Gas BMW 528i 1997 E39 Workshop Manual

[x] Cancel search | Manufacturer: BMW, Model Year: 1997, Model line: 528i, Model: BMW 528i 1997 E39Pages: 1002

Page 591 of 1002

Downloaded from www.Manualslib.com manuals search engine

Automatic Transmission

- Raise and safely support vehicle.

CA U JIOG

Male sure the car is stable and well supported at all times.

Use a professional automotive lift

orjack stands designed for

the purpose. A floorjack is not adequate support

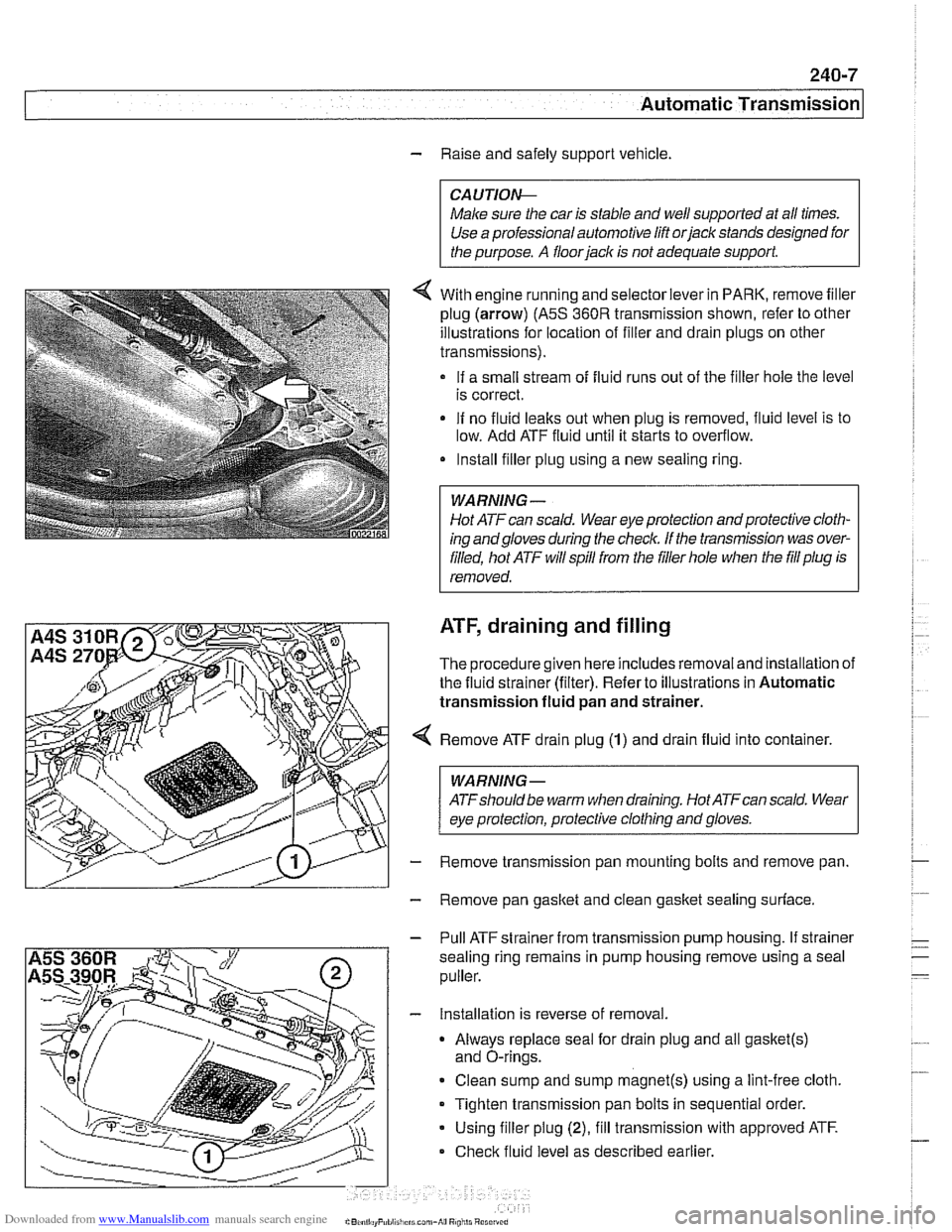

4 With engine running and selector lever in PARK, remove filler

plug (arrow)

(A5S 360R transmission shown, refer to other

illustrations for location of filler and drain plugs on other

transmissions).

If a small stream of fluid runs out of the filler hole the level

is correct.

If no fluid

leaks out when plug is removed, fluid level is to

low. Add ATF fluid until it starts to overflow.

Install filler plug using a new sealing ring.

Hot ATF can scald. Wear eye protection and protective cloth-

ing andgloves during

the check. If the tmnsmission was over-

filled, hot ATF will spill from the filler hole when the

fill plug is

removed.

ATF, draining and filling

The procedure given here includes removal and installation of

the fluid strainer (filter). Refer to illustrations in Automatic

transmission fluid

pan and strainer.

Remove ATF drain plug

(1) and drain fluid into container.

WARNING-

ATFshould be warm when draining. Hot ATFcan scald. Wear

eye protection, protective clothing and gloves.

Remove transmission pan mounting bolts and remove pan.

Remove pan gasket and clean

gasket sealing surface.

- Pull ATF strainer from transmission pump housing. If strainer

sealing ring remains in pump housing remove using a seal

puller.

- Installation is reverse of removal.

Always replace seal for drain plug and all

gasket(s)

and O-rings.

Clean sump and sump

magnet(s) using a lint-free cloth.

Tighten transmission pan bolts in sequential order.

Using filler plug

(2), fill transmission with approved ATF.

Check fluid level as described earlier.

Page 593 of 1002

Downloaded from www.Manualslib.com manuals search engine

240-9

Automatic Transmission

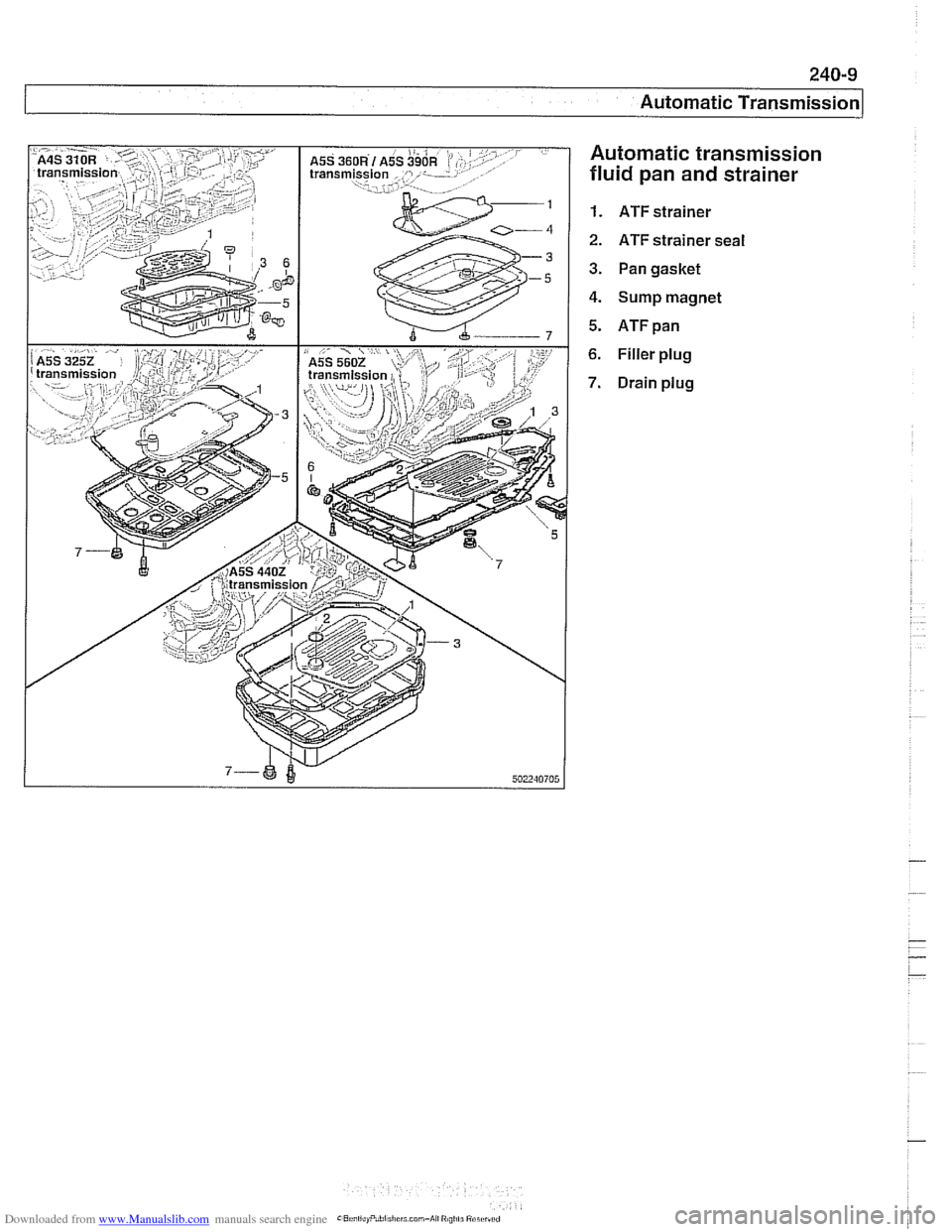

Automatic transmission

fluid pan and strainer

1. ATF strainer

2. ATF strainer seal

3. Pan gasket

4. Sump magnet

5. ATFpan

6. Filler plug

7. Drain plug

Page 620 of 1002

Downloaded from www.Manualslib.com manuals search engine

260-14

Driveshaft

Constant velocity (CV) joint, replacing

The CV joint at the rear of the driveshaft is available from

BMW as a separate part.

- Remove complete driveshaft as described earlier in this

section.

< Clean grease off CV joint. Remove retaining circlip (arrow)

from CV joint end of driveshaft.

- Drive out bolts from CV joint.

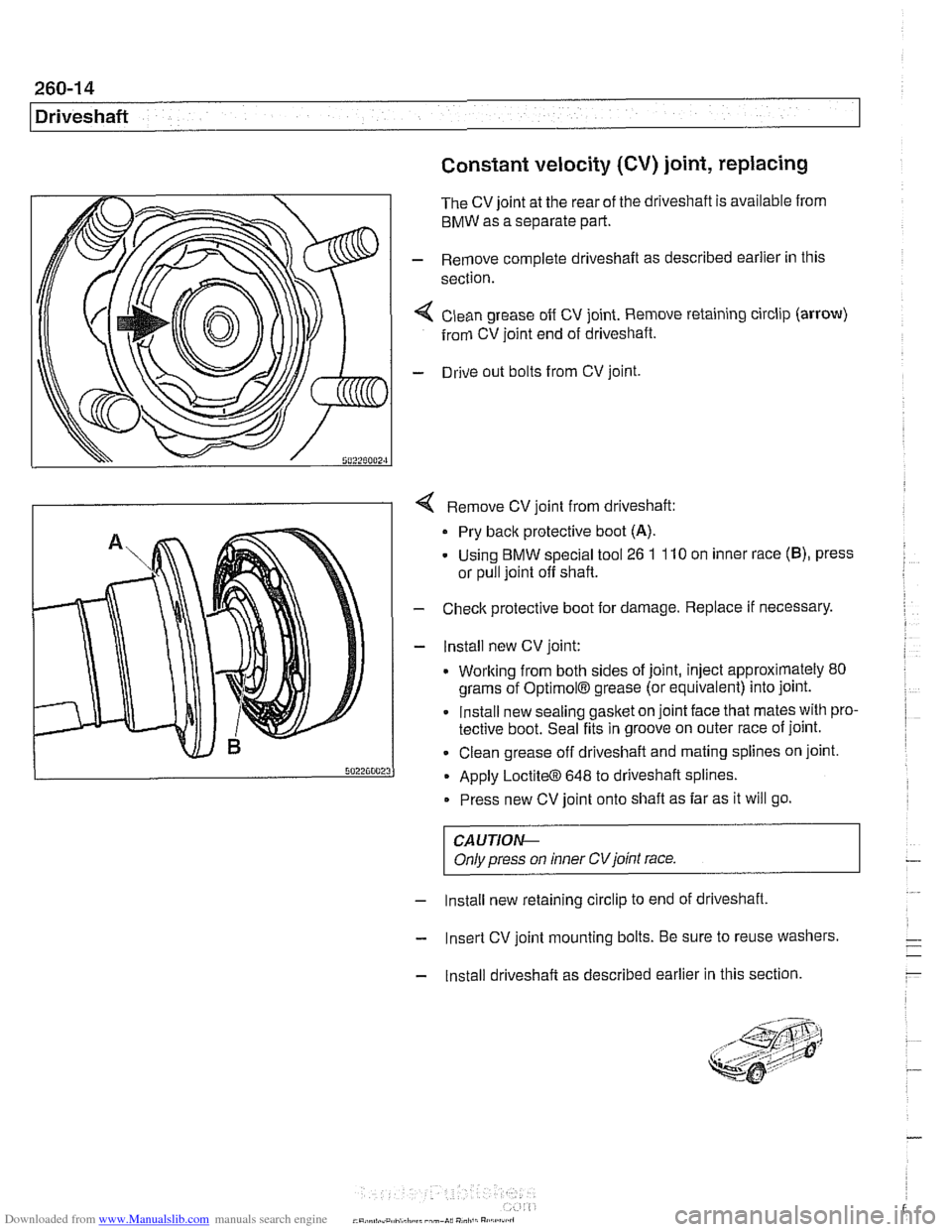

4 Remove CV joint from driveshaft:

Pry back protective boot

(A).

- Using BMW special tool 26 1 110 on inner race (B), press

or pull joint off shaft.

- Check protective boot for damage. Replace if necessary.

- lnstall new CV joint:

. Working from both sides of joint, inject approximately 80

grams of

OptimolB grease (or equivalent) into joint.

Install new sealing gasket on joint face that mates with pro-

tective boot. Seal fits in groove on outer race of joint.

Clean grease off driveshaft and mating splines on joint.

Apply

LoctiteO 648 to driveshaft splines.

Press new CV joint onto shaft as far as it will go.

CAUTIOI\C

Only press on inner CVjoint race.

- Install new retaining circlip to end of driveshaft,

- Insert CV joint mounting bolts. Be sure to reuse washers.

- Install driveshaft as described earlier in this section.

Page 756 of 1002

Downloaded from www.Manualslib.com manuals search engine

331-12

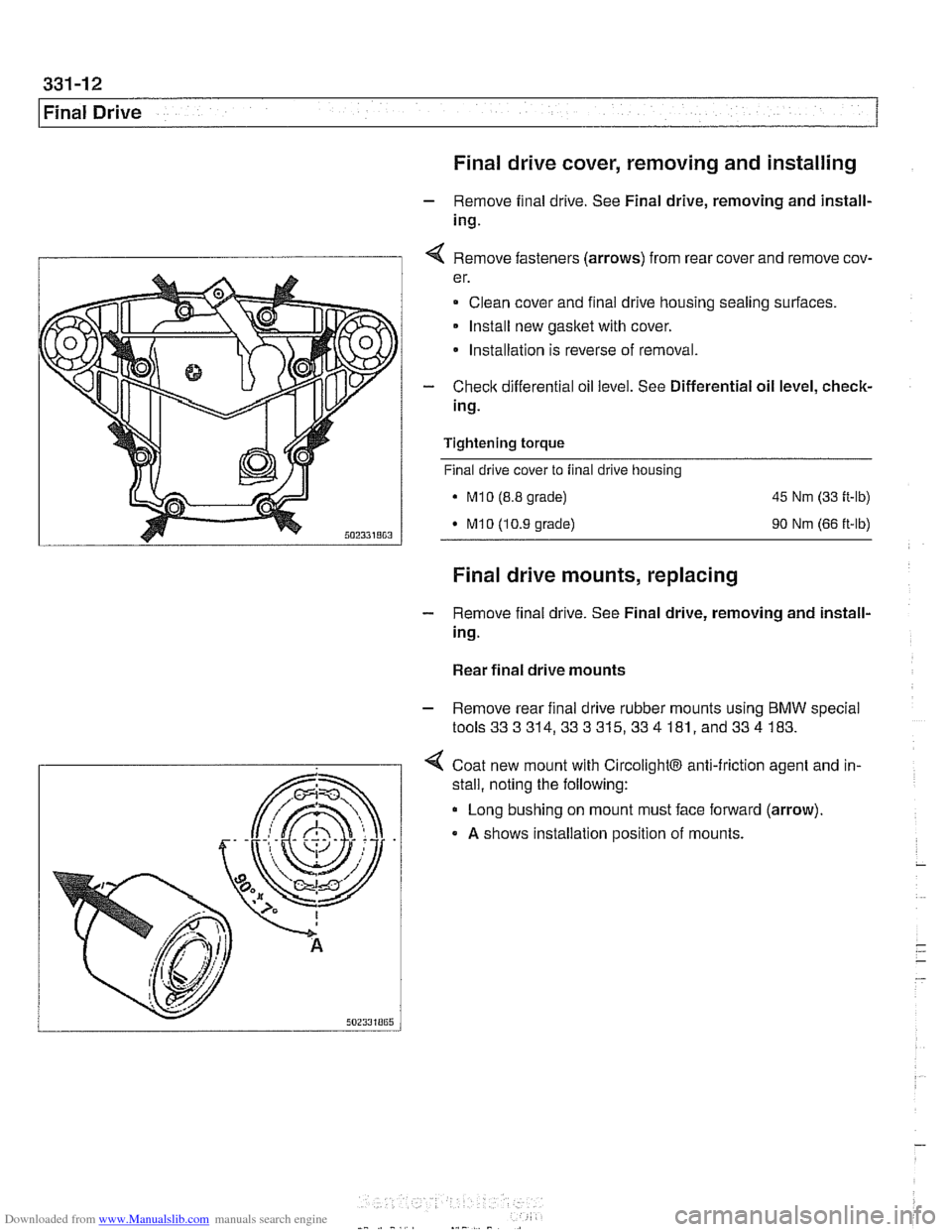

Final Drive Final drive cover, removing and installing

- Remove final drive. See Final drive, removing and install-

ing.

I 1 4 Remove fasteners (arrows) from rear cover and remove cov-

er.

Clean cover and final drive housing sealing surfaces.

Install new

gasket with cover.

* Installation is reverse of removal.

- Check differential oil level. See Differential oil level, check-

ing.

Tightening

torque

Final drive cover to final drive housing

. M10 (8.8 grade) 45 Nm (33 ft-lb)

M10 (10.9 grade) 90 Nm (66 ft-lb)

Final drive mounts, replacing

- Remove final drive. See Final drive, removing and install-

ing.

Rear final drive mounts

- Remove rear final drive rubber mounts using BMW special

tools333314,333315,334 181, and334 183.

4 Coat new mount with CircolightB anti-friction agent and in-

.

stall, noting the following:

Long bushing on mount must face forward (arrow).

A shows installation position of mounts.

Page 799 of 1002

Downloaded from www.Manualslib.com manuals search engine

400-5

Body-General

Tailgate

The E39 Sporl Wagon tailgate is large with a low sill for easy

cargo loading. The tailgate opens to an angle of

88" mea-

sured from the rear roof pillar (D-pillar) and to a height of

2029

mm (79.8 in) measured from the ground to the upper edge of

the raised tailgate.

The rear window is bonded to a load bearing frame and can

be opened separately from the main tailgate. Tailgatesupport

gas springs are recessed into cavities in the roof.

Tailgate lock system

A mechanical tailgate lock cylinder is not used; the tailgate is

opened by the unlock pad above the license plate, the remote

tailgate switch located in the drivers kick panel, or via

FZV

(Iteyless entry) control.

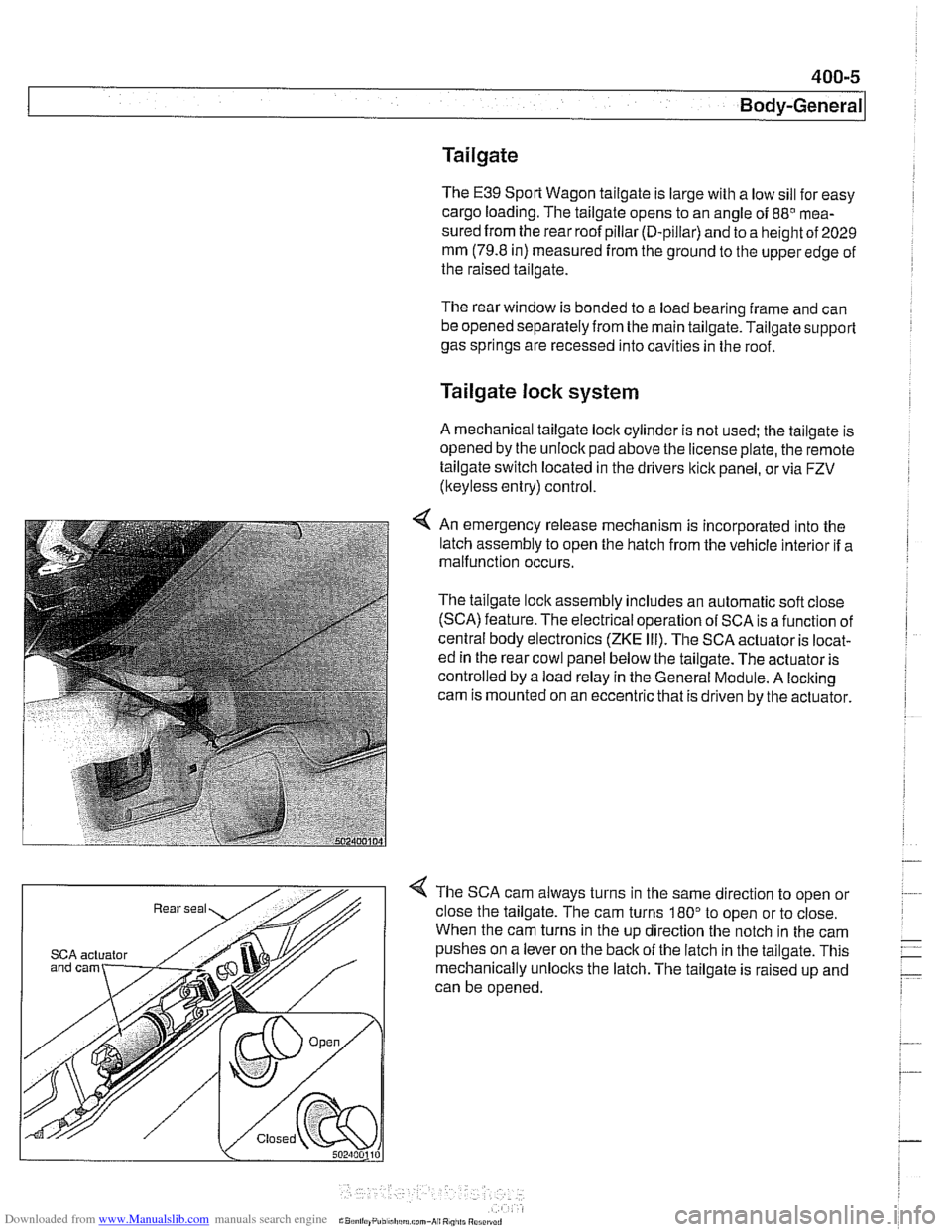

4 An emergency release mechanism is incorporated into the

latch assembly to open the hatch from the vehicle interior if a

malfunction occurs.

The tailgate lock assembly includes an automatic soft close

(SCA) feature. The electrical operation of SCA is a function of

central body electronics

(ZKE Ill). The SCA actuator is locat-

ed in the rear cowl panel below the tailgate. The actuator is

controlled by a load relay in the General Module. A locking

cam is mounted on an eccentric that is driven by the actuator.

4 The SCA cam always turns in the same direction to open or

close the tailgate. The cam turns

180" to open or to close.

When the cam turns in the up direction the notch in the cam

SCA actuator pushes on a lever on the back of the latch in the tailgate. This

mechanically unlocks the latch. The tailgate is raised up and

can be opened.

Page 816 of 1002

Downloaded from www.Manualslib.com manuals search engine

41 0-1 0

I Fenders, Engine Hood

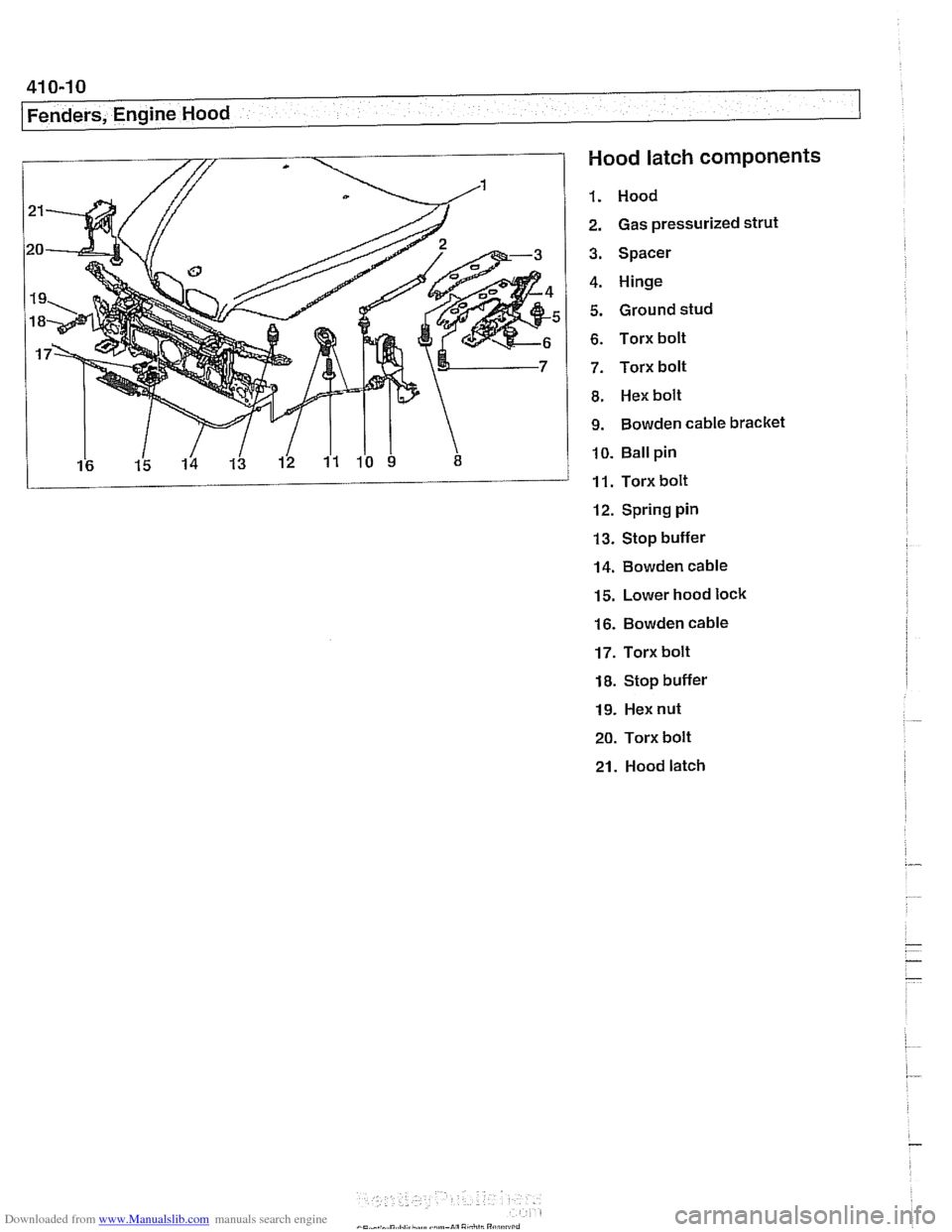

Hood latch components

1. Hood

2. Gas pressurized

Strut

3. Spacer

4. Hinge

5. Ground stud

6. Torx

bolt

7. Torx bolt

8. Hex bolt

9. Bowden cable bracket

10. Ball pin

11. Torx bolt

12. Spring pin

13. Stop buffer

14.

Bowden cable

15. Lower hood lock

16.

Bowden cable

17. Torx

bolt

18. Stop buffer

19. Hex nut

20. Torx bolt

21. Hood latch

Page 824 of 1002

Downloaded from www.Manualslib.com manuals search engine

.

1 Doors

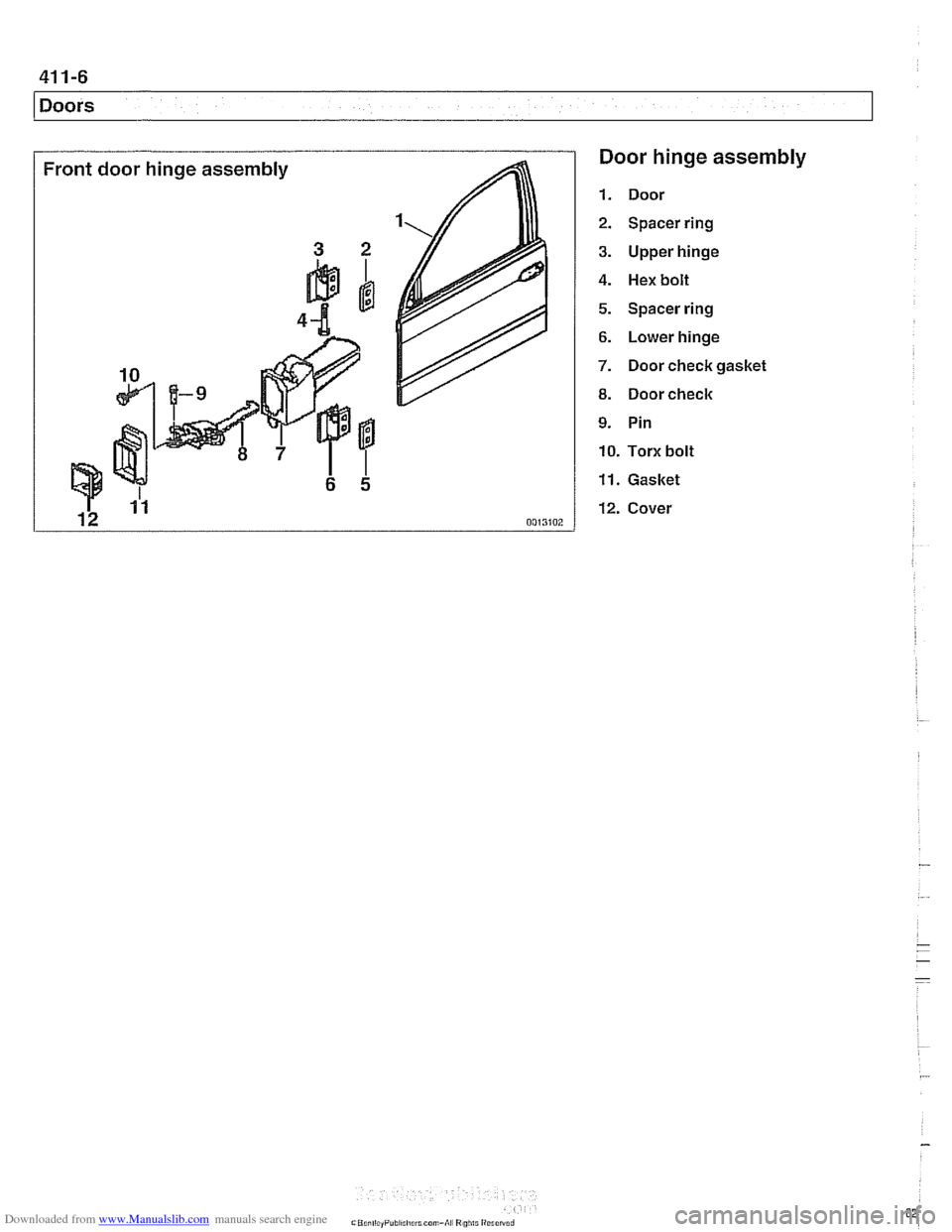

Door hinge assembly

1. Door

2. Spacer ring

3. Upper hinge

4. Hex bolt

5. Spacer ring

6. Lower hinge

7. Door check gasket

8. Doorcheck

9. Pin

10. Torx bolt

11. Gasket

12. Cover

Page 829 of 1002

Downloaded from www.Manualslib.com manuals search engine

41 2 Trunk Lid. Tailgate

........................... General

......................... Trunk Lid

Trunlc lid. removing and installing ........

Trunk lid. adjusting ...................

Trunk lid support strut.

removing and installing

................

Tailgate (Sport Wagon Models) .....

Tailgate. emergency release ...........

Tailgate and window strut diagram .......

Window strut removal diagram .......... 412-8

Rear window gas strut.

removing and installing

................ 412-9

Tailgate gas strut. removing and installing

............... 412-10

Tailgate. removing and installing

........ 412-1 1

Rear window. removing and installing

.... 412-12

Rear window and tailgate. alignment

..... 412-13

Page 830 of 1002

Downloaded from www.Manualslib.com manuals search engine

41 2-2

Trunk Lid, Tailgate

This repair group covers trunk lid and tailgate removal and in-

stallation. Also included here are replacement proceduresfor

the gas-charged support struts that hold the trunk lid or tail-

gate in the open position.

NO JE -

The body is painted at the factory after assembly. Realign-

ment of body panels may expose unpainted metal. Paint all

exposed metal once the

work is complete.

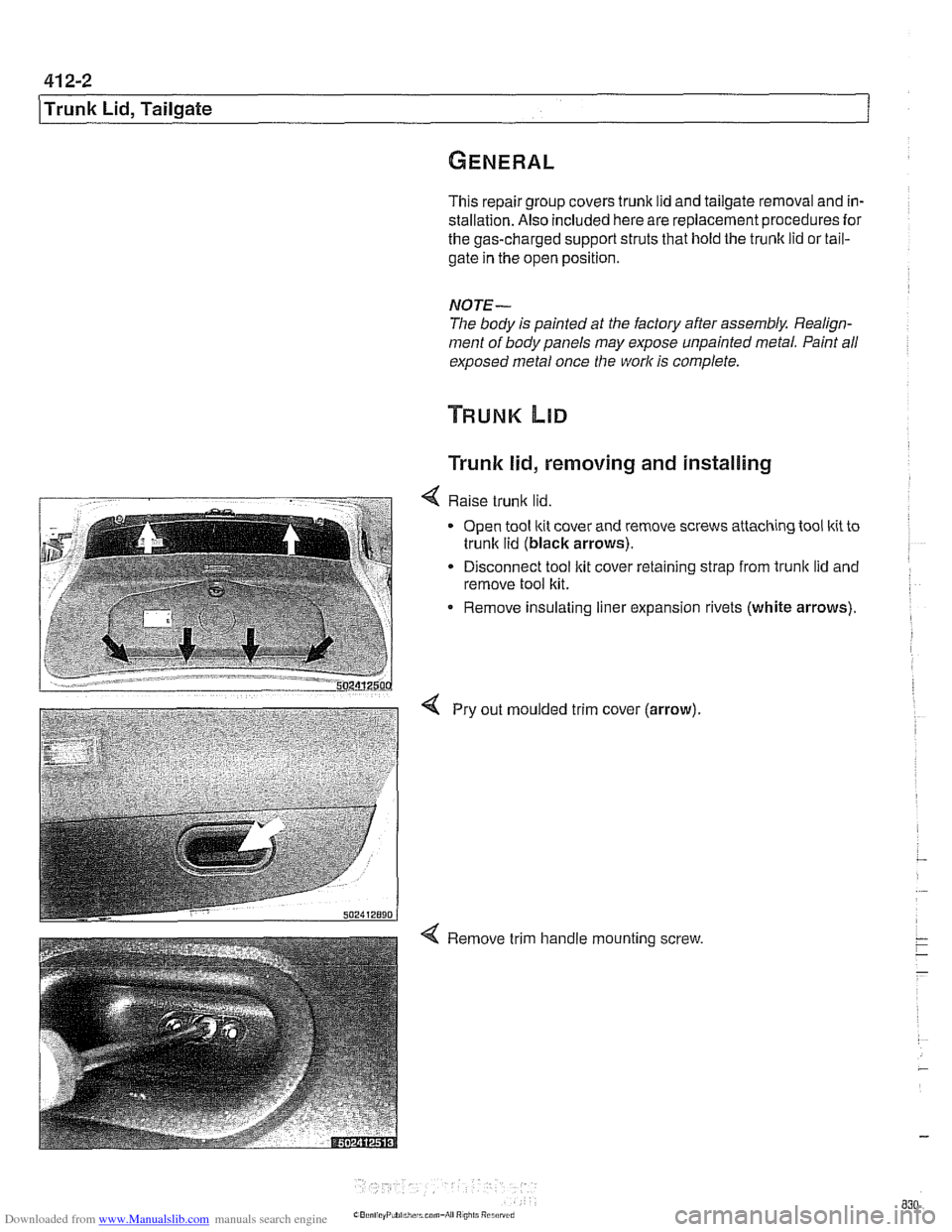

Trunk lid, removing and installing

4 Raise trunlc lid.

Open tool ltit cover and remove screws attaching tool kit to

trunlc lid (black arrows).

Disconnect tool ltit cover retaining strap from

trunk lid and

remove tool kit.

Remove insulating liner expansion rivets (white arrows).

4 Pry out moulded trim cover (arrow).

Page 835 of 1002

Downloaded from www.Manualslib.com manuals search engine

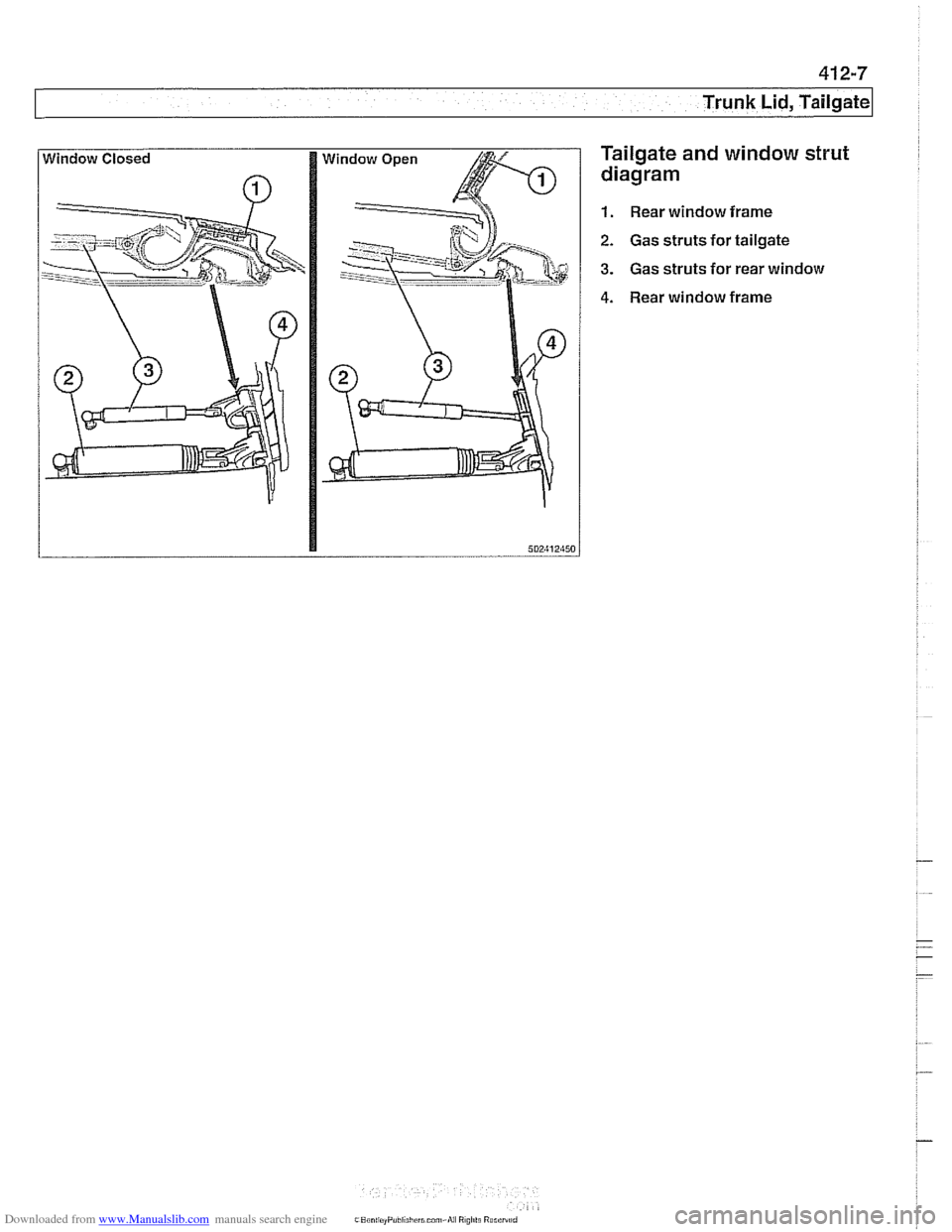

r Trunk Lid, Tailgate

Tailgate and window strut

diagram

1. Rear window frame

2. Gas struts for tailgate

3. Gas struts for rear window

4. Rear window frame