diagram BMW 525i 1998 E39 Owner's Manual

[x] Cancel search | Manufacturer: BMW, Model Year: 1998, Model line: 525i, Model: BMW 525i 1998 E39Pages: 1002

Page 444 of 1002

Downloaded from www.Manualslib.com manuals search engine

130-54

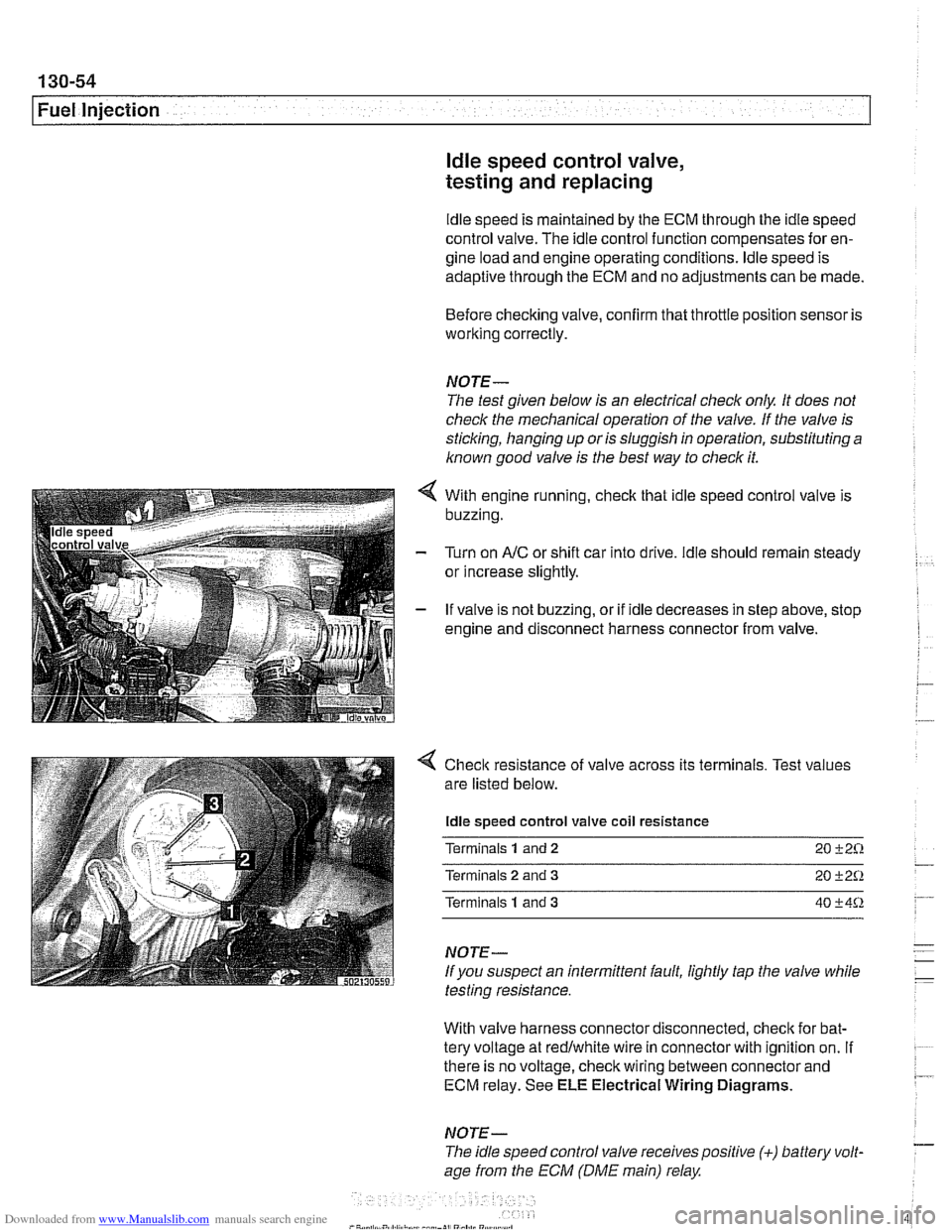

I Fuel Injection ldle speed control valve,

testing and replacing

ldle speed is maintained by the ECM through the idle speed

control valve. The idle control function compensates for en-

gine load and engine operating conditions. ldle speed is

adaptive through the ECM and no adjustments can be made.

Before checking valve, confirm that throttle position sensor is

working correctly.

NOTE-

The test given below is an electrical check only. It does not

check the mechanical operation of the valve. If the valve is

sticking, hanging up or is sluggish in operation, substituting a

Inown good valve is the best way to check it.

With engine running, check that idle speed control valve is

buzzing.

Turn on

AIC or shift car into drive. ldle should remain steady

or increase slightly.

If valve is not buzzing, or if idle decreases in step above, stop

engine and disconnect harness connector from valve.

4 Check resistance of valve across its terminals. Test values

are listed below.

ldle speed control valve coil resistance

Terminals

1 and 2 20 +2%

Terminals 2 and 3 20 +2Q

Terminals 1 and 3 40 +4%

NOTE-

If you suspect an intermittent fault, lightly tap the valve while

testing resistance.

With valve harness connector disconnected, check for bat-

tery voltage at redlwhite wire in connector with ignition on.

If . ~~ ~~

there is no voltage, check wiring between connector and 7 ECM relay. See ELE Electrical Wiring Diagrams.

NOTE- - The idle speed control valve receivespositive (+) battery volt-

age from the ECM (DME main) relay

Page 449 of 1002

Downloaded from www.Manualslib.com manuals search engine

130-59

Fuel Injection

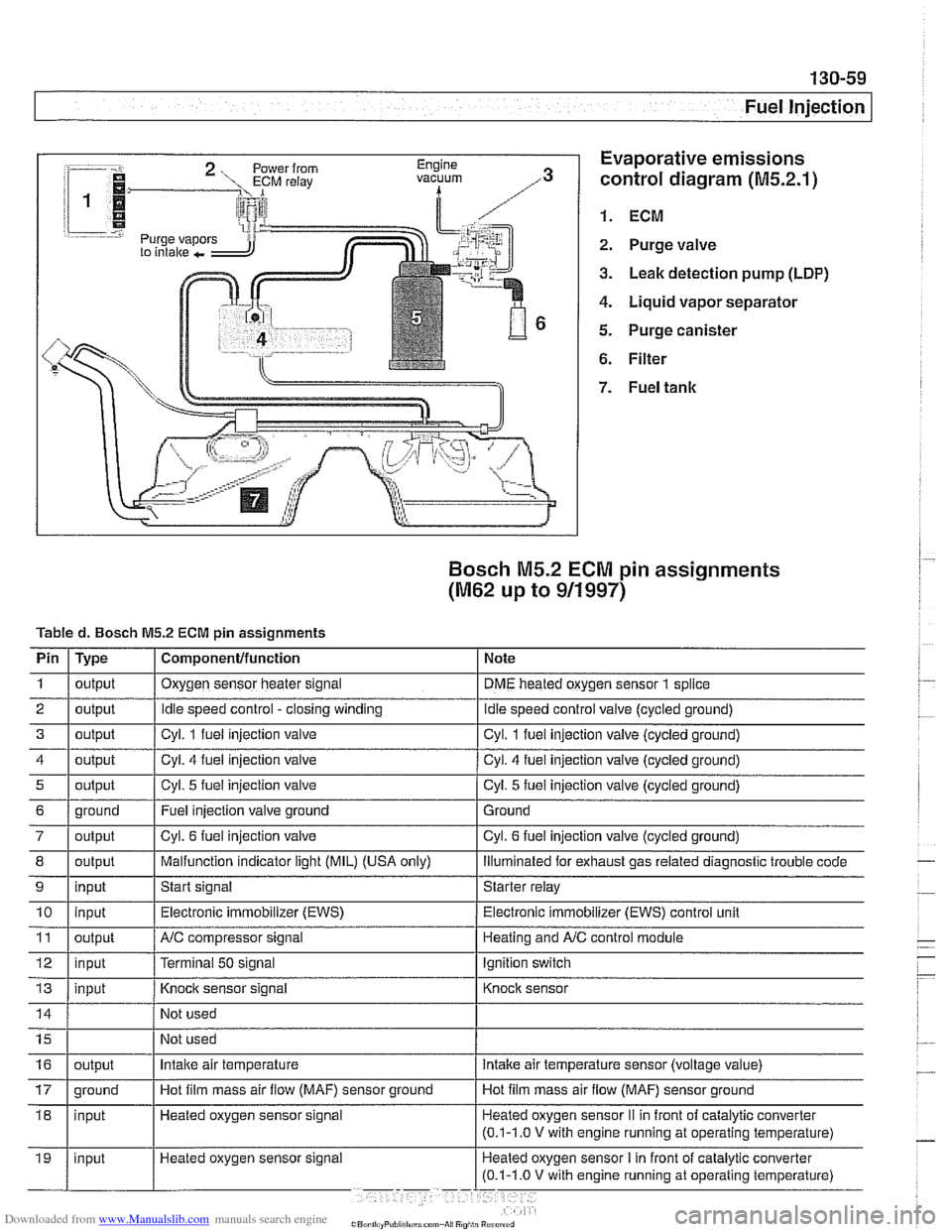

:-- -i. Evaporative emissions

1.

control diagram (M5.2.1)

i 1

i I @ 1. ECM r.=.:-:, 2. Purge valve

3. Leak detection pump (LDP)

4. Liquid vapor separator

5. Purge canister

6. Filter

Bosch M5.2 ECM pin assignments

(M62 up to 911997)

Tabled. Bosch M5.2 ECM pin assignments

I' 1- 1. . . -

4 1 output / Cyl. 4 fuel injection valve I Cyl. 4 fuel injection valve (cycled ground)

Pin

1

2

3

i I

I

7 / output I Cyl. 6 fuel injection valve I Cyl. 6 fuel injection valve (cycled ground)

Type

output

output

output

I I ,

8 1 output I Malfunction indicator light (MIL) (USA only) I lliumlnated for exhaust gas related diagnostic trouble code

5

Component/function

Oxygen sensor heater signal

Idle speed control -closing winding

Cvl. 1 fuel iniection valve Note

DME heated oxygen sensor

1 splice

idle speed control valve (cycled ground)

Cvl. 1 fuel iniection valve lcvcled around)

6 1 ground I Fuel injection valve ground 1 Ground

output

9

Not

used

Not used

11

12

13

Cyl. 5 fuel injection valve

10 1 input I Electronic immobilizer (EWS) / Electronic immobilizer (EWS) control unit

input

Heated oxygen sensor signal Cyl.

5 fuel injection

valve (cycled ground)

output

input

input

16

Start signal Starter relay

NC compressor signal

Terminal

50 signal

Knock sensor signal

17 1 ground I Hot film mass air flow (MAF) sensor ground I Hot film mass air flow (MAF) sensor ground

output Heating and

A/C control module

Ignition switch

Knock sensor

Intake air temperature intake air temperature sensor (voltage value)

Page 456 of 1002

Downloaded from www.Manualslib.com manuals search engine

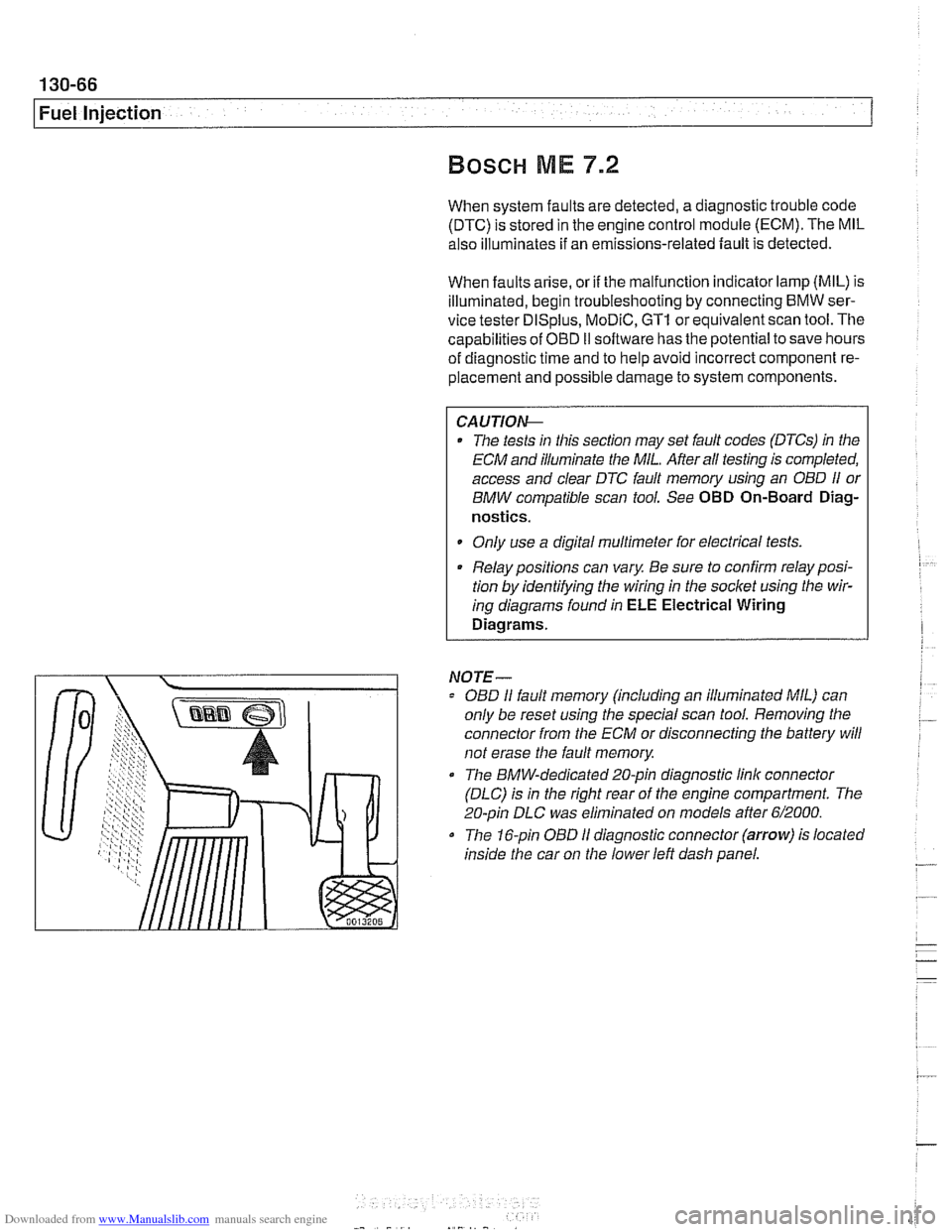

Fuel Injection

When system faults are detected, a diagnostic trouble code

(DTC) is stored in the engine control module (ECM). The MIL

also illuminates

if an emissions-related fault is detected.

When faults arise, or

if the malfunction indicator lamp (MIL) is

illuminated, begin troubleshooting by connecting BMW ser-

vice tester

DISplus, MoDiC, GTl or equivalent scan tool. The

capabilities of OBD

II software has the potential to save hours

of diagnostic time and to help avoid incorrect component re-

placement and possible damage to system components.

CA UTIOI\C

The tests in this section may set fault codes (DTCs) in the

ECM and illuminate the MIL. After all testing is completed,

access and clear DTC fault memory using an OBD

I1 or

BMW compatible scan tool. See OBD On-Board Diag-

nostics.

. Only use a digital multimeter for electrical tests.

Relay positions can vary. Be sure to confirm relay posi-

tion by identifying the wiring in the

socket using the wir-

ing diagrams found in ELE Electrical Wiring

Diaqrams.

NOTE-

= OBD I1 fault memory (including an illuminated MIL) can

only be reset using the special scan tool. Removing the

connector from the ECM or disconnecting the battery will

not erase the fault memory.

0 The BMW-dedicated 20-pin diagnostic link connector

(DLC) is in the right rear of the engine compartment. The

20-pin DLC was eliminated on models after

6/2000.

The 16-pin OBD I1 diagnostic connector (arrow) is located

inside the car on the lower left dash panel.

Page 460 of 1002

Downloaded from www.Manualslib.com manuals search engine

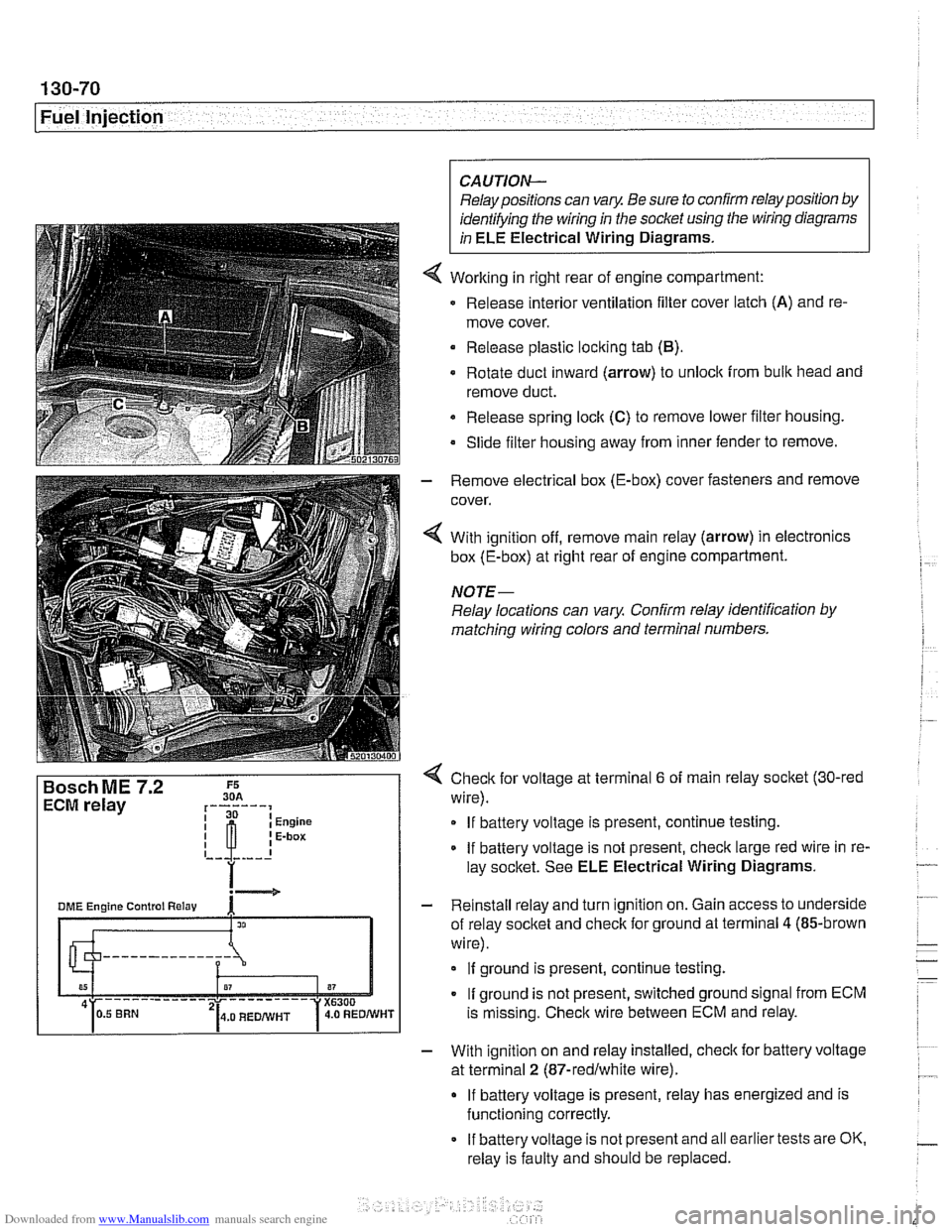

130-70

Fuel Injection

ECM relay

--

CAUTION-

Relay positions can vary Be sure to confirm relay position by

identifying the wiring in the

socl(et using the wiring diagrams

in ELE Electrical Wiring Diagrams.

Working in right rear of engine compartment:

Release interior ventilation filter cover latch

(A) and re-

move cover.

Release plastic locking tab

(B).

Rotate duct inward (arrow) to unlock from bulk head and

remove duct.

Release spring

loclt (C) to remove lower filter housing.

Slide filter housing away from inner fender to remove.

- Remove electrical box (E-box) cover fasteners and remove

cover.

4 With ignition off, remove main relay (arrow) in electronics

box (E-box) at right rear of engine compartment.

NOTE-

Relay locations can vary Confirm relay identification by

matching wiring colors and terminal numbers.

4 Check for voltage at terminal 6 of main relay socket (30-red

wire).

If battery voltage is present, continue testing.

If battery voltage is not present, check large red wire in re-

lay socltet. See ELE Electrical Wiring Diagrams.

- Reinstall relay and turn ignition on. Gain access to underside

of relay socket and check for ground at terminal

4 (85-brown

wire).

If ground is present, continue testing.

If ground is not present, switched ground signal from ECM

is missing. Check wire between ECM and relay.

- With ignition on and relay installed, check for battery voltage

at terminal

2 (87-redlwhite wire).

If battery voltage is present, relay has energized and is

functioning correctly.

If battery voltage is not present and all earlier tests are OK.

relay is faulty and should be replaced.

Page 477 of 1002

![BMW 525i 1998 E39 Owners Manual Downloaded from www.Manualslib.com manuals search engine

- Fuel Tank and Fuel pump]

Remove fuel pump

relay (arrow).

4 Connect relay socitet terminal 6 (redlviolet wire) to relay

socket termi BMW 525i 1998 E39 Owners Manual Downloaded from www.Manualslib.com manuals search engine

- Fuel Tank and Fuel pump]

Remove fuel pump

relay (arrow).

4 Connect relay socitet terminal 6 (redlviolet wire) to relay

socket termi](/img/1/2822/w960_2822-476.png)

Downloaded from www.Manualslib.com manuals search engine

- Fuel Tank and Fuel pump]

Remove fuel pump

relay (arrow).

4 Connect relay socitet terminal 6 (redlviolet wire) to relay

socket terminal

2 (whitelblue wire) with a fused jumper wire.

After completing tests, remove jumper harness.

CA

UTIOG

Relay locations may vary Use care when identifying relays

and making electrical checks at

the fuse/relay panel. See

610 Electrical Component Locations for additional re-

lay information.

The fuel pump relay has a 1.5

md red/violet wire at

terminal

6 in the relay socket. Terminal2 has a 2.5md

white/blue wire. See ELE Electrical Wiring Diagrams

for additional wiring information.

NOTE-

* The fuel pump will run as soon as the jumper wire Is at-

tached.

The jumper wire should be 1.5

md (14 ga.) and include

an in-line fuse holder with a 15A fuse. To avoid

fuse/relay

panel damage from repeated connecting and disconnect-

ing, also include a toggle switch in the jumper harness.

- If pump does not run with jumper installed, fault could be in

fuel pump, fuses

F31 or F22 1 F54, or wiring to pump. Check

pump, fuses and its wiring as described below.

Fuel pump electrical circuit, testing

- The test given below assumes that the fuel pump relay circuit

is functioning correctly as described earlier. Access to the

pump is from below the rear seat bottom cushion.

- Remove rear seat lower cushion by lifting front edge off left

and right catches.

Page 523 of 1002

Downloaded from www.Manualslib.com manuals search engine

180 Exhaust System

General Exhaust System

. . . . . . . . . . . . . . . . .

Exhaust system, removing and installing

Muffler, replacing..

. . . . . . . . . . . . . . . . .

Exhaust Manifolds . . . . . . . . . . . . . . .

Exhaust manifolds, removing

and installing (M52 engine)

. . . . . . . . . .

Exhaust manifolds, removing and

installing (M52

TU and M54 engines) . . .

Exhaust manifolds, removing

and installing (M62 engine)

. . . . . . . . . .

Oxygen Sensors. . . . . . . . . . . . . . . . . . . . 180-9

Oxygen sensors (precatalyst),

replacing

(M52 TU and M54) . . . . . . . . . . . . 180-9

Oxygen sensors (post-catalyst),

replacing (M52

TU and M54) . . . . . . . . . . . . 180-9

Oxygen sensor, replacing

(M52 and M62 engine) . . . . . . . . . . . . . . . 180-10

Exhaust System Diagrams . . . . . . . . . 180-1 1

M52 engine (528i 1997-1 998) . . . . . . . . . . 180-1 1

M52

TU and M54 engines

(528i 1999-2000 and 5251 2001-2003) . . . 180-1 2

M54 engine

(530i 2001-2003) . . . . . . . . . . 180-1 3

M62 engine

(540i 1997-1 998) . . . . . . . . . . 180-1 4

M62

TU engine (540i 1999-2003 . . . . . . . 180-1 5

Page 621 of 1002

Downloaded from www.Manualslib.com manuals search engine

300 Suspension. Steering and Brakes .

Genera8

General ........................... .30 0.2

Aluminum suspension components

...... .30 0.2

Front Suspension ................. .30 0.2

Front suspension 6-cylinder models

(525i.5281. 530i) ..................... .30 0.3

Front suspension V-8 models (540i) ...... .30 0.4

Rear Suspension .................. .30 0.5

Sedan models

....................... .30 0.5

Rear suspension sedan models ........ .30 0.6

Sport Wagon models ................. .30 0.6

Rear suspension Sport Wagon

(with coil springs)

.................... .30 0.7

Rear suspension Sport Wagon

(EHC with air springs)

................. .30 0.8

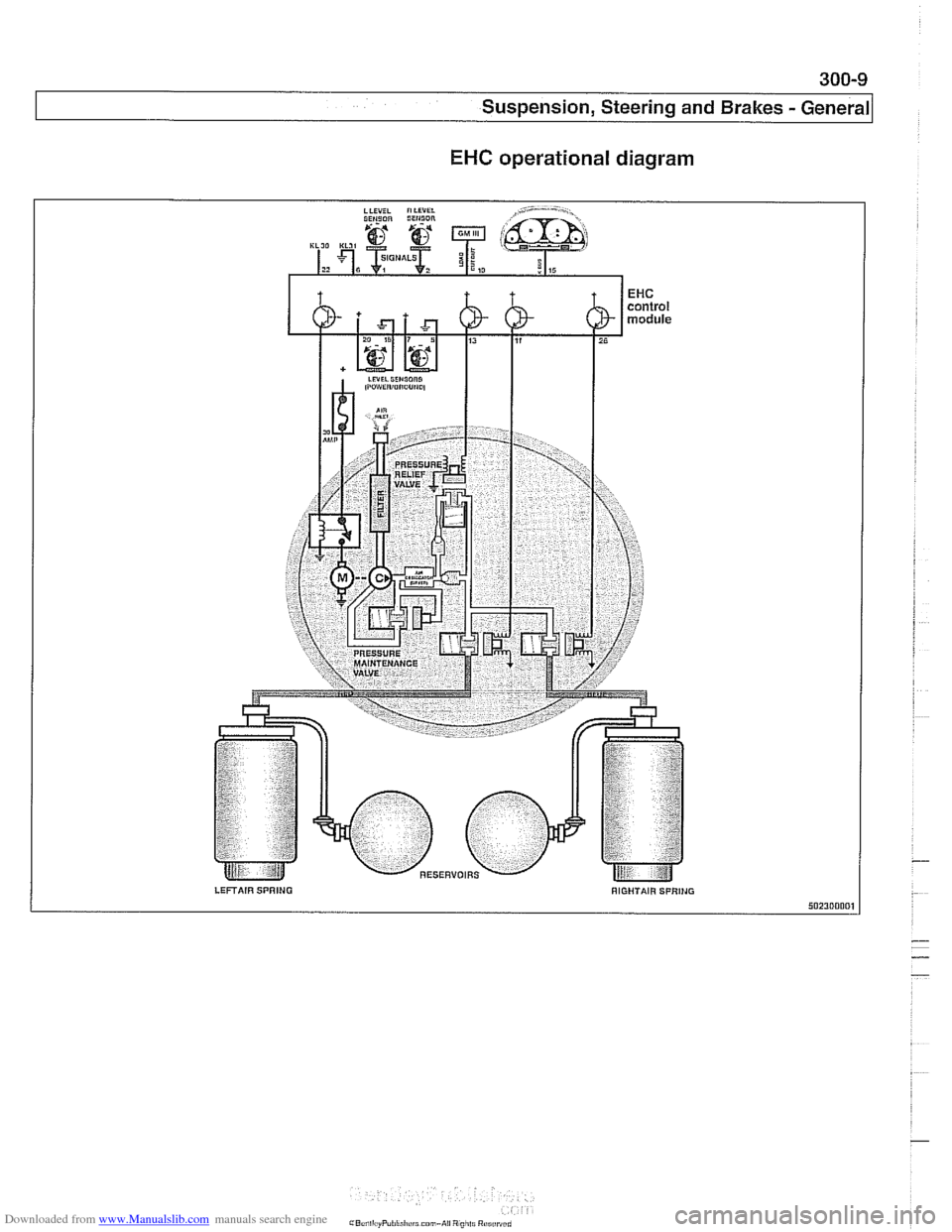

EHC operational diagram .............. .30 0.9

Steering ......................... .30 0.10

Rack-and-pinion steering ............. .30 0.10

Recirculating ball and nut steering ...... .30 0.10

..................... Brake System 300-10

Wheels and Tires ................. 300-1 1

............... Rim and tire sizes table 300-1 1

Electronic Brake and Stability

.................. Control Systems 300-1 1

E39 electronic brake and stability

........ control systems application table 300-12

........................ ABS system 300-1 2

Automatic Stability Control (ASC)

....... 300-12

ABSIASC traction control system ....... 300-13

Dynamic Stability Control (DSC)

........ 300-14

Ride Height ....................... 300-14

......... Front ride height specifications 300-1 5

......... Rear ride height specifications 300-16

Page 629 of 1002

Downloaded from www.Manualslib.com manuals search engine

EHC operational diagram

LEFTAIR SPRING RIGHTAIR SPRlNG 50230000,

-

-

-

Page 645 of 1002

Downloaded from www.Manualslib.com manuals search engine

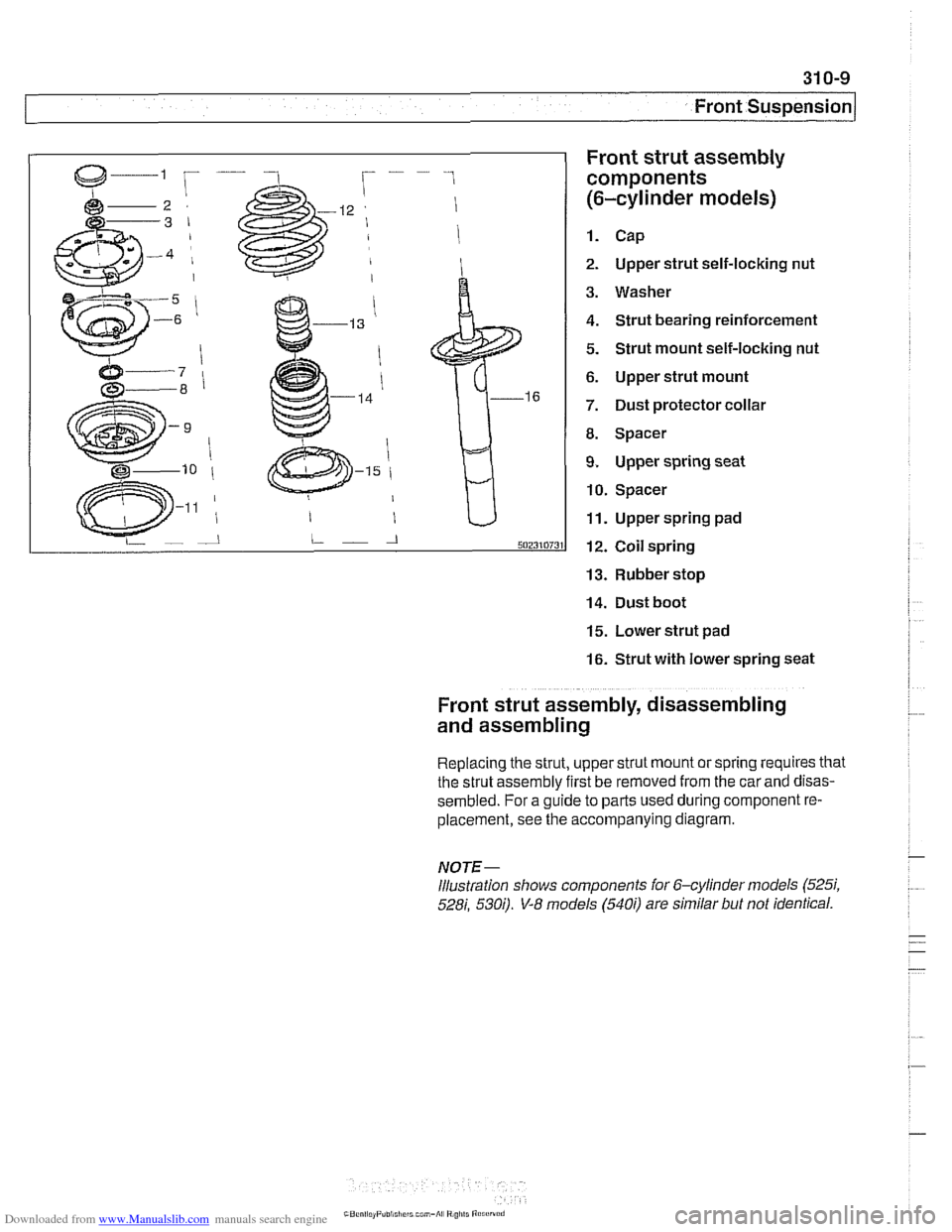

31 0-9

Front Suspension

Front strut assembly

components

(6-cylinder models)

1. Cap

2. Upper strut self-locking nut

3. Washer

4. Strut bearing reinforcement

5. Strut mount self-locking nut

6. Upper strut mount

7. Dust protector collar

8. Spacer

9. Upper spring seat

10. Spacer

11. Upper spring pad

12. Coil spring

13. Rubber stop

14. Dust boot

15. Lower strut pad

16. Strut with lower spring seat

Front strut assembly, disassembling

and assembling

Replacing the strut, upper strut mount or spring requires that

the strut assembly first be removed from the car

and disas-

sembled. For a guide to parts used during component re-

placement, see the accompanying diagram.

NOTE-

Illustration shows components ior 6-cylinder models (525i,

528i, 530;). V-8 models (540i) are similar but not identical.

Page 829 of 1002

Downloaded from www.Manualslib.com manuals search engine

41 2 Trunk Lid. Tailgate

........................... General

......................... Trunk Lid

Trunlc lid. removing and installing ........

Trunk lid. adjusting ...................

Trunk lid support strut.

removing and installing

................

Tailgate (Sport Wagon Models) .....

Tailgate. emergency release ...........

Tailgate and window strut diagram .......

Window strut removal diagram .......... 412-8

Rear window gas strut.

removing and installing

................ 412-9

Tailgate gas strut. removing and installing

............... 412-10

Tailgate. removing and installing

........ 412-1 1

Rear window. removing and installing

.... 412-12

Rear window and tailgate. alignment

..... 412-13