engine BMW 525i 1998 E39 Workshop Manual

[x] Cancel search | Manufacturer: BMW, Model Year: 1998, Model line: 525i, Model: BMW 525i 1998 E39Pages: 1002

Page 891 of 1002

Downloaded from www.Manualslib.com manuals search engine

Interior ~riml

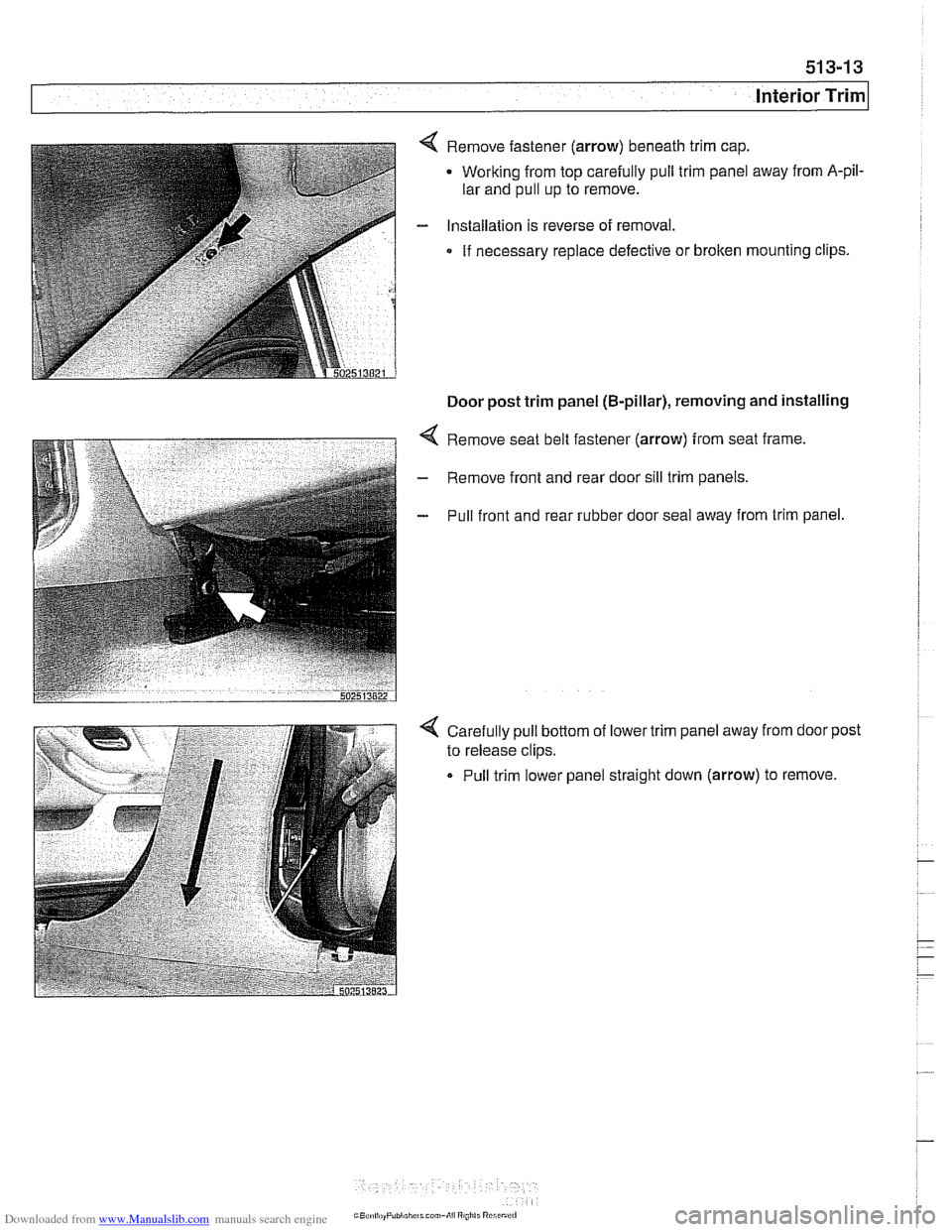

4 Remove fastener (arrow) beneath trim cap.

Working from top carefully pull trim panel away from

A-pil-

lar and pull up to remove.

- Installation is reverse of removal.

If necessary replace defective or broken mounting clips.

Door post trim panel (B-pillar), removing and installing

4 Remove seat belt fastener (arrow) from seat frame.

- Remove front and rear door sill trim panels.

- Pull front and rear rubber door seal away from trim panel.

4 Carefully pull bottom of lower trim panel away from door post

to release clips.

Pull trim lower panel straight down (arrow) to remove.

Page 892 of 1002

Downloaded from www.Manualslib.com manuals search engine

51 3-1 4

llnterior Trim

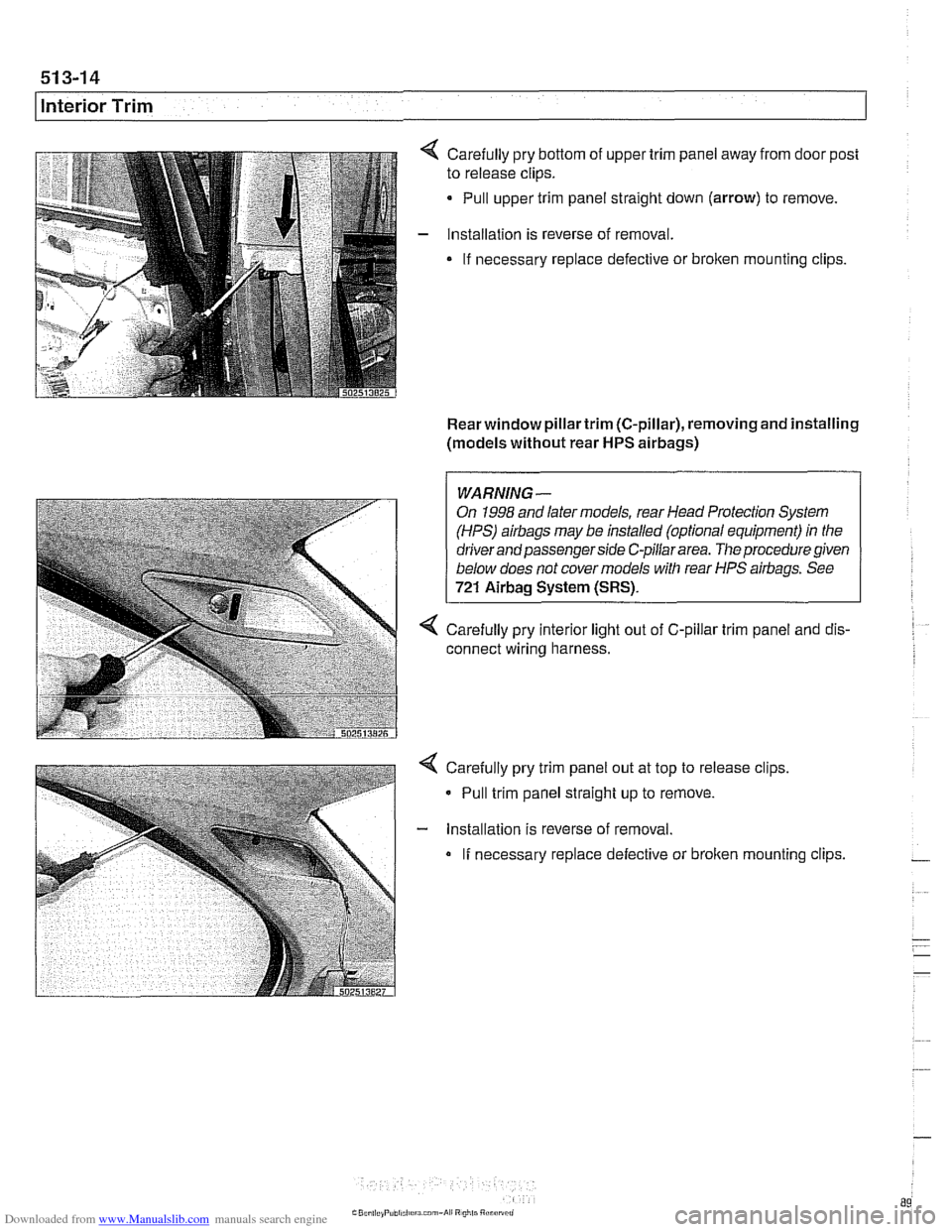

Carefully pry bottom of upper trim panel away from door post

to release clips.

Pull upper trim panel straight down (arrow) to remove.

Installation is reverse of removal.

If necessary replace defective or

broken mounting clips.

Rear window pillartrim (C-pillar), removing and installing

(models without rear

HPS airbags)

1 I

WARNING-

On 1998 and later models, rear Head Protection System

(HPS)

airbags may be installed (optional equipment) in the

driver and passenger side C-pillar area.

The procedure given

below does not cover models with rear HPS airbags. See

721 Airbag System (SRS).

4 Carefully pry interior light out of C-pillar trim panel and dis-

connect wiring harness.

Carefully pry trim panel out at top to release clips,

- Pull trim panel straight up to remove.

- lnstallation is reverse of removal.

If necessary replace defective or broken mounting clips.

Page 893 of 1002

Downloaded from www.Manualslib.com manuals search engine

51 3-1 5

I Interior Trim

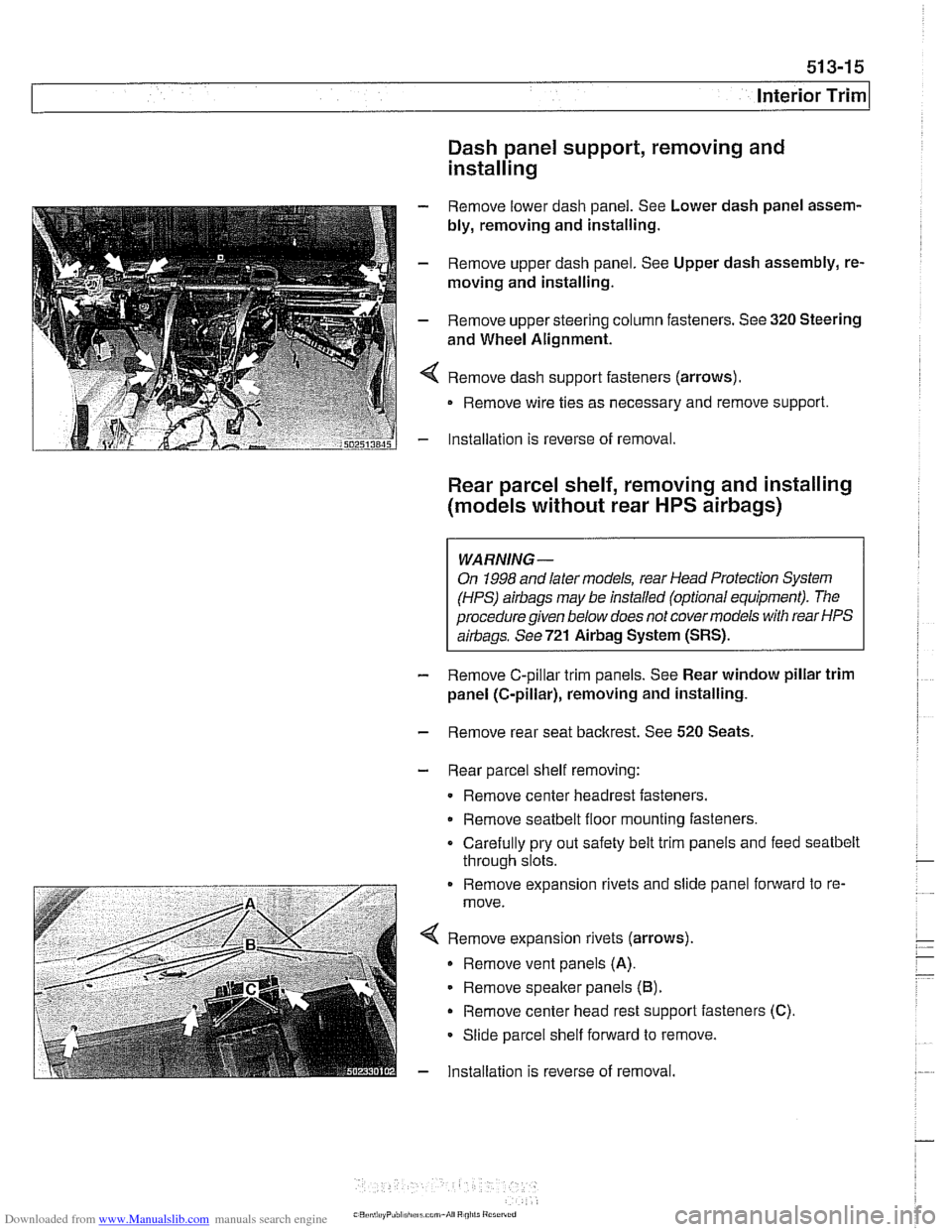

Dash panel support, removing and

installing

- Remove lower dash panel. See Lower dash panel assem-

bly, removing and installing.

- Remove upper dash panel. See Upper dash assembly, re-

moving and installing.

- Remove upper steering column fasteners. See 320 Steering

and Wheel Alignment.

4 Remove dash support fasteners (arrows).

Remove wire ties as necessary and remove support.

- Installation is reverse of removal.

Rear parcel shelf, removing and installing

(models without rear

HPS airbags)

WARNING-

On 1998 and later models, rear Head Protection System

(HPS)

airbags may be installed (optional equipment). The

procedure given below does not covermodels with rear HPS

airbags. See721

Airbag System (SRS).

- Remove C-pillar trim panels. See Rear window pillar trim

panel (C-pillar), removing and installing.

- Remove rear seat backrest. See 520 Seats.

- Rear parcel shelf removing:

Remove center headrest fasteners.

Remove

seatbelt floor mounting fasteners.

Carefully pry out safety belt trim panels and feed

seatbelt

through slots.

. . . - -. . . . . . . . . Remove expansion rivets and slide pane fonvard to re-

move.

< Remove expanson r:vets (arrows).

Remove vent panels (A).

Remove speafter pane s (B).

Remove center head rest s-pporl fasteners (C).

Slioe parcel shelf forward lo remove.

- lnsta lation s reverse of removal.

Page 894 of 1002

Downloaded from www.Manualslib.com manuals search engine

51 3-1 6

Interior Trim

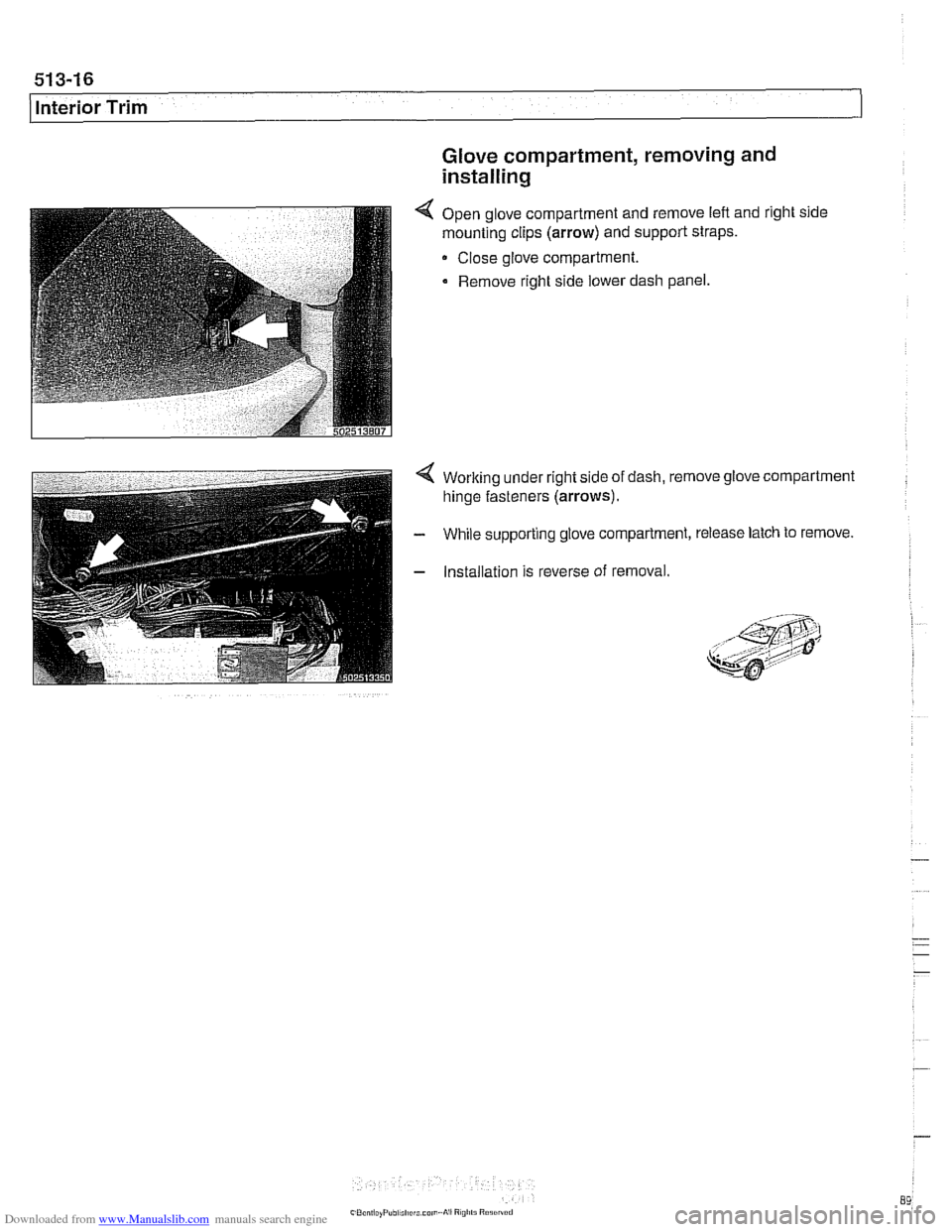

Glove compartment, removing and

installing

4 Open glove compartment and remove lefl and right side

mounting clips

(arrow) and support straps.

Close glove compartment.

Remove right side lower dash panel.

4 Working under right side of dash, remove glove compartment

hinge fasteners

(arrows).

- While supporting glove compartment, release latch to remove.

- Installation is reverse of removal.

, &j?i 8 .: ,,,, < I;; ,..9;:*?:4 *-,;: ,,

Page 895 of 1002

Downloaded from www.Manualslib.com manuals search engine

51 5 Central Locking and Anti-Theft

........................... General .51 5.2

Central Locking ................... .51 5.2

General Module

..................... .51 5.2

Central locking inputs and outputs

....... .51 5.3

Doorlocks

........................... 515-5

Trunklock

........................... 515-7

Remote entry (FZV)

.................. .51 5.7

Remote entry (FZV) inputs and outputs ... .51 5.8

Car Memory I Key Memory ............ .51 5.12

Trunk lid soft close (SCA)

............. .51 5.13

SCA subsystem

.................... .51 5.14

........ Tailgate and rear window locks

.51 5.14

Sport Wagon tailgate and rear

window

lock schematic ............... .51 5.15

Door Handles and Locks .......... .51 5.16

Door handle (outer), removing

and installing

....................... .51 5.16

Door latch, removing and installing

..... .51 5.17

Outer door lock cylinder, removing

and installing

....................... .51 5.18

Trunk Lock Assembly ............. 515-1 9

Trunk lock. removing and installing

...... 515-19

Trunk lock striker plate. removing

and installing

....................... 515-20

Tailgate lock. emergency release

....... 515-21

... Electronic Immobilization (EWS) 515-21

EWS variations

..................... 515-22

......... EWS control module. replacing 515-23

Transmitter

1 receiver module .......... 515-23

....................... Ring antenna 515-23

Anti-theft System (DWA) ........... 51 5-24

DWA LED Status

.................... 51 5-24

Tilt sensor

......................... 515-24

Interior protection .................... 51 5-25

Glass breakage sensors

.............. 515-26

Emergency disarming

................ 51 5-26

Page 896 of 1002

Downloaded from www.Manualslib.com manuals search engine

51 5-2

/Central Locking and Anti-Theft

This section covers repair information for door, trunk and car-

go compartment locks, central locking, electronic

immob~liza-

tion (EWS) and anti-theft alarm (DWA).

€39 cars are equipped with sophisticated self-diagnostic elec-

trical systems. When experiencing malfunctions relating to

central locking. EWS or anti-theft systems, start the diagnosis

process using the

BMW service tester DIS, GT 1, MoDiC or

equivalent scan tool. An advanced diagnostic scan tool can

usually pinpoint electrical faults quickly and safely.

Additional electrical information can be found in:

610 Electrical Component Locations

ELE Electrical Wiring Diagrams

Central locking in E39 vehicles controls the door

locks, trunk

or tailgate lock and fuel filler flap lock. The control module for

the Central Body Electronics system (ZKE

Ill), lknown as the

General Module (GM

Ill), controls central locking.

ZKE

Ill manages the following central locking related func-

tions:

Central locking

* Keyless entry

Key memory

Power trunk release

Electric opening of tailgate

DWA alarm system

Diagnosis

General Module

4 The General Module (GM) (arrow) is responsible for the op-

eration of central body electronics. The GM is located behind

the glove compartment.

Based on input information, the GM uses internal transistors

to switch current flow (providing voltage or ground) through

circuits and actuators. Actuators are the final controlling de-

vices used by GM to operate or control various output func-

tions such as relays and motors.

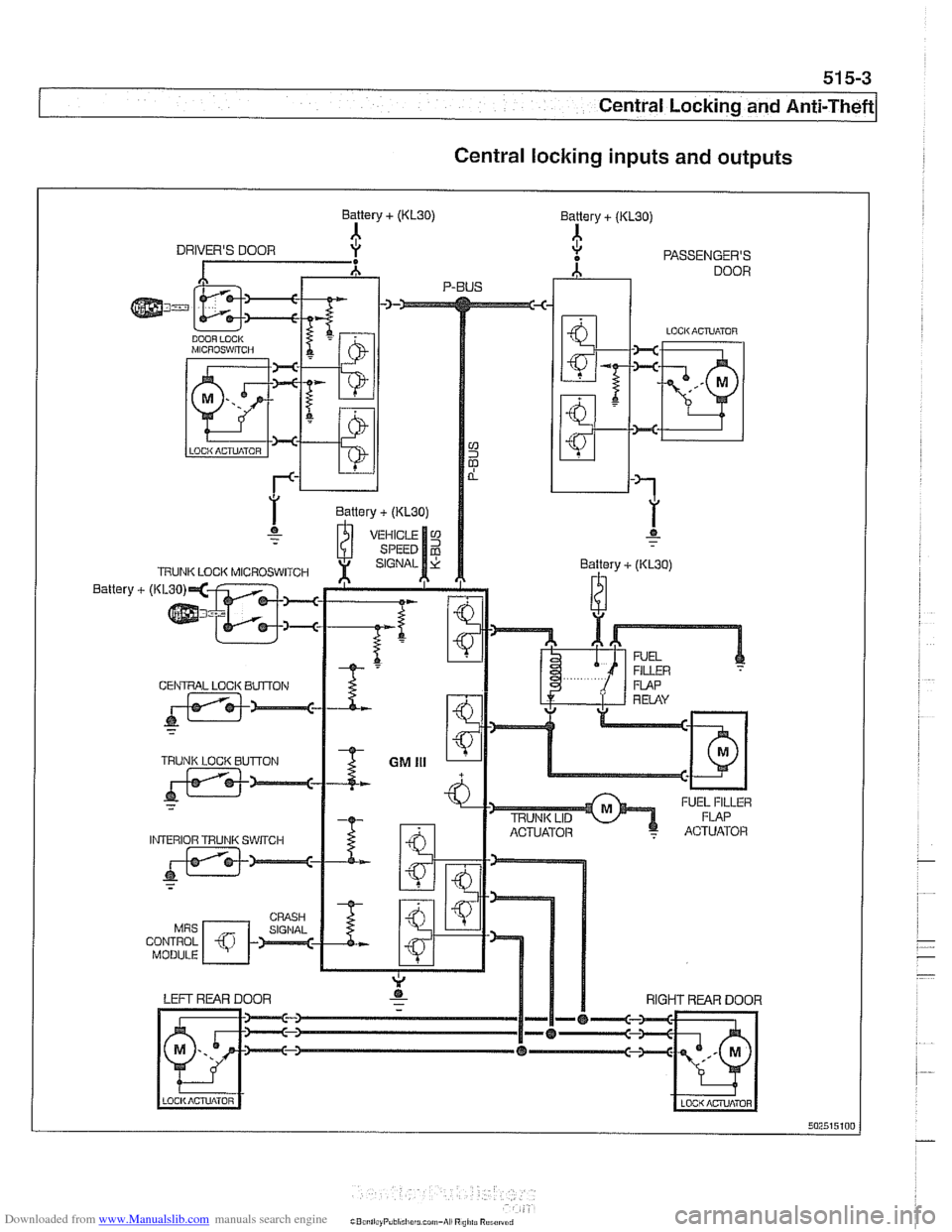

The accompanying schematic, Central locking inputs and

outputs, illustrates the GM central locking system.

Page 897 of 1002

Downloaded from www.Manualslib.com manuals search engine

51 5-3

Central Locking and ~nti- heft

Central locking inputs and outputs

iBzi~ilziPobi~~lic~u~uin-Ai Rnl>ir Rum

Page 898 of 1002

Downloaded from www.Manualslib.com manuals search engine

51 5-4

I Central Locking and Anti-Theft

Driver's door lock

The

lock/unlock signals are sent as input to the door module

from two microswitches on the lockcylinder. The driver's door

module carries out the locking

/ unlocking functions of the

driver's door through its final stage control.

The signal to lock the remaining doors, trunk or tailgate and

fuel flap is sent over the P-Bus to the GM and the passenger

door module. Activation of the passengers door

loclt is carried

out by the passenger door module. The rear doors, trunlt or

tailgate and fuel flap are

locked by the f~nal stage in the GM.

When

locked from the outside, all doors are set to the double

lock position and the GM will not carry out any unlock com-

mands from the central

loclc button or remote trunk release

button.

Selective unlocking

When unlocking with the key or the remote transmitter, the

first unloclcrequestwill only unlock the driver'sdoor. A second

unlock request will unlock the remaining doors, trunk or tail-

gate and fuel flap.

Trunk locking

I

The vehicle can be locked/unlocked from the trunlc loclc cylin-

der. The GM locks the trunk or tailgate, rear doors and fuel fill-

er. The locking command is passed over the P-Bus to the

respective door modules to lock the driver's and passengers

doors.

Locking the trunk and removing the key in the

hor~zontal posi-

tion will set the valet lock and prevent opening of the trunlt

with the central locking system.

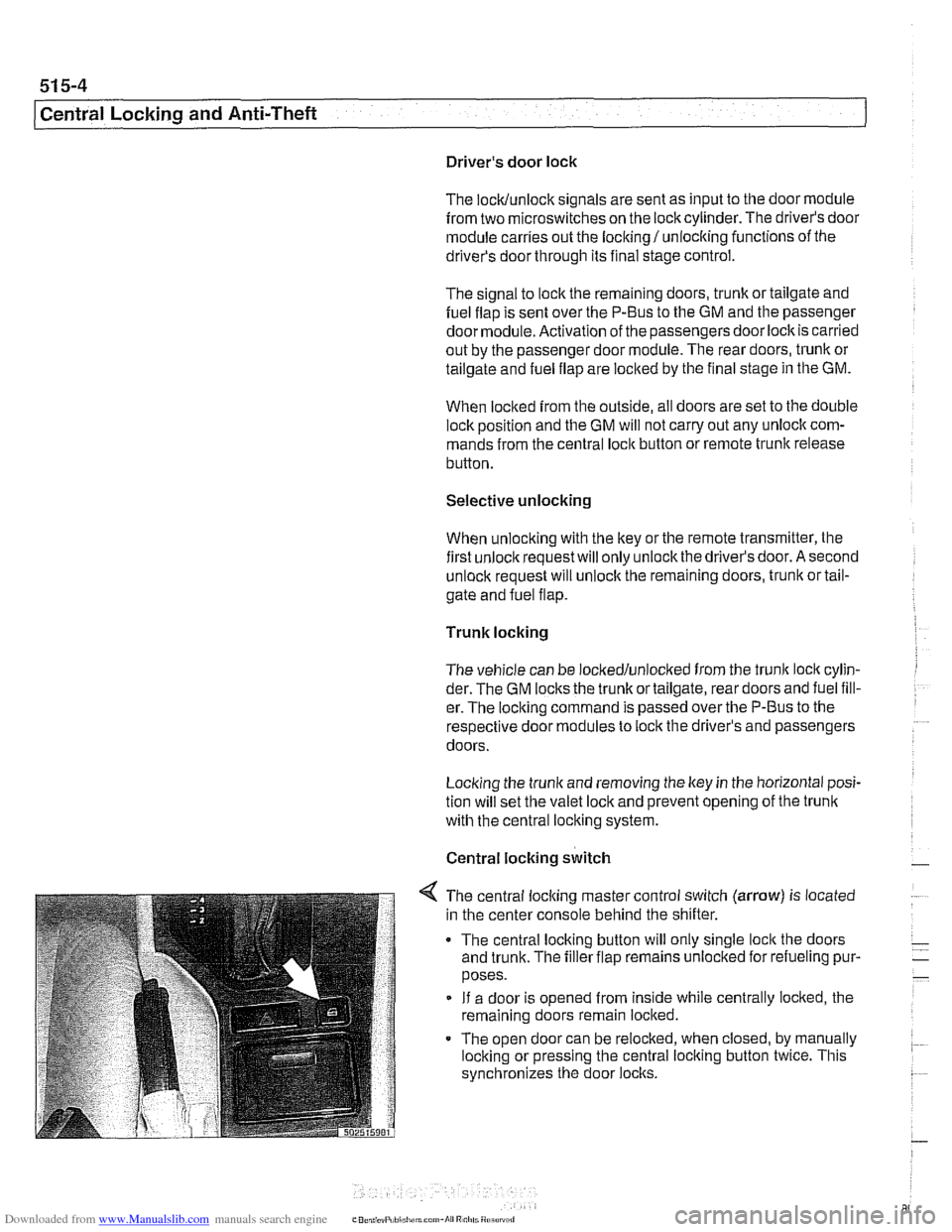

Central locking switch

-

< The central locking master control switch (arrow) is located

in the center console behind the shifter.

The central locking button will only single

loclt the doors

and trunk. The filler flap remains unloclted for refueling pur-

poses.

If a door is opened from inside while centrally locked, the

remaining doors remain locked.

The open door can be relocked, when closed, by manually

locking or pressing the central locking button twice. This

synchronizes the door

locks.

Page 899 of 1002

Downloaded from www.Manualslib.com manuals search engine

Central Locking and Anti-Theft

DWA alarm

The DWA alarm system is

armedldisarmed when thevehicle

is locked / unlocked from either the door or trunk.

Convenience closing

I opening

The windows and sun roof can be closed or opened by hold-

ing the key in the

loclc I unlock position.

Crash sensor

The crash sensor is located in the left front

kick panel. It func-

tions by unlocking all doors in the event of an accident.

NOTE-

Continuous and repeated locliing / unlocking may cause

timedarrest of

the locliing system. When activated, the timed

arrest lasts for two minutes. The timed arrest does not affect

the crash sensor

unlocliing the doors in case of an accident.

Door locks

The driver's door lock location is the only point outside of the

vehicle where the ltey can mechanically control all of the cen-

tral locking system functions.

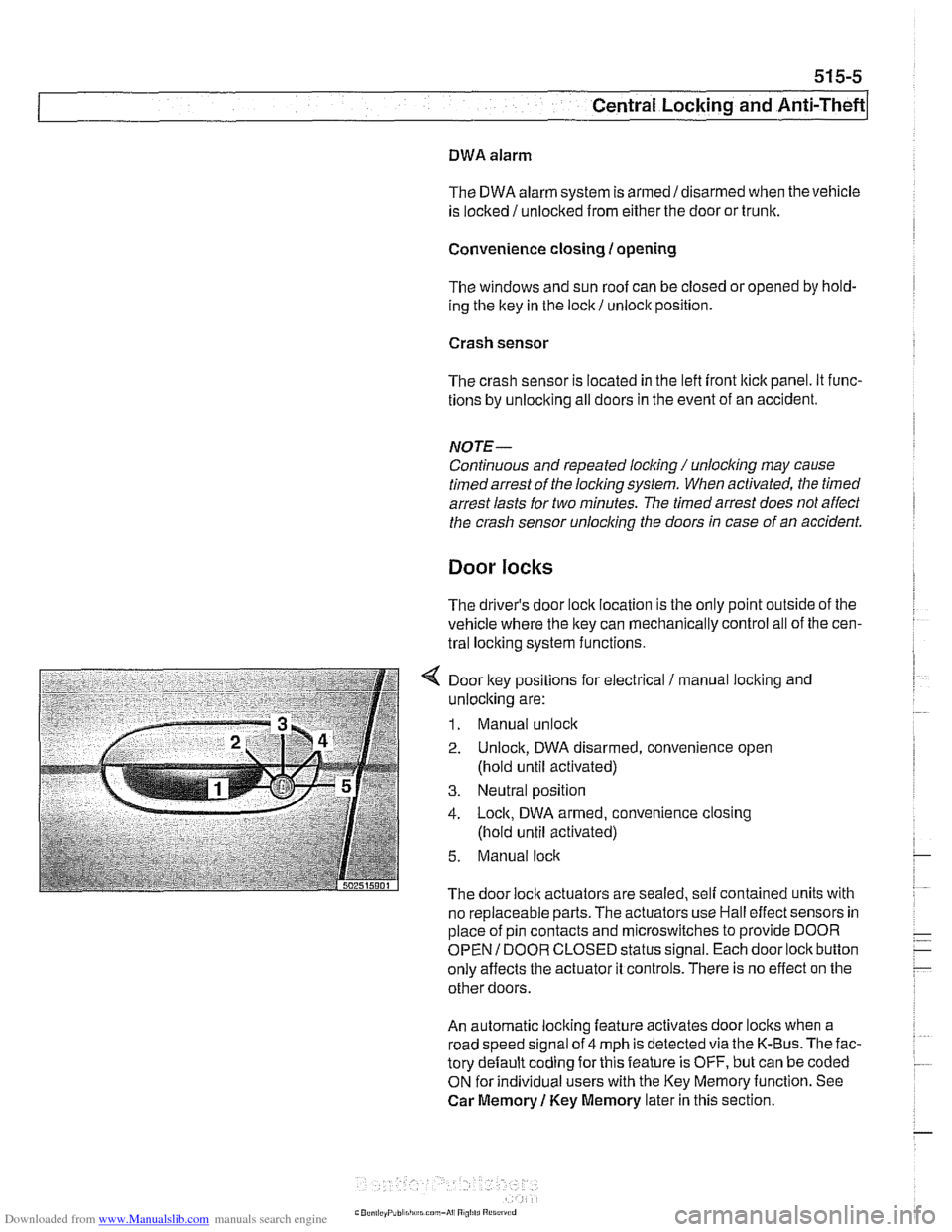

4 Door key positions for electrical / manual loclting and

unlocking are:

1. Manual unlock

2. Unlock, DWA disarmed, convenience open

(hold until activated)

3. Neutral position

4. Lock, DWA armed, convenience closing

(hold until activated)

5. Manual lock

The door lock actuators are sealed. self contained units with

no replaceable parts. The

actuators use Hall effect sensors in

place of pin contacts and microswitches to provide DOOR

OPEN

I DOOR CLOSED status signal. Each door lock button

only affects the actuator it controls. There is no effect on the

other doors.

An automatic locking feature activates door locks when a

road speed signal of 4 mph is detected via the K-Bus. The fac-

tory default coding for this feature is OFF, but can be coded

ON for individual users with the Key Memoryfunction. See

Car Memory

1 Key Memory later in this section.

Page 900 of 1002

Downloaded from www.Manualslib.com manuals search engine

51 5-6

(Central Locking and Anti-Theft

Each rear door is equipped with the child lock-out lever, pre-

venting the door from being opened from the inside regard-

less of loclc button position.

Starting with models produced afler

911997, the General

Module and electronic immobilizer (EWS) interface via the

K-

Bus to monitor double lock status and to initiate double loclc

override. This feature allows the doors to be opened from the

inside if a key accepted by EWS is switched on in the ignition.

See Single lock and double lock function.

The door loclc buttons are mechanically uncoupled from the

actuators when locked. The remote keyless entry system

(FZV) is standard equipment. This allows for elimination of

the passengers side door

loclt cylinder.

Another function of the locking system is the

sofl close trunk

(SCA) system, where applicable.

Single lock and double lock function

(2000 and later models)

On models produced after

911999, each door lock actuator in-

corporates two motors:

Single lock motor controls the mechanical loclc mechanism

when the central lock switch is pressed to single loclc the

vehicle. The loclc mechanism is fully locked at this point but

can stil. be openeo from

the interor by pulng the appropri-

are interior door nandle lwce or by pressing rhe central

lock switch again. When single

lock'function is activated,

the fuel filler flap actuator is not locked.

Double lock motor, also known as central arrest, is activat-

ed only when the vehicle is locked from the outside at the

driver's door lock with a key or when the GM receives a

lock request from the remote entry (FZV) system. In this

case the double lock motor is activated simultaneously

with the single lock motor. The function of the double loclc

motor is to mechanically offset an internal rod in the loclc

actuator, disabling it from unlocking the vehicle from the in-

terior. This prevents the doors from being unloclted by any

means except from an unlock request at the driver's door

or via the FZV remote key.

Lock cylinder safety

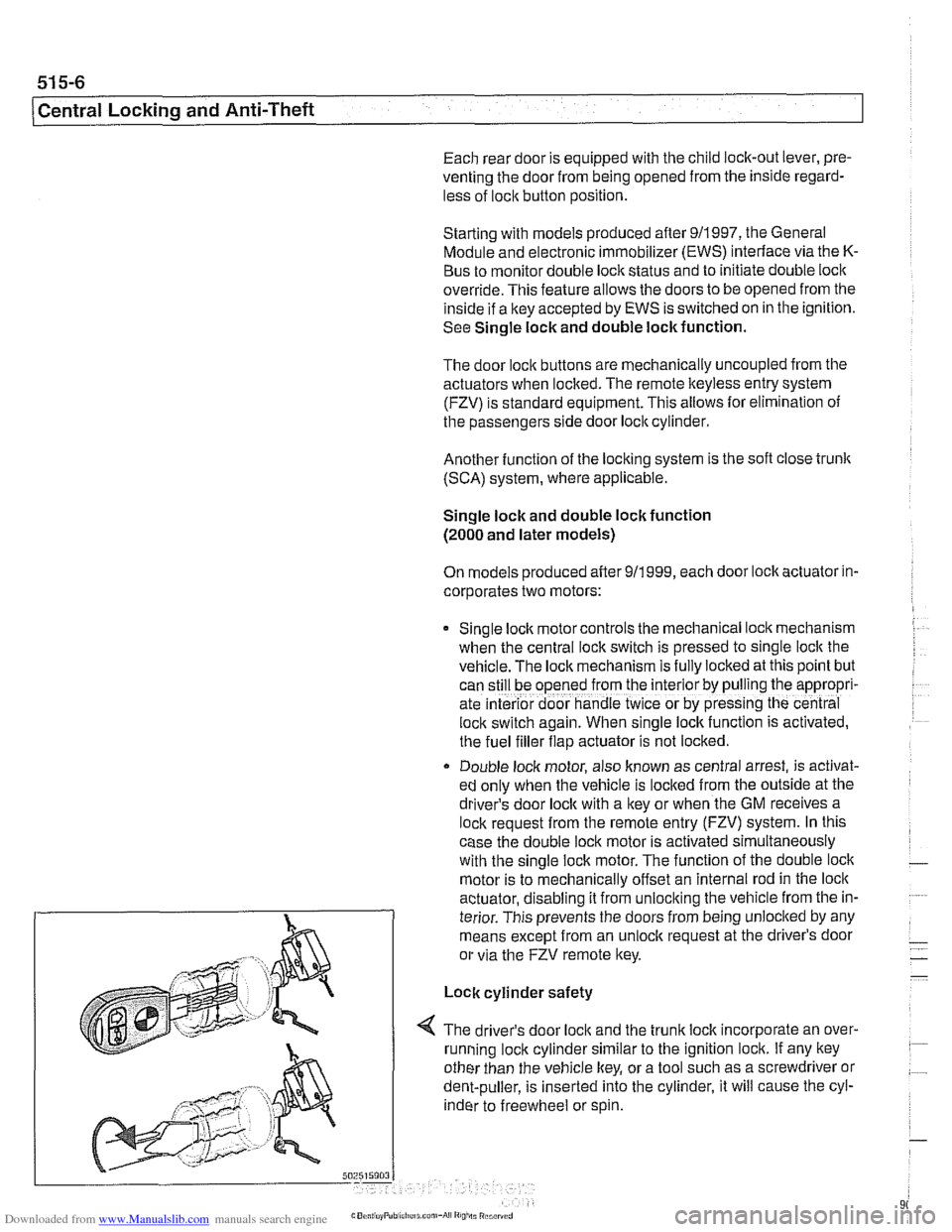

4 The driver's door loclc and the trunk loclc incorporate an over-

running loclc cylinder similar to the ignition lock. If any key

other than the vehicle key, or a tool such as a screwdriver or

dent-puller, is inserted into the cylinder, it will cause the cyl-

inder to freewheel or spin.