Drive shaft removal BMW 328i 1998 E36 Owner's Manual

[x] Cancel search | Manufacturer: BMW, Model Year: 1998, Model line: 328i, Model: BMW 328i 1998 E36Pages: 759

Page 234 of 759

240-

6

AUTOMATIC

TRANSMISSION

14

.

Remove

transmission

by

pulling

back

and

down

.

Lower

jack

to

allow

transmission

to

clear

vehicle

.

Tightening

Torques

"

ATF

drain

plug

to

ATF

sump

CA

UTION-

MS

270R/A4S

310R

....

..

....

.

..

25

Nm

(18

ft-Ib)

Do

not

allow

the

torque

converter

to

fati

off

the

ASS

310Z(M10

plug)

..

..

..

.

.

..

.

..

16

Nm

(12

ft-Ib)

transmission

inputshaft

.

"

ATF

fill

plug

to

ATF

sump

MS

270R/A4S

310R

..

..

....

..

..

.

33

Nm

(24

ft-Ib)

15

.

Installation

is

reverse

of

removal,

noting

the

following

:

MS

310Z(M30

plug)

......

.

.

..

.

.

100

Nm

(74

ft-Ib)

"Blowoutofcoolerlineswithlow-pressurecompressed

"

ATF

cooler

lines

(A4S

270R/A4S

310R)

air

and

flush

coolerwith

clean

ATF

twice

before

reat-

Coupling

nuts

............

.

.

..

..

.

20

Nm

(15

ft-Ib)

taching

lines

to

transmission

.

Hollow

bolts

.........

.

.....

..

..

.

37

Nm

(28

ft-Ib)

"

Reinforcing

cross

brace

CAUTION-

to

chassis

(M10)

.............

.

..

.

42

Nm

(31

ft-Ib)

"

Wear

safety

glasses

when

working

with

com-

"

Torque

converter

pressedair

.

to

driveplate

(M10)

.........

..

.

..

45

Nm

(33

ft-Ib)

"

Transmissionsupport

crossmember

to

chassis

"

Do

not

reuse

ATF

after

flushing

.

M8

......................

22-24

Nm

(16-17

ft-1b)

M10

................

.

....

..

.

..

42

Nm

(31

ft-Ib)

"

Install

new

sealing

washers

on

hollow

bolts

.

"

Transmissíon

to

engine

(Torx-head

with

washer)

"

Insta¡¡

new

O-rings

on

transmission

cooler

lines,

where

M8

......................

..

.

..

21

Nm

(15

ft-Ib)

applicable

.

M10

.....................

..

..

.

42

Nm

(31

ft-Ib)

"

Inspect

driveplate

for

cracks

or

elongatedholes

.

Re-

M12

................

.

....

..

.

..

72

Nm

(53ft-Ib)

place

if

necessary

.

"

Check

to

be

sure

torque

converter

is

seated

correctly

in

transmission

during

final

installation

.

"

When

mounting

transmission

to

engine,

the

three

mounting

tabs

on

torque

converter

must

be

aligned

with

indentations

on

driveplate

.

Use

an

alignment

dowel

to

line

up

bolt

holes,

if

necessary

.

"

Fill

transmission

with

clean

ATF

until

oil

leve¡

is

even

with

fill

hole

.

Then

check

fluid

leve¡

as

described

ear-

lier

.

"

Adjust

gearshift

mechanism

.

See

250

Gearshift

link-

age

.

NOTE-

Torx-head

mounting

bolts

shouldalwaysbe

used

with

washers

to

prevent

difficult

removal

.

TRANSMISSION

REMOVAL

AND

INSTALLATION

Page 235 of 759

GENERAL

.

.

.

.

.

.

.

.

.

................

.

.

.

250-1

AUTOMATIC

TRANSMISSION

GEARSHIFT

...

.

.........

.

.

.

.

.

.

.

.

.

.

.

.

.

.

250-3

MANUAL

TRANSMISSION

Gearshift

mechanism,

adjusting

GEARSHIFT

.

.

.

.

.

.

.

.....

.

..........

.

.

.

250-1

(automatictransmission)

..

.

.

.

.

.

.

.

.

.

...

.

.

250-3

Gearshift

lever,

removing

Gear

position/neutral

safety

switch,

replacing

(manual

transmission)

.

.

.

.

...

.

.

.

.......

250-1

(automatic

transmission)

..

.

.

.

.........

.

.

250-4

Gearshift

lever,

installing

Automatic

shiftlock,

checking

function

(manual

transmission)

.

.

.

.

.

.

.

.

.

.

.......

250-2

(automatic

transmission)

..

..

...

.

.

.

....

..

250-5

Shiftinterlock,

checking

function

(automatic

transmission)

.......

.

.

.

.....

.250-6

GENERAL

This

repair

group

covers

transmission

gearshift

and

linkage

service

.

Special

service

tools

are

required

for

some

of

the

proce-

dures

given

here

.

To

gain

access

to

the

complete

gearshift

mechanism

ít

is

necessary

to

remove

the

exhaust

system

and

the

driveshaft

as

described

in

180

Exhaust

System

and260

Driveshaft

.

MANUAL

TRANSMISSION

GEARSHIFT

Gearshift

lever,

removing

(manual

transmission)

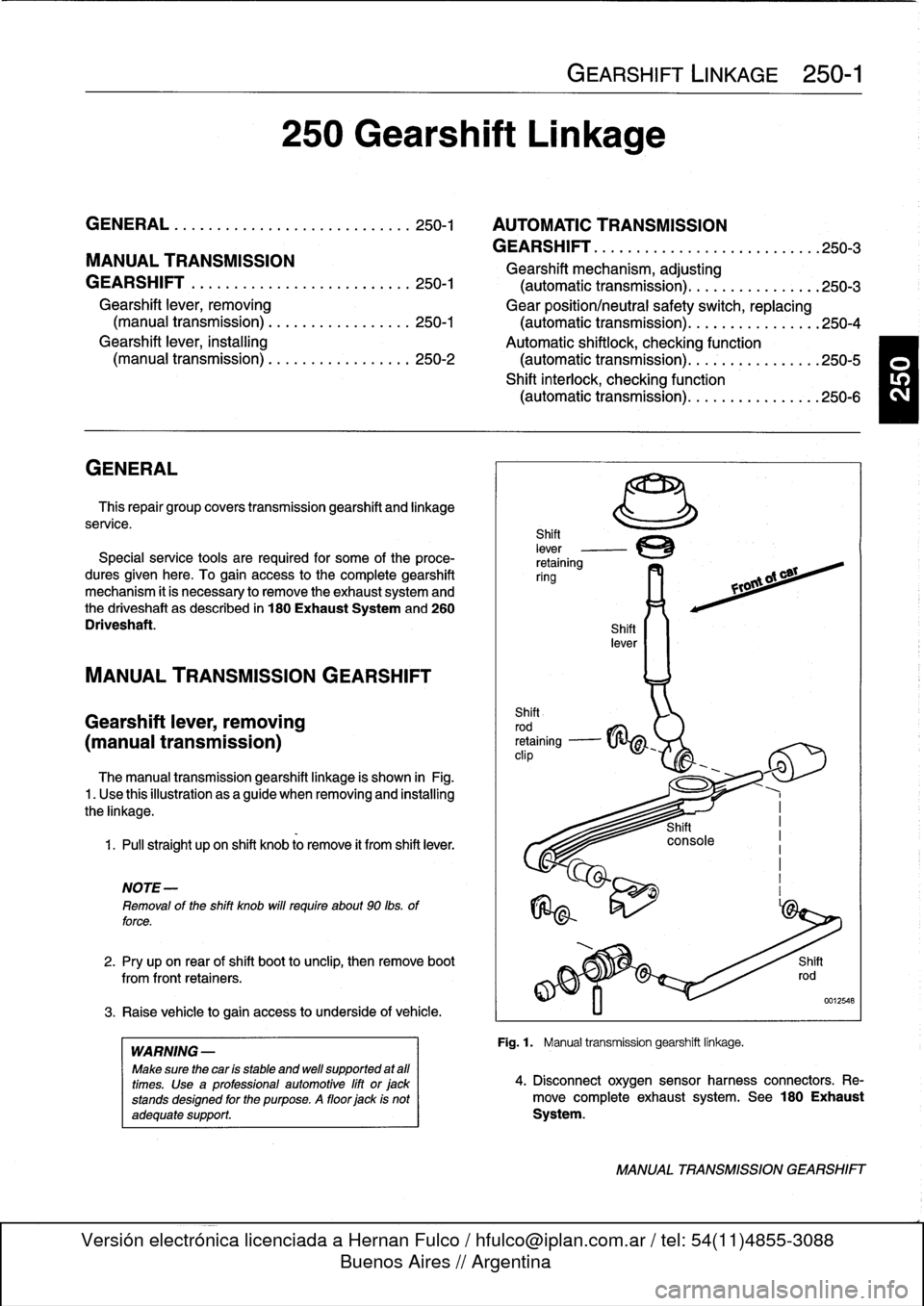

The

manual

transmission

gearshift

linkage

is

shown

in

Fig

.1

.

Use

thisillustration

asaguide

when

removing

and

installing

the

linkage

.

1

.

Pull

straight

upon

shift

knob

lo

remove

it

from

shift

lever

.

NOTE

-

Removal

of

the

shift

knob

will

require

about

90

lbs

.

of

force

.

2

.

Pry

upon

rear

of

shift

boot

tounclip,

then

remove

boot

from

front

retainers

.

3

.

Raise

vehicle

togain

access

to

underside

of

vehicle

.

WARNING

-

Make

sure

thecar

is

stable

and

well

supported

at

afl

times

.

Use

a

professional

automotive

lift

orjackstands

designed

for

the

purpose

.

A

floor

jack

is

not

adequate

support

.

250

Gearshift

Linkage

GEARSHIFT

LINKAGE

250-1

Fig

.1

.

Manual

transmission

gearshift

linkage

.

4

.

Disconnect

oxygen

sensorharness

connectors

.

Re-

move

completeexhaust

system

.

See

180

Exhaust

System

.

MANUAL

TRANSMISSION

GEARSHIFT

Page 242 of 759

260-2

DRIVESHAFT

Further

inspection

requires

removal

of

the

driveshaft

.

Check

the

front

centering

guide

on

the

transmission

output

flange

for

damage

or

misalignment

.

Also

check

runoutatthe

transmission

outputflange

and

output

shaft,

and

at

the

final

drive

input

flange

.

Check

the

bolt

hole

bores

in

theflange

for

wear

and

elongation

.

Driveshaftflange

runout

(max

.

allowable)

"

Transmission

outputflange

axial

play

...

.

..

...

..

.

.......

0

.10

mm

(0

.004

in

.)

radial

play

.......

...

.

.

.......

0

.07

mm

(0

.003

in

.)

"

Final

driveinput

flange

radial

play

(measured

at

driveshaft

centering

lip)

..

......

0

.07

mm

(0

.003

in

.)

Spinthe

center

bearing

and

check

for

the

smooth

operation

without

play

.

Check

that

thesplines

of

the

sliding

coupling

move

freely

.

Clean

and

lubricate

the

splines

with

molybdenum

disulfide

grease

(Molykote

®

Longterm

2

or

equivalent)

.

Check

the

universal

joints

for

wear

or

binding

.

If

any

joint

isdif-

ficult

to

move

or

binds,

the

driveshaft

section

should

be

replaced

.

Table

a

.

Driveshaft

Troubleshooting

NOTE-

With

the

driveshaft

installed,

theactual

amount

that

the

universal

joints

pivot

is

limited

.

For

the

most

accurate

test,

check

universal

joints

in

their

normal

range

of

movement

.

If

inspection

revealsnothing

wrong

with

the

driveshaft,

it

may

need

to

be

rebalanced

.

This

can

be

done

by

a

speciality

driveshaft

repair

shop

.

Also,

check

the

alignment

ofthe

drive-

shaft

as

described

below

.

NOTE-

Minor

driveshaftvibrations

can

often

be

correctedsim-

ply

by

disconnecting

the

driveshaftat

the

finaldrive,

and

repositíoning

the

driveshaft

90°,

180°

or270°

inre-

lationto

the

final

drive

input

flange

.

Table

a

lists

symptoms

of

driveshaft

problems

and

their

probable

causes

.

Most

of

the

repair

information

is

contained

within

this

repair

group

.

Symptom

Probable

cause

Corrective

action

1

.

Vibration

when

a

.

Incorrect

preload

of

center

bearing

.

a

.

Check

preload

of

center

bearing

.

Readjust

preload

.

See

Fig

.

6

.

starting

off

(forward

b

.

Center

bearing

rubber

deteriorated

.

b

.

Inspect

center

bearing

and

rubber

.

Replace

if

necessary

.

orreverse)

.

c

.

Flex-disc

damaged

or

worn

.

c

.

Inspect

flex-disc

.

Replace

if

necessary

.

TROUBLESHOOTING

d

.

Engine

or

transmission

mounts

faulty

.

I

d

.

Inspect

engine

and

transmission

mounts

.

Align

or

replace,

if

nec-

essary

.

e

.

Front

centering

guide

worn,

or

e

.

Check

front

centering

guide

and

replace

if

necessary

.

Check

driveshaft

mounting

flanges

out

of

runout

of

driveshaft

flanges

.

round

.

f

.

Universal

joints

worn

or

seized

.

f

.

Check

universal

joint

play

and

movement

.

Replace

driveshaft

if

necessary

.

g

.

Sliding

coupling

seized

.

g

.

Remove

driveshaft

and

check

movement

of

sliding

coupling

.

Clean

coupling

splines

and

replace

parts

asnecessary

.

h

.

Driveshaft

misaligned

.

h

.

Check

driveshaft

alignment

.

2

.

Noise

during

on/off

a

.

Finaldrive

components

worn

or

a

.

Remove

final

drive

and

repair

.

throttle

or

when

damaged

(excessive

pinion-to-ring-

engagíng

clutch

.

gear

clearance)

.

b

.

Drive

axleor

CV

joint

faulty

.

b

.

Inspect

drive

axles

and

CV

joints

.

Repair

or

replace

as

neces-

sary

.

c

.

Sliding

coupling

seized

.

c

.

Remove

driveshaft

and

check

movement

of

sliding

coupling

.

Clean

coupling

splines

and

replace

parts

as

necessary

.

3

.

Vibration

at

25

to

30

a

.

Front

centering

guideworn,

or

a

.

Check

front

centering

guide

and

replace

if

necessary

.

Check

mph

(40

to

50

driveshaft

mounting

flanges

out

of

runout

of

driveshaft

mounting

flanges

.

km/h

).

round

or

damaged

.

b

.

Universal

joints

worn

or

seized

.

b

.

Check

universal

joint

play

and

movement

.

Replace

driveshaft

if

necessary

.

c

.

Flex-disc

damaged

or

worn

.

c

.

Inspect

flex-disc

.

Replace

if

necessary

.

d

.

Center

bearing

rubber

deteriorated

.

d

.

Inspect

center

bearing

.

Replace

if

necessary

.

e

.

Sliding

coupling

seized

.

e

.

Remove

driveshaft

and

check

movement

of

sliding

coupling

.

Clean

coupling

splines

and

replace

parts

asnecessary

.

f

.

Misaligned

installed

position

.

f

.

Check

driveshaft

alignment

.

Page 244 of 759

260-

4

DRIVESHAFT

CAUTION

-

The

maximum

allowable

change

in

height

of

the

center

bearing

or

transmission

support

using

shims

is

3

mm

(0

.12

in

.)

.

Driveshaft,

removing

WARNING

-

"

Be

sure

the

wheels

are

off

the

ground

before

re-

moving

the

driveshaft

.

Set

the

parking

brake

be-

fore

removing

the

driveshaft

.

"

Once

the

driveshaft

has

been

removed,

the

vehi-

cle

can

roll

regardless

of

whether

the

transmis-

sion

isin

gear

or

not

.

"

The

driveshaft

fs

mounted

to

thetransmission

and

final

drive

with

self-locking

nuts

.

These

nuts

are

designed

to

be

used

only

once

and

should

be

replaced

during

reassembly

.

1.

Disconnect

oxygen

sensor

electrical

connectors

and

remove

complete

exhaustsystem

.

See

180

Exhaust

System

.

4

.

Remove

driveshaft

mounting

bolts

.

See

Fig

.

3

.

Discard

old

nuts

.

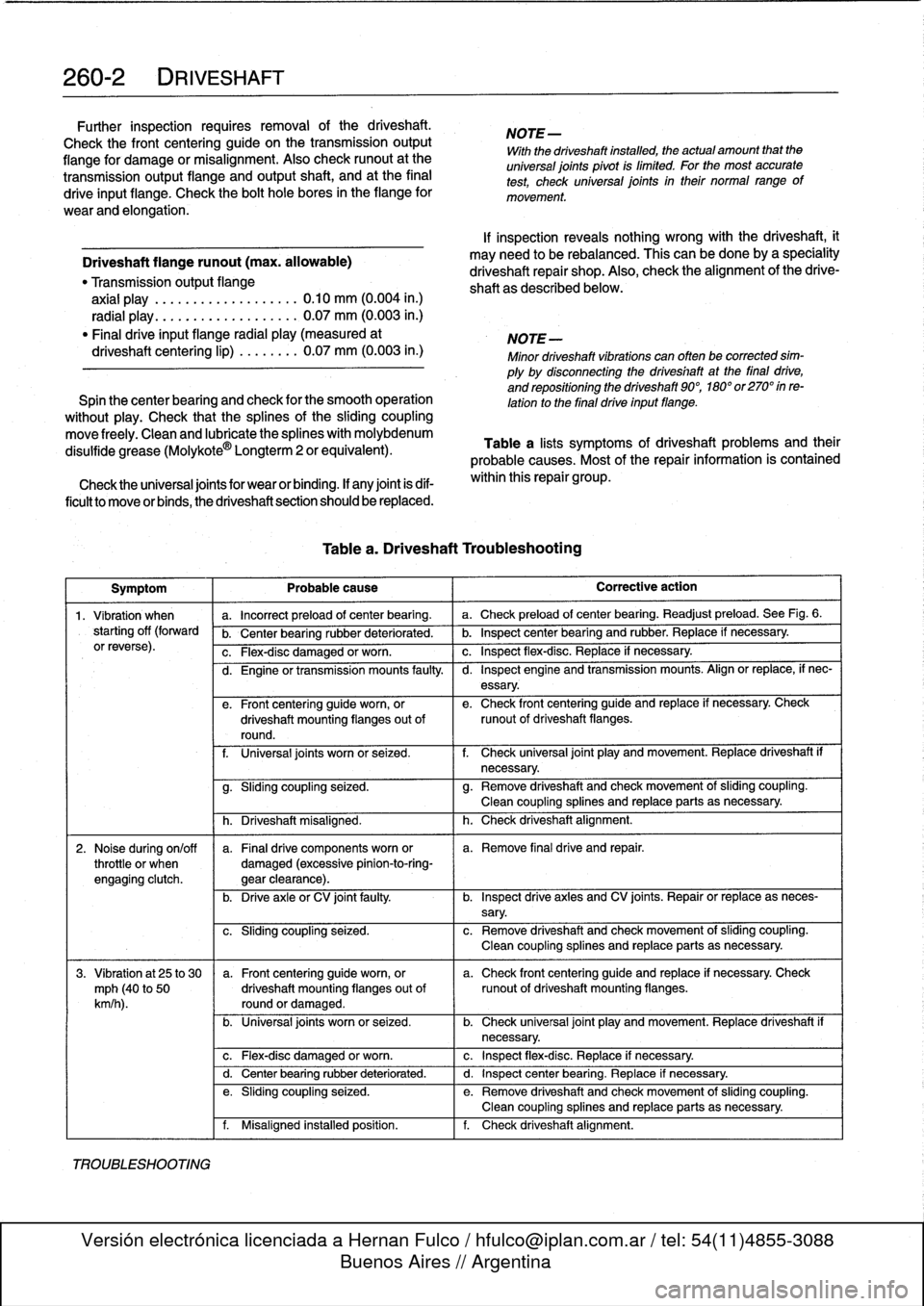

JG

Fig

.

3

.

Front

driveshaft

totransmission

mounting

bolt

being

re-

moved

.

Note

open-end

wrench

(arrow)

being

used

to

coun-

terhold

bolt

.

5

.

Loosen

threaded

clamping

sleeve

on

driveshaft

a

few

tucos

.

See

Fig

.

4

.

DRIVESHAFT

SERVICE

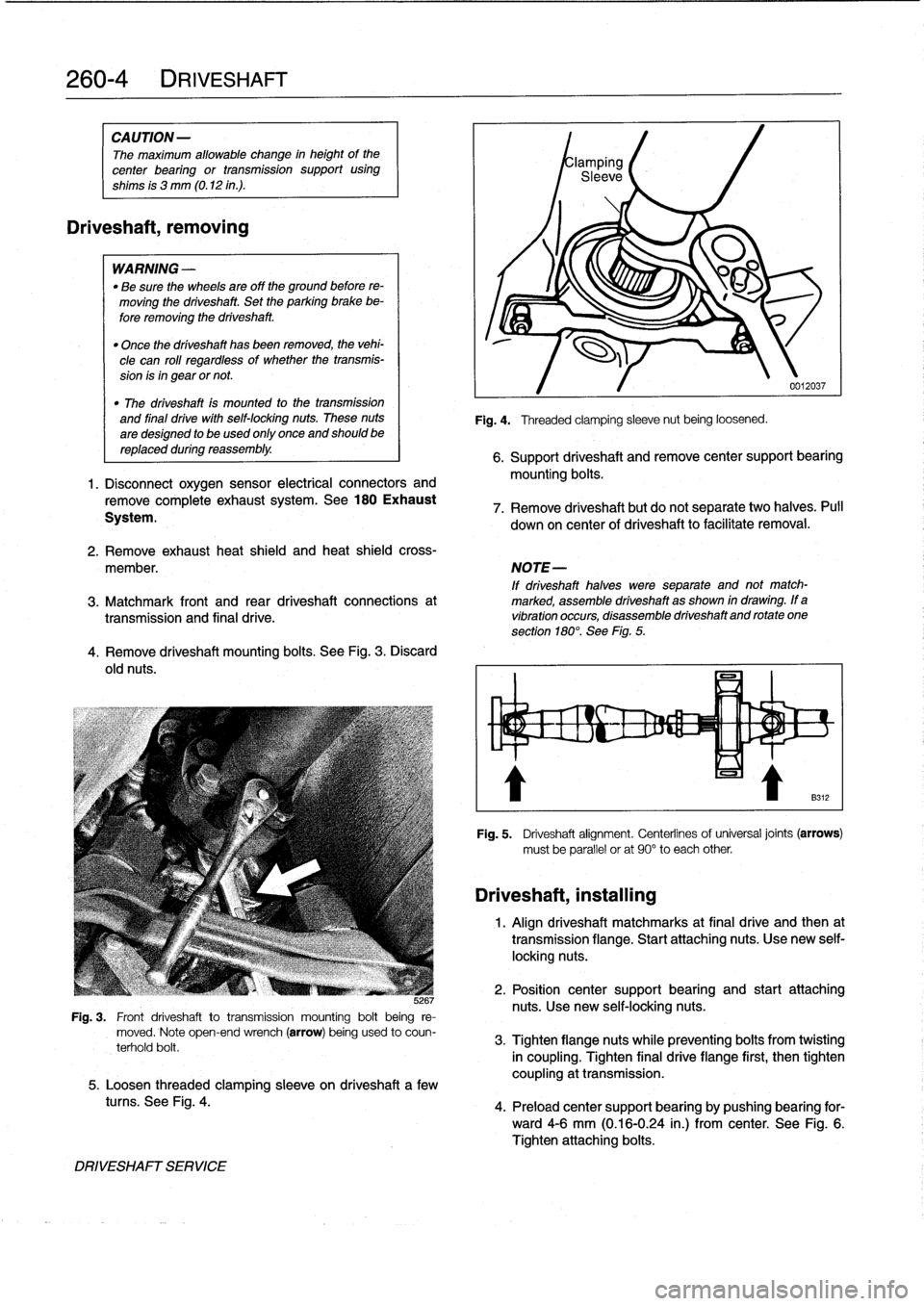

Fig

.

4

.

Threaded

clamping

sleeve

nut

being

loosened

.

0012037

6

.

Support

driveshaft

andremove

center

support

bearing

mounting

bolts

.

7

.

Remove

driveshaft

but

do

not

separate

two

halves

.

Pull

down

on

center

of

driveshaft

to

facilitate

removal

.

2

.

Remove

exhaust

heat

shield

and

heat

shieldcross-

member

.

NOTE-

If

driveshaft

halves

were

separate

and

not

match-

3

.

Matchmark

front

and

rear

driveshaft

connections

at

marked,

assemble

driveshaft

as

shown

in

drawing

.

If

a

transmissíon

and

final

drive

.

vibration

occurs,

disassemble

driveshaftand

rotate

one

section

180°

.

See

Fig

.

5

.

Driveshaft,

installing

Fig

.

5

.

Driveshaft

alignment

.

Centerlinesof

universal

joints

(arrows)

must

be

parallel

or

at

90°

to

each

other

1

.

Align

driveshaft

matchmarks

at

final

drive

and

then

at

transmission

flange

.

Start

attaching

nuts

.

Use

new

self-

locking

nuts

.

2

.

Position

center

support

bearing

and

start

attaching

nuts

.

Use

new

self-locking

nuts

.

3

.

Tighten

flangenuts

while

preventing

bolts

from

twisting

in

coupling

.

Tighten

final

drive

flange

first,

then

tighten

coupling

at

transmission

.

4

.

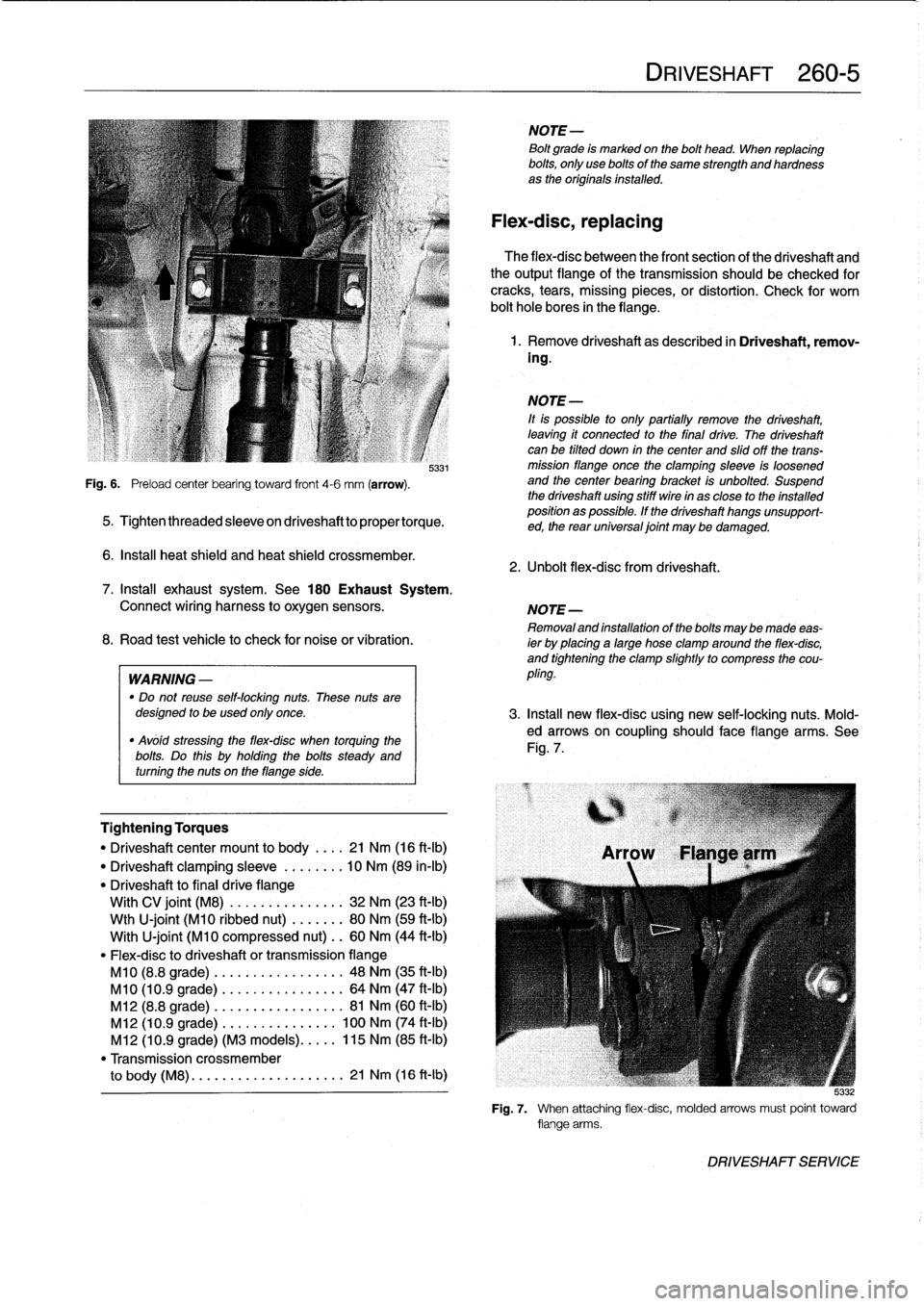

Preload

center

support

bearing

by

pushing

bearing

for-

ward4-6

mm

(0

.16-0

.24

in

.)

from

center

.

See

Fig

.

6

.

Tighten

attaching

bolts

.

Page 245 of 759

Fig

.

6

.

Preload

center

bearing

toward

front

4-6

mm

(arrow)

.

5331

5

.

Tightenthreadedsleeveondriveshafttopropertorque

.

6

.

Insta¡¡

heat

shield

and

heat

shield

crossmember

.

Tightening

Torques

"

Driveshaftcenter

mount

to

body

.

.

..

21

Nm

(16

ft-Ib)

"

Driveshaft

clamping

sleeve

.....

.

.

.

10

Nm

(89

in-lb)

"

Driveshaft

to

final

drive

flange

With

CV

joint

(M8)

............

...

32

Nm

(23

ft-Ib)

Wth

U-joint

(M10

ribbed

nut)

....

...

80

Nm

(59

ft-Ib)

With

U-joint

(M10

compressed

nut)

..

60

Nm

(44

ft-Ib)

"

Flex-disc

to

driveshaft

or

transmissionflange

M10

(8.8

grade)

.........

.

....

..

.

48

Nm

(35

ft-Ib)

M10

(10

.9

grade)

........

.

....

...

64

Nm

(47

ft-Ib)

M12

(8.8

grade)

........

.....

..

.

.

81

Nm

(60

ft-Ib)

M12

(10

.9

grade)

.

.

....

......

...

100

Nm

(74

ft-Ib)

M12

(10

.9

grade)

(M3

models)

..

.

.

.

115

Nm

(85

ft-Ib)

"

Transmission

crossmember

to

body

(M8)

.

....

...........

....

21

Nm

(16

ft-Ib)

NOTE-

Bolt

grade

is

markedon

the

bolt

head

.

When

replacing

bolts,

only

use

bolts

of

the

same

strength

and

hardnessas

the

originalsinstalled

.

Flex-disc,

replacing

The

flex-disc

between

the

front

section

of

the

driveshaft

and

theoutputflange

of

the

transmission

should

be

checked

for

cracks,

tears,

missing

pieces,

or

distortion

.

Check

for

worn

bolt

hole

bores

in

theflange

.

1

.

Remove

driveshaft

as

described

in

Driveshaft,

remov-

ing

.

NOTE-

¡t

is

possible

to

only

partially

remove

the

driveshaft,

leaving

it

connected

to

the

final

drive

.

The

driveshaft

canbe

tilted

down

in

thecenter

and

slidoff

the

trans-

mission

flange

once

the

clamping

sleeve

is

loosened

and

the

center

bearing

bracket

is

unbolted

.

Suspend

the

driveshaft

using

stiff

wire

in

as

close

to

the

installed

position

as

possible

.

If

the

driveshaft

hangs

unsupport-

ed,

the

rear

universal

joint

may

be

damaged

.

2

.

Unbolt

flex-dísc

from

driveshaft

.

DRIVESHAFT

260-

5

7

.

Install

exhaust

system

.

See

180

Exhaust

System

.

Connect

wiring

harness

to

oxygen

sensors

.

NOTE-

Removaland

installation

of

the

boltsmaybe

made

eas-

8

.

Road

test

vehicle

to

check

for

noiseor

vibration

.

ier

by

placing

a

large

hose

clamp

around

the

flex-disc,

and

tightening

the

clamp

slightlyto

compress

the

cou

WARNING

-

pling

.

"

Do

not

reuse

self-locking

nuts

.

These

nuts

aredesigned

to

beused

only

once

.

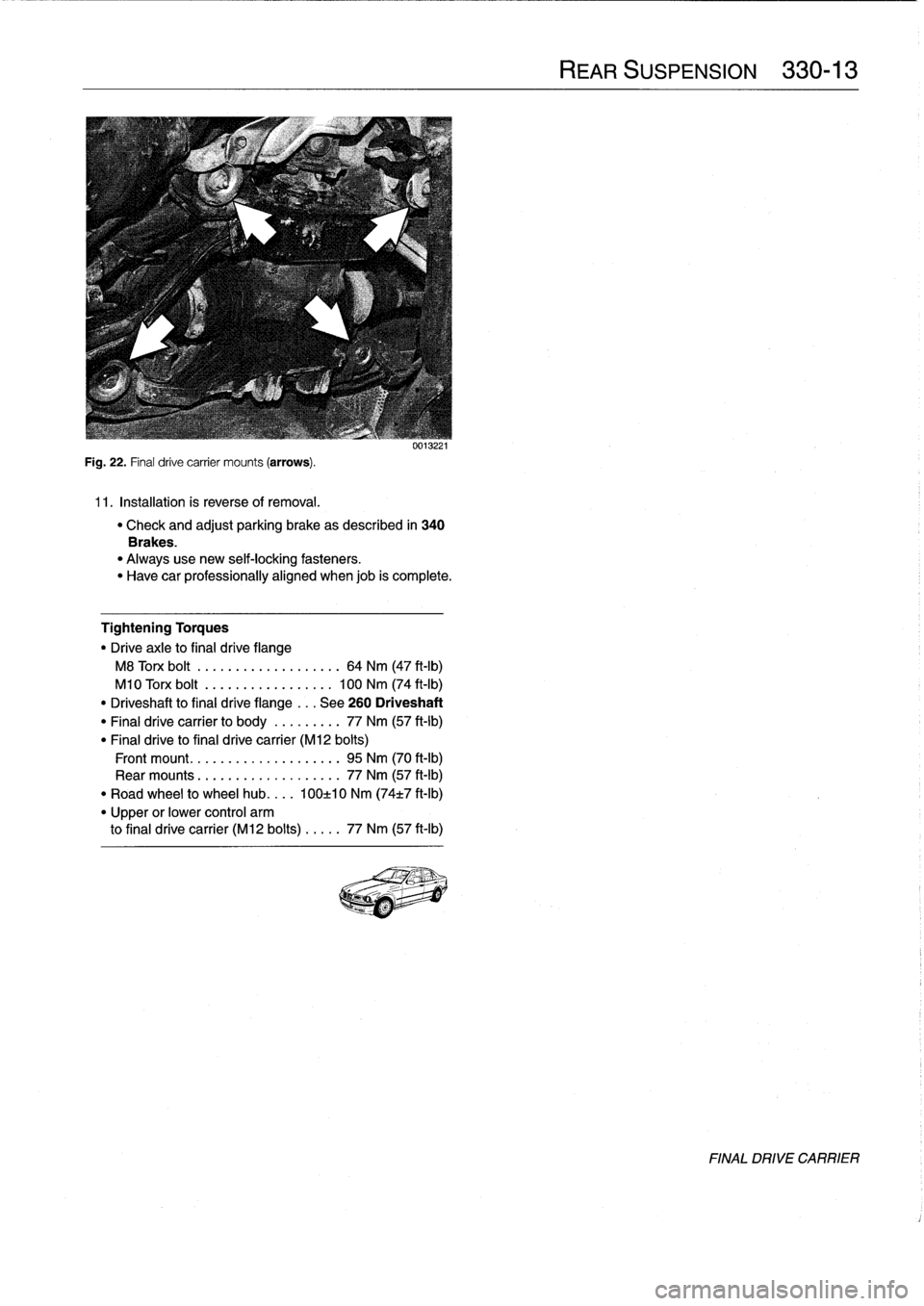

3

.

Insta¡¡

new

flex-disc

using

new

self-locking

nuts

.

Mold-

"

Avóid

stressing

the

flex-disc

when

torquing

the

ed

arrows

on

coupling

should

face

flange

arms

.

See

bolts

Do

this

holding

the

bolts

Fig

.

7

.

steady

and

.

uy

turning

the

nuts

on

theflange

side

.

5

:132

Fig

.

7

.

When

attaching

flex-disc,

molded

arrows

must

point

toward

flange

arms

.

DRIVESHAFT

SERVICE

Page 268 of 759

320-2

STEERING

AND

WHEEL

ALIGNMENT

3

.

Carefully

remove

airbag

from

front

of

steering

wheel

.

See

721

Airbag

System

(SRS)

.

Store

airbag

unit

in

a

safe

place

.

WARNING-

Improper

handling

of

theaírbag

could

cause

seri-

ous

ínjury

.

Store

theaírbag

with

the

horn

pad

facing

up

.

If

stored

facing

down,

accidental

deployment

could

propel

it

vlolently

into

the

air,

causíng

ínjury

.

4

.

Remove

steering

wheel

center

bolt

.

Lightly

punch

mark

or

scribe

position

of

steering

wheel

to

steering

column

shaft

.

See

Fig

.

1

.

0012687

Fig

.

1

.

Steering

wheel

center

bolt

(arrow)

.

Power

steering

pump,

removing

and

installing

POWER

STEERING

SYSTEM

5

.

Unlock

steering

wheel

by

turning

ignition

key

on

.

Re-

move

steering

wheel

.

WARNING-

The

SRS

contact

reel

ís

mounted

to

the

rear

of

the

steering

wheel

hub

.

The

contact

reel

ís

a

wound

coil

ofwirethat

ensures

continuous

electrícal

contact

for

the

air

bag

unit

Once

the

steering

wheel

mounting

nut

or

bolt

is

removed

the

contact

reel

is

locked

in

the

center

position

and

its

position

must

not

be

al-

tered

.

6

.

Insta¡¡

steering

wheel

while

aligning

matching

marks

.

Make

sure

airbag

contact

ring

locking

pin

engages

cutout

in

contact

reel

.

Insta¡¡

steering

column

center

nut

.

Do

not

over-torque

.

See

Fig

.

2

.

7

.

The

remainder

ofinstallation

is

reverse

of

removal

.

Carefully

install

airbag

from

front

of

steering

wheel

.

See

721

Airbag

System

(SRS)

.

Tightening

Torque

"

Steering

wheel

to

steering

column

spindle

...

..

..

.

..........

63

Nm

(46

ft-Ib)

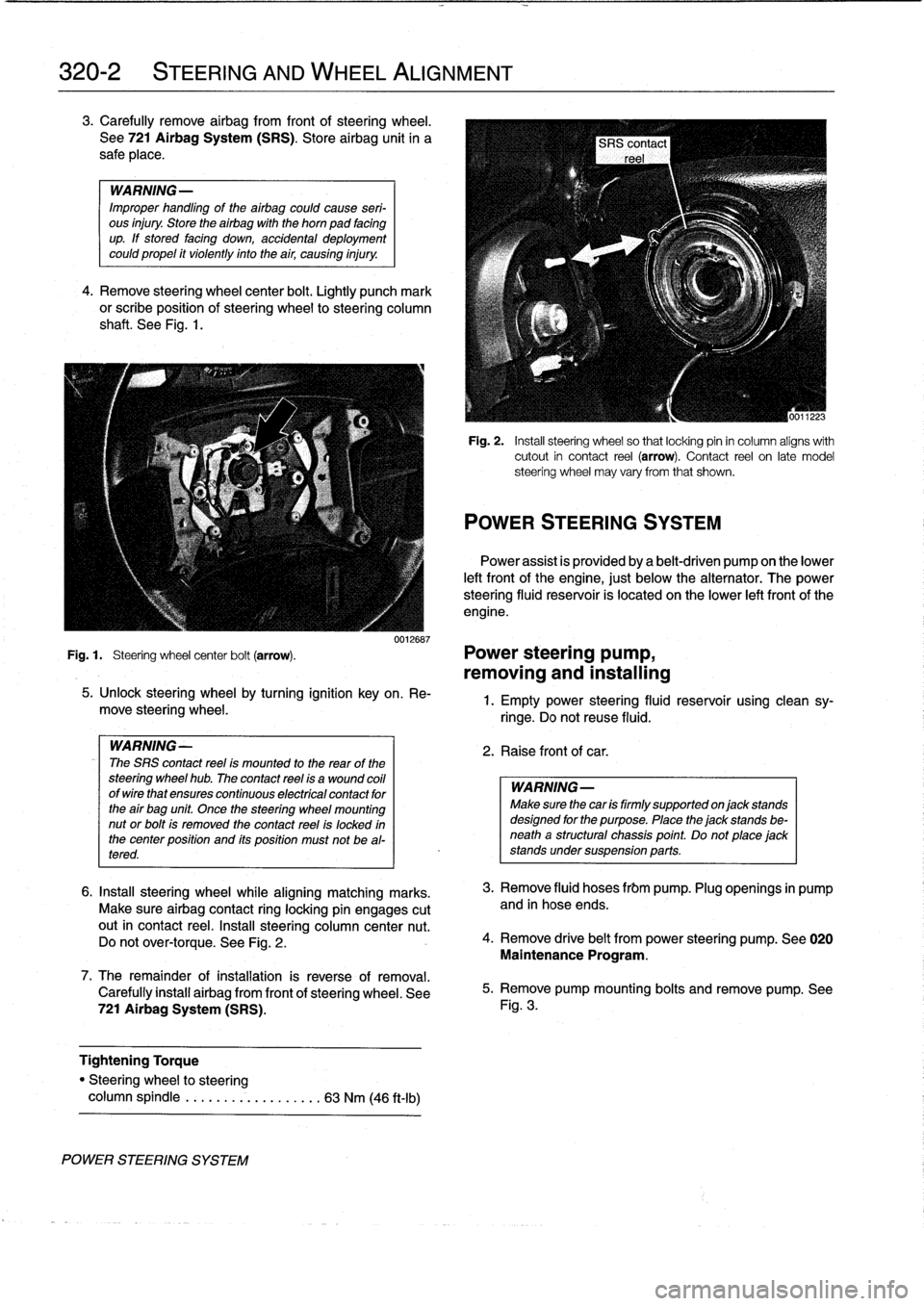

Fig

.

2

.

Insta¡¡

steering

wheel

so

that

locking

pin

in

column

aligns

with

cutout

in

contact

reel

(arrow)

.

Contact

reel

on

late

model

steering

wheel

may

vary

from

that

shown

.

POWER

STEERING

SYSTEM

Power

assist

is

províded

by

a

belt-driven

pump

on

the

lower

left

front

of

the

engine,

just

below

the

alternator

.

The

power

steering

fluid

resenroir

is

located

on

the

lower

left

front

of

the

engine

.

1

.

Empty

power

steering

fluid

reservoir

usingclean

sy-

ringe

.

Do

not

reuse

fluid

.

2

.

Raise

front

of

car

.

WARNING

Make

sure

thecar

is

firmly

supportedon

jack

stands

designed

for

the

purpose

.

Place

the

jack

stands

be-

neatha

structural

chassis

point

.

Do

not

place

jack

stands

undersuspension

parts

.

3

.

Remove

fluid

hoses

frbm

pump

.

Plug

openings

in

pump

and

in

hose

ends

.

4

.

Remove

drive

belt

from

power

steering

pump

.

See

020

Maintenance

Program

.

5

.

Remove

pump

mounting

bolts

and

remove

pump

.

See

Fig

.

3

.

Page 284 of 759

330-

1

2

REAR

SUSPENSION

Upper

control

arm,

removing

and

installing

1.

Raise

rear

end

of

car

and

remove

wheel

.

WARNING

-

Make

sure

that

the

car

is

firmly

supportedon

jack

stands

designed

for

the

purpose

.

Place

the

jack

stands

beneatha

structural

chassis

point

.

Do

not

place

jack

stands

under

suspension

parts

.

2

.

Remove

drive

axle

as

described

earlier

.

3

.

Remove

stabilizer

bar

link

fromupper

control

arm

.

4

.

Support

trailing

arm

from

below

with

a

transmission

jackorequivalent

.

WARNING

-

It

is

recommended

that

a

retaining

chain

be

in-

stalled

between

the

bottom

coil

of

the

coil

spring

and

the

upper

control

arm

to

retain

thespring

in

case

of

accidental

release

.

Personal

injury

can

re-

sult

if

the

compressed

coil

spring

ís

not

released

slowly

and

carefully

.

5

.

Remove

lower

shock

absorber

bolt

.

Refer

to

Fig

.

18

.

Slowly

lower

trailing

arm

until

coil

spring

is

fully

re-

leased

.

Remove

restraining

chain

and

remove

spring

.

7

.

Installation

is

reverse

of

removal

.

"

Always

use

new

self-locking

nuts

.

"

Have

car

professionally

aligned

when

job

is

complete

.

"

Insta¡¡

drive

axle

as

described

earlier

.

Tightening

Torques

"

Drive

axleto

final

drive

flange

M8

Torx

bolt

..........

..

.

..

....

64

Nm

(47

ft-Ib)

M10

Torx

bolt

.........

..

..

.

...

100

Nm

(74

ft-Ib)

"

Shock

absorber

to

trailing

arm

..

..

..

77

Nm

(57

ft-Ib)

"

Upper

control

arm

to

final

drive

carrier

(M12

bolt)

...

..

.

77

Nm

(57

ft-Ib)

"

Upper

control

arm

to

trailing

arm

(M12

bolt)

.........

110

Nm

(81

ft-Ib)

Lower

control

arm,

1

.

Raise

rear

end

of

car

and

support

it

securely

on

jack-

stands

.

Remove

rear

wheel

.

2

.

Remove

both

lower

control

arm

mounting

bolts

.

FINAL

DRIVE

CARRIER

3

.

Use

a

soft

hammer

to

tap

control

arm

out

of

its

mount-

ing

points

.

4

.

Installation

is

reverse

of

removal

.

NOTE-

Use

a

new

bolt

and

washer

assembly

at

the

final

drive

carrier

mountíng

point

forthe

control

arm

.

Tightening

Torque

"

Lower

control

arm

to

final

drive

carrier

(M12

bolt)

......

77

Nm

(57

ft-Ib)

"

Lower

control

arm

to

trailing

arm

(M12

bolt)

....

..

.

..

110

Nm

(81

ft-Ib)

FINAL

DRIVE

CARRIER

Final

drive

carrier,

removing

and

installing

1

.

Raise

rear

end

of

car

and

support

it

securely

on

jack

stands

.

Remove

rear

wheels

.

2

.

Remove

driveshaft

.

See

260

Driveshaft

.

3

.

Remove

both

drive

axles

as

described

earlier

.

6

.

Remove

both

upper

control

arm

mounting

bolts

.

Re-

move

control

arm

.

4

.

Disconnect

stabilizer

bar

from

upper

control

arms

.

Re-

move

stabilizer

bar

mounts

.

5

.

Disconnect

speedometer

harness

connector

on

final

drive

(where

applicable)

.

6

.

Remove

rear

section

of

exhaust

system

.

See

180

Ex-

haust

System

.

NOTE-

It

may

be

easier

to

remove

complete

exhaust

asonepiece

.

See

180

Exhaust

System

.

7

.

Remove

upper

and

lower

control

arms

as

described

earlier

.

8

.

Support

final

drive

carrierwith

transmissíon

jack

.

Re-

move

mounting

bolts

and

nuts

at

final

drive

carrier

bushing

mounts

.

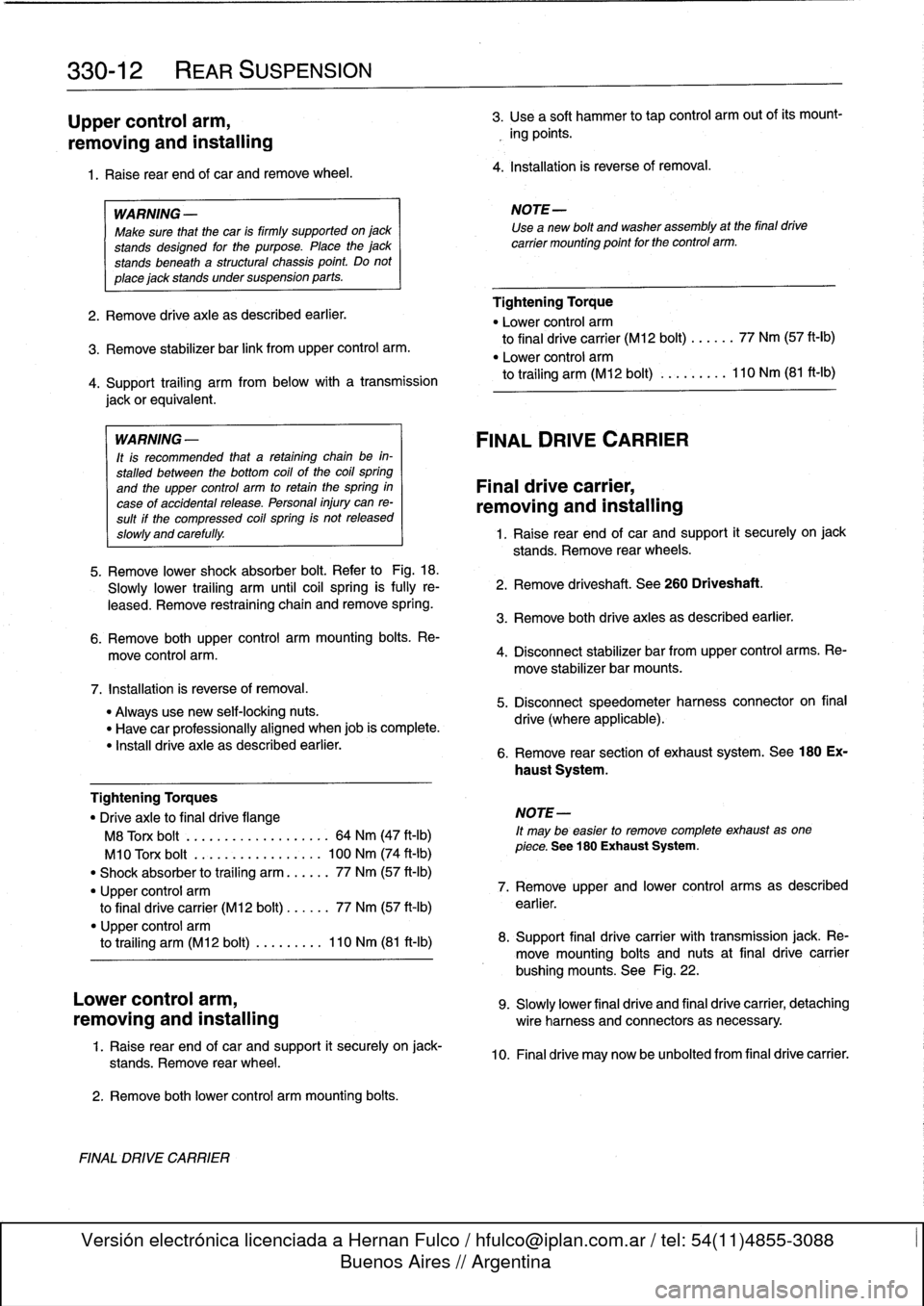

See

Fig

.

22

.

9

.

Slowly

lower

final

drive

and

final

drive

carrier,

detaching

removing

and

installing

wire

harness

and

connectors

as

necessary

.

10

.

Finaldrive

may

now

be

unbolted

from

final

drive

carrier

.

Page 285 of 759

Fig

.

22

.

Final

drive

carrier

mounts

(arrows)

.

11

.

Installation

is

reverse

of

removal

.

uu1J221

"

Check

and

adjust

parking

brake

as

described

in

340

Brakes

.

"

Alwaysuse

new

self-locking

fasteners

.

"

Have

car

professionally

aligned

when

job

is

complete

.

Tightening

Torques

"

Drive

axle

to

final

drive

flange

M8

Torx

bolt

................

...

64

Nm

(47

ft-Ib)

M10

Torx

bolt

..........

..

...

.

.

100

Nm

(74

ft-Ib)

"

Driveshaft

to

final

drive

flange

...

See

260

Driveshaft

"

Final

drive

carrier

to

body

......

...

77

Nm

(57

ft-Ib)

"

Final

drive

to

final

drive

carrier

(M12

bolts)

Front

mount

.................

...

95

Nm

(70

ft-lb)

Rear

mounts

................

...

77

Nm

(57

ft-Ib)

"

Road

wheel

to

wheel

hub

....

100±10

Nm

(74t7

ft-Ib)

"

Upper

or

lower

control

arm

to

final

drive

carrier

(M12

bolts)

....

.

77

Nm

(57

ft-Ib)

Page 287 of 759

GENERAL

......

.

.

.

.

.

.

.

.....

.

.

.

.

.

.

.

.

.

.

331-1

Final

Drive

Oil

Seals

.

.

...

.

.

.

.......

.

.

.

.

.

331-1

Finaldrive

flange

oil

sea¡,

replacing

....

.

.

.

..

331-2

FINAL

DRIVE

SERVICE

.

.....

.

.

.

.

.

.

.

.

.

.

331-1

Finaldrive

inputshaft

oil

seal,

replacing

.

.

.

.

.

331-3

Final

drive

oí¡,

draining

and

filling

.

.

.

.

.

.

.

.

.

.

331-1

Finaldrive

unit,

removíng

and

installing

.

.

.

.

.

.

331-3

GENERAL

This

repa¡r

group

covers

repair

operations

that

do

not

re-

quire

complicated

disassembly

of

the

final

drive

.

Internal

re-

pairs

and

final

drive

disassembly

are

not

covered

in

this

manual

.

FINAL

DRIVE

SERVICE

Al¡

final

drive

work

requires

some

method

of

raising

thecar

and

supporting

it

securely

while

the

work

is

performed

.

Jack

stands

and

a

floor

jack

can

easily

be

used,

but

use

extreme

caution

when

working

beneath

the

car

.

See010

Fundamen-

tais

for

the

Do-It-Yourself

Owner

.

NOTE-

Removal

of

final

drive

carrier

is

covered

in

330

Rear

Suspension

.

Final

drive

oil,

draining

and

filling

1

.

Drive

car

to

warm

final

drive

fluid

.

2

.

Raise

car

and

support

safely

.

WARNING

-

Make

sure

that

thecar

is

firmly

supported

on

jack

standsdesigned

for

the

purpose

.

Place

the

jack

standsbeneatha

structural

chassis

point

.

Do

not

place

jack

stands

under

suspension

parts

.

5

.

Fill

final

drive

with

appropriate

type

and

quantity

of

lu-

bricant

.

Insta¡¡

and

tighten

fill

plug

.

331

Final

Drive

0

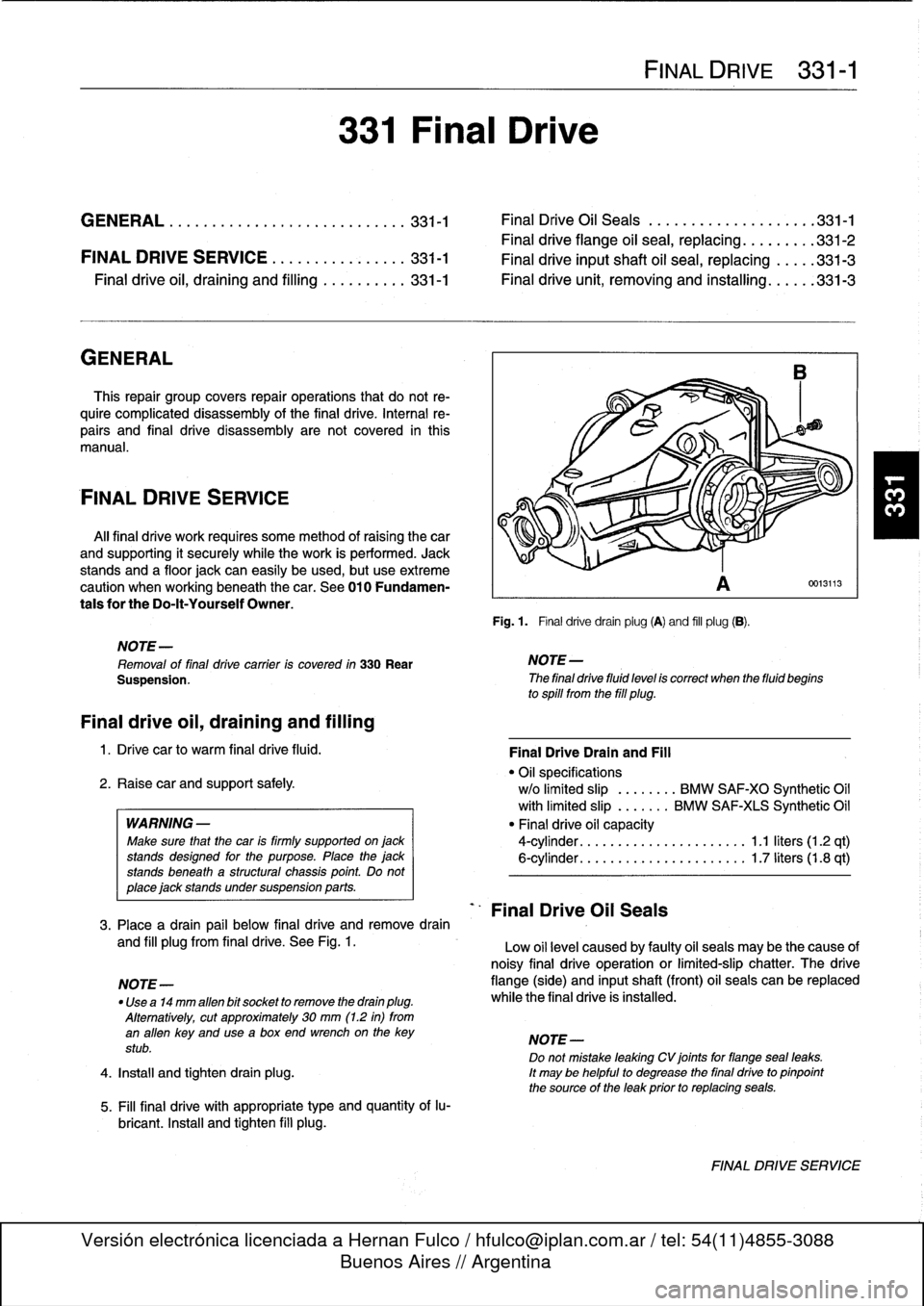

Fig

.

1

.

Final

drivedrain

plug

(A)

and

fill

plug

(B)

.

D

NOTE-

The

final

drive

fluid

level

is

correct

when

the

fluid

begins

to

spill

from

the

fill

plug

.

Final

Drive

Oil

Seals

FINAL

DRIVE

331-1

0013113

Final

DriveDrain

and

Fill

"

Oil

specifications

w/o

limited

slip

.

.......

BMW

SAF-XO

Synthetic

Oil

with

limited

slip

.

......

BMW

SAF-XIS

Synthetic

Oil

"

Final

drive

oil

capacity

4-cylinder

.

.

.

...

................

1

.1

liters

(1

.2

qt)

6-cylinder

.

.

.

...

................

1

.7liters(1.8

qt)

3

.

Place

a

drain

pail

below

final

drive

andremove

drain

and

fill

plugfrom

final

drive

.

See

Fig

.

1

.

Low

oil

level

caused

by

faulty

oil

seals

may

be

the

cause

of

noisy

final

drive

operation

or

limited-slip

chatter

.

The

drive

NOTE-

flange

(side)

and

inputshaft

(front)

oil

seals

can

be

replaced

"

Use

a14

mm

alíen

bit

socket

to

remove

the

drain

plug

.

while

the

final

drive

is

installed

.

Alternatively,

cut

approximately

30

mm

(1

.2

in)

from

an

alíen

key

and

usea

box

end

wrenchon

the

key

NOTE-

stub

.

Do

not

mistake

leaking

CV

joints

for

flangeseal

leaks

.

4

.

Install

and

tighten

drain

plug

.

It

may

be

helpful

to

degrease

the

final

drive

to

pinpoint

the

source

of

the

leak

prior

to

replacing

seals

.

FINAL

DRIVE

SERVICE

Page 290 of 759

331-

4

FINAL

DRIVE

FINAL

DRIVE

SERVICE

0013242

0013243

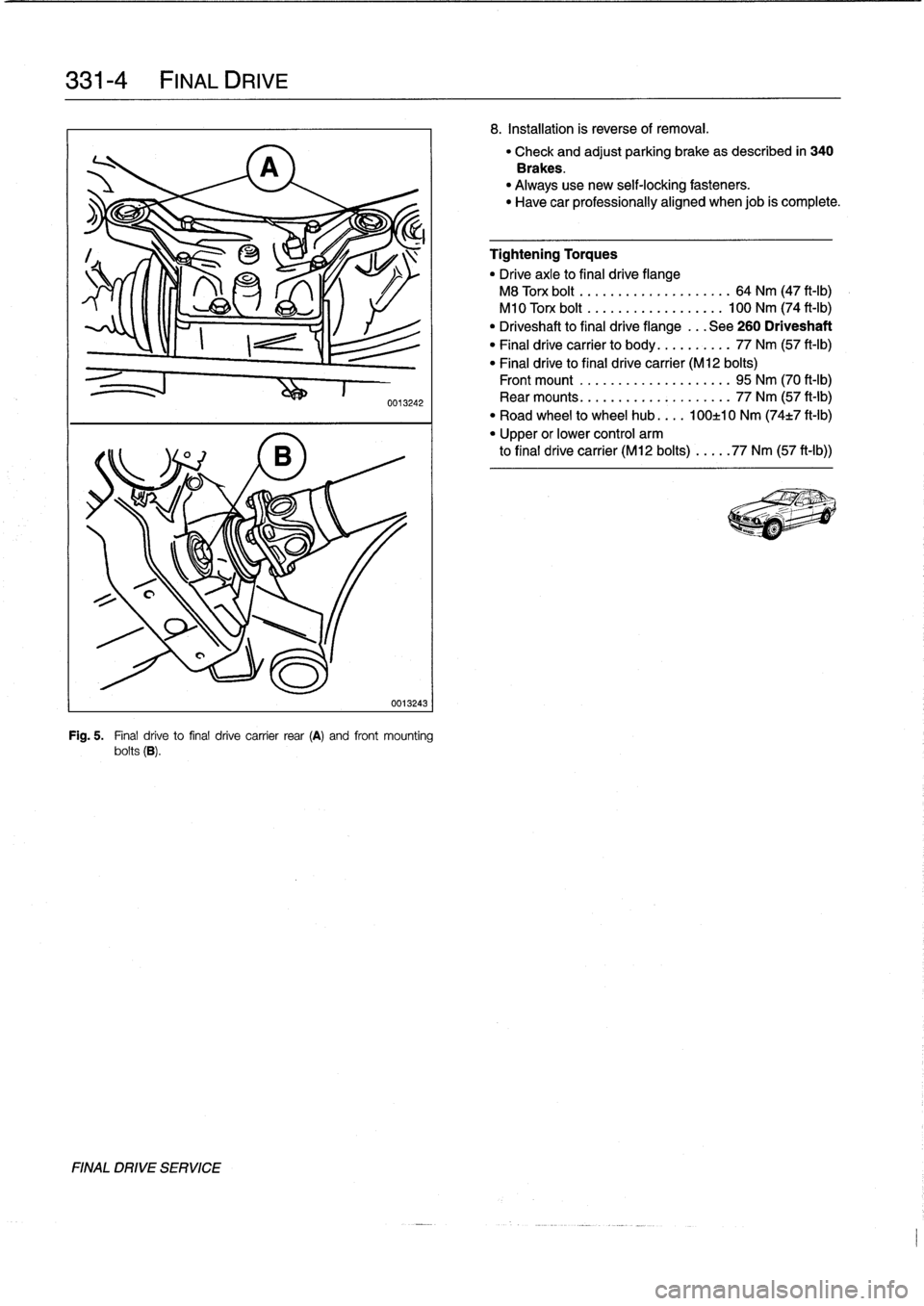

Fig

.

5

.

Final

drive

to

final

drive

carrier

rear

(A)

and

front

mounting

bolts

(B)

.

8

.

Installation

is

reverse

of

removal

.

"

Check

and

adjust

parking

brake

as

described

in

340

Brakes

.

"

Always

use

new

self-locking

fasteners

.

"

Have

car

professionally

aligned

when

job

is

complete

.

Tightening

Torques

"

Drive

axle

to

final

drive

flange

M8

Torx

bolt

..

.

...

...

..

.........

64

Nm

(47

ft-Ib)

M10

Torx

bolt

.

.

...

...

..

........

100

Nm

(74

ft-Ib)

"

Driveshaft

to

final

drive

flange

...

See

260

Driveshaft

"

Final

drive

carrier

to

body

..

........

77

Nm

(57

ft-Ib)

"

Final

drive

to

final

drive

carrier

(M12

bolts)

Front

mount

.....

...

.

...

........

95

Nm

(70

ft-Ib)

Rear

mounts

.....

.......

.

.

.

..

...

77

Nm

(57

ft-Ib)

"

Road

wheel

to

wheel

hub

....

100±10

Nm

(74±7

ft-Ib)

"

Upper

or

lower

control

arm

to

final

drive

carrier

(M12

bolts)

...

..

77

Nm

(57

ft-Ib))