wheels BMW 5 SERIES 1990 E34 User Guide

[x] Cancel search | Manufacturer: BMW, Model Year: 1990, Model line: 5 SERIES, Model: BMW 5 SERIES 1990 E34Pages: 228, PDF Size: 7.04 MB

Page 131 of 228

and cause the system to malfunction. If

the ABS wiring harness is damaged in any

way, it must be renewed.

Caution: Make sure the ignition is

turned off before unplugging or

re-making any electrical

connections.

Diagnosis and repair

If the dashboard warning light comes on

and stays on while the vehicle is in operation,

the ABS system requires attention. Although

special electronic ABS diagnostic testing

tools are necessary to properly diagnose the

system, you can perform a few preliminary

checks before taking the vehicle to a dealer

service department.

a) Check the brake fluid level in the

reservoir.

b) Verify that the electronic control unit

connectors are securely connected.

c) Check the electrical connectors at the

hydraulic control unit.

d) Check the fuses.

e) Follow the wiring harness to each front

and rear wheel, and verify that all

connections are secure and that the

wiring is undamaged.

If the above preliminary checks do not

rectify the problem, the vehicle should bediagnosed by a dealer service department.

Due to the complex nature of this system, all

actual repair work must be done by a dealer

service department.

3 Disc brake pads- renewal

2

Warning: Disc brake pads must

be renewed on both front wheels

or both rear wheels at the same

time - NEVER renew the pads on

only one wheel. Also, the dust created by

the brake system may contain asbestos,

which is harmful to your health. Never

blow it out with compressed air, and don’t

inhale any of it. An approved filtering mask

should be worn when working on the

brakes. Do not, under any circumstances,

use petroleum-based solvents to clean

brake parts. Use brake system cleaner

only! When servicing the disc brakes, use

only original-equipment or high-quality

brand-name pads.

Warning: Brake fluid is

poisonous. It is also an effective

paint stripper. Refer to the

warning at the start of Section 16.

Note:This procedure applies to both the front

and rear disc brakes.

1Remove the cap(s) from the brake fluid

reservoir, and syphon off about two-thirds of

the fluid from the reservoir. Failing to do thiscould result in the reservoir overflowing when

the caliper pistons are pressed back into their

bores.

2Loosen the wheel bolts, raise the front or

rear of the vehicle and support it securely on

axle stands.

3Remove the front or rear wheels, as

applicable. Work on one brake assembly at a

time, using the assembled brake for reference

if necessary.

4Inspect the brake disc carefully as outlined

in Section 5. If machining is necessary, follow

the information in that Section to remove the

disc, at which time the pads can be removed

from the calipers as well.

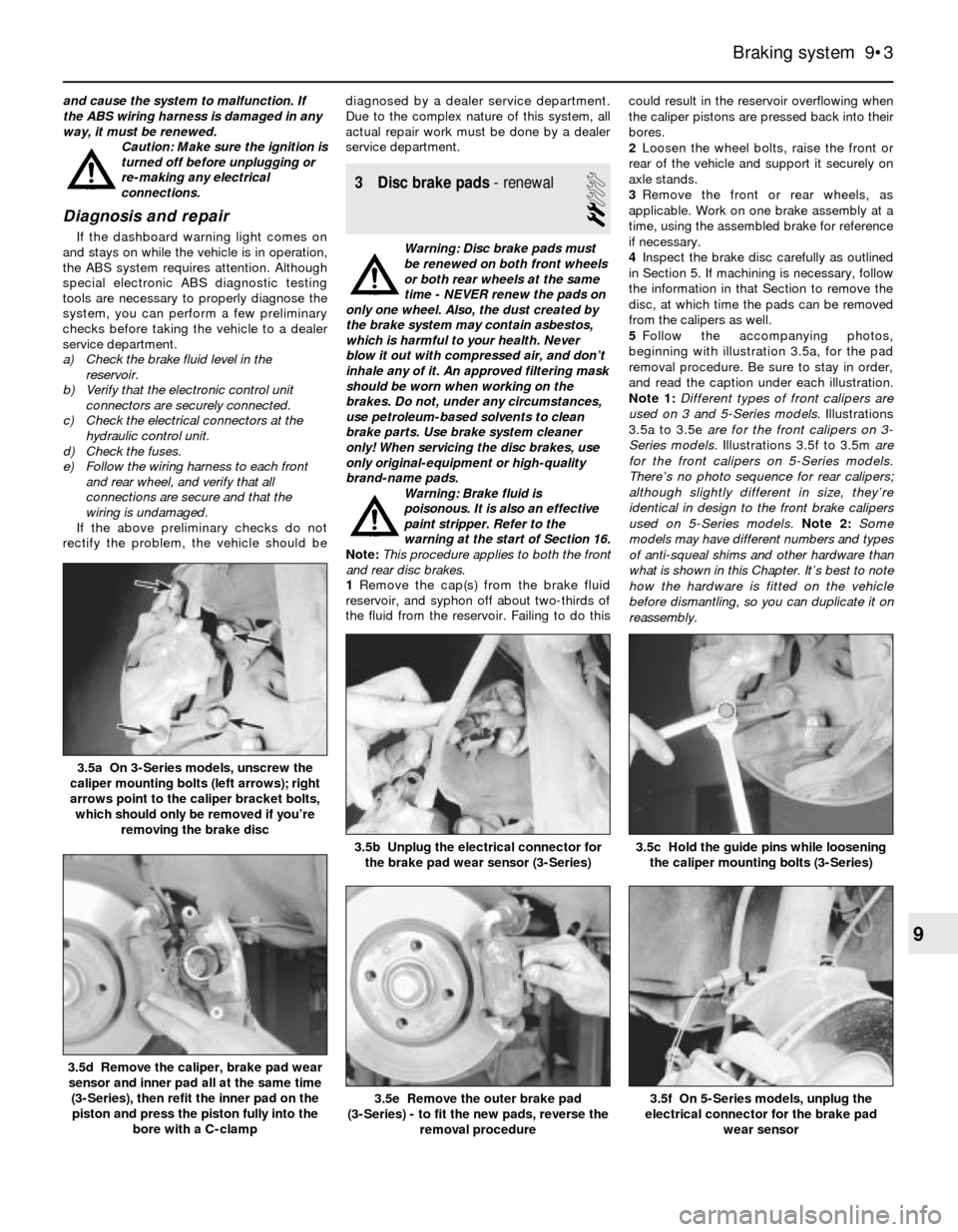

5Follow the accompanying photos,

beginning with illustration 3.5a, for the pad

removal procedure. Be sure to stay in order,

and read the caption under each illustration.

Note 1:Different types of front calipers are

used on 3 and 5-Series models. Illustrations

3.5a to 3.5e are for the front calipers on 3-

Series models.Illustrations 3.5f to 3.5m are

for the front calipers on 5-Series models.

There’s no photo sequence for rear calipers;

although slightly different in size, they’re

identical in design to the front brake calipers

used on 5-Series models.Note 2: Some

models may have different numbers and types

of anti-squeal shims and other hardware than

what is shown in this Chapter. It’s best to note

how the hardware is fitted on the vehicle

before dismantling, so you can duplicate it on

reassembly.

Braking system 9•3

3.5c Hold the guide pins while loosening

the caliper mounting bolts (3-Series)3.5b Unplug the electrical connector for

the brake pad wear sensor (3-Series)

3.5a On 3-Series models, unscrew the

caliper mounting bolts (left arrows); right

arrows point to the caliper bracket bolts,

which should only be removed if you’re

removing the brake disc

3.5f On 5-Series models, unplug the

electrical connector for the brake pad

wear sensor3.5e Remove the outer brake pad

(3-Series) - to fit the new pads, reverse the

removal procedure

3.5d Remove the caliper, brake pad wear

sensor and inner pad all at the same time

(3-Series), then refit the inner pad on the

piston and press the piston fully into the

bore with a C-clamp

9

Page 135 of 228

adjusting screw and contract the handbrake

shoes (see illustration).

Refitting

7Ensure that the disc is completely clean

before refitting. If penetrating oil was used to

remove the disc, make sure that no trace of

this is present. Place the disc on the hub, and

refit the disc retaining screw. Tighten the

screw securely.

8Refit the caliper mounting bracket (if

removed), brake pads and caliper (see

Sections 3 and 4). Tighten all fasteners to the

torques listed in this Chapter’s Specifications.

9Refit the wheel, then lower the vehicle to

the ground. Depress the brake pedal a few

times to bring the brake pads into contact

with the disc.

10Adjust the handbrake shoes, if necessary

(Section 11).

11Check the operation of the brakes

carefully before returning the vehicle to

normal service.

6 Drum brake shoes- renewal

2

Warning: Brake shoes must be

renewed on both wheels at the

same time - never renew the

shoes on only one wheel. Also,

the dust created by the brake system may

contain asbestos, which is harmful to your

health. Never blow it out with compressed

air, and don’t inhale any of it. Always wear

an approved filtering mask when servicing

the brake system. Do not, under anycircumstances, use petroleum-based

solvents to clean brake parts. Use brake

system cleaner only.

Caution: Whenever the brake

shoes are renewed, new return

and hold-down springs and new

automatic adjuster thermo-clips

should also be fitted. Due to the

continuous heating/cooling cycle to which

the springs are subjected, they may lose

their tension over a period of time,

allowing the shoes to drag on the drum,

and wear at a much faster rate than

normal. When fitting new brake shoes, use

only original-equipment or high-quality

brand name parts.

Note 1:All four rear brake shoes must be

renewed at the same time, but to avoid mixing

up parts, work on only one brake assembly at

a time. Some rear brake components are

different for left and right-hand sides, so don’t

mix them up.

Note 2:If the wheel cylinder is found to be

leaking or otherwise defective, renew it after

removing the brake shoes. This is simply a

matter of disconnecting the hydraulic line and

unbolting the cylinder from the backplate.

Attempting to overhaul a leaking cylinder is

unlikely to be satisfactory, even if spare parts

are available.

1Chock the front wheels, then loosen the

rear wheel bolts, raise the rear of the vehicle

and place it securely on axle stands. Remove

the rear wheels and release the handbrake.

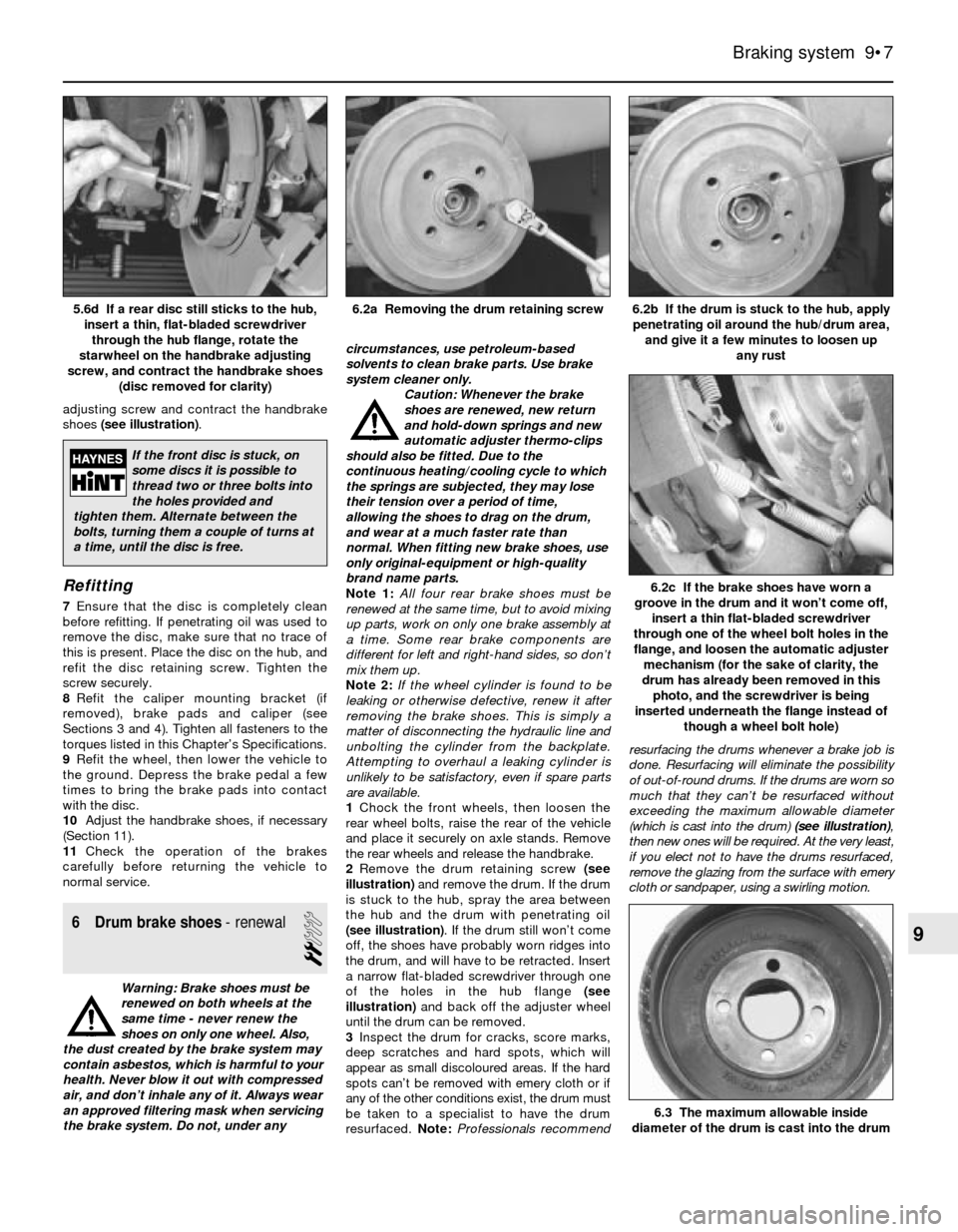

2Remove the drum retaining screw (see

illustration)and remove the drum. If the drum

is stuck to the hub, spray the area between

the hub and the drum with penetrating oil

(see illustration). If the drum still won’t come

off, the shoes have probably worn ridges into

the drum, and will have to be retracted. Insert

a narrow flat-bladed screwdriver through one

of the holes in the hub flange (see

illustration)and back off the adjuster wheel

until the drum can be removed.

3Inspect the drum for cracks, score marks,

deep scratches and hard spots, which will

appear as small discoloured areas. If the hard

spots can’t be removed with emery cloth or if

any of the other conditions exist, the drum must

be taken to a specialist to have the drum

resurfaced. Note:Professionals recommendresurfacing the drums whenever a brake job is

done. Resurfacing will eliminate the possibility

of out-of-round drums. If the drums are worn so

much that they can’t be resurfaced without

exceeding the maximum allowable diameter

(which is cast into the drum) (see illustration),

then new ones will be required. At the very least,

if you elect not to have the drums resurfaced,

remove the glazing from the surface with emery

cloth or sandpaper, using a swirling motion.

Braking system 9•7

6.2b If the drum is stuck to the hub, apply

penetrating oil around the hub/drum area,

and give it a few minutes to loosen up

any rust6.2a Removing the drum retaining screw5.6d If a rear disc still sticks to the hub,

insert a thin, flat-bladed screwdriver

through the hub flange, rotate the

starwheel on the handbrake adjusting

screw, and contract the handbrake shoes

(disc removed for clarity)

6.3 The maximum allowable inside

diameter of the drum is cast into the drum

6.2c If the brake shoes have worn a

groove in the drum and it won’t come off,

insert a thin flat-bladed screwdriver

through one of the wheel bolt holes in the

flange, and loosen the automatic adjuster

mechanism (for the sake of clarity, the

drum has already been removed in this

photo, and the screwdriver is being

inserted underneath the flange instead of

though a wheel bolt hole)

9

If the front disc is stuck, on

some discs it is possible to

thread two or three bolts into

the holes provided and

tighten them. Alternate between the

bolts, turning them a couple of turns at

a time, until the disc is free.

Page 137 of 228

friction surfaces of the brake shoes or

drums.

12Make sure the adjuster assembly is

properly engaged with its respective notch in

the handbrake lever.

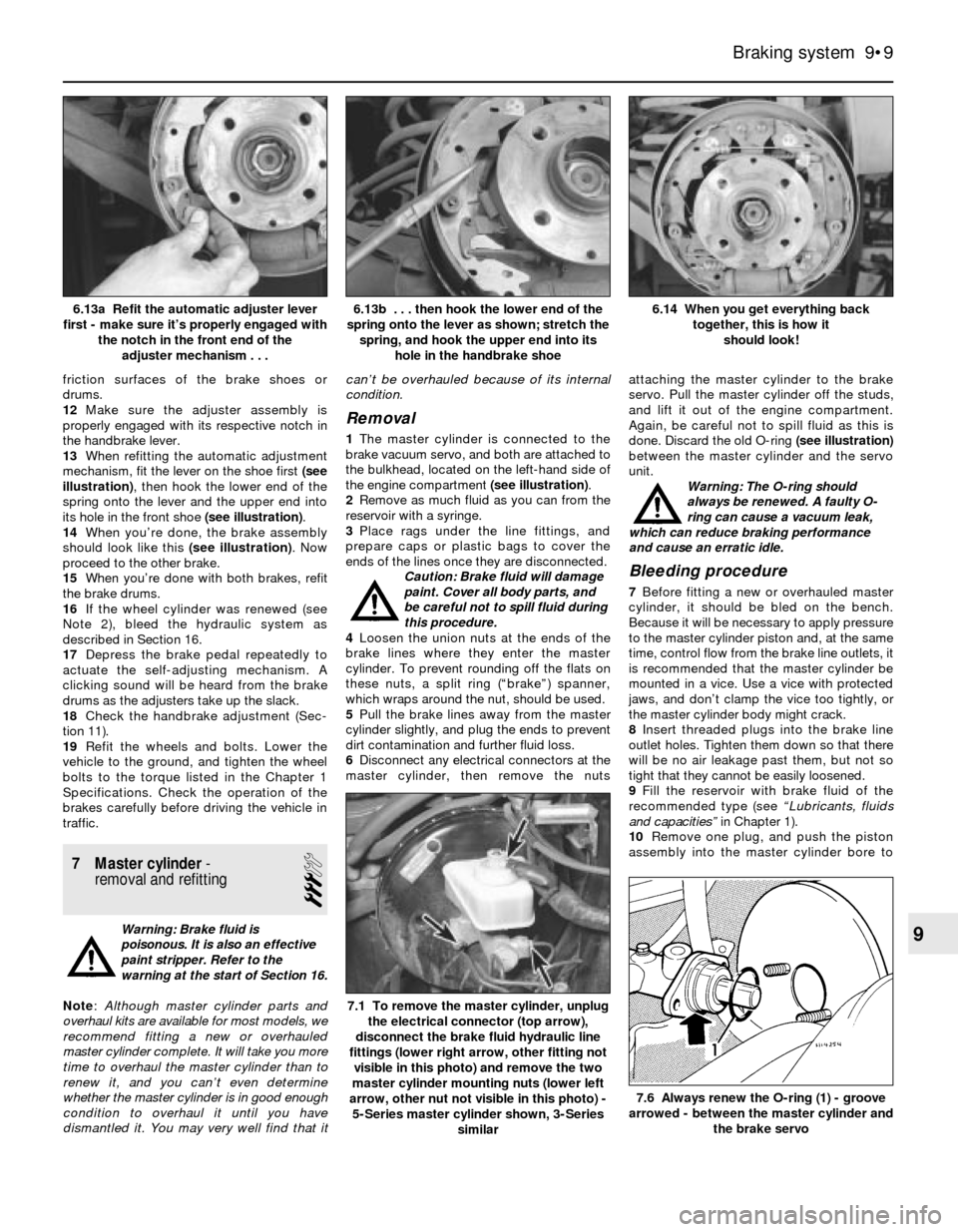

13When refitting the automatic adjustment

mechanism, fit the lever on the shoe first (see

illustration), then hook the lower end of the

spring onto the lever and the upper end into

its hole in the front shoe (see illustration).

14When you’re done, the brake assembly

should look like this (see illustration). Now

proceed to the other brake.

15When you’re done with both brakes, refit

the brake drums.

16If the wheel cylinder was renewed (see

Note 2), bleed the hydraulic system as

described in Section 16.

17Depress the brake pedal repeatedly to

actuate the self-adjusting mechanism. A

clicking sound will be heard from the brake

drums as the adjusters take up the slack.

18Check the handbrake adjustment (Sec-

tion 11).

19Refit the wheels and bolts. Lower the

vehicle to the ground, and tighten the wheel

bolts to the torque listed in the Chapter 1

Specifications. Check the operation of the

brakes carefully before driving the vehicle in

traffic.

7 Master cylinder-

removal and refitting

3

Warning: Brake fluid is

poisonous. It is also an effective

paint stripper. Refer to the

warning at the start of Section 16.

Note: Although master cylinder parts and

overhaul kits are available for most models, we

recommend fitting a new or overhauled

master cylinder complete. It will take you more

time to overhaul the master cylinder than to

renew it, and you can’t even determine

whether the master cylinder is in good enough

condition to overhaul it until you have

dismantled it. You may very well find that itcan’t be overhauled because of its internal

condition.

Removal

1The master cylinder is connected to the

brake vacuum servo, and both are attached to

the bulkhead, located on the left-hand side of

the engine compartment (see illustration).

2Remove as much fluid as you can from the

reservoir with a syringe.

3Place rags under the line fittings, and

prepare caps or plastic bags to cover the

ends of the lines once they are disconnected.

Caution: Brake fluid will damage

paint. Cover all body parts, and

be careful not to spill fluid during

this procedure.

4Loosen the union nuts at the ends of the

brake lines where they enter the master

cylinder. To prevent rounding off the flats on

these nuts, a split ring (“brake”) spanner,

which wraps around the nut, should be used.

5Pull the brake lines away from the master

cylinder slightly, and plug the ends to prevent

dirt contamination and further fluid loss.

6Disconnect any electrical connectors at the

master cylinder, then remove the nutsattaching the master cylinder to the brake

servo. Pull the master cylinder off the studs,

and lift it out of the engine compartment.

Again, be careful not to spill fluid as this is

done. Discard the old O-ring (see illustration)

between the master cylinder and the servo

unit.

Warning: The O-ring should

always be renewed. A faulty O-

ring can cause a vacuum leak,

which can reduce braking performance

and cause an erratic idle.

Bleeding procedure

7Before fitting a new or overhauled master

cylinder, it should be bled on the bench.

Because it will be necessary to apply pressure

to the master cylinder piston and, at the same

time, control flow from the brake line outlets, it

is recommended that the master cylinder be

mounted in a vice. Use a vice with protected

jaws, and don’t clamp the vice too tightly, or

the master cylinder body might crack.

8Insert threaded plugs into the brake line

outlet holes. Tighten them down so that there

will be no air leakage past them, but not so

tight that they cannot be easily loosened.

9Fill the reservoir with brake fluid of the

recommended type (see “Lubricants, fluids

and capacities” in Chapter 1).

10Remove one plug, and push the piston

assembly into the master cylinder bore to

Braking system 9•9

6.14 When you get everything back

together, this is how it

should look! 6.13b . . . then hook the lower end of the

spring onto the lever as shown; stretch the

spring, and hook the upper end into its

hole in the handbrake shoe6.13a Refit the automatic adjuster lever

first - make sure it’s properly engaged with

the notch in the front end of the

adjuster mechanism . . .

7.6 Always renew the O-ring (1) - groove

arrowed - between the master cylinder and

the brake servo

7.1 To remove the master cylinder, unplug

the electrical connector (top arrow),

disconnect the brake fluid hydraulic line

fittings (lower right arrow, other fitting not

visible in this photo) and remove the two

master cylinder mounting nuts (lower left

arrow, other nut not visible in this photo) -

5-Series master cylinder shown, 3-Series

similar

9

Page 140 of 228

and push it through until the forward end

comes out at the handbrake lever.

8Insert the cable conduit through the

backplate, and attach the rear end of the

cable to the handbrake lever (rear drum

models) or the actuator (rear disc models).

Make sure you don’t kink the cable while

connecting it.

9Refit the cable conduit to the clips on the

back of the trailing arm.

10On rear drum models, refit the brake

shoes and drum (see Section 6). On rear disc

models, refit the handbrake shoes and

actuator (see Section 12) and the rear brake

disc (see Section 5).

11Lower the vehicle, and refit the adjusting

nut at the handbrake lever. Adjust the

handbrake cable (see Section 11) and refit the

handbrake lever boot.

11 Handbrake- adjustment

2

Rear drum brake models

Note:Adjustment of the handbrake cable(s)

on models with rear drum brakes should only

be necessary when you renew a cable or

detach if from the rear brake assembly for

some reason. Failure of the handbrake system

to hold the vehicle usually indicates worn

brake shoes or a faulty self-adjusting

mechanism.

1Raise the rear of the vehicle, and place it

securely on axle stands.

2Fully release the handbrake lever, then

apply the brakes firmly several times with the

footbrake pedal.

3Pull the handbrake lever up five clicks.

4Tighten or loosen the adjusting nuts by

equal amounts until the rear brake shoes just

begin to drag on the brake drum. You should

feel the same amount of resistance at both

wheels when you rotate them.

5Release the handbrake lever, and verify that

the wheels rotate freely. If they don’t, re-

adjust them.

Rear disc brake models

Note: The handbrake system is not self-

adjusting on models with rear disc brakes. The

handbrake therefore requires periodic

adjustment to compensate for wear. It should

also be adjusted anytime either cable, brake

disc or handbrake assembly is renewed or

removed for some reason.

6Slowly apply the handbrake, and count the

number of clicks at the lever. If the lever can

be pulled up further than the eighth click,

adjust the handbrake cable as follows.

7Peel back the handbrake lever boot, and

loosen the cable adjusting nut (see

illustration 10.1). On some models, it may be

necessary to remove the centre console

completely for access.

8Loosen a single bolt in each rear wheel.Raise the vehicle and place it securely on axle

stands.

9Remove the bolt you loosened in each rear

wheel. Turn the wheel until, using a torch, you

can see the adjuster starwheel through the

bolt hole.

10Turn the adjuster - clockwise to expand

the shoes, anti-clockwise to retract them -

until the brake shoes just contact the brake

drum (see illustration 5.6d). Back off the

brake shoes so the wheel spins freely (three to

four teeth on the adjuster). Note:If the

adjuster starwheel is hard to turn, remove the

wheel and brake disc, lubricate the adjuster

wheel, and try again.

11With the disc fitted, apply the handbrake

three times to stretch and seat the cables,

then slowly pull up on the handbrake lever to

the fifth click. Tighten the cable adjusting nuts

by equal amounts until the rear brake shoes

just touch the brake drum. Verify that both

wheels have the same amount of resistance.

12Release the handbrake, and verify that

both rear wheels rotate freely.

13Tighten the wheel bolts to the torque

listed in Chapter 1 Specifications.

12 Handbrake assembly-

check, removal and refitting

2

Warning: The handbrake linings

on rear disc brake models may

be manufactured of asbestos-

based material. Refer to the

warning at the start of Section 6. When

servicing these components, do not create

dust by grinding or sanding the linings.

1The handbrake system should be checked

regularly. With the vehicle parked on a hill,

apply the handbrake, select neutral, and

check that the handbrake alone will hold the

vehicle when the footbrake is released (be

sure to stay in the vehicle during this check).

However, every 2 years (or whenever a fault is

suspected), the assembly itself should be

inspected.

2With the vehicle raised and supported onaxle stands, remove the rear wheels.

3On rear brake drum models, refer to

Chapter 1; checking the thickness of the

brake shoes is a routine maintenance

procedure.

4On rear disc brake models, remove the rear

discs as outlined in Section 5. Support the

caliper assemblies with a coat hanger or

heavy wire; do not disconnect the brake line

from the caliper.

5With the disc removed, the handbrake

components are visible, and can be inspected

for wear and damage. The linings should last

the life of the vehicle. However, they can wear

down if the handbrake system has been

improperly adjusted, or if the handbrake is

regularly used to stop the vehicle. There is no

minimum thickness specification for the

handbrake shoes, but as a rule of thumb, if

the shoe material is less than 1.5 mm thick,

you should renew them. Also check the

springs and adjuster mechanism and inspect

the drum for deep scratches and other

damage.

Removal and refitting

Note:The following procedure applies only to

models with rear disc brakes. The handbrake

system on models with rear drum brakes is an

integral part of the rear brake assembly (see

Section 6).

6Loosen the rear wheel bolts, raise the rear

of the vehicle and place it securely on axle

stands. Remove the rear wheels. Remove the

brake discs (see Section 5). Work on only one

side at a time, so you can use the other side

as a reference during reassembly, and to

avoid mixing up parts.

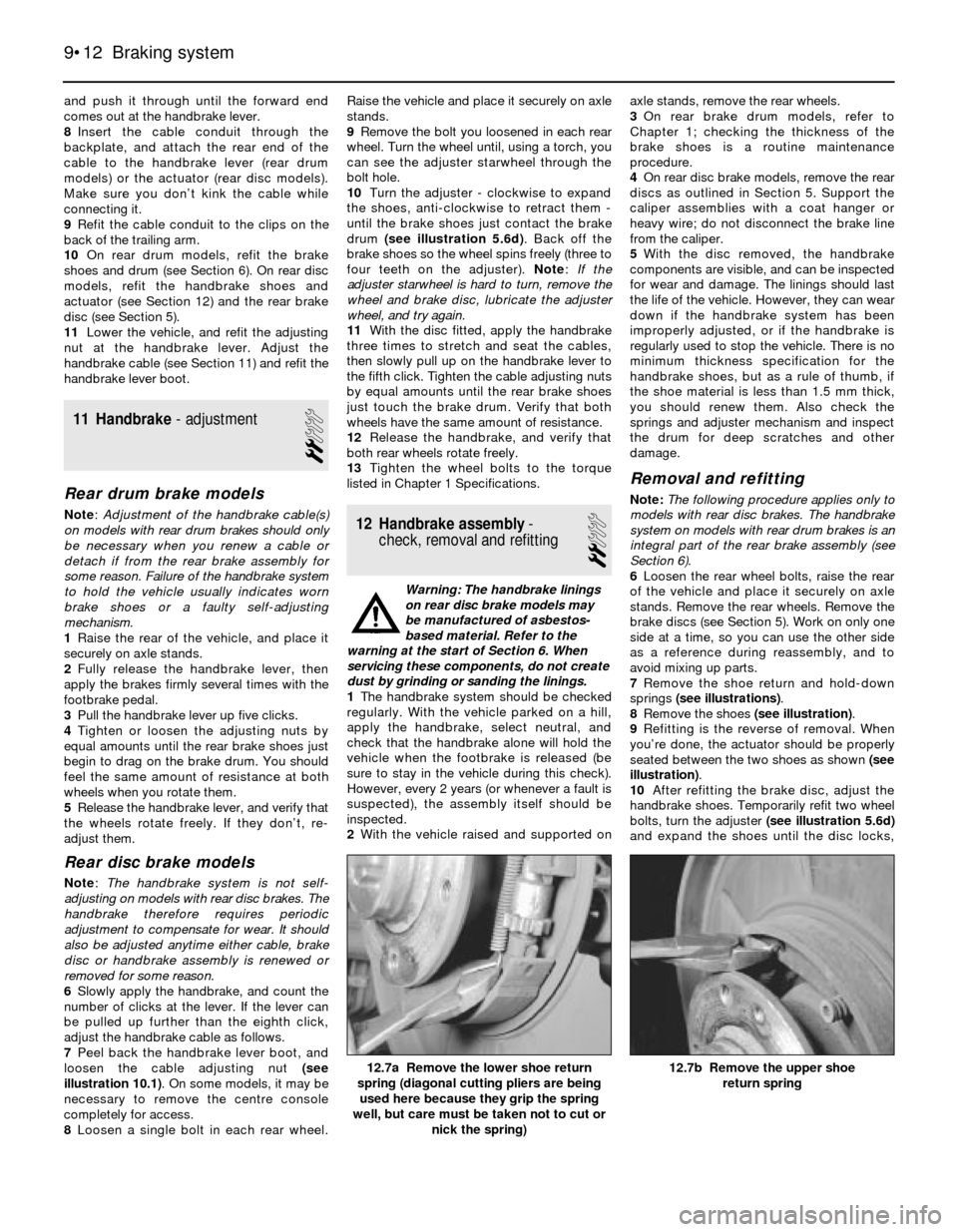

7Remove the shoe return and hold-down

springs (see illustrations).

8Remove the shoes (see illustration).

9Refitting is the reverse of removal. When

you’re done, the actuator should be properly

seated between the two shoes as shown (see

illustration).

10After refitting the brake disc, adjust the

handbrake shoes. Temporarily refit two wheel

bolts, turn the adjuster (see illustration 5.6d)

and expand the shoes until the disc locks,

9•12 Braking system

12.7b Remove the upper shoe

return spring12.7a Remove the lower shoe return

spring (diagonal cutting pliers are being

used here because they grip the spring

well, but care must be taken not to cut or

nick the spring)

Page 143 of 228

10

General

Power steering fluid type . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . See Chapter 1

Tyres

Tyre sizes

3-Series, E30

316 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 175/70x14

316i . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 175/70x14, 195/65x14

318i . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 175/70x14

320i . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 195/65x14

325i . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 195/65x14, 200/60x356, 205/55x15

5-Series, E28 (“old-shape”)

518 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 175x14

518i . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 175x14

525i . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 175x14, 195/70x14

528i . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 195/70x14

535i and M535i . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 220/55x390

5-Series, E34 (“new-shape”)

518i . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 195/65x15

520i . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 195/65x15, 225/60x15

525i . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 195/65x15, 205/65x15, 225/65x15

530i . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 205/65x15, 225/60x15

535i . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 225/60x15, 240/45x415

Tyre pressures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . See Chapter 1 Specifications

Chapter 10 Suspension and steering systems

Balljoints - check and renewal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Control arm (3-Series) - inspection, removal and refitting,

and bush renewal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Control and thrust arms (5-Series) - inspection, removal and

refitting, and bush renewal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Front anti-roll bar - removal and refitting . . . . . . . . . . . . . . . . . . . . . 2

Front hub and wheel bearing assembly - removal and refitting . . . . 8

Front strut assembly - removal and refitting . . . . . . . . . . . . . . . . . . . 5

General information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Power steering fluid level check . . . . . . . . . . . . . . . . See Chapter 1

Power steering pump - removal and refitting . . . . . . . . . . . . . . . . . . 22

Power steering system - bleeding . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Rack-and-pinion steering gear (3-Series) - removal and refitting . . . 19

Rear anti-roll bar - removal and refitting . . . . . . . . . . . . . . . . . . . . . . 12

Rear coil springs (3-Series) - removal and refitting . . . . . . . . . . . . . . 10

Rear shock absorbers (3-Series) - removal and refitting . . . . . . . . . 9

Rear shock absorber/coil spring assembly (5-Series) - removal

and refitting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11Rear trailing arms (3-Series) - removal and refitting . . . . . . . . . . . . . 13

Rear trailing arms (5-Series) - removal and refitting . . . . . . . . . . . . . 14

Rear wheel bearings - renewal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Steering and suspension check . . . . . . . . . . . . . . . . . See Chapter 1

Steering box (5-Series) - removal and refitting . . . . . . . . . . . . . . . . . 21

Steering gear boots (3-Series) - renewal . . . . . . . . . . . . . . . . . . . . . . 18

Steering linkage (5-Series) - inspection, removal and

refitting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Steering system - general information . . . . . . . . . . . . . . . . . . . . . . . 16

Steering wheel - removal and refitting . . . . . . . . . . . . . . . . . . . . . . . 24

Strut or shock absorber/coil spring - renewal . . . . . . . . . . . . . . . . . . 6

Suspension and steering checks . . . . . . . . . . . . . . . . See Chapter 1

Track rod ends - removal and refitting . . . . . . . . . . . . . . . . . . . . . . . 17

Tyre and tyre pressure checks . . . . . . . . . . . . . . . . . See Chapter 1

Tyre rotation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . See Chapter 1

Wheel alignment - general information . . . . . . . . . . . . . . . . . . . . . . . 26

Wheels and tyres - general information . . . . . . . . . . . . . . . . . . . . . . 25

10•1

Easy,suitable for

novice with little

experienceFairly easy,suitable

for beginner with

some experienceFairly difficult,

suitable for competent

DIY mechanic

Difficult,suitable for

experienced DIY

mechanicVery difficult,

suitable for expert

DIY or professional

Degrees of difficulty

Specifications Contents

Page 150 of 228

problem exists, a new subframe or steering

arm (5-Series) or steering knuckle (3-Series),

which is integral with the strut housing, should

be fitted as well as the new balljoint.

Renewal

Note: None of these balljoints can be serviced

or renewed individually. If one of them is worn,

a complete new arm must be fitted.

8 Front hub and wheel bearing

assembly-

removal and refitting

3

Note:Removing the front hub/bearing

assembly renders it unfit for re-use. A new

assembly will be required for refitting.

Removal

1Loosen the wheel bolts, then raise the front

of the vehicle, and support it securely on axle

stands. Remove the wheel bolts and the

wheel.

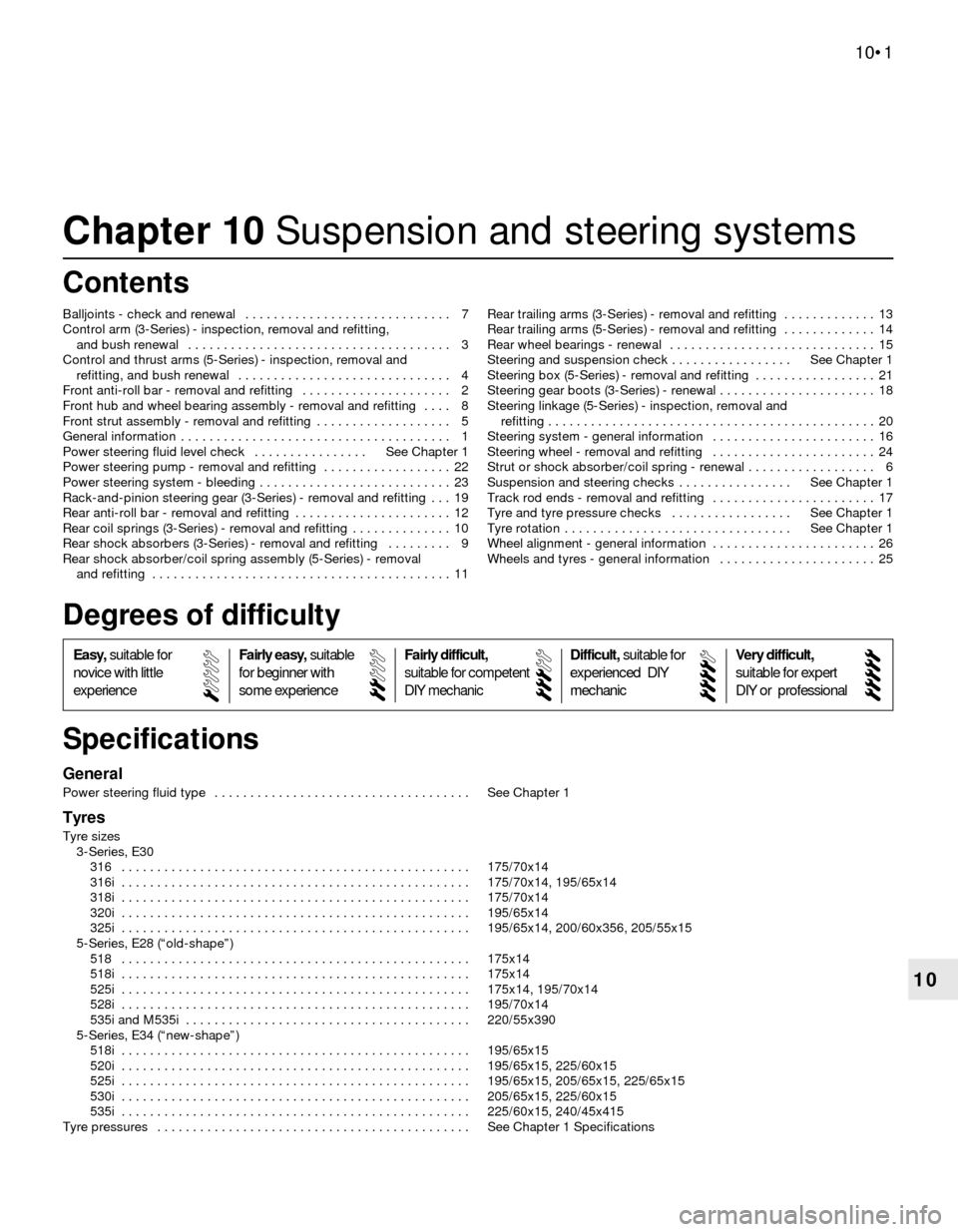

2Using a hammer and chisel, remove the

dust cap from the centre of the wheel hub

(see illustration).

3Unstake the hub nut (see illustration).

4Refit the wheel and lower the vehicle to the

ground. Loosen, but do not remove, the hub

nut.

Warning: Always loosen and

tighten the hub nut with the

vehicle on the ground. Theleverage needed to loosen the nut (which

is very tight) could topple the vehicle off a

lift or an axle stand.

5Raise the front of the vehicle, support it

securely on axle stands, and remove the front

wheel again.

6Remove the front brake caliper and

mounting bracket (see Chapter 9). There is no

need to disconnect the brake hose. Hang the

caliper out of the way with a piece of wire.

7Remove the brake disc (see Chapter 9).

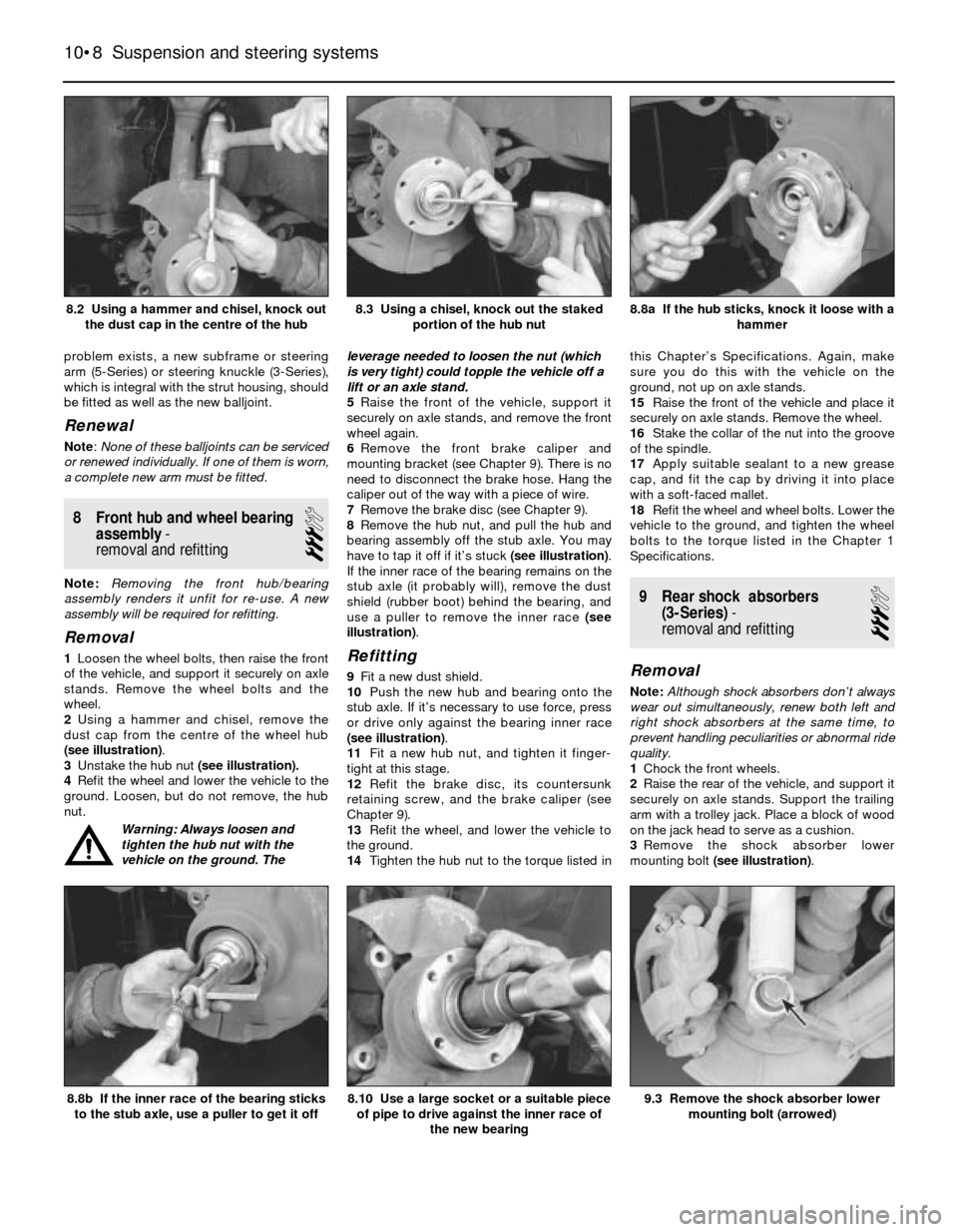

8Remove the hub nut, and pull the hub and

bearing assembly off the stub axle. You may

have to tap it off if it’s stuck (see illustration).

If the inner race of the bearing remains on the

stub axle (it probably will), remove the dust

shield (rubber boot) behind the bearing, and

use a puller to remove the inner race (see

illustration).Refitting

9Fit a new dust shield.

10Push the new hub and bearing onto the

stub axle. If it’s necessary to use force, press

or drive only against the bearing inner race

(see illustration).

11Fit a new hub nut, and tighten it finger-

tight at this stage.

12Refit the brake disc, its countersunk

retaining screw, and the brake caliper (see

Chapter 9).

13Refit the wheel, and lower the vehicle to

the ground.

14Tighten the hub nut to the torque listed inthis Chapter’s Specifications. Again, make

sure you do this with the vehicle on the

ground, not up on axle stands.

15Raise the front of the vehicle and place it

securely on axle stands. Remove the wheel.

16Stake the collar of the nut into the groove

of the spindle.

17Apply suitable sealant to a new grease

cap, and fit the cap by driving it into place

with a soft-faced mallet.

18Refit the wheel and wheel bolts. Lower the

vehicle to the ground, and tighten the wheel

bolts to the torque listed in the Chapter 1

Specifications.

9 Rear shock absorbers

(3-Series)-

removal and refitting

3

Removal

Note:Although shock absorbers don’t always

wear out simultaneously, renew both left and

right shock absorbers at the same time, to

prevent handling peculiarities or abnormal ride

quality.

1Chock the front wheels.

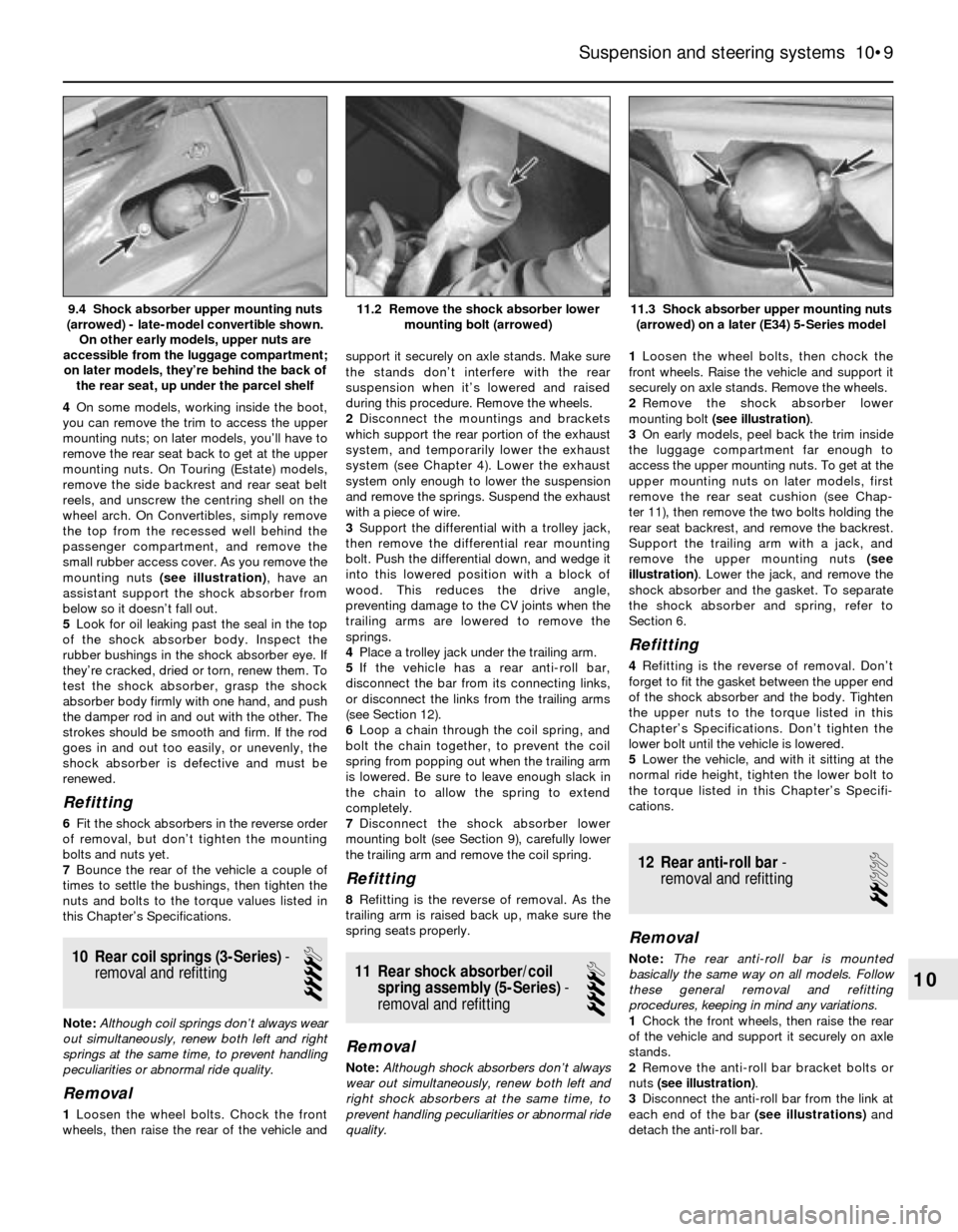

2Raise the rear of the vehicle, and support it

securely on axle stands. Support the trailing

arm with a trolley jack. Place a block of wood

on the jack head to serve as a cushion.

3Remove the shock absorber lower

mounting bolt (see illustration).

10•8 Suspension and steering systems

9.3 Remove the shock absorber lower

mounting bolt (arrowed)8.10 Use a large socket or a suitable piece

of pipe to drive against the inner race of

the new bearing8.8b If the inner race of the bearing sticks

to the stub axle, use a puller to get it off

8.8a If the hub sticks, knock it loose with a

hammer8.3 Using a chisel, knock out the staked

portion of the hub nut8.2 Using a hammer and chisel, knock out

the dust cap in the centre of the hub

Page 151 of 228

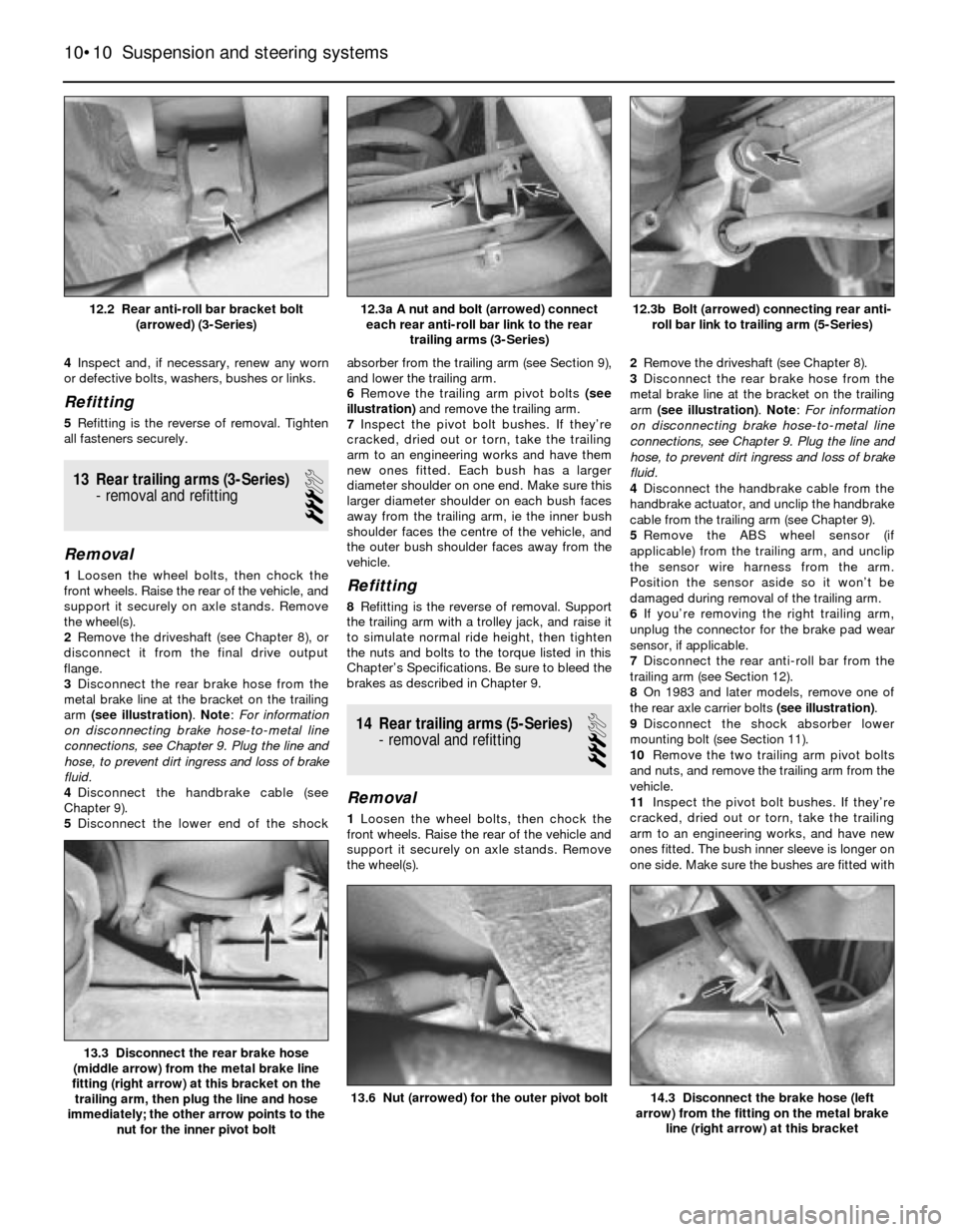

4On some models, working inside the boot,

you can remove the trim to access the upper

mounting nuts; on later models, you’ll have to

remove the rear seat back to get at the upper

mounting nuts. On Touring (Estate) models,

remove the side backrest and rear seat belt

reels, and unscrew the centring shell on the

wheel arch. On Convertibles, simply remove

the top from the recessed well behind the

passenger compartment, and remove the

small rubber access cover. As you remove the

mounting nuts (see illustration), have an

assistant support the shock absorber from

below so it doesn’t fall out.

5Look for oil leaking past the seal in the top

of the shock absorber body. Inspect the

rubber bushings in the shock absorber eye. If

they’re cracked, dried or torn, renew them. To

test the shock absorber, grasp the shock

absorber body firmly with one hand, and push

the damper rod in and out with the other. The

strokes should be smooth and firm. If the rod

goes in and out too easily, or unevenly, the

shock absorber is defective and must be

renewed.

Refitting

6Fit the shock absorbers in the reverse order

of removal, but don’t tighten the mounting

bolts and nuts yet.

7Bounce the rear of the vehicle a couple of

times to settle the bushings, then tighten the

nuts and bolts to the torque values listed in

this Chapter’s Specifications.

10 Rear coil springs (3-Series)-

removal and refitting

4

Note: Although coil springs don’t always wear

out simultaneously, renew both left and right

springs at the same time, to prevent handling

peculiarities or abnormal ride quality.

Removal

1Loosen the wheel bolts. Chock the front

wheels, then raise the rear of the vehicle andsupport it securely on axle stands. Make sure

the stands don’t interfere with the rear

suspension when it’s lowered and raised

during this procedure. Remove the wheels.

2Disconnect the mountings and brackets

which support the rear portion of the exhaust

system, and temporarily lower the exhaust

system (see Chapter 4). Lower the exhaust

system only enough to lower the suspension

and remove the springs. Suspend the exhaust

with a piece of wire.

3Support the differential with a trolley jack,

then remove the differential rear mounting

bolt. Push the differential down, and wedge it

into this lowered position with a block of

wood. This reduces the drive angle,

preventing damage to the CV joints when the

trailing arms are lowered to remove the

springs.

4Place a trolley jack under the trailing arm.

5If the vehicle has a rear anti-roll bar,

disconnect the bar from its connecting links,

or disconnect the links from the trailing arms

(see Section 12).

6Loop a chain through the coil spring, and

bolt the chain together, to prevent the coil

spring from popping out when the trailing arm

is lowered. Be sure to leave enough slack in

the chain to allow the spring to extend

completely.

7Disconnect the shock absorber lower

mounting bolt (see Section 9), carefully lower

the trailing arm and remove the coil spring.

Refitting

8Refitting is the reverse of removal. As the

trailing arm is raised back up, make sure the

spring seats properly.

11 Rear shock absorber/coil

spring assembly (5-Series)-

removal and refitting

4

Removal

Note:Although shock absorbers don’t always

wear out simultaneously, renew both left and

right shock absorbers at the same time, to

prevent handling peculiarities or abnormal ride

quality.1Loosen the wheel bolts, then chock the

front wheels. Raise the vehicle and support it

securely on axle stands. Remove the wheels.

2Remove the shock absorber lower

mounting bolt (see illustration).

3On early models, peel back the trim inside

the luggage compartment far enough to

access the upper mounting nuts. To get at the

upper mounting nuts on later models, first

remove the rear seat cushion (see Chap-

ter 11), then remove the two bolts holding the

rear seat backrest, and remove the backrest.

Support the trailing arm with a jack, and

remove the upper mounting nuts (see

illustration). Lower the jack, and remove the

shock absorber and the gasket. To separate

the shock absorber and spring, refer to

Section 6.

Refitting

4Refitting is the reverse of removal. Don’t

forget to fit the gasket between the upper end

of the shock absorber and the body. Tighten

the upper nuts to the torque listed in this

Chapter’s Specifications. Don’t tighten the

lower bolt until the vehicle is lowered.

5Lower the vehicle, and with it sitting at the

normal ride height, tighten the lower bolt to

the torque listed in this Chapter’s Specifi-

cations.

12 Rear anti-roll bar-

removal and refitting

2

Removal

Note:The rear anti-roll bar is mounted

basically the same way on all models. Follow

these general removal and refitting

procedures, keeping in mind any variations.

1Chock the front wheels, then raise the rear

of the vehicle and support it securely on axle

stands.

2Remove the anti-roll bar bracket bolts or

nuts (see illustration).

3Disconnect the anti-roll bar from the link at

each end of the bar (see illustrations)and

detach the anti-roll bar.

Suspension and steering systems 10•9

11.3 Shock absorber upper mounting nuts

(arrowed) on a later (E34) 5-Series model11.2 Remove the shock absorber lower

mounting bolt (arrowed)9.4 Shock absorber upper mounting nuts

(arrowed) - late-model convertible shown.

On other early models, upper nuts are

accessible from the luggage compartment;

on later models, they’re behind the back of

the rear seat, up under the parcel shelf

10

Page 152 of 228

4Inspect and, if necessary, renew any worn

or defective bolts, washers, bushes or links.

Refitting

5Refitting is the reverse of removal. Tighten

all fasteners securely.

13 Rear trailing arms (3-Series)

- removal and refitting

3

Removal

1Loosen the wheel bolts, then chock the

front wheels. Raise the rear of the vehicle, and

support it securely on axle stands. Remove

the wheel(s).

2Remove the driveshaft (see Chapter 8), or

disconnect it from the final drive output

flange.

3Disconnect the rear brake hose from the

metal brake line at the bracket on the trailing

arm (see illustration). Note: For information

on disconnecting brake hose-to-metal line

connections, see Chapter 9. Plug the line and

hose, to prevent dirt ingress and loss of brake

fluid.

4Disconnect the handbrake cable (see

Chapter 9).

5Disconnect the lower end of the shockabsorber from the trailing arm (see Section 9),

and lower the trailing arm.

6Remove the trailing arm pivot bolts (see

illustration)and remove the trailing arm.

7Inspect the pivot bolt bushes. If they’re

cracked, dried out or torn, take the trailing

arm to an engineering works and have them

new ones fitted. Each bush has a larger

diameter shoulder on one end. Make sure this

larger diameter shoulder on each bush faces

away from the trailing arm, ie the inner bush

shoulder faces the centre of the vehicle, and

the outer bush shoulder faces away from the

vehicle.Refitting

8Refitting is the reverse of removal. Support

the trailing arm with a trolley jack, and raise it

to simulate normal ride height, then tighten

the nuts and bolts to the torque listed in this

Chapter’s Specifications. Be sure to bleed the

brakes as described in Chapter 9.

14 Rear trailing arms (5-Series)

- removal and refitting

3

Removal

1Loosen the wheel bolts, then chock the

front wheels. Raise the rear of the vehicle and

support it securely on axle stands. Remove

the wheel(s).2Remove the driveshaft (see Chapter 8).

3Disconnect the rear brake hose from the

metal brake line at the bracket on the trailing

arm (see illustration). Note: For information

on disconnecting brake hose-to-metal line

connections, see Chapter 9. Plug the line and

hose, to prevent dirt ingress and loss of brake

fluid.

4Disconnect the handbrake cable from the

handbrake actuator, and unclip the handbrake

cable from the trailing arm (see Chapter 9).

5Remove the ABS wheel sensor (if

applicable) from the trailing arm, and unclip

the sensor wire harness from the arm.

Position the sensor aside so it won’t be

damaged during removal of the trailing arm.

6If you’re removing the right trailing arm,

unplug the connector for the brake pad wear

sensor, if applicable.

7Disconnect the rear anti-roll bar from the

trailing arm (see Section 12).

8On 1983 and later models, remove one of

the rear axle carrier bolts (see illustration).

9Disconnect the shock absorber lower

mounting bolt (see Section 11).

10Remove the two trailing arm pivot bolts

and nuts, and remove the trailing arm from the

vehicle.

11Inspect the pivot bolt bushes. If they’re

cracked, dried out or torn, take the trailing

arm to an engineering works, and have new

ones fitted. The bush inner sleeve is longer on

one side. Make sure the bushes are fitted with

10•10 Suspension and steering systems

14.3 Disconnect the brake hose (left

arrow) from the fitting on the metal brake

line (right arrow) at this bracket13.6 Nut (arrowed) for the outer pivot bolt

13.3 Disconnect the rear brake hose

(middle arrow) from the metal brake line

fitting (right arrow) at this bracket on the

trailing arm, then plug the line and hose

immediately; the other arrow points to the

nut for the inner pivot bolt

12.3b Bolt (arrowed) connecting rear anti-

roll bar link to trailing arm (5-Series)12.3a A nut and bolt (arrowed) connect

each rear anti-roll bar link to the rear

trailing arms (3-Series)12.2 Rear anti-roll bar bracket bolt

(arrowed) (3-Series)

Page 153 of 228

the longer side of the sleeve facing towards

the centre of the vehicle.

Refitting

12Refitting is the reverse of removal. Refit

the inner pivot bolt first. Don’t fully tighten the

nuts on the pivot bolts or the shock absorber

yet.

13Bleed the brakes as described in Chap-

ter 9.

14Support the trailing arm with a trolley jack,

and raise it to simulate normal ride height.

Tighten the bolts and nuts to the torques

listed in this Chapter’s Specifications.

15 Rear wheel bearings-

renewal

4

3-Series models

1Loosen the driveshaft nut and the rear

wheel bolts, then chock the front wheels.

Raise the rear of the vehicle and place it

securely on axle stands. Remove the rear

wheel. Note: Depending on the type of rear

wheel, it may be necessary to remove the

wheel first, remove the hubcap, then refit the

wheel and loosen the driveshaft nut.

2Remove the driveshaft (see Chapter 8).3On models with rear brake drums, remove

the drum. On models with rear disc brakes,

remove the brake caliper and mounting

bracket. Don’t disconnect the hose. Hang the

caliper out of the way with a piece of wire.

Remove the brake disc (see Chapter 9).

Working from behind, drive the wheel hub out

of the wheel bearing with a large socket or a

piece of pipe.

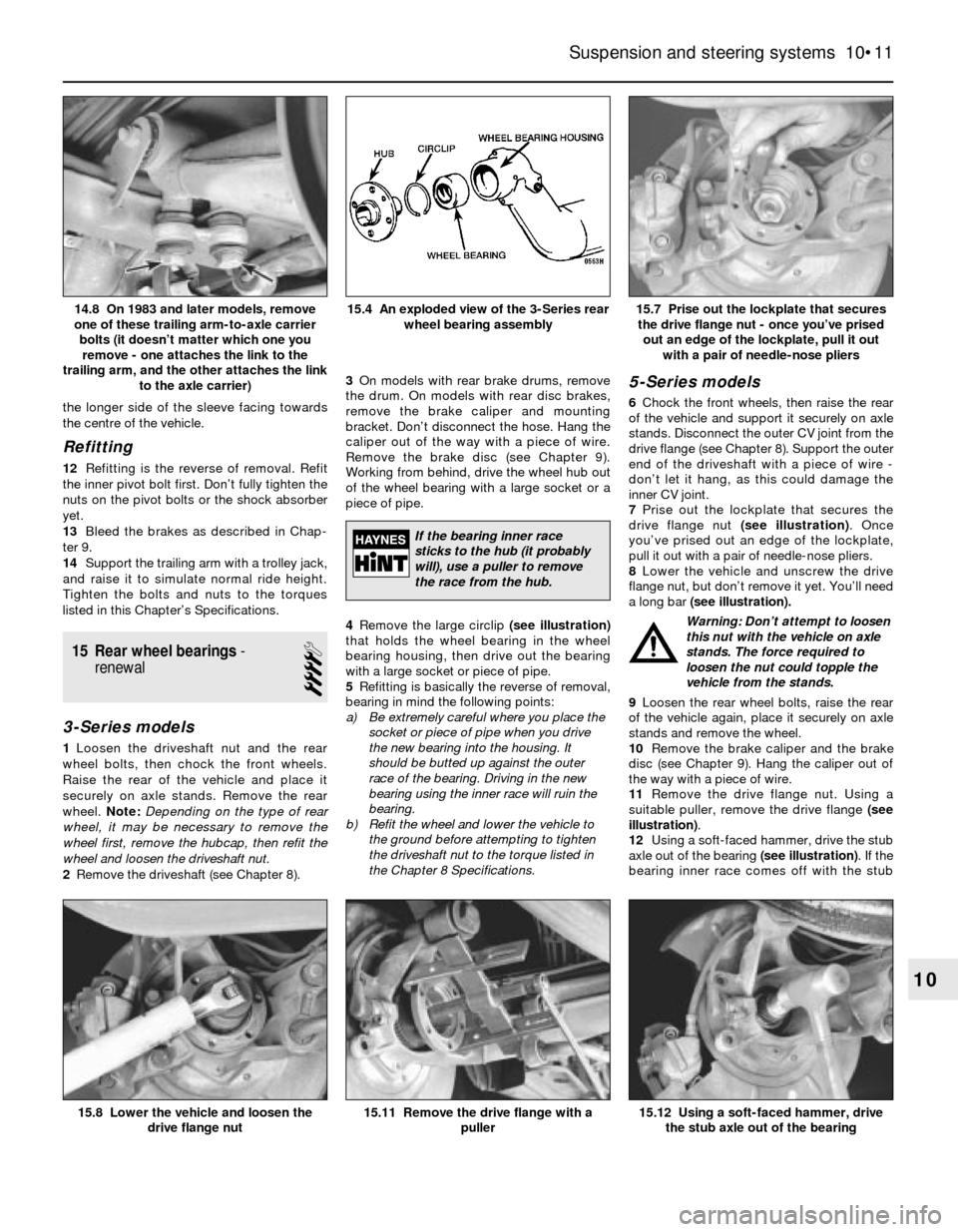

4Remove the large circlip (see illustration)

that holds the wheel bearing in the wheel

bearing housing, then drive out the bearing

with a large socket or piece of pipe.

5Refitting is basically the reverse of removal,

bearing in mind the following points:

a) Be extremely careful where you place the

socket or piece of pipe when you drive

the new bearing into the housing. It

should be butted up against the outer

race of the bearing. Driving in the new

bearing using the inner race will ruin the

bearing.

b) Refit the wheel and lower the vehicle to

the ground before attempting to tighten

the driveshaft nut to the torque listed in

the Chapter 8 Specifications.

5-Series models

6Chock the front wheels, then raise the rear

of the vehicle and support it securely on axle

stands. Disconnect the outer CV joint from the

drive flange (see Chapter 8). Support the outer

end of the driveshaft with a piece of wire -

don’t let it hang, as this could damage the

inner CV joint.

7Prise out the lockplate that secures the

drive flange nut (see illustration). Once

you’ve prised out an edge of the lockplate,

pull it out with a pair of needle-nose pliers.

8Lower the vehicle and unscrew the drive

flange nut, but don’t remove it yet. You’ll need

a long bar (see illustration).

Warning: Don’t attempt to loosen

this nut with the vehicle on axle

stands. The force required to

loosen the nut could topple the

vehicle from the stands.

9Loosen the rear wheel bolts, raise the rear

of the vehicle again, place it securely on axle

stands and remove the wheel.

10Remove the brake caliper and the brake

disc (see Chapter 9). Hang the caliper out of

the way with a piece of wire.

11Remove the drive flange nut. Using a

suitable puller, remove the drive flange (see

illustration).

12Using a soft-faced hammer, drive the stub

axle out of the bearing (see illustration). If the

bearing inner race comes off with the stub

Suspension and steering systems 10•11

15.7 Prise out the lockplate that secures

the drive flange nut - once you’ve prised

out an edge of the lockplate, pull it out

with a pair of needle-nose pliers15.4 An exploded view of the 3-Series rear

wheel bearing assembly14.8 On 1983 and later models, remove

one of these trailing arm-to-axle carrier

bolts (it doesn’t matter which one you

remove - one attaches the link to the

trailing arm, and the other attaches the link

to the axle carrier)

15.12 Using a soft-faced hammer, drive

the stub axle out of the bearing15.11 Remove the drive flange with a

puller15.8 Lower the vehicle and loosen the

drive flange nut

10

If the bearing inner race

sticks to the hub (it probably

will), use a puller to remove

the race from the hub.

Page 154 of 228

axle (it probably will), use a puller to remove

the race from the stub axle. If you can’t get

the race off with a puller, take the stub axle to

an engineering works and have it pressed off.

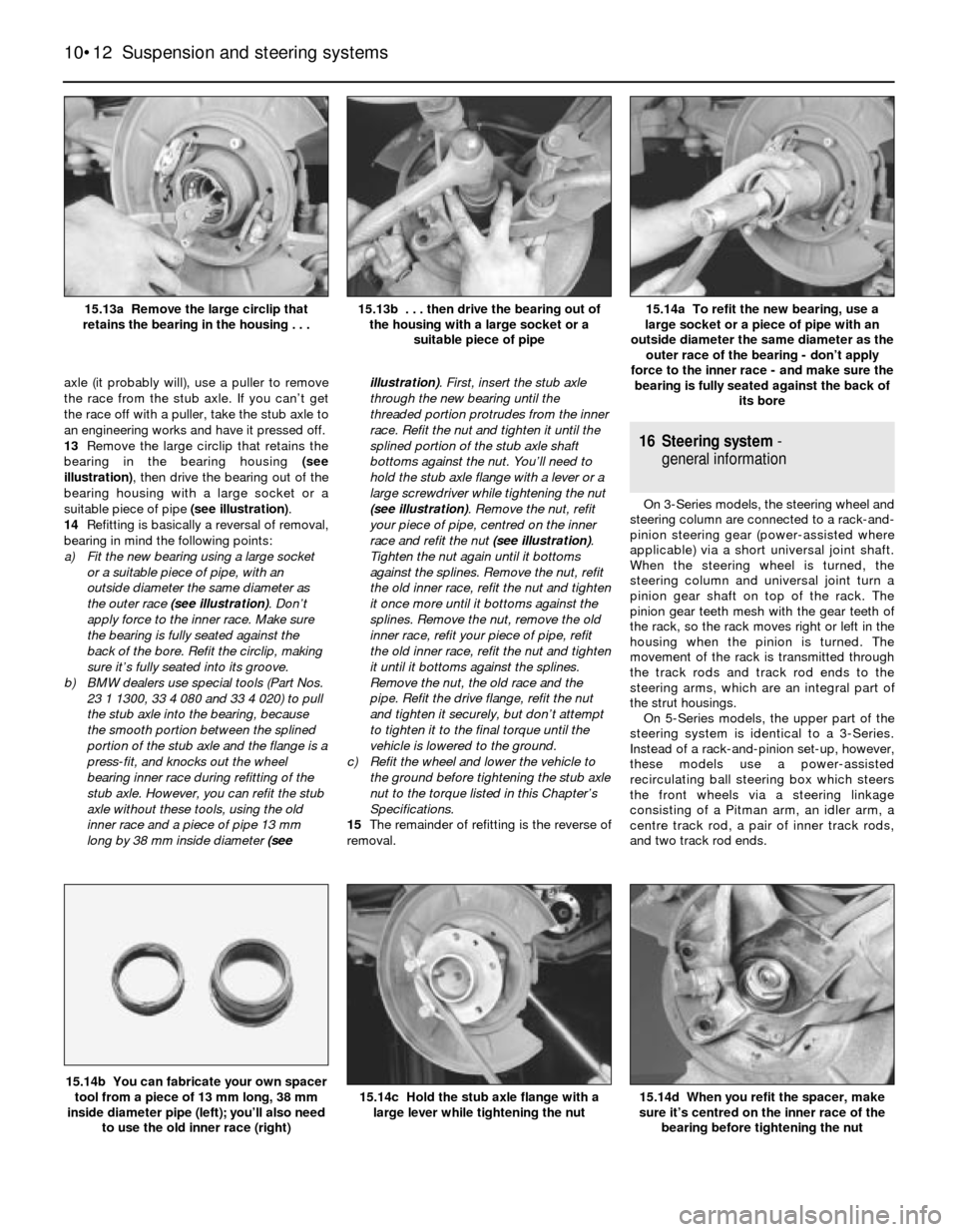

13Remove the large circlip that retains the

bearing in the bearing housing (see

illustration), then drive the bearing out of the

bearing housing with a large socket or a

suitable piece of pipe (see illustration).

14Refitting is basically a reversal of removal,

bearing in mind the following points:

a) Fit the new bearing using a large socket

or a suitable piece of pipe, with an

outside diameter the same diameter as

the outer race (see illustration). Don’t

apply force to the inner race. Make sure

the bearing is fully seated against the

back of the bore. Refit the circlip, making

sure it’s fully seated into its groove.

b) BMW dealers use special tools (Part Nos.

23 1 1300, 33 4 080 and 33 4 020) to pull

the stub axle into the bearing, because

the smooth portion between the splined

portion of the stub axle and the flange is a

press-fit, and knocks out the wheel

bearing inner race during refitting of the

stub axle. However, you can refit the stub

axle without these tools, using the old

inner race and a piece of pipe 13 mm

long by 38 mm inside diameter (seeillustration). First, insert the stub axle

through the new bearing until the

threaded portion protrudes from the inner

race. Refit the nut and tighten it until the

splined portion of the stub axle shaft

bottoms against the nut. You’ll need to

hold the stub axle flange with a lever or a

large screwdriver while tightening the nut

(see illustration). Remove the nut, refit

your piece of pipe, centred on the inner

race and refit the nut (see illustration).

Tighten the nut again until it bottoms

against the splines. Remove the nut, refit

the old inner race, refit the nut and tighten

it once more until it bottoms against the

splines. Remove the nut, remove the old

inner race, refit your piece of pipe, refit

the old inner race, refit the nut and tighten

it until it bottoms against the splines.

Remove the nut, the old race and the

pipe. Refit the drive flange, refit the nut

and tighten it securely, but don’t attempt

to tighten it to the final torque until the

vehicle is lowered to the ground.

c) Refit the wheel and lower the vehicle to

the ground before tightening the stub axle

nut to the torque listed in this Chapter’s

Specifications.

15The remainder of refitting is the reverse of

removal.

16 Steering system-

general information

On 3-Series models, the steering wheel and

steering column are connected to a rack-and-

pinion steering gear (power-assisted where

applicable) via a short universal joint shaft.

When the steering wheel is turned, the

steering column and universal joint turn a

pinion gear shaft on top of the rack. The

pinion gear teeth mesh with the gear teeth of

the rack, so the rack moves right or left in the

housing when the pinion is turned. The

movement of the rack is transmitted through

the track rods and track rod ends to the

steering arms, which are an integral part of

the strut housings.

On 5-Series models, the upper part of the

steering system is identical to a 3-Series.

Instead of a rack-and-pinion set-up, however,

these models use a power-assisted

recirculating ball steering box which steers

the front wheels via a steering linkage

consisting of a Pitman arm, an idler arm, a

centre track rod, a pair of inner track rods,

and two track rod ends.

10•12 Suspension and steering systems

15.14d When you refit the spacer, make

sure it’s centred on the inner race of the

bearing before tightening the nut15.14c Hold the stub axle flange with a

large lever while tightening the nut15.14b You can fabricate your own spacer

tool from a piece of 13 mm long, 38 mm

inside diameter pipe (left); you’ll also need

to use the old inner race (right)

15.14a To refit the new bearing, use a

large socket or a piece of pipe with an

outside diameter the same diameter as the

outer race of the bearing - don’t apply

force to the inner race - and make sure the

bearing is fully seated against the back of

its bore15.13b . . . then drive the bearing out of

the housing with a large socket or a

suitable piece of pipe15.13a Remove the large circlip that

retains the bearing in the housing . . .