lock BMW 525i 1998 E39 Workshop Manual

[x] Cancel search | Manufacturer: BMW, Model Year: 1998, Model line: 525i, Model: BMW 525i 1998 E39Pages: 1002

Page 330 of 1002

Downloaded from www.Manualslib.com manuals search engine

11 9-1 0

Lubrication System

Oil pan, removing and installing

(6-cylinder)

The engine oil pan removal procedure requires that the en-

gine be supported from the top and the front suspension

sub-

frame be lowered.

- Raise car and place securely on jack stands.

Make sure the car is stable and well supported at all times.

Use a professional automotive

lift orjackstands designed for

- Remove splash shield from under engine.

- Drain engine oil as described in 020 Maintenance.

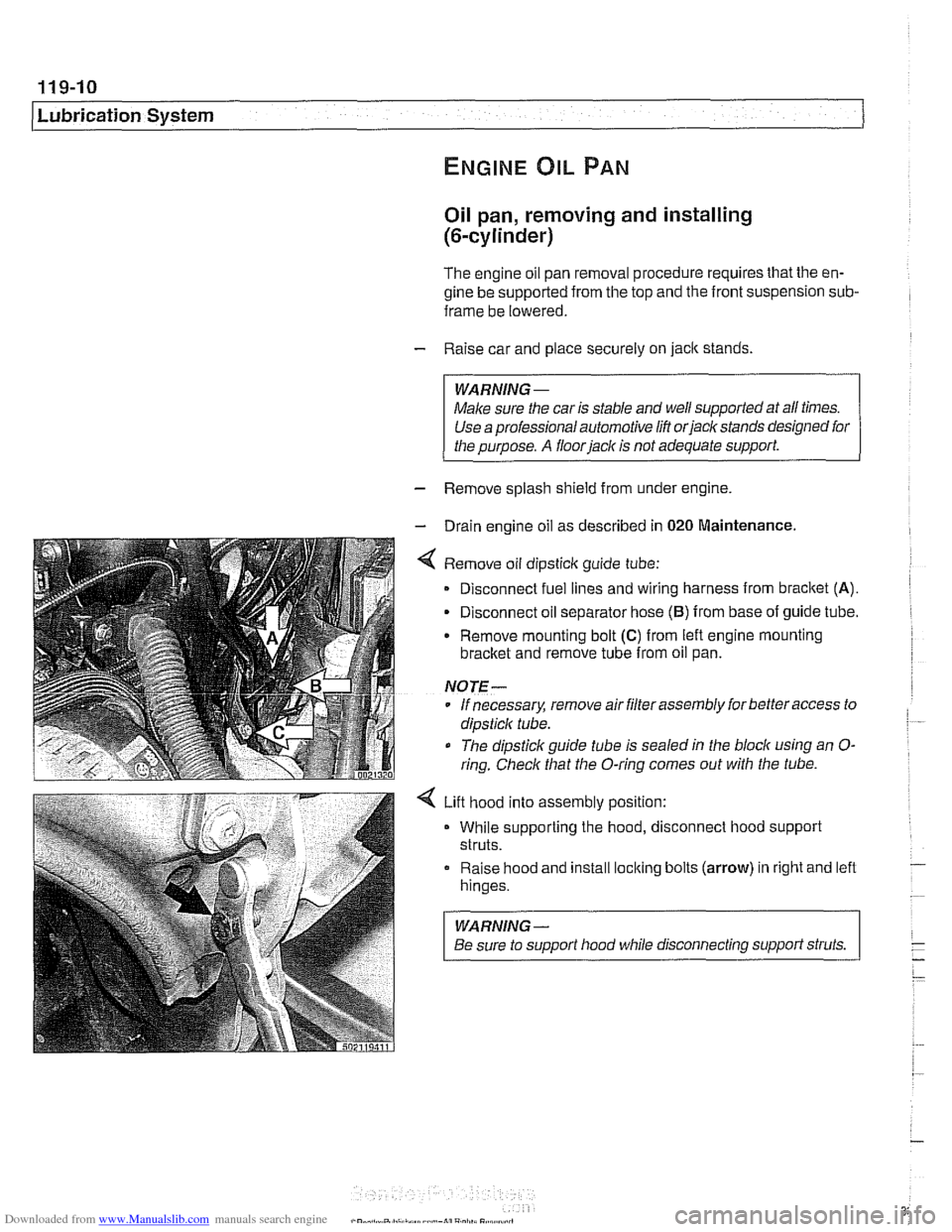

4 Remove oil dipsticlc guide tube:

Disconnect fuel lines and wiring harness from

bracket (A).

- Disconnect oil separator hose (B) from base of guide tube.

Remove mounting bolt

(C) from left engine mounting

bracket and remove tube from oil pan.

NOTE-

* If necessary, remove air filter assembly for better access to

dipsticlc tube.

The dipstick guide tube is sealed in the block using an

O-

ring. Check that the O-ring comes out with the tube.

4 Lift hood into assembly position:

While supporting the hood, disconnect hood support

struts.

Raise hood and install

loclting bolts (arrow) in right and left

hinges.

WARNING-

Be sure to support hood while disconnecting support struts.

Page 332 of 1002

Downloaded from www.Manualslib.com manuals search engine

119-12

Lubrication System 1

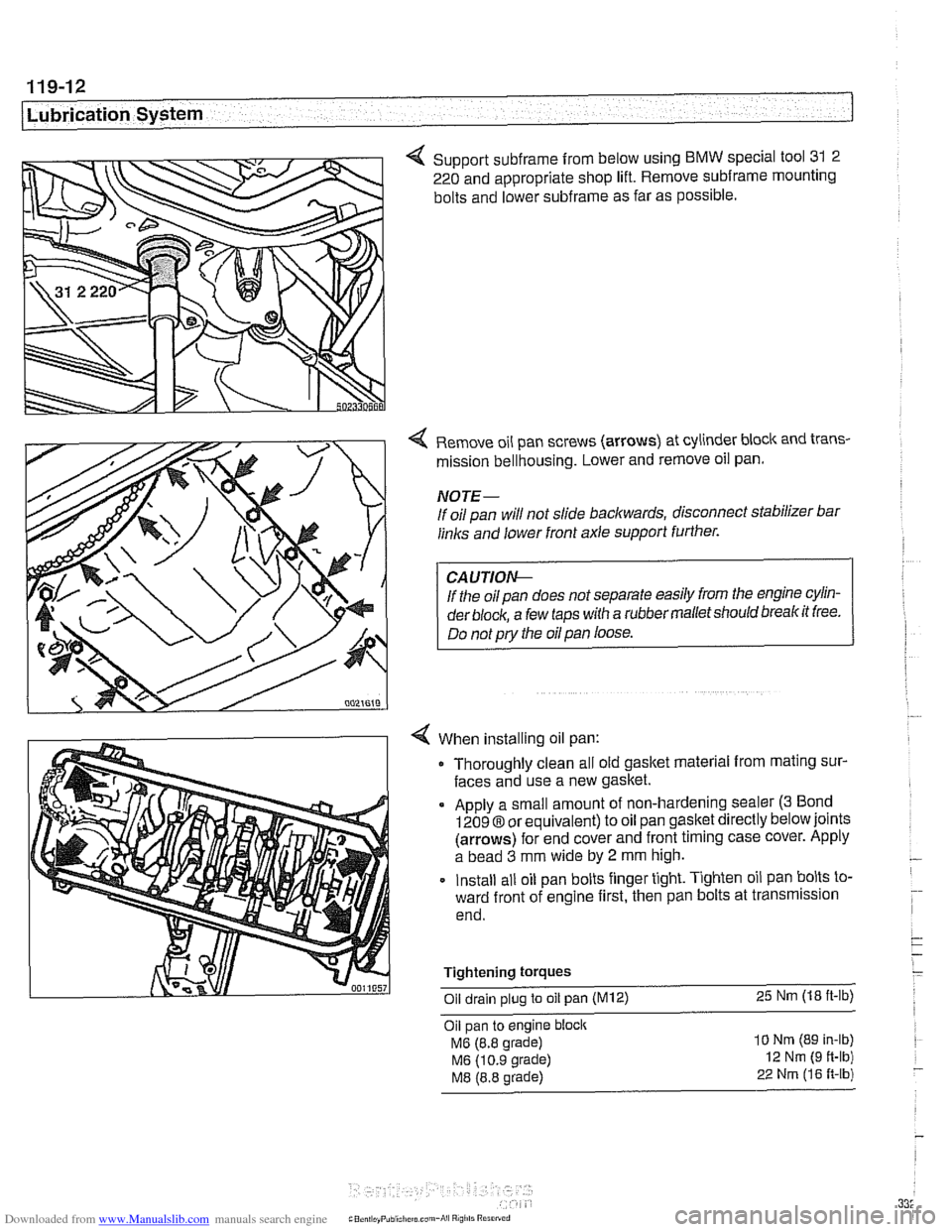

4 Support subframe from below using BMW special tool 31 2

220 and appropriate shop lift. Remove

subframe mounting

bolts and lower

subframe as far as possible.

Remove oil pan screws (arrows) at cylinder block and trans-

mission bellhousing. Lower and remove oil pan.

NOTE-

If oil pan will not slide backwards, disconnect stabilizer bar

links and lower front axle support further.

If the oil pan does not separate easily from the engine cylin-

der

block, a few taps with a rubber malletshould breakit free.

Do not

pry the oil pan loose.

When installing oil pan: Thoroughly clean all old gasket material from mating sur-

faces and use a new gasket.

Apply a small amount of non-hardening sealer

(3 Bond

12098 or equivalent) to oil pan gasket directly below joints

(arrows) for end cover and front timing case cover. Apply

a bead

3 mm wide by 2 mm high.

Install all oil pan bolts finger tight. Tighten oil pan bolts to-

ward front of engine first, then pan bolts at transmission

end.

Tightening

torques

Oil drain plug to oil pan (M12) 25 Nm (18 ft-lb)

Oil pan to engine block

MG (8.8 grade)

MG (10.9 grade)

M8 (8.8 grade)

10 Nm (89 In-lb)

12 Nm (9 ft-lb)

22 Nrn (16 R-lb)

Page 333 of 1002

![BMW 525i 1998 E39 Workshop Manual Downloaded from www.Manualslib.com manuals search engine

-- . - .. . - Lubrication system]

- Remainder of installation is reverse of removal.

Replace self-locking nuts when reinstalling front BMW 525i 1998 E39 Workshop Manual Downloaded from www.Manualslib.com manuals search engine

-- . - .. . - Lubrication system]

- Remainder of installation is reverse of removal.

Replace self-locking nuts when reinstalling front](/img/1/2822/w960_2822-332.png)

Downloaded from www.Manualslib.com manuals search engine

-- . - .. . - Lubrication system]

- Remainder of installation is reverse of removal.

Replace self-locking nuts when reinstalling front suspen-

sion components.

Use new oil dipstick tube sealing O-ring.

After adding engine oil, start and run engine. Raise engine

speed to 2,500 rpm until oil pressure warning light goes out

(about 5 seconds).

NOTE-

BMW does not specify a front end alignment following this

procedure.

Tightening torques Front subfrarne to body rail

(M12, use new bolts)

8.8 grade

10.9 grade

12.9 grade 77 Nrn

(57 ft-lb)

105 Nrn (77 ft-lb)

110 Nrn (81 ft-lb)

Stabilizer bar link to stabilizer bar

65 Nrn (48 ft-lb)

Steering shaft universal joint clamping bolt

(use new bolt)

19 Nrn (14 it-lb)

Lower oil pan, removing and installing (V-8)

- The V-8 engine is equipped with a 2-piece oil pan. The fas-

teners in

V-8 engine oil pump assembly, including the

sprocket retaining nut, are known to loosen and fall off into

the oil pan. Be sure to install these fasteners with Loctite

O

or equivalent thread locking product and torque to specifica-

tions.

CAUTION-

It is recommended that the oil pump retaining bolts and oil

pump drive sprocket retaining nut tightening torque be

checkedany time the

oilpan is removed.

- Raise car and place securely on jack stands.

WARNING-

Make sure the car is stable and well supported at all times.

Use a professional automotive lift

orjack stands designed for

- Remove splash shield from under engine.

- Drain engine oil

- On cars with automatic transmission, remove ATF cooler line

brackets from oil pan.

Page 335 of 1002

Downloaded from www.Manualslib.com manuals search engine

... . . Lubrication sy=

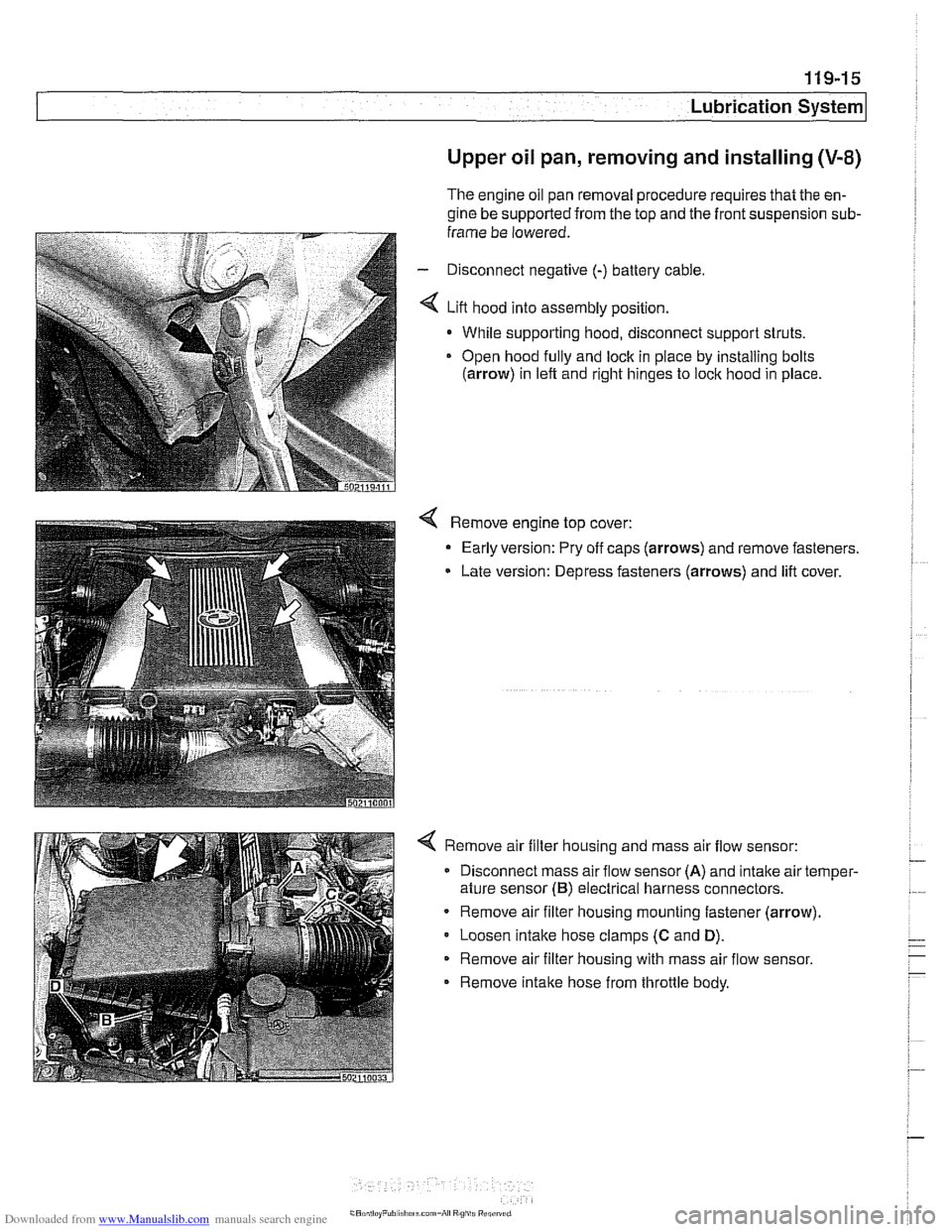

Upper oil pan, removing and installing (V-8)

The engine oil pan removal procedure requires that the en-

gine be supported from the top and the front suspension

sub-

frame be lowered.

- Disconnect negative (-) battery cable

4 Lift hood into assembly position.

- While supporting hood, disconnect support struts.

Open hood

fully and lock in piace by installing bolts

(arrow) in left and right hinges to lock hood in place

4 Remove engine top cover:

- Early version: Pry off caps (arrows) and remove fasteners.

Late version: Depress fasteners (arrows) and lift cover.

4 Remove air filter housing and mass air flow sensor:

Disconnect mass air flow sensor

(A) and intake air temper-

ature sensor

(B) electrical harness connectors.

Remove air filter housing mounting fastener (arrow)

Loosen

intake hose clamps (C and D).

Remove air filter housing with mass air flow sensor.

Remove intake hose from throttle body.

Page 337 of 1002

Downloaded from www.Manualslib.com manuals search engine

1 19-1 7

Lubrication System

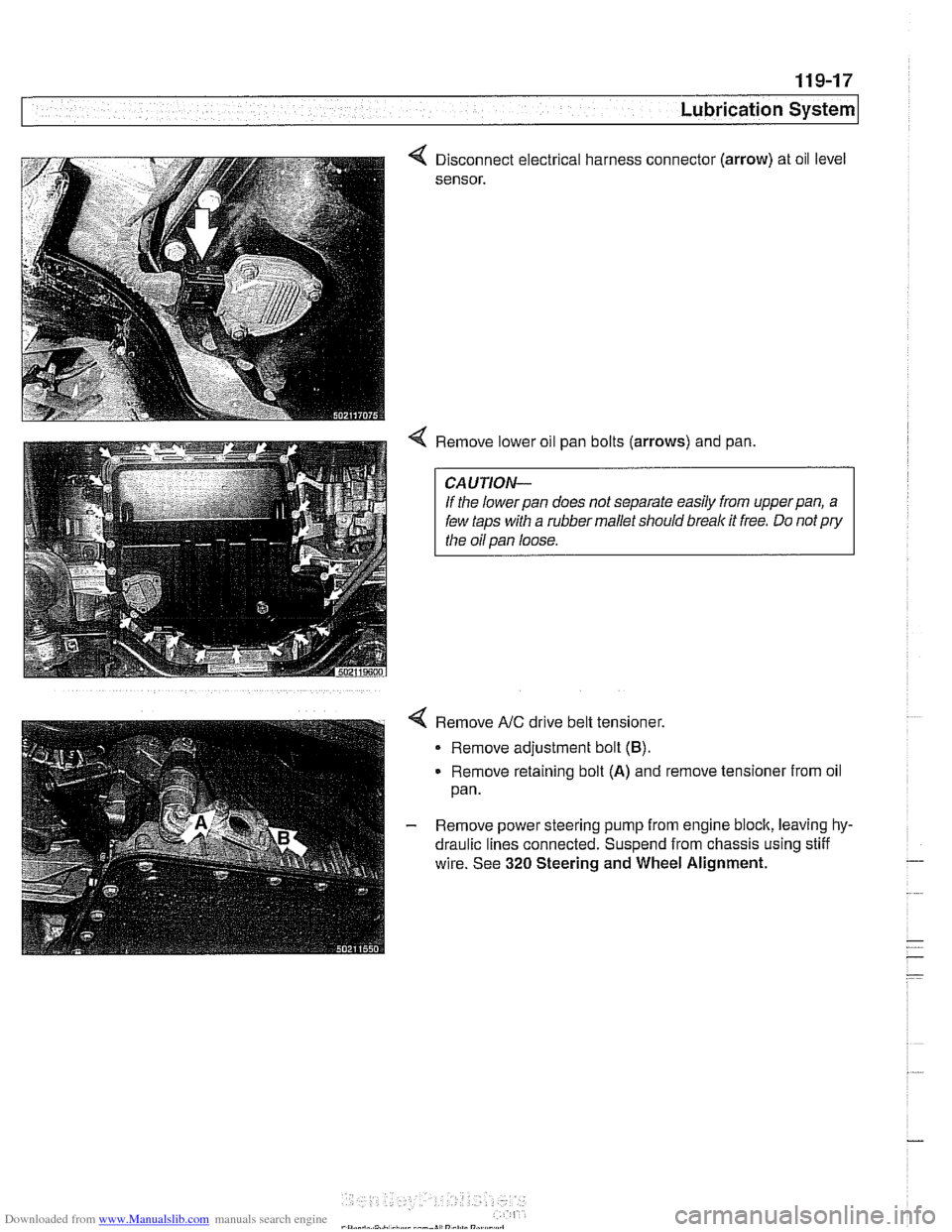

Disconnect electrical harness connect01

sensor.

. (arrow)

4 Remove lower oil pan bolts (arrows) and pan, oil

level

CAUTION-

If the lowerpan does not separate easily from upperpan, a

few taps with a rubber mallet should break it free. Do not pry

the oil pan loose.

Remove

NC drive belt tensioner.

Remove adjustment bolt

(B).

Remove retaining bolt (A) and remove tensioner from oil

pan.

- Remove power steering pump from engine block, leaving hy-

draulic lines connected. Suspend from chassis using stiff

wire. See

320 Steering and Wheel Alignment.

Page 342 of 1002

Downloaded from www.Manualslib.com manuals search engine

/Lubrication System

Oil pump, removing and installing

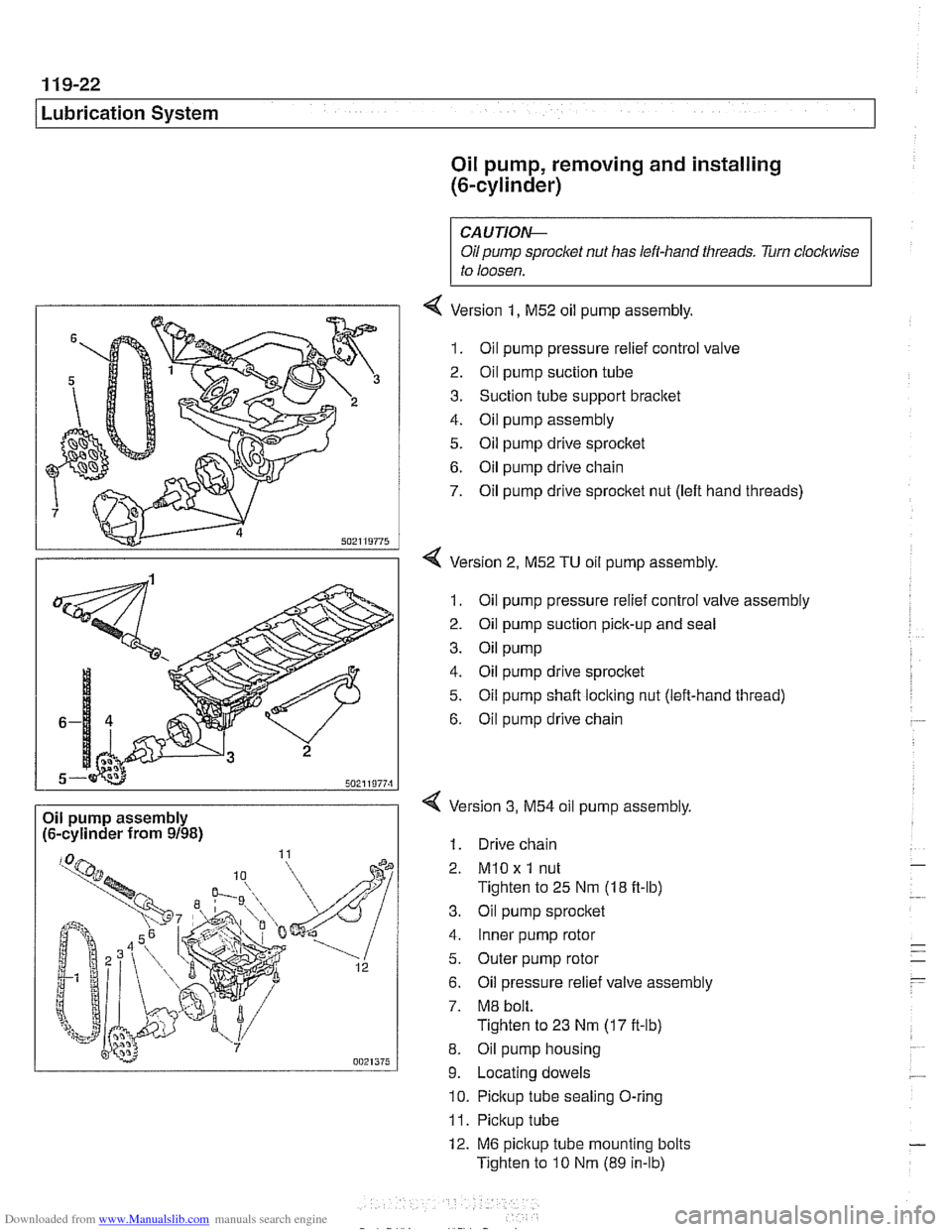

(&cylinder)

Oil pump assembly

(6-cylinder from 9/98)

CAUTIOI\C

Oil pump sproclcet nut has left-hand threads. Turn clockwise

to loosen.

4 Version 1, M52 oil pump assembly.

1. Oil pump pressure relief control valve

2. Oil pump suction tube

3. Suction tube support bracket

4. Oil pump assembly

5. Oil pump drive sprocltet

6. Oil pump drive chain

7. Oil pump drive sprocket nut (left hand threads)

4 Version 2, M52 TU oil pump assembly.

1. Oil pump pressure relief control valve assembly

2. Oil pump suction pick-up and seal

3. Oil pump

4. Oil pump drive sprocket

5. Oil pump shaft locking nut (left-hand thread)

6. Oil pump drive chain

Version

3, M54 oil pump assembly,

1. Drive chain

2.

MlO x 1 nut

Tighten to 25 Nm (18 ft-lb)

3. Oil pump sprocket

4. Inner pump rotor

5. Outer pump rotor

6. Oil pressure relief valve assembly

7. M8 bolt.

Tighten to 23 Nm

(17 it-lb)

8. Oil pump housing

9. Locating dowels

10. Pickup tube sealing O-ring

11. Pickup tube

12. M6 pickup tube mounting bolts

Tighten to

10 Nm (89 in-lb)

Page 345 of 1002

Downloaded from www.Manualslib.com manuals search engine

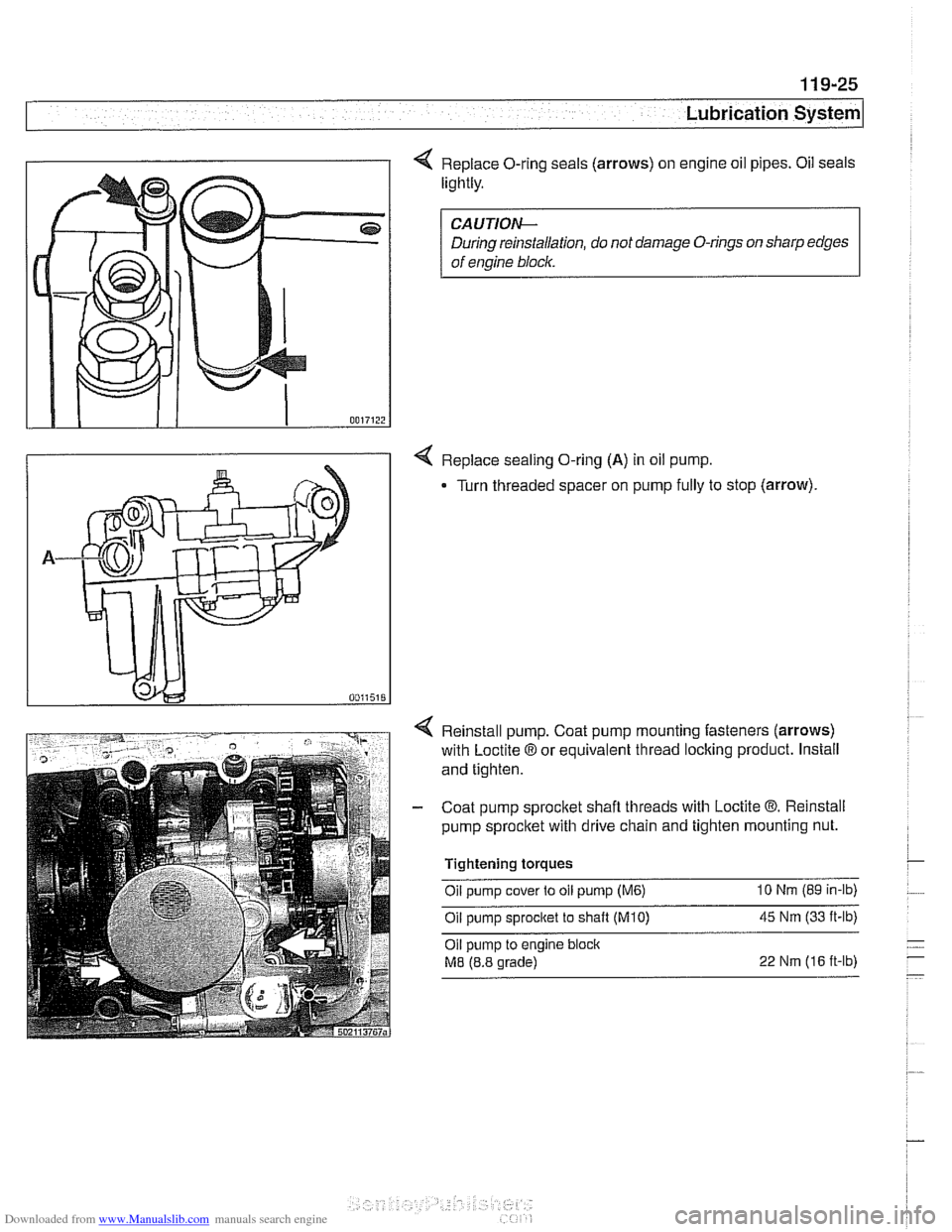

Lubrication System

4 Replace O-ring seals (arrows) on engine oil pipes. Oil seals

lightly.

CAUTIO&

During reinstallation, do not damage O-rings on sharp edges

of engine

blocl<.

4 Replace sealing O-ring (A) in oil pump.

Turn threaded spacer on pump fully to stop

(arrow).

Reinstall pump. Coat pump mounting fasteners (arrows)

with Loctite 8 or equivalent thread locking product. Install

and tighten.

Coat pump sprocltet shafl threads with Loctite

8. Reinstall

pump sprocltet with drive chain and tighten mounting nut.

Tightening torques

Oil pump cover to oil pump (M6) 10 Nm (89 in-lb)

Oil pump sprocket to shaft

(M10) 45 Nm (33 ft-lb)

Oil pump to engine block

M8 (8.8 grade) 22 Nm (16 ft-lb)

Page 360 of 1002

Downloaded from www.Manualslib.com manuals search engine

120-1 2

ignition System

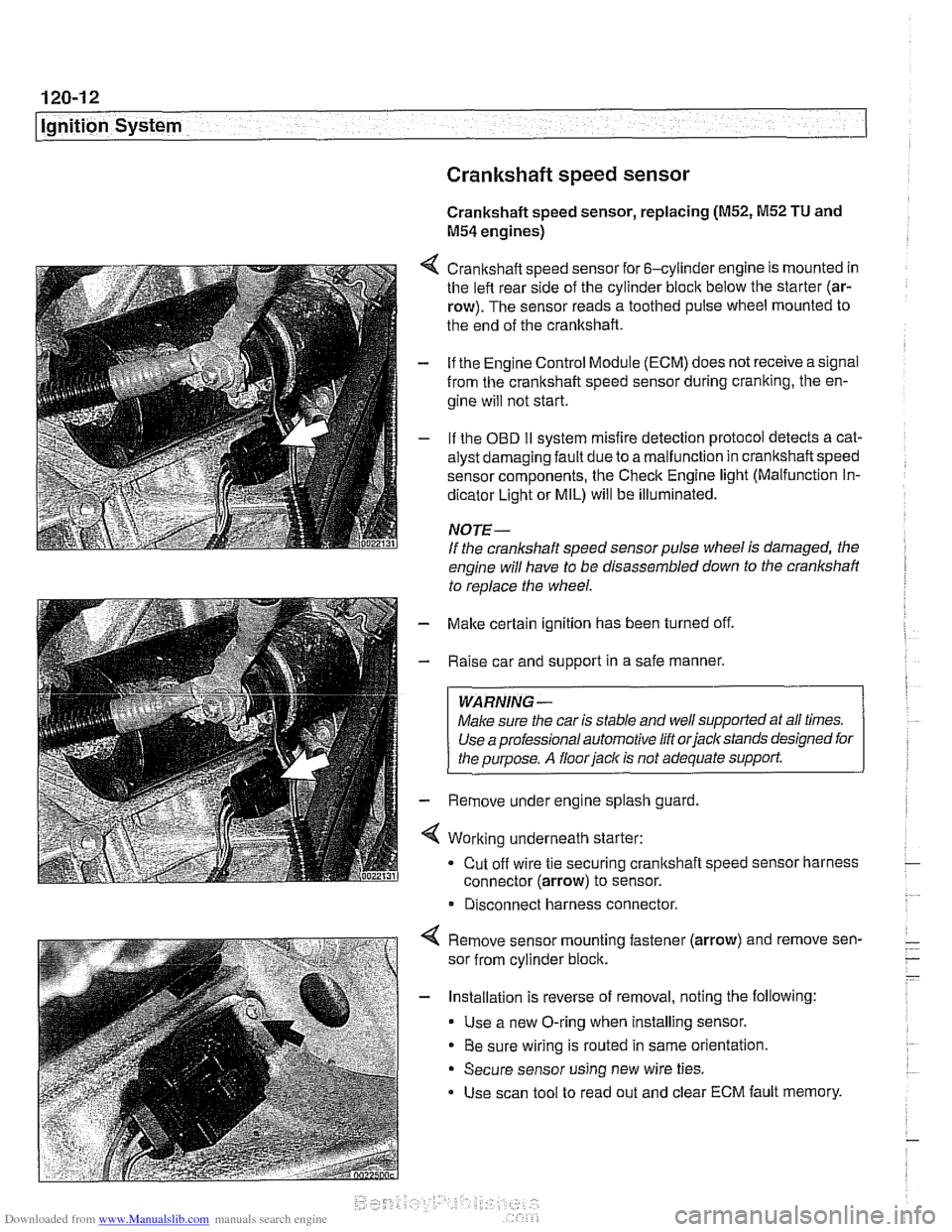

Crankshaftspeedsensor

Crankshaft speed sensor, replacing (M52, M52 TU and

M54 engines)

4 Crankshaft speed sensor for 6-cylinder engine is mounted in

the left rear side of the cylinder block below the starter (ar-

row). The sensor reads a toothed pulse wheel mounted to

the end of the crankshaft.

- if the Engine Control Module (ECM) does not receive a signal

from the crankshaft speed sensor during cranking, the en-

gine will not start.

- If the OBD II svstem misfire detection ~rotocol detects a cat- - - ~~

alysr oarnagin; faLlt oJe to a ma I-nclion in crandshafi speeo

sensor components. Ine Check Engine

lignr (Malfuncrion In-

dicator Light or MIL) will be illuminated.

NOTE-

If the crankshaft speed sensor pulse wheel is damaged, the

engine will have to be disassembled down to the crankshaft

to

reolace the wheel.

- Make certain ignition has been turned off.

- Raise car and support in a safe manner.

WARNING -

Make sure the car is stable and well supported at all times.

Use a professional automotive lift orjacltstands designed for

the ouroose.

A floor iaclc is not adequate support.

- Remove under engine splash guard

4 Working underneath starter:

Cut off wire tie securing crankshaft speed sensor harness

connector (arrow) to sensor.

* Disconnect harness connector.

4 Remove sensor mounting fastener (arrow) and remove sen-

sor from cylinder block.

- Installation is reverse of removal, noting the following:

Use a new O-ring when installing sensor.

Be sure wiring is routed in same orientation.

Secure sensor using new wire ties.

Use scan tool to read out and clear ECM fault memory.

Page 364 of 1002

Downloaded from www.Manualslib.com manuals search engine

120-1 6

Ignition System

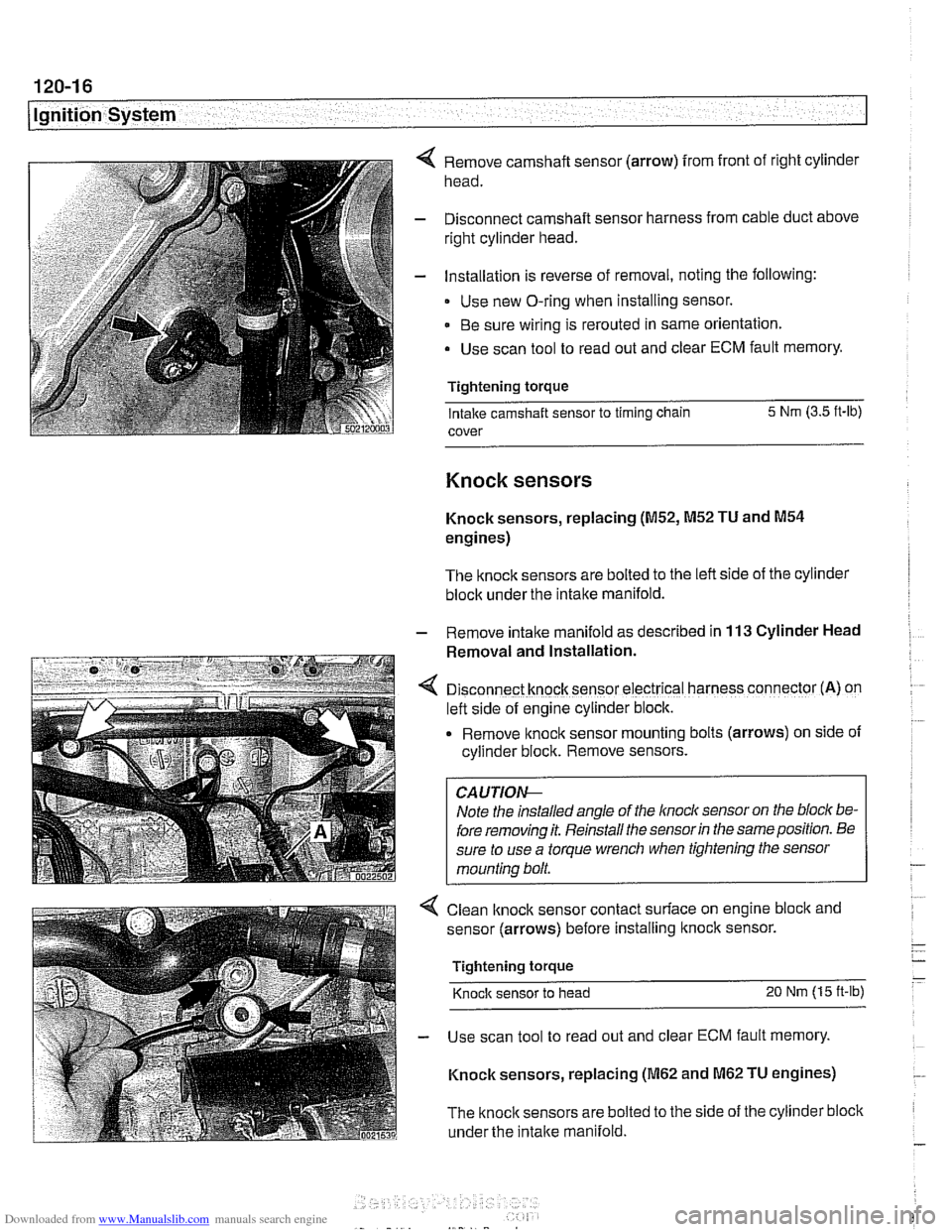

Remove camshaft sensor (arrow) from front of right cylinder

head.

Disconnect camshaft sensor harness from cable duct above

right cylinder head.

Installation is reverse of removal, noting the following:

Use new O-ring when installing sensor.

Be sure wiring is rerouted in same orientation.

Use scan tool to read out and clear ECM fault memory.

Tightening torque Intake camshaft sensor to timing chain 5 Nm

(3.5 ft-lb)

cover

Knock sensors

Knock sensors, replacing (M52, M52 TU and M54

engines)

The knock sensors are bolted to the left side of the cylinder

block under the intake manifold.

- Remove intalte manifold as described in 113 Cylinder Head

Removal and Installation.

D~sconnect knock sensor electrical harness connector (A) on

left side of engine cylinder block.

Remove knock sensor

mount~ng bolts (arrows) on side of

cyllnder block. Remove sensors.

Note the installed angle of the

lnocl~ sensor on the bloc/( be-

fore removing it. Reinstall the sensor

in the same position. Be

sure to use a torque wrench when tightening the sensor

mounting bolt.

< Clean lknock sensor contact surface on engine bloclc and

sensor (arrows) before installing

ltnock sensor.

Tightening torque

Knock sensor to head 20 Nm (15 ft-lb)

- Use scan tool to read out and clear ECM fault memory.

Knock sensors, replacing

(M62 and M62 TU engines)

The

knock sensors are bolted to the side of the cylinder block

under the

intake manifold.

Page 365 of 1002

Downloaded from www.Manualslib.com manuals search engine

Ignition System

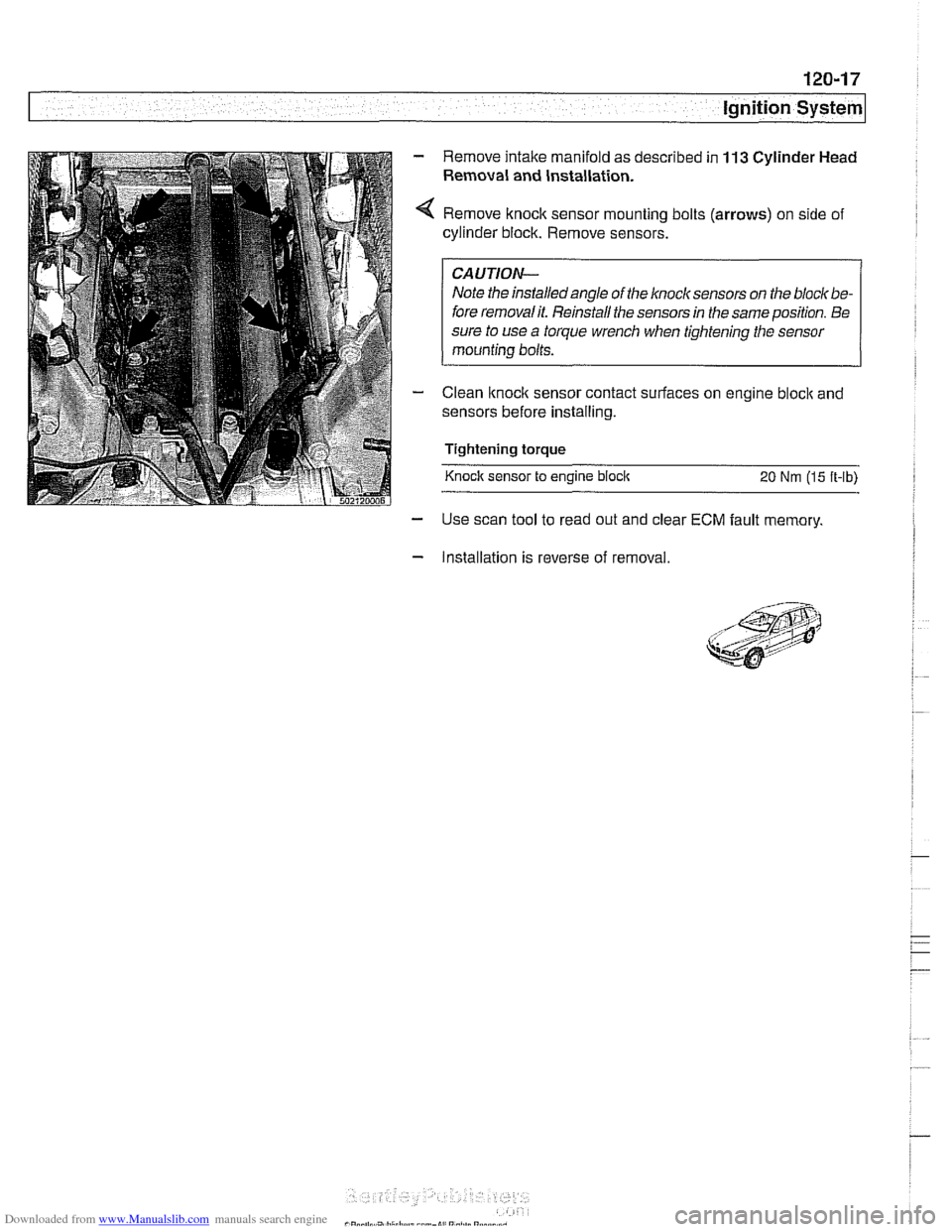

Remove intake manifold as described in 113 Cylinder Head

Remaval and Installation.

Remove knock sensor mounting bolts (arrows) on side of

cylinder block. Remove sensors.

I CAUTION- I

Note the installedangle of the knock sensors on the bloclt be-

fore removalit. Reinstall the sensors in the same position. Be

sure to use

a torque wrench when tightening the sensor

mounting bolts.

Clean

lknoclc sensor contact surfaces on engine bloclc and

sensors before installing.

Tightening torque

Knock sensor to engine

bloclc 20 Nm (15 ft-lb)

- Use scan tool to read out and clear ECM fault memory.

- Installation is reverse of removal.