spark plugs BMW 528i 1997 E39 Workshop Manual

[x] Cancel search | Manufacturer: BMW, Model Year: 1997, Model line: 528i, Model: BMW 528i 1997 E39Pages: 1002

Page 25 of 1002

Downloaded from www.Manualslib.com manuals search engine

Sockets Socltets are used with a ratchet handle for speed and conve-

nience and can be combined with extensions and universal

joints (swivels) to reach fasteners more easily. The most

common socket drive sizes are

114 inch, 318 inch and 112 inch.

Sockets come in

6 point and 12 point styles. The 6 point offers

a better grip on tight nuts and bolts.

6 mm to 19 mm socltets

are the most needed sizes. Below is a list of typical bolt

diarn-

eters and the corresponding wrench sizes.

Common bolt diameters and wrench sizes

M5 8 rnrn

M6

10 rnm

M8 12rnrnor13rnrn

MI 0 17 rnrn

MI2 19 rnrn

M14 22 mm

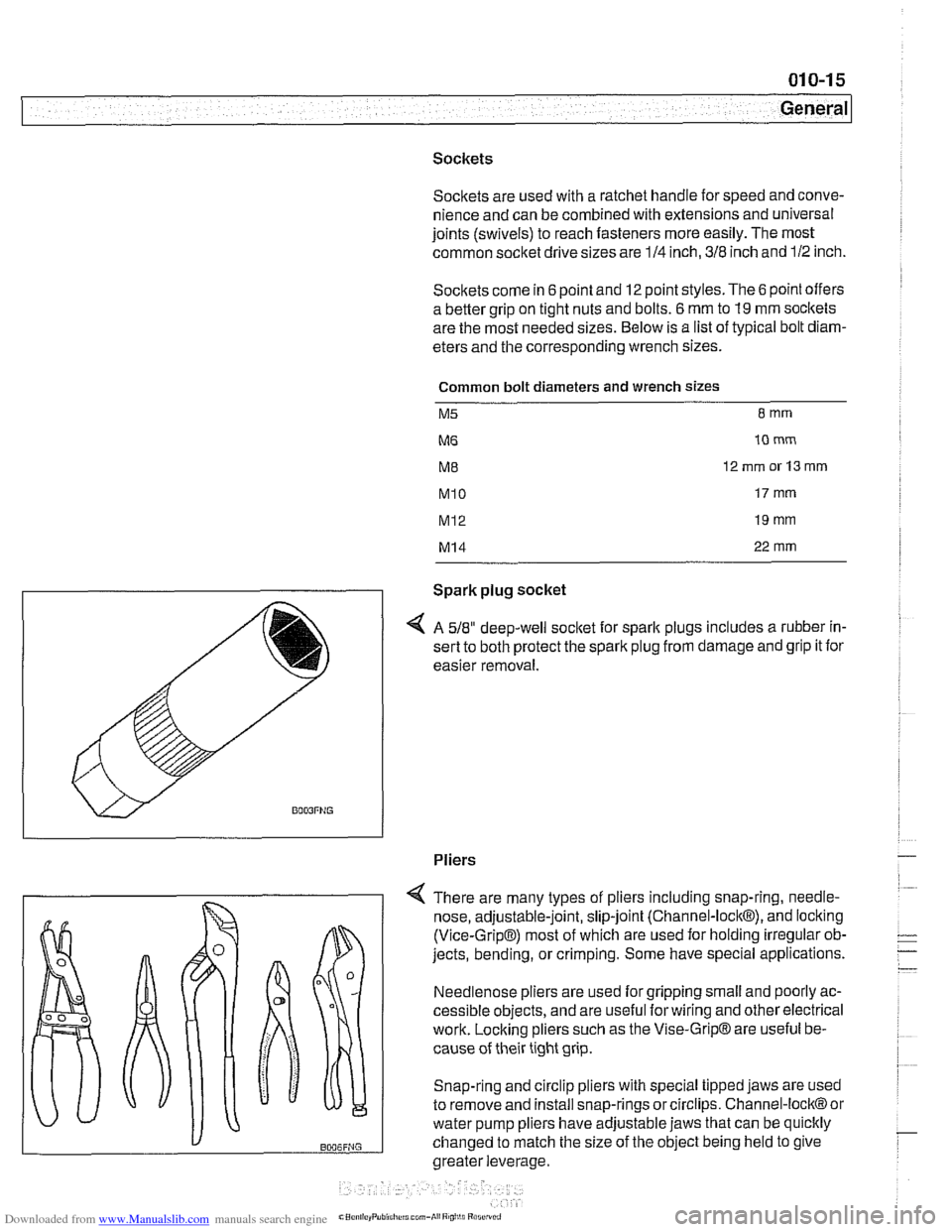

Spark plug socket

4 A 518" deep-well socket for sparlt plugs includes a rubber in-

sert to both protect the spark plug from damage and grip it for

easier removal.

Pliers

There are many types of pliers including snap-ring,

needle-

nose, adjustable-joint, slip-joint (Channel-lock@), and locking

(Vice-Grip@) most of which are used for holding irregular ob-

jects, bending, or crimping. Some have special applications.

Needlenose pliers are used for gripping small and poorly ac-

cessible objects, and are useful forwiring and other electrical

work. Locking pliers such as the Vise-Grip@ are useful be-

cause of their tight grip.

Snap-ring and circlip pliers with special tipped jaws are used

to remove and install snap-rings or circlips. Channel-lock@ or

water pump pliers have adjustable jaws that can be quicltly

changed to match the size of the object being held to give

greater leverage,

Page 33 of 1002

Downloaded from www.Manualslib.com manuals search engine

020 Maintenance

General ........................... .02 0.2

Special tools ........................ .02 0.2

Service Interval Indicator (Sll) ........... .02 0.3

Service Interval Indicator (Sll), resetting ... .02 0.3

Inspection I, Inspection 11 ............... .02 0.5

Maintenance Tables ................ .02 0.6

Fluid and Lubricant Specifications .. .02 0.9

Fluids and lubricants ................. .02 0.10

Engine Oil Service ................ .02 0.1 I

Engine oil. checking level ............. .02 0.12

Engine oil and filter. changing .......... .02 0-13

Engine Compartment Maintenance . .02 0.14

Accelerator and linkage ............... .02 0.14

Air filter. replacing ................... .02 0.1 4

Cooling system service ............... .02 0.15

Engine drive belt service .............. .02 0.16

Idlespeed .......................... 020-19

Catalytic converter and oxygen sensors .. .02 0.19

Power steering fluid, checking level ..... .02 0.20

Spark plugs ........................ .02 0.20

Spark plugs, replacing ................ .02 0.21

Interior ventilation microfilter, replacing ... .02 0.22

Other Mechanical Maintenance ..... .02 0.22

Battery, checking. cleaning. and replacing .02 0-22

Brake fluid. replacing ................. .02 0-24

Brake pad 1 rotor wear. checking ........ .02 0.24

Brake system, inspecting ............. .02 0.25

Parking brake. checking ............... 020-25

Clutch fluid. checking ................. 020-26

Differential oil level. checking ........... 020-26

Drive axle joint (CV joint) boots. inspecting 020-27

Exhaust system. inspecting ............ 020-27

Fuel filter. replacing .................. 020-27

Fuel tank and fuel lines. inspecting ...... 020-28

Suspension. front. inspecting ........... 020-29

Suspension. rear. inspecting ........... 020-29

Tires. checking inflation pressure ........ 020-29

Tires. rotating ....................... 020-29

Transmission service. automatic ........ 020-29

Transmission service. manual .......... 020-30

Transmission fluid. checking and filling

(manual transmission)

................ 020-30

Wheels. aligning ..................... 020-30

Body and Interior Maintenance ..... 020-31

Body and hinges. lubricating ........... 020-31

Exterior washing ..................... 020-31

Interior care ........................ 020-31

Leather upholstery and trim ............ 020-31

Polishing ........................... 020-32

Seat belts .......................... 020-32

Special cleaning ..................... 020-32

Washing chassis ..................... 020-32

Waxing ............................ 020-32

Windshield wiper blade maintenance ..... 020-33

Page 41 of 1002

Downloaded from www.Manualslib.com manuals search engine

--- -

Maintenance

Table c. Inspection II Service

Additional

New parts Warm engine Dealer service repair

Tools required required required recommended information

Engine compartment maintenance

Replace air filter element. (Note: reduce

replacement intervals in dusty operating

conditions).

Replace brake

fluid every 2 years (time

interval begins from vehicle production

date).

Cooling system service

Spark plug service

Brake

system maintenance

:j:

*

Replace coolant every 3 years (time

interval begins from vehicle production

date).

Replace oxygen sensor every 160,000

itm

(1 00,000 miles).

020

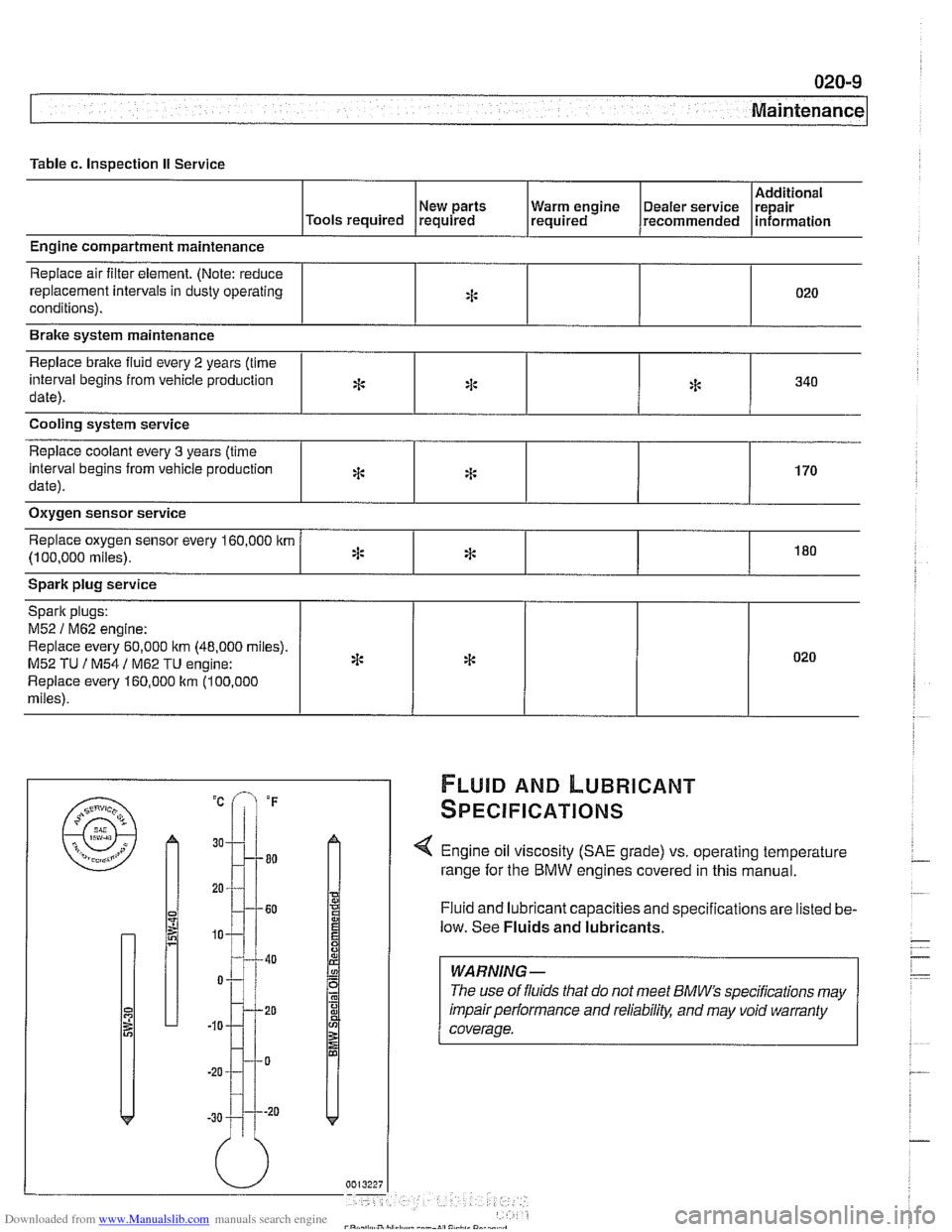

FLUID AND LUBRICANT

SPECIFICATIONS

:I:

Oxygen sensor service

*

x:

Spark plugs:

M52

1 M62 engine:

Replace every 60,000 itm (48.000 miles).

M52

TU I M54 1 M62 TU engine:

Replace every 160,000

ltm (100.000

miles).

< Engine oil viscosity (SAE grade) vs. operating temperature

range for the BMW engines covered in this manual.

Fluid and lubricant capacities and specifications are listed be-

low. See

Fluids and lubricants.

:I:

*

*

*

WARNING -

The use of fluids that do not meet BMW" specifications may

impair performance and

reliabilitl: and may void warranty

coverage.

340

170

180

* 020

Page 52 of 1002

Downloaded from www.Manualslib.com manuals search engine

Maintenance

continue to operate as designed. Extending the replacement

interval may void the emission control warranty coverage.

See

180 Exhaust System for information on replacing the

oxygen sensors.

Tightening torque

Oxvoen sensor to exhaust

manifold 50 Nrn (37 ft-lb)

NOTE-

A special soclet for replacing the oxygen sensor is available

from most automotive parts stores. The soclet has

a groove

cut down one side to allow the sensor to be installed without

damaging the wire harness.

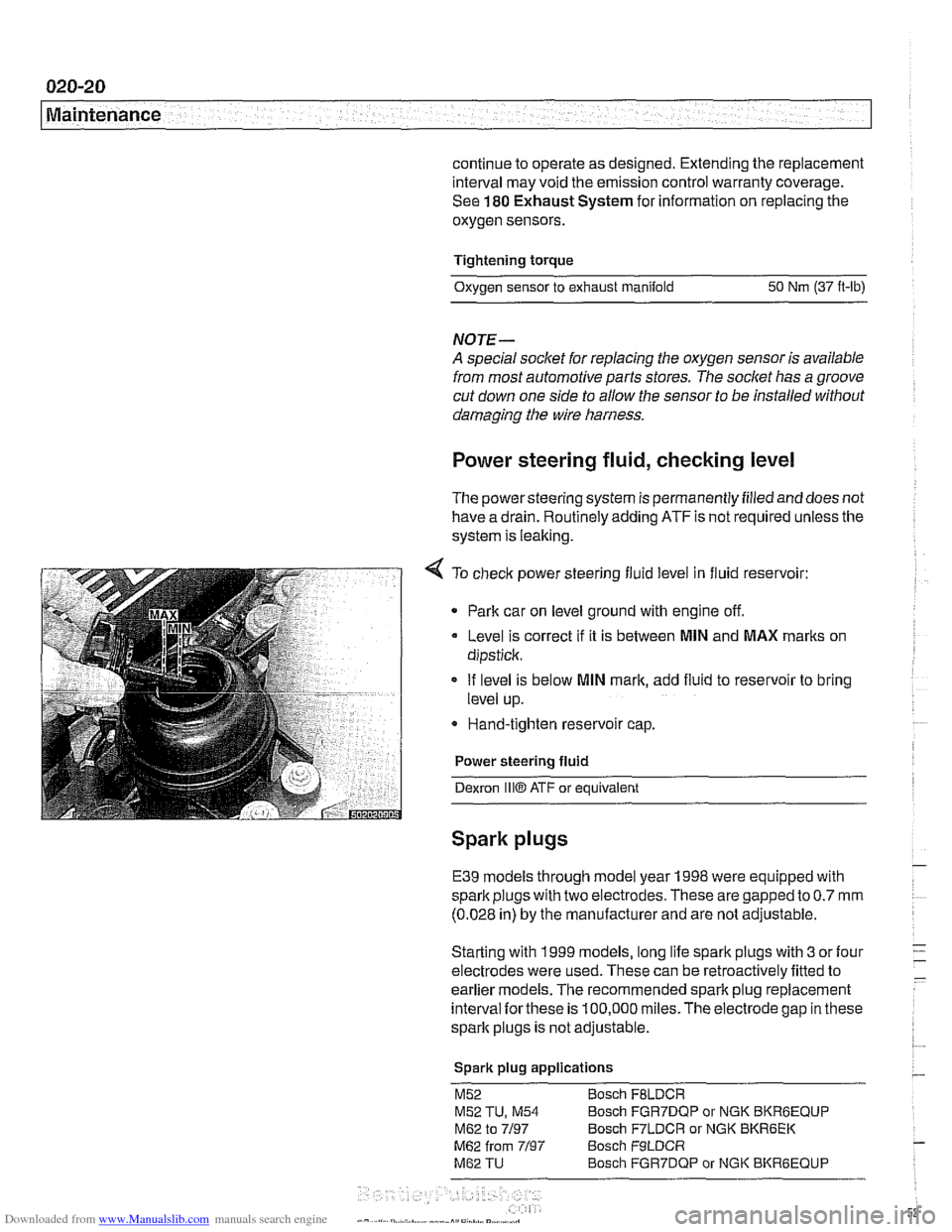

Power steering fluid, checking level

The power steering system is permanently filled and does not

have a drain. Routinely adding ATF is not required unless the

system is leaking.

4 To check power steering fluid level in fluid reservoir:

Park car on level ground with engine off.

Level is correct

if it is between MlN and MAX marks on

dipstick.

If level is below

MlN mark, add fluid to reservoir to bring

level up.

* Hand-tighten reservoir cap.

Power steering fluid

Dexron

1iiO ATF or equivalent

Spark plugs

E39 models through model year 1998 were equipped with

spark plugs with two electrodes. These are gapped to

0.7 mm

(0.028 in) by the manufacturer and are not adjustable.

Starting with 1999 models, long life spark plugs with

3 or four

electrodes were used. These can be retroactively fitted to

earlier

models. The recommended spark plug replacement

interval

forthese is 100,000 miles.The electrode gap in these

spark plugs is not adjustable.

Spark plug applications

M52 Bosch FBLDCR

M52 TU, M54 Bosch FGR7DQP or NGK BKRBEQUP

M62 to 7/97 Bosch F7LDCR or NGK BKR6EK

M62 from 7/97 Bosch F9LDCR

M62 TU Bosch FGR7DQP or NGK BKRGEQUP

Page 53 of 1002

Downloaded from www.Manualslib.com manuals search engine

020-21

Maintenance

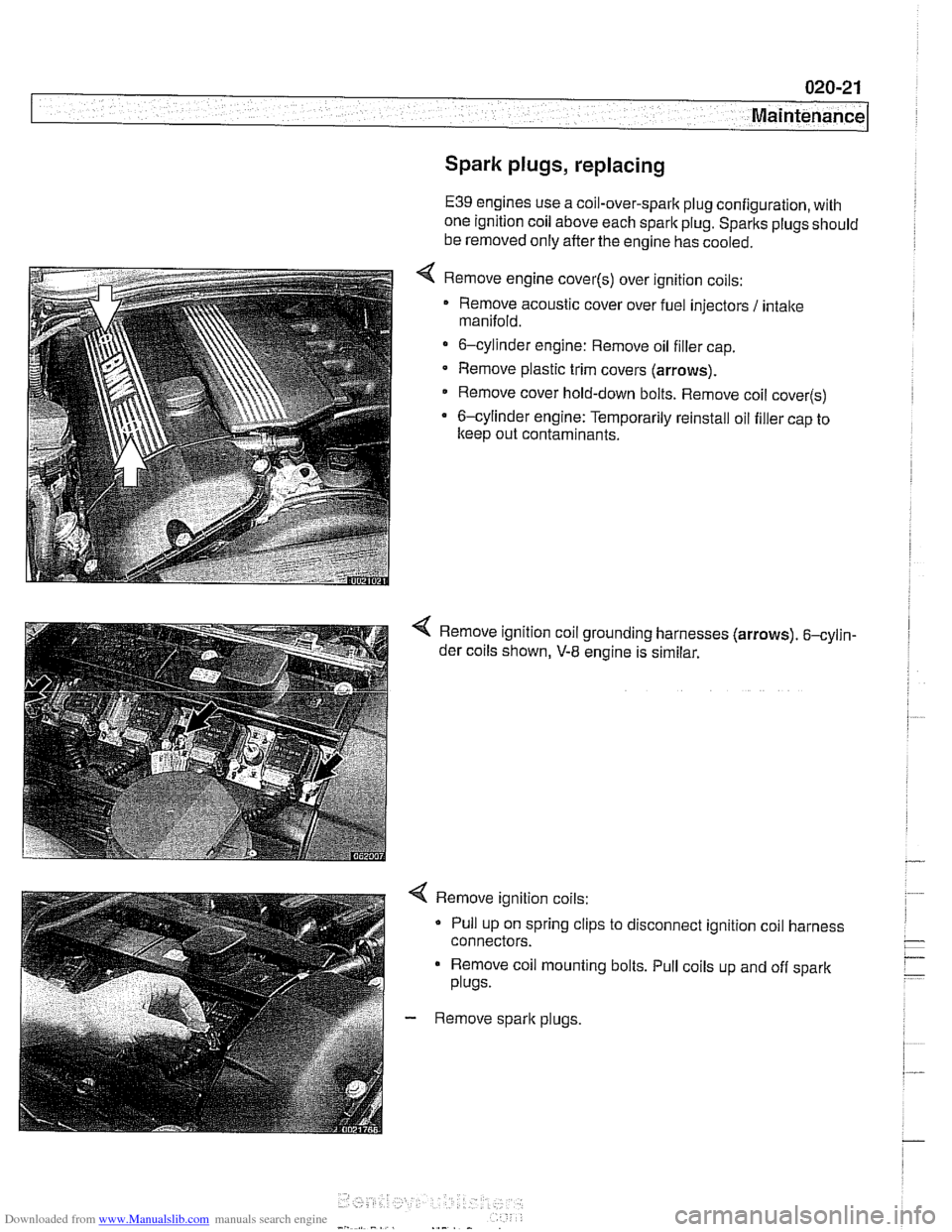

Spark plugs, replacing

E39 engines use a coil-over-spark plug configuration, with

one ignition coil above each spark plug. Sparks plugs should

be removed only after the engine has cooled.

Remove engine

cover(s) over ignition coils:

Remove acoustic cover over fuel injectors

I intake

manifold.

6-cylinder engine: Remove oil filler cap.

Remove plastic trim covers (arrows).

Remove cover hold-down bolts. Remove coil

cover(s)

6-cylinder engine: Temporarily reinstall oil filler cap to

keep out contaminants.

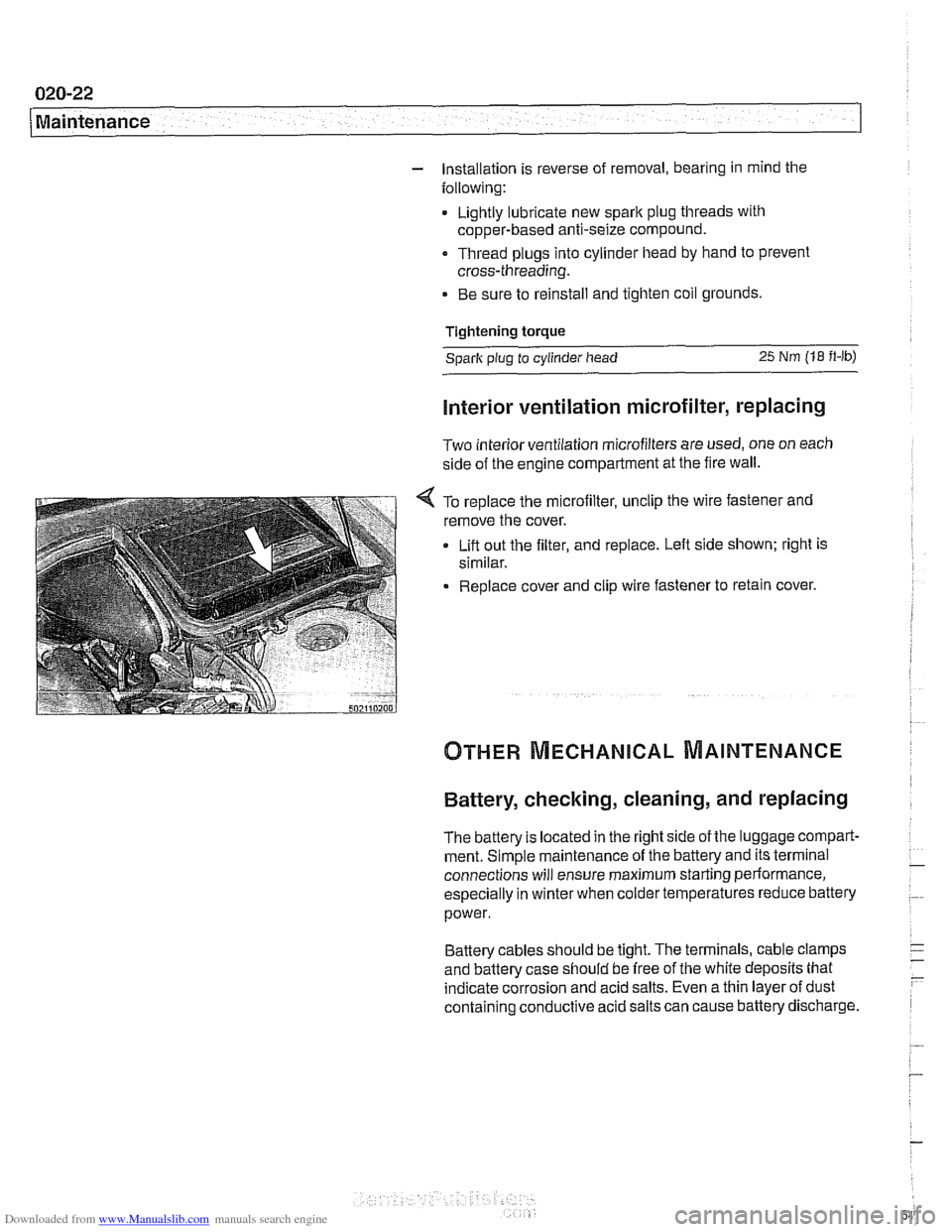

Remove ignition coil grounding harnesses (arrows). 6-cylin-

der coils shown,

V-8 engine is similar.

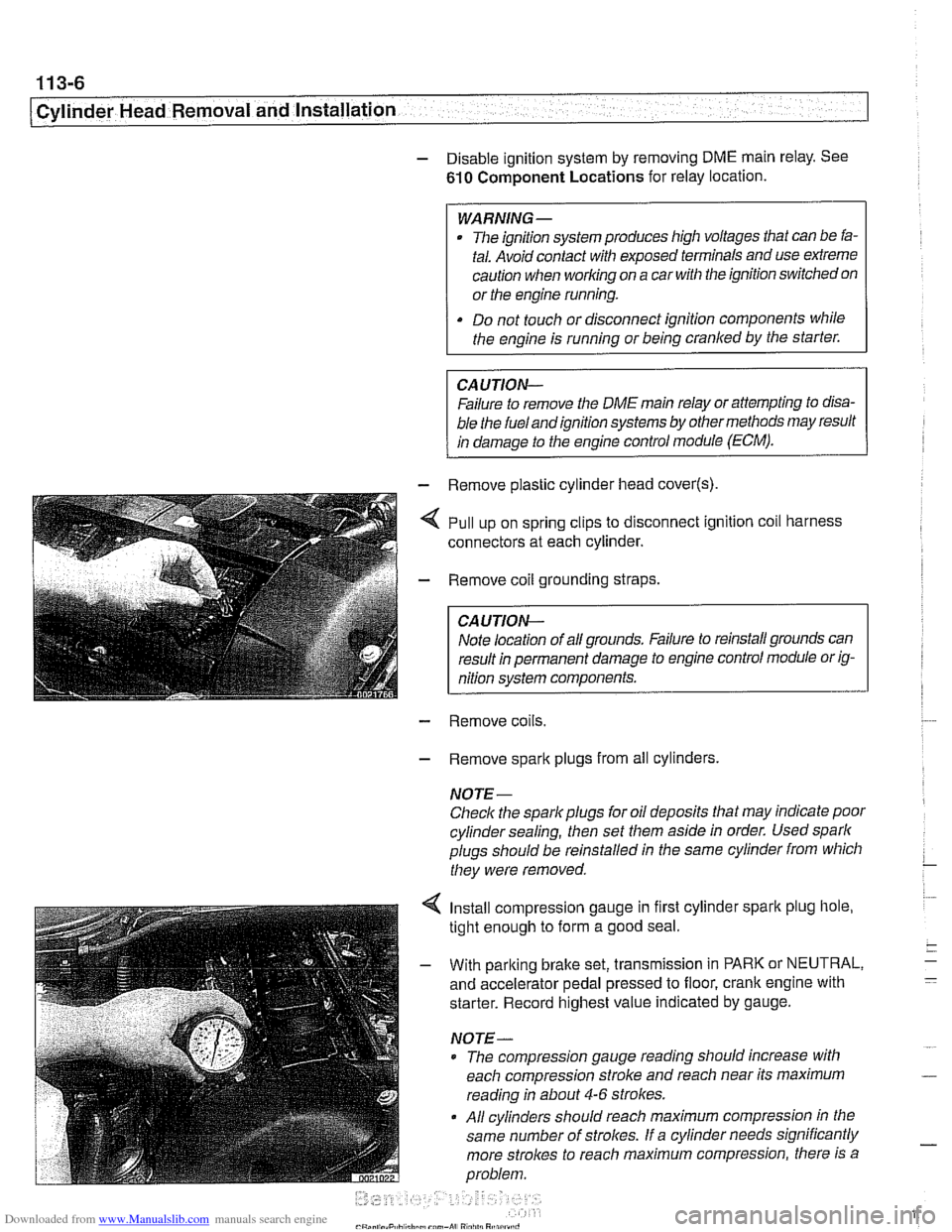

< Remove ignition coils:

Pull up on spring clips to disconnect ignition coil harness

connectors.

Remove coil mounting bolts. Pull coils up and off spark

plugs.

- Remove spark plugs.

Page 54 of 1002

Downloaded from www.Manualslib.com manuals search engine

020-22 Maintenance

1

- Installation is reverse of removal, bearing in mind the

following:

Lightly lubricate new

spark plug threads with

copper-based anti-seize compound.

Thread plugs into cylinder head by hand to prevent

cross-threading.

. Be sure to reinstall and tighten coil grounds.

Tightening torque Spark plug

to cylinder head 25 Nm (18 It-lb)

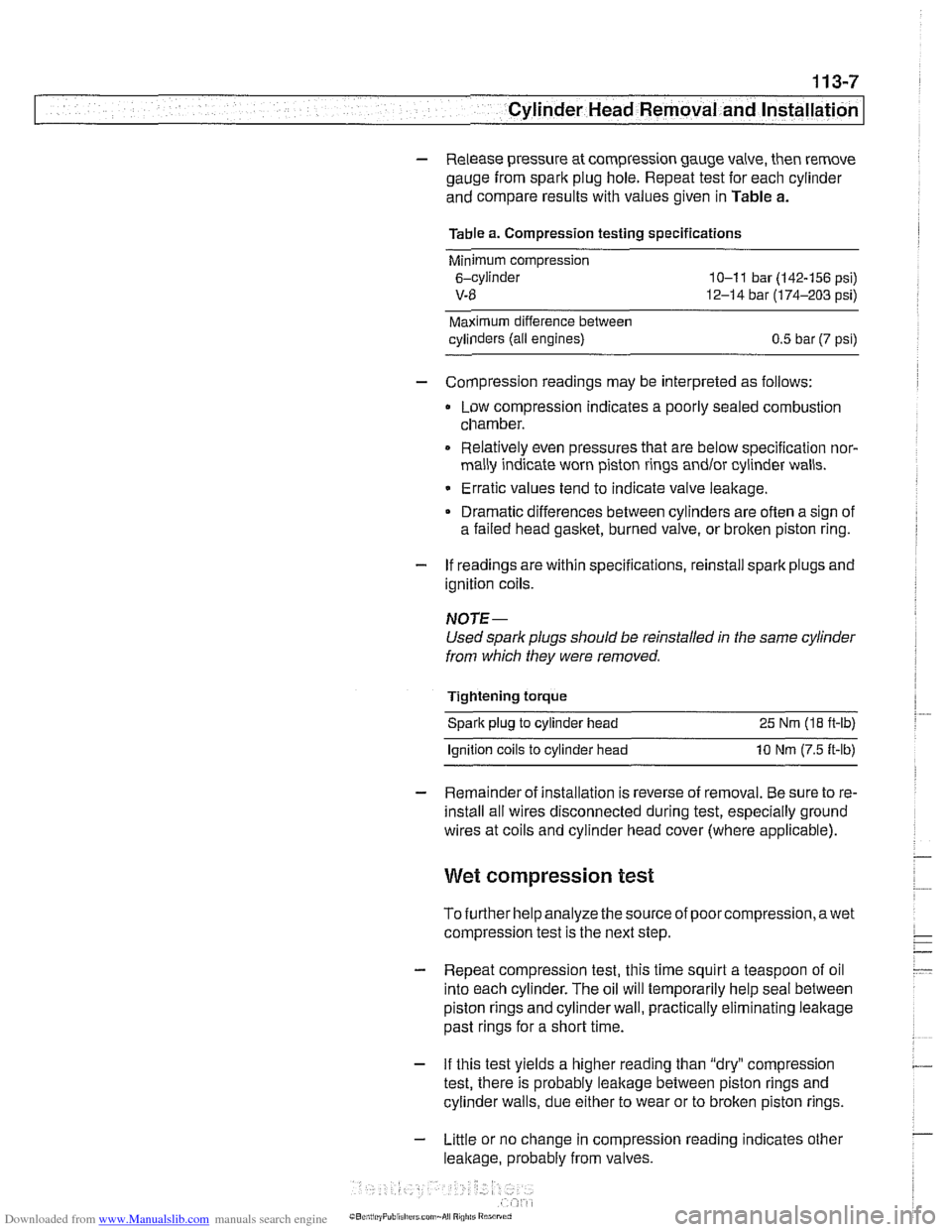

Interior ventilation microfilter, replacing

Two interior ventilation microfilters are used, one on each

side of the engine compartment at the fire wall.

< To replace the microfilter, unclip the wire fastener and

remove the cover.

Lift out the filter, and replace. Left side shown; right is

similar.

Replace cover and clip wire fastener to retain cover.

Battery, checking, cleaning, and replacing

The battery Is located in the right side of the luggage compart-

ment. Simple maintenance of the battery and its terminal

connections will ensure maximum starting periormance,

especially in winter when colder temperatures reduce battery

power.

Battery cables should be tight. The terminals, cable clamps

and battery case should be free of the white deposits that

indicate corrosion and acid salts. Even a thin layer of dust

containing conductive acid salts can cause battery discharge.

Page 100 of 1002

Downloaded from www.Manualslib.com manuals search engine

11 3-6

Cylinder Head Removal and Installation

- Disable ignition system by removing DME main relay. See

610 Component Locations for relay location.

WARNING-

. The ignition system produces high voltages that can be fa-

tal. Avoid contact with exposed terminals and use

exfreme

caution when working on a car with the ignition switched on

or the engine running.

Do not touch or disconnect ignition

components while

the engine is running or being cranked by the starter.

Failure to remove the DME main relay or attempting to

disa-

bie the fuel andignition systems by other methods may result

in damaoe to the enoine control module

(ECM).

- - Remove plastic cylinder head cover(s)

,,I . ,. .*,.,,&- - Remove coil grounding straps.

I CAUTION-

I nition system components. I

- Remove coils.

- Remove spark plugs from all cylinders.

NOTE-

Check the spark plugs for oil deposits that may indicate poor

cylinder sealing, then set them aside in order. Used spark

plugs should be reinstalled in the same cylinder from which

they were removed.

4 Install compression gauge in first cylinder spark plug hole,

tight enough to form a good seal.

- With parking brake set, transmission in PARK or NEUTRAL,

and accelerator pedal pressed to floor, crank engine with

starter. Record highest value indicated by gauge.

NOTE-

* The compression gauge reading should increase with

each compression stroke and reach near its maximum

reading in about

4-6 strokes.

All cylinders should reach maximum compression in the

same number of

strolces. If a cylinder needs significantly

more strokes to reach

maximum compression, there is a

problem.

Page 101 of 1002

Downloaded from www.Manualslib.com manuals search engine

. .- . --

Lr -- - - - -- Cylinder Head Removal and Installation I -

- Release pressure at compression gauge valve, then remove

gauge from spark plug hole. Repeat test for each cylinder

and compare results with values given in Table a.

Table a. Compression testing specifications

Minimum compression

6-cylinder

10-1 1 bar (142-156 psi)

V-8 12-14 bar (174-203 psi)

Maximum difference between

cylinders (all engines)

0.5 bar (7 psi)

- Compression readings may be interpreted as follows:

Low compression indicates a poorly sealed combustion

chamber.

0 Relatively even pressures that are below specification nor-

mally indicate worn piston rings

andlor cylinder walls.

Erratic values tend to indicate valve leakage.

Dramatic differences between cylinders are often a sign of

a failed head

gasket, burned valve, or broken piston ring.

- If readings are within specifications, reinstall spark plugs and

ignition coils.

NOTE-

Used spark plugs should be reinstalled in the same cylinder

from which they were removed.

Tightening torque Spark plug to cylinder head 25 Nm

(18 ft-lb)

lanition coils to cylinder head 10 Nm (7.5 ft-lb)

- Remainder of installation is reverse of removal. Be sure to re-

install all wires disconnected during test, especially ground

wires at coils and cylinder head cover (where applicable).

Wet compression test

To further help analyze the source of poorcompression,awet

compression test is the next step.

- Repeat compression test, this time squirt a teaspoon of oil

into each cylinder. The oil will temporarily help seal between

piston rings and cylinder wall, practically eliminating leakage

past rings for a short time.

- If this test yields a higher reading than "dry" compression

test, there is probably leakage between piston rings and

cylinder walls, due either to wear or to broken piston rings.

- Little or no change in compression reading indicates other

leakage, probably from valves.

Page 123 of 1002

Downloaded from www.Manualslib.com manuals search engine

Cylinder Head Removal and Installation

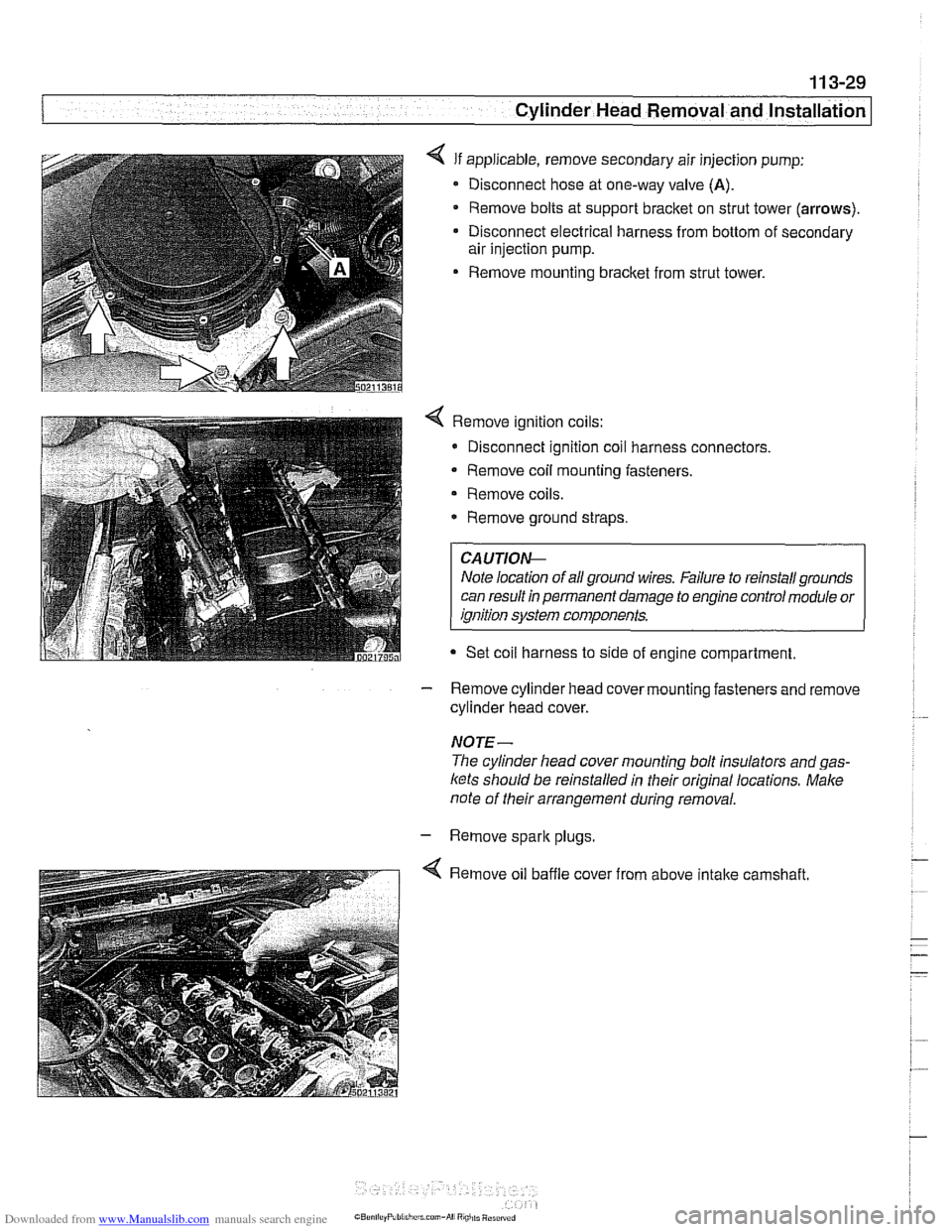

4 If applicable, remove secondary air injection pump:

Disconnect hose at one-way valve

(A).

Remove bolts at support bracket on strut tower (arrows).

Disconnect electrical harness from bottom of secondary

air injection pump.

Remove mounting bracket from strut tower.

4 Remove ignition coils:

* Disconnect ignition coil harness connectors.

Remove coil mounting fasteners.

Remove coils.

* Remove ground straps.

CA UTIOI\C

Note location of all ground wires. Failure to reinstall grounds

can result in permanent damage to engine control module or

ignition system components.

Set coil harness to side of engine compartment

- Remove cylinder head cover mounting fasteners and remove

cylinder head cover.

NOTE-

The cylinder head cover mounting bolt insulators and gas-

ltets should be reinstalled in their original locations. Male

note of their arrangement during removal.

- Remove spark plugs

4 Remove oil baffle cover from above intake camshaft.

Page 155 of 1002

Downloaded from www.Manualslib.com manuals search engine

11 3-61

Cylinder Head Removal and installation I

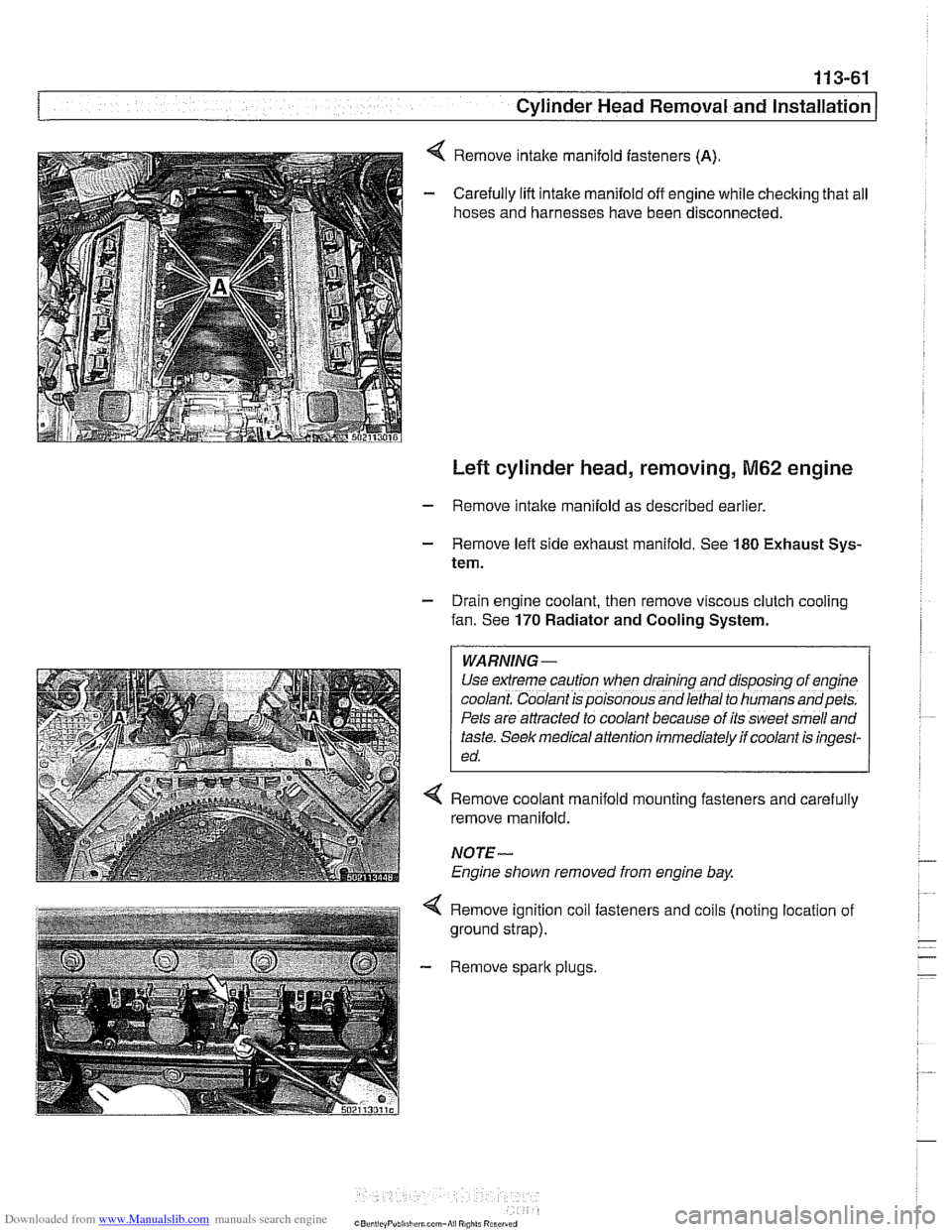

Remove intake manifold fasteners (A).

Carefully lift intake manifold off engine while checking that all

hoses and harnesses have been disconnected.

Left cylinder head, removing, M62 engine

- Remove intake manifold as described earlier

- Remove left side exhaust manifold. See 180 Exhaust Sys-

tem.

- Drain engine coolant, then remove viscous clutch cooling

fan. See

170 Radiator and Cooling System.

WARNING -

Use extreme caution when draining and disposfng of eng~ne

coolant. Coolant is poisonous and lethal to humans andpets.

Pets are attracted to coolant because of its sweet smell and

taste.

Seek med~cal attention immediately if coolant is ingest-

ed.

4 Remove coolant manifold mounting fasteners and carefully

remove manifold.

NOTE-

Engine shown removed from engine bay

4 Remove ignition coil fasteners and coils (noting location of

ground strap).

- Remove spark plugs.