Hose BMW 328i 1998 E36 Manual Online

[x] Cancel search | Manufacturer: BMW, Model Year: 1998, Model line: 328i, Model: BMW 328i 1998 E36Pages: 759

Page 311 of 759

ENGINE

HOOD

Hood,

raising

to

service

position

CA

UTION-

Do

not

switch

on

the

windshield

wipers

wlth

the

engine

hood

raised

.

As

a

precaution,

remove

the

wiper

motor

fuse

.

See

610

Electrical

Compo-

nent

Locations

.

1

.

4-door

models

:

Open

hood

fully

.

Remove

bolt

from

hood

hinge

behind

hood

supports

(left

and

right)

.

Raise

hood

to

service

position

.

See

Fig

.

5

.

2

.

2-door

models

:

Open

hood

fully

.

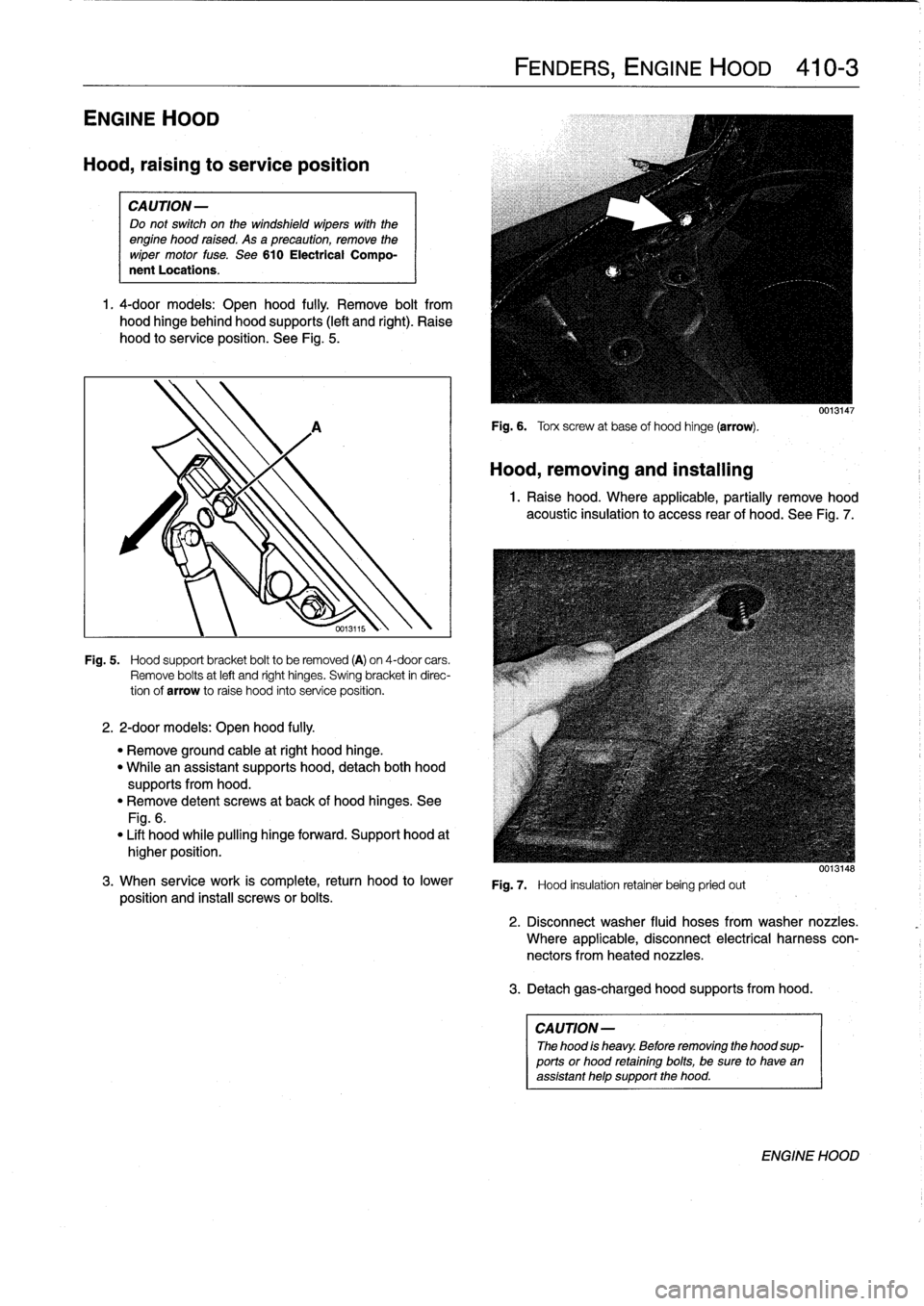

Fig

.

5

.

Hood

support

bracket

boltto

be

removed

(A)

on

4-door

cars

.

Remove

bolts

at

left

and

right

hinges

.

Swing

bracket

in

direc-

tion

of

arrow

to

raise

hood

into

service

position

.

"

Remove

ground

cable

atright

hood

hinge

.

"

Whilean

assistant

supports

hood,

detach

both

hood

supportsfrom

hood

.

"

Remove

detent

screws

at

back

of

hood

hinges

.

See

Fig

.

6

.

"

Lift

hood

while

pulling

hinge

forward

.

Support

hood

at

higher

position

.

3

.

When

service

work

is

complete,

return

hood

to

lower

position

and

instaf

screws

or

bolts

.

FENDERS,

ENGINE

HOOD

410-

3

Fig

.

6

.

Torx

screw

at

base

of

hood

hinge

(arrow)

.

Hood,

removing

and

installing

0013147

1

.

Raise

hood

.

Where

applicable,

partially

remove

hood

acoustic

insulation

to

access

rear

of

hood

.

See

Fig

.

7

.

Fig

.

7

.

Hood

insulation

retainer

being

pried

out

3

.

Detachgas-charged

hood

supportsfrom

hood

.

CAUTION

-

The

hood

is

heavy

.

Before

removing

the

hood

sup-

ports

or

hood

retainingbolts,

be

sure

to

have

an

assistant

help

support

the

hood

.

0013148

2

.

Disconnect

washer

fluid

hoses

from

washer

nozzles

.

Where

applicable,

disconnect

electrical

harness

con-

nectors

fromheated

nozzles

.

ENGINE

HOOD

Page 387 of 759

610

Electrical

Component

Locations

GENERAL

...........

.

.

.

.

.

.

.

.

.

........

610-1

FOSE

POSITION

TABLES

..

.

.

.

.

.

.....

.

610-19

FUSE

AND

RELAY

POSITIONS

.

...

.

.

.

.

.

610-1

Fuse

Positions

.

.

.

................

.

.

.

.

.

610-1

Relay

Positions

.

.

.

.....

.

.

.

........

.

.

.

.

.

610-2

Auxiliary

RelayPanel

.....

.

...

.

........

.

610-2

SplicePanel,

Left

.

.

.

...

.

.

.

...

.

........

.

610-2

SplicePanel,

Right

.

.

.

.

.

.

.

.

...

.

.........

610-3

COMPONENT

LOCATIONS

.

.

.

.

.......

.

.610-3

Component

Location

Table

.

.

.

.

.

.

.........

610-9

GENERAL

FUSE

AND

RELAY

POSITIONS

This

repair

group

covers

f

use,

relay,

and

control

module

lo-

The

front

power

distribution

box,

an

auxiliary

relay

panel,cation

information

.

Electrical

equipment

and

accessories

in-

and

two

auxiliary

splice

panels

contain

most

of

the

fuses

and

stalled

varies

depending

on

model

and

model

year

.

Always

relays

in

E36

vehicles

.

Refer

to

the

component

location

later

confirm

that

the

proper

electrical

component

has

been

identi-

in

this

section,

as

well

as

the

tables

at

the

end

of

this

repair

fied

by

using

the

electrical

wiring

diagrams

.

group

for

electrical

component

location

.

WARNING

-

On

cars

equipped

with

airbags,

special

precautionsapply

to

any

electrical

system

testing

orrepair

.

Air-

bag

units

areexplosive

devices

and

mustbe

han-

dled

with

extremecare

.

Before

starting

any

work

onan

airbag

equipped

car,

refer

to

the

wamings

and

cautions

in

721

Airbag

System

(SRS)

.

CAUTION

-

"

Prior

to

disconnectiog

the

battery,

read

the

bat-

tery

disconnection

cautions

given

at

the

front

of

this

manual

on

page

viii

.

"

Relay

and

fuse

positions

are

subject

to

changeand

may

varyfrom

car

to

car

.

If

questions

arise,

an

authorized

BMW

dealer

is

the

best

source

for

the

most

accurate

and

up-to-date

information

.

"

A

good

way

to

verify

a

relay

position

isto

com-

pare

the

wiring

colors

at

the

relay

socket

to

thecolors

indicated

on

the

wiring

diagrams

located

at

the

rear

of

this

manual

.

"

Always

switchthe

ignition

off

and

disconnect

the

negative

(-)

battery

cable

before

removing

any

electrical

components

.

"

Connect

and

disconnect

ignition

system

wires,

multiple

connectors,

and

ignition

test

equipment

leads

only

while

the

ignition

is

switched

off

.

"

Only

usea

digital

multimeter

for

electrical

tests

.

ELECTRICAL

COMPONENT

LOCATIONS

610-1

TABLES

a

.

E36Component

Locations

...........

.

.

..

...

610-10b

.

1992

E36

Fuse

Positions

..........

..

.

.

.....

610-20c

.

1993

E36

Fuse

Positions

..........

..

..

.

....

610-22d

.

1994

E36

Fuse

Positions

.........

...

.......

610-24e

.

1995

E36

Fuse

Positions

.........

...

.......

610-26

f

.

1996

E36

Fuse

Positions

.........

...

.......

610-28g

.

1997-1998

E36

Fuse

Positions

..

.

..

...

.......

610-30

Fuse

Positions

CAUTION

-

"

Replace

fuses

with

those

of

the

same

rating

.

In-

stalling

a

fuse

with

higher

rating

can

lead

to

cir-

cuit

failure

and

may

also

start

a

fire

.

"

Relay/fuse

positions

vary

by

model

and

equip-

ment

.

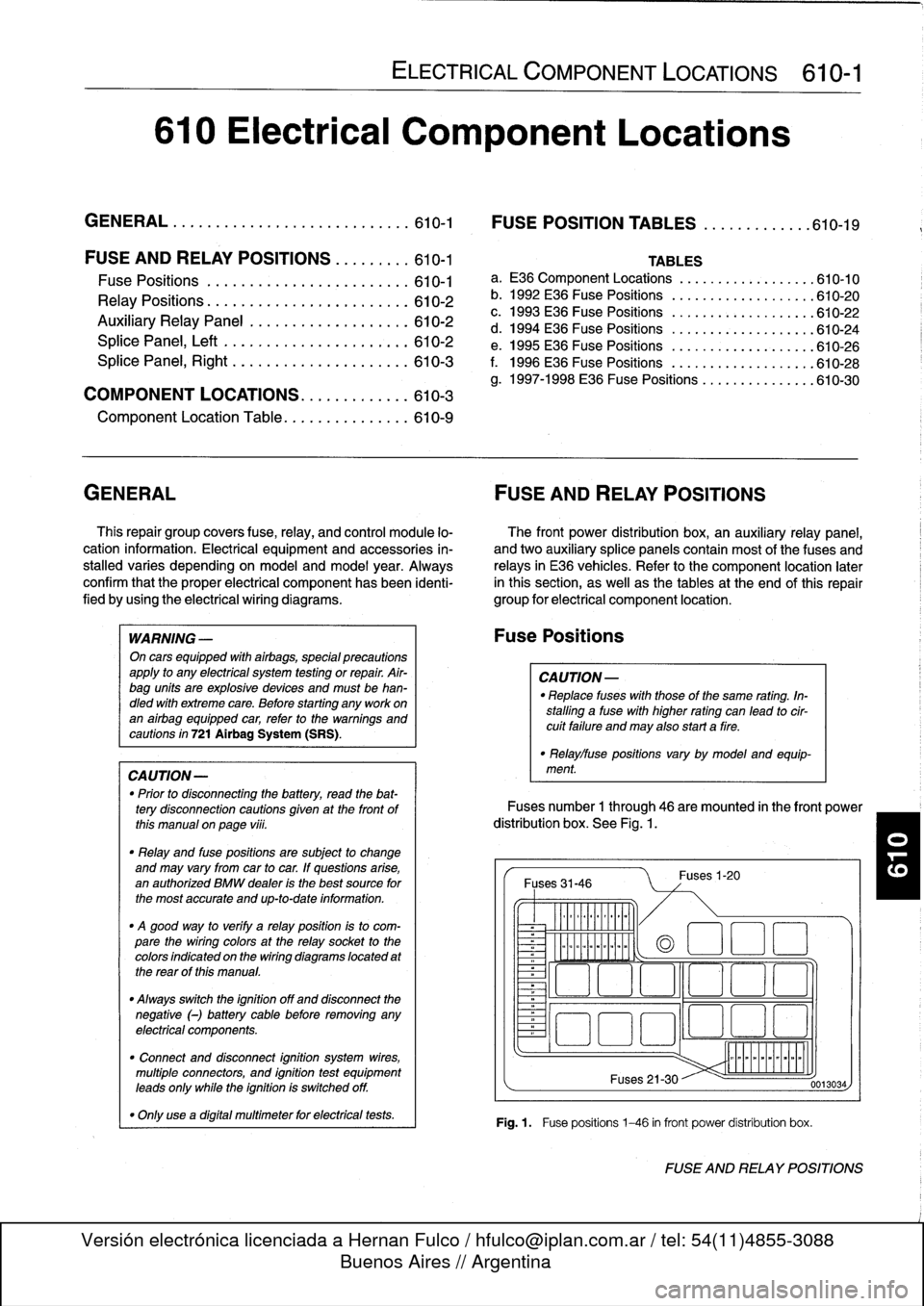

Fuses

number

1

through

46

are

mounted

in

the

front

power

distribution

box

.

See

Fig

.

1.

Fuses

31-46

~

Illlllllllll

°

-

Ilmmlmomlmoi

Fuses

1-20

(a

1

:1

E

El

~

~O!7

L~~n

4~

i

Fuses

21-30

Fig

.1.

Fuse

positions

1-46

in

front

power

distribution

box

.

0013034

FUSE

AND

RELAY

POSITIONS

Page 393 of 759

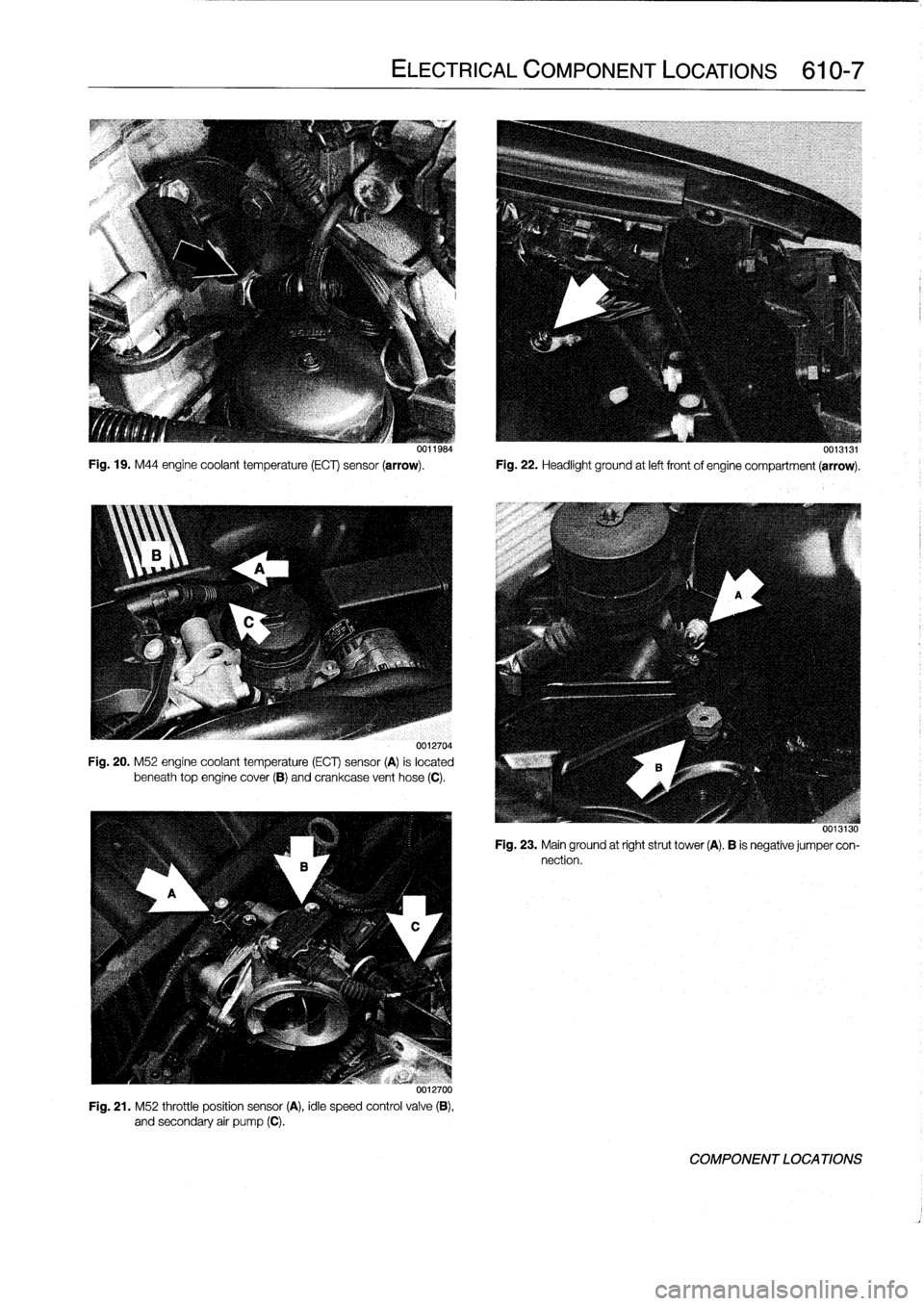

Fig

.

19

.

M44

engine

coolant

temperature

(ECT)

sensor

(arrow)

.

Fig

.

22

.

Headlight

ground

at

left

frontof

engine

compartment

(arrow)

.

0012704

Fig

.

20

.

M52

engine

coolant

temperature

(ECT)

sensor

(A)

is

located

beneath

top

enginecover

(B)

and

crankcase

vent

hose

(C)

.

uu12700

Fig

.

21

.

M52

throttle

position

sensor

(A),

idle

speed

control

valve

(B),

and

secondary

air

pump

(C)

.

ELECTRICAL

COMPONENT

LOCATIONS

610-7

00119s4

0013131

uvijijo

Fig

.

23

.

Mainground

at

right

strut

tower

(A)

.

B

is

negative

jumper

con-

nection

.

COMPONENT

LOCA

TIONS

Page 427 of 759

WINDSHIELD

CLEANING

SYSTEM

Washer

f

luid

reservoir,

replacing

1

.

Open

hood

and

siphon

out

washer

fluid

reservoir

.

The

windshieldcleaning

system

includes

the

spray

nozzles

in

the

engine

hood,

the

washer

fluid

pump,

and

the

washer

flu-

id

reservoir

in

the

front

passenger

side

of

the

engine

compart-

ment

.

The

windshield

spray

nozzles

can

be

aimed

by

using

asew-

ing

need1e

or

a

similar

diameter

stiff

piece

of

wire

.

Windshield

spray

nozzle,

removing

and

installing

1

.

Open

hood

andremove

hood

insulating

pad

retaining

clips

until

bottom

of

nozzle

canbe

fully

accessed

.

See

410

Fenders,

Engine

Hood

.

2

.

Carefully

disconnect

hose

from

nozzle

.

Disconnect

har-

ness

connectors

for

nozzleheater

.

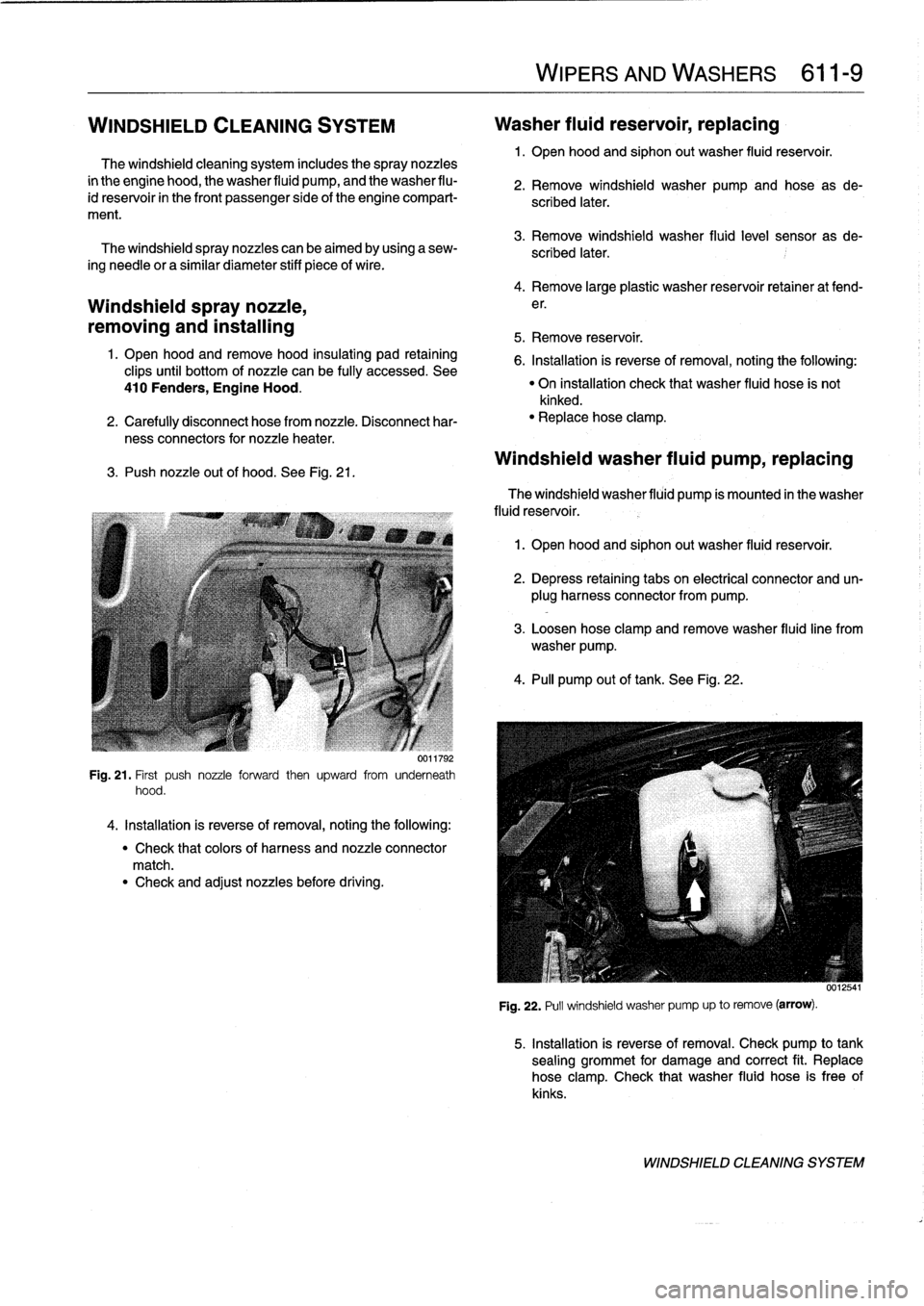

3

.

Push

nozzleout

of

hood

.

See

Fig

.

21

.

Fig

.

21

.

First

push

nozzle

forward

then

upward

from

underneath

hood

.

4

.

Installation

is

reverse

of

removal,

noting

the

following

:

"

Check

that

colors

of

harness

and

nozzle

connector

match

.

"

Check

and

adjust

nozzles

before

driving

.

WIPERSAND

WASHERS

611-

9

2

.

Remove

windshield

washer

pump

and

hose

as

de-

scribed

later

.

3

.

Remove

windshield

washer

fluid

level

sensor

as

de-

scribed

later

.

4

.

Remove

large

plastic

washer

reservoir

retainer

at

fend-

e

r

.

5

.

Remove

reservoir

.

6

.

Installation

is

reverse

of

removal,

noting

the

following

:

"

On

installation

check

that

washer

fluid

hose

is

not

kinked

.

"

Replacehose

clamp

.

Windshield

washer

fluid

pump,

replacing

The

windshield

washer

fluid

pump

ís

mounted

in

the

washer

fluid

reservoir

.

1

.

Open

hood

and

siphon

out

washer

fluid

reservoir

.

2

.

Depress

retaining

tabs

on

electrical

connector

and

un-

plug

harness

connector

from

pump

.

3

.

Loosen

hose

clamp

and

remove

washer

fluidline

from

washer

pump

.

4

.

PA

pump

out

of

tank

.

See

Fig

.

22

.

Fig

.

22

.

Pull

windshield

washer

pump

up

to

remove

(arrow)

.

5

.

Installation

is

reverse

of

removal

.

Check

pump

to

tank

sealing

grommet

for

damage

and

correct

fit

.

Replace

hose

clamp

.

Check

that

washer

fluid

hose

is

free

of

kinks

.

WINDSHIELD

CLEANING

SYSTEM

Page 449 of 759

9

.

Release

blower

motor

retaining

strap

andremove

blow-

er

motor

and

fans

fromcowl

opening

.

NOTE-

Twist

and

rotate

blowermotor

assembly

to

facilítate

re-

moval

from

opening

.

If

the

blower

motor

is

to

be

rein-stafled,

use

care

not

to

damage

fan

wheels

during

removal

.

ff

the

blower

motor

fs

to

be

replaced,

cut

offfan

wheels

at

center

to

aid

in

removal

.

10

.

Installation

is

reverse

of

removal

.

When

installing

a

re-

placement

blower

motor,

instan

motor

into

cowlarea

before

installing

fan

wheels

.

Blower

motor

test

specifi-

cations

are

listed

in

Table

a

.

NOTE

-

On

replacementblowermotors

from

BMW,

thefan

wheels

come

unattached

to

aid

in

installation

.

Locatearrow

on

blower

motor

and

instan

fan

wheels

atthis

po-

sition

.

Be

sure

color

coolng

matches

.

Retain

fan

wheels

using

the

new

clips

.

See

an

authorized

BMW

parts

de-

partment

for

the

latest

parts

information

.

Table

a

.

Blower

Motor

Test

Values

Testingvoltage

13

VDC

Operating

voltage

9-15

VDC

Max

.

current

consumption

(approx

.)

12

amps

Maximum

speed

3,600-4,000rpm

Axialplay

(max

.

allowable)

1

.0

mm

(0

.04

in

.)

Blower

motor

resistor

pack,

replacing

The

blower

resistor

pack

is

clipped

into

the

upper

left

side

of

theheater

box

.

1

.

Remove

lower

left

dash

trim

panel

.

See513

Interior

Trim

.

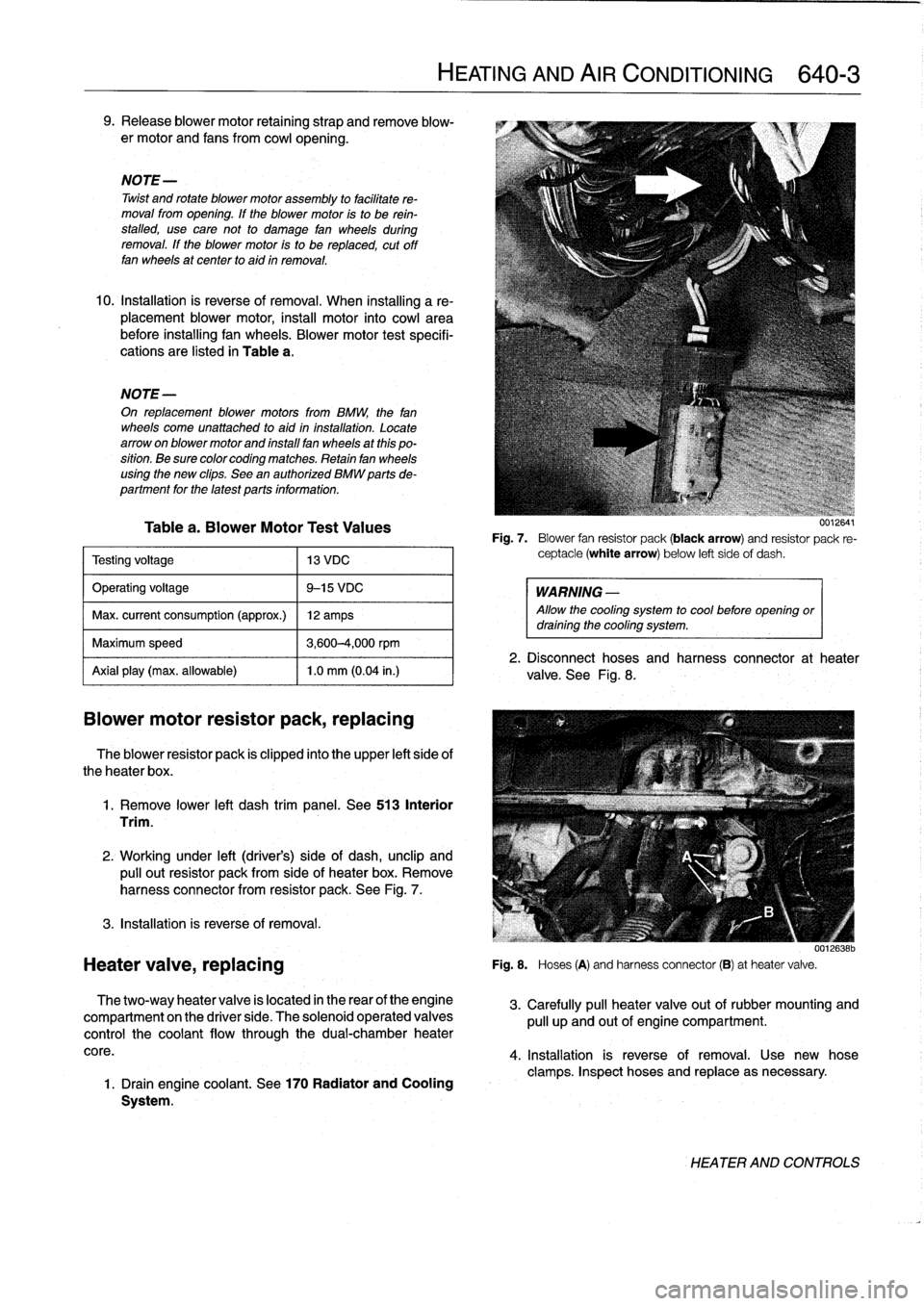

2

.

Working

under

left

(driver's)

side

of

dash,

unclip

and

pulí

out

resistor

pack

from

sideof

heater

box

.

Remove

harness

connector

from

resistor

pack

.

See

Fig

.

7

.

3

.

Installation

is

reverse

of

removal

.

Heater

valve,

replacing

The

two-way

heater

valve

is

located

in

the

rear

of

the

engine

compartment

on

the

driver

side

.

The

solenoid

operated

valves

control

the

coolant

flow

through

the

dual-chamber

heater

core

.

1

.

Drain

engine

coolant

.

See

170

Radiator

and

Cooling

System

.

HEATING

AND

AIR

CONDITIONING

640-

3

uuiGO4I

Fig

.

7

.

Blower

fan

resistor

pack

(black

arrow)

and

resistor

pack

re-

ceptacle

(white

arrow)

below

left

sideof

dash

.

WARNING

-

Allow

the

cooling

system

to

cool

before

opening

ordraining

the

cooling

system

.

2

.

Disconnect

hoses

and

harness

connector

at

heater

valve

.

See

Fig

.

8

.

001[ó38b

Fig

.

S

.

Hoses

(A)

and

harnessconnector

(B)

at

heatervalve

.

3

.

Carefully

pull

heater

valve

out

of

rubber

mounting

and

pull

up

and

out

of

engine

compartment

.

4

.

Installation

is

reverse

of

removal

.

Use

new

hose

clamps

.

Inspect

hoses

and

replace

asnecessary

.

HEATER

AND

CONTROLS

Page 450 of 759

640-4

HEATING

AND

AIR

CONDITIONING

Heater

box,

removing

and

installing

The

heater

box,

located

underneath

thecenter

of

the

dash-

board,

houses

theheater

core,

the

A/C

evaporator,

and

asso-

ciated

sensors

and

actuators

.

Removal

of

theheater

box

requires

that

the

A/C

refrigerant

be

discharged

.

CAUTION-

"

Removing

the

heater

box

requires

evacuating

the

AIC

system

.

DO

NOT

attempt

this

procedure

without

proper

tools

and

training

.

"

Any

person

who

services

a

motor

vehicle

air

con-

ditioner

must,

by

law,

be

properly

trained

and

cer-

tified,

and

use

approved

refrigerant

recycling

equipment

.

Technicians

must

complete

an

EPA-

approved

recycling

course

to

be

certified

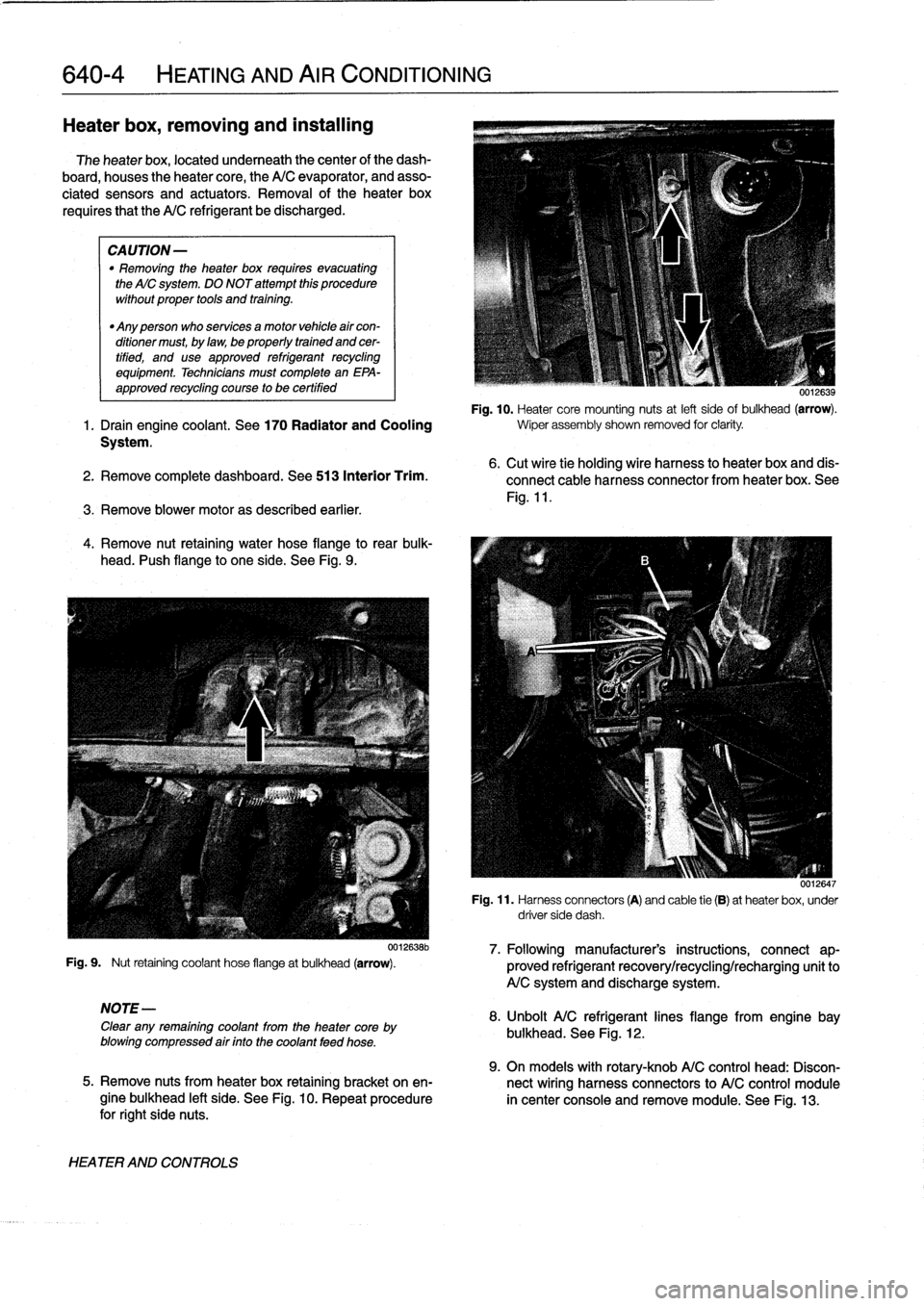

UU12639

Fig

.

10

.

Heater

core

mounting

nuts

at

left

sideof

bulkhead

(arrow)

.

1

.

Drain

engine

coolant

.

See

170

Radiator

and

Cooling

wiper

assembly

shown

removed

for

clarity

.

System

.

2

.

Remove

complete

dashboard

.

See513

Interior

Trim

.

3

.

Remove

blower

motoras

described

earlier

.

4

.

Remove

nut

retaining

water

hose

flange

to

rear

bulk-

head

.

I'ush

flange

to

one

side

.

See

Fig

.

9

.

Fig

.

9

.

Nut

retaining

coolant

hose

flangeat

bulkhead

(arrow)

.

NOTE-

Clear

any

remaining

coolant

from

the

heater

core

by

blowing

compressed

air

finto

the

coolant

feed

hose

.

HEATER

AND

CONTROLS

0012638b

6

.

Cut

wire

tie

holding

wire

harness

to

heater

box

and

dis-

connect

cable

harness

connector

from

heater

box

.

See

Fig

.

11

.

0012647

Fig

.

11

.

Harness

connectors

(A)

and

cable

tie

(B)

at

heaterbox,

under

driver

side

dash

.

7

.

Followingmanufacturer's

instructions,

connect

ap-

proved

refrigerant

recovery/recycling/recharging

unitto

A/C

system

and

discharge

system

.

8

.

Unbolt

A/C

refrigerantlines

flange

from

engine

bay

bulkhead

.

See

Fig

.

12

.

9

.

On

models

with

rotary-knob

A/C

control

head

:

Discon-

5

.

Remove

nuts

from

heater

box

retaining

bracket

on

en-

nect

wiring

harness

connectors

to

A/C

control

module

gine

bulkhead

left

side

.

See

Fig

.

10

.

Repeat

procedure

in

center

console

and

remove

module

.

See

Fig

.

13

.

for

right

side

nuts

.

Page 451 of 759

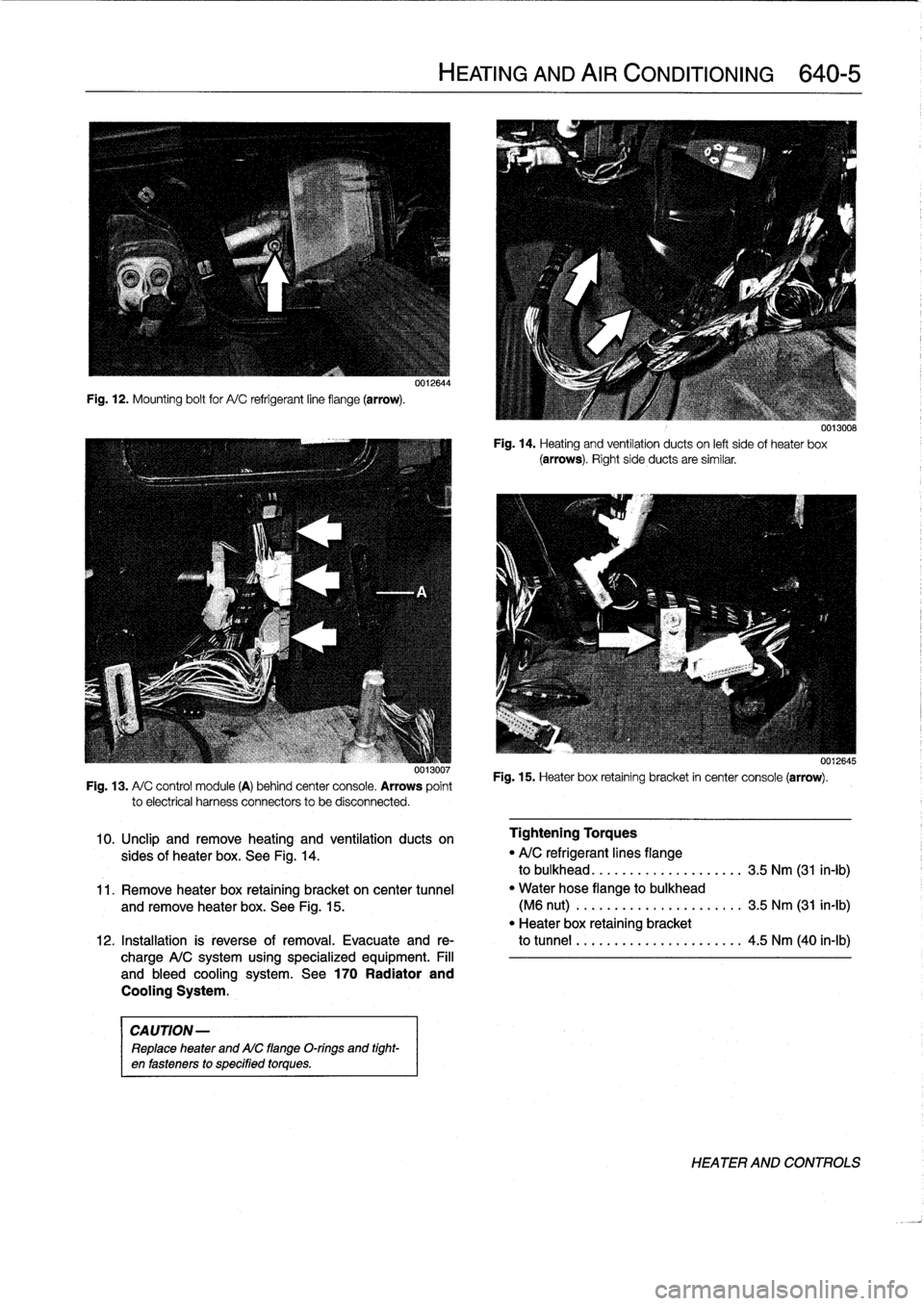

Fig

.

12

.

Mounting

bolt

for

A/C

refrigerant

line

flange

(arrow)

.

001Suu7

Fig

.

13

.

A/

C

control

module

(A)

behind

center

console

.

Arrows

pointto

electrical

harness

connectors

to

be

disconnected

.

CAUTION

-

Replace

heater

and

AIC

flange

O-rings

and

tight-

en

fasteners

to

specified

torques

.

0012644

HEATING

AND

AIR

CONDITIONING

640-5

Fig

.

14

.

Heating

and

ventilation

ducts

on

left

side

of

heater

box

(arrows)

.

Right

side

ducts

are

similar

.

Fig

.

15

.

Heater

box

retaining

bracket

in

center

console

(arrow)

.

0012645

10

.

Unclip

andremove

heating

and

ventilation

ducts

on

Tightening

Torques

sides

of

heater

box

.

See

Fig

.

14

.

"

A/C

refrigerant

lines

flange

to

bulkhead

..............

.

..

..

.

3

.5

Nm

(31

in-lb)

11

.

Remove

heater

box

retaining

bracket

on

center

tunnel

"

Water

hose

flange

to

bulkhead

and

remove

heater

box

.

See

Fig

.

15

.

(M6

nut)

................

.

...

..

3

.5

Nm

(31

in-lb)

"

Heater

box

retaining

bracket

12

.

Installation

is

reverse

of

removal

.

Evacuate

and

re-

to

tunnel

................

.

..

..

.

4

.5

Nm

(40

in-lb)

charge

A/C

system

using

specialized

equipment

.

Fill

and

bleed

cooling

system

.

See

170

Radiator

and

Cooling

System

.

HEATER

AND

CONTROLS

Page 457 of 759

To

access

the

rear

window

blower

relay,

remove

the

glove

compariment

.

See

Fig

.

32

.

Fig

.

32

.

Rear

window

blower

relay

located

in

frontof

glove

compart-

ment

(arrow)

.

AIR

CONDITIONING

Thissection

covers

removal

and

installation

of

air

condition-

ing

refrigerant

components

.

A/C

testing

and

diagnosis,

refrig-

erantdischarge,

evacuatíon

and

recharge

are

not

covered

here

.

The

subassemblies

and

lines

of

the

air

conditionerare

filled

with

either

refrigerant

R12

(1992

cars)

or

R-134a

(1993

and

later

cars)

.

The

major

components

of

the

A/Csystem

are

shown

in

Fig

.

33

.

A/CSystem

Warnings

and

Cautions

WARNING

-

"

Always

be

careful

that

refrigerant

does

not

come

in

contact

with

your

skin

.

Always

wearhand

andeye

protection

(gloves

and

goggles)

when

work-

ing

around

the

AIC

system

.

If

refrigerant

does

come

in

contact

with

your

skin

oreyes

:

-Do

not

rub

skin

oreyes

;

-Immediately

flush

skin

oreyes

withcool

water

for

15

minutes

;

-Rush

to

a

doctor

orhospital

;

-Do

not

attempt

to

treat

yourself

.

"

Work

in

a

wefl

ventilated

area

.

Avoid

breathing

re-

frigerant

vapors

.

Exposure

may

irrítate

eyes,

nose,

and

throat

.

Switch

on

exhaustlventilation

systems

when

working

on

the

refrigerant

system

.

"

Do

not

expose

any

component

of

the

AIC

system

to

high

temperatures

(Above

80°Cl176°F)or

open

flames

.

Excessive

heat

will

cause

a

pres-

sureincrease

whichcould

burst

the

system

.

HEATING

AND

AIR

CONDITIONING

640-

1

1

0013015

WARNING

-

"

Keep

refrigerant

away

from

open

llames

.

Poison-

ous

gas

will

be

produced

if

it

bums

.

Do

not

smoke

near

refrigerant

gases

for

the

same

reason

.

"

The

AICsystem

is

filled

with

refrigerant

gas

which

is

under

pressure

.

Pressurized

refrigerant

in

the

presenceof

oxygen

may

forma

combusti-

ble

mixture

.

Never

introduce

compressed

air

finto

any

refrigerant

container

(full

or

empty),

capped

off

AIC

component,

or

piece

of

service

equip-

ment

.

"

Refrígerant

gases

are

heavier

than

air,

displace

oxygen

and

may

cause

suffocation

in

areas

of

poor

círculation,

for

example

under

a

car

.

Switch

on

exhaustlventilation

systems

when

working

on

the

refrigerant

system

.

"

State

and

local

governments

may

have

additional

requirements

regarding

air

conditioning

servic-

ing

.

Alwayscomply

with

state

and

local

laws

.

"

Electric

welding

near

refrigerant

hoses

causes

R-134a

to

decompose

.

Discharge

system

before

welding

.

CA

UTION

-

-As

of

January

1,

1992,

any

person

who

services

a

motor

vehicle

air

conditioner

must,

by

law,

be

properly

trained

and

certified,

and

use

approved

refrigerant

recycling

equipment

.

Technicians

must

complete

an

EPA-approved

recycling

course

to

be

certified

.

"

It

is

recommended

that

al¡

system

refrigerant

AIC

refrigerant

be

left

to

an

authorized

BMW

dealer

or

other

qualified

AIC

service

facility

.

"

Do

not

top

off

a

partially

charged

refrigerant

sys-

tem

.

Dischargesystem,evacuate

and

then

re-

charge

system

.

"

R-134a

and

R-12

refrigerants

and

refrigerant

oils

and

system

components,

including

hoses

and

sealing

O-rings,

are

NOT

compatible

.

Compo-

nent

damage

andlor

system

contamination

will

result

.

"

The

mixture

of

refrigerant

oil

(PAG

oil)

and

refrig-

erant

R-134a

attacks

some

metals

and

alloys

(for

example,copper)

and

breaks

down

certain

hose

materials

.

Use

only

hoses

and

lines

that

are

iden-

tified

with

a

green

mark

(stripe)

or

the

lettering

R-

134a"

.

"

Immediately

plug

open

connections

on

AIC

com-

ponents

to

prevent

dirt

and

moisture

contamina-

tion

.

"

Do

not

steam

clean

condensers

or

evaporators

.

Use

only

cold

water

or

compressed

air

.

AIR

CONDITIONING

Page 459 of 759

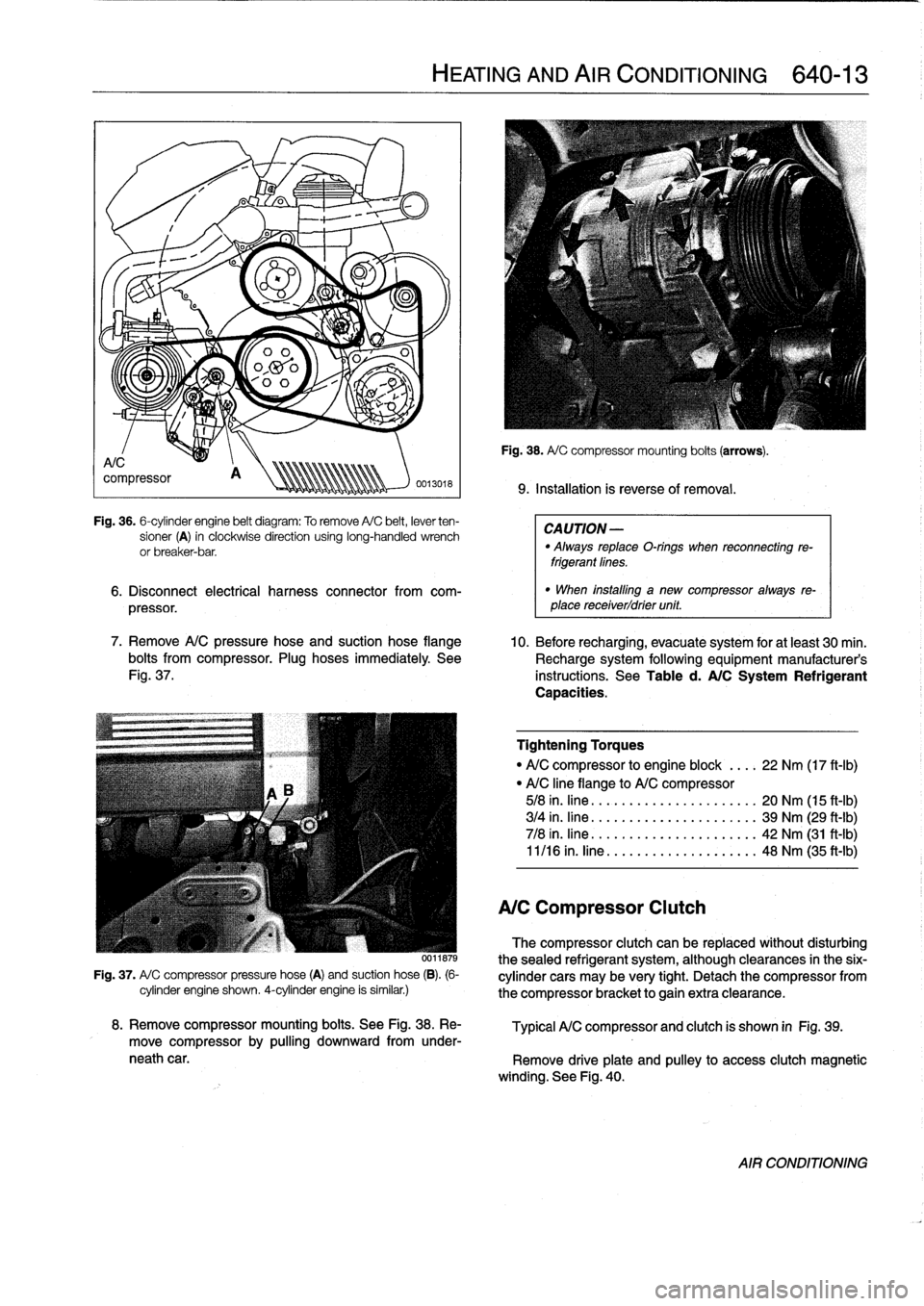

Fig

.

36

.

6-cylinder

engine

belt

diagram

:

To

remove

A/C

belt,

lever

ten-

sioner

(A)

in

clockwise

direction

using

long-handled

wrench

or

breaker-bar

.

6

.

Disconnect

electrical

harness

connector

from

com-

pressor

.

7

.

Remove

A/C

pressure

hose

and

suction

hose

flange

10

.

Before

recharging,

evacuate

system

for

at

least

30

min

.

bolts

from

compressor

.

Plug

hoses

immediately

See

Recharge

system

following

equipment

manufacturer's

Fig

.

37

.

instructions

.

See

Table

d

.

A/C

System

Refrigerant

Capacities

.

0011879

Fig

.

37

.

A/

C

compressor

pressure

hose

(A)

and

suction

hose

(B)

.

(6-

cylinder

engine

shown

.

4-cylinder

engine

is

similar

.)

HEATING

AND

AIR

CONDITIONING

640-

1

3

Fig

.

38

.

A/

C

compressor

mounting

boits

(arrows)

.

9

.

Installation

is

reverseof

removal

.

CAUTION

-

"

Always

replaceO-rings

when

reconnecting

re-

frigerantfines

.

"

When

installlng

a

new

compressor

always

re-

place

receiverldrier

unit

.

Tightening

Torques

"

A/C

compressor

to

engine

block

....

22

Nm

(17

ft-Ib)

"

A/C

line

flange

to

A/C

compressor

5/8

in

.

fine

.

......

.....

....

.

.....

20

Nm

(15

ft-Ib)

3/4

in

.

fine

.......

.....

..........

39

Nm

(29

ft-Ib)

7/8

in

.

fine

...

....

.....

..........

42

Nm

(31

ft-Ib)

11/16

in

.

fine

.....

..

..

..

...

.

.....

48

Nm

(35

ft-Ib)

A/C

Compressor

Clutch

The

compressor

clutch

can

be

replaced

without

disturbing

thesealed

refrigerant

system,

although

clearances

in

the

six-

cylinder

cars

may

be

very

tight

.

Detach

the

compressor

from

the

compressor

bracket

togain

extra

clearance

.

8

.

Remove

compressor

mounting

boits

.

See

Fig

.

38

.

Re-

Typical

A/C

compressor

and

clutch

is

shown

in

Fig

.

39

.

move

compressor

by

pulling

downward

from

under-

neath

car

.

Remove

driveplate

and

pulley

to

access

clutch

magnetic

winding

.

See

Fig

.

40

.

AIR

CONDITIONING