rear axle BMW 328i 1998 E36 Workshop Manual

[x] Cancel search | Manufacturer: BMW, Model Year: 1998, Model line: 328i, Model: BMW 328i 1998 E36Pages: 759

Page 23 of 759

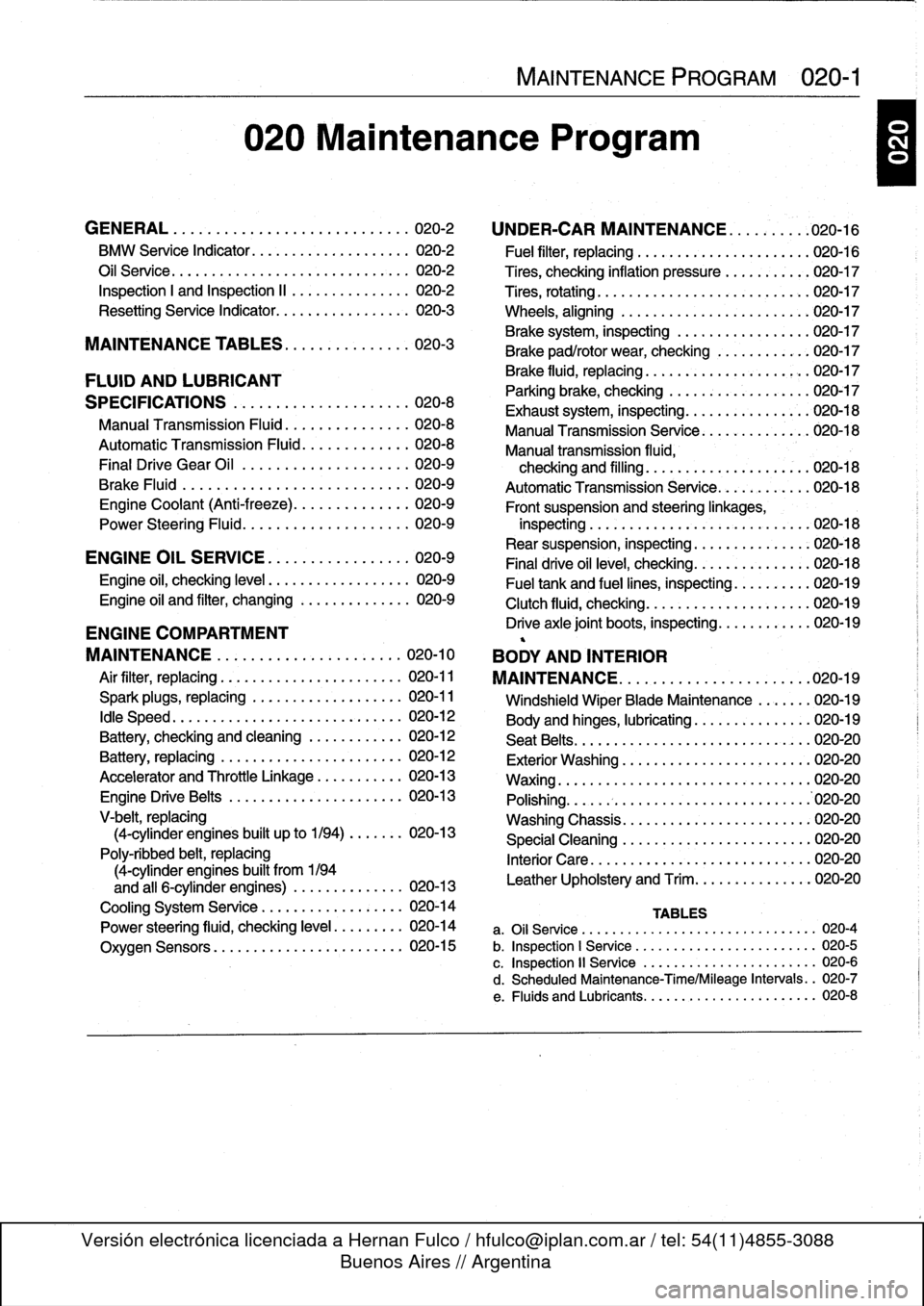

020

Maintenance

Program

GENERAL

.

.

...

.

.

.

...

.

.

.

.

.

.

.

.

.

.

.

...

.

..

020-2

BMW

Service

Indicator

......

..

....

..

...

..

.

020-2

Oil

Service

.....

.

..........

..

...

...

...

..

.

020-2

Inspection

I

and

Inspection

II

.

..

....

..

...

..

.

020-2

Resetting

Service

Indicator

....

.

....

..

...

..

.

020-3

MAINTENANCE

TABLES

..

.

.

.

.

.

........

020-3

FLUID

AND

LUBRICANT

SPECIFICATIONS

.

.

.

.

.

.

.

...

.

.

.

....

.

...

020-8

Manual

Transmission

Fluid

..

.

.

.

.

.

....

.

.

.

.

020-8

Automatic

Transmission

Fluid

.

.

.

.

.

....

.

.

.

.

020-8

Final

Drive

Gear

Oil

................

.

.

.

.

020-9

Brake

Fluid

.

.

.

.

.

................

.

.

.

.

020-9

Engine

Coolant

(Anti-freeze)

.

.

...

.

....

.

.

.

.

020-9

Power

Steering

Fluid

........

..

......

.

.

.

.

020-9

ENGINE

OIL

SERVICE

.

.

...

.

.

.

...

.

.

.

.

.

.

020-9

Engine

oil,

checking

leve¡

..

...

...

..

........

020-9

Engine

oil

and

filter,

changing

....

.

......

.

..

020-9

ENGINE

COMPARTMENT

MAINTENANCE

...

.

.

.

.

.

.

.

.

.

.

.

.

.

......

020-10

Air

filter,

replacing

.

...

...

.

.....

.

.....

.

...

020-11

Spark

plugs,

replacing

...

.

......

.

...

..

...

020-11

¡dle

Speed

.

..

...

...

....

.

......

.

...

..

...

020-12

Battery,

checking

and

cleaning

.......

..

...

020-12

Battery,

replacing

.

.....

.

.....

.

.....

..

...

020-12

Accelerator

and

Throttle

Linkage

.

.....

..

...

020-13

Engine

DriveBelts

.....

.

....

..

...

...

...

.

020-13

V-belt,

replacing

(4-cylinder

engines

built

up

to

1/94)

..

....

.

020-13

Poly-ribbed

belt,

replacing

(4-cylinder

engines

built

from

1194

and

all

6-cylinder

engines)

.

.

....

..

......

020-13

Cooling

System

Service

.

...

..

....

..

....

..

020-14

Power

steering

fluid,

checking

leve¡

.

..

....

.

.

020-14

Oxygen

Sensors

....

...

..

..

....

.

.....

.

.

020-15

MAINTENANCE

PROGRAM

020-1

UNDER-CAR

MAINTENANCE

.

..

.

...

.

.

.020-16

'

Fuel

filter,

replacing

...

.

.....

..

.....

..

..

.020-16

Tires,

checking

inflation

pressure

.

.....

.

....

020-17

Tires,

rotating

...

..

.....

..

....

..

....

.

....

020-17

Wheels,

aligning

..

.....

.

...........

.

....

'020-17

Brake

system,

inspecting

.

.

....

.

.....

..

...

020-17

Brake

pad/rotor

wear,checking

.

......

.

....

020-17

Brake

fluid,

replacing

.........

..

.

..

..

.

020-17

Parking

brake,

checking

......

.

.....

..

....

020-17

Exhaust

system,

inspecting

....

..

.....

.

...

.020-18

Manual

Transmission

Senrice

..

..

.....

.

....

020-18

Manual

transmission

fluida

checking

and

filling

..

.

....

..

.

.

..

..

....

020-18

AutomaticTransmission

Service

.

....

...

....

020-18

Front

suspension

and

steeringlinkages,

inspecting

..

.

:.....

.

....

..

.....

..

...

.

.020-18

Rear

suspension,

inspecting

.

..

...

...

....

..

020-18

Final

drive

oil

leve¡,

checking

.

.

.

...

....

...

..

020-18

Fuel

tank

and

fuel

lines,

inspecting

.

.....

....

020-19

Clutch

fluid,

checking

...

...

...

...

....

.....

020-19

Drive

axle

joint

boots,

inspecting

...

..

.....

..

020-19

BODY

AND

INTERIOR

MAINTENANCE

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

...

.

.020-19

Windshield

Wiper

Blade

Maintenance

....

.

.

020-19

Body

and

hinges,

lubricating

.

.....

..

......

.

020-19

Seat

Belts

...

..

...

...

...

..

.....

..

.....

.

.

020-20

Exterior

Washing

..

...

...

..

.

.

...

..

......

.020-20

Waxing

.....

..

...

...

...

..

.....

..

.......

020-20

Polishing

..

...

...

...

....

..

..........

..

.

.'020-20

Washing

Chassis

.

...

....

.

....

..

.....

.

...

020-20

Special

Cleaning

.

.

.....

..

...

.

.....

..

..

.020-20

Interior

Care

.

....

..

....

..

..

.

.

......

.

...

020-20

Leather

Upholstery

and

Trim

...

..

....

...

...

020-20

TABLES

a

.

Oil

Service

......

...

.

..

.............

...

---

020-4

b

.

Inspection

1

Service

..

.

.

.............

....

...

020-5

c

.

Inspection

11

Service

.

.

...

...........

..

.

..

..

020-6

d

.

Scheduled

Maintenance-Time/Mileage

Intervals

..

020-7

e

.

Fluids

and

Lubricants

..

...

...........

.....

..

020-8

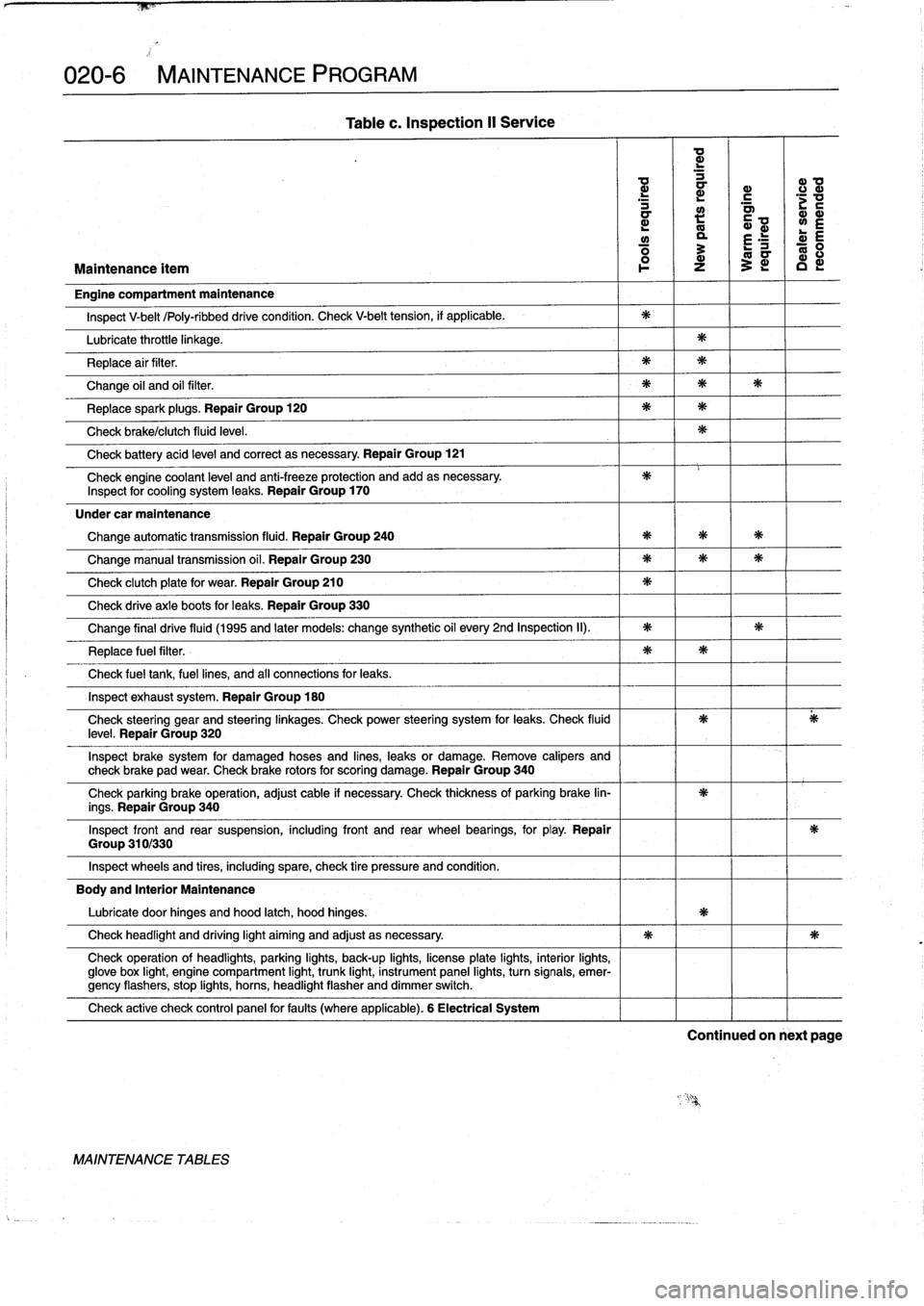

Page 28 of 759

020-6

MAINTENANCE

PROGRAM

Group

310/330

Table

c

.

Inspection

II

Service

a

d

d

a

a>

0

d

a

r

.c

mm

L

m

y

L

E

ó

3

E

ó

Maintenance

ítem

l

o-

z

~

c

Engine

compartment

maintenance

Inspect

V-belt

/Poly-ribbeddrive

condition

.

Check

V-belt

tension,

if

applicable

.

Lubricate

throttle

linkage

.

Replace

air

filter

.

Change

oil

and

oil

filter

.

Replacespark

plugs

.

Repair

Group

120

Check

brake/clutch

fluid

leve¡

.

Check

battery

acid

leve¡

and

correct

asnecessary

.

Repair

Group

121

Check

engine

coolant

leve¡

and

anti-freeze

protection

and

add

asnecessary

.

Inspect

for

cooling

system

leaks

.

Repair

Group

170

Under

car

maintenance

Change

automatic

transmission

fluid

.

Repair

Group

240

Change

manual

transmission

oil

.

Repair

Group

230

Check

clutch

plate

for

wear

.

Repair

Group

210

Check

drive

axle

boots

for

leaks

.

Repair

Group

330

Change

final

drive

fluid

(1995

and

later

models

:

change

synthetic

oil

every

2nd

Inspection

II)

.

Replace

fuel

filter

.

Check

fuel

tank,

fuel

lines,

and

af

connections

for

leaks

.

Inspect

exhaust

system

.

Repair

Group

180

Check

steering

gear

and

steering

¡inkages

.

Check

power

steering

system

for

leaks

.

Check

fluidleve¡

.

Repair

Group

320

Inspect

brake

system

for

damaged

hoses

and

lines,

leaks

or

damage

.

Remove

calipers

and

check

brake

pad

wear

.

Check

brake

rotors

for

scoring

damage

.

Repair

Group

340

Check

parking

brake

operation,

adjust

cable

if

necessary

.

Check

thickness

of

parking

brake

lin-

ings

.

Repair

Group

340

Inspect

front

and

rear

suspension,

including

front

and

rear

wheel

bearings,

for

play

.

Repair

Inspect

wheels

and

tires,

including

spare,

check

tire

pressure

and

condition

.

Body

and

Interior

Maintenance

Lubricate

door

hinges

and

hood

latch,

hood

hinges

.

Check

headlight

and

driving

light

aiming

and

adjust

asnecessary

.

Check

operation

of

headlights,

parking

lights,

back-up

lights,

licenseplate

lights,

interior

lights,

glove

box

light,

engine

compartment

light,

trunk

light,

instrument

panel

lights,

turn

signals,

emer-gency

flashers,

stop

lights,

horns,

headlight

flasher

anddimmer

switch

.

Check

active

check

control

panel

forfauits

(where

applicable)

.

6

Electrical

System

MAINTENANCE

TABLES

Continued

on

next

page

Page 39 of 759

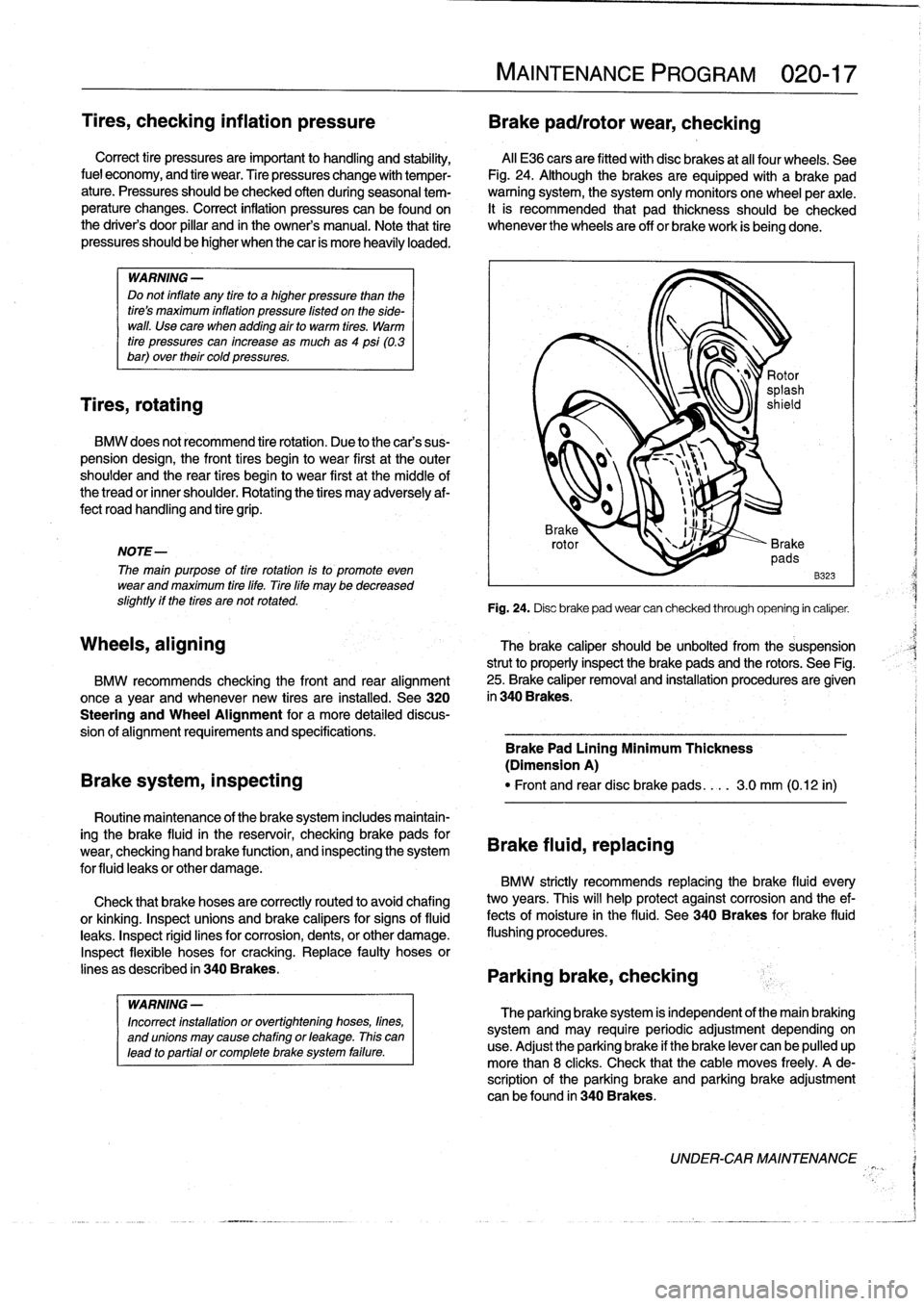

Tires,

checking

inflation

pressure

Brake

pad/rotor

wear,

checking

Correct

tire

pressuresare

important

to

handling

and

stability,

Al¡

E36

cars

are

fitted

withdisc

brakes

at

al¡

four

wheels

.

See

fuel

economy,

and

tire

wear

.

Tire

pressures

change

with

temper-

Fig

.

24

.

Although

thebrakesare

equipped

with

a

brake

pad

ature

.

Pressures

should

be

checked

often

during

seasonal

tem-

warning

system,

the

system

only

monitors

one

wheel

per

axle

.

perature

changes

.

Correct

inflation

pressures

canbe

found

on

It

is

recommended

that

pad

thickness

should

be

checked

the

driver's

door

pillar

and

in

the

owner's

manual

.

Note

that

tire

whenever

the

wheels

are

off

or

brakework

is

beggg

done

.

pressuresshould

be

higher

when

thecar

is

more

heavily

loaded

.

WARNING

-

Do

not

inflate

any

tire

to

a

higher

pressure

than

the

tiress

maximum

ínflation

pressure

listed

on

the

side-

wall

.

Use

cara

when

addlng

air

to

warm

tires

.

Warm

tire

pressures

can

increase

as

much

as4

psi

(0.3

bar)

over

their

cold

pressures

.

Tires,

rotating

BMW

does

not

recommend

tire

rotation

.

Due

to

the

cars

sus-

pension

design,

the

fronttires

begin

to

wear

first

at

the

outer

shoulder

and

the

rear

tires

begin

to

wear

first

at

themiddle

of

the

tread

or

inner

shoulder

.

Rotating

the

tires

may

adversely

af-

fect

roadhandling

and

tire

grip

.

NOTE-

The

main

purpose

of

tire

rotation

isto

promote

even

wear

and

maximum

tire

life

.

Tire

life

may

be

decreased

slightly

if

the

tires

are

not

rotated

.

Wheels,

aligning

Routine

maintenance

of

the

brake

system

includes

maintain-

ing

the

brake

fluid

in

the

reservoir,

checking

brakepads

for

wear,

checking

hand

brake

functíon,

and

inspecting

the

system

for

fluid

leaks

or

other

damage

.

Check

that

brake

hoses

are

correctly

routed

to

avoidchafing

or

kinkíng

.

Inspect

unions

and

brake

calipers

for

signs

of

fluid

leaks

.

Inspect

rigid

fines

for

corrosion,

dents,

or

other

damage

.

Inspect

flexible

hoses

for

cracking

.

Replace

faulty

hoses

or

lines

as

described

in

340Brakes

.

WARNING

-

Incorrect

installation

or

overtightening

hoses,

fines,

and

unions

may

cause

chafing

or

leakage

.

This

can

lead

to

partíal

or

completebrake

system

failure

.

MAINTENANCE

PROGRAM

020-

1

7

B323

Fig

.

24

.

Disc

brake

pad

wear

can

checked

through

opening

in

caliper

.

The

brake

caliper

should

be

unbolted

from

the

suspension

strut

to

properly

inspect

the

brake

pads

and

the

rotors

.

See

Fig

.

25

.

Brake

caliper

removal

and

installation

procedures

are

given

in

340

Brakes

.

BMW

recommends

checking

the

front

and

rear

alignment

once

a

year

and

whenever

new

tires

are

installed

.

See320

Steering

and

Wheel

Alignment

for

a

more

detailed

discus-

sion

of

alignment

requirements

and

specifications

.

Brake

Pad

Lining

Minimum

Thickness

(Dimension

A)

Brake

system,

inspecting

"

Front

and

reardisc

brake

pads

....

3

.0

mm

(0

.12

in)

Brake

fluid,

replacing

BMW

strictly

recommends

replacing

the

brake

fluid

every

two

years

.

This

will

help

protect

against

corrosion

and

the

ef-

fects

of

moisture

in

the

(luid

.

See340

Brakes

for

brake

fluid

flushing

procedures

.

Parking

brake,

checking

The

parking

brakesystem

is

independent

of

the

main

braking

system

and

may

requireperiodic

adjustment

dependingon

use

.

Adjust

the

parking

brake

if

the

brake

lever

can

be

pulled

up

more

than

8

clicks

.

Check

that

the

cable

moves

freely

.

A

de-

scription

of

the

parking

brake

and

parking

brake

adjustment

can

be

found

in

340Brakes

.

UNDER-CARMAINTENANCE

Page 40 of 759

020-

1

8

MAINTENANCE

PROGRAM

Fig

.

25

.

Inspect

brake

pads

with

the

caliper

removed

.

Minimum

brake

pad

thickness

shown

by

dimension

(A)

.

NOTE-

The

parking

brake

may

lose

some

of

its

effectiveness

if

it

is

not

used

frequently

.

This

is

due

to

corrosion

build-

up

on

the

parking

brake

drum

.

To

remove

corrosion,

ap-

plythe

parking

brake

just

until

it

begins

togrip,

then

pulí

the

lever

up

one

more

stop

(click)

.

Drive

thecar

approx-

imately

400

meters

(1,300

ft

.)

and

release

the

brake

.

To

recheck

the

adjustment

of

the

parking

brake

see340

Brakes

.

UNDER-CAR

MAINTENANCE

0011920

Manual

transmission

fluid,

checking

and

filling

The

manual

transmission

fluid

leve¡

should

be

checked

at

specified

intervals

.

Check

and

fill

the

transmission

with

the

car

ona

leve¡

surface

.

Transmission

(luid

leve¡

checking

and

re-

placement

procedures

are

covered

in

230

Manual

Transmis-

sion

.

Automatic

Transmission

Service

The

automatic

transmission

is

not

equipped

with

a

dipstíck

.

Therefore,

checking

the

ATF

level

is

an

ínvolved

procedure,

which

includes

measuring

and

maintaining

a

specified

ATF

temperature

during

the

checking

procedure

.

For

more

complete

ATF

service,

including

checking

ATF

lev-

e¡

and

ATF

filter

replacement

procedures,

see

240

Automatic

Transmission

.

Front

suspension

and

steering

linkages,

inspecting

Inspection

of

the

front

suspension'and

steering

includes

a

check

of

all

moving

parts

for

wear

and

excessive

play

.

Also

in-

spect

the

rubber

seals

and

boots

for

cracks

or

tears

that

could

allow

the

entry

of

dirt,

water,

and

other

contaminants

.

See

310

Front

Suspension

.

Exhaust

system,

inspecting

Rear

suspension,

inspecting

Exhaust

system

life

varies

widely

according

to

driving

habits

Final

drive

and

rear

drive

axle

service

consists

of

checking

and

environmental

conditions

.

If

short-distance

driving

pre-

and

changing

the

gear

oil,

inspecting

for

leaks,

and

checking

dominates,

the

moisture

and

condensation

in

the

system

will

the

rear

drive

axle

rubber

boots

for

damage

.

not

fully

dryout

.

This

will

lead

to

early

corrosion

damage

and

more

frequent

replacement

.

The

areas

where

leaks

are

most

likely

to

occur

are

around

the

driveshaft

and

drive

axle

mounting

flanges

.

For

more

infor

Scheduled

maintenance

of

the

exhaust

system

is

limitedlo

mation

on

ídentifying

oil

leaks

and

their

causes,

see330

Rear

inspection

.

Check

for

restrictions

due

to

dents

or

kinks

.

Check

Suspension

.

for

weakness

or

perforation

due

to

rust

.

Check

lo

see

that

all

the

hangers

are

in

place

and

properly

supporting

the

system

and

that

the

system

does

not

strike

the

body

.

Alignment

of

the

sys-

Final

drive

oil

leve¡,

checking

temand

the

location

of

the

hangers

aredescribed

in

180

Ex-

haust

System

.

Check

the

lubricant

leve¡

with

thecar

level

.

Remove

the

oil

filler

plug

.

The

leve¡

is

correct

when

the

fluidjust

reaches

the

edge

of

the

filler

hole

.

Install

and

tighten

the

oil

filler

plug

when

Manual

Transmission

Service

the

oil

level

is

correct

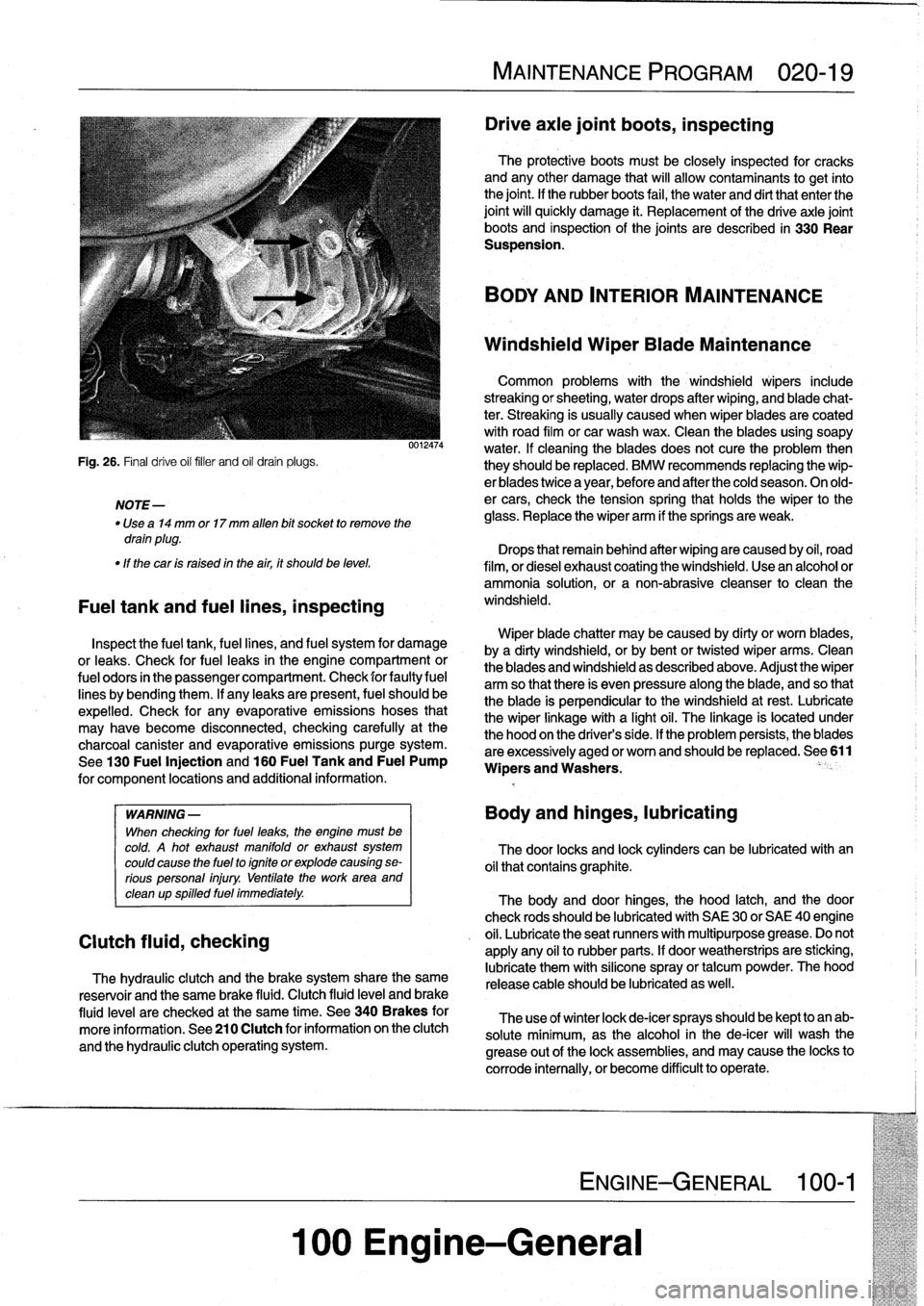

.

See

Fig

.

26

.

Manual

transmissionservice

consists

of

inspectingfor

leaks

The

final

drive

should

be

filled

with

a

special

BMW

lubricant

and

checking

and

changing

the

fluid

.

available

through

an

authorized

BMW

dealer

.

In

addition,

the

lubricant

type

varies

depending

onwhether

or

nota

limited-slip

Evidence

of

transmissionleaks

is

fkely

to

beseenaround

the

differential

is

fitted

.

driveshaft

mounting

flange

and

at

the

bottom

of

the

bellhousing

.

For

more

information

on

identifying

oil

leaks

and

their

causes,

see230ManualTransmissionand210

Clutch

.

Tightening

Torque

"

Finaldrive

filler

plug

to

final

drive

housing

..................

70

Nm

(52

ft-Ib)

Page 41 of 759

NOTE-

Use

a14

mm

or17

mm

alíen

bit

socket

to

remove

the

drain

plug

.

"

If

thecar

is

raised

in

the

air,

it

shouldbe

leve¡

.

Fuel

tank

and

fuel

fines,

inspecting

0012474

Inspect

the

fuel

tank,

fuel

lines,

and

fuel

system

for

damage

or

leaks

.

Check

for

fuel

leaks

in

the

engine

compartment

or

fuel

odors

in

the

passenger

compartment

.

Check

for

faultyfuel

lines

bybending

them

.

If

any

leaks

are

present,

fuel

should

be

expelled

.

Check

for

any

evaporative

emissions

hoses

that

may

have

become

disconnected,

checking

carefully

at

the

charcoal

canister

and

evaporative

emissionspurge

system

.

See130

Fuel

Injection

and

160

Fuel

Tank

and

Fuel

Pump

for

component

locations

and

additional

information

.

WARNING

-

When

checking

for

fuel

leaks,

the

engine

must

be

cold

.

A

hot

exhaust

manifold

or

exhaust

system

could

cause

the

fuel

to

ignite

or

explode

causing

se-

rious

personal

injury

.

Uentilate

the

workarea

and

clean

up

spilled

fuel

immediately

.

Clutch

fluid,

checking

The

hydraulic

clutch

and

the

brake

system

share

the

same

reservoir

and

the

same

brake

fluid

.

Clutch

fluid

leve¡

and

brake

fluid

level

are

checked

at

the

same

time

.

See340

Brakes

for

more

information

.

See210

Clutch

for

information

on

the

clutch

and

the

hydraulic

clutch

operating

system

.

MAINTENANCE

PROGRAM

020-19

Drive

axie

joint

boots,

inspecting

100

Engine-General

The

protective

boots

must

be

closely

inspected

for

cracks

andany

other

damage

that

will

allow

contaminants

to

get

ínto

the

joint

.

If

the

rubber

boots

faf

,

the

water

and

dirt

that

enter

the

joint

will

quickly

damage

¡t

.

Replacement

of

the

drive

axle

joint

boots

and

inspection

of

the

joints

are

described

in

330

Rear

Suspension

.

BODY

AND

INTERIOR

MAINTENANCE

Windshield

Wiper

Biade

Maintenance

Common

problems

with

the

windshield

wipers

include

streaking

or

sheeting,

water

drops

after

wiping,

and

blade

chat-

ter

.

Streaking

is

usually

caused

when

wiper

blades

are

coated

with

road

film

or

car

wash

wax

.

Clean

the

blades

using

soapy

water

.

If

cleaning

theblades

does

not

cure

the

problem

then

they

should

be

replaced

.

BMW

recommends

replacing

the

wip-

er

blades

twice

a

year,

before

and

after

the

cold

season

.

Onold-

er

cars,

check

the

tension

spring

that

holds

the

wiper

to

the

glass

.

Replace

the

wiper

arm

if

the

springs

are

weak

.

Drops

that

remainbehind

after

wipingare

caused

by

oil,

road

film,

or

diesel

exhaust

coating

the

windshield

.

Use

an

alcohol

or

ammonia

solution,

or

a

non-abrasive

cleanser

to

clean

the

windshield

.

Wiper

blade

chatter

may

be

caused

by

dirty

or

worn

blades,

bya

dirty

windshield,

or

by

bentor

twisted

wiper

arms

.

Clean

the

blades

and

windshield

as

described

above

.

Adjust

the

wiper

arm

so

that

there

is

even

pressure

along

the

blade,

and

so

that

the

blade

is

perpendicular

to

the

windshield

atrest

.

Lubricate

the

wiper

linkage

with

a

light

oil

.

The

linkage

is

located

under

the

hood

on

the

drivers

side

.

If

the

problem

persists,

theblades

are

excessively

aged

or

worn

and

should

be

replaced

.

See

611

Wipers

and

Washers

.

Body

and

hinges,

lubricating

The

door

locks

and

lock

cylinders

canbe

lubricated

with

an

oil

that

contains

graphite

.

The

body

and

door

hinges,

the

hood

latch,

and

the

door

check

rods

should

be

lubricated

with

SAE

30

or

SAE

40

engine

oil

.

Lubricate

the

seat

runners

with

multipurpose

grease

.

Do

not

apply

any

oil

to

rubber

parts

.

If

door

weatherstrips

are

sticking,

lubricate

them

with

silicone

spray

or

talcum

powder

.

The

hood

release

cable

should

be

lubricated

as

well

.

The

use

of

winter

lock

de-icer

spraysshould

be

kept

to

an

ab-

solute

minimum,

as

the

alcohol

in

the

de-icer

will

wash

the

grease

out

of

the

lock

assemblies,

and

may

cause

the

locks

to

corrode

internally,

or

become

difficult

to

operate

.

ENGINE-GENERAL

100-1

Page 213 of 759

GENERAL

..

.

......

.

.

.

.....

.

...

.

.

.

.

.

.

.

.

200-1

Manual

Transmission

.

.

.....

.

.

.

.'

.

.

.

.

.

.

.

.

200-1

Automatic

Transmission

.........

.

.

.

.

.

.

.

.

200-1

Transmission

ID

Codes

..........

.

.

.

.

.

.

.

.

200-2

GENERAL

E36

models

areequipped

with

a

longitudinal

drivetrain

.

The

transmission

is

bolted

directly

to

the

rear

of

the

engine

.

A

driveshaft

connects

the

output

shaft

of

thetransmission

to

the

final

drive

.

The

final

drive

is

mounted

lo

the

rear

suspension

and

the

body

.

Individual

drive

axles

with

integrated

constant

velocity

joints

transfer

rotational

power

to

the

rear

wheels

.

Manual

Transmission

Due

to

different

power

characteristics

and

performance

re-

quirements,

four

different

manual

transmissions

are

used

in

the

models

coveredby

this

manual

.

Manual

transmission

ap-

plications

are

given

in

Table

a

.

TRANSMISSION-GENERAL

200-1

200

Transmission-General

TABLES

a

.

Manual

Transmission

Applications

..

...........

200-1

b

.

Automatic

Transmission

Applications

...........

200-1

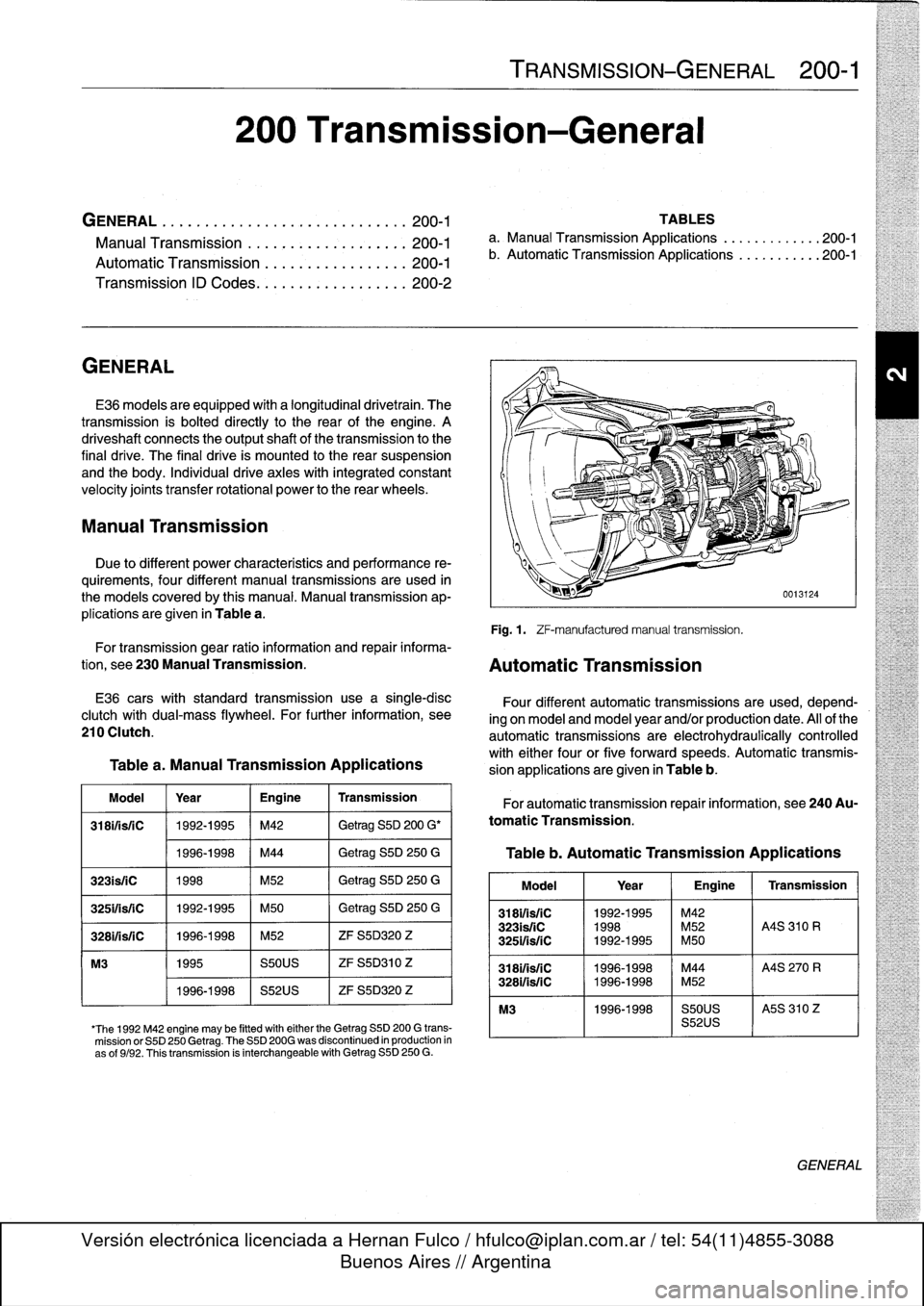

Fig

.

1

.

ZF-manufacturedmanual

transmission

.

For

transmission

gear

ratio

information

and

repair

informa-

tion,

see

230

Manual

Transmission

.

Automatic

Transmission

E36

carswith

standard

transmission

use

a

single-disc

clutch

with

dual-mass

flywheel

.

For

further

information,

see

210

Clutch

.

Table

a

.

Manual

Transmission

Applications

Model

Year

Engine

Transmission

318ifisfC

1992-1995

M42

Getrag

S5D

200

G'

1996-1998

M44

Getrag

S5D

250

G

323is/iC

1998

M52

Getrag

S5D

250

G

325ifsriC

1992-1995

M50

Getrag

S5D

250

G

3281/isfC

1996-1998

M52

ZF

S5D320

Z

M3

1995

S50US

ZF

S5D310

Z

1996-1998

S52US

ZF

S5D320

Z

'The

1992

M42

engine

may

be

fitted

witheither

the

Getrag

SSD

200

G

trans-

mission

or

S5D

250

Getrag

.

The

S5D

200G

was

discontinued

in

production

in

as

of

9/92

.

Thistransmission

is

interchangeable

with

Getrag

S5D

250

G

.

Four

different

automatic

transmissions

are

used,

depend-

ing

on

model

and

model

year

and/or

production

date

.

All

of

the

automatic

transmissions

are

electrohydraulically

controlled

with

either

four

or

five

forward

speeds

.

Automatic

transmis-

sion

applications

are

given

in

Table

b

.

For

automatic

transmission

repair

information,

see

240Au-

tomatic

Transmission

.

Table

b

.

Automatic

Transmission

Applications

Model

1

Year

1

Engine

1

Transmission

318i1is/1C

1992-1995

~

M42

323isfiC

1998

M52

A4S

310

R

3251/is/1C

1992-1995

M50

3181/isfC

11996-1998

M44

A4S

270

R

328i/is/1C

1996-1998

M52

M3

1996-1998

S50US

I

A5S

310

Z

S52US

GENERAL

Page 241 of 759

DRIVESHAFT

SERVICE

.

...

.

.

.

...

.

..

.

.

.260-3

Driveshaft,

aligning

...............

.

...

.

.

260-3

Driveshaft,

removing

..............

.

.

.

.

.

.

260-4

260

Driveshaft

DRIVESHAFT

260-1

GENERAL

.

.

.

.

.

.

.

.....

.

.

.

........

.

...

.

260-1

Driveshaft,

installing

.

....

.

..

.

............

260-4

Flex-disc,

replacing

.....

.

.

.

.............

260-5

TROUBLESHOOTING

..

.

.

.

...

.

.........

260-1

Center

bearing

assembly,

replacing

.

......

.260-6

Frontcentering

guide,

replacing

..

.

.......

.

260-7

TABLE

a

.

Driveshaft

Troubleshooting

.

.

...

......

.

....

..

.

.

260-2

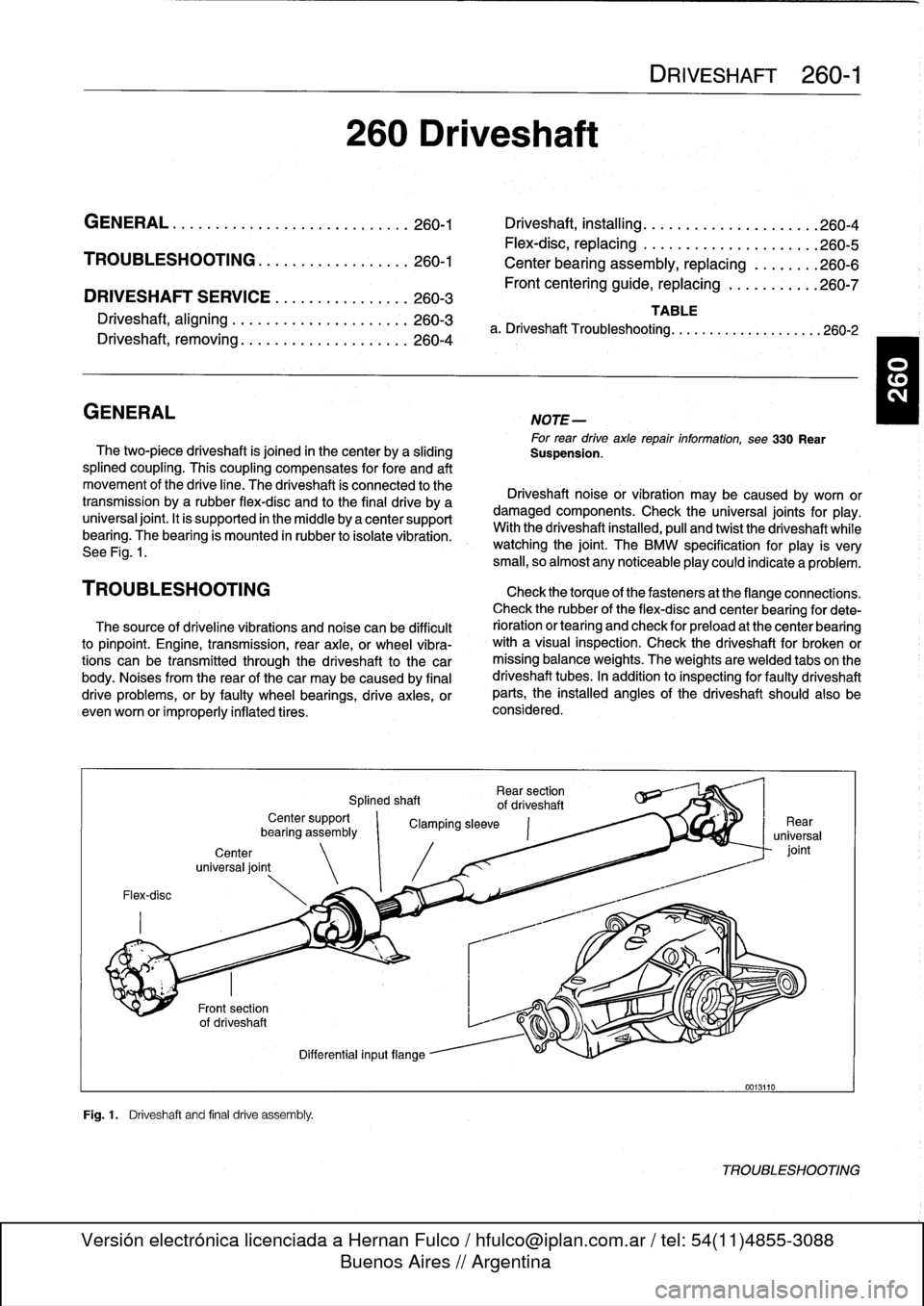

GENERAL

NOTE-

For

rear

drive

axlerepair

information,

see330

Rear

The

two-piece

driveshaft

is

joined

in

thecenter

by

a

sliding

Suspension

.

splined

coupling

.

This

coupling

compensates

for

fore

and

aft

movement

of

the

drive

line

.

The

driveshaft

ís

connected

to

the

Driveshaft

noise

or

vibration

may

be

caused

by

worn

or

transmission

bya

rubber

flex-disc

and

to

the

final

drive

by

a

damaged

components

.

Check

the

universal

joints

for

play

.

universal

joint

.

It

is

supported

in

the

micidle

by

a

center

support

With

the

driveshaft

installed,

pull

and

twist

the

driveshaft

while

bearing

.

The

bearing

is

mounted

in

rubber

to

isolate

vibration

.

watching

the

joint

.

The

BMW

specificationfor

play

is

very

See

Fig

.

1

.

small,

so

almost

any

noticeableplay

could

indicate

a

problem

.

TROU

BLESHOOTING

Check

thetorque

of

thefasteners

at

the

flange

connections

.

Check

therubber

of

the

flex-disc

and

center

bearing

for

dete

The

source

of

driveline

vibrations

and

noise

can

be

difficult

rioration

or

tearíng

and

check

for

preload

at

the

center

bearing

to

pinpoint

.

Engine,

transmission,

rear

axle,

or

wheel

vibra-

with

a

visual

inspection

.

Check

the

driveshaft

for

broken

or

tions

can

be

transmitted

through

the

driveshaft

to

the

car

missing

balance

weights

.

The

weights

are

welded

tabs

on

the

body

.

Noises

from

the

rear

of

thecar

may

be

caused

by

final

driveshaft

tubes

.

In

addition

to

inspecting

for

faulty

driveshaft

drive

problems,

orby

faulty

wheel

bearings,

drive

axies,

or

parts,

the

installed

angles

of

the

driveshaft

should

also

be

evenworn

or

improperly

inflatedtires

.

considered

.

Flex-disc

Center

universal

joint

Fig

.1

.

Driveshaft

and

final

drive

assembly

.

Rear

section

Splined

shaft

of

driveshaft

Center

support

`

Clamping

sleeve

bearíng

assembly

Differential

inputflange

0013110

TROUBLESHOOTING

Page 249 of 759

SUSPENSION,

STEERING

ANDBRAKES-GENERAL

300-1

300

Suspension,

Steering

and

Brakes-General

GENERAL

.....

.

....

.

.....

.

.

.

........

.300-1

M3

SUSPENSION

AND

BRAKES

.......

.

...

300-7

Front

Suspension

..........

.

.

.

...

.

.....

300-1

Steering

...

.

.

.

.

.

....

.

.

.

...

.

.

.

...

.

...

.

.

300-2

SUSPENSION

AND

STEERING

Rear

Suspension

....

.

.

.

...

.

.

.

...

.

.....

300-2

TROUBLESHOOTING

..

.

.

.

.............

300-7

Brakes

.

.

.

.

.

.

.

.

....

.

...........

.

.

.

.

.

.

300-2

Tires

and

wheeis

.

................

.

.

.

.

.

.

300-2

TABLE

a

.

AST

Indicator

Lamp

Function

..

..

.

..

.

.........

300-5

INTEGRATED

SYSTEMS

.........

.

.

.

.

.

.

300-2

b

.

Suspension

and

Steering

Troubleshooting

......

.300-8

Antilock

Brake

System

(ABS)

.......

.

.

.

.

.

.

300-2

Al¡

Season

Traction

(AST)

.........

.

.

.

.

.

.

300-4

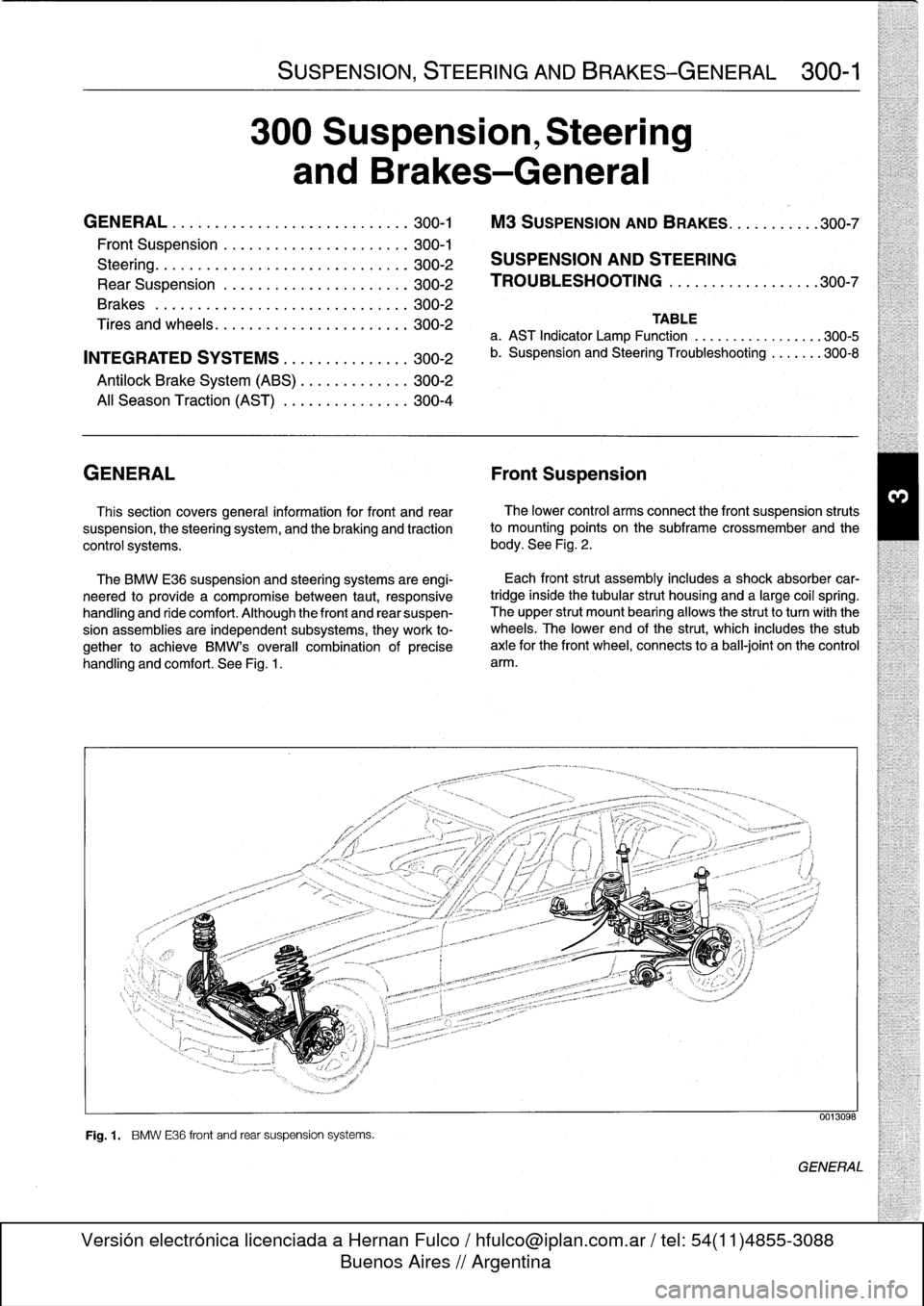

GENERAL

Front

Suspension

This

section

covers

general

information

for

front

and

rear

The

lower

control

arms

connect

the

front

suspension

struts

suspension,

the

steering

system,

and

the

brakíng

and

traction

to

mounting

points

on

the

subframe

crossmember

and

the

control

systems

.

body

.

See

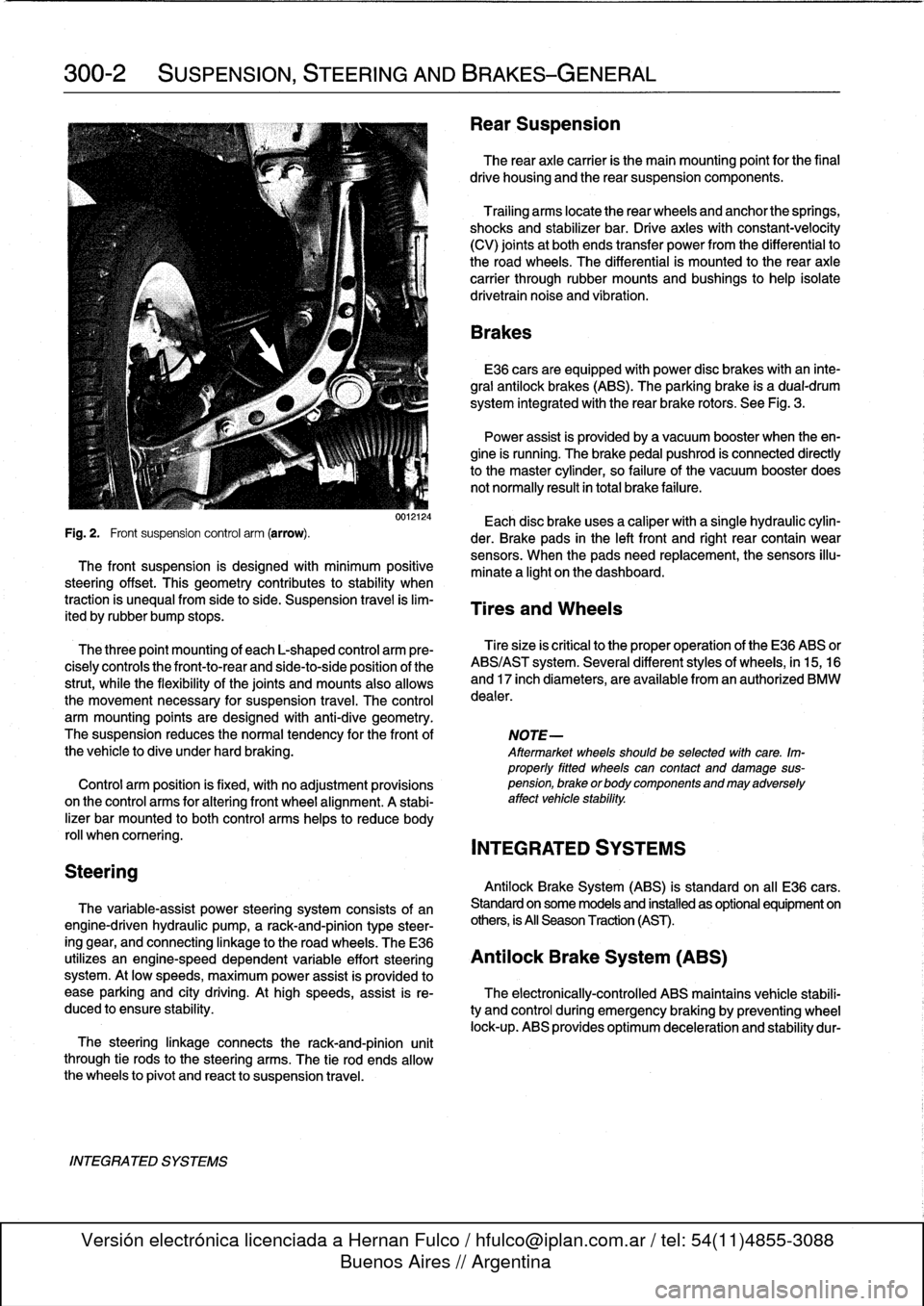

Fig

.

2

.

The

BMW

E36

suspension

and

steering

systems

are

engi-

neered

to

provide

a

compromise

between

taut,

responsive

handling

and

ride

comfort

.

Although

the

front

and

rear

suspen-

sion

assemblies

are

independent

subsystems,

they

work

to-

gether

to

achieve

BMW's

overall

combination

of

precise

handling

and

comfort

.

See

Fig

.

1

.

Fig

.

1

.

BMW

E36

front

and

rear

suspension

systems

.

Each

front

strut

assembly

includes

a

shock

absorber

car-

tridgeinside

the

tubular

strut

housing

and

a

large

coil

spring

.

The

upper

strut

mount

bearing

allows

the

strutto

turnwith

the

wheels

.

The

lower

end

of

the

strut,

which

includes

the

stub

axle

for

the

front

wheel,

connects

to

a

ball-joint

on

the

control

arm

.

0013098

GENERAL

Page 250 of 759

300-2

SUSPENSION,

STEERING

AND

BRAKES-GENERAL

Steering

INTEGRATED

SYSTEMS

The

steering

linkage

connects

the

rack-and-pinion

unit

through

tie

rodsto

the

steering

arms

.

The

tie

rod

ends

allow

the

wheels

to

pivot

and

react

to

suspension

travel

.

Rear

Suspension

The

rear

axle

carrier

is

the

main

mounting

point

for

the

final

drive

housing

and

the

rear

suspension

components

.

Trailing

arms

locatethe

rear

wheels

and

anchorthe

springs,

shocks

and

stabilizer

bar

.

Driveaxies

with

constant-velocity

(CV)

joints

at

both

ends

transfer

power

from

the

differential

to

the

road

wheels

.

The

differential

is

mounted

to

the

rearaxle

carrier

through

rubber

mountsand

bushings

to

hele

isolate

drivetrain

noise

and

vibration

.

Brakes

E36

cars

areequipped

with

power

disc

brakes

with

an

inte-

gral

antilock

brakes

(ABS)

.

The

parking

brake

is

a

dual-drum

system

integrated

with

the

rear

brake

rotors

.

See

Fig

.

3

.

Power

assist

is

provided

by

a

vacuum

booster

when

the

en-

gine

is

running

.

The

brakepedal

pushrod

is

connected

directly

to

the

master

cylinder,

so

failure

of

the

vacuum

booster

does

not

normally

result

in

total

brake

failure

.

0012124

Each

disc

brakeuses

a

caliper

with

a

single

hydraulic

cylin-

Fig

.

2

.

Front

suspension

control

arm

(arrow)

.

der

.

Brake

pads

in

the

left

front

and

right

rear

contain

wear

sensors

.

When

the

padsneed

replacement,the

sensors

illu-

The

front

suspension

is

designed

with

minimum

positive

minate

a

light

on

the

dashboard

.

steering

offset

.

This

geometry

contributes

to

stability

when

traction

is

unequalfrom

side

to

side

.

Suspension

travel

is

lim-

Tires

and

Wheels

ited

by

rubber

bump

stops

.

The

three

point

mounting

of

each

L-shaped

control

arm

ere-

Tiresize

is

critica¡

to

the

proper

operatíon

of

the

E36

ABS

or

cisely

controls

the

front-to-rear

and

side-to-side

position

of

the

ABS/AST

system

.

Severa¡

different

styles

of

wheels,

in

15,16

strut,

while

the

flexibility

of

the

joints

and

mounts

alsoallows

and

17

inch

diameters,

are

available

from

an

authorized

BMW

the

movement

necessary

for

suspension

travel

.

The

control

dealer

.

arm

mounting

points

are

designed

with

anti-dive

geometry

.

The

suspension

reduces

the

normaltendency

for

the

front

of

NOTE-

the

vehicle

to

dive

under

hard

braking

.

Aftermarket

wheelsshould

be

selected

wlth

care

.

Im-

properly

fitted

wheels

can

contact

anddamage

sus

Control

arm

position

is

fixed,

with

no

adjustment

provisions

pension,

brakeorbodycomponentsandmayadversely

on

the

control

arms

for

alter¡ng

front

wheel

al

ignment

.

A

stabi-

affect

vehicle

stability

.

lizer

bar

mounted

to

both

control

arms

heles

to

reduce

body

rol¡

whencomering

.

INTEGRATED

SYSTEMS

Antilock

Brake

System

(ABS)

is

standard

on

all

E36

cars

.

The

variable-assist

power

steering

system

consists

of

an

Standard

on

some

models

and

installed

as

optional

equipment

on

engine-driven

hydraulic

pump,

a

rack-and-pinion

type

steer-

others,

is

All

Season

Traction

(AST)

.

ing

gear,

and

connecting

linkage

to

the

road

wheels

.

TheE36

utilizes

an

engine-speed

dependent

variable

effort

steering

Antilock

Brake

System

(ABS)

system

.

At

low

speeds,

maximum

power

assist

is

provided

to

ease

parking

and

city

driving

.

Athigh

speeds,

assist

is

re-

The

electronically-controlled

ABS

maintains

vehícle

stabili

duced

to

ensure

stability

.

ty

and

control

during

emergency

braking

by

preventing

wheel

lock-up

.

ABS

provides

optimum

deceleration

and

stability

dur-

Page 255 of 759

increased

power

output

and

road-handling

demands

.

The

steering

geometry

is

modified

by

changing

the

cast-

er/camber

angles

slightly

.

This

is

accomplishedby

reposition-

ing

the

upper

strut

mounting

holes

in

the

frontstrut

towers

and

through

different

front

and

rear

control

arms

.

M3

Brake

System

Improvements

"

Vented

directionalfront

rotors

:

315

mm

dia

.

x

28

mm

thick

.

"

Vented

directional

rear

rotors

:

312

mm

dia

.

x20

mm

thick

.

"

Larger

brake

pads

and

calipers

.

"

Modified

Teves

ABS

system

.

SUSPENSION,

STEERING

AND

BRAKES-GENERAL

300-

7

M3

SUSPENSION

AND

BRAKES

NOTE-

M3

brake

rotors

are

directional,

having

a

different

part

TheE36

M3

was

introduced

in

late

1994

as

a

1995

model

.

number

for

each

side

.

Rotors

with

an

odd

part

number

The

design

of

the

M3

suspension,

steering

and

brakes

is

a

go

on

the

left

while

rotors

with

en

even

part

numbergo

modification

of

existing

E36

systems

which

accommodates

on

the

right

.

M3

Front

SuspensionImprovements

"

Reinforced

spring

plates,control

arms,

control

arm

bush-

ings,

steering

arms

.

"

Recalibrated

struts,

firmer

springs

.

"

Stiffer

stabilizerbar,

larger

stabilizer

bar

bushings

.

"

Front

stabilizer

linked

to

struts

.

M3

Wheels/Tires

"

Front

wheels

1992-1998

:.....

7

.5J

x

17

in

.

light

alloy

"

Rear

wheel

1992-1997

.......

7

.5J

x17

in

.

light

alloy

"

Rear

wheel

(option)

........

.8

.5

Jx17

in

.

light

alloy

"

Front

and

rear

tire

1992-1997

.............

.

.

.

...

...

235/40

x

17

in

.

"

Front

tire

1998

only

......

...

.

.

.

...

225/45

x

17

in

.

"

Rear

tire

1998

only

.......

.

.

.

...

...

245/40

x

17

in

.

CAUTION-

In

en

emergency,

an

M3

front

wheel/tire

assembly

may

be

mounted

on

the

rearaxle

.

However

a

rear

wheel/tire

assemblymust

not

be

mounted

on

the

front

axle

.

M3

RearSuspensionImprovements

"

Reinforced

trailing

arms

.

"

Recalibrated

shock

absorbers,

firmer

springs

.

SUSPENSION

AND

STEERING

TROUBLESHOOTING

Stable

handling

and

ride

comfort

both

depend

on

the

integ-

rity

of

the

suspension

and

steering

components

.

Any

symp-

tom

of

instability

or

imprecise

road

feel

may

be

caused

by

worn

or

damaged

suspension

components

.

When

troubleshooting

suspension

and

steering

problems,

also

consider

the

condition

of

tires,

wheels,

and

their

align-

ment

.

Tire

wear

and

incorrect

inflation

pressures

can

dramati-

cally

affect

handling

.

Subtie

irregularities

in

wheel

alignment

angles

also

affect

stabílity

.

Mixing

different

types

or

sizes

of

tires,

particularly

on

the

same

axle,

can

affect

alignment

and

may

unbalancea

car's

handling

.

Table

b

lists

the

symptoms

of

common

suspension

and

steering

problems

and

their

probable

causes,

and

suggests

corrective

actions

.

Bold

type

indicates

the

repair

groups

where

applicable

test

and

repair

procedures

can

befound

.

SUSPENSION

AND

STEERING

TROUBLESHOOTING