electrical BMW 525i 2001 E39 User Guide

[x] Cancel search | Manufacturer: BMW, Model Year: 2001, Model line: 525i, Model: BMW 525i 2001 E39Pages: 1002

Page 25 of 1002

Downloaded from www.Manualslib.com manuals search engine

Sockets Socltets are used with a ratchet handle for speed and conve-

nience and can be combined with extensions and universal

joints (swivels) to reach fasteners more easily. The most

common socket drive sizes are

114 inch, 318 inch and 112 inch.

Sockets come in

6 point and 12 point styles. The 6 point offers

a better grip on tight nuts and bolts.

6 mm to 19 mm socltets

are the most needed sizes. Below is a list of typical bolt

diarn-

eters and the corresponding wrench sizes.

Common bolt diameters and wrench sizes

M5 8 rnrn

M6

10 rnm

M8 12rnrnor13rnrn

MI 0 17 rnrn

MI2 19 rnrn

M14 22 mm

Spark plug socket

4 A 518" deep-well socket for sparlt plugs includes a rubber in-

sert to both protect the spark plug from damage and grip it for

easier removal.

Pliers

There are many types of pliers including snap-ring,

needle-

nose, adjustable-joint, slip-joint (Channel-lock@), and locking

(Vice-Grip@) most of which are used for holding irregular ob-

jects, bending, or crimping. Some have special applications.

Needlenose pliers are used for gripping small and poorly ac-

cessible objects, and are useful forwiring and other electrical

work. Locking pliers such as the Vise-Grip@ are useful be-

cause of their tight grip.

Snap-ring and circlip pliers with special tipped jaws are used

to remove and install snap-rings or circlips. Channel-lock@ or

water pump pliers have adjustable jaws that can be quicltly

changed to match the size of the object being held to give

greater leverage,

Page 27 of 1002

Downloaded from www.Manualslib.com manuals search engine

.

General

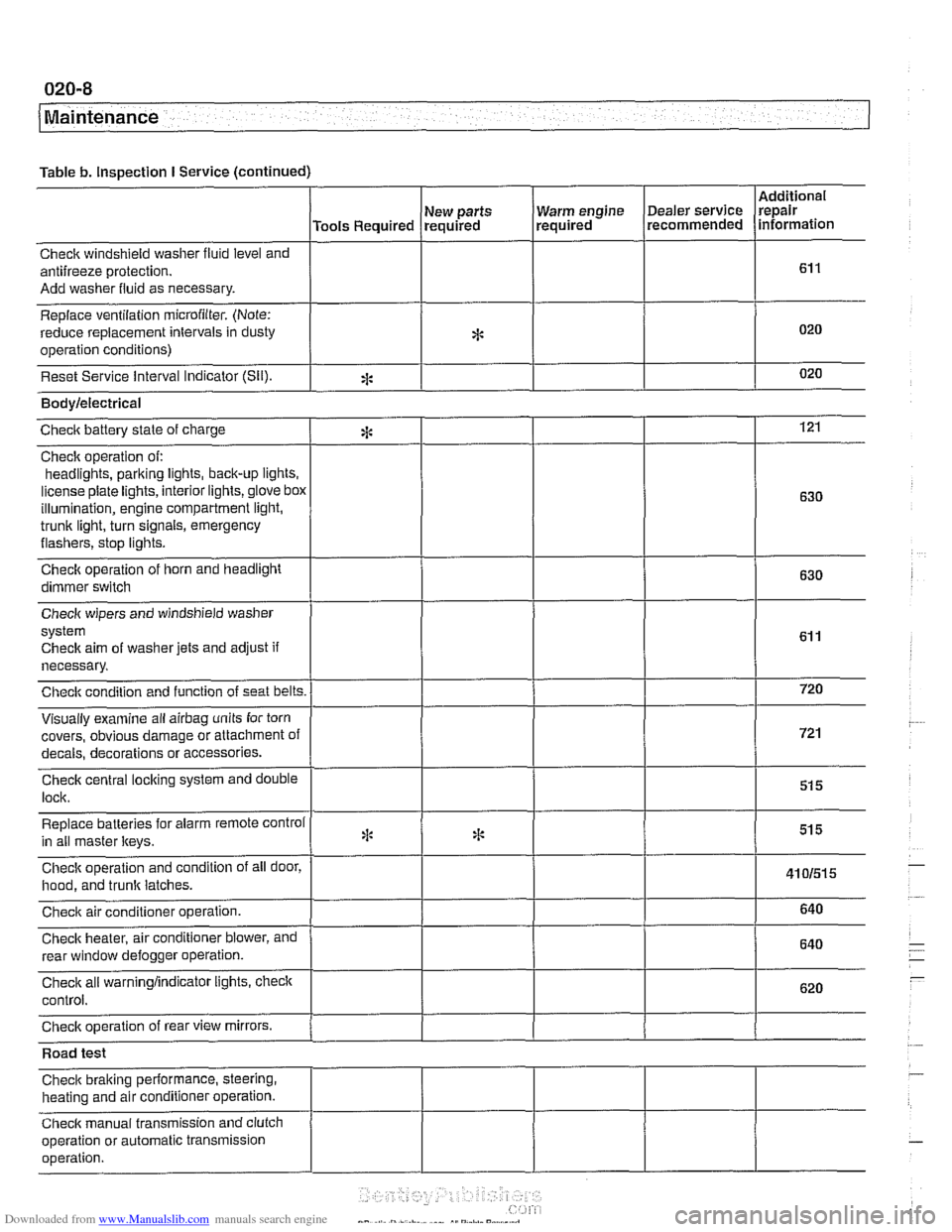

Torque wrench

A torque wrench is used to precisely tighten threaded fasten-

ers to a predetermined value. Many of the repair procedures

in this manual include BMW-specified torque values

in New-

ton-meters (Nm) and the equivalent values in foot-pounds

(ft-

Ib).

4 Several types of torque wrenches are available. An inexpen-

sive beam-type (top) is adequate but must be read visually. A

ratchet-type (bottom) can be preset to indicate (click) when

the torque value has been reached. They all do the same job,

but offer different convenience features at different prices.

The most convenient ones have a built-in ratchet, and can be

preset to indicate when a specific torque value has been

reached. Follow the wrench manufacturer's directions

for use

to achieve the greatest accuracy.

A torque wrench with a range up to about 150 Nm (1 10 ft-lb) BOIBFNG has adequate capacity for most of the repairs covered in this

manual. For recommended torque values of

10 Nm orbelow,

the English system equivalent is given in inch-pounds (in-lb).

These small values may be most easily reached using a

torque wrench calibrated in inch-pounds. To convert

inch-

pounds to foot-pounds, divide by 12.

Digital multimeter

4 Many of the electrical tests in this manual call for the mea-

surement of resistance (ohms) or voltage values. For safe

and accurate tests of sensitive electronic component and

systems, a multimeter or digital

volt/ohm meter (DVOM) with

high input impedance (at least

10,000Sr) should be used.

Some meters have automotive functions such as dwell and

pulse width that are useful for troubleshooting ignition and

fuel injection problems.

CAUTIOI\C

Vehicle electronic systems may be damaged by the high cur-

rent draw of a test light with a normal incandescent bulb. As

a general rule, use a high impedance digital multimeter or an

LED test light for all electrical testing.

Page 40 of 1002

Downloaded from www.Manualslib.com manuals search engine

--- -

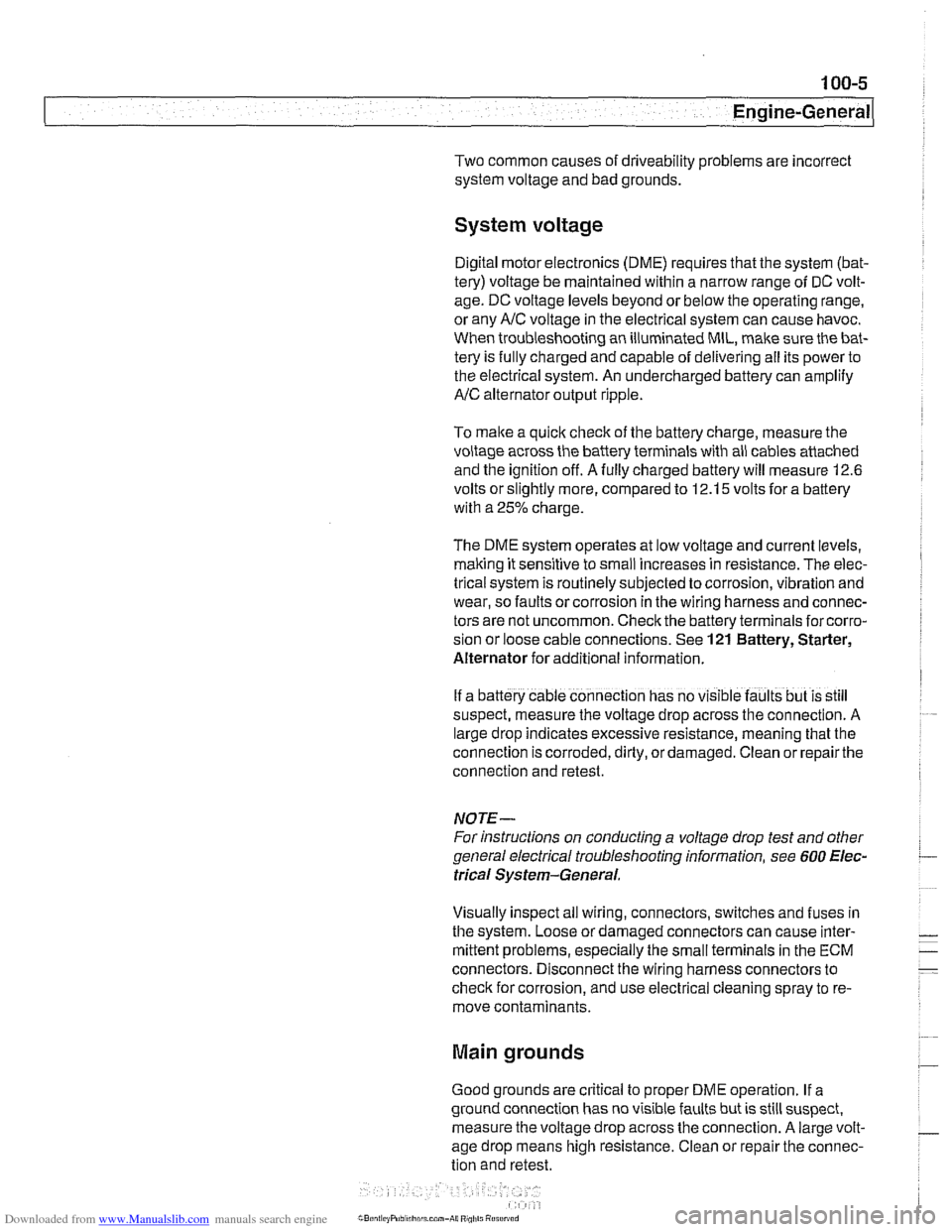

Maintenance

Table b. Inspection I Service (continued)

I I I I

Warm engine Dealer service

required recommended

Check windshield

washer fluid level and

antifreeze protection.

Add washer fluid as necessary.

Replace ventilation

microfilter. (Note:

reduce replacement intervals in dusty

operation conditions)

Reset Service interval Indicator

(Sil).

Additional

repair

information

Tools Required

*

eck aim of washer jets and adjust if

necessary.

covers, obvious damage or attachment o

s or accessories.

Road test

Check braking performance, steering,

heating and air conditioner operation.

Check manual transmission and clutch

operation or automatic transmission

operation. New

parts

required

*

Bodylelectrical

121

630

630

Checic battery state of charge

Check operation of:

headlights,

parking iights, back-up lights.

license plate lights, interior lights,

glove box

illumination, engine compartment light,

trunk light, turn signals, emergency

flashers, stop iights.

Check operation of horn and headlight

dimmer switch

:i:

Page 71 of 1002

Downloaded from www.Manualslib.com manuals search engine

Two common causes of driveability problems are incorrect

system voltage and bad grounds.

System voltage

Digital motor electronics (DME) requires that the system (bat-

tery) voltage be maintained within a narrow range of DC volt-

age.

DC voltage levels beyond or below the operating range,

or any

AIC voltage in the electrical system can cause havoc.

When troubleshooting an illuminated MIL, make sure the bat-

tery is fully charged and capable of delivering all its power to

the electrical system. An undercharged battery can amplify

AIC alternator output ripple.

To

make a quick check of the battery charge, measure the

voltage across the battery terminals with all cables attached

and the ignition off.

Afully charged battery will measure 12.6

volts or slightly more, compared to 12.1 5 volts for a battery

with a 25% charge.

The DME system operates at low voltage and current levels,

making it sensitive to small increases in resistance. The elec-

trical system is routinely subjected to corrosion, vibration and

wear, so faults or corrosion in the wiring harness and connec-

tors are not uncommon. Check the battery terminals

forcorro-

sion or loose cable connections. See 121 Battery, Starter,

Alternator for additional information.

If a battery cable connection has no

v~sible faults but is still

suspect, measure the voltage drop across the connection. A

large drop indicates excessive resistance, meaning that the

connection is corroded, dirty, or damaged. Clean or repairthe

connection and retest.

NOTE-

For instructions on conducting a voltage drop test and other

general electrical troubleshooting information, see

600 Elec-

trical System-General.

Visually inspect all wiring, connectors, switches and fuses in

the system. Loose or damaged connectors can cause inter-

mittent problems, especially the small terminals in the ECM

connectors. Disconnect the wiring harness connectors to

check for corrosion, and use electrical cleaning spray to re-

move contaminants.

Main grounds

Good grounds are critical to proper DME operation. If a

ground connection has no visible faults but is still suspect.

measure the voltage drop across the connection. A large volt-

age drop means high resistance. Clean or repair the connec-

tion and retest.

LBuntr.yP~sbhnllcn.can#-AII A,~iltl Rcsrwsd

Page 72 of 1002

Downloaded from www.Manualslib.com manuals search engine

100-6

( Engine-General

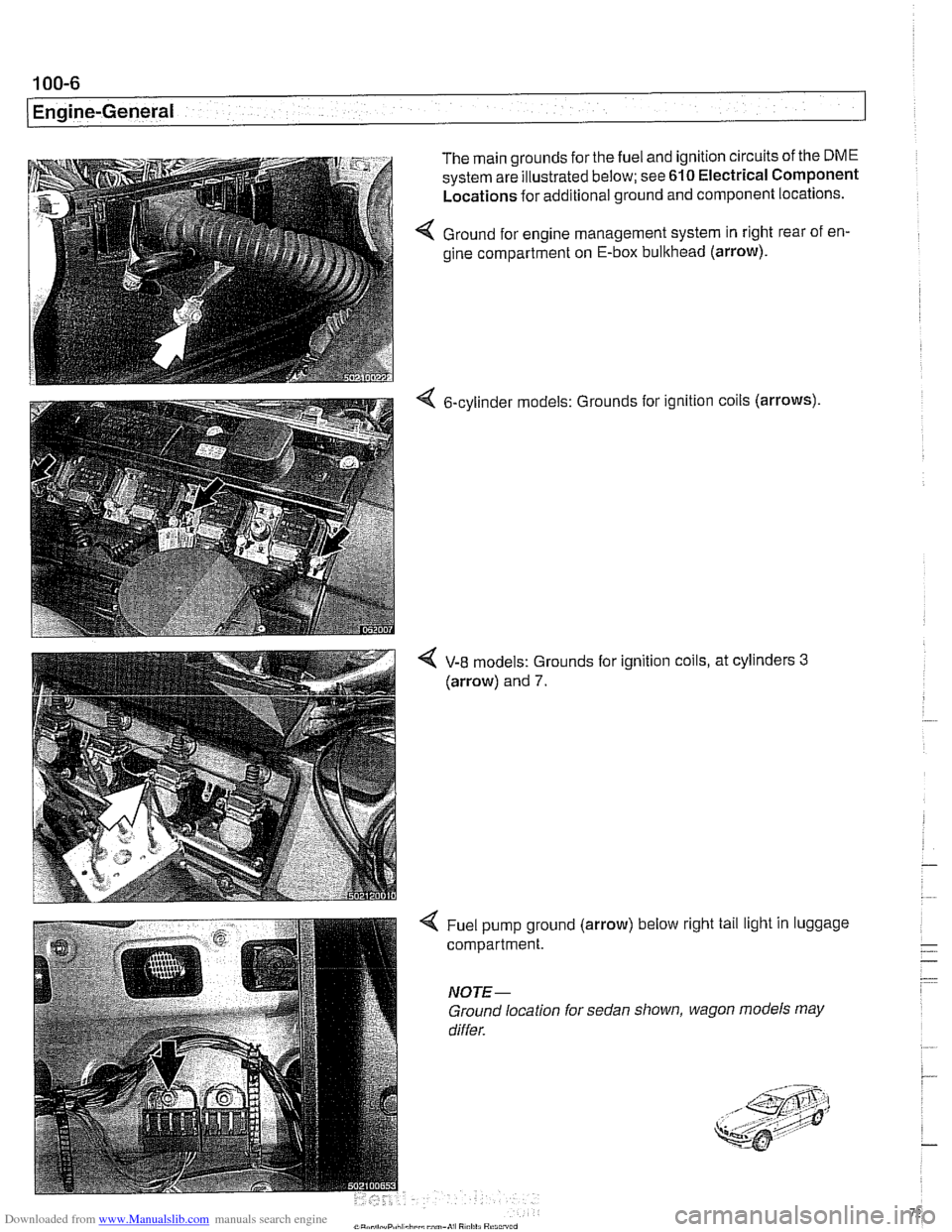

The main grounds for the fuel and ignition circuits of the DME

system are illustrated below; see 610 Electrical Component

Locations for additional ground and component locations.

4 Ground for engine management system in right rear of en-

gine compartment on E-box bulkhead (arrow).

6-cylinder models: Grounds

for ignition coils (arrows)

4 V-8 models: Grounds for ignition coils, at cylinders 3

(arrow) and 7.

4 Fuel pump ground (arrow) below right tail light in luggage

compartment.

NOTE-

Ground location for sedan shown, wagon models may

differ.

Page 76 of 1002

Downloaded from www.Manualslib.com manuals search engine

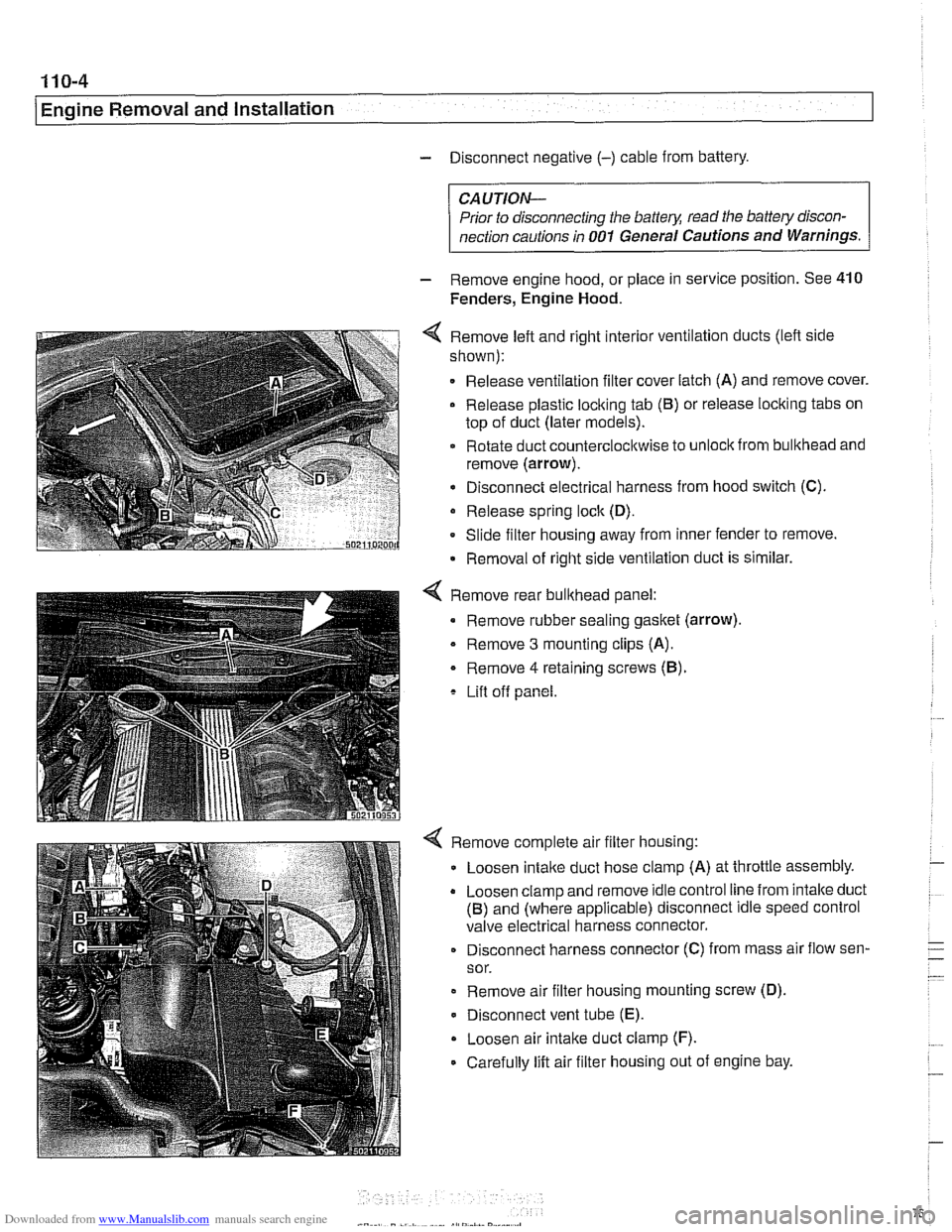

11 0-4

/Engine Removal and Installation

- Disconnect negative (-) cable from battery.

CAUTION- Prior to disconnecting the

batteg read the battery discon-

nection cautions

in 001 General Cautions and Warnings.

- Remove engine hood, or place in service position. See 410

Fenders, Engine Hood.

4 Remove left and right interior ventilation ducts (lefl side

shown):

Release ventilation filter cover latch (A) and remove cover.

Release plastic loclting tab

(6) or release locking tabs on

top of duct (later models).

Rotate duct counterclocltwise to

unloclt from bulkhead and

remove (arrow).

Disconnect electrical harness from hood switch (C).

Release spring

loclt (D).

Slide filter housing away from inner fender to remove.

Removal of right side ventilation duct is similar.

Remove rear bulkhead panel:

Remove rubber sealing gasket (arrow).

- Remove 3 mounting clips (A).

Remove

4 retaining screws (6).

Lift off panel.

Remove complete air filter housing:

Loosen

intalte duct hose clamp (A) at throttle assembly.

Loosen clamp and remove idle control line from intalte duct

(6) and (where applicable) disconnect idle speed control

valve electrical harness connector.

Disconnect harness connector (C) from mass air flow sen-

sor.

Remove air filter housing mounting screw (D).

Disconnect vent tube

(E).

Loosen air intake duct clamp (F).

Carefully lift air filter housing out of engine bay.

Page 77 of 1002

Downloaded from www.Manualslib.com manuals search engine

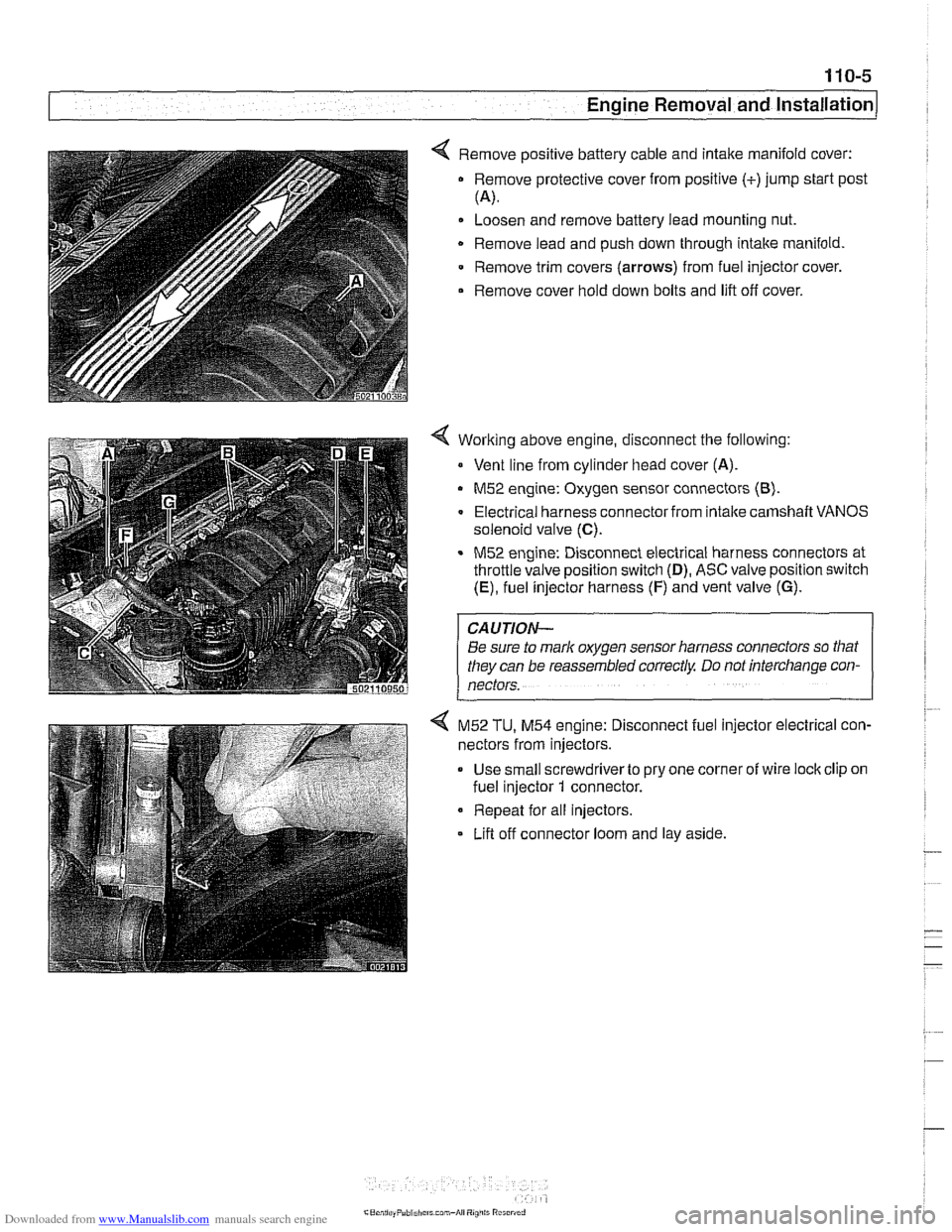

Engine Removal and lnstallationl

< Remove positive battery cable and intake manifold cover:

Remove protective cover from positive (+)jump start post

(4.

Loosen and remove battery lead mounting nut.

Remove lead and push down through intake manifold

Remove trim covers

(arrows) from fuel injector cover.

Remove cover hold down bolts and lift off cover.

Working above engine, disconnect the following:

Vent line from cylinder head cover (A).

M52 engine: Oxygen sensor connectors (8).

Electrical harness connector from intalte camshaft VANOS

solenoid valve

(C).

M52 engine: Disconnect electrical harness connectors at

throttle valve position switch

(D), ASC valve position switch

(E), fuel injector harness (F) and vent valve (G).

CAUTION-

Be sure to mark oxygen sensor harness connectors so that

they can be reassembled correctly Do not interchange con-

nectors.

4 M52 TU, M54 engine: Disconnect fuel injector electrical con-

nectors from injectors.

Use small screwdriverto pry one corner of wire lock clip on

fuel injector

1 connector.

Repeat for all injectors.

Lifl off connector loom and lay aside.

Page 80 of 1002

Downloaded from www.Manualslib.com manuals search engine

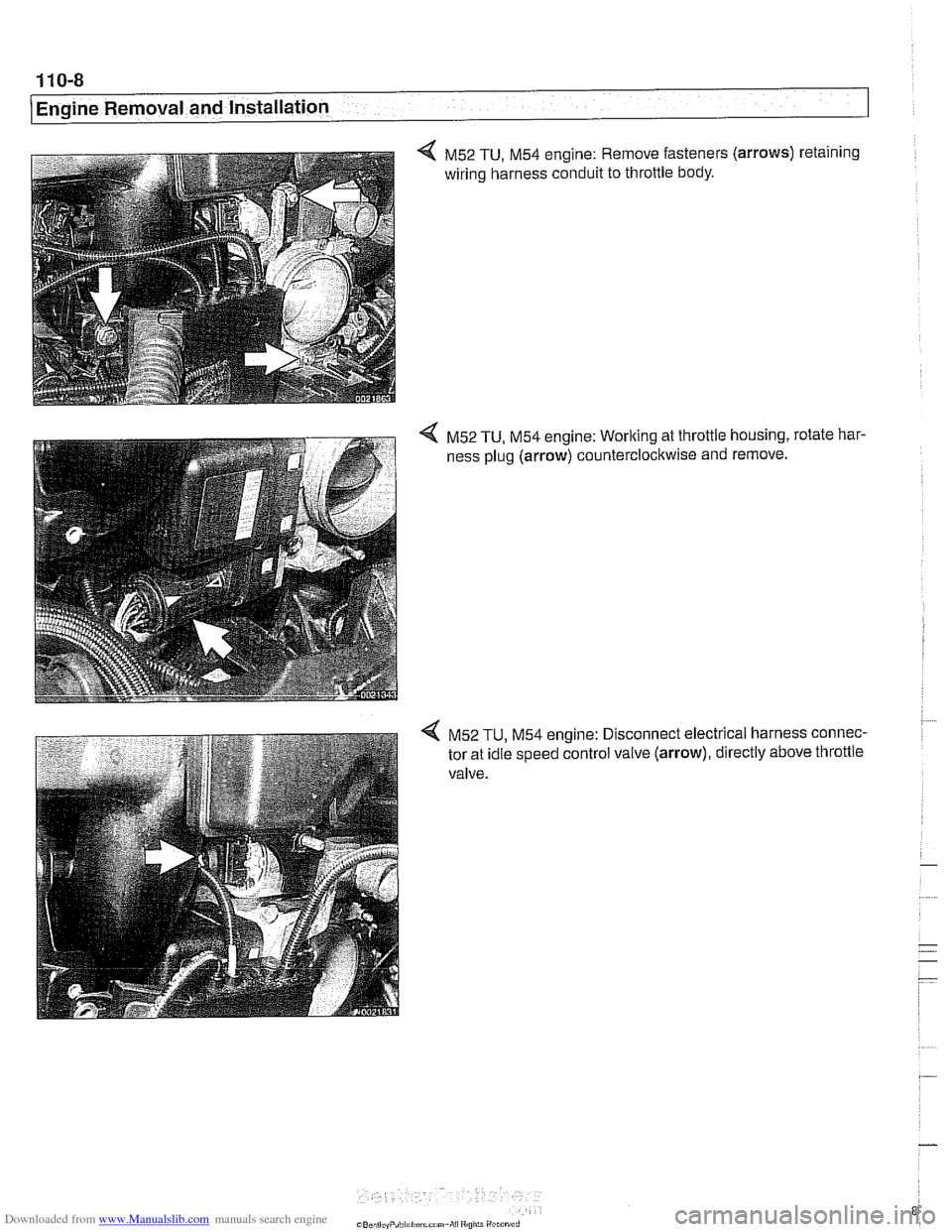

110-8

1 Engine Removal and Installation

4 M52 TU, M54 engine: Remove fasteners (arrows) retaining

wiring harness conduit to throttle body.

4 M52 TU, M54 engine: Working at throttle housing, rotate har-

ness plug (arrow) counterclockwise and remove.

4 M52 TU, M54 engine: Disconnect electrical harness connec-

tor at idle speed control valve (arrow), directly above throttle

valve.

Page 81 of 1002

Downloaded from www.Manualslib.com manuals search engine

Engine Removal and lnstallationl

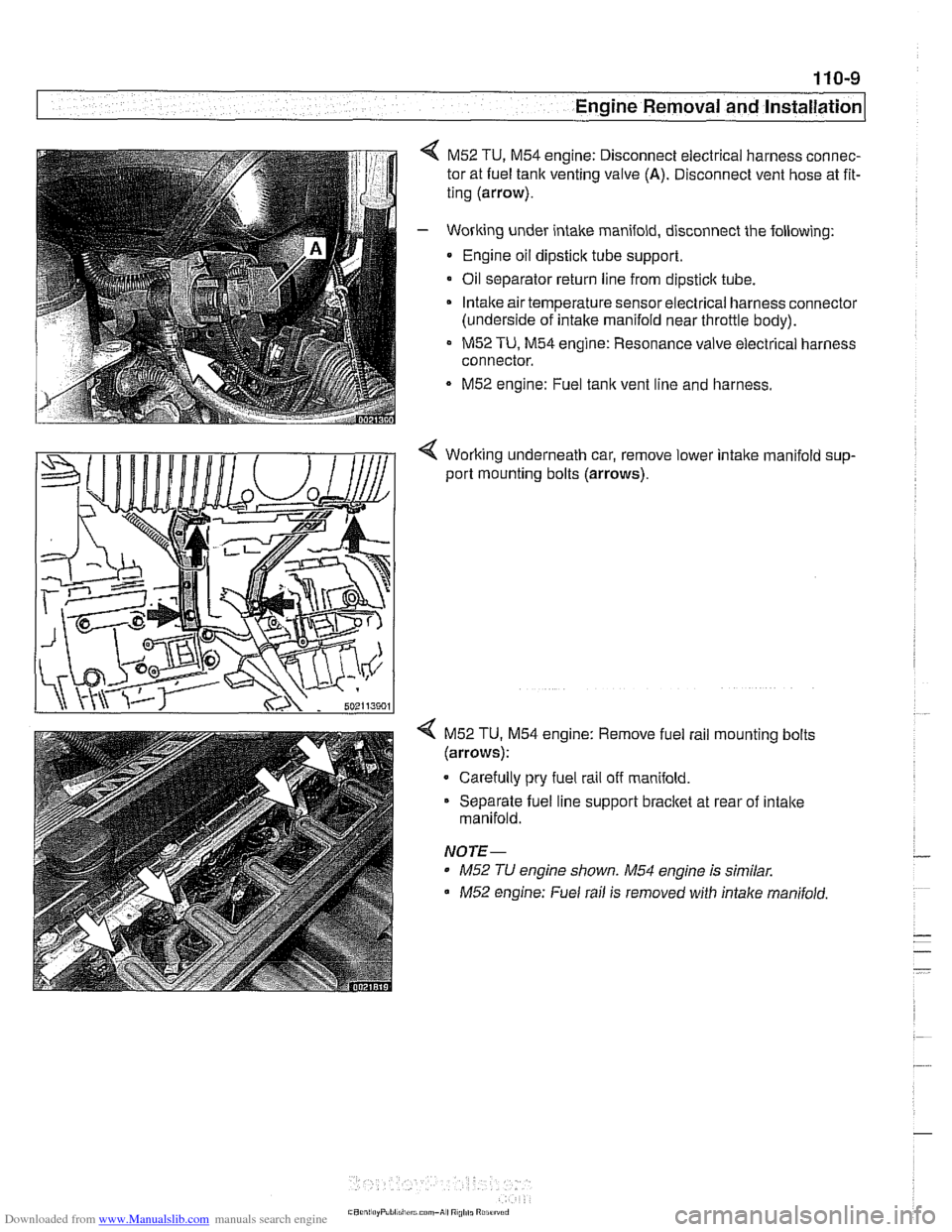

M52 TU, M54 engine: Disconnect electrical harness connec-

tor at fuel tank venting valve

(A). Disconnect vent hose at fit-

ting (arrow).

- Working under intake manifold, disconnect the following:

Engine oil dipstick tube support.

Oil separator return line from

dipsticlc tube.

Intake air temperature sensorelectrical harness connector

(underside of intake manifold near throttle body).

M52 TU, M54 engine: Resonance valve electrical harness

connector.

M52 engine: Fuel tank vent line and harness.

< Working underneath car, remove lower intalte manifold sup-

port mounting bolts (arrows).

4 M52 TU. M54 engine: Remove fuel rail mounting bolts

(arrows):

Carefully pry fuel rail off manifold.

Separate fuel line support bracket at rear of intake

manifold.

NOTE-

* M52 TU engine shown. M54 engine is similar.

M52 engine: Fuel rail is removed with intalte manifold.

Page 82 of 1002

Downloaded from www.Manualslib.com manuals search engine

.-

-6val and Installation -

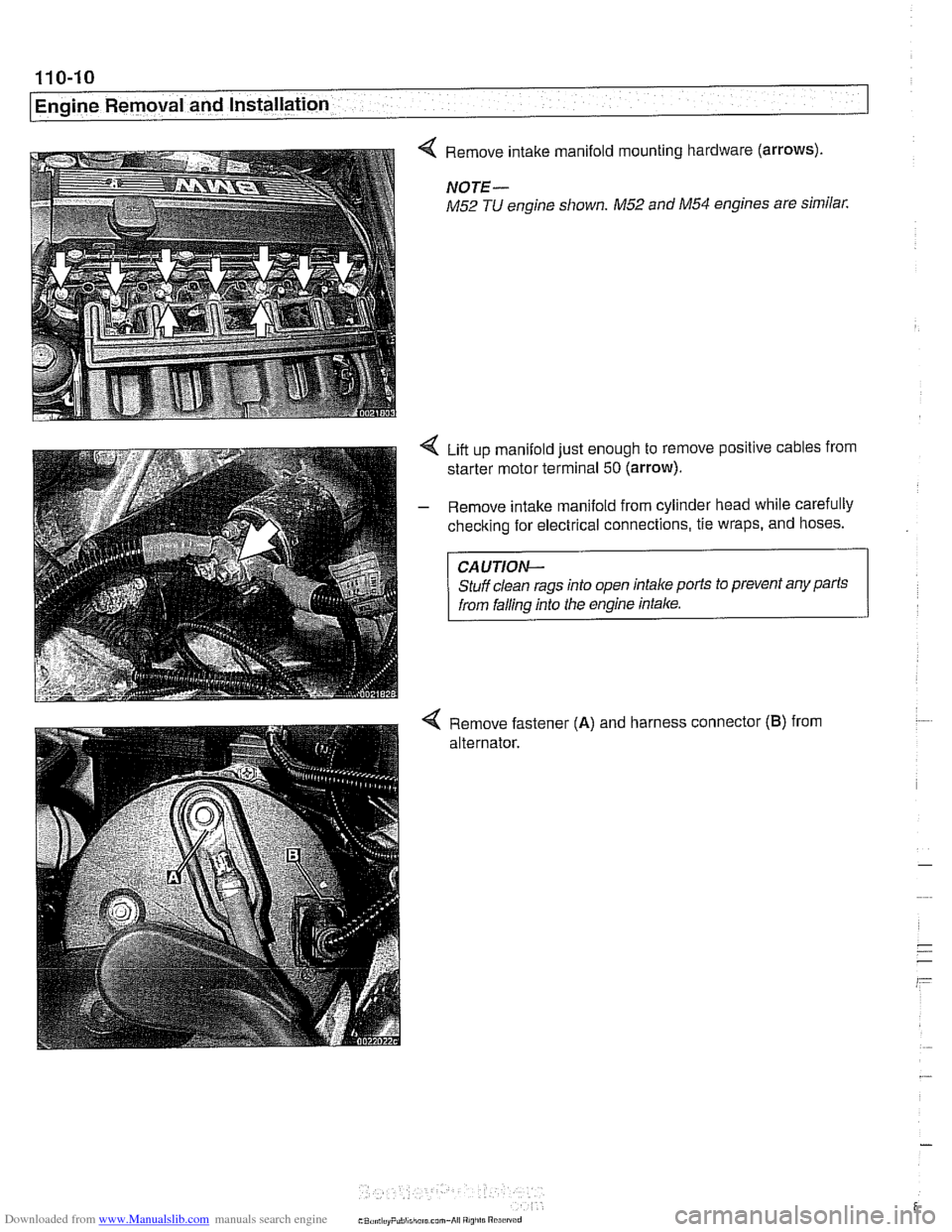

< Remove intake manifold mounting hardware (arrows).

NOTE-

M52 TU engine shown. M52 and M54 engines are similar.

Liit up manifold just enough to remove positive cables from

starter motor terminal

50 (arrow).

- Remove intake manifold from cylinder head while carefully

checking for electrical connections, tie wraps, and hoses.

CAUTION-

Stuff clean rags into open intake ports to prevent any parts

from falling into the engine intake.

4 Remove fastener (A) and harness connector (B) from

alternator.