tow bar BMW 525i 2000 E39 Workshop Manual

[x] Cancel search | Manufacturer: BMW, Model Year: 2000, Model line: 525i, Model: BMW 525i 2000 E39Pages: 1002

Page 118 of 1002

Downloaded from www.Manualslib.com manuals search engine

. .- -

Cylinder Head Removal and Installation

- Working at side of intake manifold near left strut tower, dis-

connect intake manifold resonance valve electrical harness

connector.

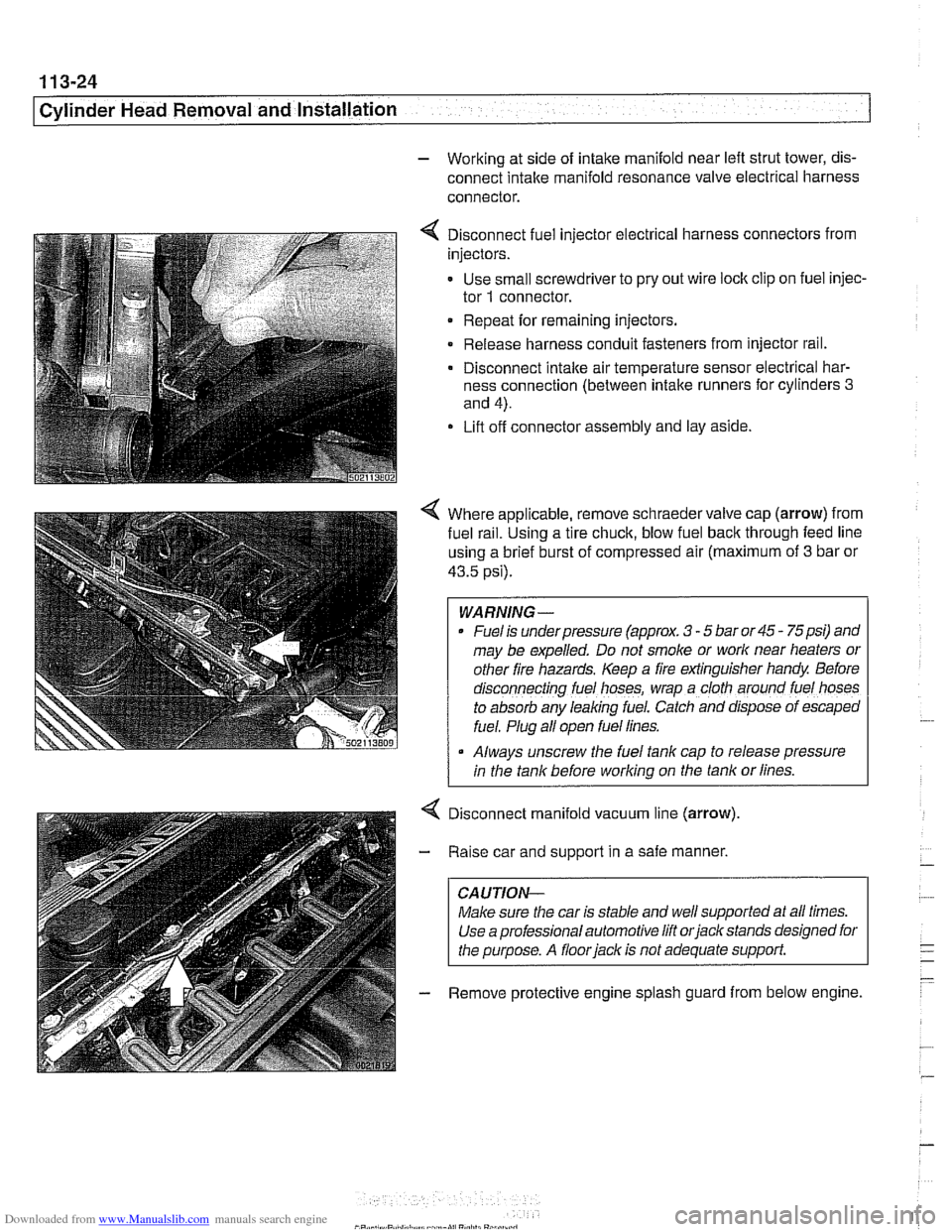

4 Disconnect fuel injector electrical harness connectors from

injectors.

- Use small screwdriver to pry out wire lock clip on fuel injec-

tor

1 connector.

Repeat for remaining injectors.

Release harness conduit fasteners from injector rail.

- Disconnect intake air temperature sensor electrical har-

ness connection (between intake runners for cylinders

3

and 4).

Lift off connector assembly and lay aside.

4 Where applicable, remove schraeder valve cap (arrow) from

fuel

ra~l. Using a tire chuck, blow fuel back through feed line

using a brief burst of compressed air (maximum of

3 bar or

43.5 psi).

WARNING-

Fuel is underpressure (approx. 3 - 5 bar or 45 - 75psi) and

may be expelled. Do not smoke or

work near heaters or

other fire hazards. Keep a fire extinguisher handy Before

d~sconnecting fuel hoses, wrap a cloth around fuel hoses

to absorb any leaking fuel. Catch and

dfspose of escaped

fuel. Plug all open fuel lines.

Always unscrew the fuel tank cap to release pressure

I in the tank before working on the tank or lines.

Disconnect manifold vacuum line (arrow)

Raise car and support in a safe manner,

CAUTION-

Make sure the car is stable and well supported at all times.

Use a professional automotive lift

orjack stands designed for

the purpose. A

floorjack is not adequate support.

Remove protective engine splash guard from below engine.

Page 124 of 1002

Downloaded from www.Manualslib.com manuals search engine

Cylinder Head Removal and installation - - .- - - - -

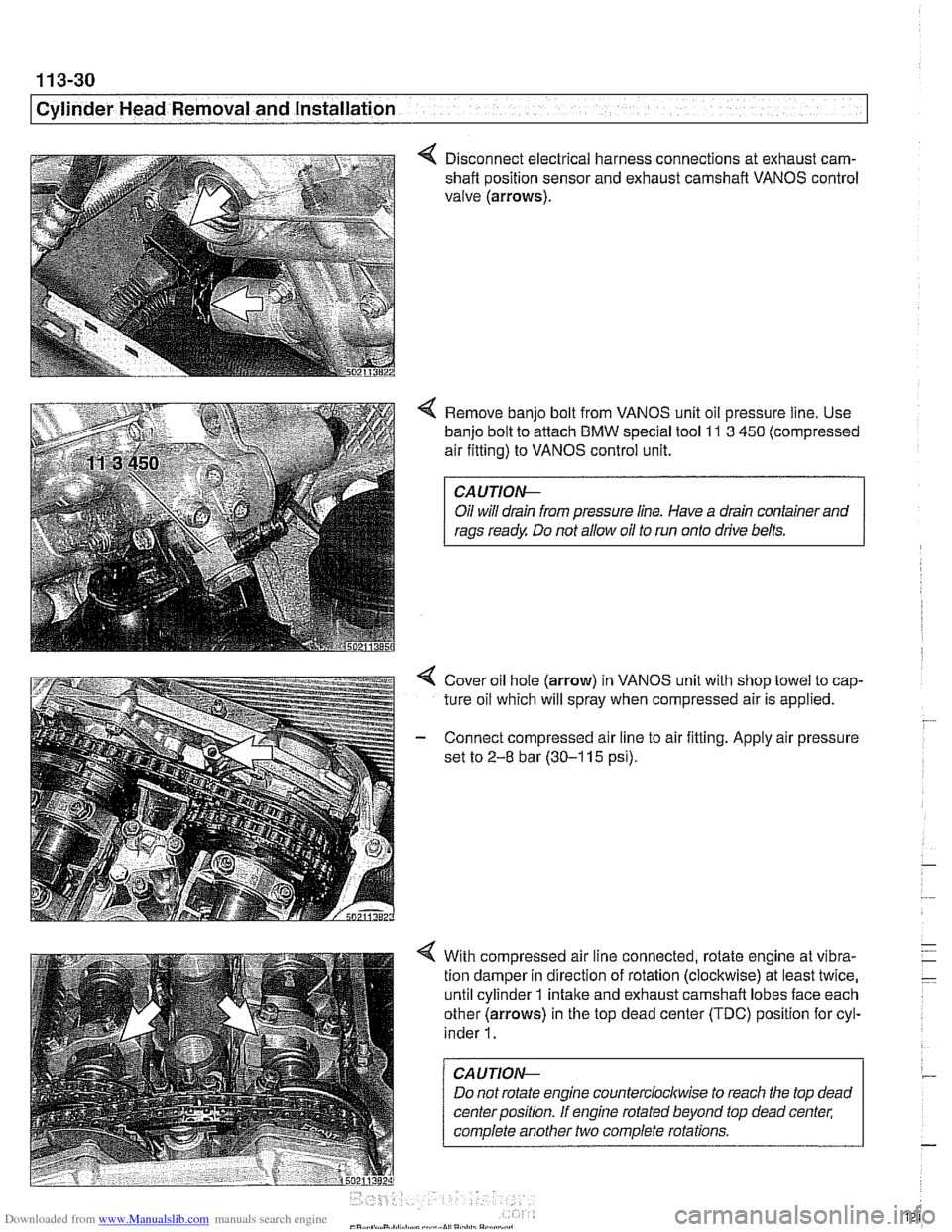

4 Disconnect electrical harness connections at exhaust cam-

shaft position sensor and exhaust camshaft VANOS control

valve (arrows).

4 Remove banjo bolt from VANOS unit oil pressure line. Use

banjo bolt to attach

BMW special tool 11 3 450 (compressed

air fitting) to VANOS control unit.

CAUTIOI\C

Oil will drain from pressure line. Have a drain container and

rags ready Do not allow oil to run onto drive belts.

4 Cover oil hole (arrow) in VANOS unit with shop towel to cap-

ture oil which will spray when compressed air is applied.

- Connect compressed air line to air fitting. Apply air pressure

set to

2-8 bar (30-1 15 psi).

4 With compressed air line connected, rotate engine at vibra-

tion damper in direction of rotation (clockwise) at least twice,

until cylinder 1 intake and exhaust camshaft lobes face each

other (arrows) in the top dead center (TDC) position for cyl-

inder

1.

CAUTION--

Do not rotate engine counterclocltwise to reach the top dead

center position. If engine rotated beyond top dead center;

complete another two complete rotations.

Page 275 of 1002

Downloaded from www.Manualslib.com manuals search engine

11 7-39

Camshaft Timing Chain

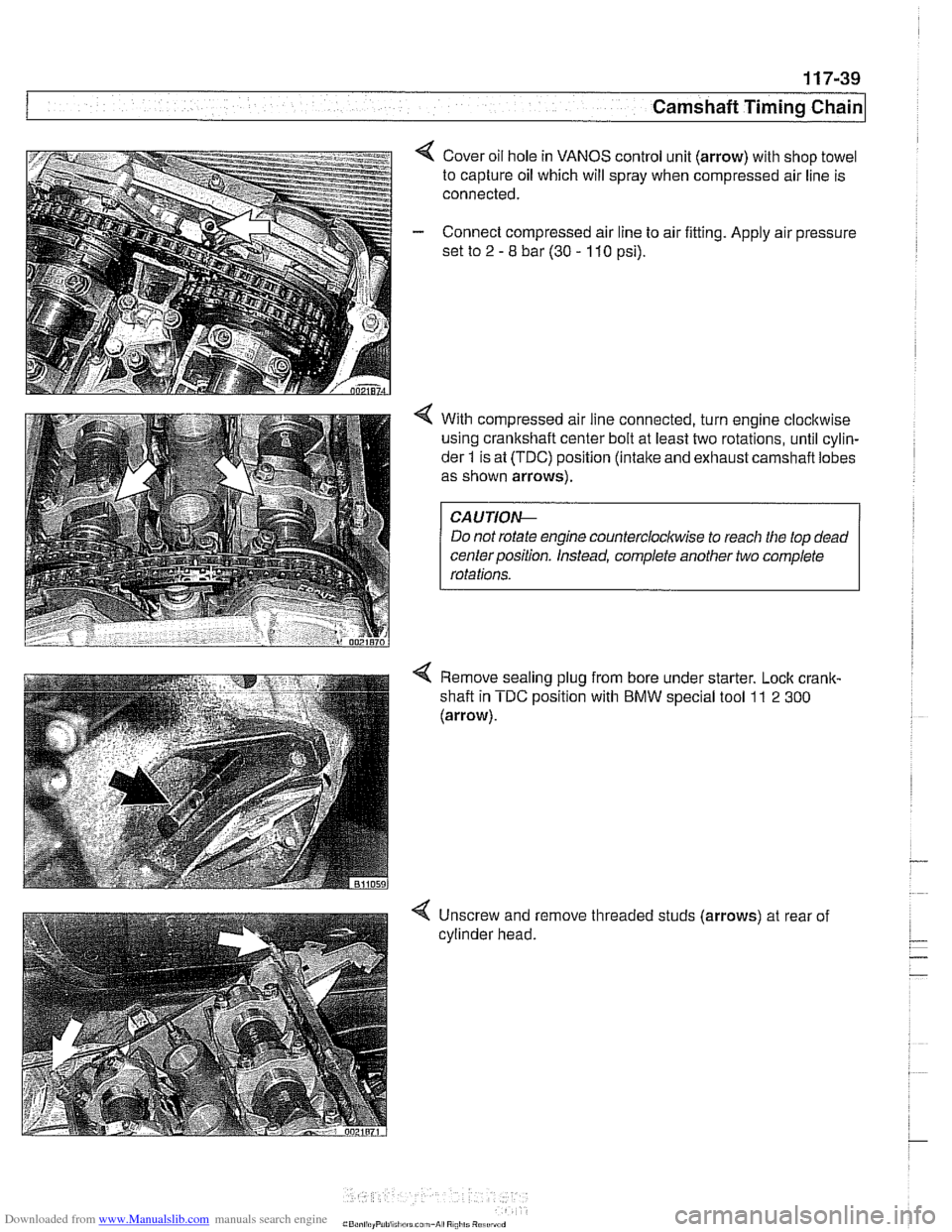

4 Cover oil hole in VANOS control unit (arrow) with shop towel

to capture oil which will spray when compressed air line is

connected.

- Connect compressed air line to air fitting. Apply air pressure

set to

2 - 8 bar (30 - 110 psi).

4 With compressed air line connected, turn engine clocltwise

using crankshaft center bolt at least two rotations, until cylin-

der

1 is at (TDC) position (intake and exhaust carnshafl lobes

as shown arrows).

Do not rotate engine

countercloclwise to reach the top dead

centerposition. Instead, complete another two complete

Remove sealing plug from bore under starter. Lock

crank-

shafl in TDC position with BMW special tool 11 2 300

(arrow).

-

4 Unscrew and remove threaded studs (arrows) at rear of

cylinder head.

Page 324 of 1002

Downloaded from www.Manualslib.com manuals search engine

-

I Lubrication System - I

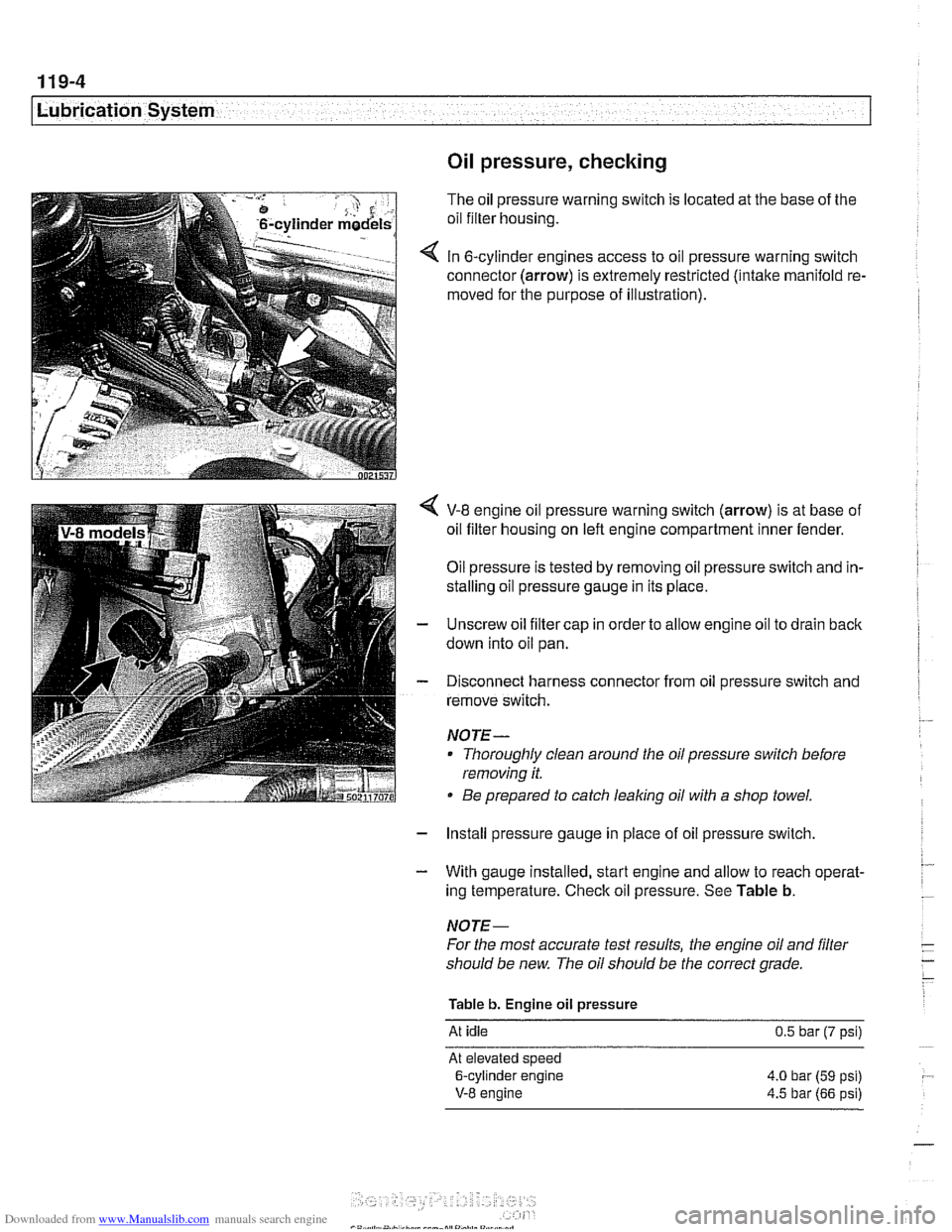

Oil pressure, checking

The oil pressure warning switch is located at the base of the

oil filter housing.

In 6-cylinder engines access to oil pressure warning switch

connector (arrow) is extremely restricted (intake manifold re.

moved for the purpose of illustration).

V-8 engine oil pressure warning switch (arrow) is at base of

oil filter housing on left engine compartment inner fender.

Oil pressure is tested by removing oil pressure switch and in-

stalling oil pressure gauge in its place.

Unscrew oil filter cap in order to allow engine oil to drain back

down into oil pan.

Disconnect harness connector from oil pressure switch and

remove switch.

NOJE-

Thoroughly clean around the oil pressure switch before

removing it.

Be prepared to catch leaking oil with a shop towel.

- Install pressure gauge in place of oil pressure switch,

- With gauge installed, start engine and allow to reach operat-

ing temperature. Check oil pressure. See Table b.

NOJE-

For the most accurate test results, the engine oil and filter

should be new. The oil should be the correct grade.

Table b. Engine oil pressure

At idle 0.5 bar (7 psi)

At elevated speed

6-cylinder engine 4.0 bar

(59 psi)

V-8 engine 4.5 bar (66 psi)

Page 407 of 1002

Downloaded from www.Manualslib.com manuals search engine

Fuel Injection 1

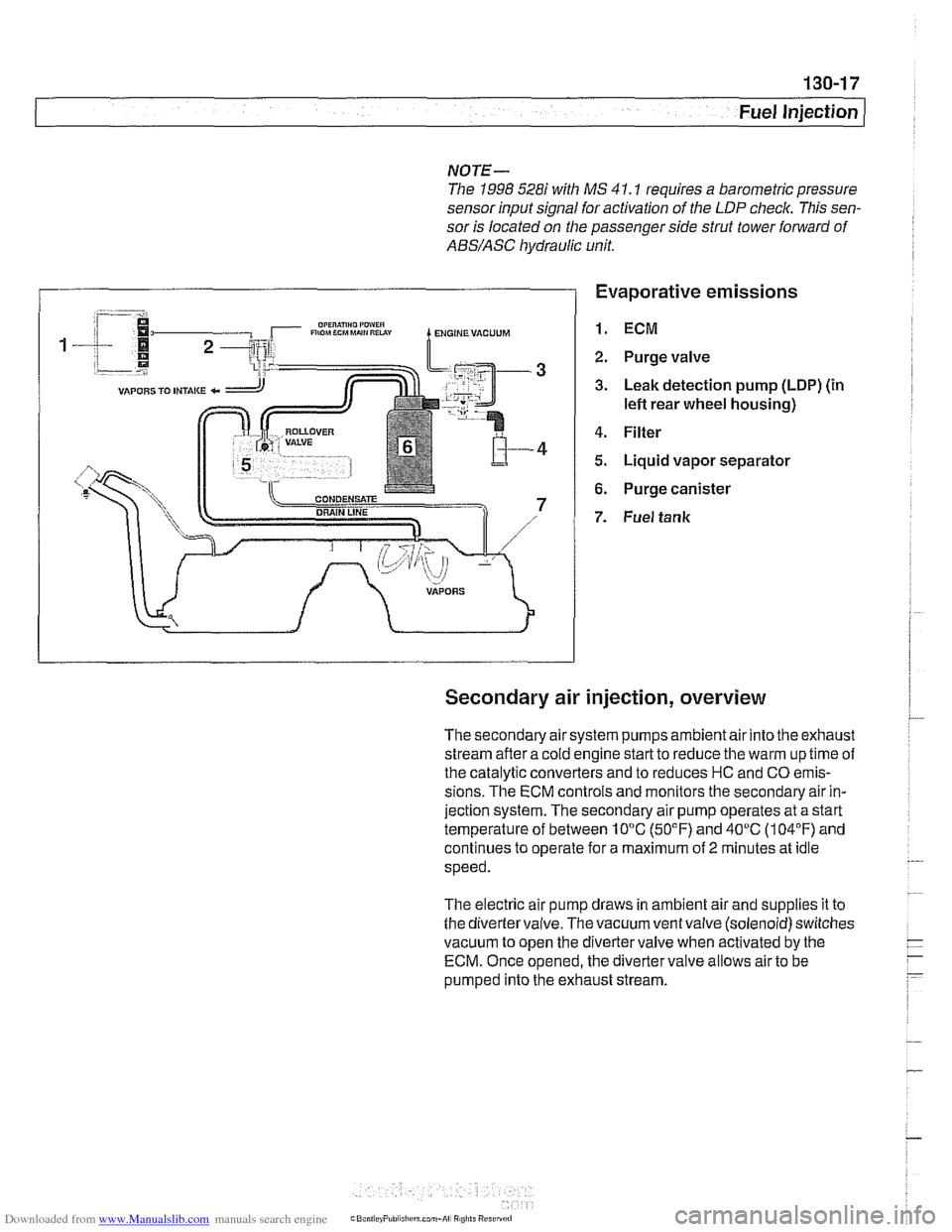

NOTE-

The 1998 5281' with MS 41.1 requires a barometric pressure

sensor input signal for activation of the

LDP check. This sen-

sor is located on the passenger side strut tower

fo~lard of

ABS/ASC hydraulic unit.

Evaporative emissions

1. ECM

2. Purge valve

3. Leak detection pump (LDP) (in

lefl rear wheel housing)

4. Filter

5. Liquid vapor separator

6. Purge canister

7. Fuel tank

Secondary air injection, overview

The secondary air system pumps ambient air into the exhaust

stream afler a cold engine start to reduce the warm up time of

the catalytic converters and to reduces HC and CO emis-

sions. The ECM controls and monitors the secondary air in-

jection system. The secondary air pump operates at a start

temperature of between 10°C (50°F) and 40°C (104°F) and

continues to operate for a maximum of

2 minutes at idle

speed.

The electric air pump draws in ambient air and supplies it to

the divertervalve. The vacuum ventvalve (solenoid) switches

vacuum to open the divertervalve when activated by the

ECM. Once opened, the diverter valve allows air to be

pumped into the exhaust stream.

Page 644 of 1002

Downloaded from www.Manualslib.com manuals search engine

31 0-8

Front Suspension

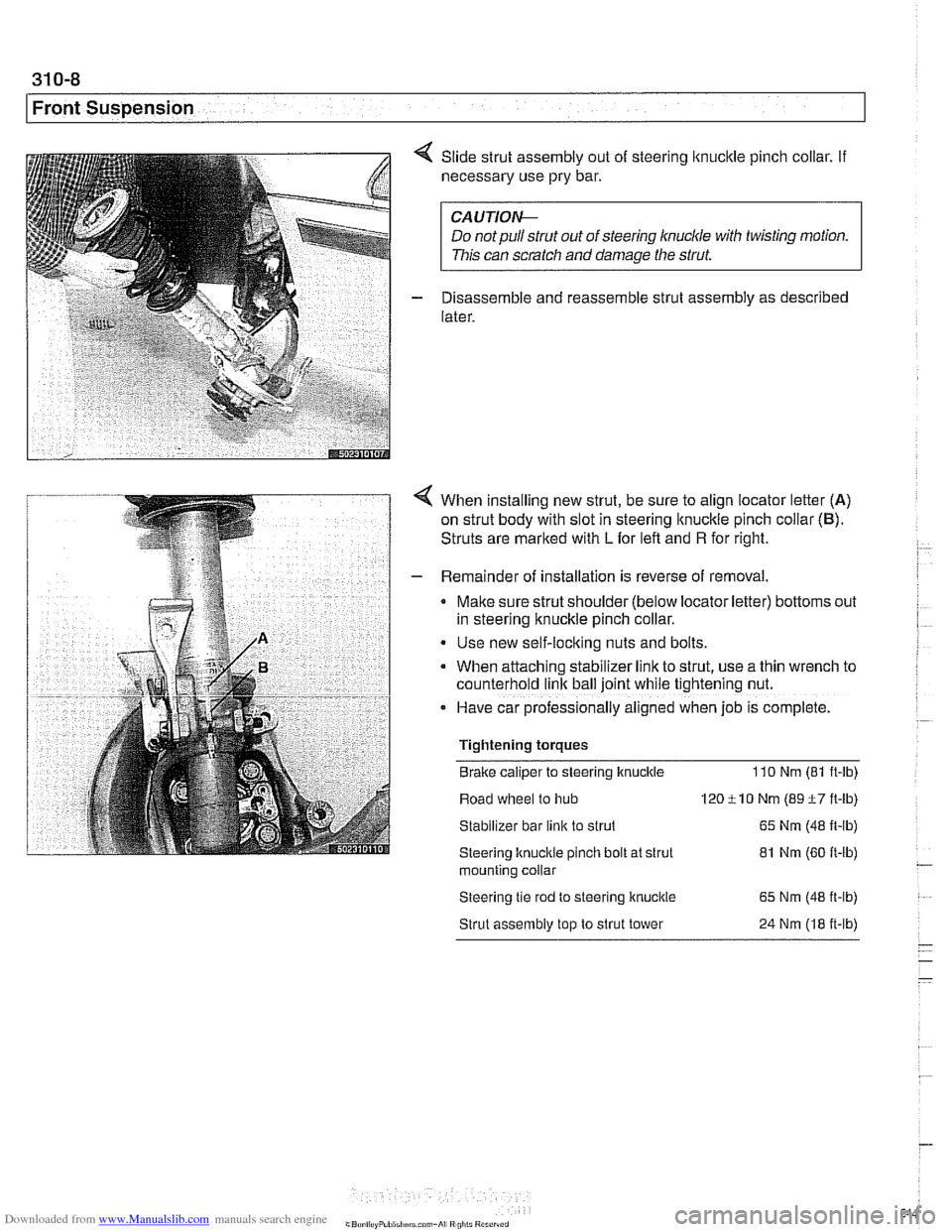

Slide strut assembly out of steering lknucltle pinch collar. If

necessary use pry bar.

CA UTIOI\C

Do notpullstrut out of steering knuckle with twisting motion.

This can scratch and damage the strut.

Disassemble and reassemble strut assembly as described

later.

When installing new strut, be sure to align locator letter (A)

on strut body with slot in steering

lknuckle pinch collar (6).

Struts are marked with L for left and R for right.

Remainder of installation is reverse of removal.

Make sure strut shoulder (below locator letter) bottoms out

in steering knuckle pinch collar.

Use new self-locking nuts and bolts.

When attaching stabilizer

lrnk to strut, use a thin wrench to

counterhold

link ball joint while t~ghtening nut.

- Have car professionally al~gned when job IS complete.

Tightening torques

Brake caliper to steering knuckle

110 Nm (81 ft-ib)

Road wheel to hub 120 ti0 Nm (89 t7 ft-lb)

Stabilizer bar

link to strut 65 Nm (48 It-lb)

Steering knucltle pinch bolt at strut 81 Nm (60 It-lb) - mountlng collar

Steering tle rod to steerlng knuckle 65 Nm (48 it-lb)

Strut assembly top to strut tower 24 Nm (18 it-lb)

- - -

Page 870 of 1002

Downloaded from www.Manualslib.com manuals search engine

Door Windows

Window anti-trap strip, testing

- To test function of anti-trap strip on any window:

With key

ON and window down, pull up window switch to

second detent, thus activating one-touch close operation.

Insert wooden block or other soft object between glass

and upper door frame.

Window should contact block, then immediately reverse

direction and lower by approximately

25 mm (1 in).

NOTE-

Anti-trap strip is integrated into the molding strip of the door

window frame.

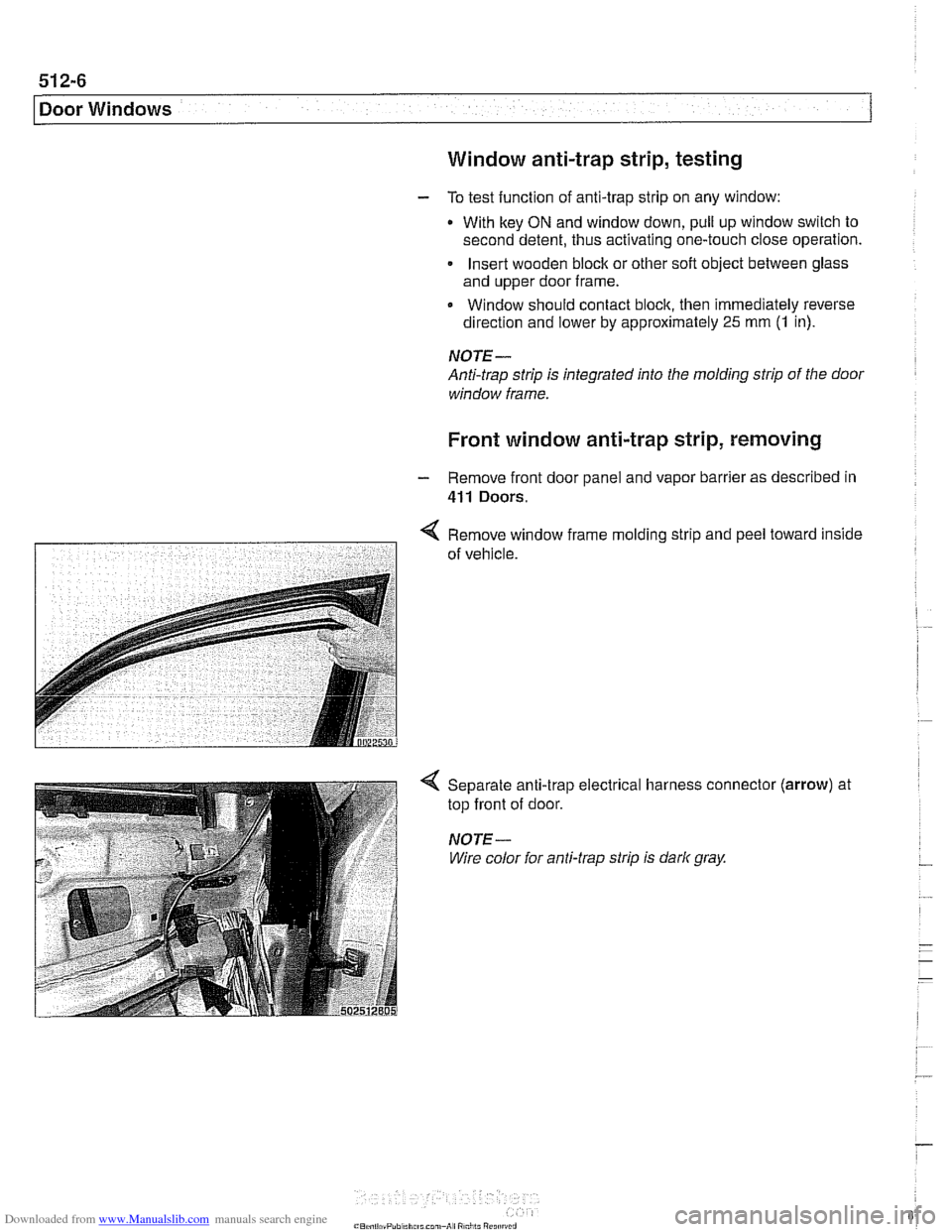

Front window anti-trap strip, removing

- Remove front door panel and vapor barrier as described in

411 Doors.

< Remove window frame mold~ng strlp and peel toward inside

7 of vehrcle.

Separate anti-trap electrical harness connector

top front of door.

NOTE-

Wire color for anti-trap strip is dark gray.

(arrow) at