amplifier BMW 525i 2001 E39 Workshop Manual

[x] Cancel search | Manufacturer: BMW, Model Year: 2001, Model line: 525i, Model: BMW 525i 2001 E39Pages: 1002

Page 800 of 1002

Downloaded from www.Manualslib.com manuals search engine

.

I Body-General 1

Rear wiper system

The rear wiper assembly on the E39 Sport Wagon is a self-

contained unit. The control electronics are integrated into the

gear drive that is part of the motor assembly. The control elec-

tronics contain two hall sensors, one

forthe park position and

one

forthe end stop or to signal reverse direction of the wiper

motor.

-

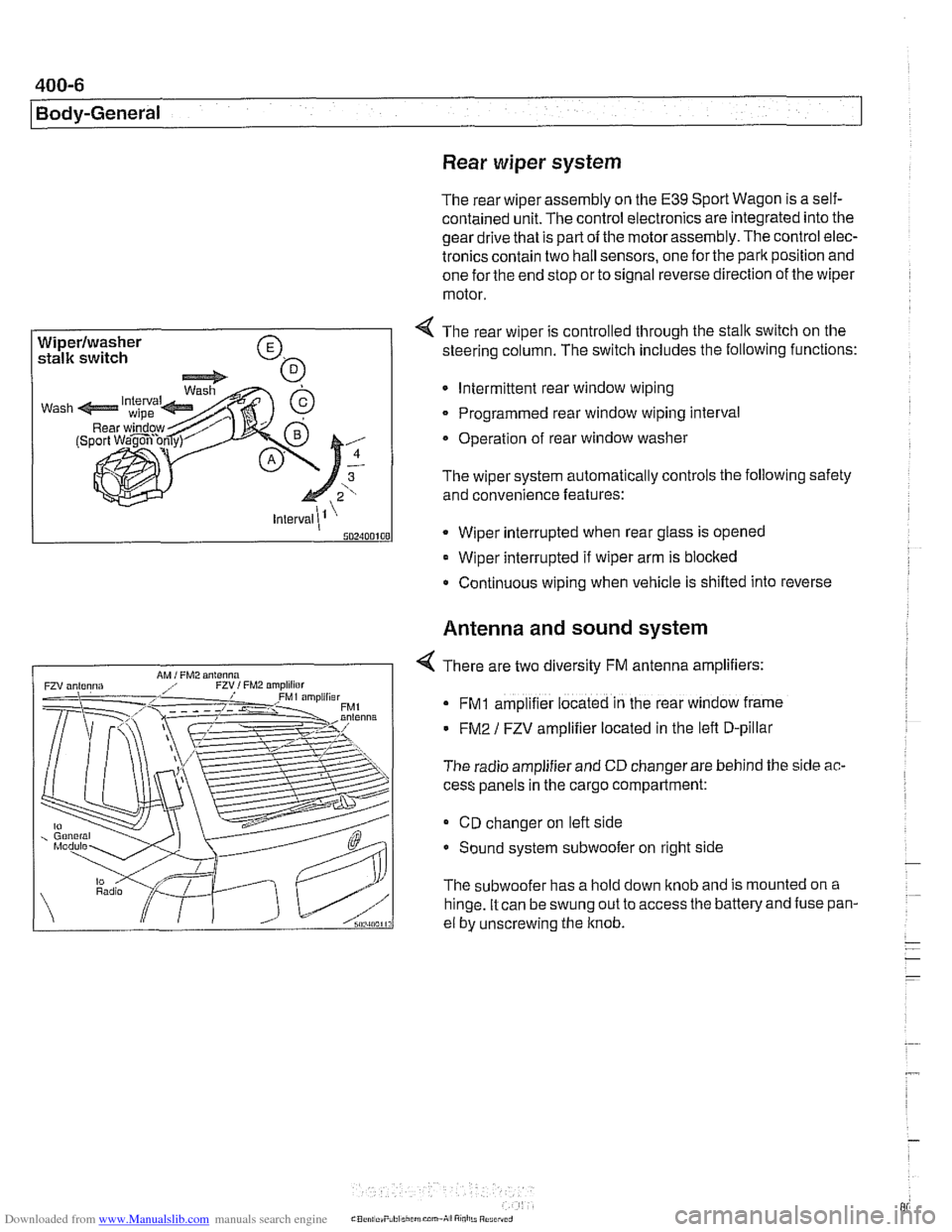

Wiperlwasher

stalk switch

/ 4 - 3

502400100

4 The rear wiper is controlled through the stalk switch on the

steering column. The switch includes the following functions:

Intermittent rear window wiping

Programmed rear window wiping interval

Operation of rear window washer

The wiper system automatically controls the following safety

and convenience features:

* Wiper interrupted when rear glass is opened

Wiper interrupted if wiper arm is blocked

Continuous wiping when vehicle is shifled into reverse

Antenna and sound system

4 There are two diversity FM antenna amplifiers:

FMI amplifier located in the rear window frame

FM2 / FZV amplifier located in the lefl D-pillar

The radio amplifier and CD changer are behind the side

ac-

cess panels in the cargo compartment:

CD changer on lefl side

Sound system subwoofer on right side

The subwoofer has a hold down knob and is mounted on a

hinge. It can be swung out to access

the batteryand fuse pan-

el by unscrewing the knob.

Page 839 of 1002

Downloaded from www.Manualslib.com manuals search engine

Trunk Lid, Tailgate

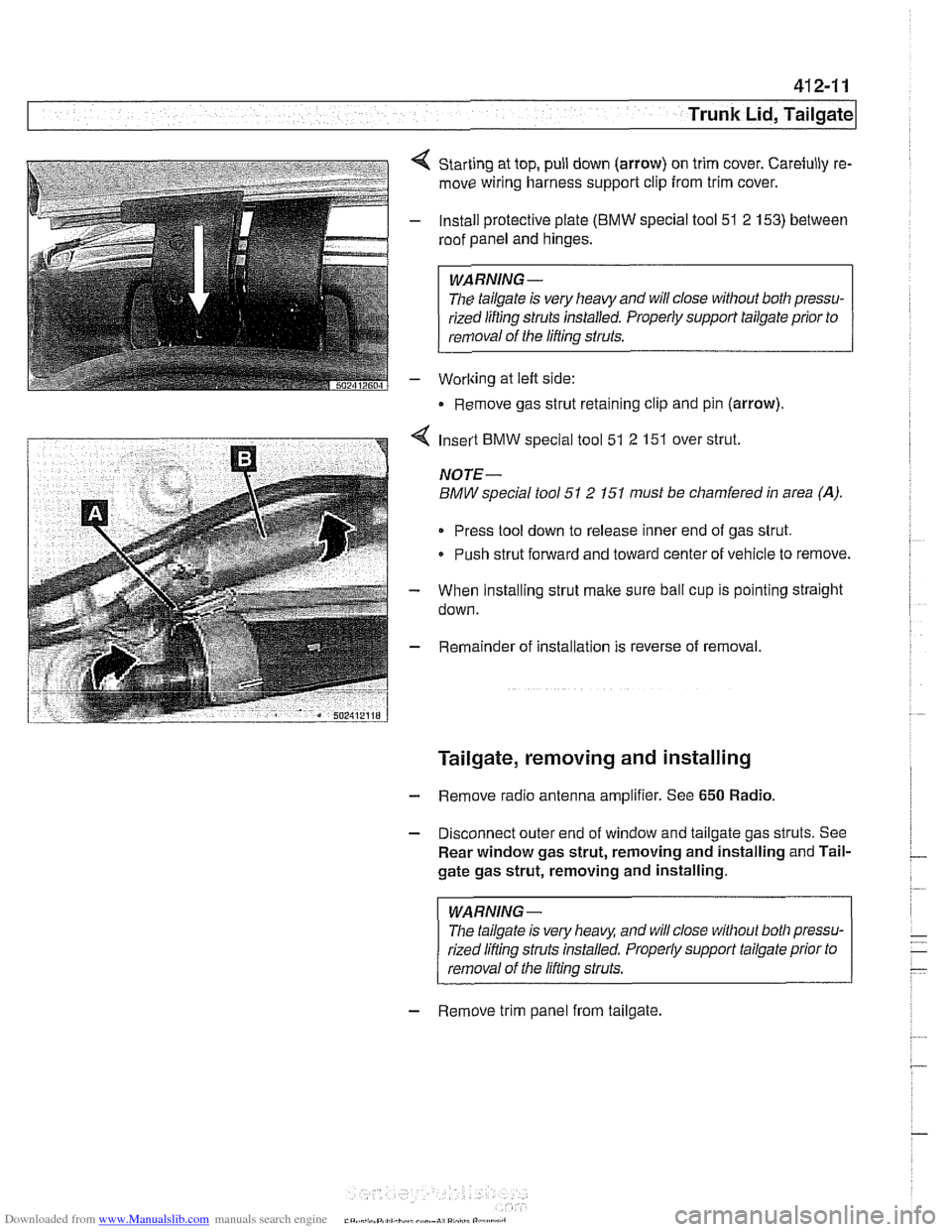

Starting at top, pull down (arrow) on trim cover. Carefully re-

move wiring harness support clip from trim cover.

Install protective plate

(BMW special tool 51 2 153) between

roof panel and hinges.

WARNING -

The tailgate is very heavy and will close without both pressu-

rized lifting

struts installed. Properly support tailgate prior to

removal of the lifting struts.

Worlting at left side:

Remove gas strut retaining clip and pin (arrow).

4 Insert BMW special tool 51 2 151 over strut.

NOTE-

BMW special tool 51 2 151 must be chamfered in area (A).

Press tool down to release inner end of gas strut.

Push strut forward and toward center of vehicle to remove.

- When installing strut make sure ball cup is pointing straight

down.

- Remainder of installation is reverse of removal.

Tailgate, removing and installing

- Remove radio antenna amplifier. See 650 Radio.

- Disconnect outer end of window and tailgate gas struts. See

Rear window gas strut, removing and installing and Tail-

gate gas strut, removing and installing.

WARNING-

The tailgate is very heaq and will close without both pressu-

rized lifling struts installed. Properly support tailgate prior to

removal of the lifling struts.

- Remove trim panel from tailgate.

Page 989 of 1002

Downloaded from www.Manualslib.com manuals search engine

On-Board ~ia~nosticsl

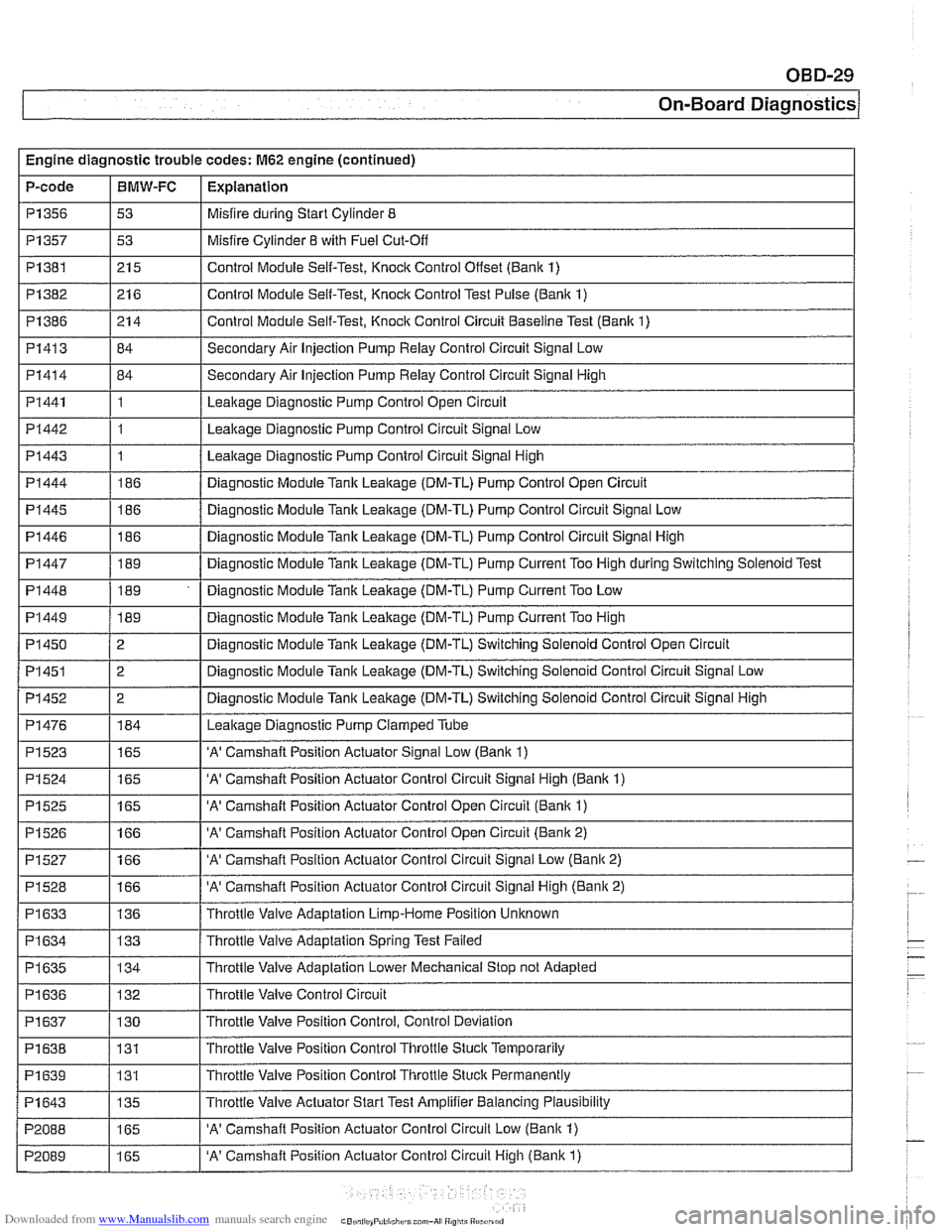

Engine diagnostic trouble codes: M62 engine (continued)

P-code

I I -

I I - -.

PI445 1186 / Diagnostic Module Tank Leakage (DM-TL) Pump Control Circuit Signal Low

PI357

PI382

PI386

PI413

PI414

PI441

PI442

PI443

PI444

P1356 1 53 I Misfire during Start Cylinder 8

BMW-FC

I P1523

I

I - -

1165 I 'A' Camshaft Position Actuator Signal Low (Banlc 1)

Explanation

P1381 1215 I Control Module Self-Test, Knock Control Onset (Bank 1)

53

21 6

21 4

84

84

1

1

1

186

PI 446

PI 447

PI 448

PI449

PI 450

PI451

PI452

PI476

Misfire Cylinder 8 with Fuel Cut-Off

Control Module Self-Test, Knock Control Test Pulse (Bank 1)

Control Module Self-Test, Knock Control Circuit Baseline Test (Bank 1)

Secondary Air Injection Pump Relay Control Circuit Signal Low

Secondary Air Injection Pump

Relay Control Circuit Signal High

Leakage Diagnostic Pump Control Open Circuit

Leakage Diagnostic Pump Control Circuit Signal Low

Leakage Diagnostic Pump Control Circuit Signal High

Diagnostic Module Tank Leakage (DM-TL) Pump Control Open Circuit

186

189

189

189

2

2

2

184

P1524

P1525

P1526

PI527

PI528

PI633

PI 634

PI 635

I I

PI 638 / 131 I Throttle Valve Position Control Throttle Stuck Temporarily

. -

Diagnostic Module Tank Leakage (DM-TL) Pump Control Circuit Signal High

Diagnostic Module

Tank Leakage (DM-TL) Pump Current Too High during Switching Solenoid Test

Diagnostic Module Tank Leakage (DM-TL) Pump Current Too Low

Diagnostic Module

Tank Leakage (DM-TL) Pump Current Too High

Diagnostic Module Tank Leakage (DM-TL) Switching Solenoid Control Open Circuit

Diagnostic Module

Tank Leakage (DM-TL) Switching Solenoid Control Circuit Signal Low

Diagnostic Module

Tank Leakage (DM-TL) Switching Solenoid Control Circuit Signal High

Leakaqe Diaqnostic Pump Clamped Tube

I I

165

165

166

166

166

136

133

134

'A' Camshaft Position Actuator Control Circuit Signal High (Banlc 1)

'A' Camshaft Position Actuator Control Open Circuit (Bank 1)

'A' Camshaft Position Actuator Control Open Circuit (Bank 2)

'A' Camshaft Position Actuator Control Circuit Signal Low (Bank 2)

'A' Camshaft Position Actuator Control Circuit Signal High (Bank 2)

Throttle Valve Adaptation Limp-Home Position Unknown

Throttle Valve Adaptation Spring Test Failed

Throttle Valve Adaptation Lower Mechanical Stop not Adapted

Throttle Valve Control Circuit

PI 636

PI639

P1643

P2088

P2089

PI 637 / 130 I Throttle Valve Position Control, Control Deviation

132

131

135

165

165 Throttle

Valve Position Control Thronle Stuck Permanently

Throttle Valve Actuator Start Test Amplifier Balancing Plausibility

'A' Camshaft Position Actuator Control Circuit Low (Banlc 1)

'A' Camshaft Position Actuator Control Circuit High (Bank 1)

Page 991 of 1002

Downloaded from www.Manualslib.com manuals search engine

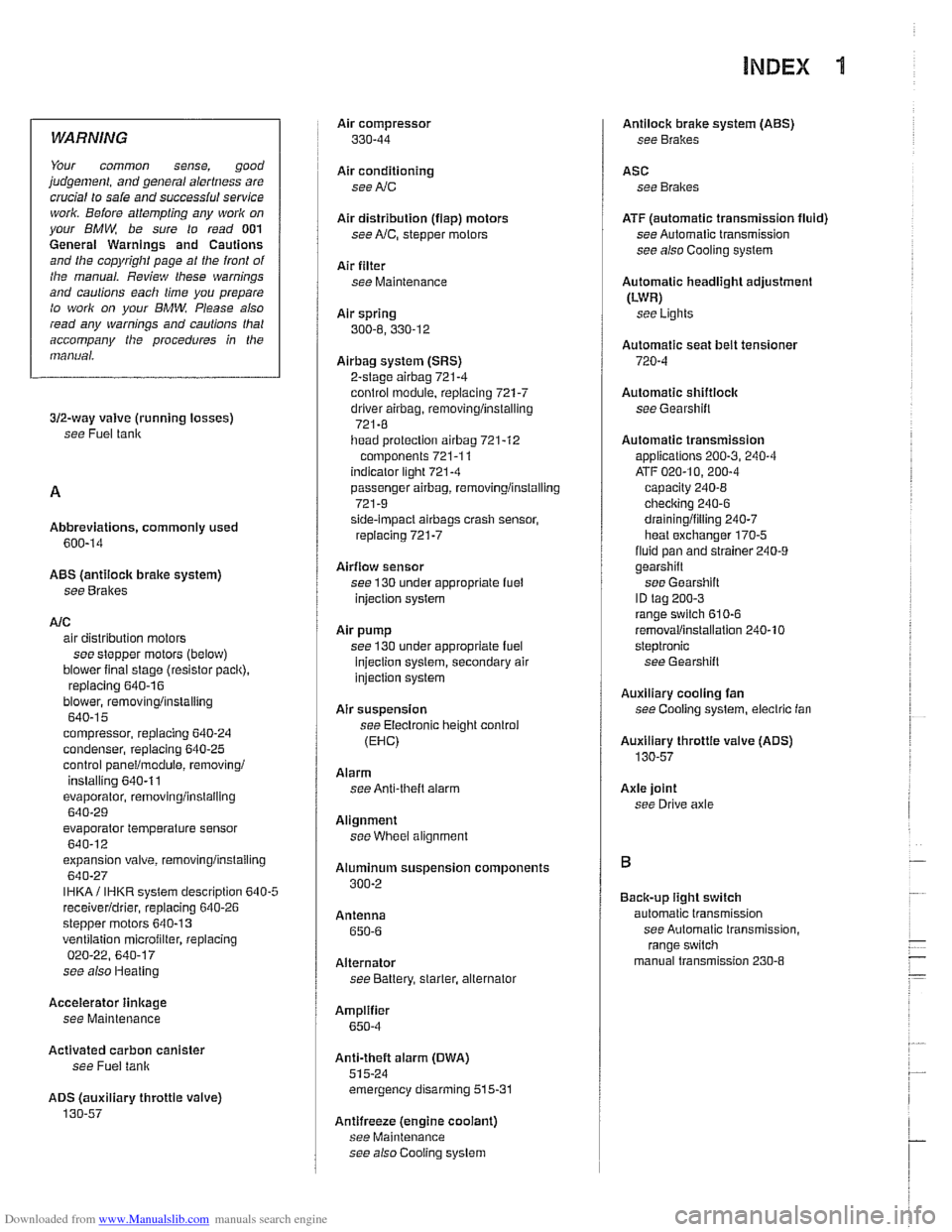

INDEX 'tl

WARNING

Your common sense, good

judgemenl, and general alertness are

crucial to sale and successiul service

worlr. Belore attempting any work on

your

BMM be sure lo read 001

General Warnings and Cautions

and the

copyriglll page at the front 01

the manual. Review these warnings

and

caulions each lime you prepare

lo work on your BMW. Please also

read any warnings and cautions that

accompany

tile procedures in the

manual.

312-way valve (running losses)

see Fuel tank

Abbreviations, commonly used 600-14

ABS (antilock brake system)

see

Bral(es

A/C air distribution motors

see stepper motors (below)

blower final stage (resistor pack),

replacing

640-16

blower, removinglinslalling

640-1 5

compressor, replacing

640-24 condenser, replacing 64045

control panellmodule, removing1

installing

640-1 1

evaporakr, removinglinstalling 640-29

evaporator temperature sensor

640-12 expansion valve, removinglinstailing

640-27

IHKA/ IHKR system description 640-5

receiveridrier, replacing 640-26

stepper motors 640-1 3 ventilation microiilter, replacing

020-22. 640-17

see also Heating

Accelerator

iinlcage

see Maintenance

Activated carbon canister

see Fuel tank

ADS (auxiliary throttle valve)

130-57

Air compressor

330-44

Air conditioning

see

AIC

Air distribution (flap) motors

seeNC, stepper motors

Air filter see Maintenance

Air spring

300-6, 330-12

Airbag system (SRS)

2-stage

airbag 721-4

control module, replacing 721-7 driver airbag, removinglinstalling

721-8

iiead protection airbag 721-12 components 721-1 1

indicator

lighl721-4

passenger airbag, removinglinstalling

721-9 side-impact airbags crash sensor,

replacing

721-7

Airflow sensor see 130 under appropriate

fuel

injection system

Air pump

see 130 under appropriate fuel

injection system, secondary air

injection system

Air suspension

see Electronic height control

(EHC)

Alarm

see Anti-theft alarm

Alignment see

Wheei alignment

Aluminum suspension components

300-2

Antenna 650-6

Alternator see Battery, starter, alte rnator

Amplifier

650-4

Anti-theft alarm (DWA)

515-24 emergency disarming 515-31

Antifreeze (engine coolant)

see Maintenance

see also Cooling system

Antilock brake system (ABS) see Brakes

ASC see Brakes

ATF (automatic transmission fluid)

see Automatic transmission

see also Cooling systern

Automatic headlight adjustmenl

(LWR) see Lights

Automatic seat belt tensioner

720-4

Automatic shiftloclc

see

Gearshift

Automatic transmission

applications

200-3, 240-4

ATF 020-10, 200-4

capacity 240-8 checking 240-6

drainingifilling 240-7

heat exchanger 170-5

fluid pan and strainer 240-9 gearshift

see Gearshift

ID tag

200-3 range switch 610-6

removaliinstallation 240-10

steptronic see Gearshift

Auxiliary cooling fan

see

Coollng system, electric Ian

Auxiliary throttle valve (ADS)

130-57

Axle joint

see Drive axle

Back-up light switch

automatic transmission see Automatic transmission. range switch

- .~.~~~

manual transmission 230-8 -

- I