Front BMW 525i 2001 E39 Owner's Manual

[x] Cancel search | Manufacturer: BMW, Model Year: 2001, Model line: 525i, Model: BMW 525i 2001 E39Pages: 1002

Page 114 of 1002

Downloaded from www.Manualslib.com manuals search engine

--

Cylinder Head Removal and Installation

NOTE-

BMW special tool 11 4 220 is an adjustable primary chain

tensioner and simulates the function of the hydraulic

tensioner.

- Check that elongated holes in primary sprocket are now cen-

tered to bolt holes in camshaft and chain is free of slack. If

not, reposition sprocket to chain and reinstall.

- lnstall secondary timing chain guide and secondary chain

tensioner. Tighten mounting bolts (tensioner remains locked

down for now using

BMW special tool 11 3 292).

- Install cylinder identification trigger plate to front of intake

camshaft with studs.

- Install spacer to front of intake camshaft.

- Install secondary chain sprockets and chain as an assembly

so that arrows on sprockets are pointing up. Center mounting

holes in sprockets to bolt holes in camshafts.

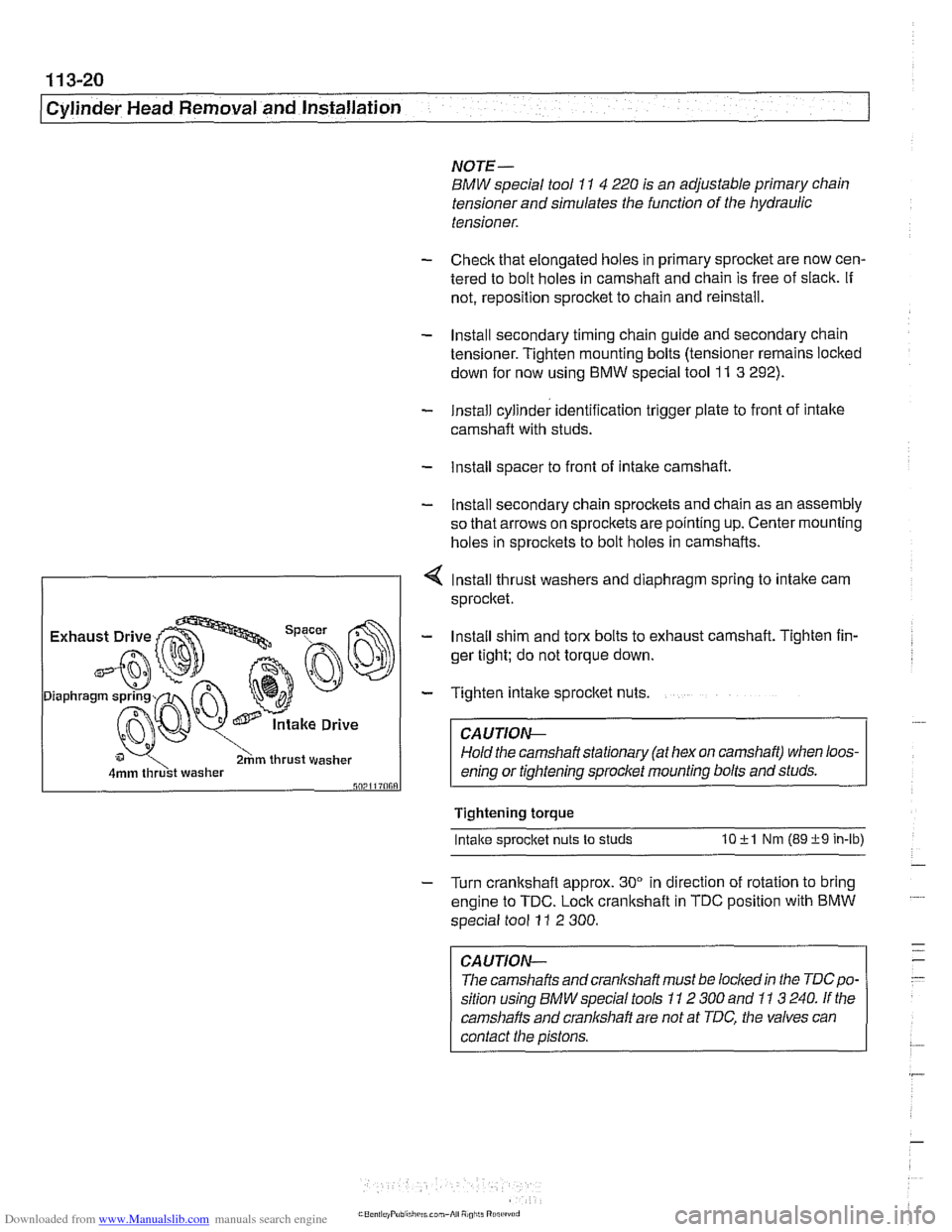

4 lnstall thrust washers and diaphragm spring to intake cam

sprocket.

I 2hm thrust washer I

- Install shim and torx bolts to exhaust camshaft. Tighten fin-

ger tight; do not torque down.

- Tighten intake sprocket nuts.

CA UTIOG

Hold the camshaft stationary (at hex on camshaft) when loos-

enino or tiahtenino sorocket mounting bolts and studs.

Tightening torque

Intake s~rocket nuts to studs 10 +l Nm (89 +9 in-lb)

- Turn crankshaft approx. 30" in direction of rotation to bring

engine to TDC. Lock crankshaft in TDC position with BMW

special tool

11 2 300.

CAUTION-

The camshafts andcranlshaft must be lockedin the TDCpo-

sition using BMW special tools 11 2 300 and 11 3 240. If the

camshafts and cranl(shaft are not at TDC, the valves can

contact the pistons.

Page 115 of 1002

Downloaded from www.Manualslib.com manuals search engine

- -.

Cylinder Head Removal and lnstallation

NOTE-

Be Sure the secondary timing chain tensioner is locked down

and the exhaust

camshaif mounting bolts are loose before

proceeding.

- Install VANOS control unit. See VANOS control unit, install-

ing

(M52 engine) in 117 Camshaft Timing Chain.

CAUTION--

Incorrect installation ofthe VANOS control may result in dam-

age to the engine valvefrain.

- Install exhaust manifolds using new gaskets and nuts. Coat

manifold studs with copper paste prior to installing nuts.

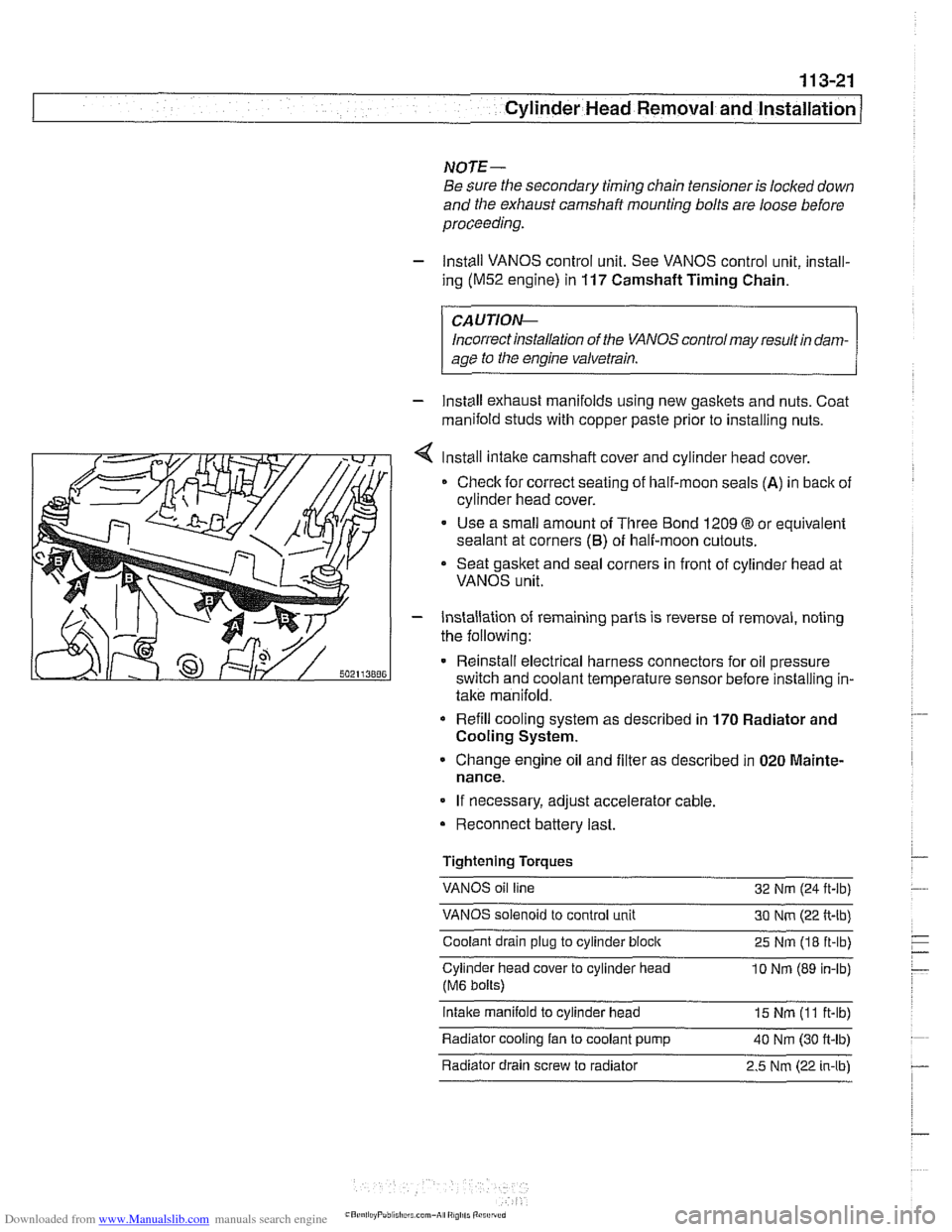

Install intake camshaft cover and cylinder

head cover.

Check for correct seating of half-moon seals

(A) in back of

cylinder head cover.

Use a small amount of Three Bond 1209

O or equivalent

sealant at corners

(6) of half-moon cutouts.

Seat gasket and seal corners in front of cylinder head at

VANOS unit.

- Installation of remaining parts is reverse of removal, noting

the following:

Reinstall electrical harness connectors for oil pressure

switch and coolant temperature sensor before installing in-

take manifold.

Refill cooling system as described in 170 Radiator and

Cooling System.

Change engine oil and filter as described in 020 Mainte-

nance.

If necessary, adjust accelerator cable.

Reconnect battery last.

Tightening Torques

VANOS oil line

32 Nm (24

ft-lb)

VANOS solenoid to control unit 30 Nm (22 ft-lb)

Coolant drain plug to cylinder

block 25 Nm (18 ft-lb)

Cylinder head cover to cylinder head

10 Nrn (89 in-lb)

(M6 bolts)

intake manifold to cylinder head 15 Nm (I 1 ft-lb)

Radiator cooling fan to coolant pump

40 Nm (30 ft-lb) - . .

Radiator drain screw to radiator 2.5 Nm (22 in-lbl

Page 117 of 1002

Downloaded from www.Manualslib.com manuals search engine

- --

Cylinder Head Removal and Installation 1 --

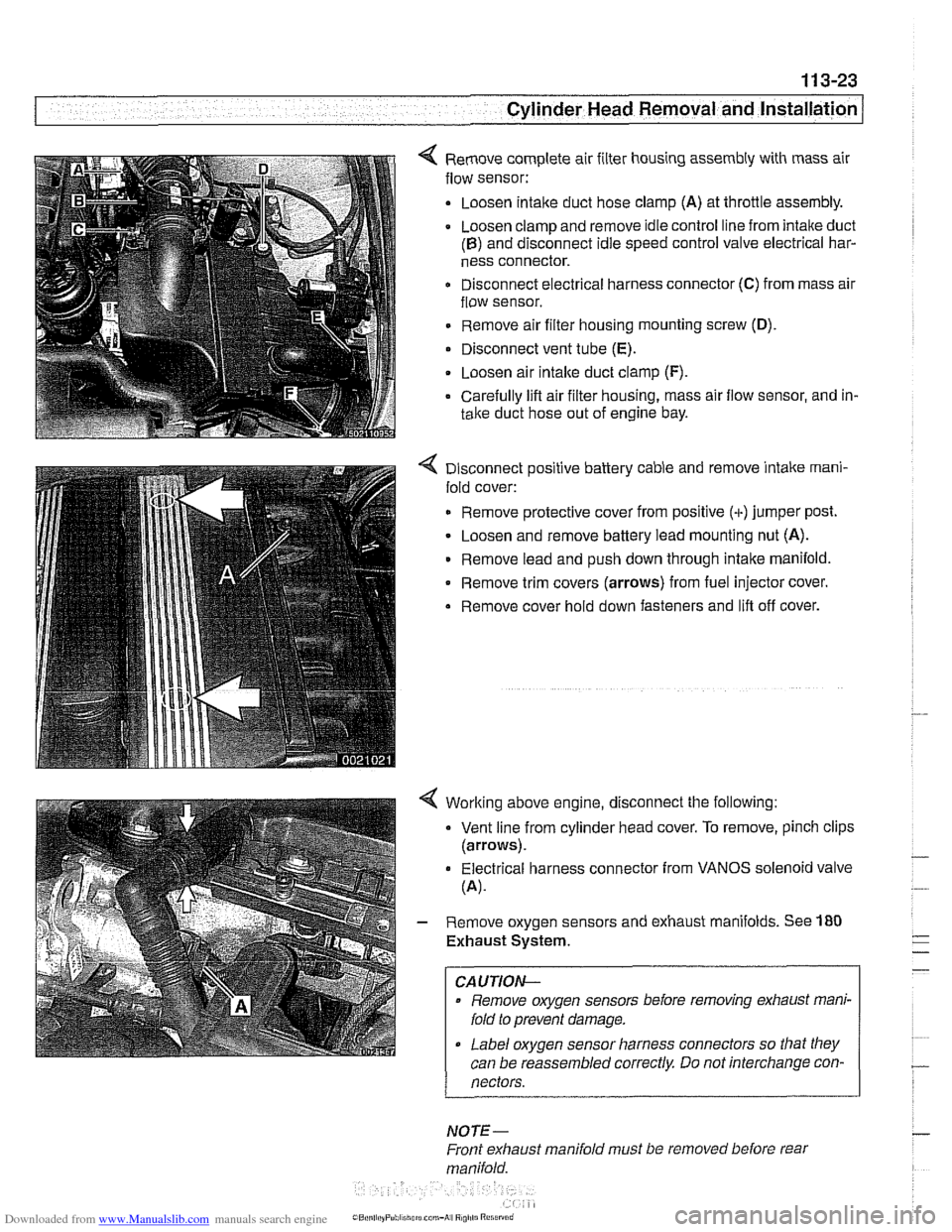

< Remove complete air filter housing assembly with mass air

flow sensor:

Loosen

intalte duct hose clamp (A) at throttle assembly.

Loosen clamp and remove idle control line from intake duct

(B) and disconnect idle speed control valve electrical har-

ness connector.

Disconnect electrical harness connector

(C) from mass air

flow sensor.

Remove air filter housing mounting screw

(D).

Disconnect vent tube (E).

. Loosen air intalte duct clamp (F).

Carefully lifl air filter housing, mass air flow sensor, and in-

take duct hose out of engine bay.

4 Disconnect positive battery cable and remove intake rnani-

fold cover:

Remove protective cover from positive (+)jumper post.

Loosen and remove battery lead mounting nut (A).

Remove lead and push down through intake manifold.

* Remove trim covers (arrows) from fuel injector cover.

Remove cover hold down fasteners and lifl off cover.

4 Worlting above engine, disconnect the following:

Vent line from cylinder head cover. To remove, pinch clips

(arrows).

Electrical harness connector from VANOS solenoid valve

(A).

- Remove oxygen sensors and exhaust manifolds. See 180

Exhaust System.

CAUTION-

Remove oxygen sensors before removing exhaust mani-

fold to prevent damage.

Label oxygen sensor harness connectors so that they

can be reassembled correctly Do not interchange con-

nectors.

NOTE-

Front exhaust manifold must be removed before rear

manifold.

Page 128 of 1002

Downloaded from www.Manualslib.com manuals search engine

- -

I Cylinder Head emo oval and Installation -

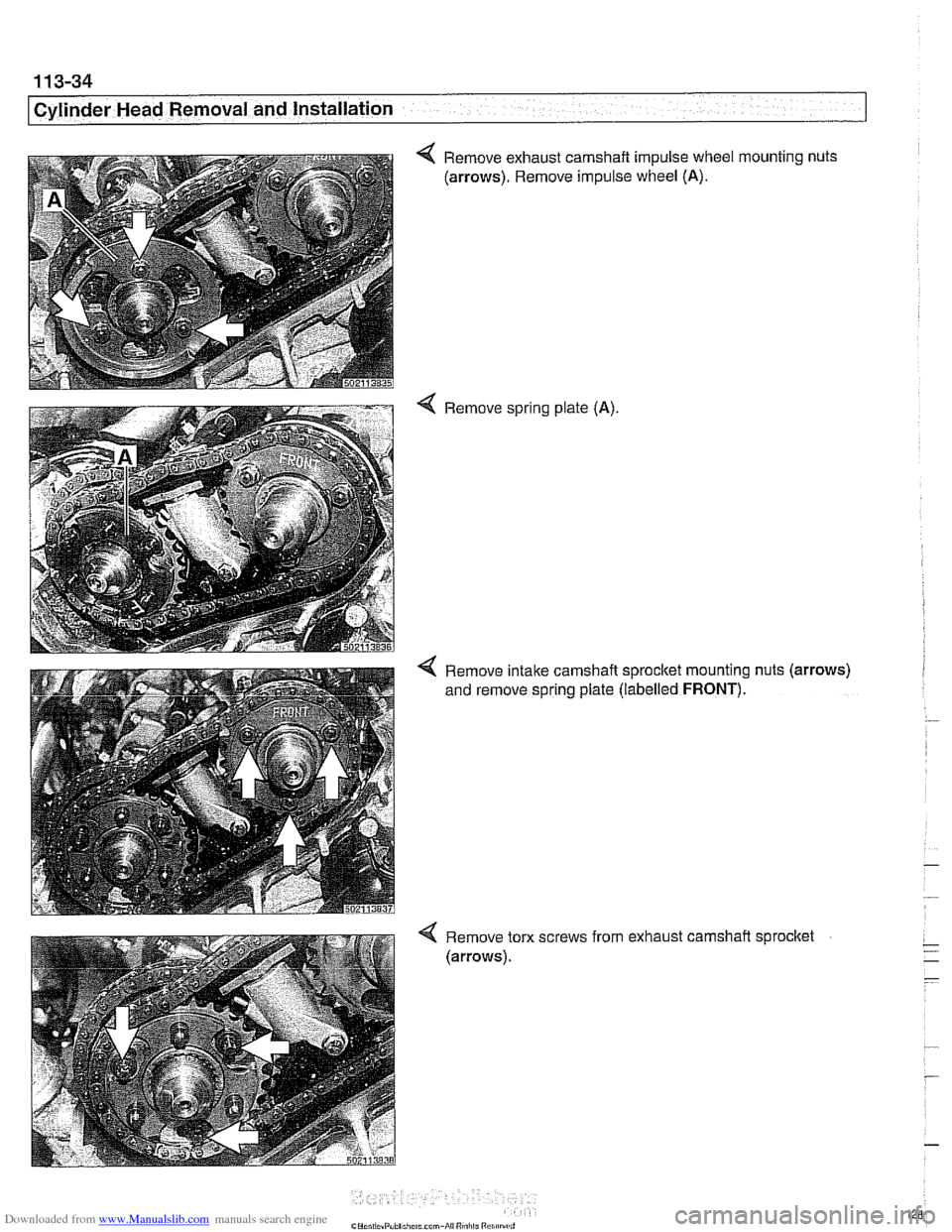

< Remove exhaust camshaft impulse wheel mounting nuts

(arrows). Remove impulse wheel

(A).

4 Remove spring plate (A).

4 Remove intake camshaft sprocltet mounting nuts (arrows)

and remove spring plate (labelled

FRONT).

< Remove torx screws from exhaust camshaft sprocket

(arrows).

Page 139 of 1002

Downloaded from www.Manualslib.com manuals search engine

Cylinder Head Removal and Installation

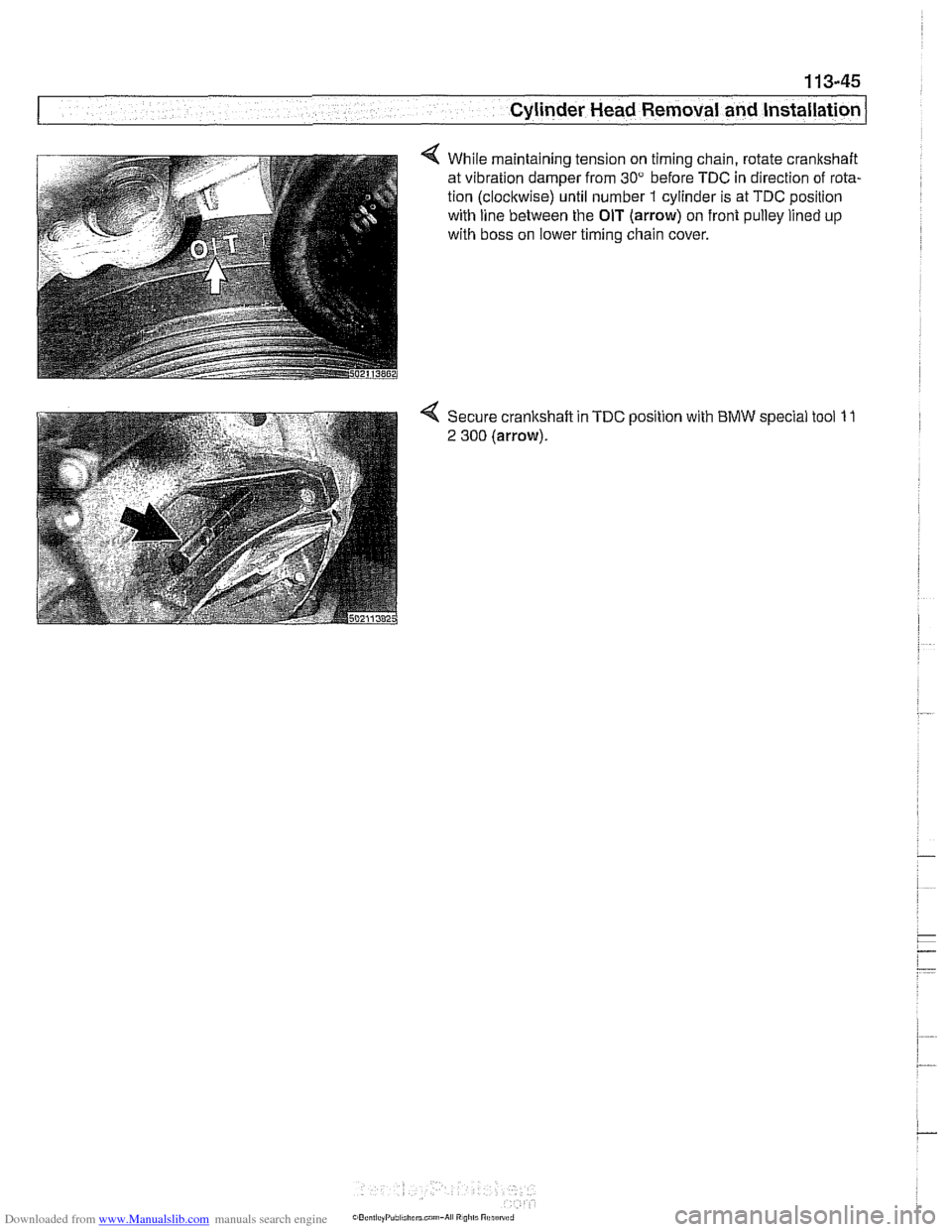

4 While maintaining tension on timing chain, rotate crankshaft

at vibration damper from

30" before TDC in direction of rota-

tion (clockwise) until number

1 cylinder is at TDC position

with line between the

OIT (arrow) on front pulley lined up

with boss on lower timing chain cover.

Page 143 of 1002

Downloaded from www.Manualslib.com manuals search engine

-7 Cylinder Head Removal and lnstallat~on -- -- - -

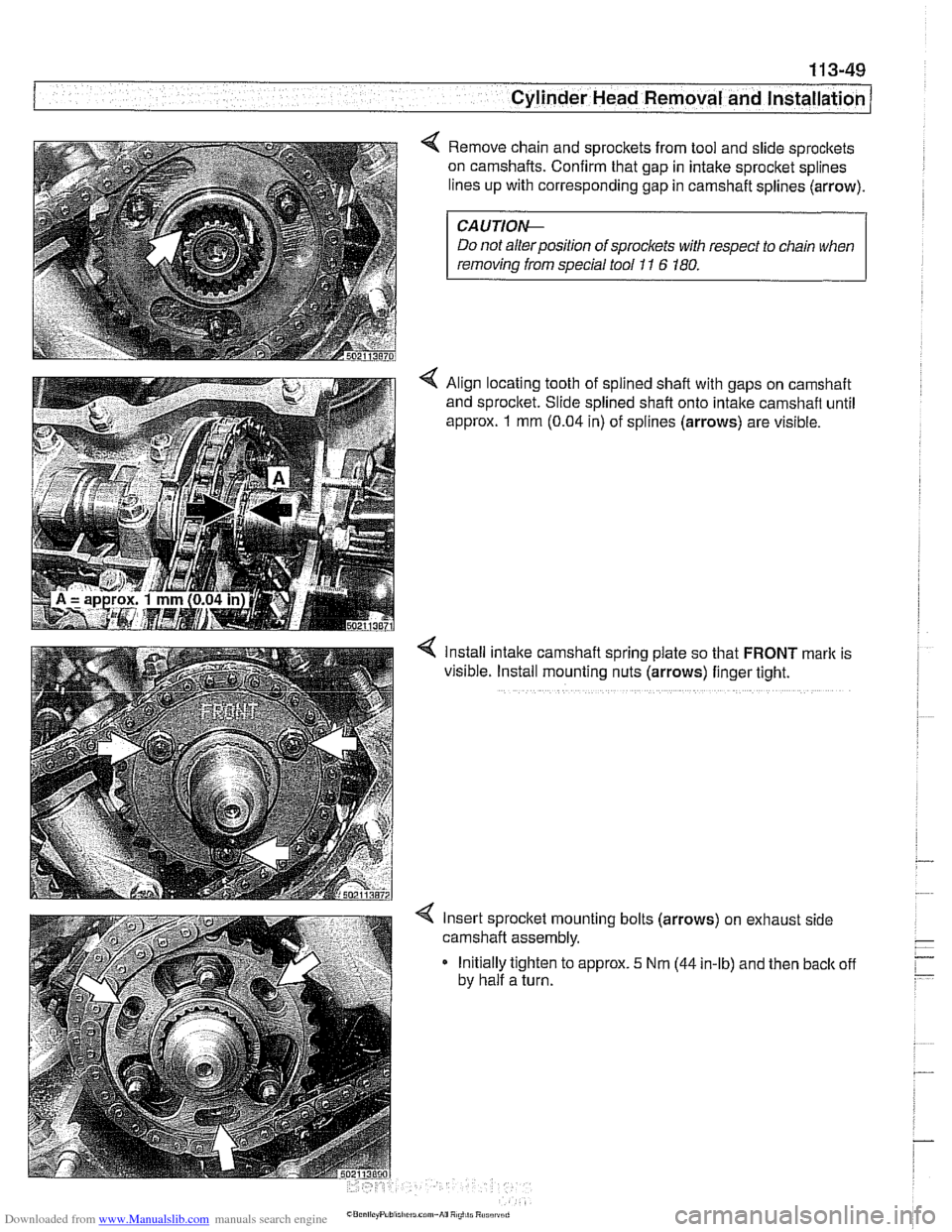

Remove chain and sprockets from tool and slide sprockets

on camshafts. Confirm that gap in intake sprocket splines

lines up with corresponding gap in camshaft splines (arrow).

CAUTIOI\C

Do not alter position of sprockets with respect to chain when

removing

from special tool 11 6 180.

< Align locating tooth of splined shaft with gaps on camshaft

and sprocket. Slide splined shaft onto intake camshaft until

approx.

1 mm (0.04 in) of splines (arrows) are visible.

4 Install intake camshafl spring plate so that FRONT mark is

visible. Install mounting nuts (arrows) finger tight.

Insert sprocket mounting bolts (arrows) on exhaust side

camshaft assembly.

Initially tighten to approx.

5 Nm (44 in-lb) and then back off

by half a turn.

Page 145 of 1002

Downloaded from www.Manualslib.com manuals search engine

113-51

Cylinder Head Removal and Installation

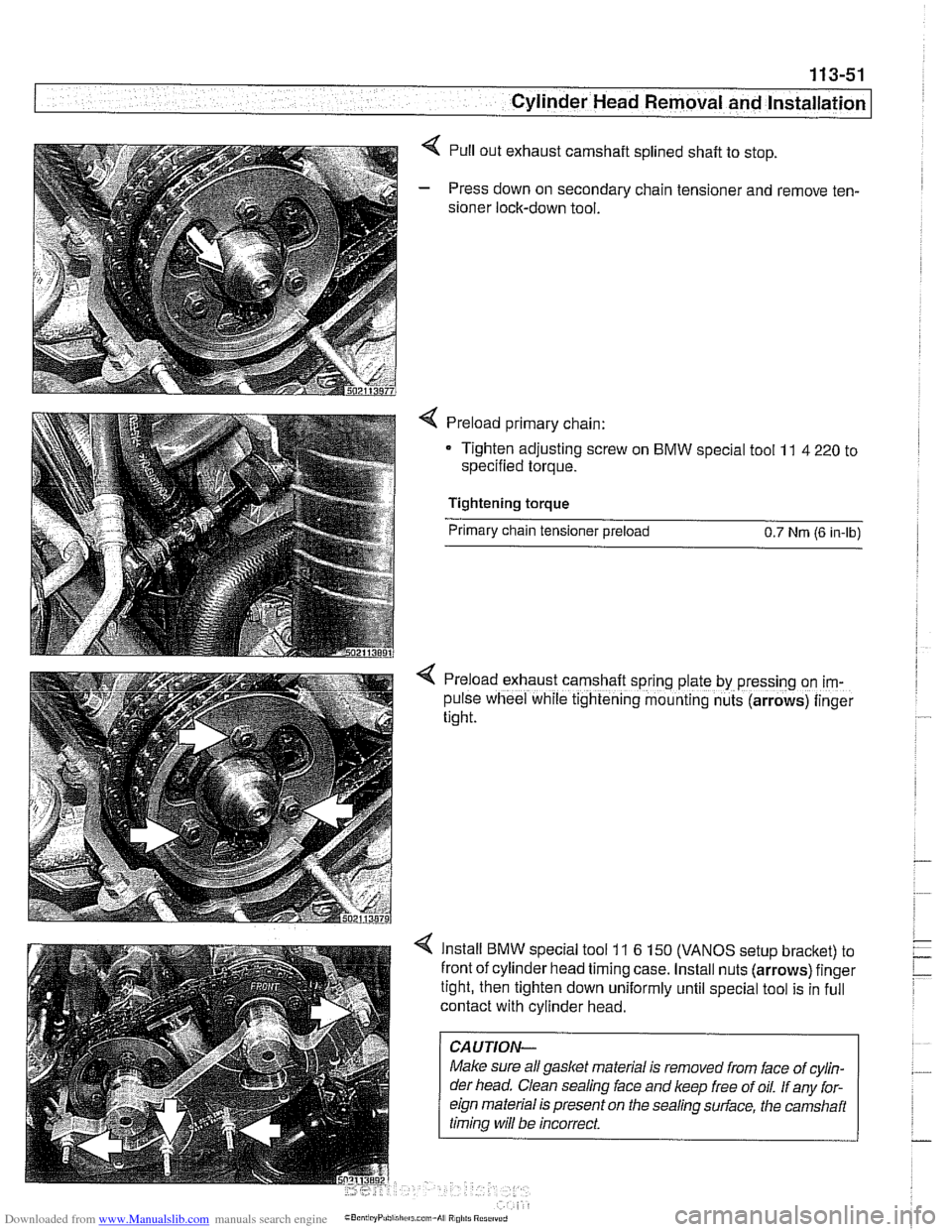

< Pull out exhaust camshaft splined shaft to stop.

- Press down on secondary chain tensioner and remove ten-

sioner lock-down tool.

Preload primary chain:

Tighten adjusting screw on

BMW special tool 11 4 220 to

specified torque.

Tightening torque

Primary chain tensioner preload

0.7 Nrn (6 in-lb)

< Preload exhaust camshaft sprrng plate by pressing on im-

pulse wheel while tightening mounting nuts (arrows) finger

tight.

Install BMW special tool 11 6 150 (VANOS setup bracket) to

front of cylinder head timing case. Install nuts (arrows) finger

tight, then tighten down uniformly until special tool is in full

contact with cylinder head.

CAUTION-

Make sure all gasket material is removed from face of cylin-

der head. Clean sealing

face and keep free of oil. If any for-

eign material is present on the sealing

sudace, the camshait

timina will be incorrect.

Page 146 of 1002

Downloaded from www.Manualslib.com manuals search engine

. .- --

Cylinder Head Removal and Installation

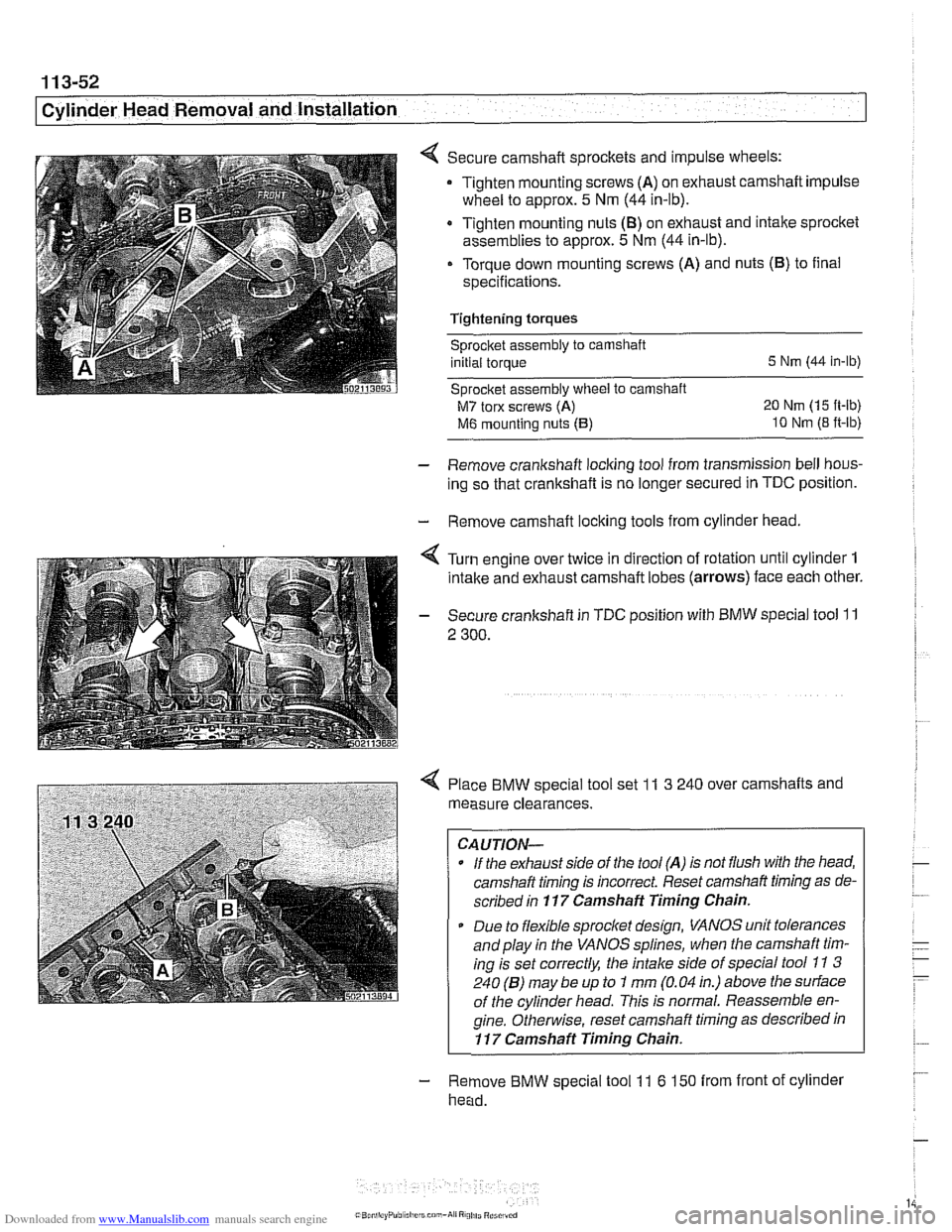

Secure camshaft sprockets and impulse wheels:

Tighten mounting screws

(A) on exhaust camshaft impulse

wheel to approx.

5 Nm (44 in-lb).

Tighten mounting nuts

(8) on exhaust and intake sprocket

assemblies to approx.

5 Nm (44 in-lb).

Torque down mounting screws (A) and nuts (B) to final

specifications.

Tightening torques

sprocket assembly to camshaft

initial torque

5 Nm (44 in-lb)

Sprocket assembly

wheel to camshaft

M7 torx screws (A) 20 Nm (15 ft-lb)

M6 mounting nuts (5) 10 Nm (8 ft-lb)

- Remove crankshaft locking tool from transmission bell hous-

ing so that crankshaft is no longer secured in

TDC position.

- Remove camshaft locking tools from cylinder head.

4 Turn engine over twice in direction of rotation until cylinder 1

intake and exhaust camshaft lobes (arrows) face each other.

- Secure crankshaft in TDC position with BMW special tool 11

2 300.

4 Place BMW special tool set 11 3 240 over camshafts and

measure clearances.

CAUTION-

- If the exhaust side of the tool (A) is not flush with tlie head,

camshaft timing is incorrect Reset camshaft timing as de-

scribed in

117 Camshaft Timing Chain.

* Due to flexible sprocket design, VANOS unit tolerances

and play in the VANOS splines, when the camshaft tim-

ing is set correctly, the intake side of special tool

11 3

240 (6) may be up to 1 mm (0.04 in.) above the surface

of the cylinder head. This is normal. Reassemble en-

gine.

Othe~lise, reset camshaft timing as described in

11 7 Camshaft Timing Chain.

- Remove BMW special tool 11 6 150 from front of cylinder

head.

Page 147 of 1002

Downloaded from www.Manualslib.com manuals search engine

Cylinder Head Removal and Installation /

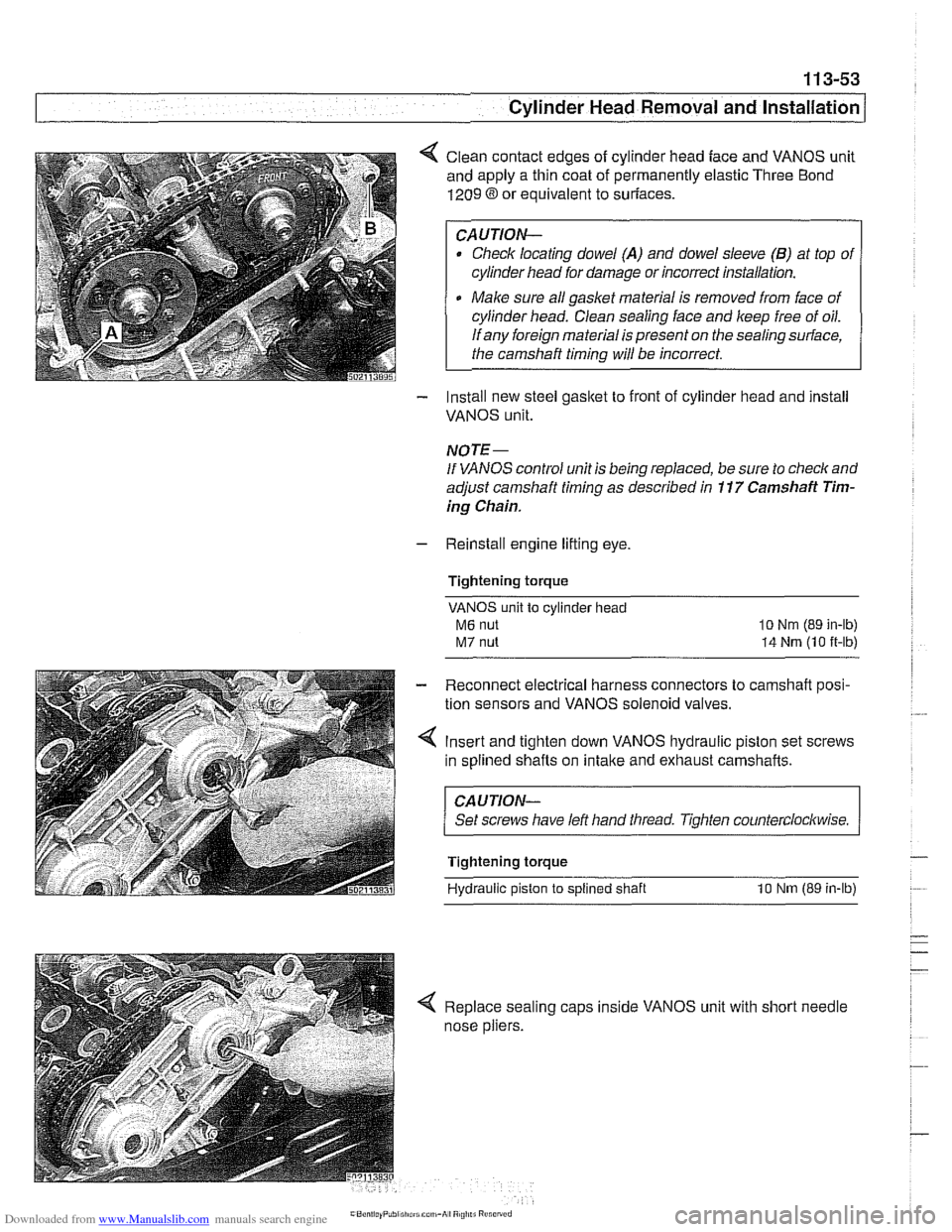

< Clean contact edges of cylinder head face and VANOS unit

and apply a thin coat of permanently elastic Three Bond

1209 8 or equivalent to suriaces.

CAUTION-

Check locating dowel (A) and dowel sleeve (B) at top of

cylinder head for damage or incorrect installation.

Make sure all gasket material is removed from face of

cylinder head. Clean sealing face and keep free of oil.

If any foreign material is present on the sealing surface,

the camshaft timing will be incorrect.

- Install new steel gasket to front of cylinder head and install

VANOS unit.

NOTE -

If VANOS control unit is being replaced, be sure to check and

adjust camshaft timing as described in

11 7 Camshaft Tim-

ing Chain.

- Reinstall engine lifting eye.

Tightening torque

VANOS unit to cylinder head

M6 nut

M7 nut

lo Nm (89 in-lb)

14 Nrn (10 it-lb)

- Reconnect electrical harness connectors to camshaft posi-

tion sensors and VANOS solenoid valves.

4 Insert and tighten down VANOS hydraulic piston set screws

in splined shafts on

intake and exhaust camshafts.

CAUJION-

Set screws have left hand tliread. Tighten counterclockwise.

Tightening torque

Hydraulic piston

to splined shaft 10 Nm (89 in-lb)

< Replace sealing caps inside VANOS unit with short needle

nose pliers.

Page 148 of 1002

Downloaded from www.Manualslib.com manuals search engine

. ." ".

[Cylinder Head Removal and Installation - .. - -1 -

4 Insert and secure VANOS sealing plugs (arrows) with new

sealing O-rings.

Tightening torque Sealing

plug to VANOS 50

Nm (37 ft-lb)

4 Install coolant pipe fasteners at base of cylinder head and

tighten fasteners (arrows).

NOTE-

Use new sealing O-ring on coolant pipe.

- lnstall VANOS oil line banjo bolt with new seals. Attach oil

line to VANOS unit.

Tightening torque Oil line to VANOS unit

(banjo bolt) 32

Nm (24 ft-ib)

- Remove adjustable timing chain tensioner tool and reinstall

chain tensioner.

Tightening torque Primary chain tensioner cylinder to

cylinder head 70

Nm

(52 fi-ib)

- Remove flywheel locking tool from transmission bell housing.

Replace special tool bore sealing plug.

- Remove camshaft locking tools from cylinder head

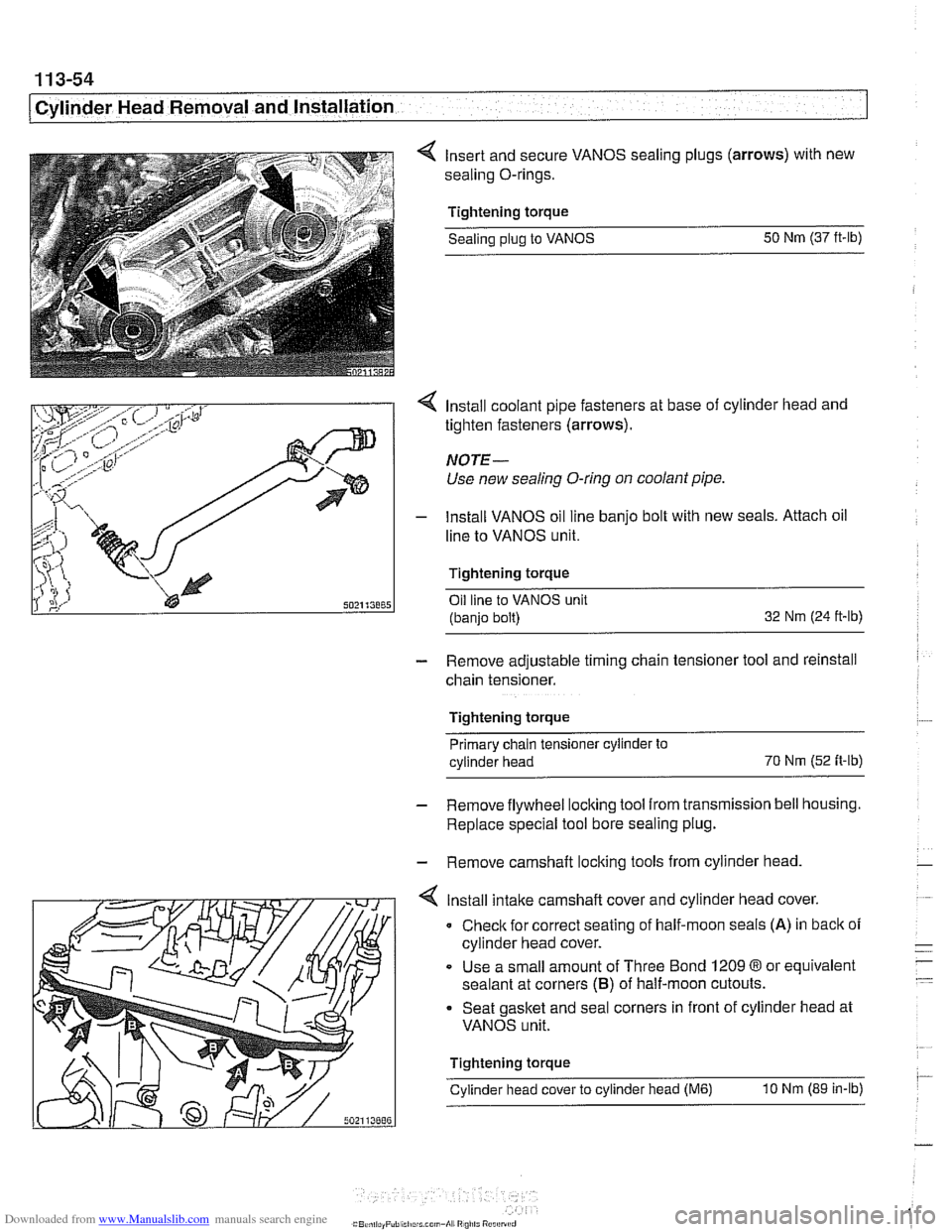

4 lnstall intake camshaft cover and cylinder head cover.

0 Check for correct seating of half-moon seals (A) in back of

cylinder head cover.

Use a small amount of Three Bond

1209 8 or equivalent

sealant at corners

(B) of half-moon cutouts.

Seat gasket and seal corners in front of cylinder head at

VANOS unit.

Tightening torque

Cylinder head cover to cylinder head

(M6) 10 Nm (89 in-lb)