Troubleshoot BMW 525i 2001 E39 Workshop Manual

[x] Cancel search | Manufacturer: BMW, Model Year: 2001, Model line: 525i, Model: BMW 525i 2001 E39Pages: 1002

Page 13 of 1002

Downloaded from www.Manualslib.com manuals search engine

General

0 GENERAL, MAINTENANCE covers general vehicle infor-

mation

(010 General) as well as the recommended mainte-

nance schedules and service procedures to perform BMW

scheduled maintenance

work (020 Maintenance).

The next seven sections

(1 through 7) are repair based and

organized by three digit repair groups. Most major sections

begin with a GENERAL repair group,

e.g. 100 Engine-Gen-

eral. These "00 (double zero) groups contain descriptive the-

ory of operation and system troubleshooting information. The

remainder of the repair groups within a section contain the

service and repair information. The last two sections contain

detailed electrical wiring schematics and OBD

II scan tool and

diagnostic information.

Warnings, cautions and notes

Throughout this manual are many passages with the head-

ings WARNING, CAUTION, or NOTE. These very important

headings have different meanings.

WARNING-

The text under this heading warns of unsafe practices that

are very

likely to cause injury, either by direct threat to the per-

son(~) performing the work

orby increasedrisl( of accident or

mechanical failure while

drivinq.

CAUTION-

A CAUTION calls attention to importantprecautions to be ob-

senfed during the repair work that will help prevent acciden-

tally damaging the car or its parts.

NOTE-

A NOTE contains helpful information, tips that will help in do-

ing a betterjob and completing it more easily.

Please read every WARNING, CAUTION, AND NOTE in

001

General Warnings and Cautions and as they appear in re-

pair procedures. They are very important. Read them before

you begin any maintenance or repair job.

Page 27 of 1002

Downloaded from www.Manualslib.com manuals search engine

.

General

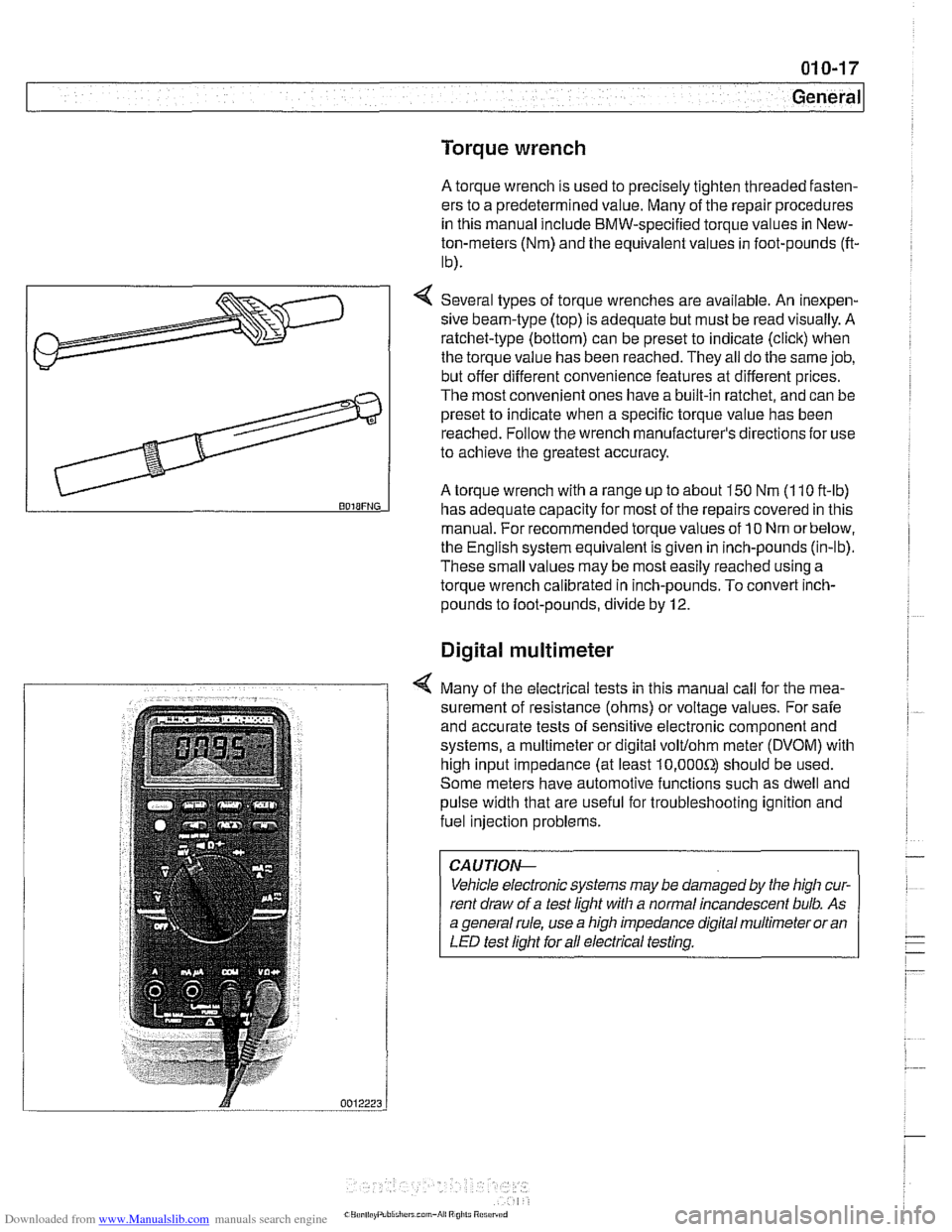

Torque wrench

A torque wrench is used to precisely tighten threaded fasten-

ers to a predetermined value. Many of the repair procedures

in this manual include BMW-specified torque values

in New-

ton-meters (Nm) and the equivalent values in foot-pounds

(ft-

Ib).

4 Several types of torque wrenches are available. An inexpen-

sive beam-type (top) is adequate but must be read visually. A

ratchet-type (bottom) can be preset to indicate (click) when

the torque value has been reached. They all do the same job,

but offer different convenience features at different prices.

The most convenient ones have a built-in ratchet, and can be

preset to indicate when a specific torque value has been

reached. Follow the wrench manufacturer's directions

for use

to achieve the greatest accuracy.

A torque wrench with a range up to about 150 Nm (1 10 ft-lb) BOIBFNG has adequate capacity for most of the repairs covered in this

manual. For recommended torque values of

10 Nm orbelow,

the English system equivalent is given in inch-pounds (in-lb).

These small values may be most easily reached using a

torque wrench calibrated in inch-pounds. To convert

inch-

pounds to foot-pounds, divide by 12.

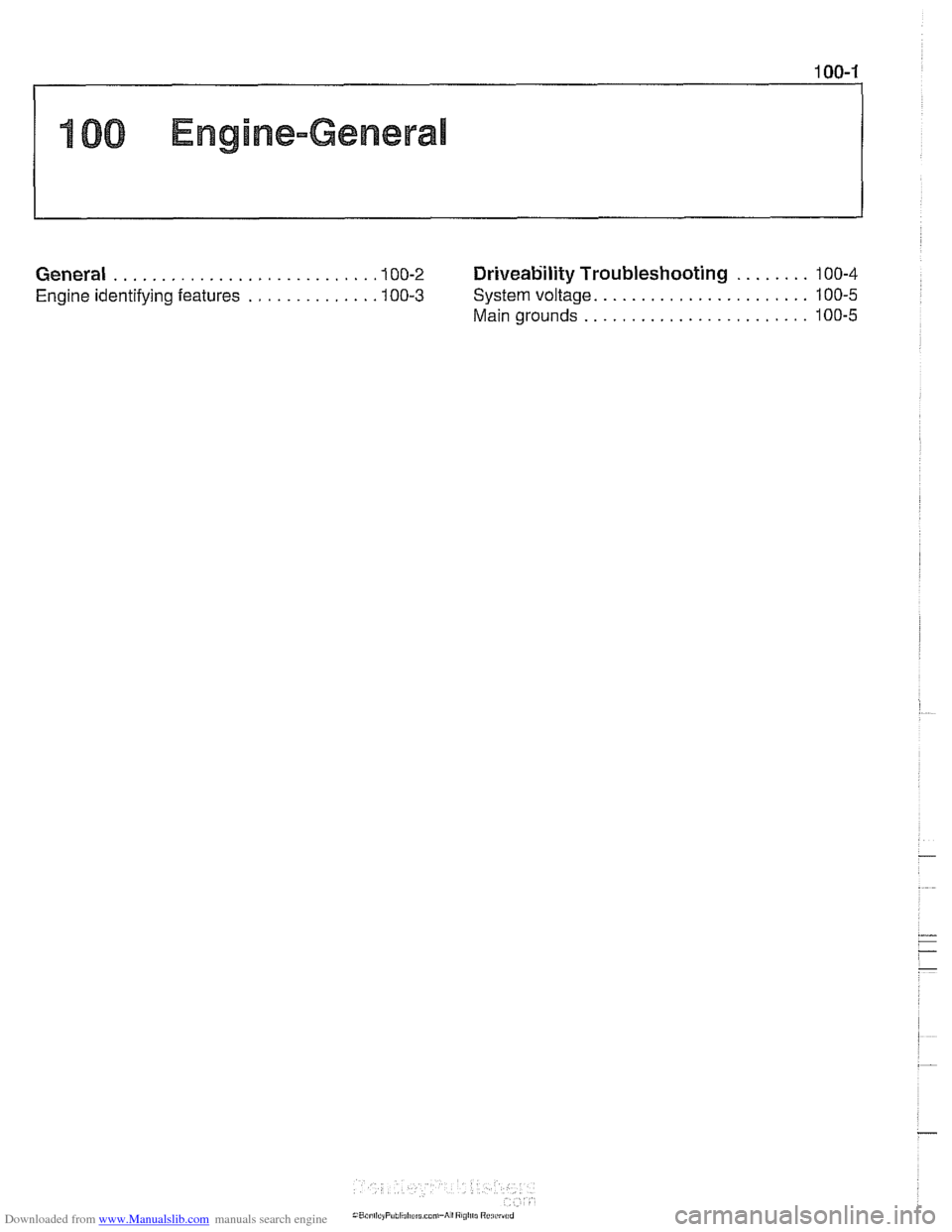

Digital multimeter

4 Many of the electrical tests in this manual call for the mea-

surement of resistance (ohms) or voltage values. For safe

and accurate tests of sensitive electronic component and

systems, a multimeter or digital

volt/ohm meter (DVOM) with

high input impedance (at least

10,000Sr) should be used.

Some meters have automotive functions such as dwell and

pulse width that are useful for troubleshooting ignition and

fuel injection problems.

CAUTIOI\C

Vehicle electronic systems may be damaged by the high cur-

rent draw of a test light with a normal incandescent bulb. As

a general rule, use a high impedance digital multimeter or an

LED test light for all electrical testing.

Page 67 of 1002

Downloaded from www.Manualslib.com manuals search engine

100 Engine-General

........ General ........................... .I0 0.2 Driveability Troubleshooting 100-4

....................... Engine identifying features ............. .I0 0.3 System voltage 100-5

........................ Main grounds 100-5

Page 68 of 1002

Downloaded from www.Manualslib.com manuals search engine

Engine-General

This section covers system descriptions and general informa-

tion on engines and engine management systems. Also cov-

ered is basic engine troubleshooting.

For specific repair procedures, refer to the appropriate repair

group:

110 Engine Removal and Installation

0 113 Cylinder Head Removal and Installation

116 Cylinder Head and Valvetrain

0 117 Camshaft Timing Chain

119 Lubrication System

120 Ignition System

130 Fuel Injection

0 170 Radiator and Cooling System

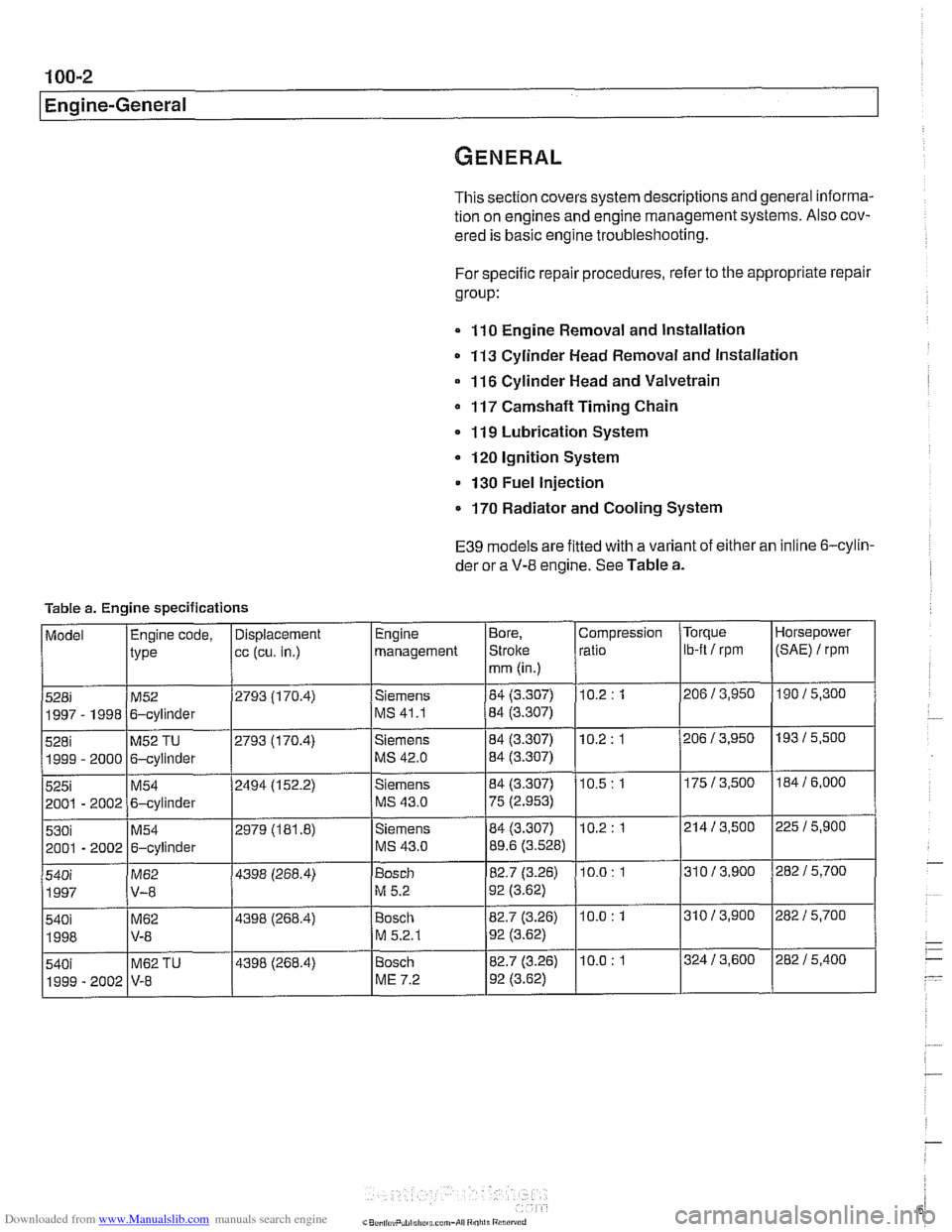

E39 models are fitted with a variant of either an inline 6-cylin-

der or a

V-8 engine. See Table a.

Table a. Engine specifications

Page 71 of 1002

Downloaded from www.Manualslib.com manuals search engine

Two common causes of driveability problems are incorrect

system voltage and bad grounds.

System voltage

Digital motor electronics (DME) requires that the system (bat-

tery) voltage be maintained within a narrow range of DC volt-

age.

DC voltage levels beyond or below the operating range,

or any

AIC voltage in the electrical system can cause havoc.

When troubleshooting an illuminated MIL, make sure the bat-

tery is fully charged and capable of delivering all its power to

the electrical system. An undercharged battery can amplify

AIC alternator output ripple.

To

make a quick check of the battery charge, measure the

voltage across the battery terminals with all cables attached

and the ignition off.

Afully charged battery will measure 12.6

volts or slightly more, compared to 12.1 5 volts for a battery

with a 25% charge.

The DME system operates at low voltage and current levels,

making it sensitive to small increases in resistance. The elec-

trical system is routinely subjected to corrosion, vibration and

wear, so faults or corrosion in the wiring harness and connec-

tors are not uncommon. Check the battery terminals

forcorro-

sion or loose cable connections. See 121 Battery, Starter,

Alternator for additional information.

If a battery cable connection has no

v~sible faults but is still

suspect, measure the voltage drop across the connection. A

large drop indicates excessive resistance, meaning that the

connection is corroded, dirty, or damaged. Clean or repairthe

connection and retest.

NOTE-

For instructions on conducting a voltage drop test and other

general electrical troubleshooting information, see

600 Elec-

trical System-General.

Visually inspect all wiring, connectors, switches and fuses in

the system. Loose or damaged connectors can cause inter-

mittent problems, especially the small terminals in the ECM

connectors. Disconnect the wiring harness connectors to

check for corrosion, and use electrical cleaning spray to re-

move contaminants.

Main grounds

Good grounds are critical to proper DME operation. If a

ground connection has no visible faults but is still suspect.

measure the voltage drop across the connection. A large volt-

age drop means high resistance. Clean or repair the connec-

tion and retest.

LBuntr.yP~sbhnllcn.can#-AII A,~iltl Rcsrwsd

Page 271 of 1002

Downloaded from www.Manualslib.com manuals search engine

Camshaft Timing Chain

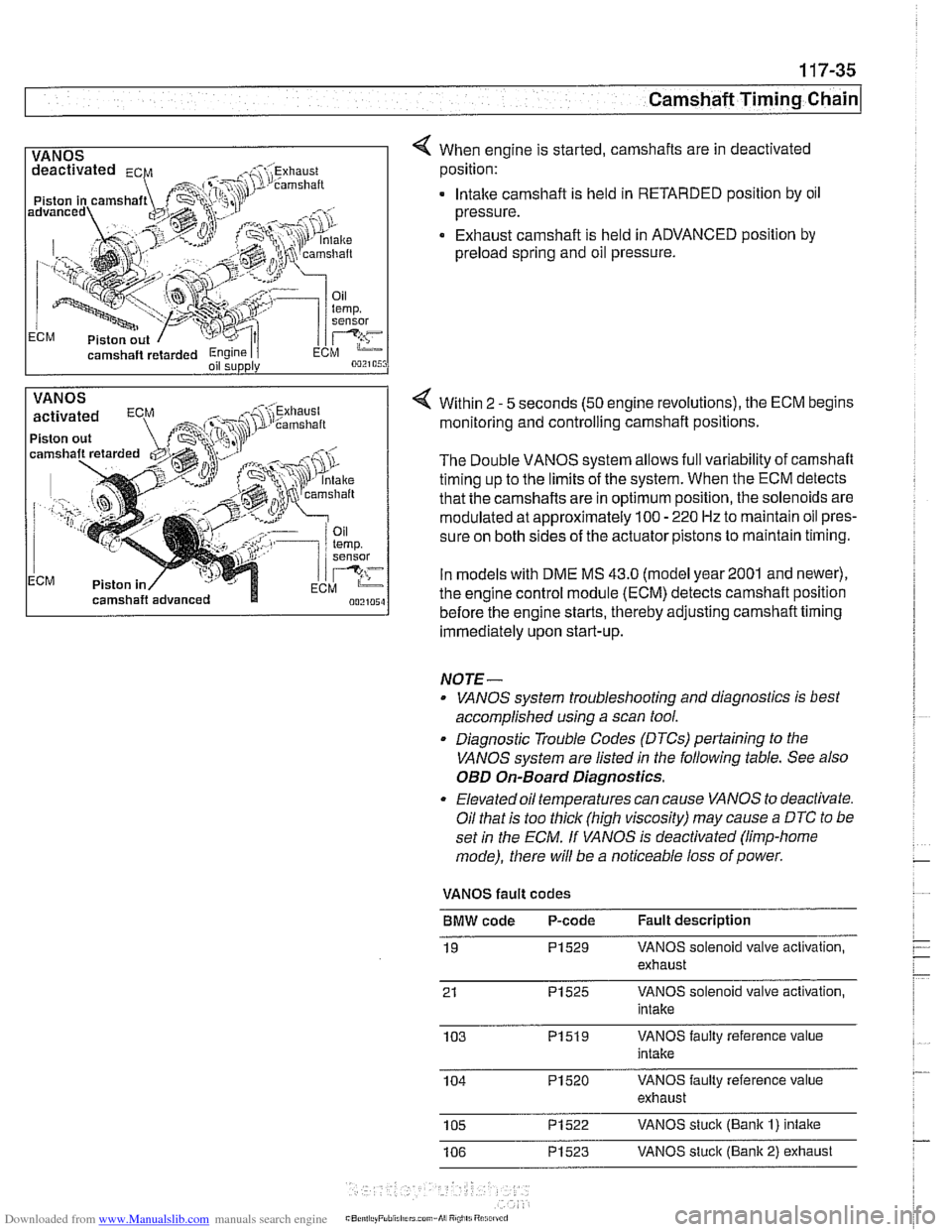

1 VANOS I 4 When engine is started, camshafts are in deactivated

camshaft

retarded Engine I i oil supply

position:

. lntalte camshaft is held in RETARDED position by oil

pressure.

Exhaust camshaft is held in ADVANCED position by

preload spring and oil pressure.

VANOS

Piston out

ECM Piston in Within 2

- 5

seconds (50 engine revolutions), the ECM begins

monitoring and controlling camshaft positions.

The Double VANOS system allows full variability of camshaft

timing up to the limits of the system. When the ECM detects

that the camshafts are in optimum position, the solenoids are

modulated at approximately 100

- 220 Hz to maintain oil pres-

sure on both sides of the actuator pistons to maintain timing.

In models with DME

MS 43.0 (model year2001 and newer),

the engine control module (ECM) detects camshaft position

before the engine starts, thereby adjusting camshaft timing

immediately upon start-up.

NOTE-

. VANOS system troubleshooting and diagnostics is best

accomplished using a scan tool.

. Diagnostic Trouble Codes (DTCs) pertaining to the

VANOS system are listed

in the following table. See also

OED On-Board Diagnostics.

Elevated oil temperatures can cause VANOS to deactivate.

Oil that is too thick (high viscosity) may cause

a DTC to be

set

in the ECM. If VANOS is deactivated (limp-home

mode), there will be a noticeable loss of power.

VANOS fault codes

BMW code P-code Fault description

19

PI529 VANOS solenoid valve activation,

exhaust

21

PI525 VANOS solenoid valve activation,

intake

103

PI519 VANOS faulty reference value

intake

104

PI520 VANOS faulty reference value

exhaust

105

PI522 VANOS stuck (Bank I) intake

106

PI523 VANOS stuck (Bank 2) exhaust

Page 321 of 1002

Downloaded from www.Manualslib.com manuals search engine

11 9 Lubrication System

General ............................ 11 9-2

Special tools

......................... 11 9-2

..................... Engine lubrication 11 9-3

Troubleshooting .................... 11 9-3

................. Oil pressure. checking 11 9-4

...... Oil pressure warning system. testing 11 9-5

Crankshaft Rear Main Seal ......... .I1 9-6

Crankshaft rear main seal.

replacing (6-cylinder)

.................. 11 9-6

Crankshaft rear main seal. replacing (V-8)

. . 11 9-8

Engine Oil Pan .................... .I1 9-10

Oil pan. removing and

................. installing (6-cylinder) .I1 9-10

Lower oil pan. removing and

installing (V-8)

....................... 1 19-1 3

Upper oil pan. removing and

installing (V-8)

....................... 11 9-1 5

.......... Component Replacement 11 9-20

Oil pressure warning switch. replacing

.................. (6-cylinder and V-8) 11 9-20

Oil level warning switch. replacing

.................. (6-cylinder and V-8) 11 9-21

Oil pump. removing and

................. installing (6-cylinder) 11 9-22

Oil pump. removing and installing (V-8)

. . 11 9-24

..... Oil pressure relief valve (6-cylinder) 119-26

.......... Oil pressure

relief valve (V-8) 11 9-27

Page 322 of 1002

Downloaded from www.Manualslib.com manuals search engine

11 9-2

Lubrication System

This repair group covers lubrication system troubleshooting

as well as oil pan removal and oil pump replacement.

In 6-cylinder models, removal of the oil pan requires the re-

moval of the exhaust system and some front suspension

components. Those procedures are fully covered in:

180 Exhaust System

210 Clutch

230 Manual Transmission

0 240 Automatic Transmission

310 Front Suspension

320 Steering and Wheel Alignment

NOTE-

Oil change procedure and oil filter replacement are covered

in

020 Maintenance.

CAUTIOG

V8 engines: The oil pump fasteners (including the sprocket

retaining nut) are known to vibrate loose. This can result in oil

starvation and engine failure. Be sure to check oil bolts and

nut tightness whenever the

oilpump is accessible. If any fas-

teners are found to be loose, remove them and reinstall with

Loctite

Band torque to specifications.

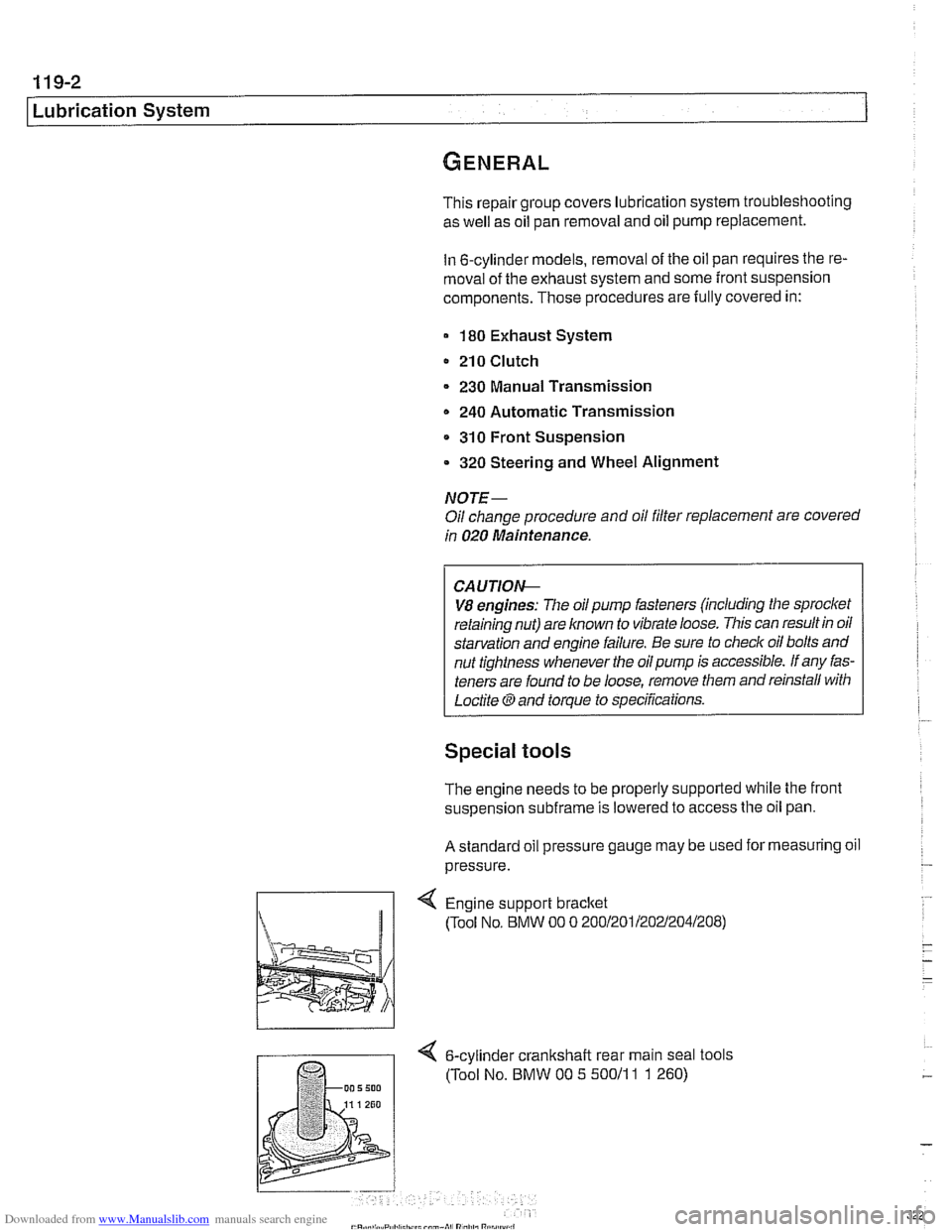

Special tools

The engine needs to be properly supported while the front

suspension

subframe is lowered to access the oil pan.

A standard oil pressure gauge may be used for measuring oil

pressure.

Engine support bracket

(Tool No, BMW 00 0 20012011202~2041208)

4 6-cylinder crankshalt rear main seal tools

(Tool No. BMW 00 5 50011

1 1 260)

Page 349 of 1002

Downloaded from www.Manualslib.com manuals search engine

120 lgnition System

...................... General

Special tools ...................

Warnings and cautions ...........

Engine management .............

................. lgnition system

Ignition system. troubleshooting

....

... Oscilloscope diagnostic diagrams

................ Misfire detection

............. Ignition System Service 120-9

.................... Ignition firing order 120-9

.............. Disabling ignition system 120-10

................... Checking for spark 120-1 0

lgnition coil assembly.

................. testing and replacing 120-1 0

.............. Crankshaftspeedsensor 120-12

............. Camshaft position sensors 120-1 4

...................... Knocksensors 120-16

Page 350 of 1002

Downloaded from www.Manualslib.com manuals search engine

Ignition System

This repair group covers component troubleshooting and re-

placement information for the ignition system.

When diagnosing engine management problems, including

on-board diagnostics (OBD

11) fault code analysis, also refer

to these repair groups:

* 130 Fuel Injection

* ELE Electrical Wiring Diagrams

OED On-Board Diagnostics

Special tools

System diagnosis and testing of the ignition system requires

special test equipment.

4 LED test light

(Tool No. Baum

1 1 15)

4 Automotive digital multimeter

4 Primary voltage test harness

(Tool No. BMW 12

7 020)

-

4 Secondary voltage test harness

(Tool No. BMW 12

7 030)