Settings BMW 5 SERIES 1991 E34 Workshop Manual

[x] Cancel search | Manufacturer: BMW, Model Year: 1991, Model line: 5 SERIES, Model: BMW 5 SERIES 1991 E34Pages: 228, PDF Size: 7.04 MB

Page 13 of 228

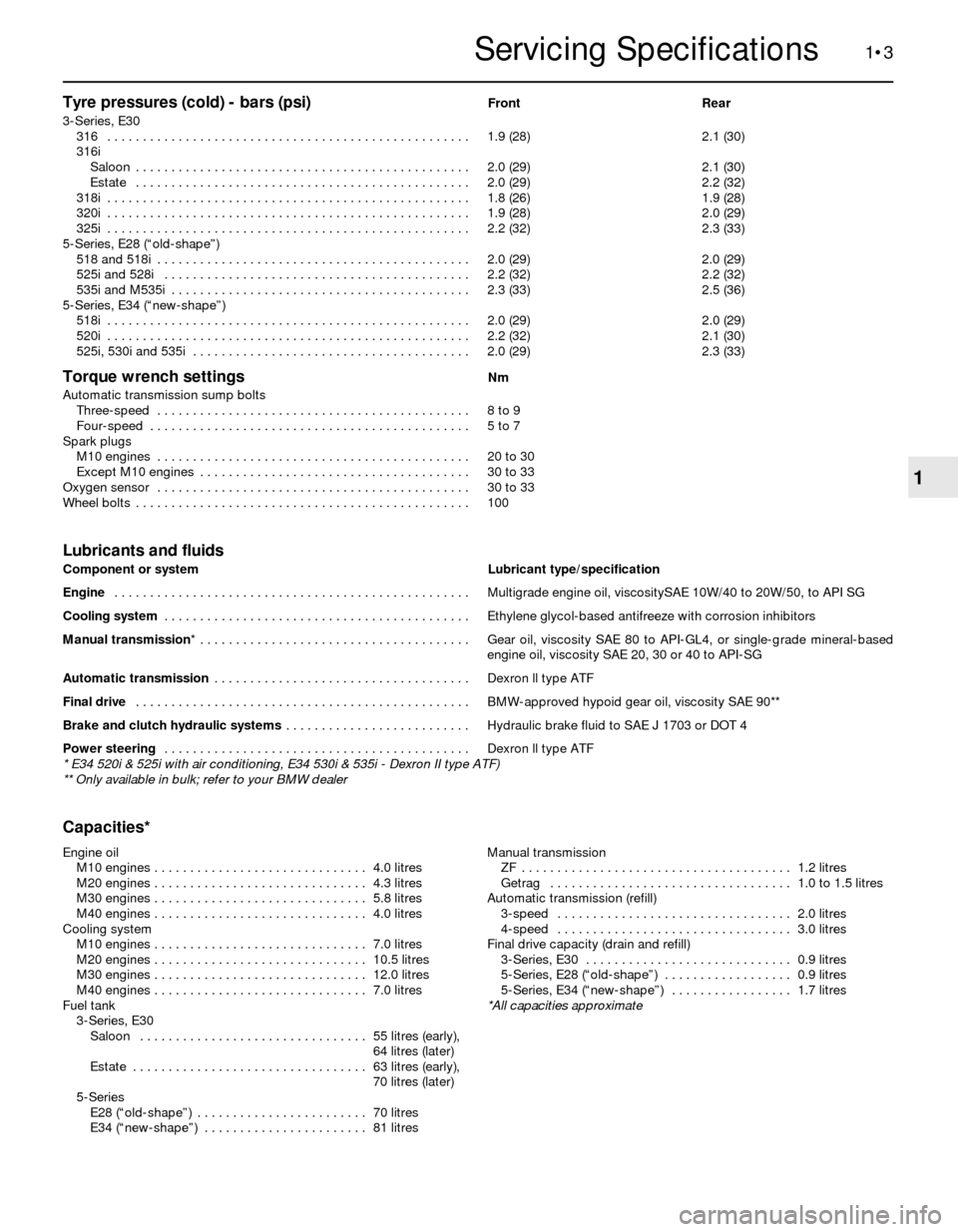

Tyre pressures (cold) - bars (psi)Front Rear

3-Series, E30

316 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1.9 (28) 2.1 (30)

316i

Saloon . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2.0 (29) 2.1 (30)

Estate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2.0 (29) 2.2 (32)

318i . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1.8 (26) 1.9 (28)

320i . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1.9 (28) 2.0 (29)

325i . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2.2 (32) 2.3 (33)

5-Series, E28 (“old-shape”)

518 and 518i . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2.0 (29) 2.0 (29)

525i and 528i . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2.2 (32) 2.2 (32)

535i and M535i . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2.3 (33) 2.5 (36)

5-Series, E34 (“new-shape”)

518i . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2.0 (29) 2.0 (29)

520i . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2.2 (32) 2.1 (30)

525i, 530i and 535i . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2.0 (29) 2.3 (33)

Torque wrench settingsNm

Automatic transmission sump bolts

Three-speed . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8 to 9

Four-speed . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 to 7

Spark plugs

M10 engines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20 to 30

Except M10 engines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30 to 33

Oxygen sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30 to 33

Wheel bolts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100

Lubricants and fluids

Component or system Lubricant type/specification

Engine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Multigrade engine oil, viscositySAE 10W/40 to 20W/50, to API SG

Cooling system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Ethylene glycol-based antifreeze with corrosion inhibitors

Manual transmission* . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Gear oil, viscosity SAE 80 to API-GL4, or single-grade mineral-based

engine oil, viscosity SAE 20, 30 or 40 to API-SG

Automatic transmission . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Dexron ll type ATF

Final drive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . BMW-approved hypoid gear oil, viscosity SAE 90**

Brake and clutch hydraulic systems . . . . . . . . . . . . . . . . . . . . . . . . . . Hydraulic brake fluid to SAE J 1703 or DOT 4

Power steering . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Dexron ll type ATF

* E34 520i & 525i with air conditioning, E34 530i & 535i - Dexron II type ATF)

** Only available in bulk; refer to your BMW dealer

Capacities*

1•3

1

Engine oil

M10 engines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4.0 litres

M20 engines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4.3 litres

M30 engines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5.8 litres

M40 engines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4.0 litres

Cooling system

M10 engines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7.0 litres

M20 engines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10.5 litres

M30 engines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12.0 litres

M40 engines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7.0 litres

Fuel tank

3-Series, E30

Saloon . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55 litres (early),

64 litres (later)

Estate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63 litres (early),

70 litres (later)

5-Series

E28 (“old-shape”) . . . . . . . . . . . . . . . . . . . . . . . . 70 litres

E34 (“new-shape”) . . . . . . . . . . . . . . . . . . . . . . . 81 litresManual transmission

ZF . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1.2 litres

Getrag . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1.0 to 1.5 litres

Automatic transmission (refill)

3-speed . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2.0 litres

4-speed . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3.0 litres

Final drive capacity (drain and refill)

3-Series, E30 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0.9 litres

5-Series, E28 (“old-shape”) . . . . . . . . . . . . . . . . . . 0.9 litres

5-Series, E34 (“new-shape”) . . . . . . . . . . . . . . . . . 1.7 litres

*All capacities approximate

Servicing Specifications

Page 38 of 228

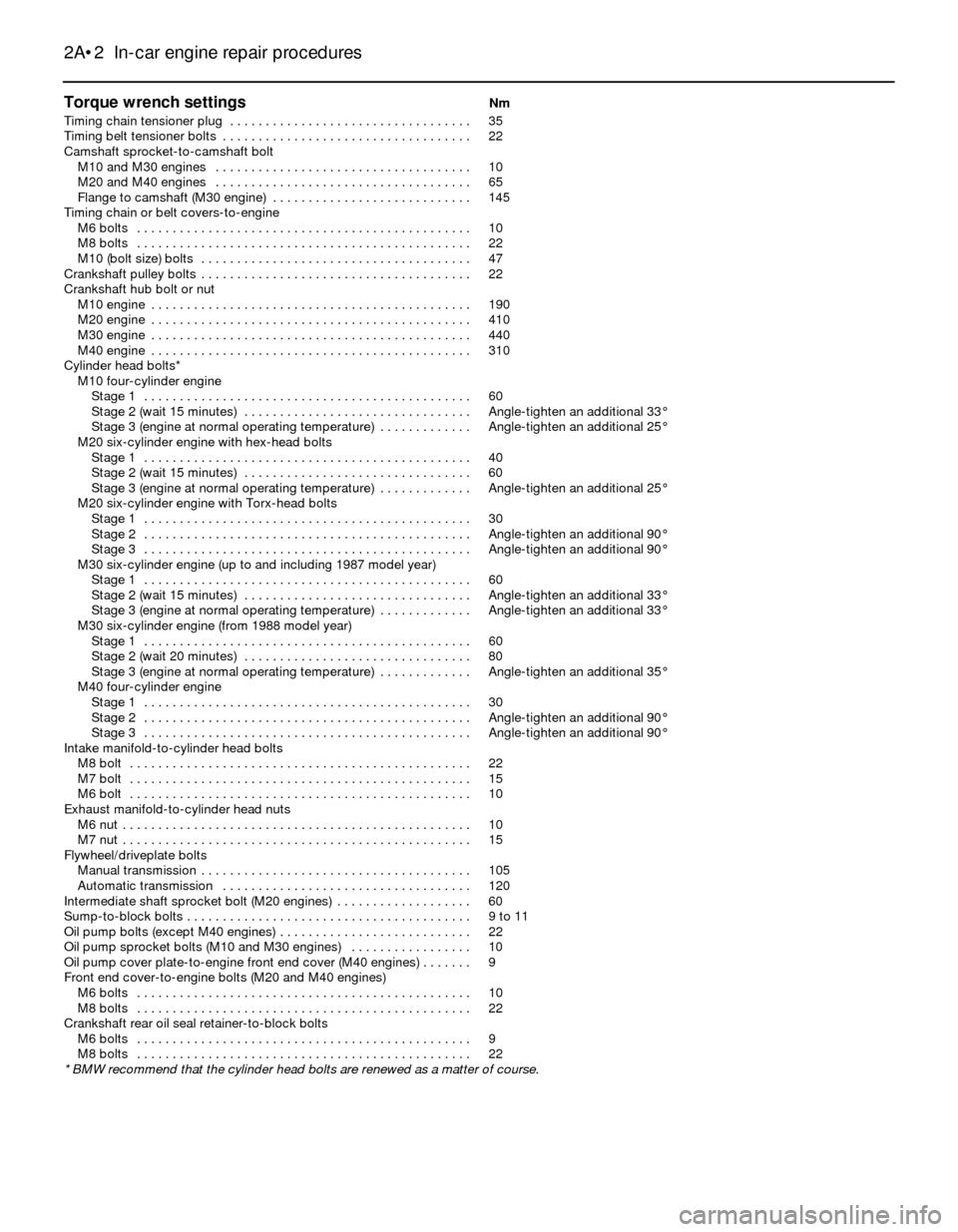

Torque wrench settingsNm

Timing chain tensioner plug . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Timing belt tensioner bolts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Camshaft sprocket-to-camshaft bolt

M10 and M30 engines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

M20 and M40 engines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

Flange to camshaft (M30 engine) . . . . . . . . . . . . . . . . . . . . . . . . . . . . 145

Timing chain or belt covers-to-engine

M6 bolts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

M8 bolts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

M10 (bolt size) bolts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Crankshaft pulley bolts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Crankshaft hub bolt or nut

M10 engine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 190

M20 engine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 410

M30 engine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 440

M40 engine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 310

Cylinder head bolts*

M10 four-cylinder engine

Stage 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

Stage 2 (wait 15 minutes) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Angle-tighten an additional 33°

Stage 3 (engine at normal operating temperature) . . . . . . . . . . . . . Angle-tighten an additional 25°

M20 six-cylinder engine with hex-head bolts

Stage 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Stage 2 (wait 15 minutes) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

Stage 3 (engine at normal operating temperature) . . . . . . . . . . . . . Angle-tighten an additional 25°

M20 six-cylinder engine with Torx-head bolts

Stage 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Stage 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Angle-tighten an additional 90°

Stage 3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Angle-tighten an additional 90°

M30 six-cylinder engine (up to and including 1987 model year)

Stage 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

Stage 2 (wait 15 minutes) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Angle-tighten an additional 33°

Stage 3 (engine at normal operating temperature) . . . . . . . . . . . . . Angle-tighten an additional 33°

M30 six-cylinder engine (from 1988 model year)

Stage 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

Stage 2 (wait 20 minutes) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

Stage 3 (engine at normal operating temperature) . . . . . . . . . . . . . Angle-tighten an additional 35°

M40 four-cylinder engine

Stage 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Stage 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Angle-tighten an additional 90°

Stage 3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Angle-tighten an additional 90°

Intake manifold-to-cylinder head bolts

M8 bolt . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

M7 bolt . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

M6 bolt . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Exhaust manifold-to-cylinder head nuts

M6 nut . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

M7 nut . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Flywheel/driveplate bolts

Manual transmission . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 105

Automatic transmission . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 120

Intermediate shaft sprocket bolt (M20 engines) . . . . . . . . . . . . . . . . . . . 60

Sump-to-block bolts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9 to 11

Oil pump bolts (except M40 engines) . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Oil pump sprocket bolts (M10 and M30 engines) . . . . . . . . . . . . . . . . . 10

Oil pump cover plate-to-engine front end cover (M40 engines) . . . . . . . 9

Front end cover-to-engine bolts (M20 and M40 engines)

M6 bolts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

M8 bolts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Crankshaft rear oil seal retainer-to-block bolts

M6 bolts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

M8 bolts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

* BMW recommend that the cylinder head bolts are renewed as a matter of course.

2A•2 In-car engine repair procedures

Page 54 of 228

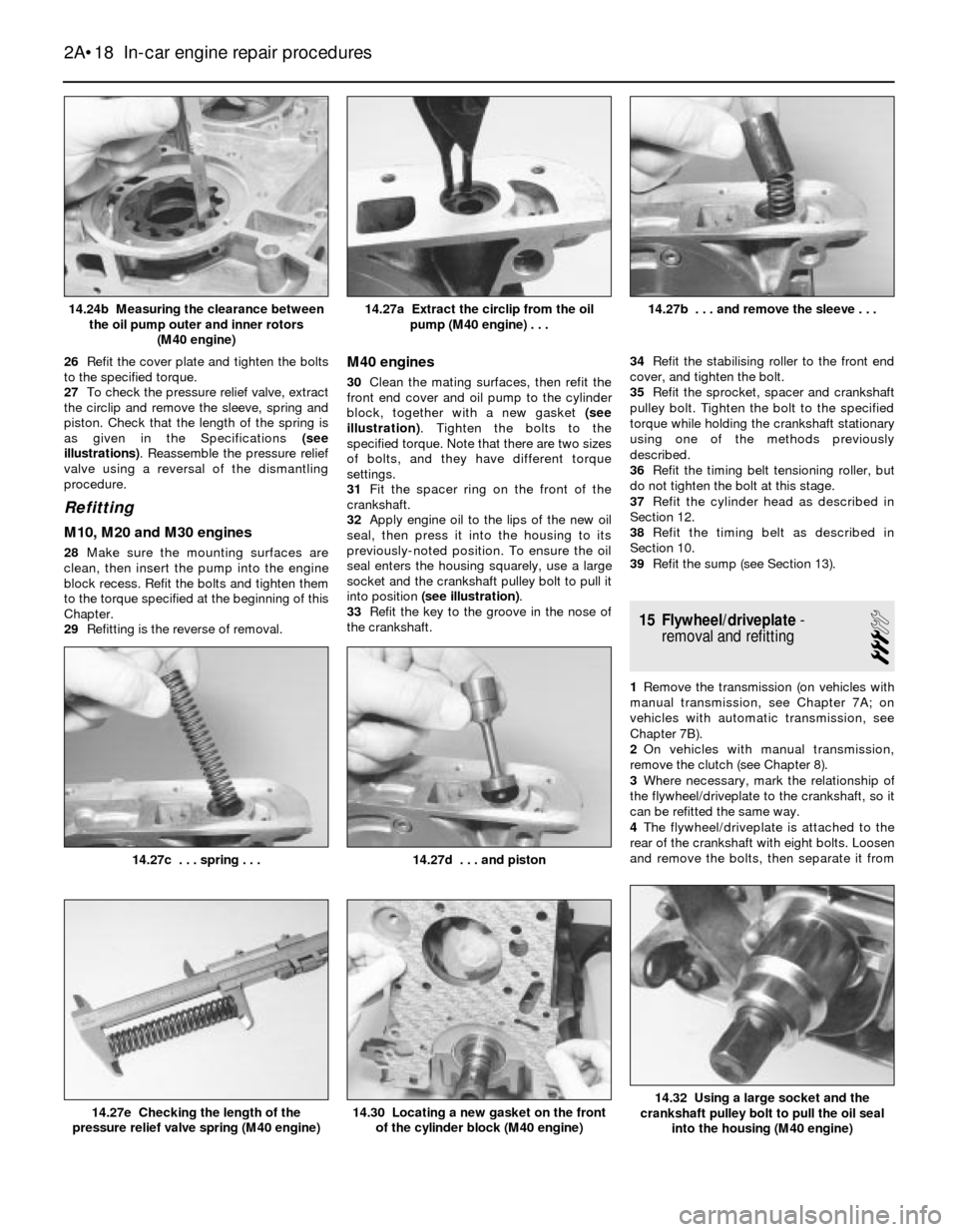

26Refit the cover plate and tighten the bolts

to the specified torque.

27To check the pressure relief valve, extract

the circlip and remove the sleeve, spring and

piston. Check that the length of the spring is

as given in the Specifications (see

illustrations). Reassemble the pressure relief

valve using a reversal of the dismantling

procedure.

Refitting

M10, M20 and M30 engines

28Make sure the mounting surfaces are

clean, then insert the pump into the engine

block recess. Refit the bolts and tighten them

to the torque specified at the beginning of this

Chapter.

29Refitting is the reverse of removal.

M40 engines

30Clean the mating surfaces, then refit the

front end cover and oil pump to the cylinder

block, together with a new gasket (see

illustration). Tighten the bolts to the

specified torque. Note that there are two sizes

of bolts, and they have different torque

settings.

31Fit the spacer ring on the front of the

crankshaft.

32Apply engine oil to the lips of the new oil

seal, then press it into the housing to its

previously-noted position. To ensure the oil

seal enters the housing squarely, use a large

socket and the crankshaft pulley bolt to pull it

into position (see illustration).

33Refit the key to the groove in the nose of

the crankshaft.34Refit the stabilising roller to the front end

cover, and tighten the bolt.

35Refit the sprocket, spacer and crankshaft

pulley bolt. Tighten the bolt to the specified

torque while holding the crankshaft stationary

using one of the methods previously

described.

36Refit the timing belt tensioning roller, but

do not tighten the bolt at this stage.

37Refit the cylinder head as described in

Section 12.

38Refit the timing belt as described in

Section 10.

39Refit the sump (see Section 13).

15 Flywheel/driveplate-

removal and refitting

3

1Remove the transmission (on vehicles with

manual transmission, see Chapter 7A; on

vehicles with automatic transmission, see

Chapter 7B).

2On vehicles with manual transmission,

remove the clutch (see Chapter 8).

3Where necessary, mark the relationship of

the flywheel/driveplate to the crankshaft, so it

can be refitted the same way.

4The flywheel/driveplate is attached to the

rear of the crankshaft with eight bolts. Loosen

and remove the bolts, then separate it from

2A•18 In-car engine repair procedures

14.32 Using a large socket and the

crankshaft pulley bolt to pull the oil seal

into the housing (M40 engine)14.30 Locating a new gasket on the front

of the cylinder block (M40 engine)14.27e Checking the length of the

pressure relief valve spring (M40 engine)

14.27d . . . and piston14.27c . . . spring . . .

14.27b . . . and remove the sleeve . . .14.27a Extract the circlip from the oil

pump (M40 engine) . . .14.24b Measuring the clearance between

the oil pump outer and inner rotors

(M40 engine)

Page 59 of 228

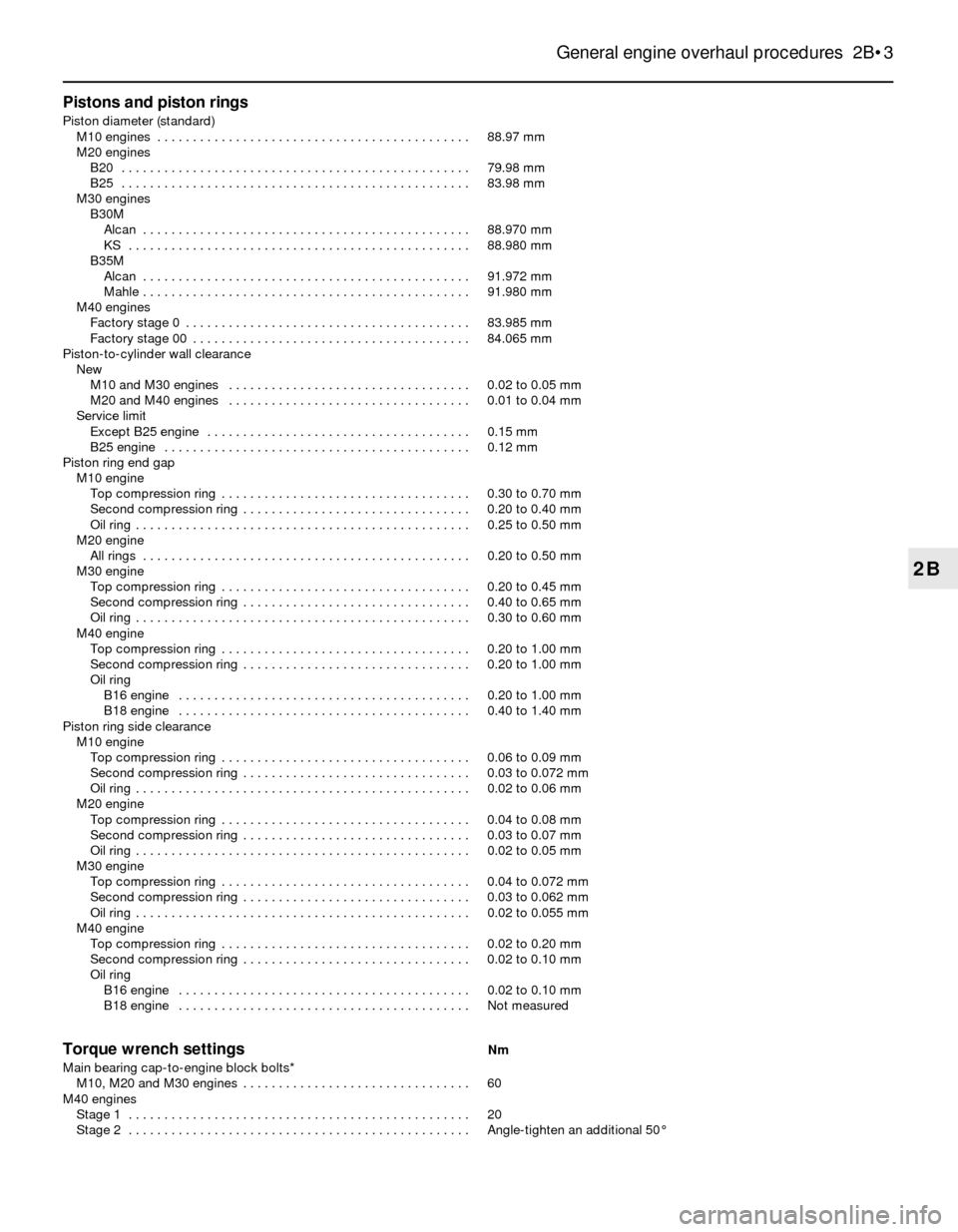

Pistons and piston rings

Piston diameter (standard)

M10 engines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88.97 mm

M20 engines

B20 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79.98 mm

B25 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83.98 mm

M30 engines

B30M

Alcan . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88.970 mm

KS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88.980 mm

B35M

Alcan . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 91.972 mm

Mahle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 91.980 mm

M40 engines

Factory stage 0 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83.985 mm

Factory stage 00 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84.065 mm

Piston-to-cylinder wall clearance

New

M10 and M30 engines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0.02 to 0.05 mm

M20 and M40 engines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0.01 to 0.04 mm

Service limit

Except B25 engine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0.15 mm

B25 engine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0.12 mm

Piston ring end gap

M10 engine

Top compression ring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0.30 to 0.70 mm

Second compression ring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0.20 to 0.40 mm

Oil ring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0.25 to 0.50 mm

M20 engine

All rings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0.20 to 0.50 mm

M30 engine

Top compression ring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0.20 to 0.45 mm

Second compression ring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0.40 to 0.65 mm

Oil ring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0.30 to 0.60 mm

M40 engine

Top compression ring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0.20 to 1.00 mm

Second compression ring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0.20 to 1.00 mm

Oil ring

B16 engine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0.20 to 1.00 mm

B18 engine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0.40 to 1.40 mm

Piston ring side clearance

M10 engine

Top compression ring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0.06 to 0.09 mm

Second compression ring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0.03 to 0.072 mm

Oil ring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0.02 to 0.06 mm

M20 engine

Top compression ring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0.04 to 0.08 mm

Second compression ring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0.03 to 0.07 mm

Oil ring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0.02 to 0.05 mm

M30 engine

Top compression ring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0.04 to 0.072 mm

Second compression ring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0.03 to 0.062 mm

Oil ring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0.02 to 0.055 mm

M40 engine

Top compression ring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0.02 to 0.20 mm

Second compression ring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0.02 to 0.10 mm

Oil ring

B16 engine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0.02 to 0.10 mm

B18 engine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Not measured

Torque wrench settingsNm

Main bearing cap-to-engine block bolts*

M10, M20 and M30 engines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

M40 engines

Stage 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Stage 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Angle-tighten an additional 50°

General engine overhaul procedures 2B•3

2B

Page 60 of 228

Torque wrench settings (continued)Nm

Connecting rod cap bolts/nuts

M10 and M30 engines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

M20 and M40 engines

Stage 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Stage 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Angle-tighten an additional 70°

Camshaft bearing caps (M40 engine) . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Intermediate shaft sprocket-to-shaft bolt (M20 engine) . . . . . . . . . . . . . 60

Oil supply tube bolt(s)

M6 (normal) and M8 (banjo) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

M5 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

* BMW recommend that the main bearing bolts are renewed as a matter of course.

2B•4 General engine overhaul procedures

1 General information

Included in this Part of Chapter 2 are the

general overhaul procedures for the cylinder

head and engine internal components.

The information ranges from advice

concerning preparation for an overhaul and

the purchase of new parts to detailed,

paragraph-by-paragraph procedures covering

removal and refitting of internal components

and the inspection of parts.

The following Sections have been written

based on the assumption that the engine has

been removed from the vehicle. For

information concerning in-vehicle engine

repair, as well as removal and refitting of the

external components necessary for the

overhaul, see Chapter 2A, and Section 7 of

this Part.

The Specifications included in this Part are

only those necessary for the inspection and

overhaul procedures which follow. Refer to

Part A for additional Specifications.

2 Engine overhaul-

general information

It’s not always easy to determine when, or

if, an engine should be completely

overhauled, as a number of factors must be

considered.

High mileage is not necessarily an

indication that an overhaul is needed, while

low mileage doesn’t preclude the need for an

overhaul. Frequency of servicing is probably

the most important consideration. An engine

that’s had regular and frequent oil and filter

changes, as well as other required

maintenance, will most likely give many

thousands of miles of reliable service.

Conversely, a neglected engine may require

an overhaul very early in its life.

Excessive oil consumption is an indication

that piston rings, valve seals and/or valve

guides are in need of attention. Make sure

that oil leaks aren’t responsible before

deciding that the rings and/or guides are

worn. Perform a cylinder compression check

to determine the extent of the work required

(see Section 3).Check the oil pressure: Unscrew the oil

pressure sender unit, and connect an oil

pressure gauge in its place. Measure the oil

pressure with the engine at its normal

operating temperature. Compare your

readings to the oil pressures listed in this

Chapter’s Specifications. If the readings are

significantly below these (and if the oil and oil

filter are in good condition), the crankshaft

bearings and/or the oil pump are probably

worn out. On M10 and M30 engines, the oil

pressure sender unit is located high on the left

rear of the cylinder head. On M20 engines, the

sender unit is threaded into the side of the

engine block, below the oil filter. On M40

engines, the sender unit is threaded into the

rear of the oil filter housing.

Loss of power, rough running, knocking or

metallic engine noises, excessive valve train

noise and high fuel consumption may also

point to the need for an overhaul, especially if

they’re all present at the same time. If a

complete tune-up doesn’t remedy the

situation, major mechanical work is the only

solution.

An engine overhaul involves restoring the

internal parts to the specifications of a new

engine. During an overhaul, new piston rings

are fitted and the cylinder walls are

reconditioned (rebored and/or honed). If a

rebore is done by an engineering works, new

oversize pistons will also be fitted. The main

bearings and connecting big-end bearings are

generally renewed and, if necessary, the

crankshaft may be reground to restore the

journals. Generally, the valves are serviced as

well, since they’re usually in less-than-perfect

condition at this point. While the engine is

being overhauled, other components, such as

the distributor, starter and alternator, can be

rebuilt as well. The end result should be a like-

new engine that will give many thousands of

trouble-free miles. Note: Critical cooling

system components such as the hoses,

drivebelts, thermostat and water pump MUST

be renewed when an engine is overhauled.

The radiator should be checked carefully, to

ensure that it isn’t clogged or leaking (see

Chapters 1 or 3). Also, we don’t recommend

overhauling the oil pump - always fit a new

one when an engine is rebuilt.

Before beginning the engine overhaul, read

through the entire procedure to familiarise

yourself with the scope and requirements ofthe job. Overhauling an engine isn’t difficult if

you follow all of the instructions carefully,

have the necessary tools and equipment and

pay close attention to all specifications;

however, it is time consuming. Plan on the

vehicle being tied up for a minimum of two

weeks, especially if parts must be taken to an

automotive machine shop for repair or recon-

ditioning. Check on availability of parts and

make sure that any necessary special tools

and equipment are obtained in advance. Most

work can be done with typical hand tools,

although a number of precision measuring

tools are required for inspecting parts to

determine if they must be replaced. Often an

automotive machine shop will handle the

inspection of parts and offer advice

concerning reconditioning and renewal. Note:

Always wait until the engine has been

completely disassembled and all components,

especially the engine block, have been

inspected before deciding what service and

repair operations must be performed by an

automotive machine shop. Since the block’s

condition will be the major factor to consider

when determining whether to overhaul the

original engine or buy a rebuilt one, never

purchase parts or have machine work done on

other components until the block has been

thoroughly inspected. As a general rule, time

is the primary cost of an overhaul, so it doesn’t

pay to refit worn or substandard parts.

As a final note, to ensure maximum life and

minimum trouble from a rebuilt engine,

everything must be assembled with care, in a

spotlessly-clean environment.

3 Compression check

2

1A compression check will tell you what

mechanical condition the upper end (pistons,

rings, valves, head gaskets) of your engine is

in. Specifically, it can tell you if the

compression is down due to leakage caused

by worn piston rings, defective valves and

seats, or a blown head gasket. Note:The

engine must be at normal operating

temperature, and the battery must be fully-

charged, for this check.

2Begin by cleaning the area around the

spark plugs before you remove them

(compressed air should be used, if available,

Page 79 of 228

3General

Coolant capacity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . See Chapter 1

Thermostat rating

Opening temperature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80°C (176°F)

Fully open at . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100°C (212°F)

Cooling fan thermo-switch - switching temperatures

Low-speed . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 91°C (196°F)

High-speed . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 99°C (210°F)

Torque wrench settingsNm

Mechanical cooling fan clutch-to-water pump securing

nut (left-hand thread) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Mechanical cooling fan-to-clutch bolts . . . . . . . . . . . . . . . . . . . . . . . . . 10

Water pump bolts

Small bolts (M6) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Large bolts (M8) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Thermostat housing bolts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Chapter 3

Cooling, heating and air conditioning systems

Air conditioner receiver-drier - removal and refitting . . . . . . . . . . . . 16

Air conditioning blower motor (E28/”old-shape” 5-series

models) - removal and refitting . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Air conditioning compressor - removal and refitting . . . . . . . . . . . . . 13

Air conditioning condenser - removal and refitting . . . . . . . . . . . . . . 15

Air conditioning system - precautions and maintenance . . . . . . . . . 12

Antifreeze - general information . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Coolant level check . . . . . . . . . . . . . . . . . . . . . . . . . . See Chapter 1

Coolant temperature sender unit - check and renewal . . . . . . . . . . . 8

Cooling system check . . . . . . . . . . . . . . . . . . . . . . . . See Chapter 1

Cooling system servicing (draining, flushing and refilling)See Chapter 1Engine cooling fan(s) and clutch - check, removal and refitting . . . . 5

Evaporator matrix - removal and refitting . . . . . . . . . . . . . . . . . . . . . 17

General information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Heater and air conditioner control assembly - removal and refitting 10

Heater and air conditioning blower motor - removal,testing and

refitting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Heater matrix - removal and refitting . . . . . . . . . . . . . . . . . . . . . . . . 11

Radiator - removal and refitting . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Thermostat - check and renewal . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Water pump - check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Water pump - removal and refitting . . . . . . . . . . . . . . . . . . . . . . . . . 7

3•1

Easy,suitable for

novice with little

experienceFairly easy,suitable

for beginner with

some experienceFairly difficult,

suitable for competent

DIY mechanic

Difficult,suitable for

experienced DIY

mechanicVery difficult,

suitable for expert

DIY or professional

Degrees of difficulty

Specifications Contents

1 General information

Engine cooling system

All vehicles covered by this manual employ

a pressurised engine cooling system, with

thermostatically-controlled coolant circulation.

An impeller-type water pump mounted on

the front of the block pumps coolant through

the engine. The coolant flows around each

cylinder, and towards the rear of the engine.

Cast-in coolant passages direct coolantaround the intake and exhaust ports, near the

spark plug areas, and in close proximity to the

exhaust valve guides.

A wax-pellet-type thermostat is located in-

line in the bottom hose on M10 engines, in a

housing near the front of the engine on M20

and M30 engines, or behind an elbow under

the timing belt upper cover (on the front of the

cylinder head) on M40 engines. During warm-

up, the closed thermostat prevents coolant

from circulating through the radiator. As the

engine nears normal operating temperature,

the thermostat opens and allows hot coolant

to travel through the radiator, where it’s

cooled before returning to the engine.The pressure in the system raises the

boiling point of the coolant, and increases the

cooling efficiency of the radiator. The cooling

system is sealed by a pressure-type cap. If

the system pressure exceeds the cap

pressure relief value, the excess pressure in

the system forces the spring-loaded valve

inside the cap off its seat, and allows the

coolant to escape through the overflow tube.

The pressure cap on four-cylinder models is

on the top of the radiator; on six-cylinder models,

it’s on top of a translucent plastic expansion

tank. The cap pressure rating is moulded into the

top of the cap. The pressure rating is either

1.0 bar (14 psi) or 1.2 bars (17 psi).

Page 90 of 228

Carburettor (Solex 2BE)

Main jet

Stage 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . X120

Stage 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . X110

Air correction jet

Stage 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 140

Stage 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

Venturi diameter

Stage 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24 mm

Stage 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28 mm

Idle fuel jet

Stage 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47.5 mm

Idle air jet

Stage 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 180

Float needle valve diameter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2.0 mm

Throttle positioner coil resistance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0.97 to 1.63 ohms

Intake air temperature resistance

-10º C . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8200 to 10 500 ohms

20º C . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2200 to 2700 ohms

80º C . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 300 to 360 ohms

Float level

Stage 1 float chamber . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27.0 to 29.0 mm

Stage 2 float chamber . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29.0 to 31.0 mm

Fuel pressure checks (carburettor engines)

Fuel pump delivery pressure (engine idling) . . . . . . . . . . . . . . . . . . . . . . 0.1 to 0.3 bars

Fuel pressure checks (fuel injection engines)

Fuel system pressure (relative to intake manifold pressure)

3-Series (E30)

316i with M40/B16 engine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3.0 ± 0.06 bars

318i with M10/B18 engine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2.5 to 3.0 bars

318i with M40/B18 engine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3.0 ± 0.06 bars

320i with M20/B20 engine (L-Jetronic) . . . . . . . . . . . . . . . . . . . . . . 2.5 to 3.0 bars

320i with M20/B20 engine (Motronic) . . . . . . . . . . . . . . . . . . . . . . . 2.5 ± 0.05 bars

325i with M20/B25 engine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3.0 ± 0.05 bars

5-Series (E28/”old-shape”)

All models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2.5 to 3.0 bars

5-Series (E34/”new-shape”)

518i with M40/B18 engine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3.0 ± 0.06 bars

All other models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2.5 to 3.0 bars

Fuel system hold pressure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2.1 bars

Fuel pump maximum pressure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6.3 to 6.9 bars

Fuel pump hold pressure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5.5 bars

Transfer pump pressure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0.28 to 0.35 bars

Injectors

Injector resistance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14.5 to 17.5 ohms

Accelerator cable free play . . . . . . . . . . . . . . . . . . . . . . . . . . . 1.0 mm

Torque wrench settingsNm

Carburettor mountings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Fuel pump to cylinder head . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Throttle body nuts/bolts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19 to 26

4•2 Fuel and exhaust systems

1 General information

With the exception of early models (316 and

518 models) all engines are equipped with

electronic fuel injection.

Early 316 and 518 models are equipped

with Solex carburettors. The carburettor fitted

is either a Solex 2B4 (early models) or

2BE (later models). The mechanical fuel pumpis driven by an eccentric lobe on the

camshaft.

Fuel injection models are equipped with

either the L-Jetronic or the Motronic fuel

injection system. From 1988, fuel injection

models are equipped with an updated version

of the Motronic system - this system is easily

distinguished from the earlier system by the

absence of a cold start injector. The electric

fuel pump is located beneath the rear of the

vehicle, or inside the fuel tank. The fuel pump

relay on Motronic systems is activated from aearth signal from the Motronic control unit

(ECU). The fuel pump operates for a few

seconds when the ignition is first switched on,

and it continues to operate only when the

engine is actually running.Air intake system

The air intake system consists of the air

filter housing, the airflow meter and throttle

body (fuel injection models), and the intake

manifold. All components except the intake

manifold are covered in this Chapter; for

Page 98 of 228

Caution: If the radio in your

vehicle is equipped with an anti-

theft system, make sure you

have the correct activation code before

disconnecting the battery. Refer to the

information on page 0-7 at the front of this

manual before detaching the cable.

Note: If, after connecting the battery, the

wrong language appears on the instrument

panel display, refer to page 0-7 for the

language resetting procedure.

8Loosen the cable adjuster locknuts, and

detach the cable from its support bracket

located on the intake manifold (see

illustration).

9Pinch the plastic retainer with a pair of

needle-nose pliers, and push it out of the

bracket (see illustration).10Pull the cable down through the slot and

away from the bracket (see illustrations).

11Working from underneath the driver’s side

of the facia, reach up and detach the

accelerator cable from the top of the pedal.

12Pull the cable through the bulkhead, from

the engine compartment side.

13Refitting is the reverse of removal. Adjust

the cable as described earlier.

10 Carburettor-

general information

1Early models are fitted with a Solex 2B4

carburettor, and later models are fitted with a

Solex 2BE carburettor. Both carburettors are

of downdraught, two-stage type. The first

stage is operated mechanically by the

accelerator pedal, and the second stage by

vacuum control.

2Each stage has its own float chamber, float

assembly and needle valve, designed to

reduce the effects of braking and centrifugal

forces.

3On the 2B4 version, the primary stage

choke valve is operated by an automatic

choke (a bi-metal spring which is electrically

heated) during the warm-up period. Warm-up

enrichment is also provided by a coolant-

operated thermal valve and air temperature-

controlled flow valve.

4On the 2BE version, an electronic controlunit is used to automatically adjust the

carburettor settings during warm-up and

normal temperature operation. The control

unit is located beneath the right-hand side of

the facia.

11 Carburettor-

removal and refitting

2

Removal

1Remove the air cleaner as described in

Section 8.

2Disconnect the accelerator cable from the

carburettor with reference to Section 9.

3On automatic transmission models,

disconnect the kickdown cable.

4Disconnect the wiring from the carburettor,

noting the location of each wire.

5Remove the screw, and disconnect the

earth cable from the throttle positioner

bracket (see illustration).

6Disconnect the vacuum hoses, noting that

the hose with the white tracer is located on

the white plastic ‘T’ piece, and the distributor

vacuum hoses are located on the side of the

carburettor (see illustration).

7On the 2B4 carburettor, disconnect and

plug the coolant hoses from the TM (thermal

starter) valve.

8Disconnect the fuel supply hose (see

illustration).

4•10 Fuel and exhaust systems

11.8 Disconnect the fuel supply hose

(arrowed)11.6 Note the locations of the carburettor

vacuum hoses (arrowed) before

disconnecting them11.5 Remove the screw, and disconnect

the carburettor earth cable (arrowed)

9.10b After the cable is off the throttle

valve assembly, remove the plastic

retainer from the cable

9.10a Rotate the throttle valve and remove

the cable end from the slotted portion of

the valve9.9 Pinch the plastic retainer, and push it

through the bracket recess on the throttle

valve9.8 Push the rubber grommet from the

rear, and separate the cable from the

bracket

Page 101 of 228

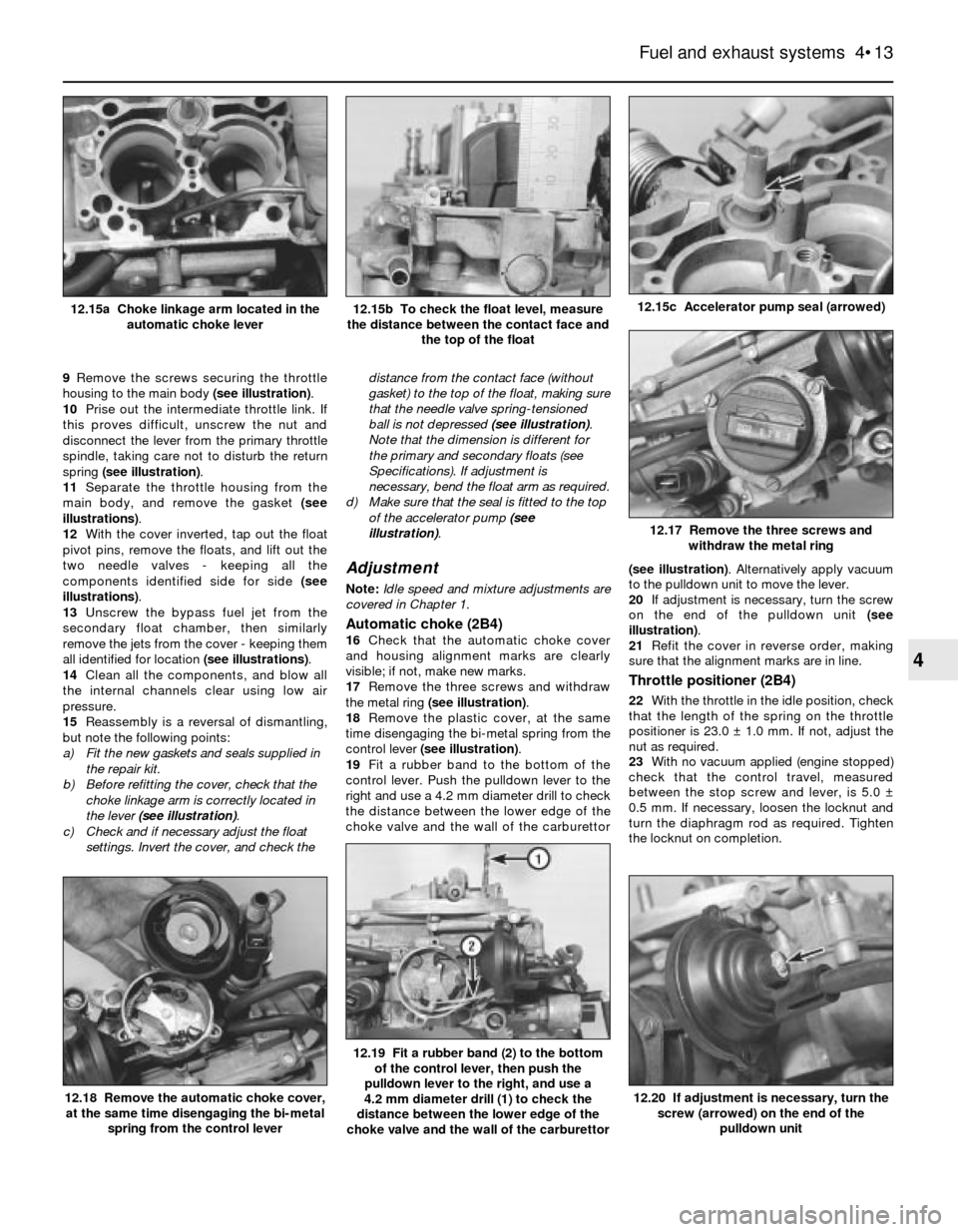

9Remove the screws securing the throttle

housing to the main body (see illustration).

10Prise out the intermediate throttle link. If

this proves difficult, unscrew the nut and

disconnect the lever from the primary throttle

spindle, taking care not to disturb the return

spring (see illustration).

11Separate the throttle housing from the

main body, and remove the gasket (see

illustrations).

12With the cover inverted, tap out the float

pivot pins, remove the floats, and lift out the

two needle valves - keeping all the

components identified side for side (see

illustrations).

13Unscrew the bypass fuel jet from the

secondary float chamber, then similarly

remove the jets from the cover - keeping them

all identified for location (see illustrations).

14Clean all the components, and blow all

the internal channels clear using low air

pressure.

15Reassembly is a reversal of dismantling,

but note the following points:

a) Fit the new gaskets and seals supplied in

the repair kit.

b) Before refitting the cover, check that the

choke linkage arm is correctly located in

the lever (see illustration).

c) Check and if necessary adjust the float

settings. Invert the cover, and check thedistance from the contact face (without

gasket) to the top of the float, making sure

that the needle valve spring-tensioned

ball is not depressed (see illustration).

Note that the dimension is different for

the primary and secondary floats (see

Specifications). If adjustment is

necessary, bend the float arm as required.

d) Make sure that the seal is fitted to the top

of the accelerator pump (see

illustration).

Adjustment

Note:Idle speed and mixture adjustments are

covered in Chapter 1.

Automatic choke (2B4)16Check that the automatic choke cover

and housing alignment marks are clearly

visible; if not, make new marks.

17Remove the three screws and withdraw

the metal ring (see illustration).

18Remove the plastic cover, at the same

time disengaging the bi-metal spring from the

control lever (see illustration).

19Fit a rubber band to the bottom of the

control lever. Push the pulldown lever to the

right and use a 4.2 mm diameter drill to check

the distance between the lower edge of the

choke valve and the wall of the carburettor(see illustration). Alternatively apply vacuum

to the pulldown unit to move the lever.

20If adjustment is necessary, turn the screw

on the end of the pulldown unit (see

illustration).

21Refit the cover in reverse order, making

sure that the alignment marks are in line.

Throttle positioner (2B4)

22With the throttle in the idle position, check

that the length of the spring on the throttle

positioner is 23.0 ± 1.0 mm. If not, adjust the

nut as required.

23With no vacuum applied (engine stopped)

check that the control travel, measured

between the stop screw and lever, is 5.0 ±

0.5 mm. If necessary, loosen the locknut and

turn the diaphragm rod as required. Tighten

the locknut on completion.

Fuel and exhaust systems 4•13

12.15b To check the float level, measure

the distance between the contact face and

the top of the float12.15a Choke linkage arm located in the

automatic choke lever

12.20 If adjustment is necessary, turn the

screw (arrowed) on the end of the

pulldown unit

12.19 Fit a rubber band (2) to the bottom

of the control lever, then push the

pulldown lever to the right, and use a

4.2 mm diameter drill (1) to check the

distance between the lower edge of the

choke valve and the wall of the carburettor

12.17 Remove the three screws and

withdraw the metal ring

12.15c Accelerator pump seal (arrowed)

12.18 Remove the automatic choke cover,

at the same time disengaging the bi-metal

spring from the control lever

4

Page 130 of 228

Torque wrench settingsNm

Front disc brake caliper

Caliper guide (mounting) bolts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30 to 35

Caliper bracket-to-strut housing bolts

3-Series, E30 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 123

5-Series, E28 (“old-shape”) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 123

5-Series, E34 (“new-shape”) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 110

Rear disc brake caliper

Caliper guide (mounting) bolts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30 to 35

Carrier-to-trailing arm bolts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

Brake hose-to-caliper fitting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14 to 17

Master cylinder-to-brake servo nuts

3-Series . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

5-Series . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25 to 29

Brake servo mounting nuts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22 to 24

Hydraulic line-to-hydraulic brake servo threaded

fittings - 5-Series, E28 (“old-shape”) . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Wheel bolts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . See Chapter 1

9•2 Braking system

1 General information

All 3-Series models, and 5-Series E28 (“old-

shape”) models, are equipped with front disc

brakes and either rear drum or rear disc

brakes. 5-Series E34 (“new-shape”) models

have disc brakes front and rear. Front and

rear brakes are self-adjusting on all models.

Some later models are equipped with an Anti-

lock Braking System (ABS); this is described

in Section 2.

Hydraulic system

The hydraulic system consists of two

separate circuits. The master cylinder has

separate reservoirs for the two circuits; in the

event of a leak or failure in one hydraulic

circuit, the other circuit will remain operative.

Brake servo

The vacuum brake servo, utilising engine

manifold vacuum and atmospheric pressure

to provide assistance to the hydraulically

operated brakes, is mounted on the bulkhead

in the engine compartment.

A hydraulic brake servo system is used on

5-Series E28 models. This system uses

hydraulic pressure from the power steering

pump to assist braking.

Handbrake

The handbrake operates the rear brakes,

and is cable-operated via a lever mounted in

the centre console. The handbrake assembly

on rear drum brake models is part of the rear

drum brake assembly, and is self-adjusting.

On rear disc brake models, the handbrake

uses a pair of brake shoes located inside the

centre portion of the rear brake disc, and is

manually-adjusted.

Brake pad wear warning system

The brake pad wear warning system is

linked to a red warning light in the instrumentcluster, which comes on when the brake pads

have worn down to the point at which they

require renewal. DO NOT ignore this reminder.

If you don’t renew the pads shortly after the

brake pad wear warning light comes on, the

brake discs will be damaged.

On some models, the brake pad wear

warning system also includes an early

warning light that comes on only when the

brake pedal is depressed, letting you know in

advance that the pads need to be renewed.

The wear sensor is attached to the brake

pads. The sensor is located at the left front

wheel; on some models, there is another

sensor at the right rear wheel. The wear

sensor is part of a closed circuit. Once the

pads wear down to the point at which they’re

flush with the sensor, the disc grinds away the

side of the sensor facing the disc. Thus, the

wire inside the sensor is broken, and the red

light on the instrument panel comes on.

Always check the sensor(s) when renewing

the pads. If you change the pads before the

warning light comes on, the sensor(s) may still

be good; once the light has come on, renew

the sensor.

Service

After completing any operation involving

dismantling of any part of the brake system,

always test drive the vehicle to check for

proper braking performance before resuming

normal driving. When testing the brakes, try to

select a clean, dry, road with no camber (ie as

flat as possible) and with no other traffic.

Conditions other than these can lead to

inaccurate test results.

Test the brakes at various speeds with both

light and heavy pedal pressure. The vehicle

should stop evenly, without pulling to one side

or the other. Avoid locking the brakes,

because this slides the tyres and diminishes

braking efficiency and control of the vehicle.

Tyres, vehicle load and wheel alignment are

factors which also affect braking

performance.

2 Anti-lock Braking system

(ABS)- general information

The Anti-lock Braking System is designed

to maintain vehicle control, directional stability

and optimum deceleration under severe

braking conditions on most road surfaces. It

does so by monitoring the rotational speed of

each wheel and controlling the brake line

pressure to each wheel during braking. This

prevents the wheels from locking up.

The ABS system has three main

components - the wheel speed sensors, the

electronic control unit, and the hydraulic

control unit. The sensors - one at each wheel

since 1985, but at both front wheels and one

at the rear differential on earlier models - send

a variable voltage signal to the control unit,

which monitors these signals, compares them

to its program information, and determines

whether a wheel is about to lock up. When a

wheel is about to lock up, the control unit

signals the hydraulic unit to reduce hydraulic

pressure (or not increase it further) at that

wheel’s brake caliper. Pressure modulation is

handled by electrically-operated solenoid

valves.

If a problem develops within the system, an

“ABS” warning light will glow on the

dashboard. Sometimes, a visual inspection of

the ABS system can help you locate the

problem. Carefully inspect the ABS wiring

harness. Pay particularly close attention to the

harness and connections near each wheel.

Look for signs of chafing and other damage

caused by incorrectly-routed wires. If a wheel

sensor harness is damaged, the sensor

should be renewed (the harness and sensor

are integral).

Warning: DO NOT try to repair an

ABS wiring harness. The ABS

system is sensitive to even the

smallest changes in resistance. Repairing

the harness could alter resistance values