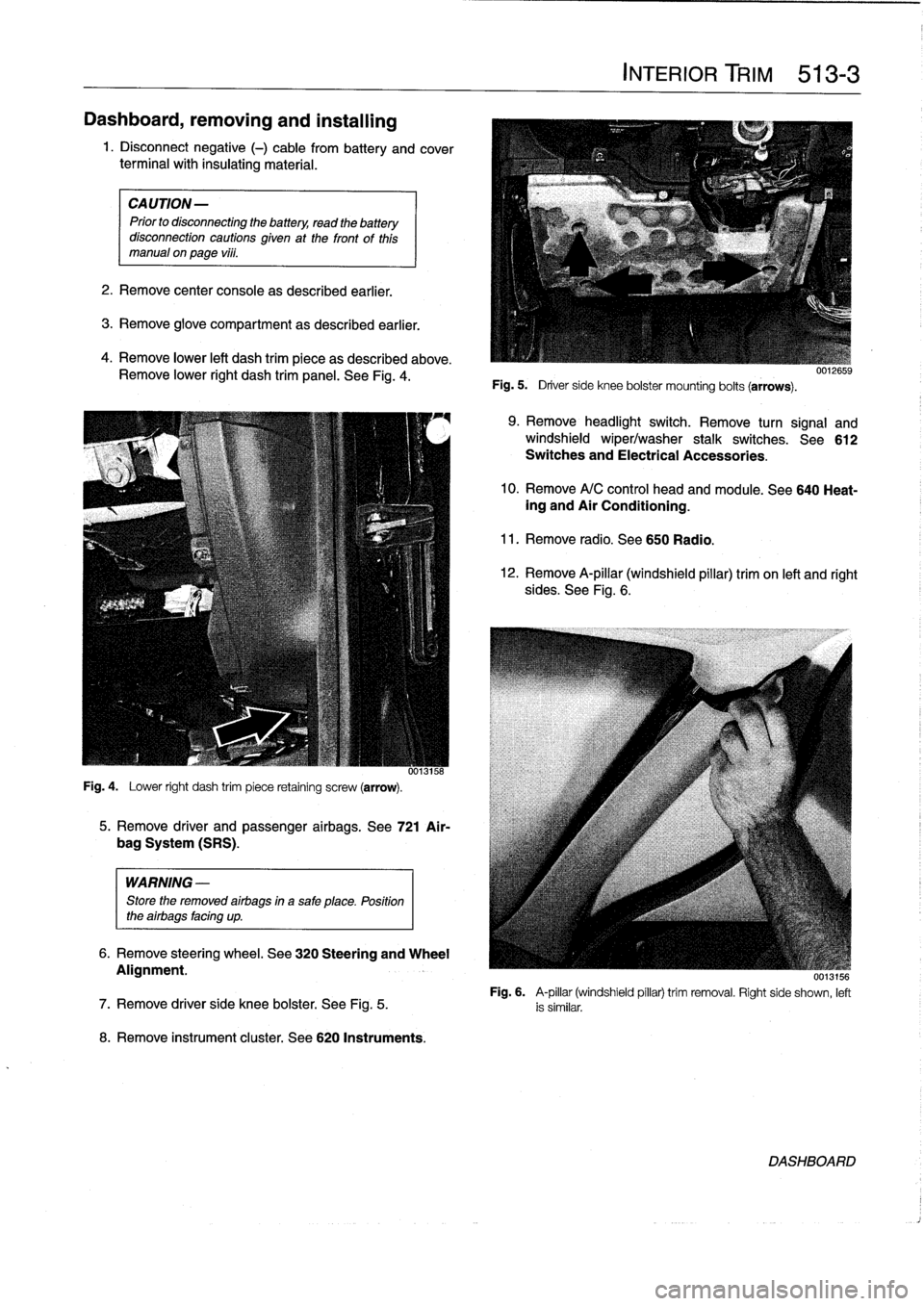

Fig

.

5

.

Driver

side

knee

bolster

mounting

bolts

(arrows)

.

9

.

Remove

headlight

switch

.

Remove

turn

signal

and

windshield

wiper/washer

stalk

switches

.

See612

Switches

and

Electrical

Accessories

.

10

.

Remove

A/C

control

head

and

module

.

See

640

Heat-ing

and

Air

Conditioning

.

11

.

Remove

radio

.

See650

Radio

.

12

.

Remove

A-pillar

(windshield

pillar)

trim

on

left

and

right

sides

.

See

Fig

.

6

.

UU13156

Fig

.

6

.

A-pillar

(windshield

pillar)

trim

removal

.

Right

side

shown,

left

7

.

Remove

driver

side

knee

bolster

.

See

Fig

.

5

.

is

similar

.

DASHBOARD