Air condition BMW 525i 2001 E39 Owner's Guide

[x] Cancel search | Manufacturer: BMW, Model Year: 2001, Model line: 525i, Model: BMW 525i 2001 E39Pages: 1002

Page 767 of 1002

Downloaded from www.Manualslib.com manuals search engine

Brakes

Troubleshooting

Brake performance is mainly affected by three things:

Q Level and condition of brake fluid

Ability of bralte system to create and maintain pressure

Condition of friction components

Air in bralte fluid will

make the brake pedal feel spongy during

braking

orwill increase the bralte pedal force required to stop.

Fluid contaminated by moisture or dirt can corrode the sys-

tem. lnspect the brake fluid inside the reservoir. If it is dirty or

murky, or is more then two years old, replace fluid.

To

check the function of the master cylinder hold the bralte

pedal down hard with the engine running. If the pedal slowly

falls to the floor, either the master cylinder is leaking internal-

ly, or fluid is leaking externally.

lnspect the rotors for glazing, discoloration and scoring.

Steering wheel vibration while braking at speed is often

caused by warped rotors, but can also be caused by worn

suspension components.

When troubleshooting, keep in mind that tire inflation, wear

and temperature can all have an affect on braking. See

300

Suspension, Steering and Brakes-General for additional

suspension and brake system troubleshooting.

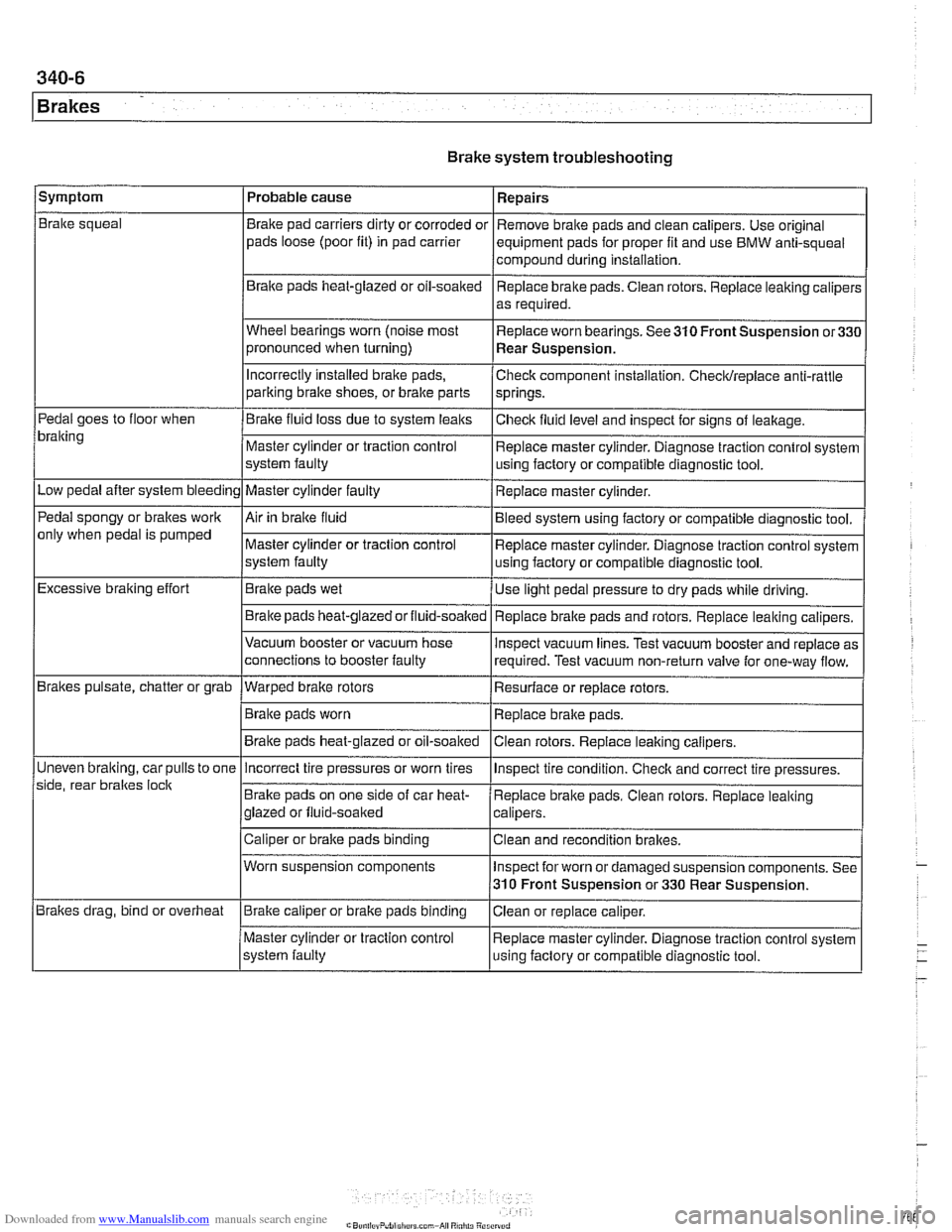

The table Brake system troubleshooting lists symptoms of

brake problems, probable causes, and suggested corrective

actions. Unless noted otherwise, relevant repairs are de-

scribed later in this repair group.

Page 768 of 1002

Downloaded from www.Manualslib.com manuals search engine

340-6

1 Brakes

Brake system troubleshooting

/symptom I Probable cause 1 Repairs

Brake squeal

Pedal goes to floor when

bralting

Low pedal after system bleeding

Pedal spongy or brakes work

only when pedal is pumped

Excessive braking effort

Brakes pulsate, chatter or grab

Uneven

bralting, car pulls to one

side, rear braltes

loclt

Brakes drag, bind or overheat Brake

pad carriers dirty or corroded or

pads loose (poor fit) in pad carrier

Braite pads heat-glazed or oil-soaked

Wheel bearings worn (noise most

pronounced when turning)

Incorrectly Installed brake pads,

parking bralte shoes, or bralte parts

Brake fluid loss due to system leaks

Master cylinder or traction control

system faulty

Master cylinder faulty

Air in braite fluid

Master cylinder or traction control

system faulty

Brake pads wet

Brake pads

heat-glazedorfluid-soalted

Vacuum booster or vacuum hose

connections to booster faulty

--- Warped brake rotors

Brake pads worn

Brake pads heat-glazed or oil-soaked Remove

brake pads and clean calipers. Use original

equipment pads for proper fit and use BMW anti-squeal

compound during installation,

Replace brake pads. Ciean rotors. Replace leaking caliper:

as required.

Replace worn bearings. See 310 Front Suspension

or33C

Rear Suspension.

Check component installation. Checldreplace anti-rattle

springs.

Checlt fluid level and inspect for signs of leakage.

Replace master cylinder. Diagnose traction control system

using factory or compatible diagnostic tool.

Replace master cylinder.

Bleed system using factory or compatible diagnostic tool.

Replace master cylinder. Diagnose traction control system

using factory or compatible diagnostic tool.

Use light pedal pressure to dry pads while driving.

Replace

bralte pads and rotors. Replace leaking calipers.

lnspect vacuum lines. Test vacuum booster and replace as

required. Test vacuum non-return valve for one-way flow.

Resurface or replace rotors.

Replace brake pads.

Clean rotors. Replace leaiting calipers.

Incorrect tire pressures or worn tires

Brake pads on one side of car heat-

glazed or fluid-soaked

Caliper or brake pads binding

Worn suspension components

Brake caliper or brake pads binding

Master cylinder or traction control

system faulty lnspect

tire condition. Checlt and correct tire pressures.

Replace brake pads. Clean rotors. Replace leaking

calipers.

Clean and recondition brakes.

Inspect for worn or damaged suspension components. See

310 Front Suspension or 330 Rear Suspension.

Ciean or replace caliper.

Replace master cylinder. Diagnose traction control system

using faclory or compatible diagnostic tool.

Page 778 of 1002

Downloaded from www.Manualslib.com manuals search engine

1 Brakes

Max. machine limit per

friction ring side 0.8 mm (0.03

in) I

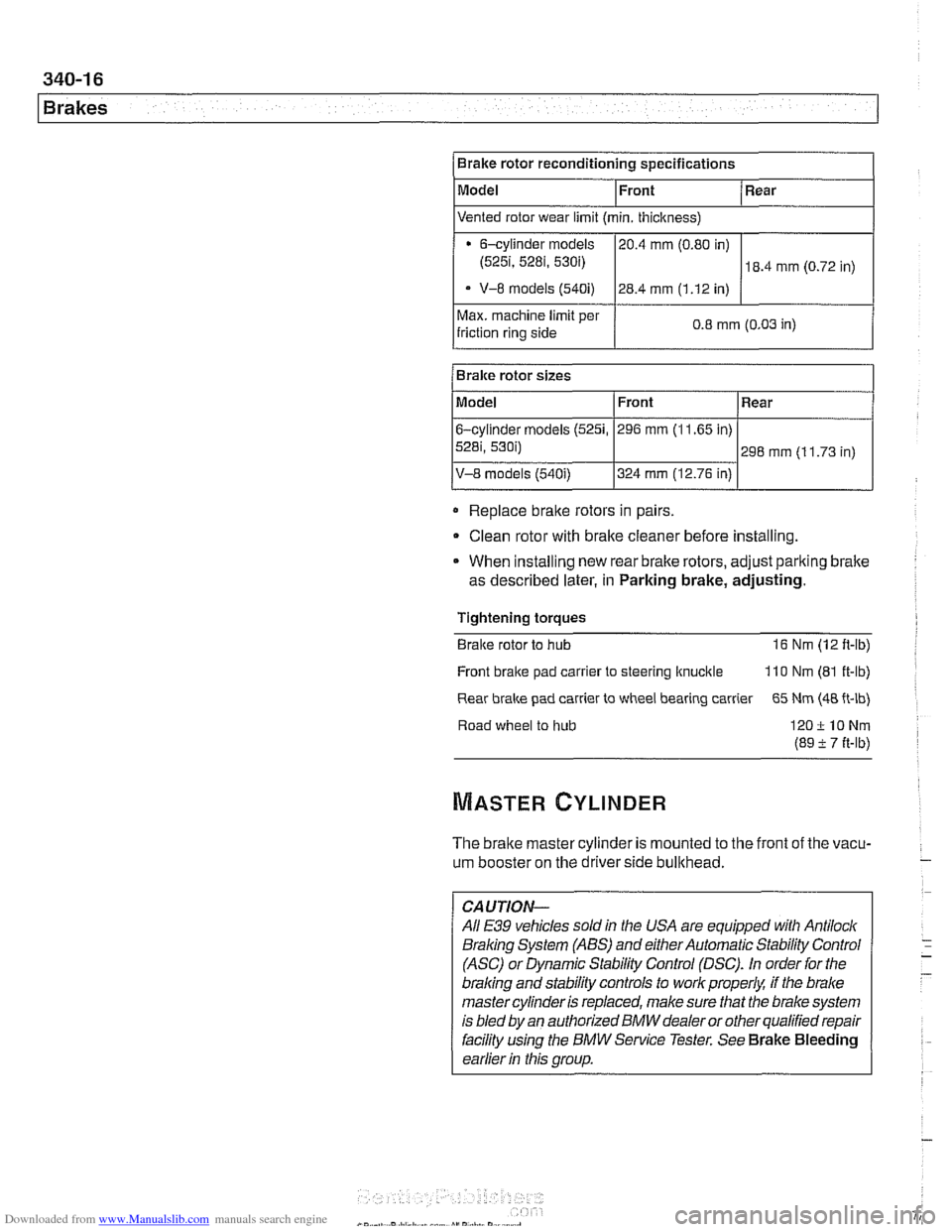

Brake rotor reconditioning specifications

Model

Replace

braite rotors in pairs

Bralre rotor sizes

Clean rotor with brake cleaner before installing.

Front

Model

6-cylinder

models (5251,

5281, 530i)

V-8 models (540i)

* When installing new rear brake rotors, adjust pariting brake

as described later, in Parking brake, adjusting. Rear

Vented rotor wear limit (min. thickness)

Tightening torques

Braite rotor to hub 16 Nm (12 ft-lb)

6-cylinder models

(525i, 5281, 530i)

- V-8 models (540i)

Front

296 mm (1 1.65 in)

324 mm (12.76 in)

Front bralte pad

carrler to steering ltnucitle 110 Nm (81 ft-lb)

Rear

298 mm (1 1.73 in)

Rear

brake pad carrier to wheel bearing carrier 65 Nm (48 ft-lb)

20.4

mm (0.80 in)

28.4 mm (1.12 in)

Road wheel to hub

120ilONm

(89 -t 7 it-lb)

18.4 mm (0.72 in)

The brake master cylinder is mounted to the front of the vacu-

um booster on the driverside bullthead.

-

CAUTION-

All E39 vehicles soldin the USA are equipped with Antilock

Braling System (ABS) and either Automatic Stability Control

(ASC) or Dynamic Stability Control (DSC).

In order for the

braling and stability controls to work properk if the brake

master cylinder is replaced, make sure that the brake system

is bled

by an authorized BMW dealer or other qualified repair

facility

using the BMW Service Tester. See Brake Bleeding

earlier

in this group.

Page 795 of 1002

Downloaded from www.Manualslib.com manuals search engine

400 Body-General

........................ General ........................... .40 0.2 Roof paddin~ 400-7

Body Assembly ................... .40 0.2

Body dimensions (in inches)

............ .40 0.2

Bodyshell

........................... 400-3

Exterior and aerodynamics

............. .40 0.3

Sport Wagon ...................... .40 0.4

Tailgate

............................ .40 0.5

Tailgate lock system

.................. .40 0.5

Rear wiper system ................... .40 0.6

Antenna and sound system ............ .40 0.6

Safety and Security Features ....... .40 0.7

Safety cage

......................... .40 0.7

Door locks and door handles

........... .40 0.7

.

........................... Seat belts 400-7

Airbags ............................ 400-8

Battery safety terminal (BST)

........... 400-9

Security

............................ 400-9

Interior Features ................... 400-9

............................. Seats 400-10

Instruments and controls .............. 400-10

Central body electronics

.............. 400-1 1

Heating and Air

Conditioning (IHKA)

............... 400-12

Page 801 of 1002

Downloaded from www.Manualslib.com manuals search engine

Body-General

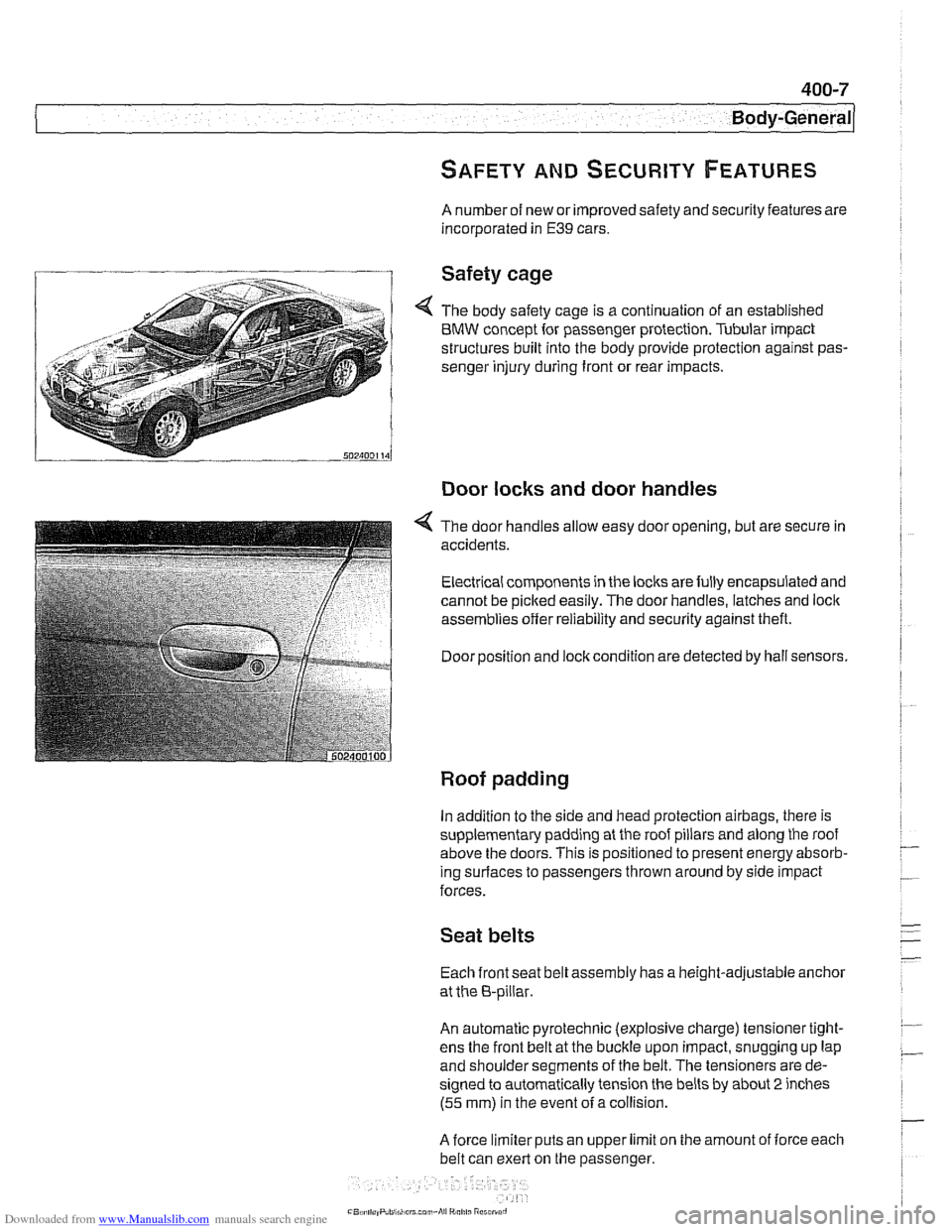

SAFETY AND SECURITY FEATURES

A number of new or improved safety and security features are

incorporated in

E39 cars.

Safety cage

4 The body safety cage is a continuation of an established

BMW concept for passenger protection. Tubular impact

structures built into the body provide protection against pas-

senger injury during front or rear impacts.

Door locks and door handles

4 The door handles allow easy door opening, but are secure in

accidents.

Electrical components in the locks are fully encapsulated and

cannot be picked easily. The door handles, latches and

loclc

assemblies offer reliability and security against theft.

Door position and

loclc condition are detected by hall sensors.

Roof padding

In addition to the side and head protection airbags, there is

supplementary padding at the roof pillars and along the roof

above the doors. This is positioned to present energy absorb-

ing

surlaces to passengers thrown around by side impact

forces.

Seat belts

Each front seat belt assembly has a height-adjustable anchor

at the 8-pillar.

An automatic pyrotechnic (explosive charge) tensioner tight-

ens the front belt at the buckle upon impact, snugging up lap

and shoulder segments of the belt. The tensioners are de-

signed to automatically tension the belts by about

2 inches

(55 mm) in the event ofa collision.

A force limiter puts an upper limit on the amount of iorce each

belt can exert on the passenger.

Page 806 of 1002

Downloaded from www.Manualslib.com manuals search engine

400-12

I Body-General

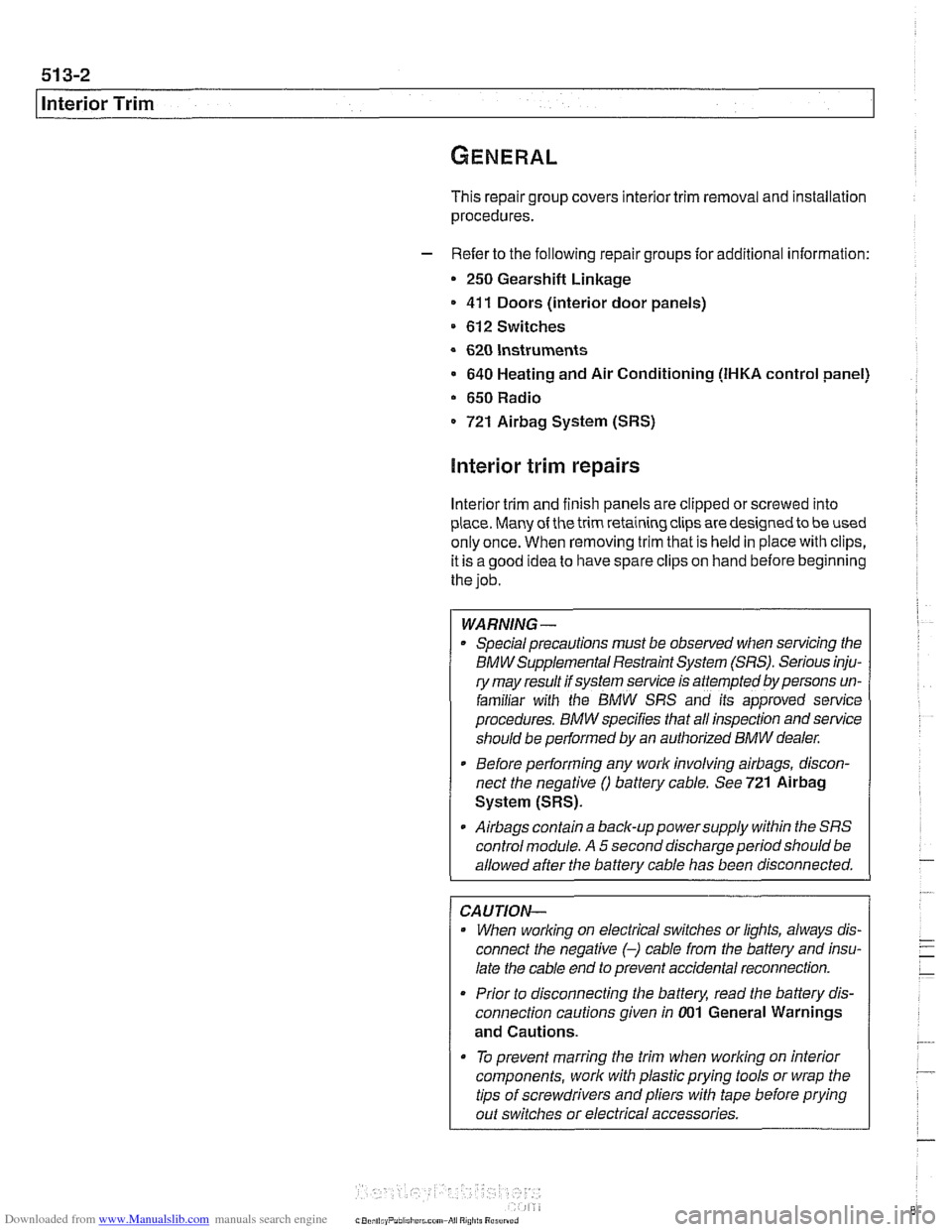

HEATING AND AIR ~ONDITIONING

(I H KA)

4 The integrated heating and air conditioning (IHKA) system

uses an extra large, infinitely variable radial blower motor for

good distribution of air. Fresh air enters through the grille

be.

low the engine hood and into the passenger compartment via

the dashboard and

footwell vents.

- Repair information for the heating and air conditioning

system is covered

in 640 Heating and Air Conditioning.

Page 880 of 1002

Downloaded from www.Manualslib.com manuals search engine

I lnterior Trim

This repair group covers interior trim removal and installation

procedures.

- Refer to the following repair groups for additional information:

250 Gearshift Linkage

41 1 Doors (interior door panels)

@ 612 Switches

620 Instruments

640 Heating and Air Conditioning [IHKA control panel!

650 Radio

721 Airbag System (SRS)

lnterior trim repairs

lnterior trim and finish panels are clipped or screwed into

place. Many of the trim retaining clips are designed

to be used

only once. When removing trim that is held in place with clips,

it is a good idea to have spare clips on hand before beginning

the job.

WARNING-

Special precautions must be observed when servicing the

BMWSupplementai Restraint System (SRS). Serious inju-

ry may result if system service is attempted by persons un-

familiar with the BMW

SRS and its approved service

procedures. BMW

speciiies that all inspection and service

should be performed by an authorized BMW

dealer.

Before performing any work involving airbags, discon-

nect the negative

() battery cable. See 721 Airbag

System (SRS).

Airbags contain a back-uppowersupply within the SRS

control module. A

5 second discharge period should be

allowed after the battery cable has been disconnected.

CAUTION-

* When working on electrical switclies or lights, always dis-

connect the negative

(-) cable from the battery and insu-

late the cable end to prevent accidental reconnection.

a Prior to disconnecting the battery, read the battery dis-

connection cautions given in

W1 General Warnings

and Cautions.

To prevent marring the trim when working on interior

components, work with plastic prying

tools or wrap the

tips of screwdrivers and pliers with tape before prying

Page 962 of 1002

Downloaded from www.Manualslib.com manuals search engine

OED-2

On-Board Diagnostics

Specialized OED II scan tool equipment is needed to access

the fault memory and

OED I1 data.

The extra hardware needed to operate the OED

I1 system

consists mainly of the following:

* Additional oxygen sensors downstream of the catalytic

converters.

Fuel tank pressure sensor and device to pressurize

fuel

storage system.

Several engine and performance monitoring devices

Standardized 16-pin

OED II connector under the

dashboard.

Upgraded components for the federally required reliability

mandate.

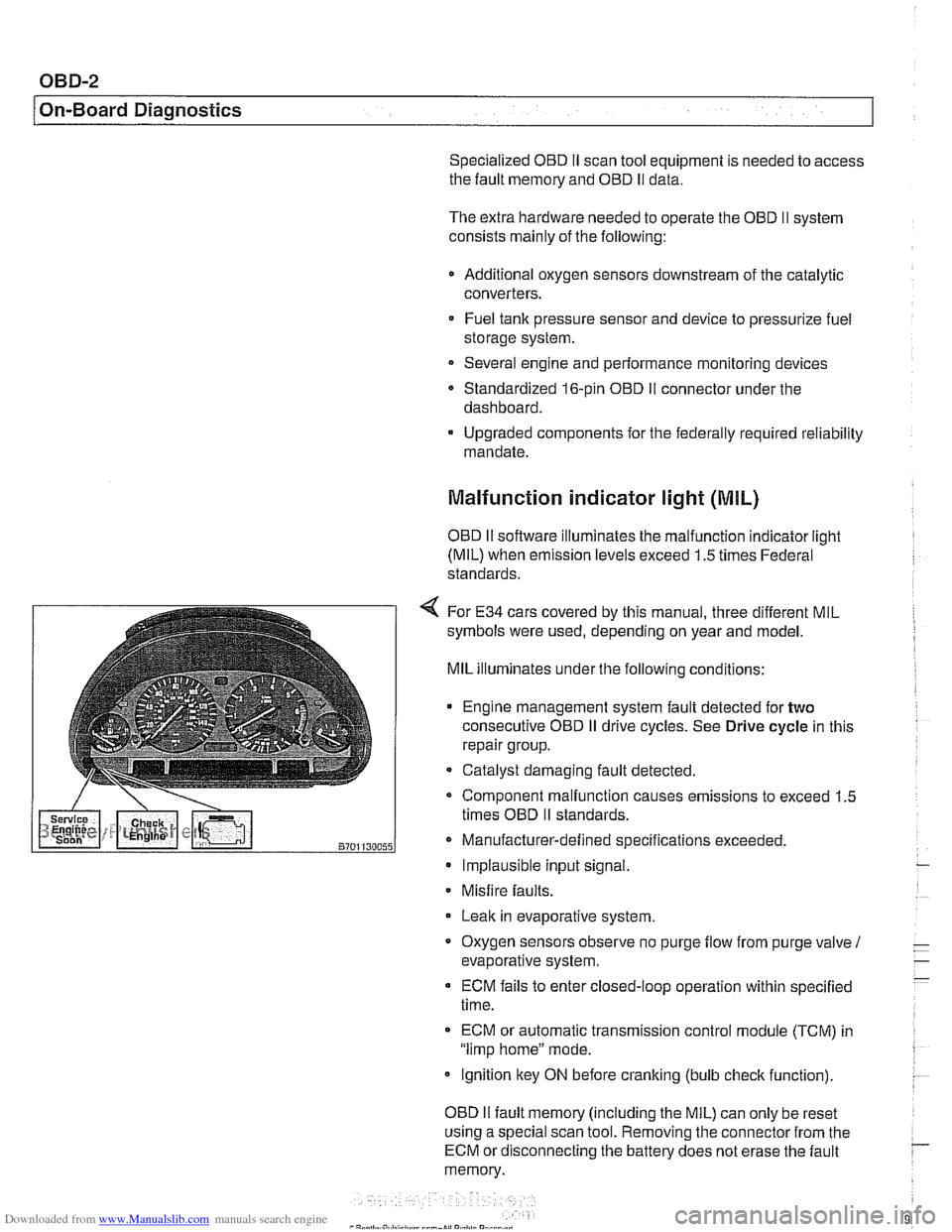

Malfunction indicator light (MIL)

OED II software illuminates the malfunction indicator light

(MIL) when emission levels exceed 1.5 times Federal

standards.

4 For E34 cars covered by this manual, three different MIL

symbols were used, depending on year and model.

MIL illuminates under the following conditions:

Engine management system fault detected for

two

consecutive OED iI drive cycles. See Drive cycle in this

repair group.

- Catalyst damaging fault detected.

Component malfunction causes emissions to exceed 1.5

times OED

II standards.

Manufacturer-defined specifications exceeded. Implausible input signal.

Misfire

faults.

Leak in evaporative system,

Oxygen sensors observe no purge

flow from purge valve 1

evaporative system.

ECM fails to enter closed-loop operation within specified

time.

ECM or automatic transmission control

module (TCM) in

"limp home" mode.

ignition key ON before cranking (bulb

check function).

OED

II fault memory (including the MIL) can only be reset

using a special scan tool. Removing the connector from the

ECM or disconnecting the battery does not erase the fault

memory.

Page 964 of 1002

Downloaded from www.Manualslib.com manuals search engine

- -

On-Board Diagnostics

Professional diagnostic scan tools available atthe time of this

printing include the BMW factory tools

(DISplus, GTI,

MoDiC) and a small number of aftermarket BMW-specific

tools. See

020 Maintenance.

In addition to the professional line of scan tools, inexpensive

generic OBD

II scan tool software programs and handheld

units are readily available. Though limited, they are

nonetheless powerful diagnostic tools. These tools read live

data streams and freeze frame data as well as a host of other

valuable diagnostic data.

Diagnostic monitors

Diagnostic monitors run tests and checks on specific

emission control systems, components, and functions.

A complete drive cycle is requiredforthe tests to bevalid. See

Drive cycle in this repair group. The diagnostic monitor

signals the

ECM of the loss or impairment of the signal or

component and determines if a signal or sensor is faulty

based on

3 conditions:

* Signal or component shorted to ground

Signal or component shorted to

B+

Signal or component missing (open circuit)

The OBD

II system monitors all emission control systems that

are installed. Emission control systems vary by vehicle model

and year. For example, a vehicle may not be equipped with

secondary air injection, so no secondary air readiness code

would be present.

OBD

II software monitors the following:

Oxygen sensors

Catalysts

Engine misfire

- Fuel tank evaporative control system

Secondary air injection Fuel system

Oxygen sensor monitoring. When driving conditions allow,

response rate and switching time of each oxygen sensor is

monitored. The oxygen sensor heater function is also

monitored. The OBD

II system differentiates between

precataylst and post-catalyst oxygen sensors and reads each

one individually. In order

forthe oxygen sensor to be

effectively monitored, the system must be in closed loop

operation.

Page 965 of 1002

Downloaded from www.Manualslib.com manuals search engine

On-Board Diagnostics

Catalyst monitoring. Thisstrategy monitors the outputofthe

precatalyst and post-catalyst oxygen sensors, comparing the

oxygen content going into the catalytic converter to the

oxygen leaving the converter.

The diagnostic executive

lknows that most of the oxygen

should be used up during the oxidation phase. If it detects

higherthan programmed values, afault is set and the MIL

illuminates.

Misfire detection. This strategy monitors crankshaft speed

fluctuations and determines if an enoine misfire occurs bv

monitoring variations in speed between each crankshaft

sensortrigger point. This strategy is so finely tuned that it can

determine the severity of the misfire.

The system determines

if a misfire is occurring, as well as

other pertinent misfire

information such as:

Specific

cylinder(s)

Severity of the misfire event

Emissions relevant or catalyst damaging

Misfire detection is an on-going monitoring process that is

only disabled under certain limited conditions.

Secondary air injection monitoring. Secondary air

injection is used to reduce HC and CO emissions during

engine warm up. Immediately following a cold engine start

(-1 0" to 40°C), fresh air (and therefore oxygen) is pumped

directly into the exhaust

manifold. By injecting additional

oxygen into the exhaust manifold, catalyst warm-up time is

reduced.

Secondary air system components are:

Electric air injection pump

* Electric pump relay

* Non-return valve

Vacuum

I vent valve

- Stainless steel air injection pipes

Vacuum reservoir

The secondary air system is monitored via the use

of the pre-

catalyst oxygen sensors. Once the air pump is active and air

is injected into the system, the signal at the oxygen sensor

reflects a lean condition. If the oxygen sensor signal does not

change, a fault is set and the faulty

bank(s) identified. If after

completing the next cold startafault is again present, the MIL

illuminates.