battery BMW 525i 1998 E39 Workshop Manual

[x] Cancel search | Manufacturer: BMW, Model Year: 1998, Model line: 525i, Model: BMW 525i 1998 E39Pages: 1002

Page 478 of 1002

Downloaded from www.Manualslib.com manuals search engine

160-8

I Fuel Tank and Fuel Pump

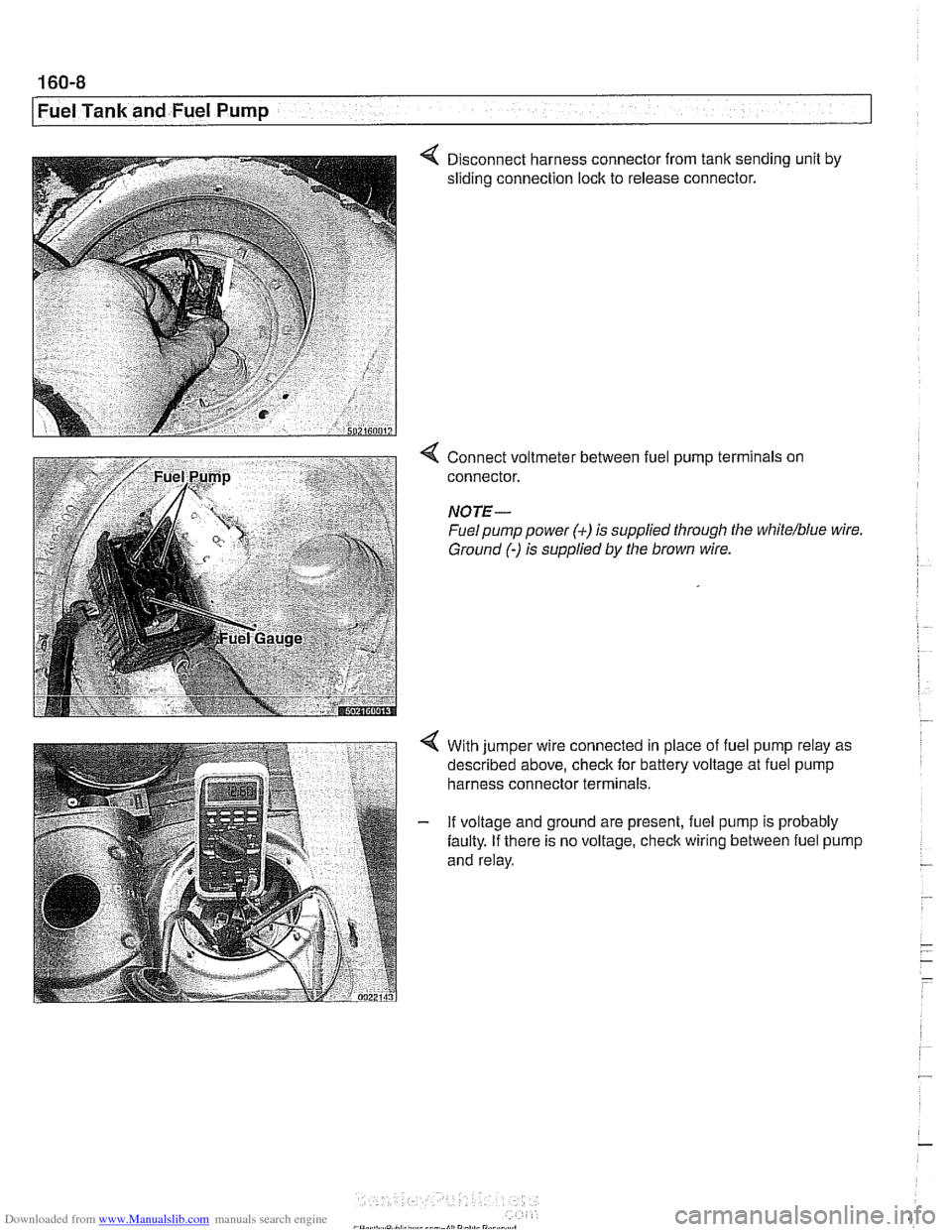

4 Disconnect harness connector from tank sending unit by

sliding connection lock to release connector.

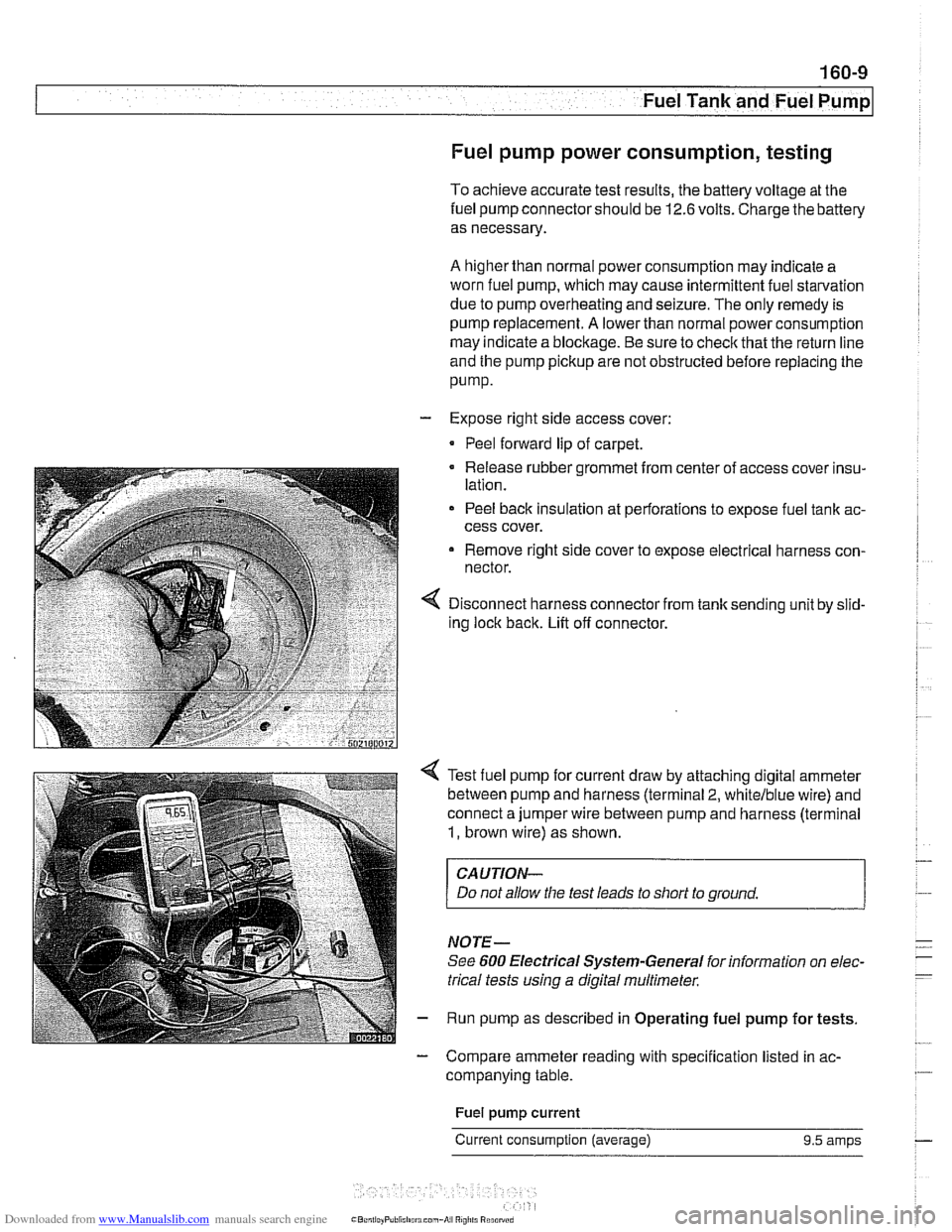

Connect voltmeter between fuel pump terminals on

connector.

NOTE-

Fuel pump power (+) is supplied through the white/blue wire

Ground

(-) is supplied by the brown wire.

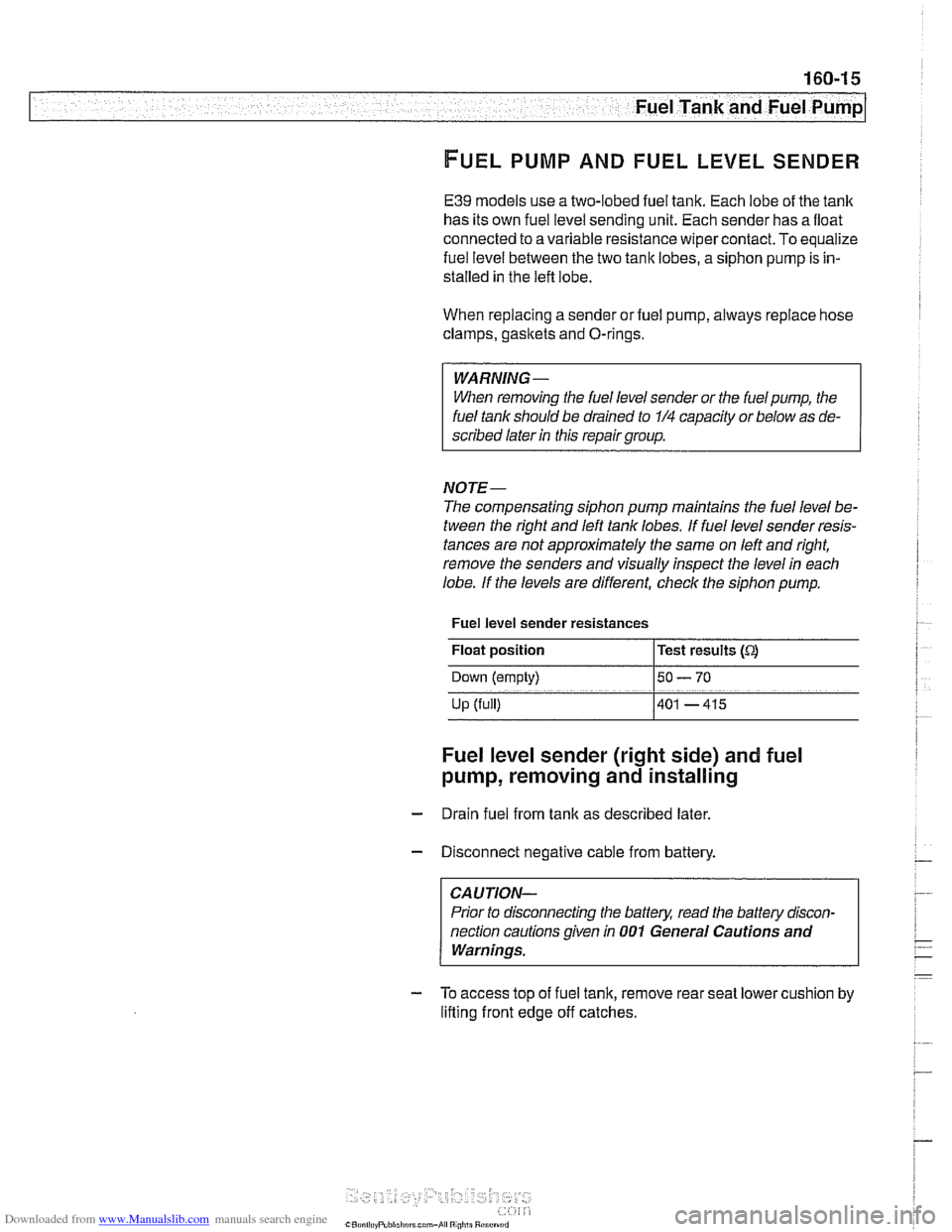

With jumper wire connected in place of fuel pump relay as

described above, check for battery voltage at fuel pump

harness connector terminals.

If voltage and ground are present, fuel pump is probably

faulty. If there is no voltage, check wiring between fuel pump

and relay.

Page 479 of 1002

Downloaded from www.Manualslib.com manuals search engine

.- -

Fuel Tank and Fuel purnpl

Fuel pump power consumption, testing

To achieve accurate test results, the battery voltage at the

fuel pump connector should be

12.6 volts. Charge the battery

as necessary.

A higher than normal power consumption may indicate a

worn fuel pump, which may cause intermittent fuel starvation

due to pump overheating and seizure. The only remedy is

pump replacement.

A lower than normal power consumption

may indicate a blockage. Be sure to check that the return line

and the pump pickup are not obstructed before replacing the

pump.

- Expose right side access cover:

Peel forward lip of carpet.

Release rubber grommet from center of access cover insu-

lation.

Peel back insulation at perforations to expose fuel tank ac-

cess cover.

Remove right side cover to expose electrical harness con-

nector.

Disconnect harness connector from tank sending unit by slid-

ing lock back. Lift off connector.

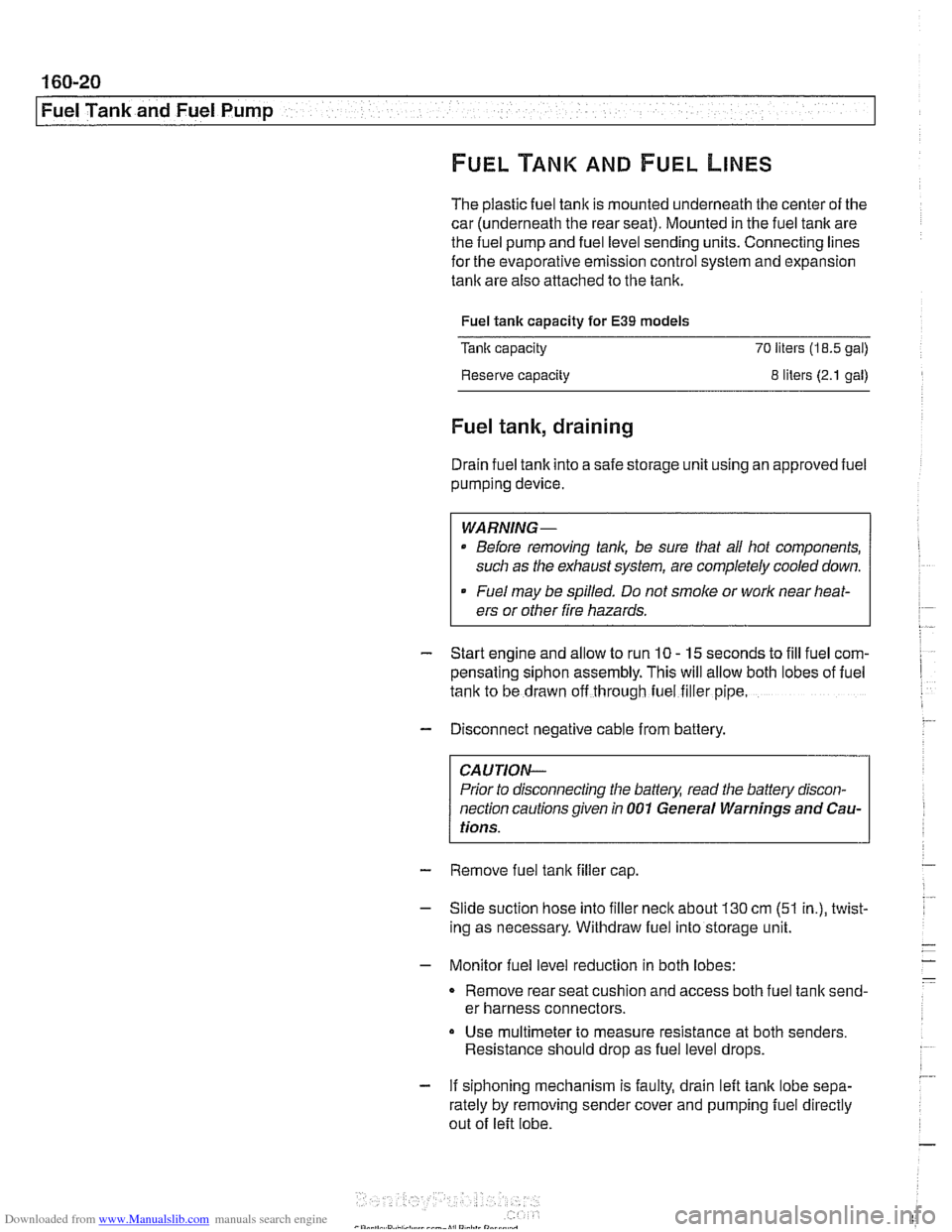

Test fuel pump for current draw by attaching digital ammeter

between pump and harness (terminal

2, whitelblue wire) and

connect a jumper wire between pump and harness (terminal

1, brown wire) as shown.

CAUTION-

Do not allow the test leads to short to ground.

NOTE-

See 600 Electrical Systern-General for information on elec-

trical tests

using a digital multirneter.

Run pump as described in Operating fuel pump for tests.

- Compare ammeter reading with specification listed in ac-

companying table.

Fuel

pump current

Current consumption (average) 9.5 amps

Page 485 of 1002

Downloaded from www.Manualslib.com manuals search engine

.-

err- .- Fuel Tank and Fuel Pump

FUELPUMP AND FUELLEVELSENDER

E39 models use a two-lobed fuel tank. Each lobe of the tank

has its own fuel level sending unit. Each sender has a float

connected to a variable resistance wipercontact. To equalize

fuel level between the two

tank lobes, a siphon pump is in-

stalled in the left lobe.

When replacing asender or fuel pump, always replace hose

clamps,

gasltets and O-rings.

WARNING

-

When removing the fuel level sender or the fuel pump, the

fuel tank should be drained to

1/4 capacity or below as de-

scribed later in this repair group.

NOTE-

The compensating siphon pump maintains the fuel level be-

tween the right and left tank lobes. If fuel level sender resis-

tances are not approximately the same on left and right,

remove the senders and visually inspect the level in each

lobe. If the levels are different, check the siphon pump.

Fuel level sender resistances

Float position

l~est results (Q

Down (empty) 150- 70

Up (full) 1401 -415

Fuel level sender (right side) and fuel

pump, removing

and installing

- Drain fuel from tank as described later.

- Disconnect negative cable from battery.

CAUTION-

Prior to disconnecting the battery, read the battery discon-

nection cautions given in

001 General Cautions and

Warnings.

- To access top of fuel tank, remove rear seat lower cushion by

lifting front edge

off catches.

Page 490 of 1002

Downloaded from www.Manualslib.com manuals search engine

--

I Fuel Tank and Fuel Pump

The plastic fuel tank is mounted underneath the center of the

car (underneath the rear seat). Mounted in the fuel tank are

the fuel pump and fuel level sending units. Connecting lines

for the evaporative emission control system and expansion

tank are also attached to the tank.

Fuel

tank capacity for E39 models

Tank capacity

70 liters (18.5 gal)

Reserve capacity

8 liters (2.1 gal)

Fuel tank, draining

Drain fuel tank into a safe storage unit using an approved fuel

pumping device.

WARNING-

# Before removing tank, be sure that all hot components,

such as the exhaust system, are completely cooled down.

Fuel may be spilled. Do not smoke or

work near heat-

ers or other fire hazards.

- Start engine and allow to run 10 - 15 seconds to fill fuel com-

pensating siphon assembly. This will allow both lobes of fuel

tank to he drawn off through fuel filler pipe,

- Disconnect negative cable from battery.

CAUTION-

Prior to disconnecting the batteg read the battery discon-

nection cautions given

in 001 General Warnings and Cau-

tions.

- Remove fuel tank filler cap

- Slide suction hose into filler neck about 130 cm (51 in.), twist-

ing as necessary. Withdraw fuel into storage unit.

- Monitor fuel level reduction in both lobes:

- Remove rear seat cushion and access both fuel tank send-

er harness connectors.

Use multimeter to measure resistance at both senders,

Resistance should drop as fuel level drops.

- If siphoning mechanism is faulty, drain left tank lobe sepa-

rately by removing sender cover and pumping fuel directly

out of left lobe.

Page 491 of 1002

Downloaded from www.Manualslib.com manuals search engine

Fuel Tank and Fuel pump/

- Remove suction hose from tank filler neck carefully to avoid

damaging filler neck baffle plate.

CAUTION-

After finishing repairs but before starling engine, be sure

there is at least

5 liters (1.5 gallons) of fuel in tanlc. The fuel

pump will be damaged if run without fuel.

Fuel tank, removing and installing

- Remove fuel tank filler cap and drain tank as described

earlier.

- Disconnect negative cable from battery.

CAUTION-

Prior to disconnecting the battea read the battery discon-

nection cautions given in

001 General Cautions and

Warnings.

- Remove rear seat bottom cushion. Peel forward lip of carpet

from beneath seat cushion and carefully peel back insulation

to expose fuel tank access cover on left and right sides. Re-

move covers.

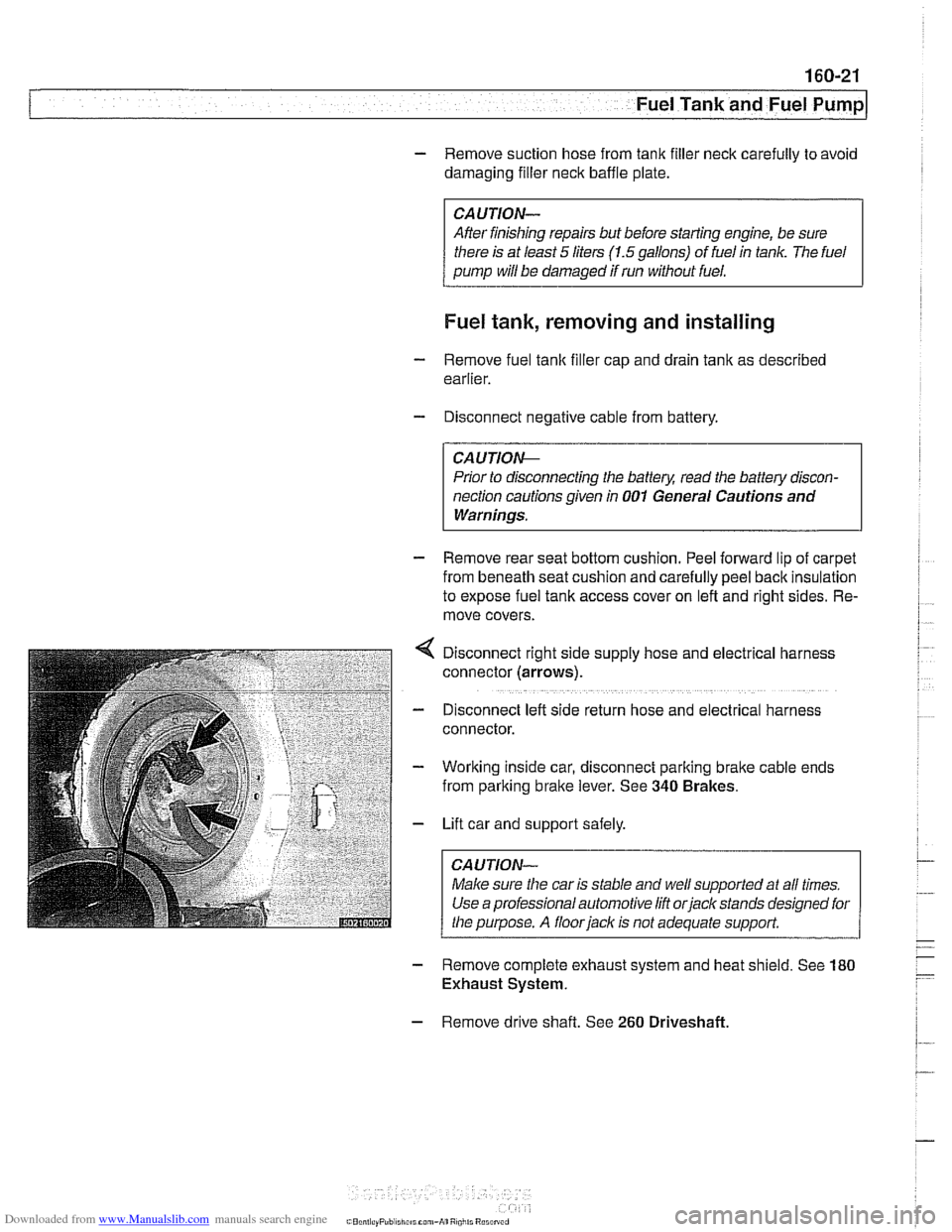

Disconnect right side supply hose and

electr~cal harness

connector (arrows).

D~sconnect left side return hose and electrical harness

connector.

Working inside car, disconnect parking

bralte cable ends

from parking brake lever. See

340 Brakes.

Lift car and support safely.

Make sure the car is stable and

we/ supported at all times.

Use a professional automotive lift

orjack stands designed for

the purpose. A floorjaclc is not adequate support.

- Remove complete exhaust system and heat shield. See 180

Exhaust System.

- Remove drive shaft. See 260 Driveshaft

Page 501 of 1002

Downloaded from www.Manualslib.com manuals search engine

170-5

Radiator and Cooling System

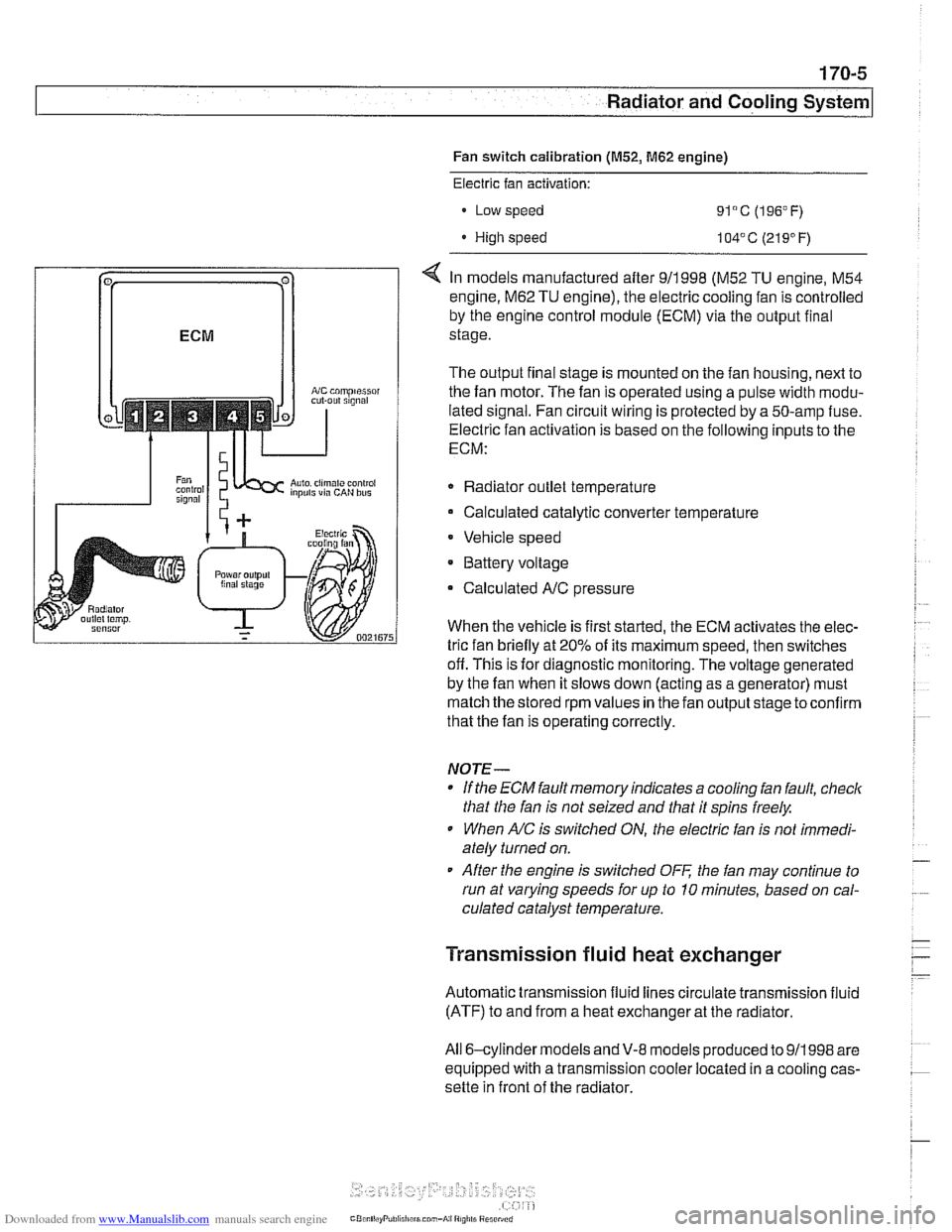

Fan switch calibration (M52, M62 engine)

coniprairoi OUt rlgnal

Auto. ciimilte ~ontioi inpuls via CAN bus

Electric fan activation:

Low speed

91°C (196°F)

High speed 104' C (21 9' F)

< In models manufactured after 911998 (M52 TU engine, M54

engine.

M62 TU engine), the electric cooling fan is controlled

by the engine control module (ECM) via the output final

stage.

The output final stage is mounted on the fan housing, next to

the fan motor. The fan is operated using a pulse width modu-

lated signal. Fan circuit wiring is protected by a 50-amp fuse.

Electric fan activation is based on the following inputs to the

ECM:

Radiator outlet temperature

Calculated catalytic converter temperature

Vehicle speed

* Battery voltage

Calculated

A/C pressure

When the vehicle is first started, the ECM activates the elec-

tric fan briefly at 20% of its maximum speed, then switches

off. This is for diagnostic monitoring. The voltage generated

by the fan when it slows down (acting as a generator) must

match the stored rpm values in the fan output stage toconfirm

that the fan is operating correctly.

NOTE-

If the ECM fault memory indicates a cooling fan fault, check

that the fan is not seized and that it spins freely.

When

A/C is switched ON, the electric fan is not immedi-

ately turned on.

After the engine is switched

OFF the fan may continue to

run at varying speeds for up to 10 minutes, based on cal-

culated catalyst temperature.

Transmission fluid heat exchanger

Automatic transmission fluid lines circulate transmission fluid

(ATF) to and from a heat exchanger at the radiator.

All 6-cylinder

models andV-8 models produced to 911998 are

equipped with a transmission cooler located in a cooling cas-

sette in front of the radiator.

Page 503 of 1002

Downloaded from www.Manualslib.com manuals search engine

Warnings and cautions

Obse~e the following warnings and cautions when worlting

on the cooling system.

WARNING -

. At normal operating temperature the cooling system is

pressurized. Allow the system to cool as long as possible

before opening (a minimum of one hour), then release the

cap slowly to allow safe release ofpressure.

a Releasing the coolant system pressure lowers the cool-

ant boilingpoint and the coolant may boil suddenly. Use

1 heavy and wear eye and face protection to

guard against scalding.

Use extreme care when draining and disposing of en-

gine coolant. Coolant is poisonous and lethal to hu-

mans andpets. Pets are attracted to coolant because

of its sweet smell and taste. Seek medical attention im-

mediately if coolant is ingested.

CAUTIOG

Avoid adding cold water to the coolant while the engine is

hot or overheated. If it is necessary to add coolant to a

hol

system, do so only with the engine running and coolanl

pump turning.

To avoid excess silicate gel precipitation in the cooling

system and loss of cooling capacity, use BMW coolant

or equivalent low silicate antifreeze.

a If oil enters the cooling system, the radiator, expansion

tank and heating circuit must be flushed with cleaning

agent. BMW recommends removal of the radiator and

expansion

tank to flush.

When

worlcing on the cooling system, cover the alter-

nator to protect it against coolant drips.

Prior to disconnecting the battery, read the battery dis-

connection cautions given in

001 General Warnings

and Cautions.

Begin the diagnosis of cooling system problems with a thor-

ough visual inspection.

If no visual faults are found, it is rec-

ommend that the engine control module (ECM) fault memory

be checked for stored diagnostic trouble codes

(DTCs) using

BMW scan tool

DlSplus or equivalent.

Page 580 of 1002

Downloaded from www.Manualslib.com manuals search engine

Manual Transmission

- Thoroughly clean guide sleeve mounting bolts, sealing sur-

faces, and threads. Apply

Loctite8243 or equivalent thread

locking compound to guide sleeve bolts. Reinstall guide

sleeve and

spacer(s).

Tightening torques

Guide sleeve to transmission case

M6 10 Nm (89 in-lb)

* M8 x 22 18 Nm (13 ft-lb)

- Max30 25 Nm (18 ft-lb)

- Reinstall transmission.

TRANSMISSION REMOVAL AND

~NSTALLATION

Removal and installation of the transmission is best accorn-

plished on a lifl using a transmission jack.The engine must be

supported using appropriate support equipment. This allows

the engine to pivot on its mounts to access the upper

Torx-

head bolts at the bellhousing.

WARNING-

Male sure the car is stable and well supported at all times.

Use a professional aulomorive lift or jack slanos des~gned

lor the purpose. A floor jack is nor adequare supporr.

The removal of the transmission may upset the balance

of the vehicle on a

lifl.

Transmission, removing and installing

- Disconnect negative (-) cable from battery.

CAUTION-

Prior to disconnecting the battery, read the battery discon-

nection cautions given

in 001 Warnings and Cautions.

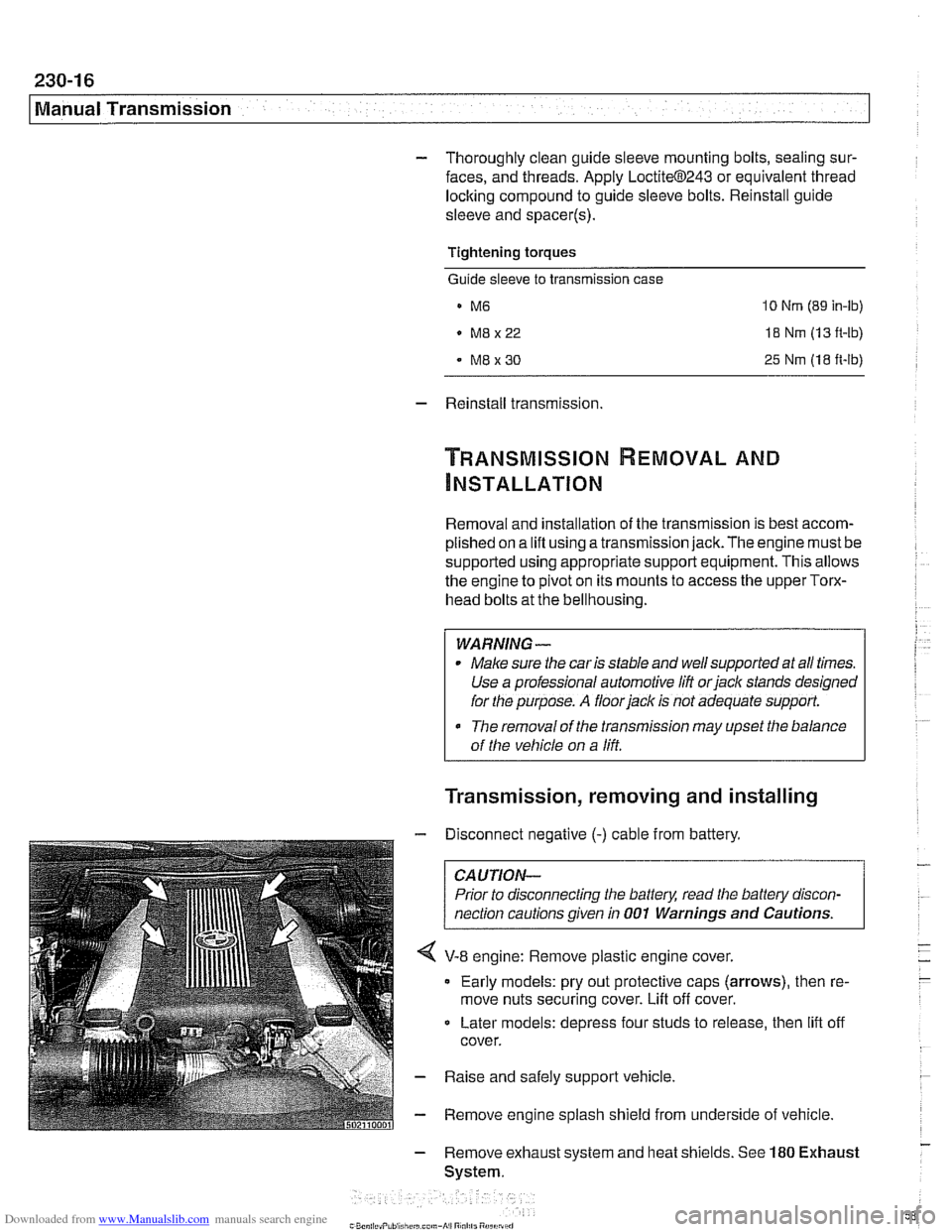

V-8 engine: Remove plastic engine cover.

Early models: pry out protective caps (arrows), then re-

move nuts securing cover. Lift off cover.

Later models: depress four studs to release, then

lift off

cover.

- Raise and safely support vehicle

- Remove engine splash shield from underside of vehicle

- Remove exhaust system and heat shields. See 180 Exhaust

System.

Page 594 of 1002

Downloaded from www.Manualslib.com manuals search engine

240-1 0

Automatic Transmission

TRANSMISSION REMOVAL AND

INSTALLATION

Removal and installation of the transmission is best accorn-

plished on an automotive lift using a transmission jack. Use

caution and safe workshop practices when working beneath

car and lowering transmission.

Torx-head bolts are used to mount the transmission to the

bellhousing.

Besure to have appropriate tools on hand before

starting the job.

WARNING-

Be sure the vehicle is properly supported. The removal of the

transmission may upset the balance of the vehicle on a lift

CAUJION-

Tilting the engine to remove the transmission can lead to

damaae to various components due to

laclc of clearance. 1

Transmission, removing and installing

WARNING -

Allow engine and transmission to cool down before starting

work on the transmission.

- Disconnect negative (-) cable from battery.

CAUTION-

Prior to disconnecting the battery, read the battery discon-

nection cautions given in

001 General Cautions and

Warninas.

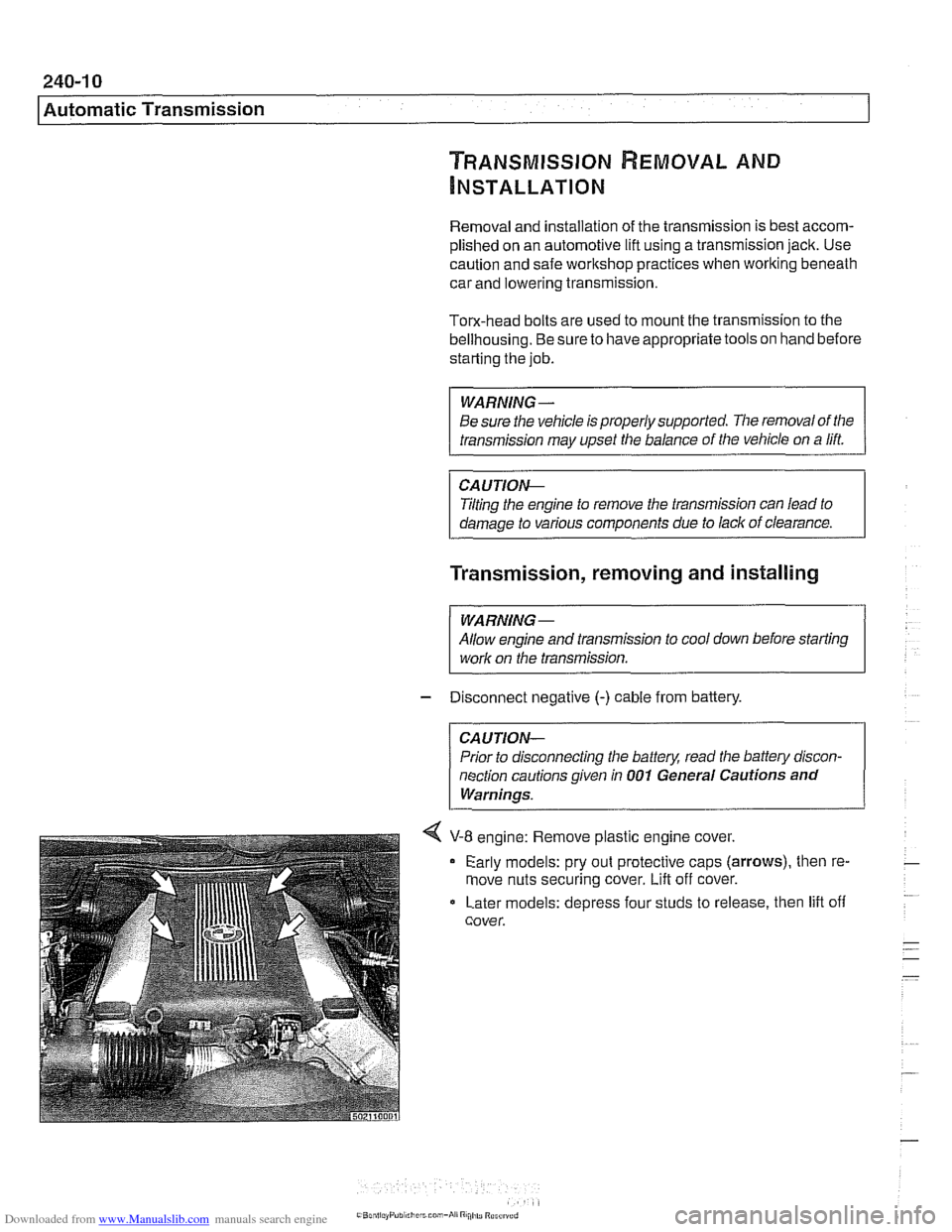

4 V-8 engine: Remove plastic engine cover.

Early models: pry out protective caps

(arrows), then re-

move nuts securing cover.

Lift off cover.

Later models: depress four studs to release, then lift off

cover.

Page 622 of 1002

Downloaded from www.Manualslib.com manuals search engine

[~us~ension, Steering and Brakes - General

This section of the manual covers front and rear suspension,

braking and steering systems, and contains wheel, tire and

wheel alignment information and specifications. Also covered

here are the integrated braking and suspension systems in-

cluding

antilock braking (ABS), traction control (ASCIDSC),

and electronic height control (EHC).

Vehicle ride height information is at the end of this repair

group. Alignment information is in

320 Steering and Wheel

Alignment.

Aluminum suspension components

In order to reduce vehicle weight, aluminum suspension com-

ponents are used in some models. A test with a magnet will

easily reveal the metal used. If working with aluminum com-

ponents, be sure to read and follow the cautions below.

CAUTION-

* Due to the chemical and corrosion characteristics of alumi-

num, do not bring into contact with battery acid.

Do not use wire brushes with brass or iron bristles.

Only use brushes with stainless steel bristles.

Do not expose to flying sparks from

grinding/cutting op-

erations.

Do not subject to steel welding splashes.

Do not expose to temperatures over

80°C (176"F),

even for short periods. Temperatures in painting facili-

ties are not a problem.

The E39 front suspension subframe is used as a rigid mount-

ing platform for the front suspension arms, stabilizer bar and

steering gear.

The suspension arms, known as the lower control arms and

the tension struts (thrust arms), are connected to the

sub-

frame through rubber bushings. The arms are connected to

the steering

knucltles in a double pivot configuration.

Each front strut assembly includes a tubular strut and a coil

spring. The upper strut mount includes a bearing. The lower

end of each strut housing is fitted to the steering knuckle. The

integral wheel bearing and hub are bolted to the steering

Iknucltle.

6-cylinder and V-8 models use different steering systems and

other front suspension components.