rear BMW 328i 1997 E36 Manual PDF

[x] Cancel search | Manufacturer: BMW, Model Year: 1997, Model line: 328i, Model: BMW 328i 1997 E36Pages: 759

Page 187 of 759

2

.

Remove

fuel

tank

filler

cap

.

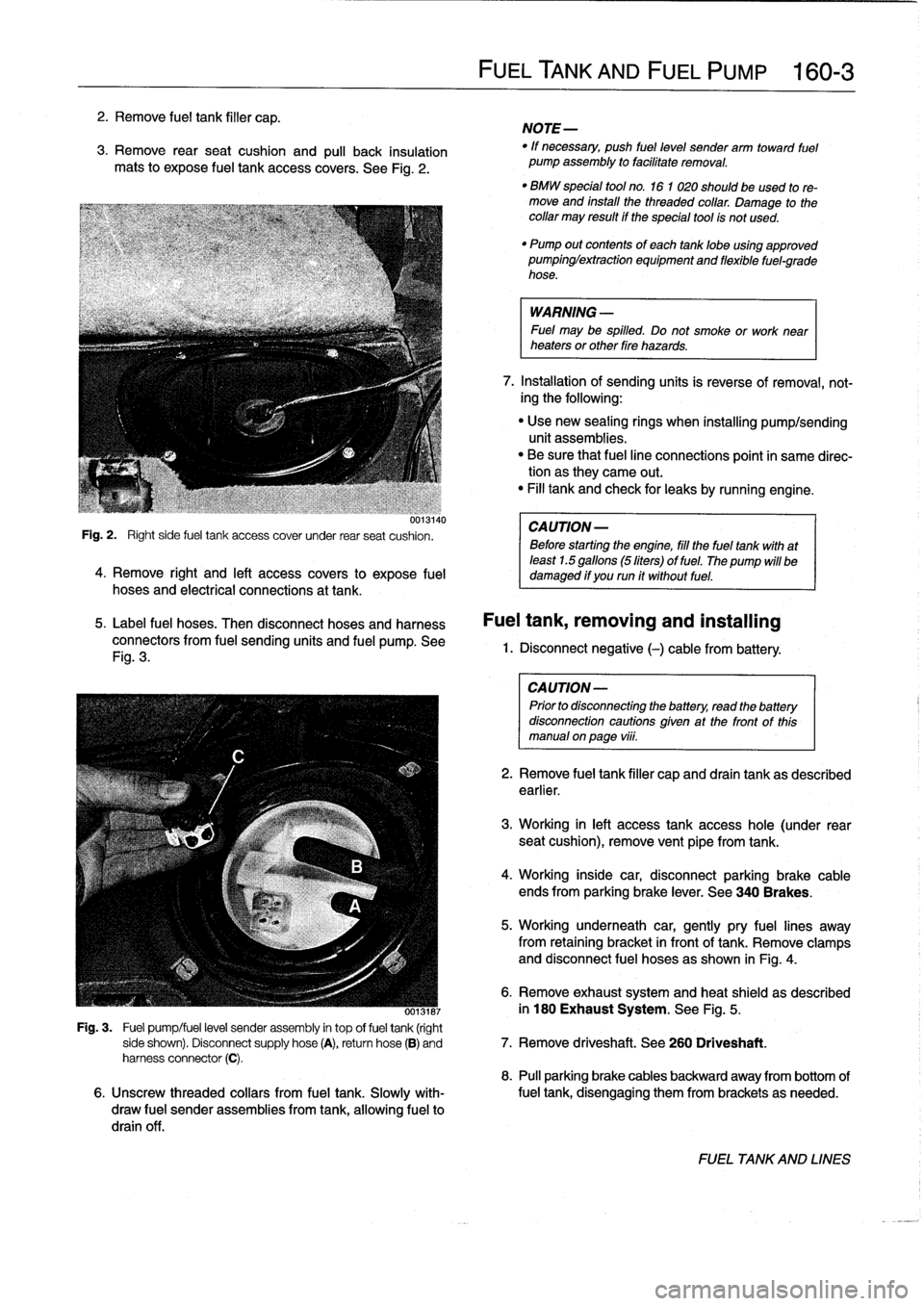

3

.

Remove

rearseat

cushion

and

pull

back

insulation

mats

to

expose

fuel

tank

access

covers

.

See

Fig

.

2

.

uui3140

Fig

.

2

.

Right

side

fuel

tank

access

cover

under

rear

seat

cushion

.

4

.

Remove

right

and

left

access

covers

to

expose

fuel

hoses

and

electrical

connections

at

tank

.

5

.

Label

fuel

hoses

.

Then

disconnect

hoses

and

harness

connectors

from

fuel

sending

units

and

fuel

pump

.

See

Fig

.

3

.

FUELTANK

AND

FUEL

PUMP

160-

3

NOTE-

"

If

necessary,

push

fuel

level

sender

arm

toward

fuel

pump

assembly

to

facilitate

removal

.

"

BMW

special

tool

no

.

16

1

020

should

beused

tore-

move

and

install

the

threaded

collar

.

Damage

to

thecollar

may

result

if

the

special

tool

is

not

used

.

"

Pump

out

contents

of

each

tanklobe

using

approved

pumpinglextraction

equipment

and

flexible

fuel-grade

hose

.

WARNING

-

Fuel

may

be

spilled

.

Do

not

smoke

or

work

near

heaters

or

other

fire

hazards

.

7

.

Installation

of

sending

units

is

reverse

of

removal,

not-

ing

the

following

:

"

Use

new

sealing

rings

when

installing

pump/sending

unit

assemblies

.

"

Be

sure

that

fuel

line

connections

point

in

same

direc-tion

as

they

carne

out

.

"

Fill

tank

and

check

for

leaks

by

running

engine

.

CA

UTION-

Before

starting

the

engine,

fill

the

fuel

tank

with

at

least

1.5

gallons

(5liters)

of

fuel

.

The

pump

will

be

damaged

if

you

run

it

without

fuel

.

Fuel

tank,

removing

and

installing

1.

Disconnect

negative

(-)cablefrom

battery

:

CAUTION-

Prior

to

disconnectiog

the

battery,

read

the

battery

disconnection

cautions

given

at

the

front

of

this

manual

onpage

viii

.

2

.

Remove

fuel

tank

filler

capand

drain

tank

as

described

earlier

.

3

.

Working

in

left

access

tank

access

hole

(under

rear

seat

cushion),

remove

vent

pipe

fromtank

.

4

.

Working

inside

car,

disconnectparking

brake

cable

ends

from

parking

brake

lever

.

See

340

Brakes

.

5

.

Working

underneath

car,

gently

pry

fuel

lines

away

from

retaining

bracket

in

front

of

tank

.

Remove

clamps

and

disconnect

fuel

hoses

as

shown

in

Fig

.

4

.

6

.

Remove

exhaust

system

and

heat

shield

as

described

ooisiai

in

180

Exhaust

System

.

See

Fig

.

5

.

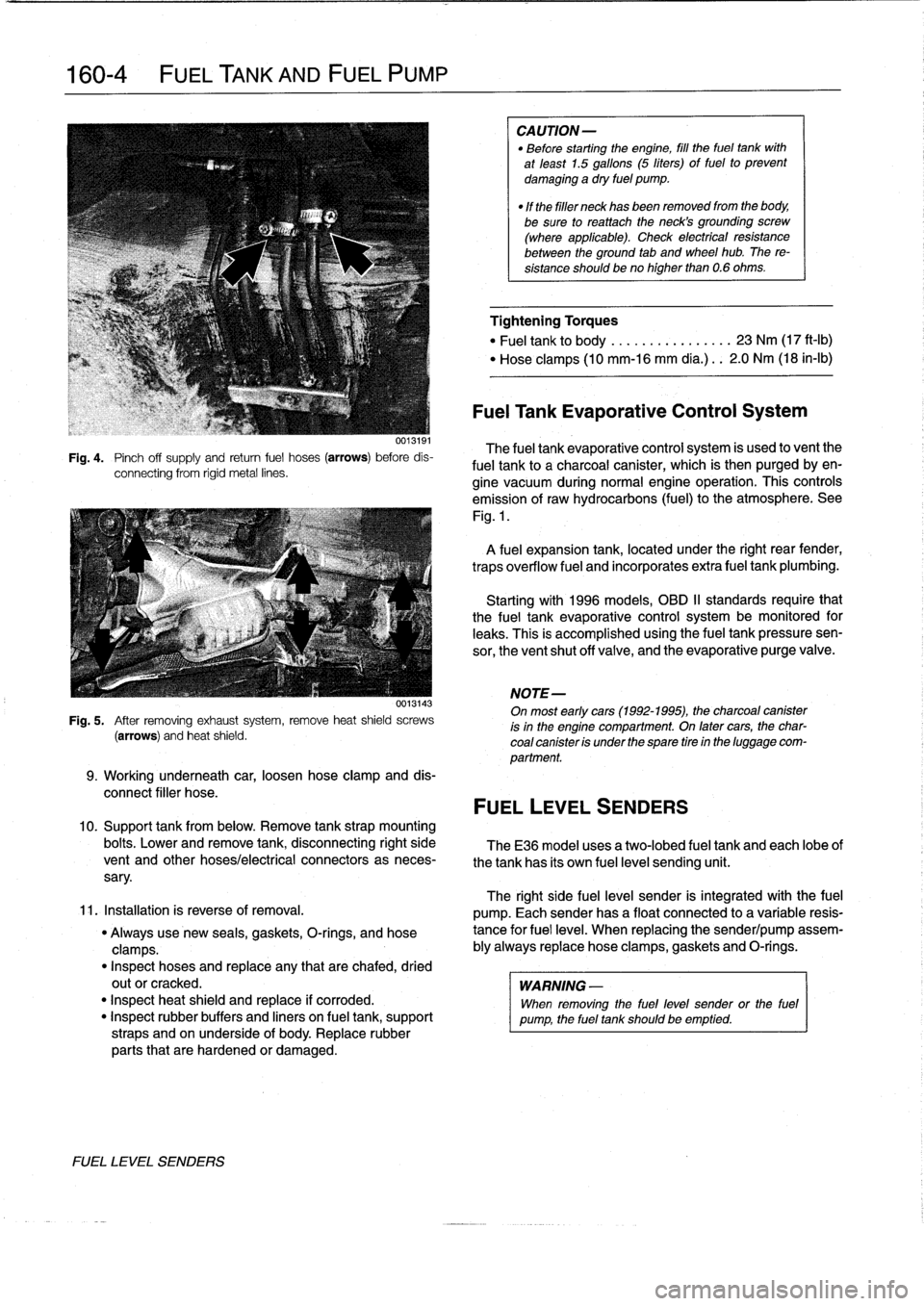

Fig

.

3

.

Fuel

pump/fuel

level

sender

assembly

in

top

offuel

tank

(right

side

shown)

.

Disconnect

supply

hose

(A),

return

hose

(B)

and

7

.

Remove

driveshaft

.

See

260

Driveshaft

.

harness

connector

(C)

.

8

.

Pull

parking

brake

cables

backward

away

from

bottom

of

6

.

Unscrew

threaded

collars

from

fuel

tank

.

Slowly

with-

fuel

tank,

disengaging

them

from

brackets

as

needed

.

draw

fuel

sender

assemblies

from

tank,allowing

fuel

to

drain

off

.

FUEL

TANKAND

LINES

Page 188 of 759

160-

4

FUEL

TANK

AND

FUEL

PUMP

Fig

.

4

.

Pinch

off

supply

and

retum

fuel

hoses

(arrows)

before

dis-

connecting

from

rigid

metal

lines

.

0013143

Fig

.

5

.

After

removing

exhaustsystem,

remove

heat

shield

screws

(arrows)

and

heat

shield

.

9

.

Working

underneath

car,

loosen

hose

clamp

and

dis-

connect

filler

hose

.

10

.

Support

tank

from

below

.

Remove

tank

strap

mounting

bolts

.

Lower

and

remove

tank,

disconnecting

right

side

TheE36

model

uses

a

two-lobed

fuel

tank

and

each

lobeof

vent

and

other

hoses/electrical

connectors

as

neces-

the

tank

has

its

own

fuel

level

sending

unit

.

sary

.

11

.

Installation

is

reverse

of

removal

.

"

Always

use

new

seals,

gaskets,

O-rings,

and

hose

clamps

.

"

Inspect

hoses

and

replace

any

that

are

chafed,

dried

outor

cracked

.

"

Inspect

heat

shield

and

replace

if

corroded

.

"

Inspect

rubber

buffers

and

liners

on

fuel

tank,

support

straps

and

on

underside

of

body

.

Replace

rubber

parts

that

are

hardened

or

damaged

.

FUEL

LEVEL

SENDERS

CAUTION-

"

Before

starting

the

engine,

fill

the

fuel

tank

with

at

least

1.5

gallons

(5

liters)

of

fuel

to

prevent

damaging

a

dry

fuel

pump

.

"

If

the

filler

neck

has

been

removed

from

the

body,

be

sure

toreattach

theneck's

grounding

screw

(where

applicable)

.

Check

electrical

resistance

between

the

ground

tab

and

wheel

hub

.

The

re-

sistance

shouldbeno

higher

than

0

.6

ohms

.

Tightening

Torques

"

Fuel

tank

to

body

.............

...

23

Nm

(17

ft-Ib)

"

Hose

clamps

(10

mm-16

mm

día

.)

..

2

.0

Nm

(18

in-lb)

Fuel

Tank

Evaporative

Control

System

The

fuel

tank

evaporative

control

system

is

used

to

vent

the

fuel

tank

to

a

charcoal

canister,

which

is

then

purgedby

en-

gine

vacuum

during

normal

engine

operatíon

.

This

controls

emission

of

raw

hydrocarbons

(fuel)

to

the

atmosphere

.

See

Fig

.

1

.

A

fuel

expansion

tank,

located

under

the

right

rear

fender,

traps

overflow

fuel

and

incorporates

extra

fuel

tank

plumbing

.

Startingwith

1996

models,

OBD

II

standards

require

that

the

fuel

tank

evaporative

control

system

be

monitored

for

leaks

.

This

is

accomplished

usingthe

fuel

tankpressuresen-

sor,

the

ventshut

off

valve,

and

the

evaporative

purge

valve

.

NOTE-

On

most

early

cars(1992-1995),

the

charcoal

canister

is

in

the

engine

compartment

.

On

latercars,

the

char-

coal

canister

is

under

the

spare

tire

in

the

luggage

com-

partment

.

FUEL

LEVEL

SENDERS

The

right

side

fuel

leve¡

sender

is

integrated

with

the

fuel

pump

.

Each

senderhas

a

float

connected

to

a

variable

resis-

tance

for

fuel

leve¡

.

When

replacing

the

sender/pump

assem-

bly

always

replace

hose

clamps,gaskets

and

O-rings

.

WARNING

-

When

removing

the

fuel

level

sender

or

the

fuel

pump,

the

fuel

tank

should

be

emptied

.

Page 189 of 759

Fuel

leve¡

senders,

testing

Fuel

leve¡

sender

(right

side)

The

left

and

right

fuelleve¡

sending

units

are

wired

in

series

.

and

fuel

pump,

removing

and

installing

The

fuel

gauge

receives

a

signal

that

is

the

average

of

the

two

1

.

Disconnect

negative

(-)

cable

from

battery

.

input

values

.

1

.

Remove

rear

seat

cushion,

lift

up

insulation

mats,

andremove

both

fuel

tank

access

covers

.

2

.

Disconnect

white

plug

on

each

sending

unit

.

See

Fig

.

6

.

3

.

Check

resistance

value

of

eachsending

unit

.

Values

should

be

the

same

.

5

.

If

valuesare

different,

remove

sending

units

as

described

below,

and

check

resistance

valuésacross

terminals

.

Table

a

lists

resistance

values

for

senders

at

various

float

positions

.

Table

a

.

Fuel

Leve¡

Sender

Resistances

Float

position

Test

result

(ohms)

Right

side

empty

10

ohm

t2

Right

side

full

250

ohm

±

5

Left

side

empty

10

ohm

t

2

Left

side

fui¡

250

ohm

±

5

FUEL

TANK

AND

FUEL

PUMP

160-

5

CAUTION

-

Prior

to

disconnecting

the

battery,

read

the

battery

disconnection

cautionsglven

at

the

front

of

this

manual

onpage

viii

.

2

.

Drain

fuel

from

tank

as

described

earlier

.

WARNING

-

Always

unscrew

the

fuel

tank

cap

to

release

pres-

sure

in

the

tank

before

working

on

the

tank

or

fines

.

3

.

Remove

rear

seat

cushion

and

pull

back

insulation

pad

under

right

side

.

4

.

Remove

screws

holding

rightfuel

tank

accesscover

.

Remove

cover

.

5

.

Label

fuel

hoses

.

Disconnect

hoses

and

harness

con-

nectors

from

fuel

sending

unit

and

fuel

pump

.

6

.

Unscrew

threaded

collar

from

fuel

pumplfuel

leve¡

sender

.

Slowly

withdraw

assembly

from

tank,allowing

fuelto

drain

off

.

See

Fig

.

7

.

0013187

&

0013194

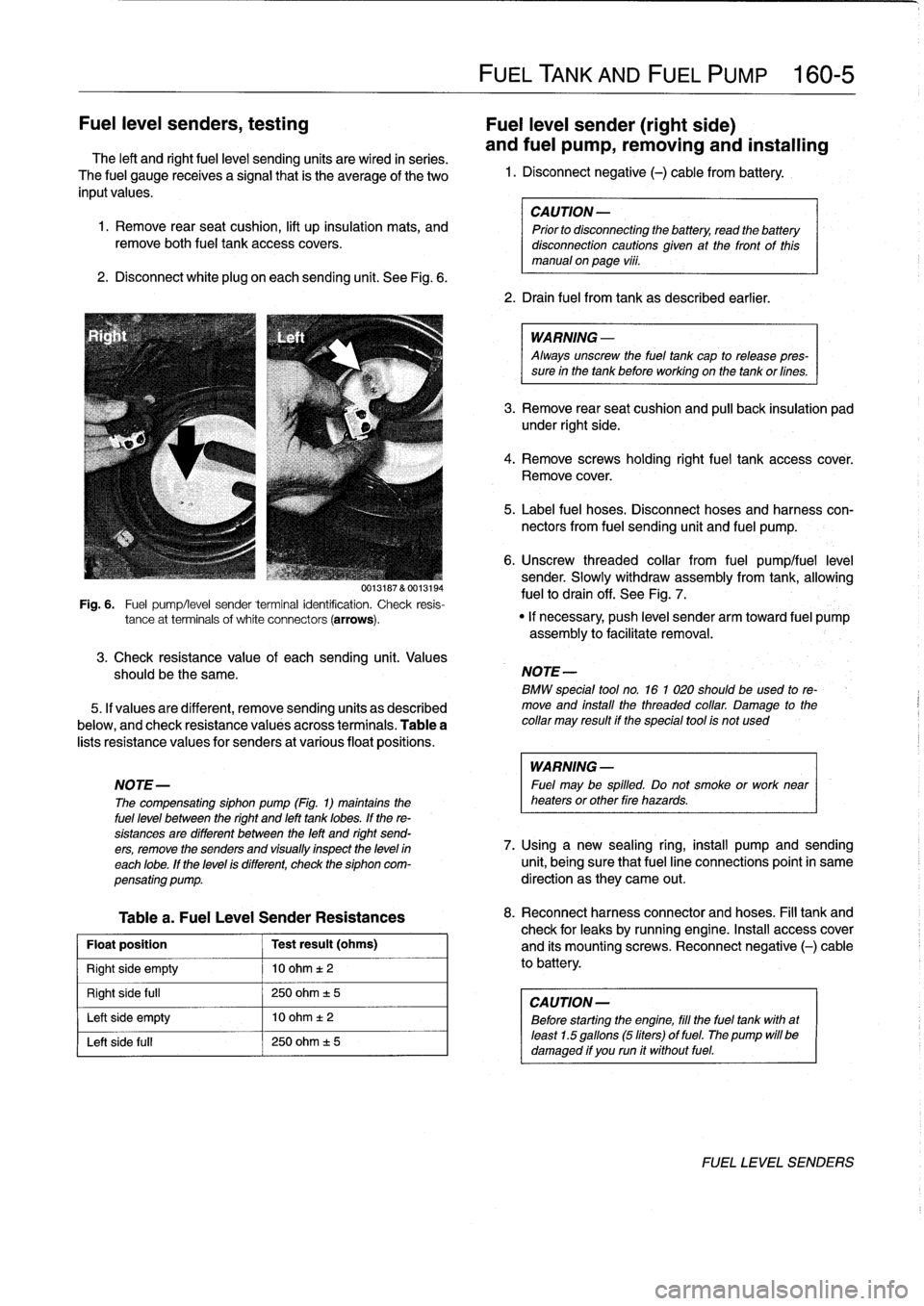

Fig

.

6

.

Fuel

pump/leve¡

sender

terminal

identification

.

Check

resis-

tance

at

terminals

of

white

connectors

(arrows)

.

"

If

necessary,

push

leve¡

sender

arm

toward

fuel

pump

assembly

to

facilitate

removal

.

NOTE

-

BMW

special

tool

no

.

16

1

020

should

beused

to

re-

move

and

install

the

threaded

collar

.

Damage

to

the

collar

may

result

if

the

special

tool

is

not

used

WARNING

-

NOTE-

Fuel

may

be

spilled

.

Do

not

smoke

or

work

near

The

compensating

siphon

pump

(Fig

.

1)

maintains

the

heaters

or

other

fire

hazards

.

fuel

leve¡

between

the

right

and

left

tank

lobes

.

If

the

re-

sistances

are

different

between

the

left

and

right

send-

ers,

remove

the

senders

and

visually

inspect

the

leve)

in

7

.

Using

a

new

sealing

ring,

install

pump

and

sending

each

lobe

.

If

the

leve¡

is

different,

check

the

siphon

com-

unit,

being

sure

that

fuel

line

connections

point

in

same

pensating

pump

.

direction

as

they

carne

out

.

8

.

Reconnect

harnessconnector

and

hoses

.

Fill

tank

and

check

for

leaks

by

running

engine

.

Insta¡¡

access

cover

and

its

mountingscrews

.

Reconnect

negative

(-)

cable

to

battery

.

CAUTION

-

Before

starting

the

engine,

fill

the

fuel

tank

with

at

least

1

.5

gallons

(5liters)

of

fuel

.

The

pump

will

be

damaged

if

you

run

it

without

fuel

.

FUEL

LEVEL

SENDERS

Page 191 of 759

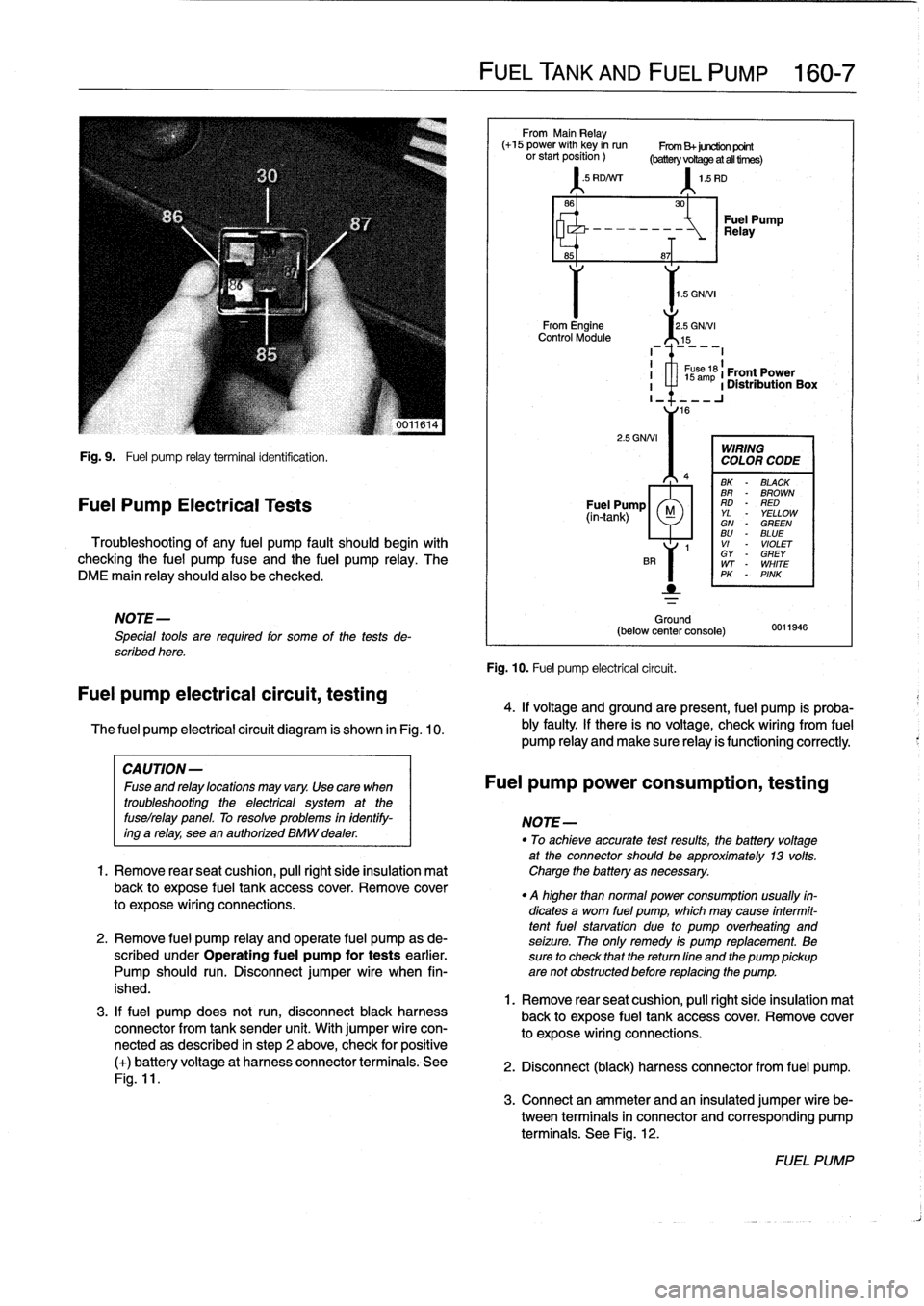

Fig

.

9

.

Fuel

pump

relay

terminal

identification

.

Fuel

Pump

Electrical

Tests

Troubleshooting

of

any

fuel

pump

fault

should

begin

with

checking

the

fuel

pump

fuse

and

the

fuel

pump

relay

.

The

DME

main

relay

should

also

be

checked

.

NOTE-

Special

tools

are

requíred

for

some

of

the

tests

de-

scribed

here

.

Fuel

pump

electrical

circuit,

testing

The

fuel

pump

electrical

circuit

diagram

is

shown

in

Fig

.

10

.

3

.

If

fuel

pump

does

not

run,

disconnect

black

harness

connector

from

tank

sender

unit

.

With

jumper

wire

con-

nectedas

described

in

step

2

above,

check

for

positive

(+)

batteryvoltage

at

harness

connector

terminals

.

See

Fig

.

11

.

FUEL

TANK

AND

FUEL

PUMP

160-

7

From

Main

Relay

(+15

power

with

key

in

run

From

B+juretion

point

orstartposition)

(batteryvoRageatalltirnes)

'

.5

RD/Nrr

1

.5

RD

1

.5

GNNI

From

Engine

2

.5

GNNI

Control

Module

15

2

.5

GNNI

Ground

(below

center

console)

Fig

.

10

.

Fuel

pump

electrical

circuit

.

30

-~

Relay

Fuel

Pump

8~T

I

1

s

ám

61

Front

Power

I

a

1

Distribution

Box

I_

16

WIRING

COLOR

CODE

BK

-

BLACK

BR

-

BROWN

Fuel

Pump

RD

-

RED

(in-tank)

M

YL

YELLOWGN

-

GREENBU

-

BLUE

1

VI

-

VIOLET

GY

-

GREY

WT

-

WHITE

PK

-

PINK

0011946

4

.

If

voltage

and

groundare

present,

fuel

pump

is

proba-

bly

faulty

.

If

there

is

no

voltage,

check

wiring

From

fuel

pump

Reay

and

make

sure

Reay

is

functioning

correctly

.

CAUTION-

Fuseandrelaylocationsmayvary

.

Usecara

when

Fuel

pump

power

consumption,

testing

troubleshooting

the

electrical

system

at

the

fuselrelay

panel

.

To

resolve

problems

in

identify-

NOTE-

ing

a

relay,

see

en

authorízed

BMW

dealer

.

"

To

achieveaccurate

testresults,

fhe

battery

voltage

at

the

connector

should

be

approximately

13

volts

.

1.

Remove

rearseat

cushion,

pull

right

side

insulation

mat

Charge

the

battery

asnecessary

.

back

to

expose

fuel

tank

accesscover

.

Remove

cover

.

q

higher

than

normal

power

consumption

usually

fin-

to

expose

wiring

connections

.

dicates

a

worn

fuel

pump,

which

may

cause

intermit-

tentfuel

starvation

due

lo

pump

overheating

and

2

.

Remove

fuel

pump

relay

and

opérate

fuel

pump

as

de-

seizure

.

The

only

remedy

is

pump

replacement

.

Be

scribed

under

Operating

fuel

pump

for

tests

earlier

.

sure

to

check

that

thereturn

fine

and

the

pump

pickup

Pump

should

run

.

Disconnect

jumper

wire

when

fin-

are

not

obstructed

before

replacing

the

pump

.

ished

.

1

.

Remove

rear

seat

cushion,

pull

right

side

insulation

mal

back

to

expose

fuel

tank

accesscover

.

Remove

cover

to

expose

wiring

connections

.

2

.

Disconnect

(black)

harness

connector

from

fuel

pump

.

3

.

Connect

an

ammeter

and

an

insulated

jumper

wire

be-

tween

terminals

in

connector

and

corresponding

pump

terminals

.

See

Fig

.

12

.

FUEL

PUMP

Page 193 of 759

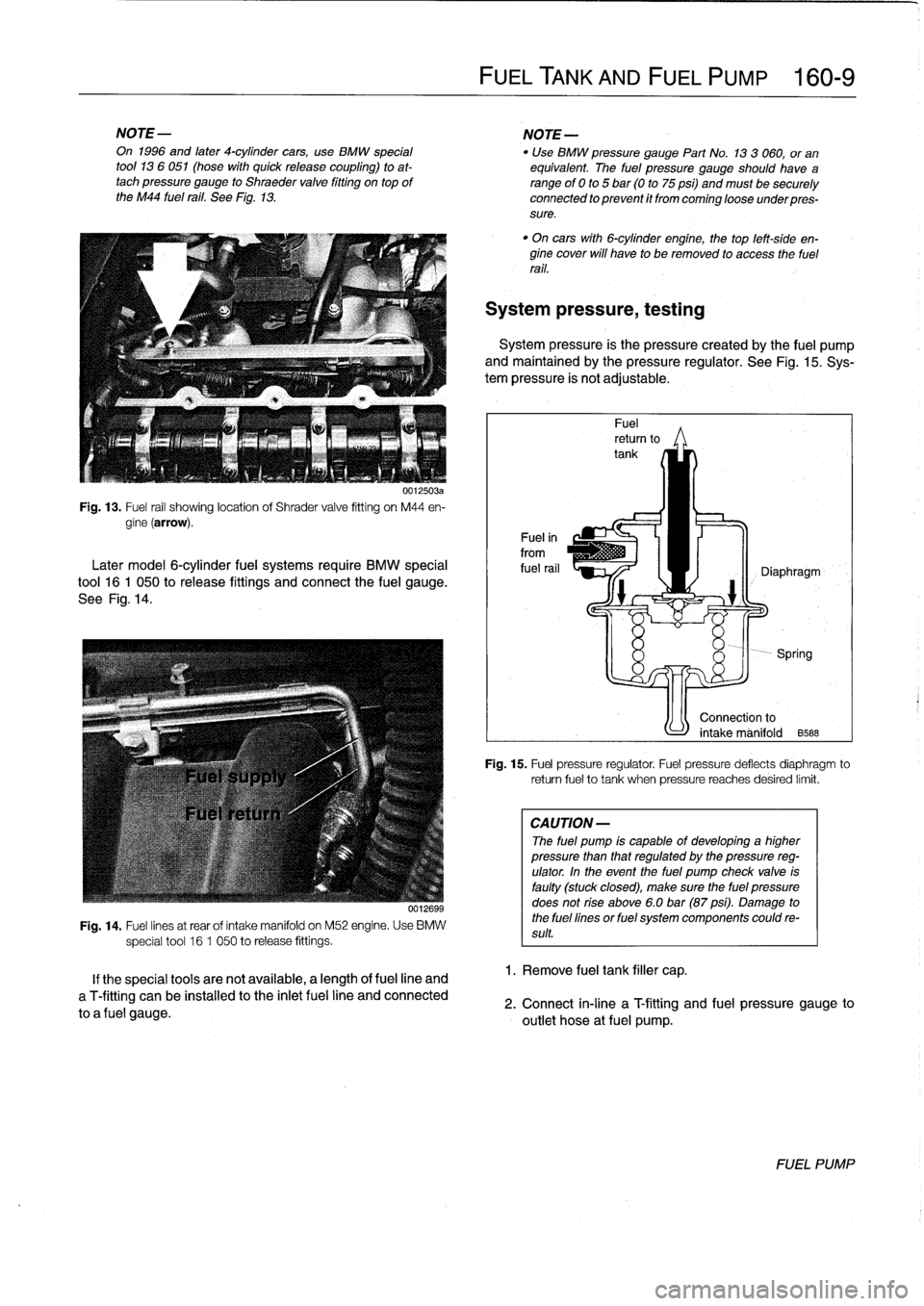

NOTE-

NOTE

-

On

1996

and

later

4-cylinder

cars,

use

BMW

special

"

Use

BMW

pressure

gauge

Part

No

.

133

060,or

an

tool

13

6051

(hose

with

quick

release

coupling)

toat-

equivalent

.

The

fuel

pressure

gauge

should

have

a

tach

pressure

gauge

to

Shraeder

valve

fitting

on

top

of

rangeof

0

to

5bar

(0

to

75

psi)

and

mustbe

securely

the

M44

fuel

rail

.

See

Fig

.

13

.

connected

to

prevent

it

from

coming

loose

under

pres-

sure

.

u012503a

Fig

.

13

.

Fuel

rail

showing

location

of

Shrader

valve

fitting

on

M44

en-

gine

(arrow)

.

Later

model

6-cylinder

fuel

systems

require

BMW

specíal

tool

16

1

050

to

release

fittings

and

connect

the

fuel

gauge

.

See

Fig

.

14

.

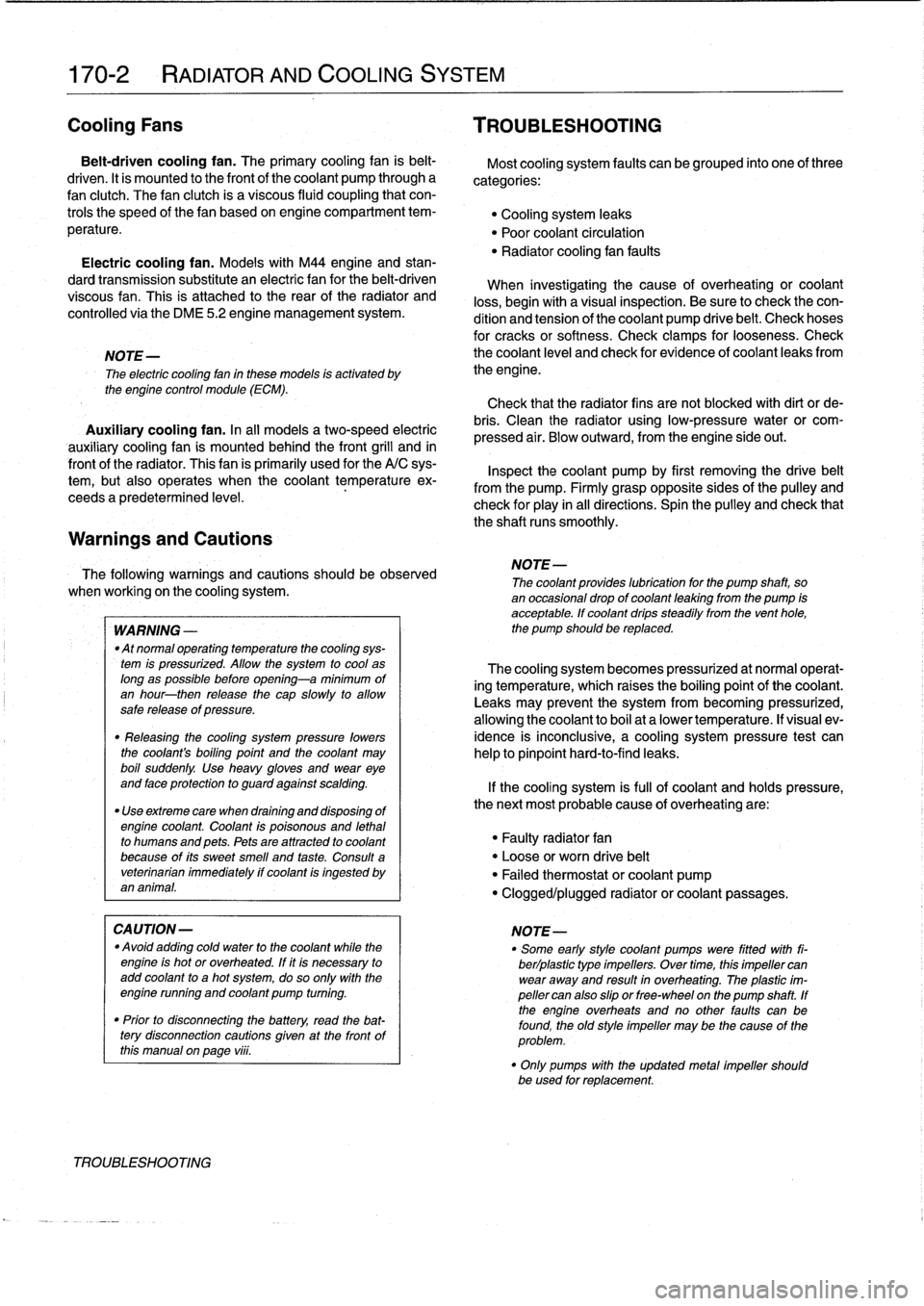

0012699

Fig

.

14

.

Fuel

lines

at

rear

of

íntake

manifold

on

M52

engine

.

Use

BMW

special

tool

16

1

050

to

release

fittings

.

If

the

special

tools

arenot

available,

a

length

offuel

line

and

a

T-fitting

can

be

installed

tothe

inlet

fuel

line

and

connected

to

a

fuel

gauge

.

FUEL

TANK

AND

FUEL

PUMP

160-

9

"

On

cars

with

6-cylinder

engine,

thetop

left-side

en-

Bine

cover

will

have

to

be

removed

to

access

the

fuel

rail

.

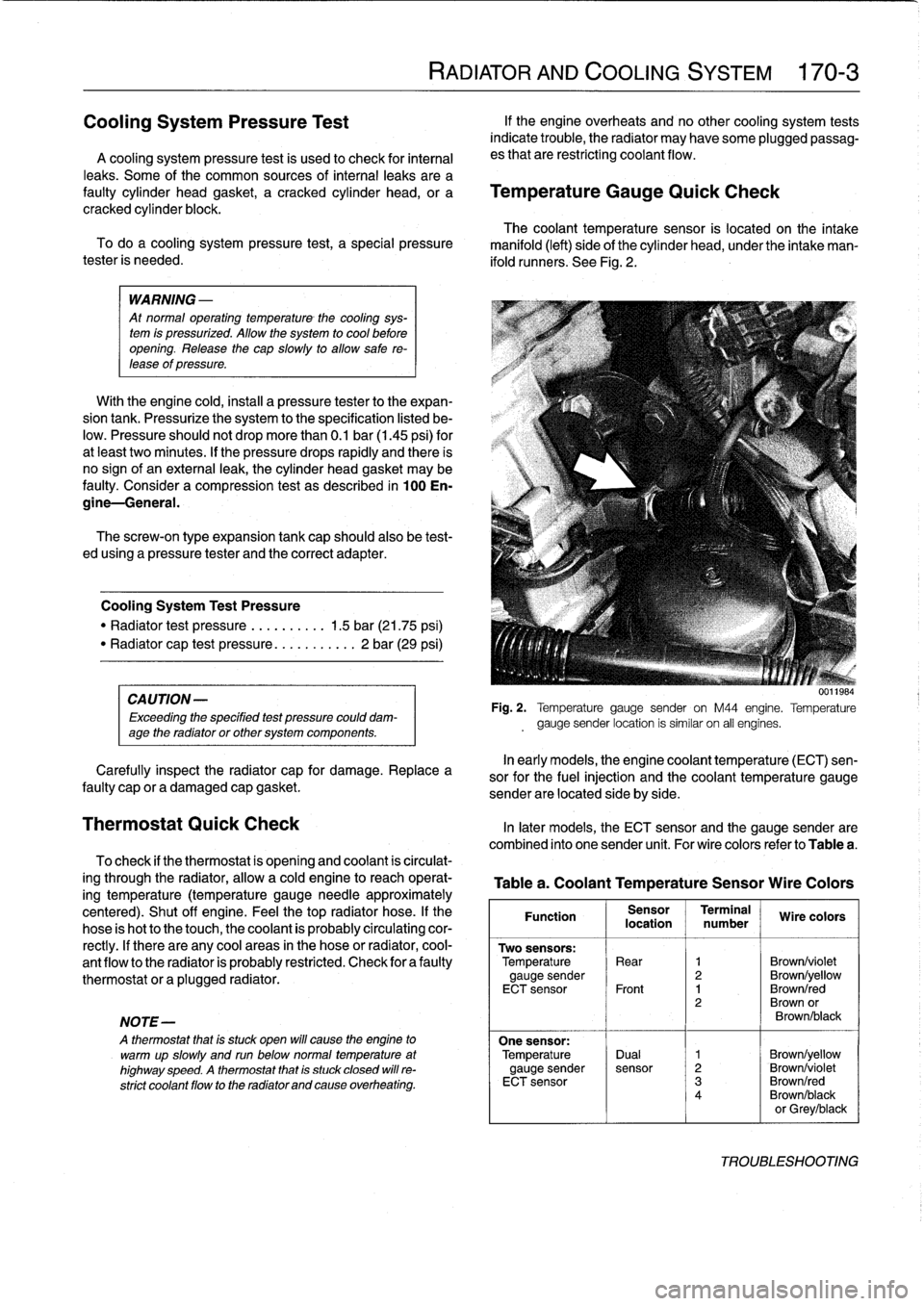

System

pressure,

testing

System

pressure

is

the

pressure

created

by

the

fuel

pump

and

maintained

by

the

pressure

regulator

.

See

Fig

.

15

.

Sys-

tem

pressure

is

not

adjustable

.

1

.

Remove

fuel

tank

filler

cap

.

Fig

.

15

.

Fuel

pressure

regulator

.

Fuel

pressure

deflects

diaphragm

to

retum

fuel

to

tank

when

pressure

reaches

desired

limit

.

CA

UTION-

The

fuel

pump

is

capable

of

developing

a

higher

pressure

than

that

regulated

by

the

pressure

reg-

ulator

.

In

the

event

the

fuel

pump

check

valve

is

faulty

(stuck

closed),

make

sure

the

fuel

pressure

does

not

rise

aboye

6

.0

bar(87

psi)

.

Damage

to

the

fuel

fines

or

fuel

system

components

could

re-

sult

.

2

.

Connect

in-fine

a

Tfitting

and

fuel

pressure

gauge

to

outlet

hose

atfuel

pump

.

FUEL

PUMP

Page 196 of 759

170-2

RADIATOR

AND

COOLING

SYSTEM

Cooling

Fans

TROUBLESHOOTING

Belt-driven

coolingfan

.

The

primary

cooling

fan

is

belt-

driven

.

It

is

mounted

to

the

frontof

the

coolant

pump

through

a

fan

clutch

.

The

fan

clutch

is

a

viscous

fluid

coupling

that

con-

trols

the

speed

of

thefan

based

on

engine

compartment

tem-

perature

.

Electric

cooling

fan

.

Models

with

M44

engine

and

stan-

dard

transmission

substitute

an

electric

fan

for

the

belt-driven

viscous

fan

.

This

is

attached

to

the

rear

of

the

radiator

and

controlledvia

the

DME

5

.2

engine

management

system

.

NOTE-

The

electric

cooling

fan

in

these

models

is

activated

by

the

engine

control

module

(ECM)

.

Auxiliary

coolingfan

.

In

al¡

models

a

two-speed

electric

auxiliary

cooling

fan

is

mounted

behind

the

front

grill

and

in

front

of

the

radiator

.

This

fan

is

primarily

used

for

the

A/C

sys-

tem,

but

also

operates

when

the

coolant

temperature

ex-

ceeds

a

predetermined

leve¡

.

Warnings

and

Cautions

The

following

warnings

and

Cautions

should

beobserved

when

working

on

the

cooling

system

.

WARNING

-

"

Atnormal

operating

temperature

the

cooling

sys-

tem

is

pressurized

.

Allow

the

system

to

cool

as

long

as

possible

before

opening-a

minimum

of

an

hour-then

release

the

cap

slowly

to

allow

sale

release

of

pressure

.

"

Releasing

the

cooling

system

pressure

lowers

the

coolants

boiling

point

and

the

coolant

may

boíl

suddenly

.

Use

heavy

gloves

and

wear

eye

and

laceprotection

to

guard

against

scalding

.

"

Use

extreme

care

when

draining

and

disposing

of

engine

coolant

.

Coolant

is

poisonous

and

lethal

to

humans

and

pets

.

Pets

are

attracted

to

coolant

because

of

its

sweet

smell

and

taste

.

Consult

a

veterinarian

immediately

if

coolant

is

ingested

byan

animal

.

CAUTION-

"

Avoidadding

cold

water

to

the

coolant

while

the

engine

is

hot

or

overheated

.

If

it

is

necessary

to

add

coolant

to

ahot

system,

do

so

only

with

the

engine

running

and

coolant

pump

tuming

.

"

Prior

to

disconnecting

the

battery,

read

the

bat-

tery

disconnection

cautions

given

at

the

front

of

this

manual

on

page

viii

.

TROUBLESHOOTING

Most

cooling

system

faults

can

be

grouped

into

one

of

three

categories

:

"

Cooling

system

leaks

"

Poor

coolant

circulation

"

Radiator

cooling

fan

faults

When

investigating

the

cause

of

overheating

or

coolant

loss,

begin

with

a

visual

inspection

.

Be

sure

to

check

the

con-

dition

and

tension

of

the

coolant

pump

drive

belt

.

Check

hoses

for

cracks

or

softness

.

Check

clamps

for

looseness

.

Check

the

coolant

leve¡

and

check

for

evidence

of

coolantleaks

from

the

engine

.

Check

that

the

radiator

fins

are

not

blocked

with

dirt

or

de-

bris

.

Clean

the

radiator

using

low-pressure

water

or

com-

pressed

air

.

Blow

outward,

fromthe

engine

side

out

.

Inspect

the

coolant

pump

by

first

removing

the

drive

belt

from

the

pump

.

Firmly

grasp

opposite

sídes

of

the

pulley

and

check

for

play

in

all

directions

.

Spin

the

pulley

and

check

that

the

shaft

runs

smoothly

.

NOTE-

The

coolant

provides

lubrication

for

the

pump

shaft,

soan

occasional

drop

of

coolant

leaking

from

the

pump

is

acceptable

.

If

coolant

drips

steadily

from

the

vent

hole,

the

pump

should

be

replaced

.

The

cooling

system

becomes

pressurized

at

normal

operat-

ing

temperature,

which

raises

the

boiling

point

of

the

coolant

.

Leaks

may

prevent

the

system

from

becoming

pressurized,

allowing

the

coolant

to

boil

at

a

lower

temperature

.

If

visual

ev-

idence

is

inconclusive,

a

cooling

system

pressure

test

can

help

to

pinpointhard-to-find

leaks

.

If

the

cooling

system

is

full

of

coolant

and

holds

pressure,

the

next

most

probable

cause

of

overheating

are

:

"

Faulty

radiator

fan

"

Loose

or

worn

drive

belt

"

Failed

thermostat

or

coolant

pump

"

Clogged/plugged

radiator

or

coolant

passages

.

NOTE

-

"

Some

early

style

coolant

pumps

were

fitted

wíth

fi-

berlplastic

type

impellers

.

Over

time,

this

impeller

can

wear

away

and

result

in

overheating

.

The

plastic

im-

peller

can

also

slip

or

free-wheel

on

the

pump

shaft

.

If

the

engine

overheats

and

no

other

faults

canbe

found,

theold

style

impeller

may

be

the

cause

of

the

problem

.

"

Only

pumps

with

the

updated

metal

impeller

should

be

used

for

replacement

.

Page 197 of 759

Cooling

System

Pressure

Test

If

the

engine

overheats

and

no

other

cooling

system

testsindicate

trouble,

the

radiator

may

have

some

pluggedpassag-

A

cooling

system

pressure

test

is

used

to

check

for

internal

es

that

are

restricting

coolant

flow

.

leaks

.

Some

of

the

common

sources

ofinternal

leaks

are

a

faulty

cylinder

head

gasket,

a

cracked

cylinder

head,

or

a

Temperature

Gauge

Quick

Check

cracked

cylinder

block

.

The

coolant

temperature

sensor

is

located

on

the

intake

To

doa

cooling

system

pressure

test,

a

special

pressure

manifold

(left)

side

of

the

cylinder

head,

under

the

intake

man-

tester

is

needed

.

ifold

runners

.

See

Fig

.

2

.

WARNING

-

At

normal

operating

temperature

-

the

cooling

sys-

tem

is

pressurized

.

Allow

the

system

to

cool

before

opening

.

Release

the

cap

slowly

to

allow

sale

re-

tease

of

pressure

.

With

the

engine

cold,instan

a

pressure

tester

to

the

expan-

sion

tank

.

Pressurize

thesystem

to

the

specification

listed

be-

low

.

Pressure

should

not

drop

more

than

0

.1

bar

(1

.45

psi)

for

at

leakt

two

minutes

.

If

the

pressure

drops

rapidly

and

there

is

no

sign

of

an

externa¡

leak,

the

cylinder

head

gasket

may

be

faulty

.

Considera

compression

test

as

described

in

100

En-

gine-General

.

The

screw-on

type

expansion

tank

cap

should

also

be

test-

ed

using

a

pressure

tester

and

the

correct

adapter

.

Cooling

System

Test

Pressure

"

Radiator

test

pressure

.........

.

1

.5

bar

(21

.75

psi)

"

Radiator

cap

test

pressure

..

.

........

2

bar

(29

psi)

CA

UTION-

Exceeding

the

speclfied

test

pressure

could

dam-

age

the

radiatoror

other

system

components

.

Carefully

inspect

the

radiator

cap

for

damage

.

Replace

a

faulty

cap

or

a

damaged

cap

gasket

.

Thermostat

Quick

Check

In

later

models,

the

ECT

sensor

and

the

gauge

sender

are

combined

into

one

sender

unit

.

For

wire

colors

refer

to

Table

a

.

To

check

if

the

thermostat

is

opening

and

coolant

is

circulat-

ing

through

the

radiator,

allow

a

cold

engine

to

reach

operat-

ing

temperature

(temperature

gauge

needieapproximately

centered)

.

Shut

off

engine

.

Feel

the

top

radiator

hose

.

If

the

hose

is

hot

to

the

touch,

the

coolant

is

probably

circulating

cor-

rectly

.

If

there

are

any

cool

areas

in

the

hose

or

radiator,

cool-

ant

flow

to

the

radiator

is

probably

restricted

.

Check

for

a

faulty

thermostat

or

aplugged

radiator

.

NOTE-

A

thermostat

that

is

stuck

open

will

cause

the

engine

to

warmup

slowly

and

run

belownormal

temperature

at

highway

speed

.

A

thermostat

that

is

stuck

closed

will

re-

strict

coolant

flow

to

the

radiator

and

cause

overheating

.

RADIATOR

AND

COOLING

SYSTEM

170-

3

U

.¡ig

.v

Fig

.

2

.

Temperature

gauge

sender

on

M44

engine

.

Temperature

gauge

sender

location

is

similar

on

al]

engines

.

In

early

models,

the

engine

coolant

temperature

(ECT)

sen-

sor

for

the

fuel

injection

and

the

coolant

temperature

gauge

sender

are

located

side

by

side

.

Table

a

.

Coolant

Temperature

Sensor

Wire

Colors

Function

Sensor

Terminal

Wire

colors

location

number

Two

sensors

:

Temperature

Rear

1

Brown/violet

gauge

sender

2

Brown/yellow

ECT

sensor

Front

1

Brown/red

2

Brown

or

Brown/black

One

sensor

:

Temperature

Dual

1

Brown/yellow

gauge

sender

sensor

2

Brown/violet

ECT

sensor

3

Brown/red

4

Brown/black

or

Grey/black

TROUBLESHOOTING

Page 199 of 759

NOTE-

Some

cars

covered

by

this

manual

may

have

an

alter-

nate

cooling

fan

switchwith

switching

temperatures

of

176%190W

(80%88°C)

.

When

replacing

the

switch

check

theswitching

specifications,

whichshouldbe

stamped

on

the

switch

body

.

1

.

If

coolant

is

circulating

at

normal

operating

tempera-

ture,

but

auxiliary

cooling

fan

does

not

run,

disconnect

connector

from

radiator

temperature

switch

and

make

tests

listed

in

Table

c

.

Table

c

.

Auxiliary

Cooling

Fan

Temperature

Switch

Tests

Wires

jumpered

Test

Test

resuits

conditions

Black/green

(terminal2)

and

Ignition

ON

Fan

runs

on

brown

(terminal

1)

low

speed

Black/gray

(terminal

3)

and

Ignition

ON

Fan

runson

brown

(terminal

I

1)

high

speed

2

.

If

fan

runs

only

when

powered

directly

by

jumpered

connector

and

hot

coolant

is

circulating

through

radia-

tor,

radiator

temperature

switch

is

most

likelyfaulty

.

Use

a

new

sealing

ring

when

replacing

switch

Tightening

Torque

"

Temperature

switch

to

radiator

......

15

Nm

(11

ft-Ib)

3

.

If

auxiliary

fan

does

notrun

when

powered

directly,

check

for

battery

voltage

at

temperature

switch

connec-

tor

(black/green

wire)

with

ignition

on

.

If

battery

voltage

is

not

present,

check

fuses

.

See

610

Electrical

Com-

ponent

Locations

.

RADIATOR

AND

COOLING

SYSTEM

170-

5

~r~nmm

a

00

0

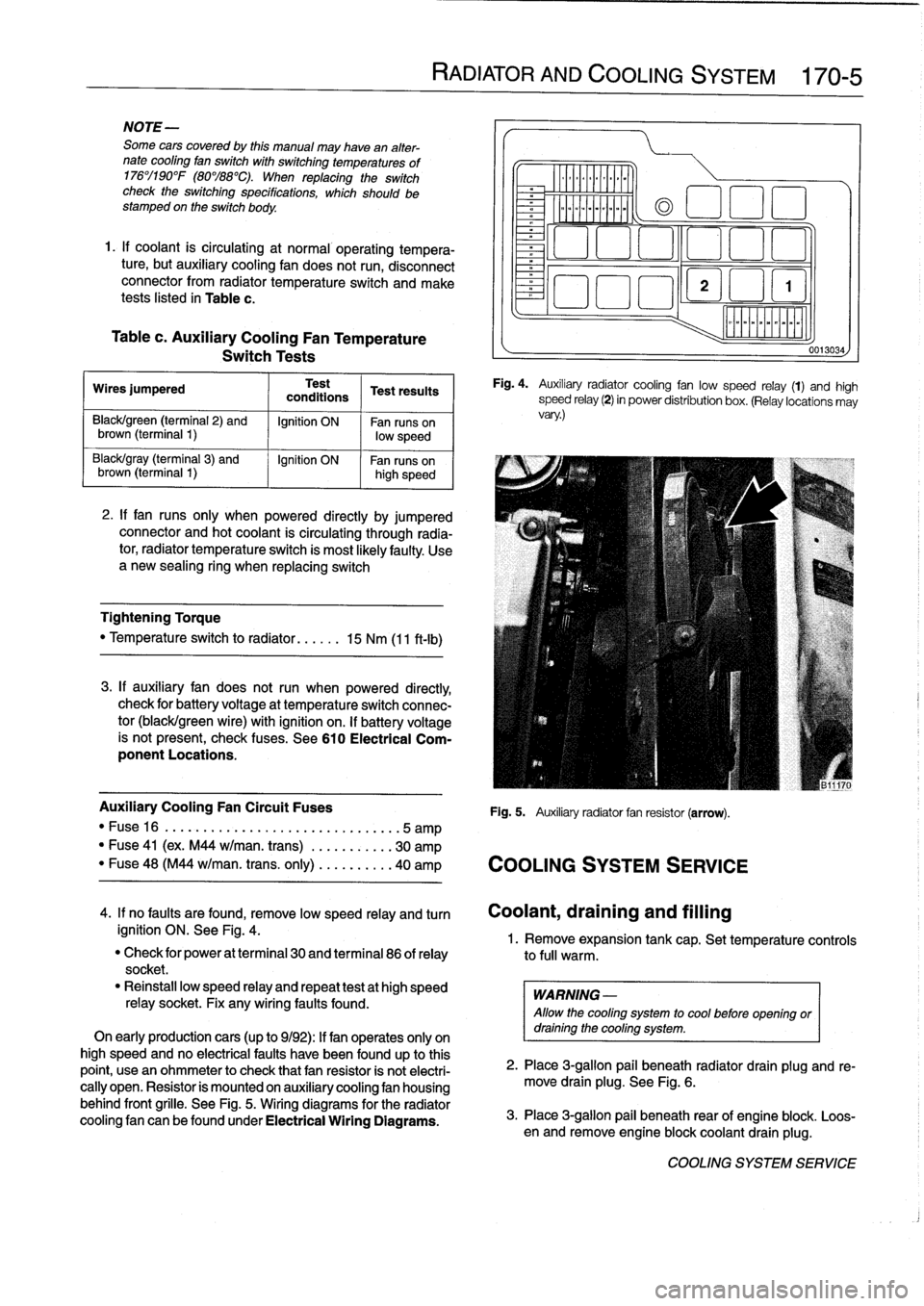

Fig

.

4

.

Auxiliary

radiator

cooling

fan

low

speed

relay

(1)

and

high

speed

relay

(2)

in

power

distribution

box

.

(Relay

locations

may

vary

.)

Auxiliary

Cooling

Fan

Circuit

Fuses

Fig

.

5

.

Auxiliary

radiator

fan

resistor

(arrow)

.

"

Fuse16

.

...................

..

..

...

...

.5

amp

"

Fuse

41

(ex

.

M44

w/man

.

trans)

.

..

.

..

.....

30

amp

"

Fuse

48

(M44

w/man

.

trans

.

only)

..

.

..

.....

40

amp

COOLING

SYSTEM

SERVICE

0013034

4

.

If

no

faults

are

found,

remove

low

speed

relay

and

turn

Coolant,draining

and

filling

ignition

ON

.

See

Fig

.

4

.

1

.

Remove

expansion

tank

cap

.

Set

temperature

controls

"

Check

for

power

at

terminal

30

and

terminal

86

of

relay

to

full

warm

.

socket

.

"

Reinstall

low

speed

relay

and

repeat

testat

high

speed

WARNING

-

relay

socket

.

Fix

any

wiring

faults

found

.

Allow

the

cooling

system

to

cool

before

openlng

or

On

early

productioncars

(up

to

9/92)

:

If

fan

operates

only

on

draining

the

cooling

system

.

high

speed

and

no

electrical

faults

have

been

foundup

to

this

point,

usean

ohmmeter

to

check

that

fan

resistor

is

not

electri-

2

.

Place

3

ra

allo

ug

.

beneath

radiator

drain

plug

and

re-

cally

open

.

Resistor

is

mounted

on

auxiliary

cooling

fan

housing

move

drain

plg

.

See

Fig

.

6

.

behind

front

grille

.

See

Fig

.

5

.

Wiring

diagrams

for

the

radiator

cooling

fan

canbefoundunder

Electrical

Wiring

Diagrams

.

3

.

Place

3-g

pail

beneath

rear

of

engine

blo

.

Loos-

en

and

re

mlon

ove

engine

blockcoolant

drain

plug

k

.

COOLING

SYSTEM

SERVICE

Page 207 of 759

GENERAL

.

.

.......

.

......

.

...

.

.

.

.

.

...

180-1

Exhaust

system,

removing

and

installing

.

...

.180-3

EXHAUST

SYSTEM

REPLACEMENT

.

...

180-1

Exhaust

manifolds,

removing

and

installing

.

.

.180-5

GENERAL

The

exhaust

system

is

designed

to

be

maintenance

free,

al-

though

regular

inspection

is

warranted

due

to

the

harsh

oper-

atingconditions

.

Under

normal

conditions,

the

catalytic

converter

does

not

require

replacement

unless

it

is

damaged

.

On

1996

and

later

cars,

a

pre-

and

post-catalytic

converter

oxygen

sensor

is

used

at

each

catalytic

converter

.

Be

sure

to

take

care

when

removingthe

system

not

to

damage

the

sen-

EXHAUST

SYSTEMREPLACEMENT

sors

.

See

130

Fuel

Injection

for

information

on

testing

oxygen

sensors

.

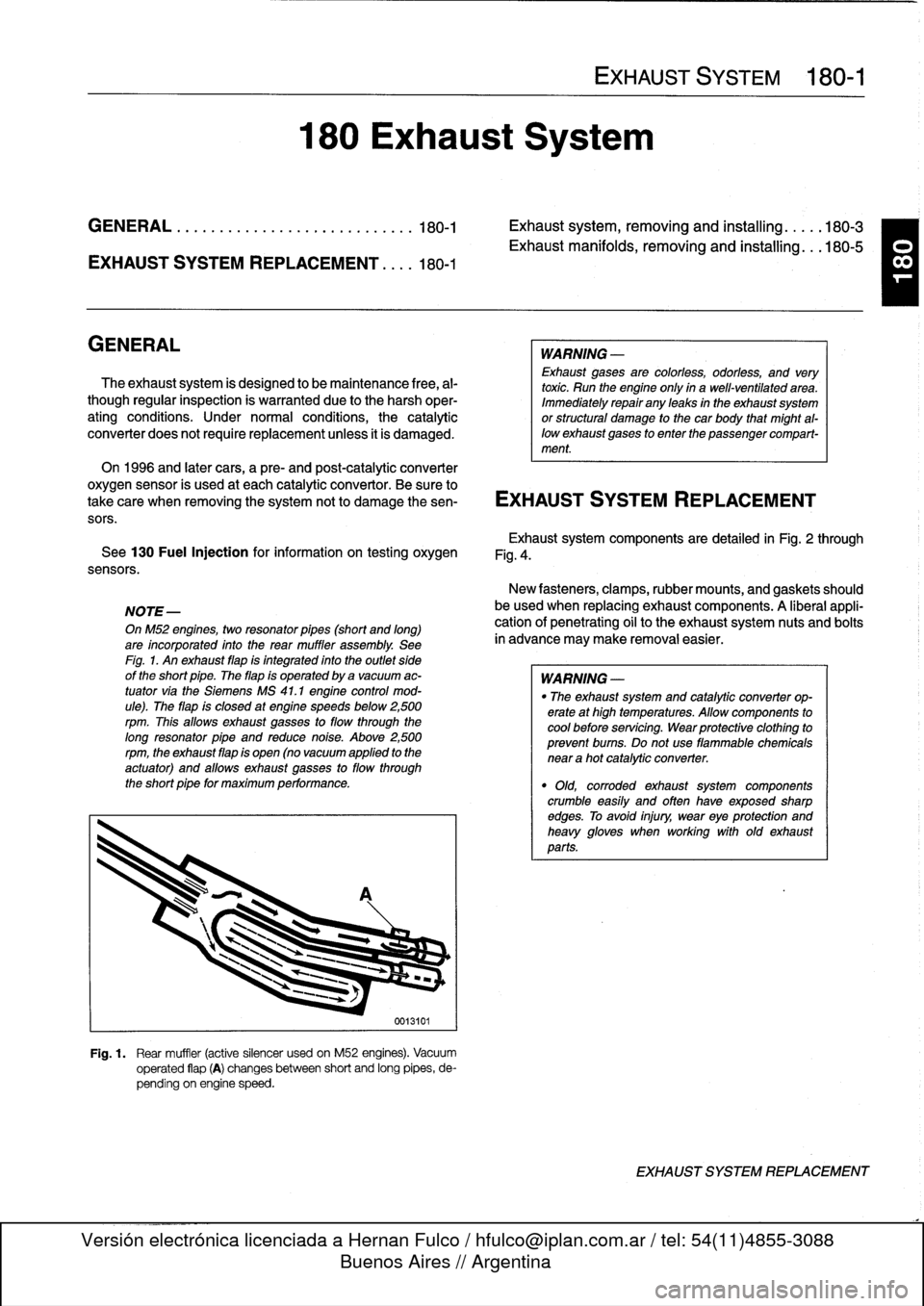

NOTE-

OnM52

engines,

two

resonator

pípes

(short

and

long)

are

incorporated

into

the

rear

muffler

assembly

.

See

Fíg

.

1

.

An

exhaust

flap

is

integrated

into

the

outlet

side

of

the

short

pipe

.

The

flap

is

operated

by

a

vacuum

ac-

tuator

via

the

Siemens

MS

41

.1

engine

control

mod-

ule)

.

The

flap

is

closed

at

engine

speeds

below

2,500

rpm

.

This

allows

exhaust

gasses

to

flow

through

the

long

resonator

pipe

and

reduce

noise

.

Above

2,500rpm,

the

exhaust

flap

is

open

(no

vacuum

applied

to

the

actuator)

and

allows

exhaust

gasses

to

flow

through

the

short

pipe

for

maximum

performance

.

180

Exhaust

System

0013101

Fig

.

1

.

Rear

muffler

(active

silencer

usedon

M52

engines)

.

Vacuum

operated

flap

(A)

changesbetween

short

and

long

pipes,

de-

pending

on

engine

speed

.

EXHAUST

SYSTEM

180-1

WARNING

-

Exhaust

gases

are

colorless,

odorless,

and

very

toxic

.

Run

the

engine

only

ín

a

well-ventilated

area

.

Immediately

repair

any

leaks

in

the

exhaust

system

or

structural

damage

to

the

car

body

that

might

al-

lowexhaust

gases

to

enter

the

passenger

compart-

ment

.

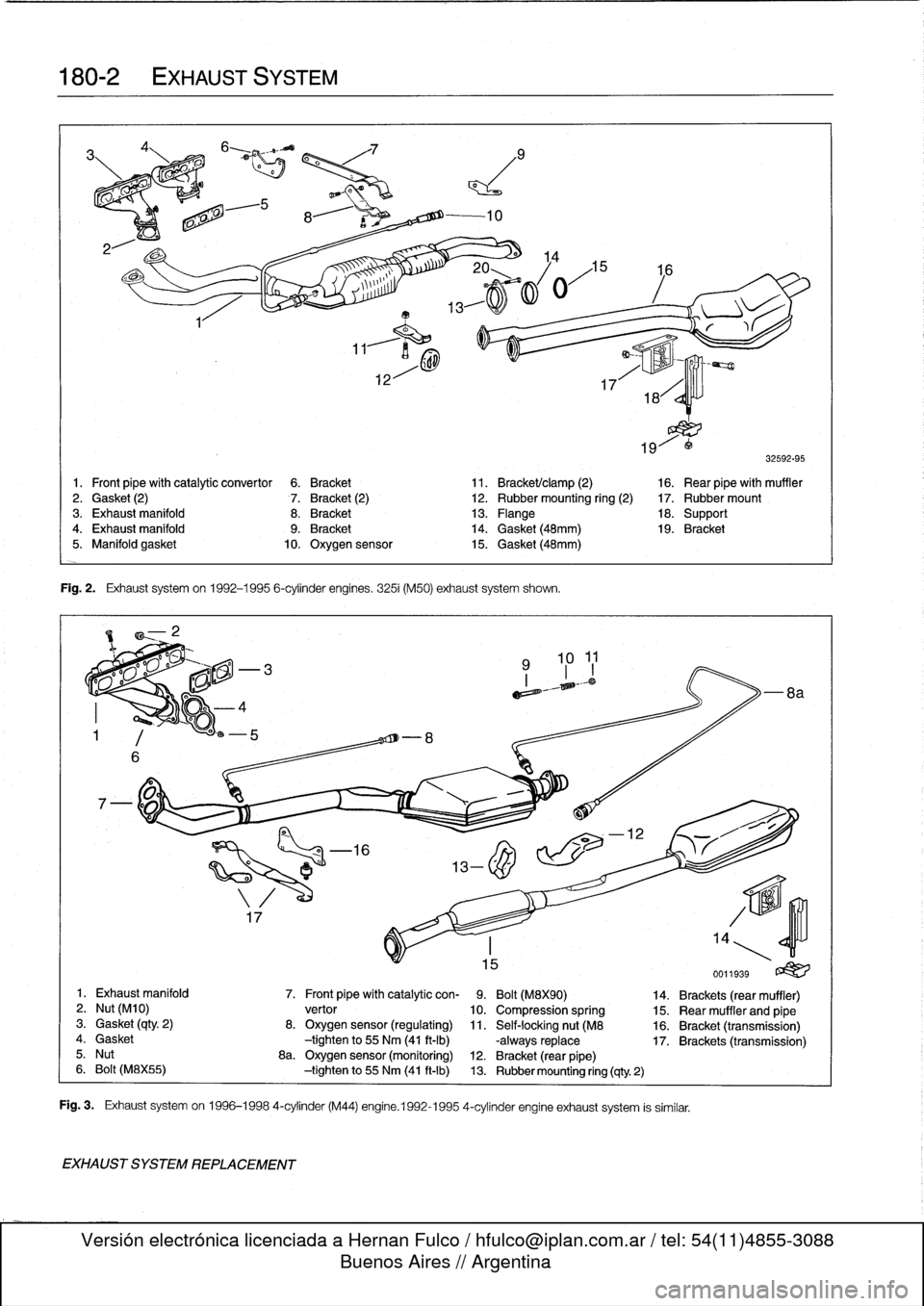

Exhaustsystem

components

are

detailed

in

Fig

.

2

through

Fig

.

4

.

New

fasteners,

clamps,rubber

mounts,

and

gaskets

should

be

used

when

replacing

exhaust

components

.

A

liberal

appli-

cationof

penetrating

oil

to

the

exhaustsystem

nuts

and

bolts

in

advance

may

make

removal

easier

.

WARNING

-

"

The

exhaust

system

and

catalytic

converter

op-

erate

at

high

temperatures

.

Allow

components

to

cool

before

servicing

.

Wear

protectíve

clothíng

to

prevent

bums

.

Do

not

use

flammable

chemicals

near

a

hot

catalytic

converter

.

"

Old,

corroded

exhaust

system

components

crumble

easíly

and

often

have

exposed

sharp

edges

.

To

avoid

injury,

wear

eye

protection

and

heavy

gloves

when

working

with

old

exhaust

parts

.

EXHAUST

SYSTEM

REPLACEMENT

T

Page 208 of 759

180-2

EXHAUST

SYSTEM

a

EXHAUST

SYSTEM

REPLACEMENT

Fig

.

2

.

Exhaust

systemon

1992-1995

6-cylinder

engines

.

3251

(M50)

exhaust

system

shown

.

E~

)l-,malo

m~=

i

32592-95

1

.

Front

pipe

with

catalytic

convertor

6

.

Bracket

11

.

Bracket/clamp

(2)

16

.

Rear

pipewith

muffler

2

.

Gasket

(2)

7

.

Bracket

(2)

12

.

Rubber

mounting

ring

(2)

17

.

Rubber

mount

3

.

Exhaust

manifold

8

.

Bracket

13

.

Flange

18

.

Support4

.

Exhaust

manifold

9

.

Bracket

14

.

Gasket

(48mm)

19

.

Bracket

5

.

Manifold

gasket

10

.

Oxygen

sensor

15

.

Gasket

(48mm)

eme°"

k

:I>

-

8a

1

.

Exhaust

manifold

7

.

Front

pipe

with

catalytic

con-

9

.

Bolt

(M8X90)

14

.

Brackets

(rear

muffier)

2

.

Nut

(M10)

vertor

10

.

Compression

spring

15

.

Rear

muffler

and

pipe

3

.

Gasket

(clty

.

2)

8

.

Oxygen

sensor

(regulating)

11

.

Self-lockingnut

(M8

16

.

Bracket

(transmission)

4

.

Gasket

-tightento

55

Nm

(41

ft-Ib)

-always

replace

17

.

Brackets

(transmission)

5

.

Nut

8a

.

Oxygen

sensor

(monitoring)

12

.

Bracket

(rear

pipe)

6

.

Bolt

(M8X55)

-tightento

55

Nm

(41

ft-Ib)

13

.

Rubber

mounting

ring

(9ty

2)

Fig

.

3

.

Exhaust

systemon

1996-1998

4-cylinder

(M44)

engine

.1992-1995

4-cylinder

engine

exhaust

system

is

similar

.