electrical system BMW 528i 1997 E39 Workshop Manual

[x] Cancel search | Manufacturer: BMW, Model Year: 1997, Model line: 528i, Model: BMW 528i 1997 E39Pages: 1002

Page 783 of 1002

Downloaded from www.Manualslib.com manuals search engine

1 Brakes

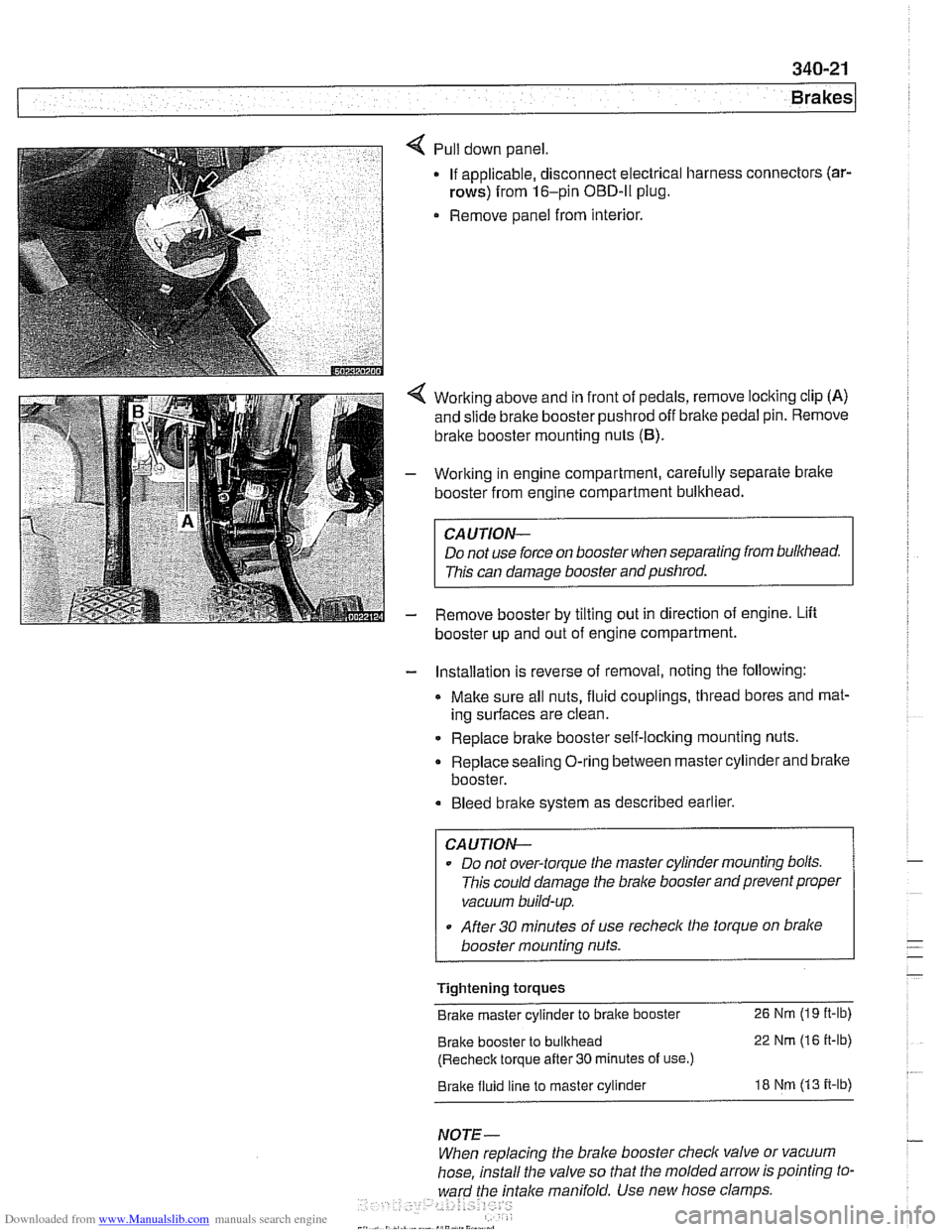

Pull down panel

If applicable, disconnect electrical harness

rows) from 16-pin OBD-ll plug.

Remove panel from interior. connectors

(ar-

Working

above and in front of pedals, remove locking clip (A)

and slide brake booster pushrod off bralte pedal pin. Remove

brake booster mounting nuts

(6).

Working in engine compartment, carefully separate bralte

booster from engine compartment bulkhead.

CAUTION-

Do not use force on booster when separating from bulkhead.

This can damage booster and pushrod.

Remove booster by tilting out in direction of engine. Lift

booster up and out of engine compartment.

- Installation is reverse of removal, noting the following:

Make sure all nuts, fluid couplings, thread bores and mat-

ing surfaces are clean.

Replace bralte booster self-locking mounting nuts.

Replace sealing O-ring between master cylinder and bralte

booster.

Bleed bralte system as described earlier.

CAUTION--

Do not over-torque tlie master cylinder mounting bolts.

This could damage the

bralce booster and prevent proper

vacuum build-up.

After

30 minutes of use recheclc the torque on bralce

booster mounting nuts.

Tightening torques

Brake master cylinder to brake booster

26 Nm (19 it-lb)

Brake booster to bulkhead 22 Nm (16 it-lb)

(Recheck torque after

30 minutes of use.)

Brake fluid line to master cylinder 18 Nm (13 it-lb)

NOTE-

When replacing the brake booster check valve or vacuum

hose, install the valve so that the molded arrow is pointing to-

ward the

fntalce manifold. Use new hose clamps

Page 789 of 1002

Downloaded from www.Manualslib.com manuals search engine

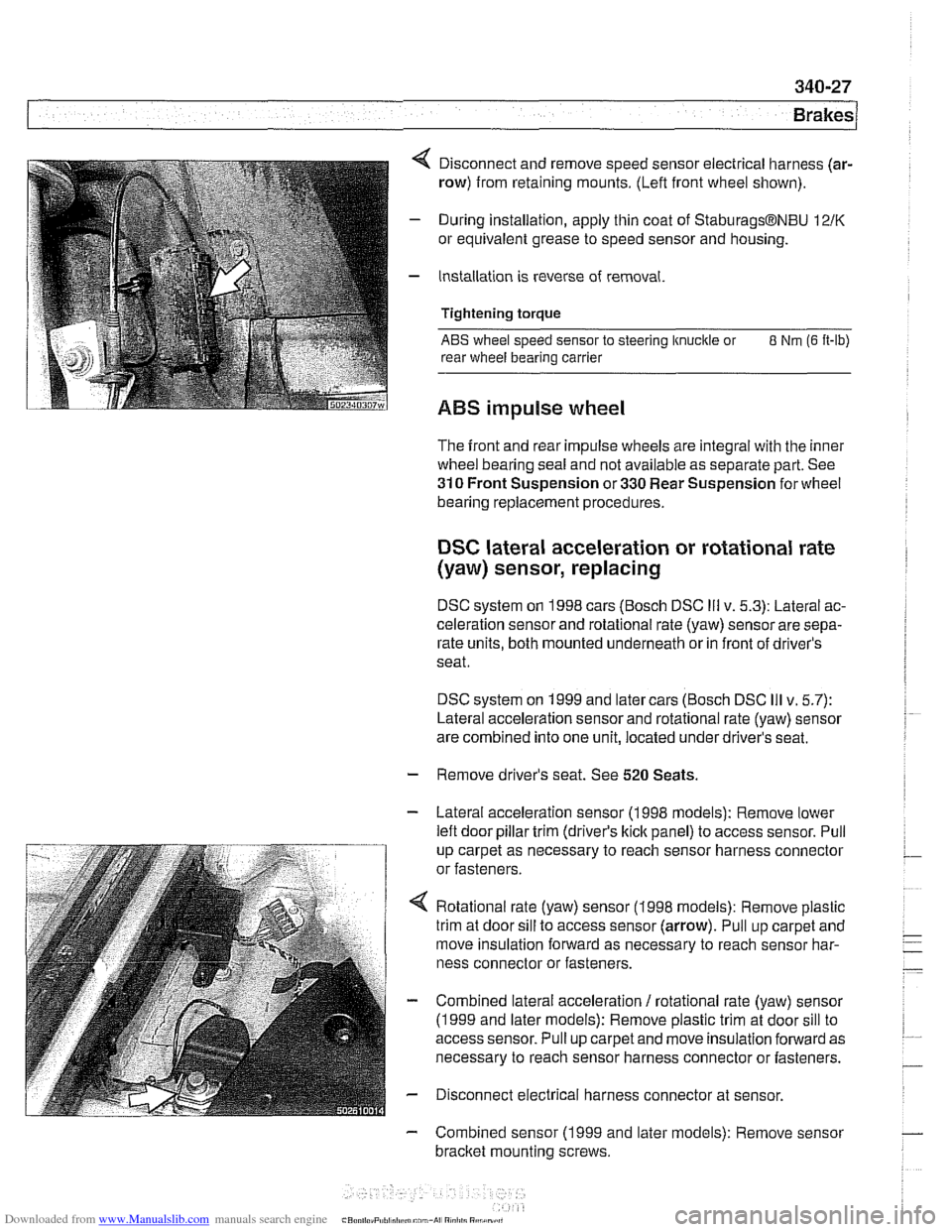

4 Disconnect and remove speed sensor electrical harness (ar-

row) from retaining mounts. (Lefl front wheel shown).

- During installation, apply thin coat of StaburagsBNBU 12/K

or equivalent grease to speed sensor and housing.

- Installation is reverse of removal.

Tightening torque

ABS wheel speed sensor to steering knuckle or 8 Nm (6 It-lb)

rear wheel bearing carrier

ABS impulse wheel

The front and rear impulse wheels are integral with the inner

wheel bearing seal and not available as separate part. See

310 Front Suspension or 330 Rear Suspension for wheel

bearing replacement procedures.

DSC lateral acceleration or rotational rate

(yaw) sensor, replacing

DSC system on 1998 cars (Bosch DSC Ill v. 5.3): Lateral ac-

celeration sensor and rotational rate (yaw) sensor are sepa-

rate units, both mounted underneath or in front of driver's

seat.

DSC system on 1999 and later cars (Bosch DSC

Ill v. 5.7):

Lateral acceleration sensor and rotational rate (yaw) sensor

are combined into one unit, located under driver's seat.

- Remove driver's seat. See 520 Seats.

- Lateral acceleration sensor (1 998 models): Remove lower

lefl door pillar trim (driver's

kick panel) to access sensor. Pull

up carpet as necessary to reach sensor harness connector

or fasteners.

4 Rotational rate (yaw) sensor (1998 models): Remove plastic

trim at door sill to access sensor (arrow). Pull up carpet and

move insulation forward as necessary to reach sensor har-

ness connector or fasteners.

- Combined lateral acceleration / rotational rate (yaw) sensor

(1 999 and later models): Remove plastic trim at door sill to

access sensor. Pull up carpet and move insulation forward as

necessary to reach sensor harness connector or fasteners.

- Disconnect electrical harness connector at sensor.

- Combined sensor (1 999 and later models): Remove sensor

bracket mounting screws.

Page 791 of 1002

Downloaded from www.Manualslib.com manuals search engine

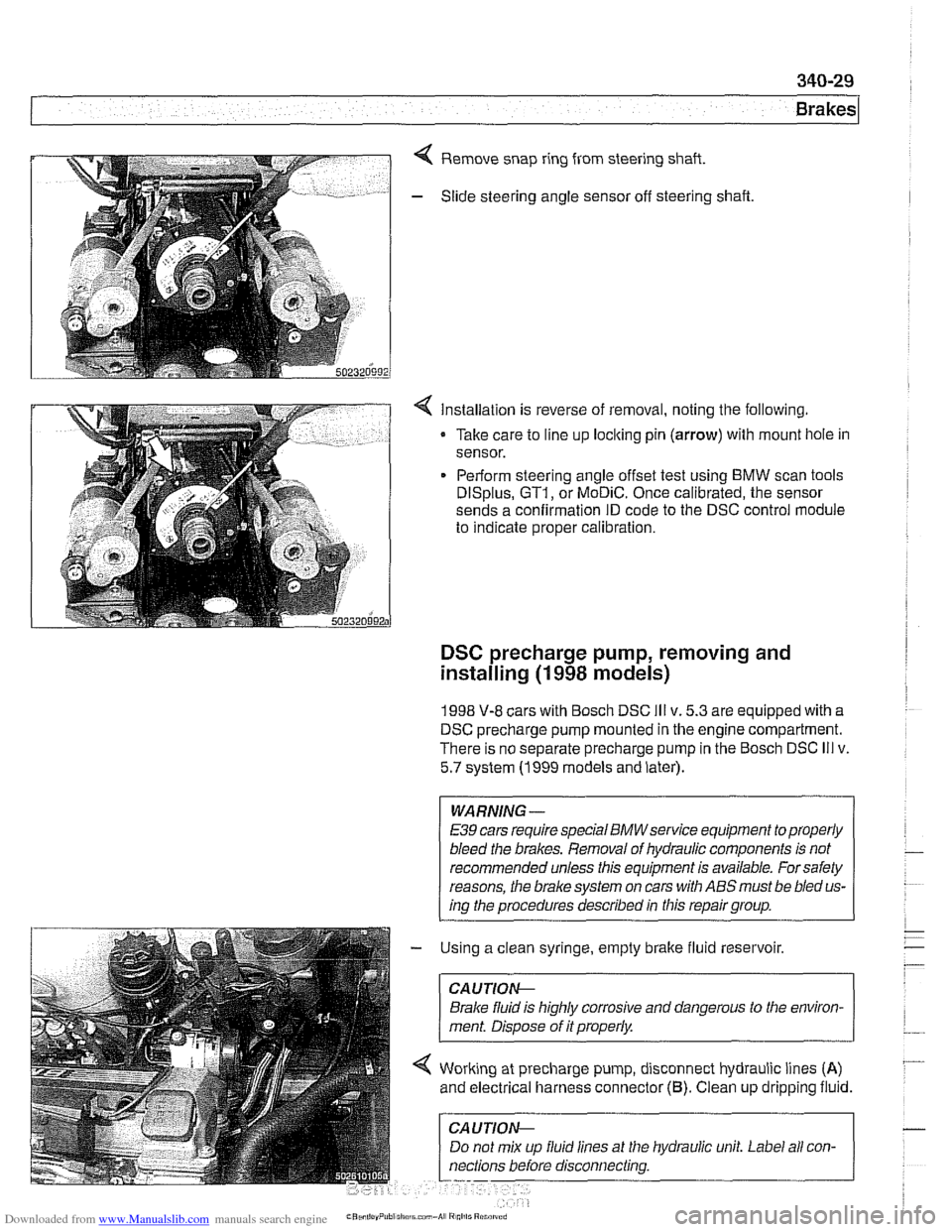

Remove snap ring from steering shaft.

- Slide steering angle sensor off steering shaft

< Installation is reverse of removal, noting the following.

Take care to line up loclting pin

(arrow) with mount hole in

sensor.

Perform steering angle offset test using BMW scan tools

DISplus, GT1, or MoDiC. Once calibrated, the sensor

sends a confirmation ID code to the DSC control module

to indicate proper calibration.

DSC precharge pump, removing and

installing

(1 998 models)

1998 V-8 cars with Bosch DSC Ill v. 5.3 are equipped with a

DSC precharge pump mounted in the engine compartment.

There is no separate precharge pump in the Bosch DSC

Ill v.

5.7 system (1999 models and later).

WARNING-

E39 cars require special BMWservice equipment to properly

bleed the brakes. Removal of hydraulic components is not

recommended unless this equipment is available. For safety

reasons, the

brake system on cars with ABS must be bled us-

ing the procedures described in this repair group.

- Using a clean syringe, empty brake fluid reservoir.

CAUTIOI\C

Brake fluid is highly corrosive and dangerous to the environ-

ment. Disoose of it

orooerlv.

Working at precharge pump, disconnect hydraulic lines (A)

and electrical harness connector (6). Clean up dripping fluid.

hydraulic unit. Label all

con-

Page 792 of 1002

Downloaded from www.Manualslib.com manuals search engine

1 Brakes

- Remove precharge pump mounting bracket fasteners and re-

move pump.

- Installation is reverse of removal, noting the following:

Be sure to replace rubber pump mounts if damaged

01

worn.

Bleed brakes as described earlier.

Tightening torque Brake line

to precharge pump 18 Nrn (13 ft-lb)

DSC pressure sensor (1 999 - 2002 models)

On 1999 and later DSC systems, the DSC pressure sensor is

screwed into the DSC hydraulic unit (right rear of engine com-

partment).

WARNING-

* €39 cars require special BMW service equipment to prop-

erly bleed the brakes. Removal of the

DSCpressure sensor

is not recommended unless this equipment is available. For

safety reasons, the brake system on cars with ABS must be

bled using the procedures described in this repair group.

Switch off ignition and remove

key to male sure brake

system cannot be activated.

- Disconnect electrical harness connector at switch.

- Use BMW special tool 34 5 160 to remove and install sensor.

Inspect threads and sealing surfaces for damage.

* Work quicltly to avoid excessive brake fluid leakage.

Tightening torque

Pressure sensor

to hydraulic 19 Nrn (14ft-lb)

unit

- Reconnect harness connector

- Bleed front brakes as described earlier.

- Press on brakes and check for leaks at sensor.

- Turn on ignition and firmly depress brake pedal. Check that

DSC warning light does not come on.

Page 799 of 1002

Downloaded from www.Manualslib.com manuals search engine

400-5

Body-General

Tailgate

The E39 Sporl Wagon tailgate is large with a low sill for easy

cargo loading. The tailgate opens to an angle of

88" mea-

sured from the rear roof pillar (D-pillar) and to a height of

2029

mm (79.8 in) measured from the ground to the upper edge of

the raised tailgate.

The rear window is bonded to a load bearing frame and can

be opened separately from the main tailgate. Tailgatesupport

gas springs are recessed into cavities in the roof.

Tailgate lock system

A mechanical tailgate lock cylinder is not used; the tailgate is

opened by the unlock pad above the license plate, the remote

tailgate switch located in the drivers kick panel, or via

FZV

(Iteyless entry) control.

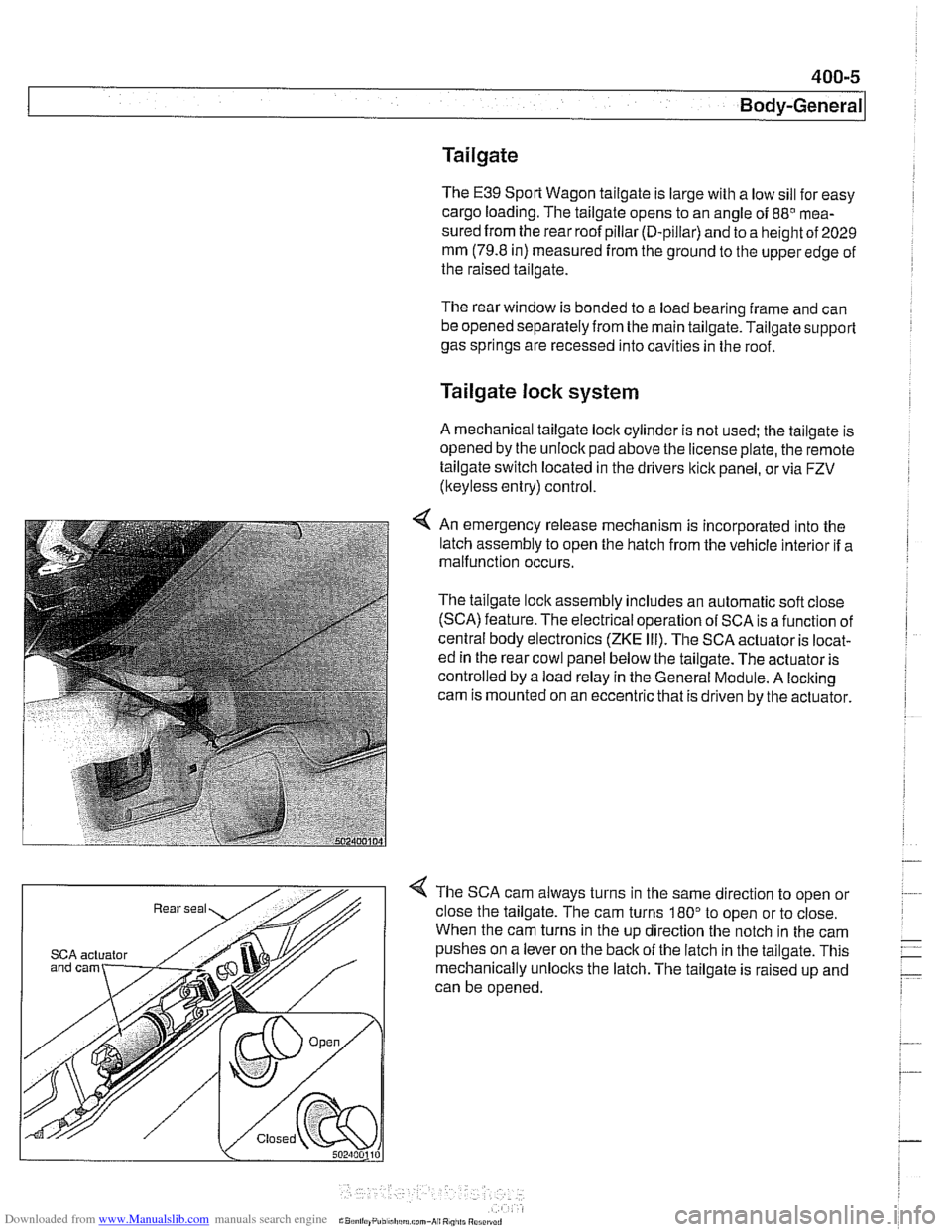

4 An emergency release mechanism is incorporated into the

latch assembly to open the hatch from the vehicle interior if a

malfunction occurs.

The tailgate lock assembly includes an automatic soft close

(SCA) feature. The electrical operation of SCA is a function of

central body electronics

(ZKE Ill). The SCA actuator is locat-

ed in the rear cowl panel below the tailgate. The actuator is

controlled by a load relay in the General Module. A locking

cam is mounted on an eccentric that is driven by the actuator.

4 The SCA cam always turns in the same direction to open or

close the tailgate. The cam turns

180" to open or to close.

When the cam turns in the up direction the notch in the cam

SCA actuator pushes on a lever on the back of the latch in the tailgate. This

mechanically unlocks the latch. The tailgate is raised up and

can be opened.

Page 803 of 1002

Downloaded from www.Manualslib.com manuals search engine

400-9

Body-General

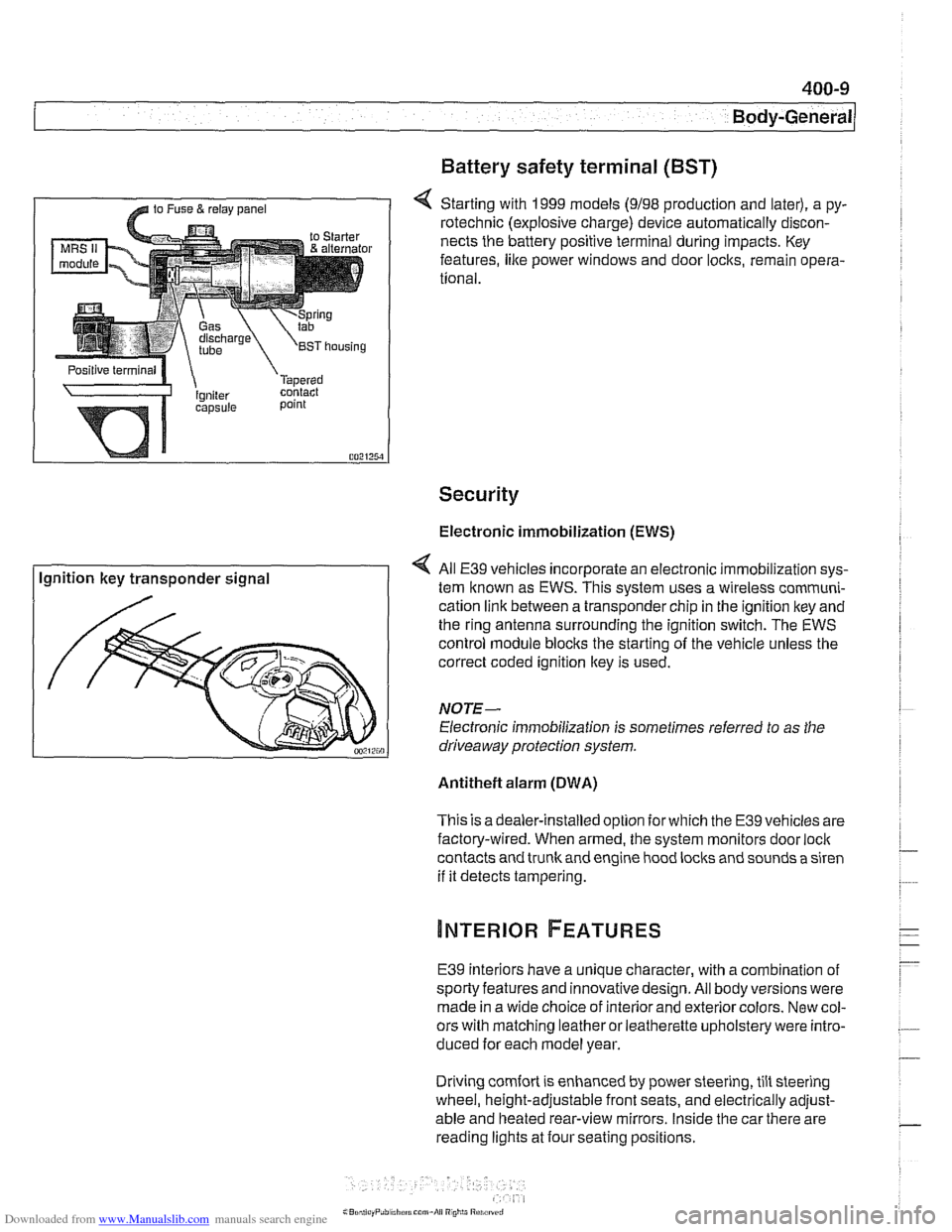

Battery safety terminal

(BST)

4 Starting with 1999 models (9198 production and later), a py-

rotechnic (explosive charge) device automatically discon-

nects the battery positive terminal during impacts. Key

features,

like power windows and door locks, remain opera-

tional.

Security

Electronic immobilization (EWS)

Ignition key transponder signal All

E39 vehicles incorporate an electronic immobilization sys-

tem known as EWS. This svstem uses a wireless comrnuni-

cation link between a transponder chip in the ignition key and

the ring antenna surrounding the ignition switch. The EWS

control module blocks the starting of the vehicle unless the

correct coded ignition key is used.

NOTE-

Electronic immobilization is sometimes referred to as the

driveaway protection system.

Antitheft alarm (DWA)

This is adealer-installed option for which the E39 vehicles are

factory-wired. When armed, the system monitors door

loci(

contacts and trunk and engine hood locks and sounds a siren

if it detects tampering.

E39 interiors have a unique character, with a combination

of

sporty features and innovativedesign. All body versions were

made in a wide choice of interior and exterior colors. New col-

ors with matching leather or leatherette upholstery were intro-

duced for each model year.

Driving

comfort is enhanced by power steering, tilt steering

wheel, height-adjustable front seats, and electrically adjust-

able and heated rear-view mirrors. Inside the car there are

reading lights at four seating positions.

Page 805 of 1002

Downloaded from www.Manualslib.com manuals search engine

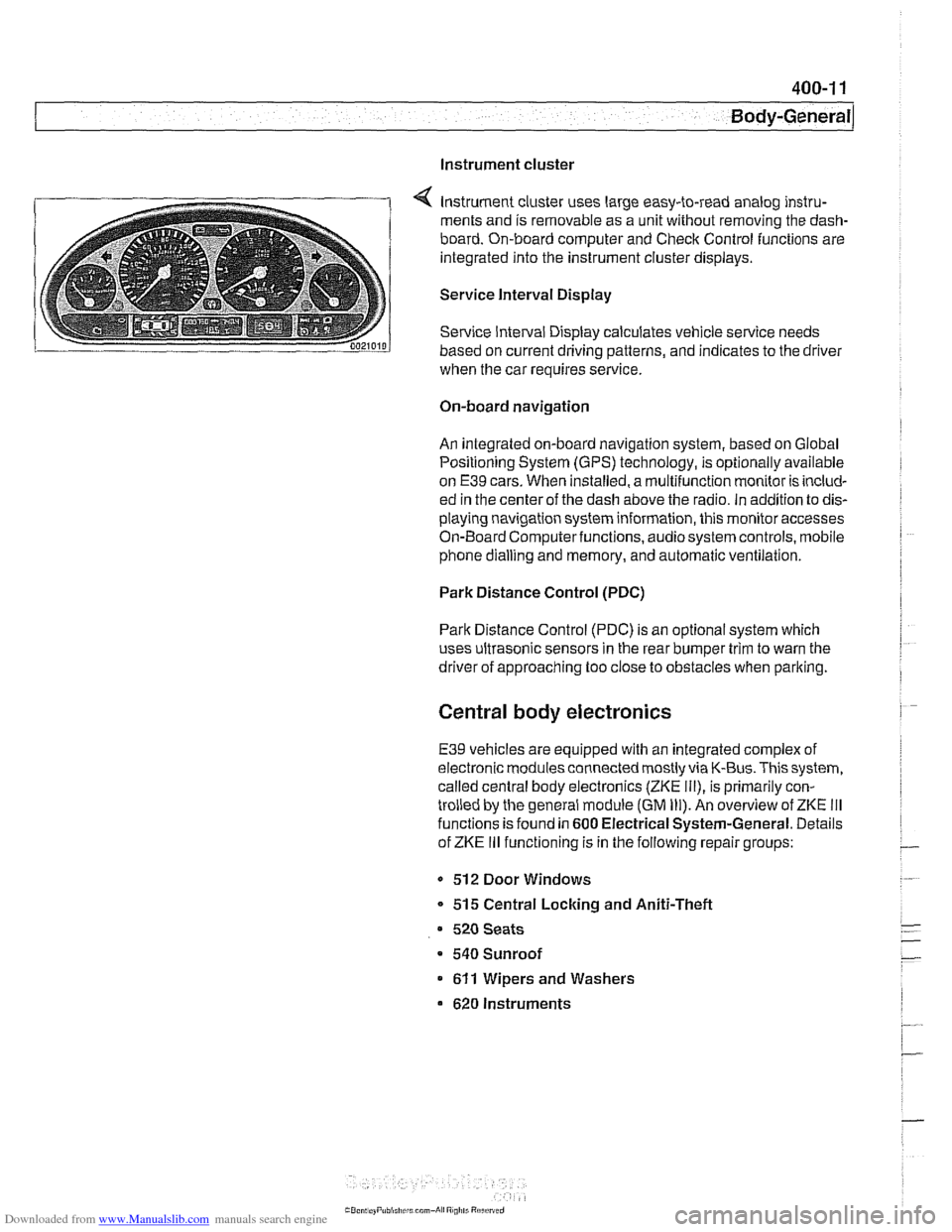

Instrument cluster

Instrument cluster uses large easy-to-read analog instru-

ments and is removable as a unit without removing the dash-

board. On-board computer and Check Control functions are

integrated into the instrument cluster displays.

Service Interval Display

Service Interval Display calculates vehicle service needs

based on current driving patterns, and indicates to the driver

when the car requires

service

On-board navigation

An integrated on-board navigation system, based on Global

Positioning System (GPS) technology, is optionally available

on

E39 cars. When installed, a multifunction monitor is includ-

ed in the center of the dash above the radio. in addition to dis-

playing navigation system information, this monitor accesses

On-Board Computerfunctions, audiosystem controls, mobile

phone dialling and memory, and automatic ventilation.

Park Distance Control (PDC)

Park Distance Control (PDC) is an optional system which

uses ultrasonic sensors in the rear bumper trim to warn the

driver of approaching too close to obstacles when parlting.

Central body electronics

E39 vehicles are equipped with an integrated complex of

electronic modules connected mostly via K-Bus. This system,

called central body electronics (ZKE

Ill), is primarily con-

trolled by the general module (GM

Ill). An overview of ZKE Ill

functions is found in 600 Electrical System-General. Details

of ZKE

Ill functioning is in the following repair groups:

- 512 Door Windows

* 515 Central Locking and Aniti-Theft

520 Seats

a 540 Sunroof

611 Wipers and Washers

620 Instruments

Page 880 of 1002

Downloaded from www.Manualslib.com manuals search engine

I lnterior Trim

This repair group covers interior trim removal and installation

procedures.

- Refer to the following repair groups for additional information:

250 Gearshift Linkage

41 1 Doors (interior door panels)

@ 612 Switches

620 Instruments

640 Heating and Air Conditioning [IHKA control panel!

650 Radio

721 Airbag System (SRS)

lnterior trim repairs

lnterior trim and finish panels are clipped or screwed into

place. Many of the trim retaining clips are designed

to be used

only once. When removing trim that is held in place with clips,

it is a good idea to have spare clips on hand before beginning

the job.

WARNING-

Special precautions must be observed when servicing the

BMWSupplementai Restraint System (SRS). Serious inju-

ry may result if system service is attempted by persons un-

familiar with the BMW

SRS and its approved service

procedures. BMW

speciiies that all inspection and service

should be performed by an authorized BMW

dealer.

Before performing any work involving airbags, discon-

nect the negative

() battery cable. See 721 Airbag

System (SRS).

Airbags contain a back-uppowersupply within the SRS

control module. A

5 second discharge period should be

allowed after the battery cable has been disconnected.

CAUTION-

* When working on electrical switclies or lights, always dis-

connect the negative

(-) cable from the battery and insu-

late the cable end to prevent accidental reconnection.

a Prior to disconnecting the battery, read the battery dis-

connection cautions given in

W1 General Warnings

and Cautions.

To prevent marring the trim when working on interior

components, work with plastic prying

tools or wrap the

tips of screwdrivers and pliers with tape before prying

Page 896 of 1002

Downloaded from www.Manualslib.com manuals search engine

51 5-2

/Central Locking and Anti-Theft

This section covers repair information for door, trunk and car-

go compartment locks, central locking, electronic

immob~liza-

tion (EWS) and anti-theft alarm (DWA).

€39 cars are equipped with sophisticated self-diagnostic elec-

trical systems. When experiencing malfunctions relating to

central locking. EWS or anti-theft systems, start the diagnosis

process using the

BMW service tester DIS, GT 1, MoDiC or

equivalent scan tool. An advanced diagnostic scan tool can

usually pinpoint electrical faults quickly and safely.

Additional electrical information can be found in:

610 Electrical Component Locations

ELE Electrical Wiring Diagrams

Central locking in E39 vehicles controls the door

locks, trunk

or tailgate lock and fuel filler flap lock. The control module for

the Central Body Electronics system (ZKE

Ill), lknown as the

General Module (GM

Ill), controls central locking.

ZKE

Ill manages the following central locking related func-

tions:

Central locking

* Keyless entry

Key memory

Power trunk release

Electric opening of tailgate

DWA alarm system

Diagnosis

General Module

4 The General Module (GM) (arrow) is responsible for the op-

eration of central body electronics. The GM is located behind

the glove compartment.

Based on input information, the GM uses internal transistors

to switch current flow (providing voltage or ground) through

circuits and actuators. Actuators are the final controlling de-

vices used by GM to operate or control various output func-

tions such as relays and motors.

The accompanying schematic, Central locking inputs and

outputs, illustrates the GM central locking system.

Page 899 of 1002

Downloaded from www.Manualslib.com manuals search engine

Central Locking and Anti-Theft

DWA alarm

The DWA alarm system is

armedldisarmed when thevehicle

is locked / unlocked from either the door or trunk.

Convenience closing

I opening

The windows and sun roof can be closed or opened by hold-

ing the key in the

loclc I unlock position.

Crash sensor

The crash sensor is located in the left front

kick panel. It func-

tions by unlocking all doors in the event of an accident.

NOTE-

Continuous and repeated locliing / unlocking may cause

timedarrest of

the locliing system. When activated, the timed

arrest lasts for two minutes. The timed arrest does not affect

the crash sensor

unlocliing the doors in case of an accident.

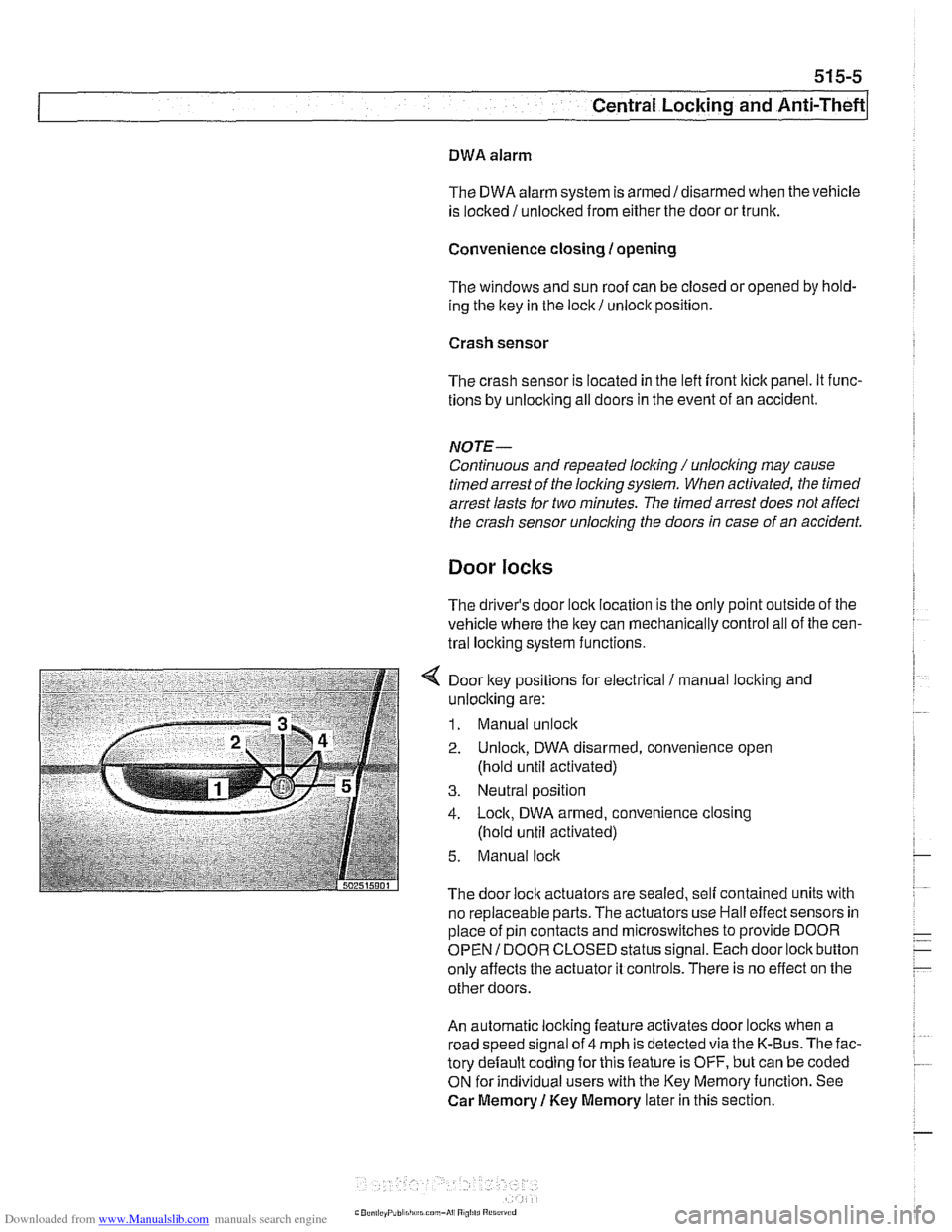

Door locks

The driver's door lock location is the only point outside of the

vehicle where the ltey can mechanically control all of the cen-

tral locking system functions.

4 Door key positions for electrical / manual loclting and

unlocking are:

1. Manual unlock

2. Unlock, DWA disarmed, convenience open

(hold until activated)

3. Neutral position

4. Lock, DWA armed, convenience closing

(hold until activated)

5. Manual lock

The door lock actuators are sealed. self contained units with

no replaceable parts. The

actuators use Hall effect sensors in

place of pin contacts and microswitches to provide DOOR

OPEN

I DOOR CLOSED status signal. Each door lock button

only affects the actuator it controls. There is no effect on the

other doors.

An automatic locking feature activates door locks when a

road speed signal of 4 mph is detected via the K-Bus. The fac-

tory default coding for this feature is OFF, but can be coded

ON for individual users with the Key Memoryfunction. See

Car Memory

1 Key Memory later in this section.