wheel BMW 435I GRAN COUPE 2015 Repair Manual

[x] Cancel search | Manufacturer: BMW, Model Year: 2015, Model line: 435I GRAN COUPE, Model: BMW 435I GRAN COUPE 2015Pages: 249, PDF Size: 5.3 MB

Page 199 of 249

Approved wheels and tires

You should only use wheels and tires

that have been approved by the vehicle manu‐

facturer for your vehicle type; otherwise, e.g.,

despite having the same official size ratings,

variations can lead to chassis contact and with

it, the risk of severe accidents

The manufacturer of your vehicle cannot eval‐

uate non-approved wheels and tires to deter‐

mine if they are suited for use, and therefore

cannot guarantee the operating safety of the

vehicle.◀

Recommended tire brands

For each tire size, the manufacturer of your ve‐

hicle recommends certain tire brands. These

can be identified by a star on the tire sidewall.

With proper use, these tires meet the highest

standards for safety and handling.

New tires Tire traction is not optimal due to manufactur‐

ing circumstances when tires are brand-new;

they achieve their full traction potential after a

break-in time.

Drive conservatively for the first

200 miles/300 km.

Retreaded tires

The manufacturer of your vehicle does not rec‐

ommend the use of retreaded tires.

Retreaded tires

Possibly substantial variations in the de‐

sign and age of the tire casing structures can

limit service life and have a negative impact on

road safety.◀

Winter tires

Winter tires are recommended for operating on

winter roads.

Although so-called all-season M+S tires pro‐

vide better winter traction than summer tires, they do not provide the same level of perform‐

ance as winter tires.

Maximum speed of winter tires If the maximum speed of the vehicle is higher

than the permissible speed for the winter tires,

then a respective symbol is displayed in your

field of vision. You can obtain this sign from the

tire specialist or from your service center.

Maximum speed for winter tires

Do not exceed the maximum speed for

the respective winter tires; otherwise, tire dam‐

age and accidents can occur.◀

Run-flat tires If you are already using run-flat tires, for your

own safety you should replace them only with

the same kind. No spare tire is available in the

case of a flat tire. Your service center will be

glad to advise you.

Rotating wheels between axlesDifferent wear patterns can occur on the frontand rear axles depending on individual driving

conditions. The tires can be rotated between

the axles to achieve even wear. Your service

center will be glad to advise you. After rotating,

check the tire pressure and correct if needed.

Rotating the tires is not permissible on vehi‐

cles with different tire sizes or rim sizes on the

front and rear axles.Seite 195Wheels and tiresMobility195

Online Edition for Part no. 01 40 2 960 707 - II/15

Page 200 of 249

StorageStore wheels and tires in a cool, dry place with

as little exposure to light as possible.

Always protect tires against all contact with oil,

grease and fuels.

Do not exceed the maximum tire inflation pres‐

sure indicated on the side wall of the tire.

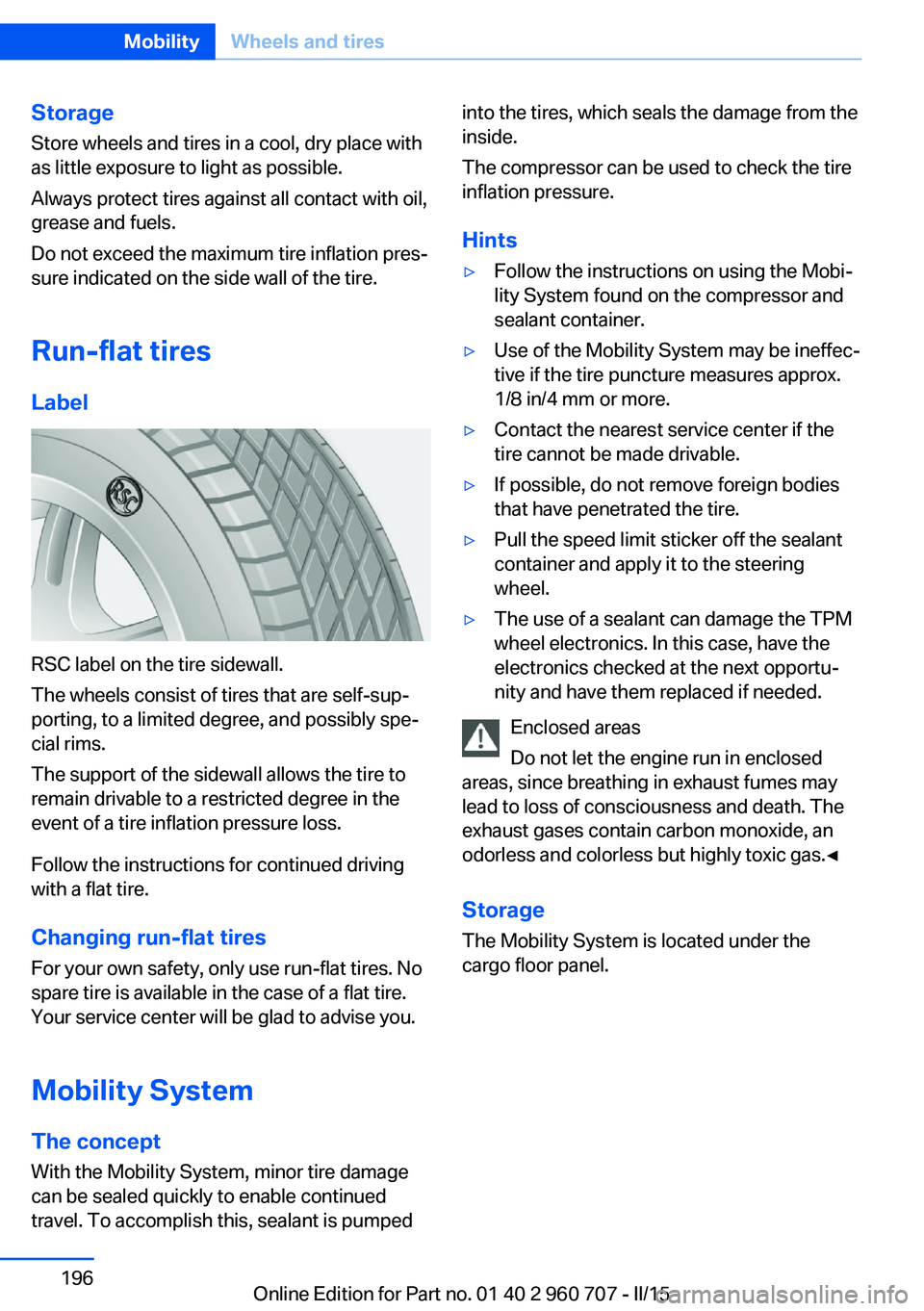

Run-flat tires Label

RSC label on the tire sidewall.

The wheels consist of tires that are self-sup‐

porting, to a limited degree, and possibly spe‐

cial rims.

The support of the sidewall allows the tire to

remain drivable to a restricted degree in the

event of a tire inflation pressure loss.

Follow the instructions for continued driving

with a flat tire.

Changing run-flat tires

For your own safety, only use run-flat tires. No

spare tire is available in the case of a flat tire.

Your service center will be glad to advise you.

Mobility System

The concept With the Mobility System, minor tire damagecan be sealed quickly to enable continued

travel. To accomplish this, sealant is pumped

into the tires, which seals the damage from the inside.

The compressor can be used to check the tire inflation pressure.

Hints▷Follow the instructions on using the Mobi‐

lity System found on the compressor and

sealant container.▷Use of the Mobility System may be ineffec‐

tive if the tire puncture measures approx.

1/8 in/4 mm or more.▷Contact the nearest service center if the

tire cannot be made drivable.▷If possible, do not remove foreign bodies

that have penetrated the tire.▷Pull the speed limit sticker off the sealant

container and apply it to the steering

wheel.▷The use of a sealant can damage the TPM

wheel electronics. In this case, have the

electronics checked at the next opportu‐

nity and have them replaced if needed.

Enclosed areas

Do not let the engine run in enclosed

areas, since breathing in exhaust fumes may

lead to loss of consciousness and death. The

exhaust gases contain carbon monoxide, an

odorless and colorless but highly toxic gas.◀

Storage The Mobility System is located under the

cargo floor panel.

Seite 196MobilityWheels and tires196

Online Edition for Part no. 01 40 2 960 707 - II/15

Page 201 of 249

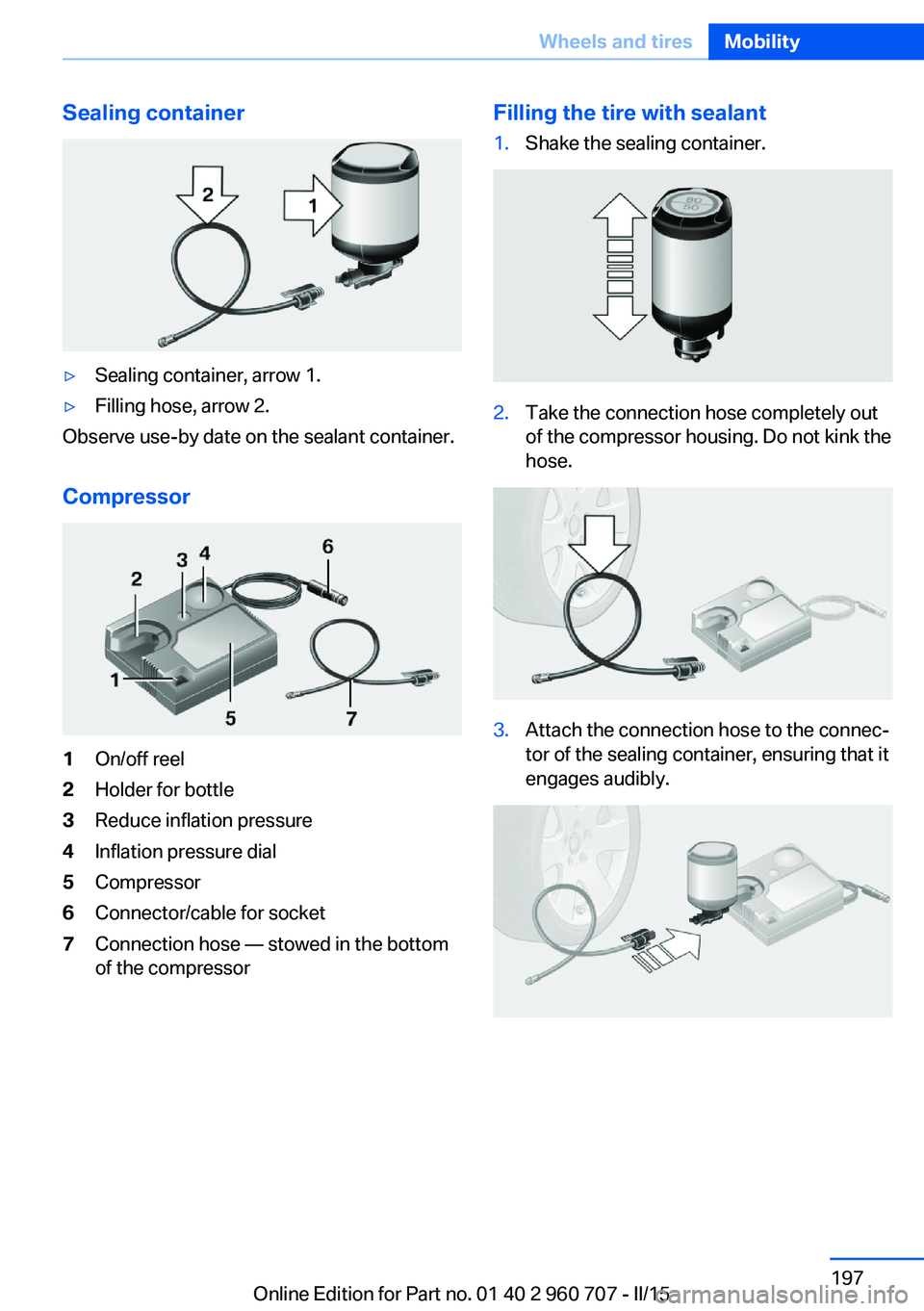

Sealing container▷Sealing container, arrow 1.▷Filling hose, arrow 2.

Observe use-by date on the sealant container.

Compressor

1On/off reel2Holder for bottle3Reduce inflation pressure4Inflation pressure dial5Compressor6Connector/cable for socket7Connection hose — stowed in the bottom

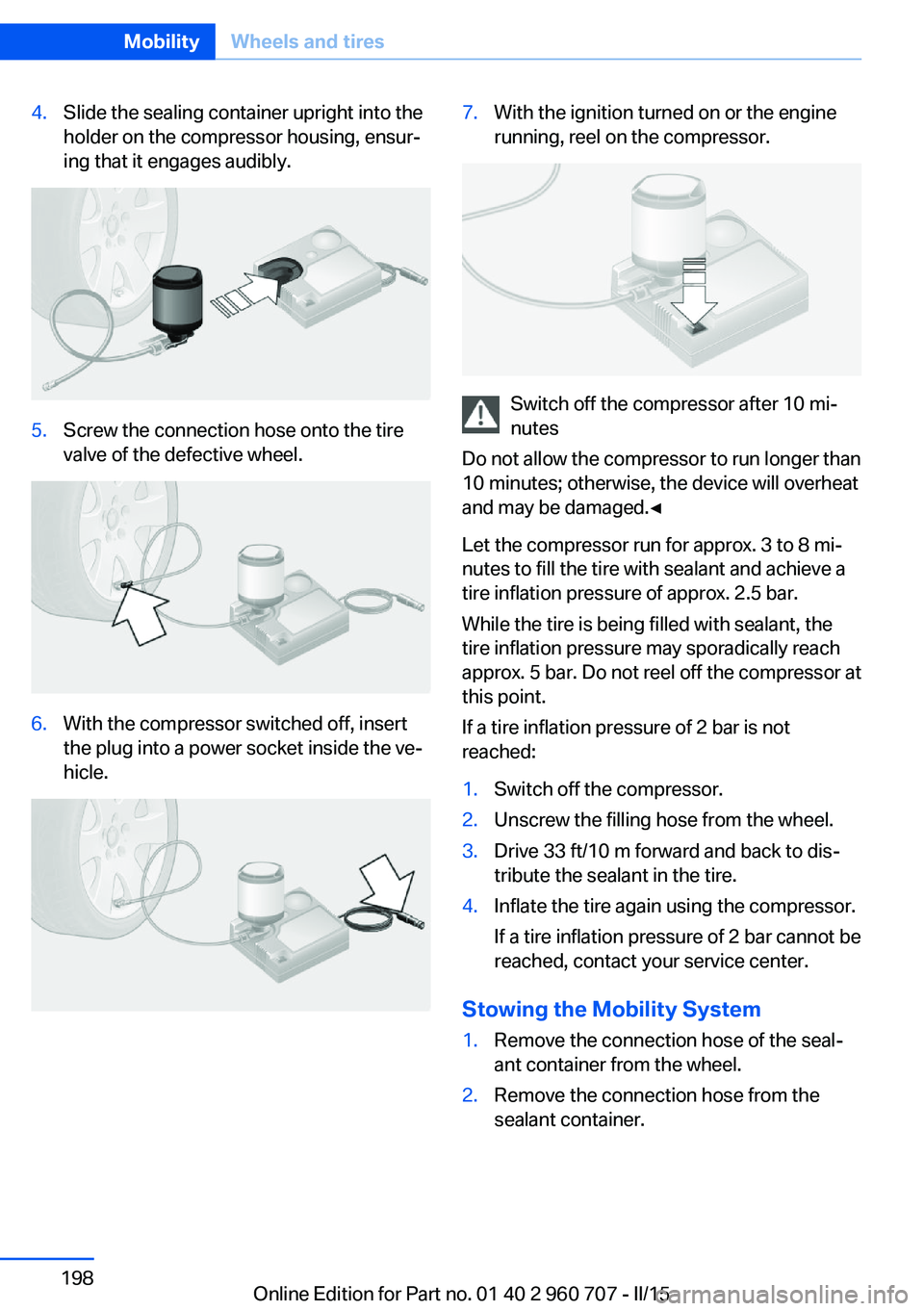

of the compressorFilling the tire with sealant1.Shake the sealing container.2.Take the connection hose completely out

of the compressor housing. Do not kink the

hose.3.Attach the connection hose to the connec‐

tor of the sealing container, ensuring that it

engages audibly.Seite 197Wheels and tiresMobility197

Online Edition for Part no. 01 40 2 960 707 - II/15

Page 202 of 249

4.Slide the sealing container upright into the

holder on the compressor housing, ensur‐

ing that it engages audibly.5.Screw the connection hose onto the tire

valve of the defective wheel.6.With the compressor switched off, insert

the plug into a power socket inside the ve‐

hicle.7.With the ignition turned on or the engine

running, reel on the compressor.

Switch off the compressor after 10 mi‐

nutes

Do not allow the compressor to run longer than

10 minutes; otherwise, the device will overheat

and may be damaged.◀

Let the compressor run for approx. 3 to 8 mi‐

nutes to fill the tire with sealant and achieve a

tire inflation pressure of approx. 2.5 bar.

While the tire is being filled with sealant, the

tire inflation pressure may sporadically reach

approx. 5 bar. Do not reel off the compressor at

this point.

If a tire inflation pressure of 2 bar is not

reached:

1.Switch off the compressor.2.Unscrew the filling hose from the wheel.3.Drive 33 ft/10 m forward and back to dis‐

tribute the sealant in the tire.4.Inflate the tire again using the compressor.

If a tire inflation pressure of 2 bar cannot be

reached, contact your service center.

Stowing the Mobility System

1.Remove the connection hose of the seal‐

ant container from the wheel.2.Remove the connection hose from the

sealant container.Seite 198MobilityWheels and tires198

Online Edition for Part no. 01 40 2 960 707 - II/15

Page 203 of 249

3.Wrap the empty sealant container and con‐

nection hose in suitable material to avoid

dirtying the cargo area.4.Stow the Mobility System back in the vehi‐

cle.

Distributing the sealant

Immediately drive approx. 5 miles/10 km to en‐

sure that the sealant is evenly distributed in the

tire.

Do not exceed a speed of 50 mph/80 km/h.

If possible, do not drive at speeds less than

12 mph/20 km/h.

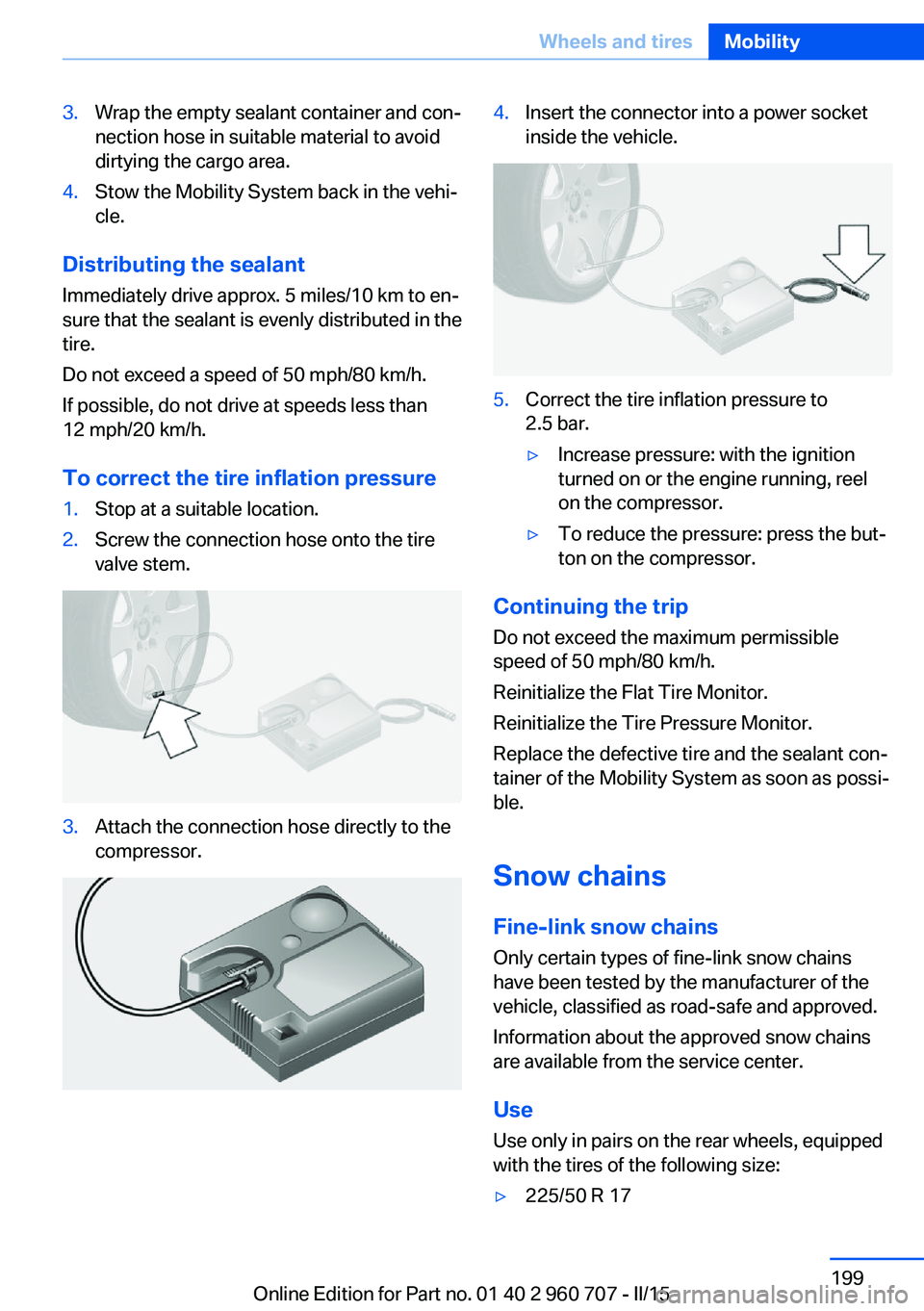

To correct the tire inflation pressure

1.Stop at a suitable location.2.Screw the connection hose onto the tire

valve stem.3.Attach the connection hose directly to the

compressor.4.Insert the connector into a power socket

inside the vehicle.5.Correct the tire inflation pressure to

2.5 bar.▷Increase pressure: with the ignition

turned on or the engine running, reel

on the compressor.▷To reduce the pressure: press the but‐

ton on the compressor.

Continuing the trip

Do not exceed the maximum permissible

speed of 50 mph/80 km/h.

Reinitialize the Flat Tire Monitor.

Reinitialize the Tire Pressure Monitor.

Replace the defective tire and the sealant con‐

tainer of the Mobility System as soon as possi‐

ble.

Snow chains Fine-link snow chains

Only certain types of fine-link snow chains

have been tested by the manufacturer of the

vehicle, classified as road-safe and approved.

Information about the approved snow chains

are available from the service center.

Use

Use only in pairs on the rear wheels, equipped

with the tires of the following size:

▷225/50 R 17Seite 199Wheels and tiresMobility199

Online Edition for Part no. 01 40 2 960 707 - II/15

Page 204 of 249

▷225/45 R 18

Follow the snow chain manufacturer's instruc‐

tions.

Make sure that the snow chains are always

sufficiently tight. Retighten as needed accord‐

ing to the chain manufacturer's instructions.

Do not initialize the Flat Tire Monitor after

mounting snow chains, as doing so may result

in incorrect readings.

Do not initialize the Tire Pressure Monitor after

mounting snow chains, as doing so may result

in incorrect readings.

When driving with snow chains, briefly activate

Dynamic Traction Control if needed.

Maximum speed with snow chains Do not exceed a speed of 30 mph/50 km/hwhen using snow chains.

Seite 200MobilityWheels and tires200

Online Edition for Part no. 01 40 2 960 707 - II/15

Page 215 of 249

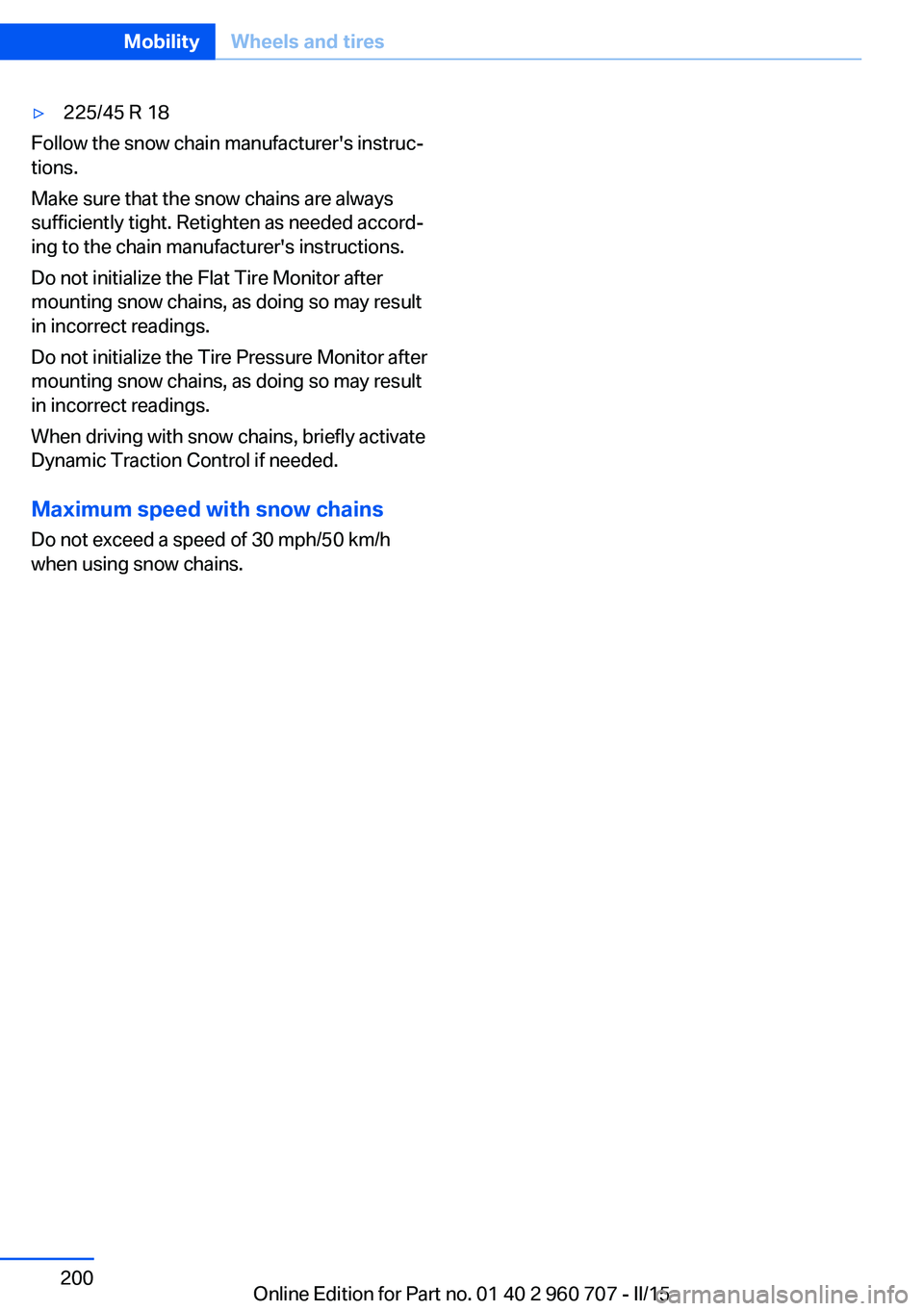

Headlights1Parking lights / daytime running lights2Low beams/high beams/headlight flasher3Turn signal

Low beams and high beams are designed with

xenon technology.

The parking lights and daylight running lights

are made using LED technology.

Contact your service center in the event of a

malfunction.

Turn signal

Follow general instructions, refer to page 209.

21-watt bulb, PY21W1.In the wheel house, loosen the two brack‐

ets and remove the cover.2.If necessary, pull the inside trim of the

wheel house slightly inward. Turn the bulb

socket counterclockwise and remove.3.Press the bulb gently into the socket, turn

counterclockwise and remove.4.Install the new bulb and bulb holder in re‐

verse order of removal.5.Attach the cover to the wheel house.

LED headlights

Light-emitting diodes (LEDs)

With LED headlights, all front lights and side

indicators are designed with LED technology.

If an LED fails, switch on the front fog lights

and continue the trip with great care. Comply

with local regulations.

Contact your service center in the event of a

malfunction.

Seite 211Replacing componentsMobility211

Online Edition for Part no. 01 40 2 960 707 - II/15

Page 216 of 249

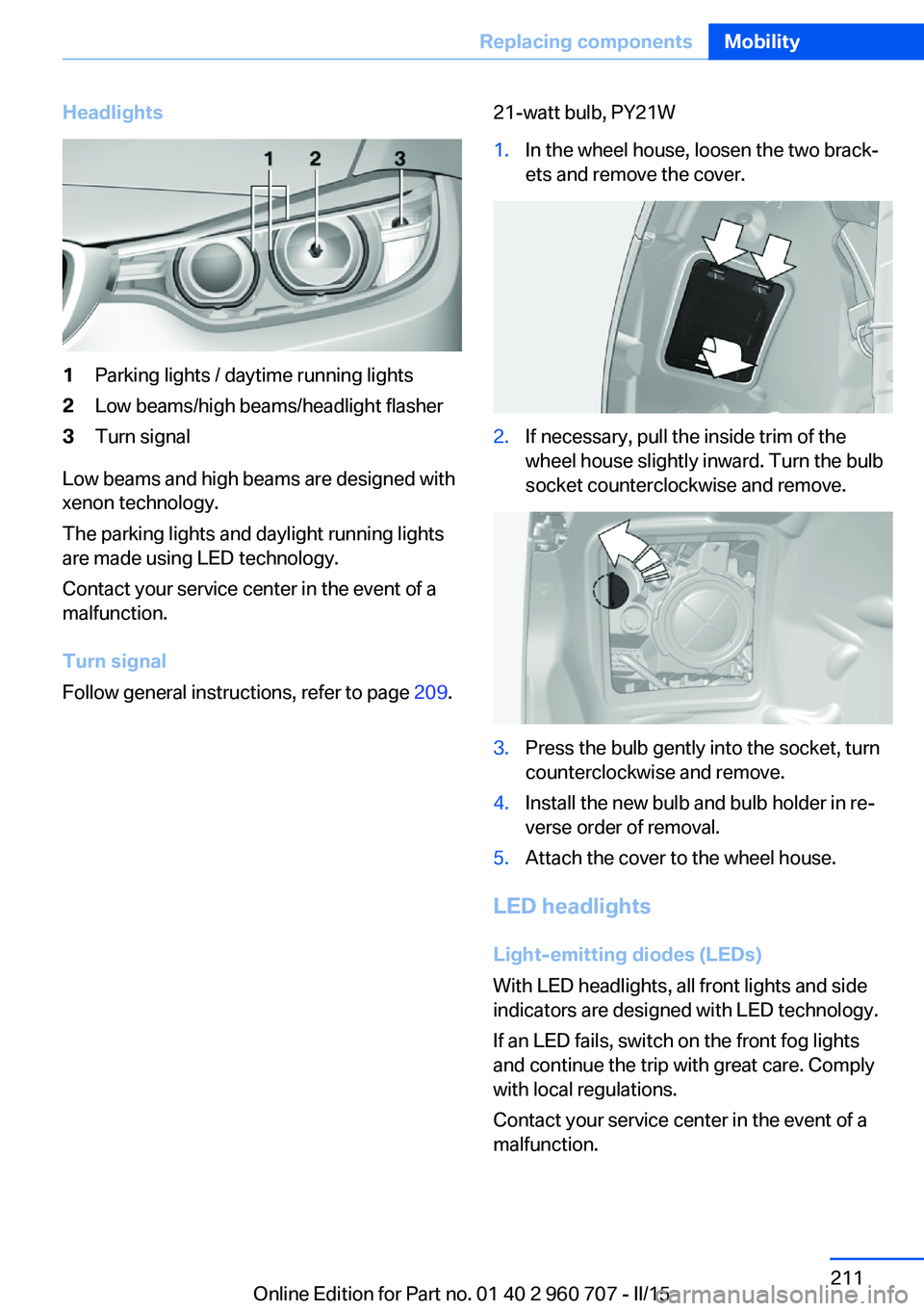

Headlights1Cornering light2Low beams/headlight flasher3High beams/headlight flasher4Parking lights / daytime running lights5Turn signal6Side marker lights

Contact your service center in the event of a

malfunction.

Front fog lights

Follow general instructions, refer to page 209.

35-watt bulb, H8.

1.Use the handle of the screwdriver from the

onboard vehicle tool kit to remove the

three wheel house panel screws, arrow 1.

Carefully pull back the wheel house panel,

arrow 2.2.Pull off the bulb connector, arrow 1.

Turn the bulb, arrow 2.

Left side of vehicle: turn clockwise.

Right side of vehicle: turn counterclock‐

wise.Remove the bulb.3.Insert the new bulb, connect the connector

and screw on the wheel house panel.

Turn signal in exterior mirror

Follow general instructions, refer to page 209.

The turn signals in the exterior mirrors feature

LED technology. Contact your service center

in the event of a malfunction.

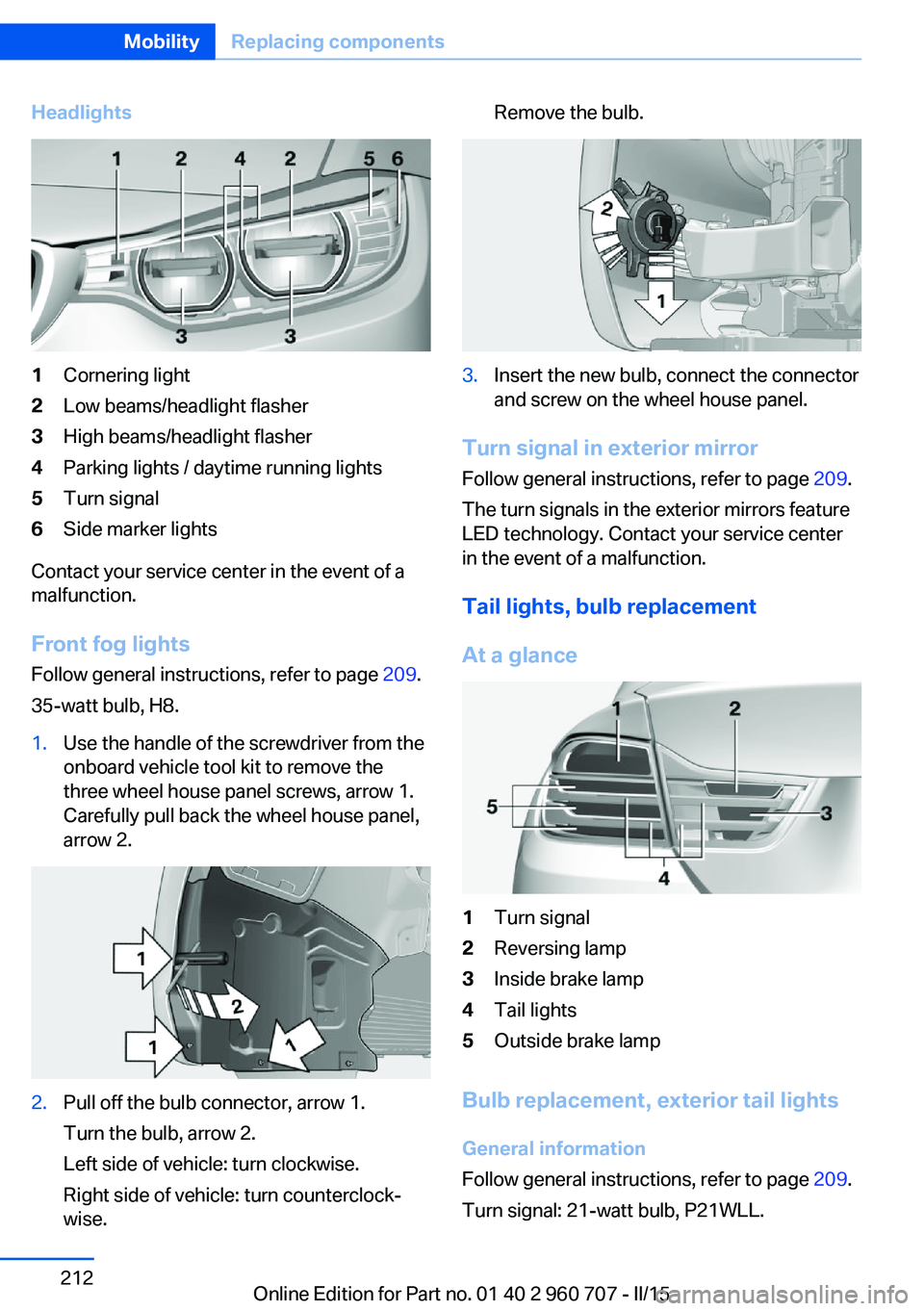

Tail lights, bulb replacement

At a glance

1Turn signal2Reversing lamp3Inside brake lamp4Tail lights5Outside brake lamp

Bulb replacement, exterior tail lights General information

Follow general instructions, refer to page 209.

Turn signal: 21-watt bulb, P21WLL.

Seite 212MobilityReplacing components212

Online Edition for Part no. 01 40 2 960 707 - II/15

Page 219 of 249

These lights are made using LED technology.

Contact your service center in the event of a

malfunction.

Changing wheels

Hints When using run-flat tires or sealants, a tire

does not need to be changed immediately in

the event of pressure loss due to a flat tire.

Which is why no spare tire is available.

The tools for changing wheels are available as

accessories from your service center.

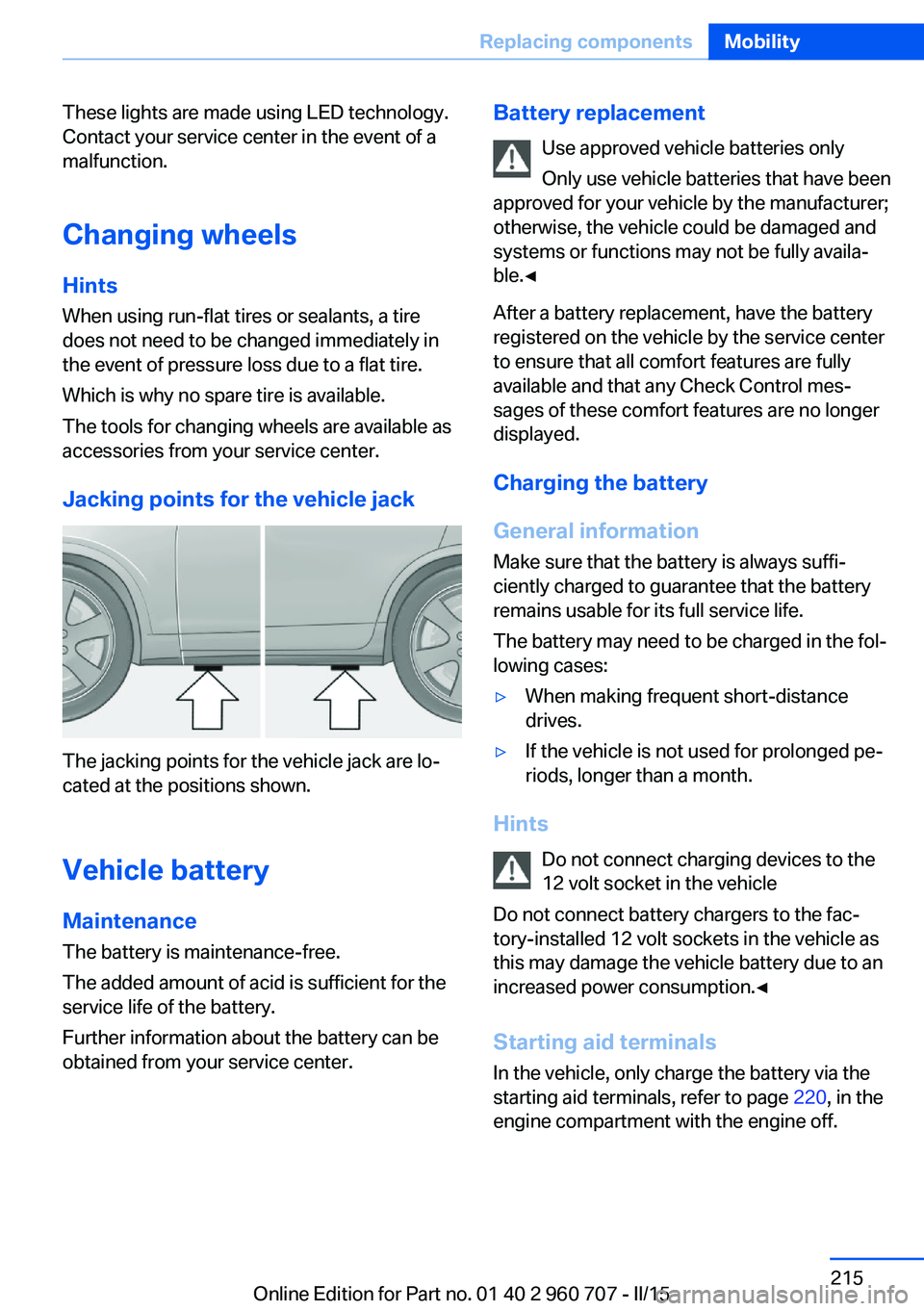

Jacking points for the vehicle jack

The jacking points for the vehicle jack are lo‐

cated at the positions shown.

Vehicle battery Maintenance

The battery is maintenance-free.

The added amount of acid is sufficient for the

service life of the battery.

Further information about the battery can be

obtained from your service center.

Battery replacement

Use approved vehicle batteries only

Only use vehicle batteries that have been

approved for your vehicle by the manufacturer;

otherwise, the vehicle could be damaged and

systems or functions may not be fully availa‐

ble.◀

After a battery replacement, have the battery registered on the vehicle by the service center

to ensure that all comfort features are fully

available and that any Check Control mes‐

sages of these comfort features are no longer

displayed.

Charging the battery

General information Make sure that the battery is always suffi‐

ciently charged to guarantee that the battery

remains usable for its full service life.

The battery may need to be charged in the fol‐

lowing cases:▷When making frequent short-distance

drives.▷If the vehicle is not used for prolonged pe‐

riods, longer than a month.

Hints

Do not connect charging devices to the

12 volt socket in the vehicle

Do not connect battery chargers to the fac‐

tory-installed 12 volt sockets in the vehicle as

this may damage the vehicle battery due to an

increased power consumption.◀

Starting aid terminals

In the vehicle, only charge the battery via the

starting aid terminals, refer to page 220, in the

engine compartment with the engine off.

Seite 215Replacing componentsMobility215

Online Edition for Part no. 01 40 2 960 707 - II/15

Page 225 of 249

Tow-starting and towingNote Tow-starting and towing

For tow-starting or towing, switch off the

Intelligent Safety systems; otherwise malfunc‐

tions of the individual braking systems might

lead to accidents.◀

Manual transmission Gearshift lever in neutral position.

Towing Follow the towing instructions

Follow all towing instructions; otherwise,

vehicle damage or accidents may occur.◀▷Make sure that the ignition is switched on;

otherwise, the low beams, tail lights, turn

signals, and wipers may be unavailable.▷Do not tow the vehicle with the rear axle

tilted, as the front wheels could turn.▷When the engine is stopped, there is no

power assist. Consequently, more force

needs to be applied when braking and

steering.▷Larger steering wheel movements are re‐

quired.▷The towing vehicle must not be lighter

than the vehicle being towed; otherwise,

it will not be possible to control the vehi‐

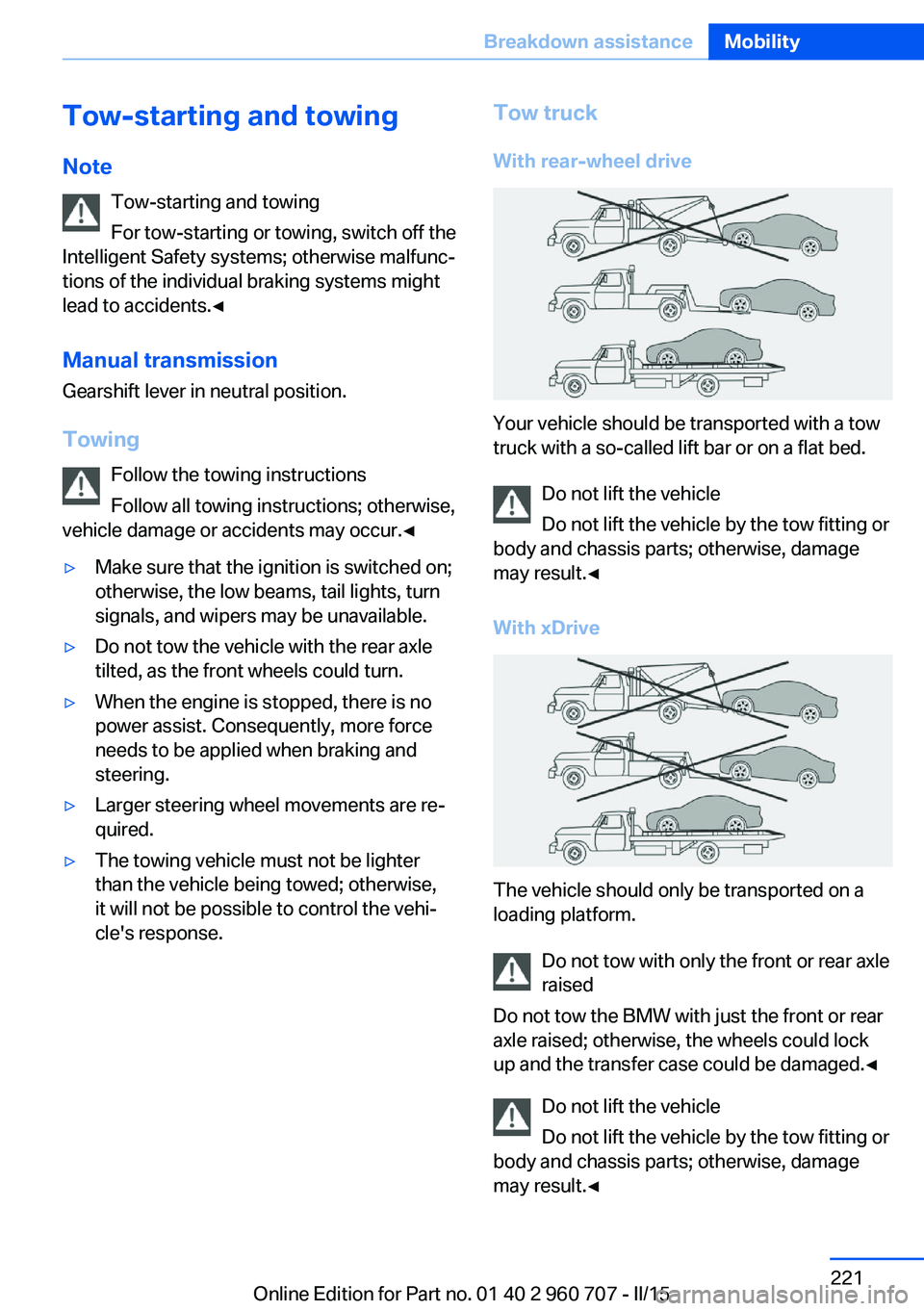

cle's response.Tow truck

With rear-wheel drive

Your vehicle should be transported with a tow

truck with a so-called lift bar or on a flat bed.

Do not lift the vehicle

Do not lift the vehicle by the tow fitting or

body and chassis parts; otherwise, damage

may result.◀

With xDrive

The vehicle should only be transported on a

loading platform.

Do not tow with only the front or rear axle

raised

Do not tow the BMW with just the front or rear

axle raised; otherwise, the wheels could lock

up and the transfer case could be damaged.◀

Do not lift the vehicle

Do not lift the vehicle by the tow fitting or

body and chassis parts; otherwise, damage

may result.◀

Seite 221Breakdown assistanceMobility221

Online Edition for Part no. 01 40 2 960 707 - II/15