Car engin BMW 528i 1997 E39 Workshop Manual

[x] Cancel search | Manufacturer: BMW, Model Year: 1997, Model line: 528i, Model: BMW 528i 1997 E39Pages: 1002

Page 493 of 1002

Downloaded from www.Manualslib.com manuals search engine

.- Fuel Tank and Fuel pump( -

Fuel expansion tank, removing

and installing

- Raise rear end of car and support safely.

CA U TIOG

Make sure the car is stable and well supported at all times.

Use a professional automotive lift

orjack stands designed for

the

ouroose. A floor iack is not adequate support

- Remove left rear wheel and wheel housing inner shield.

4 Remove plastic nut (A) and disconnect hose (B).

4 Tilt vent tank down and loosen or cut off hose clamps

(arrows). Pull hoses off fittings.

- Release vacuum line loclting clips and remove tank

- Installation is reverse of removal. Use new hose clamps.

Tightening torques

Hose clamp 8 - 13 mm dia. 2 Nrn (18 in-lb)

Hose clamp 13 - 16 mm dia. 3 Nm (27 in-lb)

Hose clamp

42 - 48 mm dia. 4 Nm (36 in-lb)

Page 494 of 1002

Downloaded from www.Manualslib.com manuals search engine

Fuel Tank and Fuel Pump 1

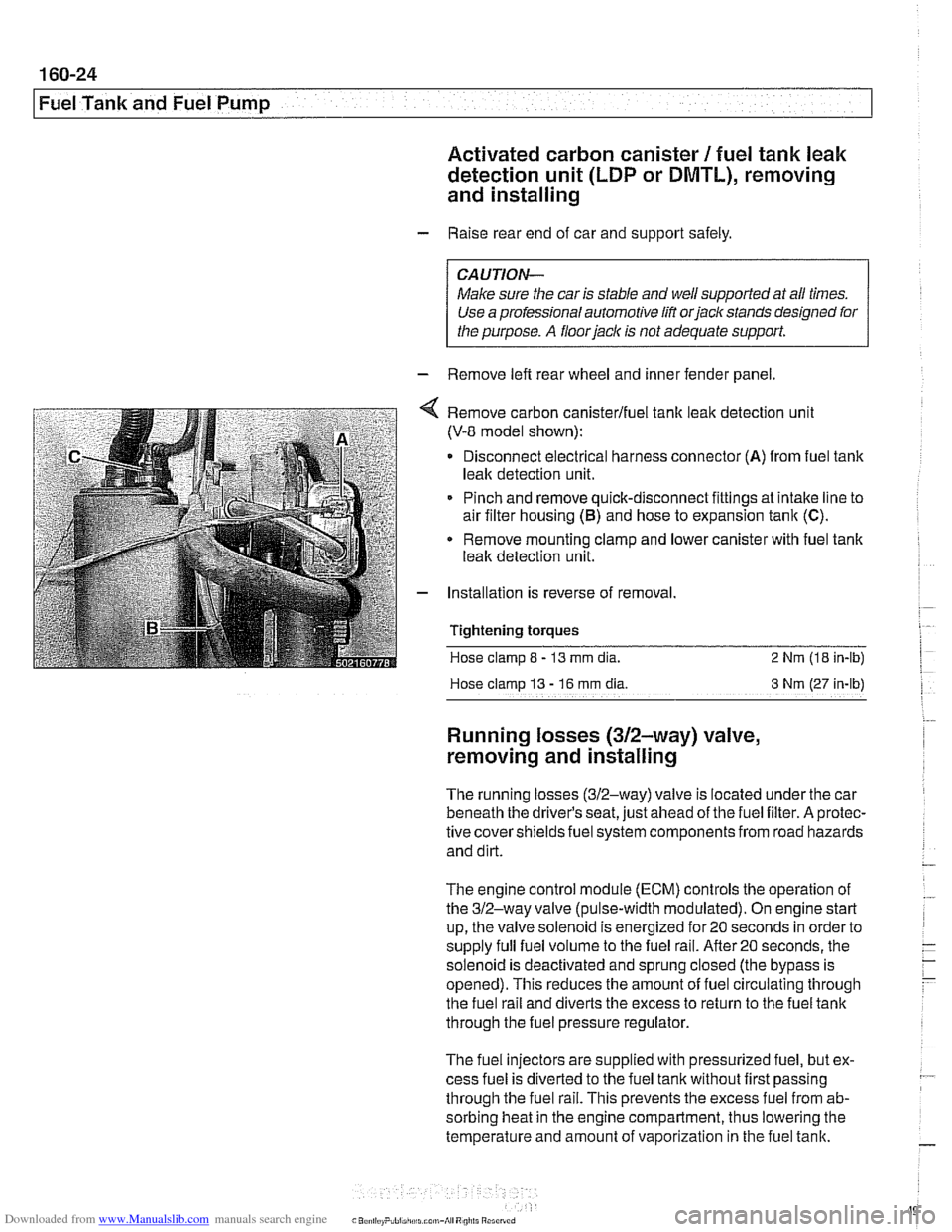

Activated carbon canister I fuel tank leak

detection unit

(LDP or DMTL), removing . . -

and installing

- Raise rear end of car and support safely.

CAUTION-

Make sure the car is stable and well supported at all times.

Use a professional automotive lift

orjack stands designed for

the purpose.

A floor jack is not adequate support.

- Remove left rear wheel and inner fender panel

Remove carbon canisterlfuel tank leak detection unit

(V-8 model shown):

Disconnect electrical harness connector

(A) from fuel tank

leak detection unit.

Pinch and remove quick-disconnect fittings at intake line to

air filter housing

(5) and hose to expansion tank (C).

* Remove mounting clamp and lower canister with fuel tank

leak detection unit.

Installation is reverse of removal.

Tightening

torques

Hose clamp 8 - 13 mm dia. 2 Nrn (18 in-lb)

Hose clamp

13 - 16 rnm dia 3 Nm (27 in-lb)

Running losses (312-way) valve,

removing and installing

The running losses (312-way) valve is located under the car

beneath the driver's seat, just ahead of the fuel filter. A protec-

tive covershieldsfuel system components from road hazards

and dirt.

The engine control module

(ECM) controls the operation of

the 312-way valve (pulse-width modulated). On engine start

up, the valve solenoid is energized for 20 seconds in order to

supply full fuel volume to the fuel rail.

After20 seconds, the

solenoid is deactivated and sprung closed (the bypass is

opened). This reduces the amount of fuel circulating through

the fuel rail and diverts the excess to return to the fuel tank

through the fuel pressure regulator.

The fuel injectors are supplied with pressurized fuel, but ex-

cess fuel is diverted to the fuel tank without first passing

through the fuel rail. This prevents the excess fuel from ab-

sorbing heat in the engine compartment, thus lowering the

temperature and amount of vaporization in the fuel tank.

Page 495 of 1002

Downloaded from www.Manualslib.com manuals search engine

160-25

Fuel Tank and Fuel pump1

The 312-way valve is also activated briefly if an engine misfire

is detected. This provides full fuel flow through the fuel rail to

determine if the misfire was caused by a lean fuel condition.

The valve is monitored by the ECM forfaults.

- Using BMW or compatible scan tool, read out fault memory.

See

OBD On-Board Diagnostics.

- Turn off ignition.

- Raise car and support safely.

CA UTIOW

Male sure the car is stable and well suppodedat all times.

Use a professional automotive lift

orjack stands designed for

the purpose.

A floor jack is not adequate support.

- Worlting under car beneath driver's seat, remove protective

panel from fuel filter and 312-way valve.

- Clamp off fuel lines at 312-way valve.

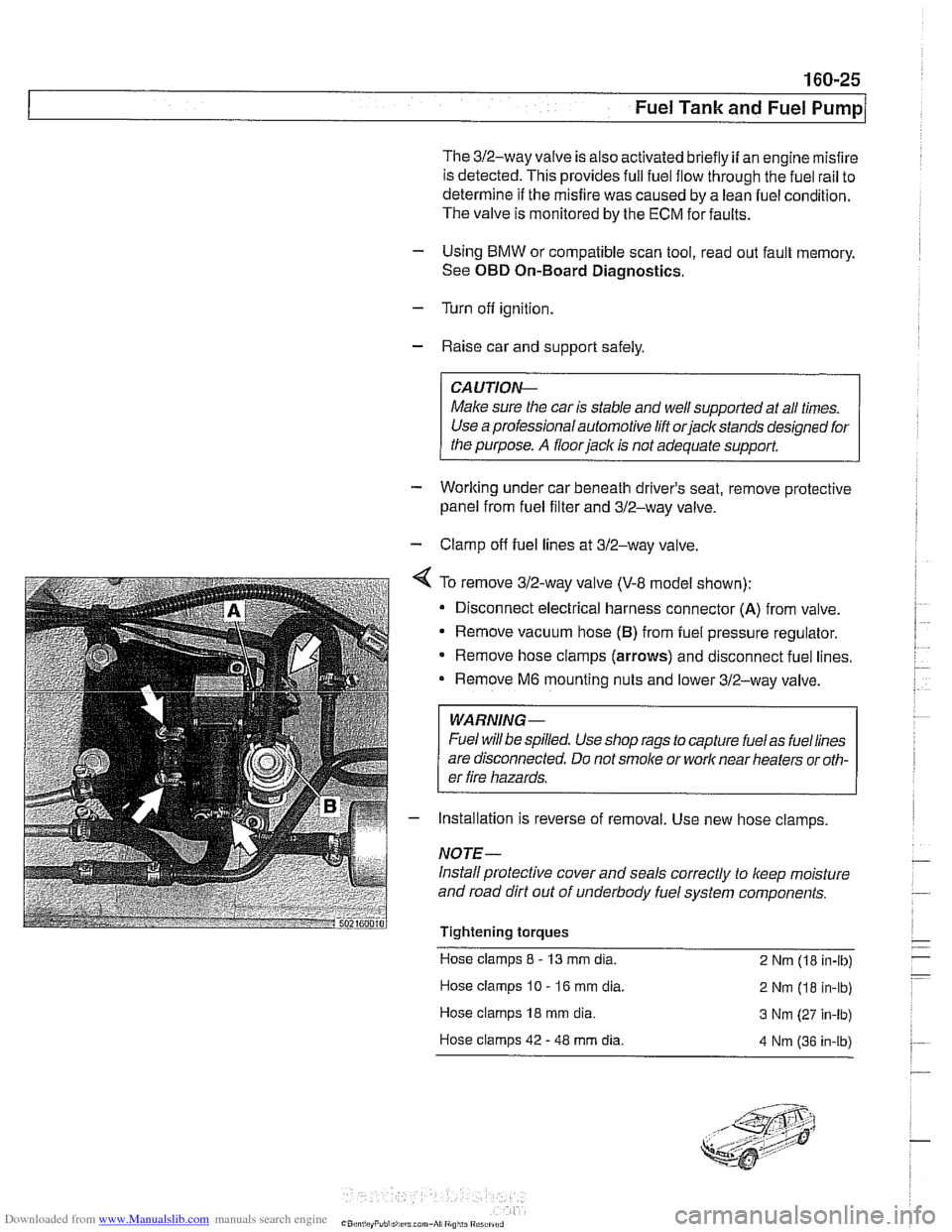

4 To remove 312-way valve (V-8 model shown):

Disconnect electrical harness connector

(A) from valve.

Remove vacuum hose

(B) from fuel pressure regulator.

* Remove hose clamps (arrows) and disconnect fuel lines.

Remove

M6 mounting nuts and lower 312-way valve.

WARNING-

Fuel will be spilled. Use shop rags to capture fuelas fuellines

are disconnected. Do not

smoke or work near heaters or oth-

er fire hazards.

- Installation is reverse of removal. Use new hose clamps

NOTE-

Install protective cover and seals correctly to keep moisture

and road dirt out of underbody fuel system components.

Tightening torques Hose clamps

8 - 13 mm dia.

2 Nm (18 in-lb)

Hose clamps

10 - 16 mm dia.

2 Nm (18 in-lb)

Hose clamps

18 mm dia. 3 Nm (27 in-lb)

Hose clamps 42

- 48 mm dia. 4 Nm 136 in-ib)

Page 499 of 1002

Downloaded from www.Manualslib.com manuals search engine

- -

L- -

--

-. - - - Radiator and Cooling sYstelll/ --

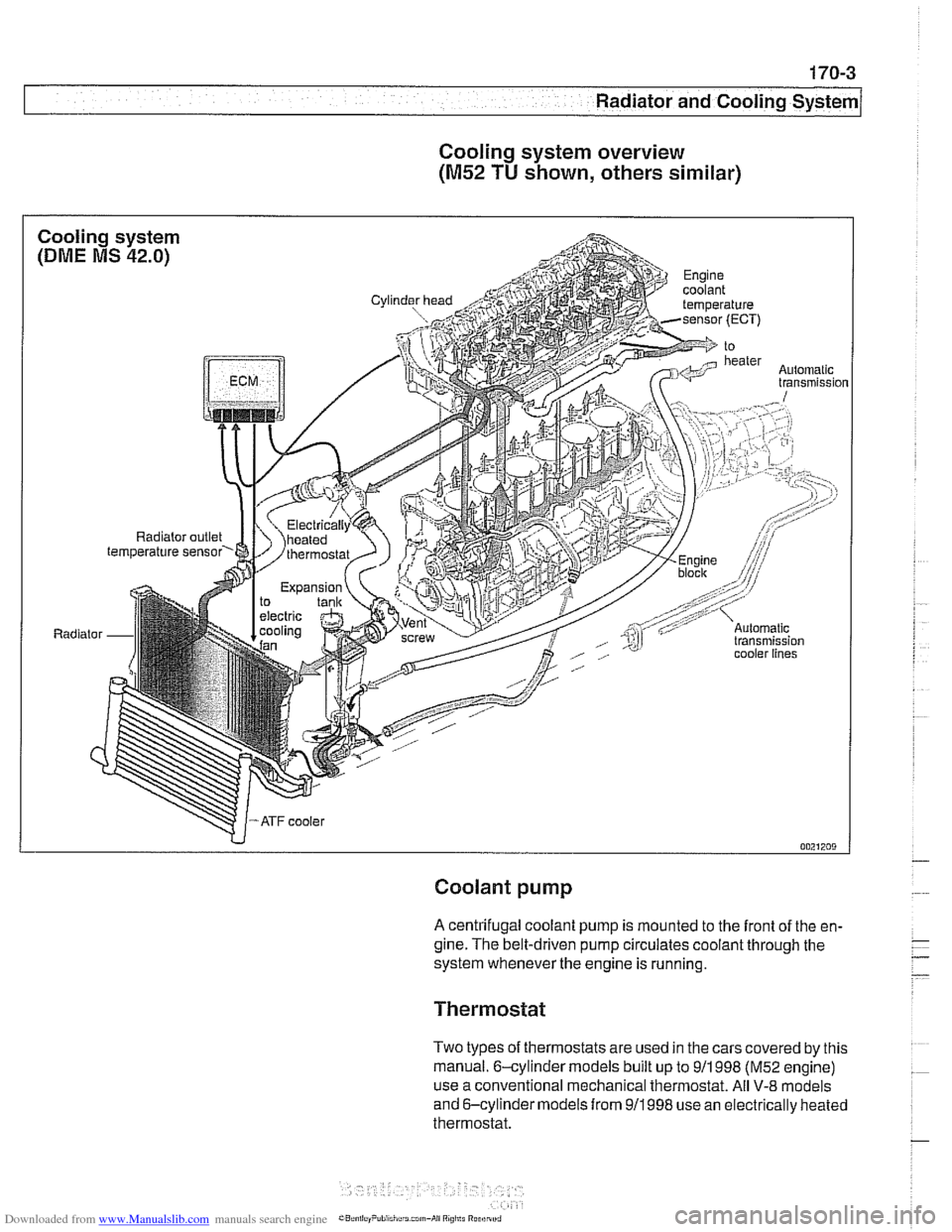

Cooling system overview

(M52 TU shown, others similar)

Coolant pump

A centrifugal coolant pump is mounted to the front of the en-

gine. The belt-driven pump circulates coolant through the

system whenever the engine is running.

Thermostat

Two types of thermostats are used in the cars covered by this

manual. 6-cylinder models built up to

911 998 (M52 engine)

use a conventional mechanical thermostat. All

V-8 models

and 6-cylinder models from

911998 use an electrically heated

thermostat.

Page 500 of 1002

Downloaded from www.Manualslib.com manuals search engine

-

I Radiator and Cooling System

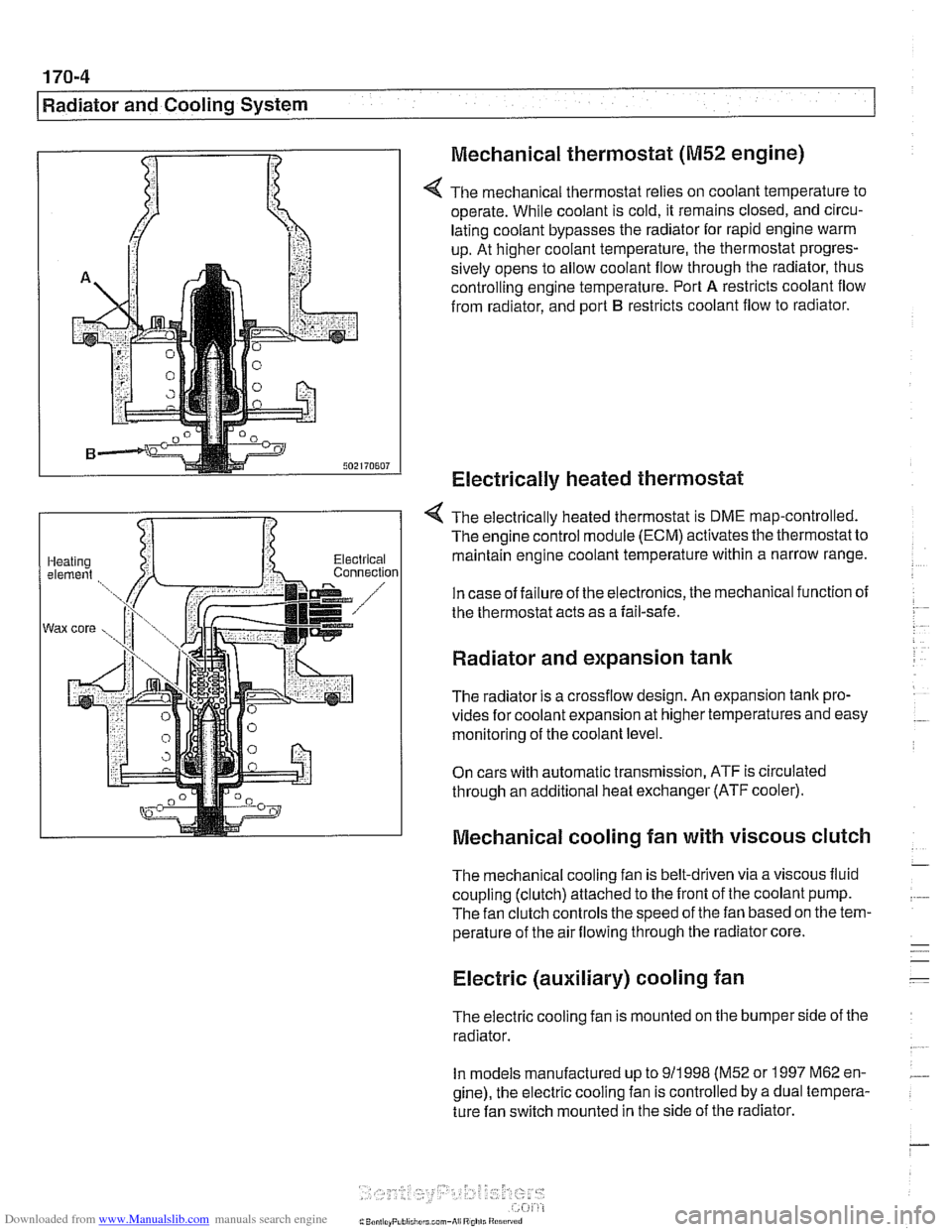

Mechanical thermostat

(M52 engine)

4 The mechanical thermostat relies on coolant temperature to

operate. While coolant is cold, it remains closed, and circu-

lating coolant bypasses the radiator for rapid engine warm

up. At higher coolant temperature, the thermostat progres-

sively opens to allow coolant flow through the radiator, thus

controlling engine temperature. Port

A restricts coolant flow

from radiator, and port

B restricts coolant flow to radiator.

Electrically heated thermostat

4 The electrically heated thermostat is DME map-controlled.

The engine control module (ECM) activates the thermostat to

maintain engine coolant temperature within a narrow range.

In case of failure of the electronics, the mechanical function of

the thermostat acts as a fail-safe.

Radiator and expansion tank

The radiator is a crossflow design. An expansion tank pro-

vides for coolant expansion at higher temperatures and easy

monitoring of the coolant level.

On cars with automatic transmission, ATF is circulated

through an additional heat exchanger (ATF cooler).

Mechanical cooling fan with viscous clutch

The mechanical cooling fan is belt-driven via a viscous fluid

coupling (clutch) attached to the front of the coolant pump.

The fan clutch controls the speed of the fan based on the tem-

perature of the air flowing through the radiator core.

Electric (auxiliary) cooling fan

The electric cooling fan is mounted on the bumper side of the

radiator.

In models manufactured up to

911 998 (M52 or 1997 M62 en-

gine), the electric cooling fan is controlled by a dual tempera-

ture fan switch mounted in the side of the radiator.

Page 502 of 1002

Downloaded from www.Manualslib.com manuals search engine

.. - -

I Radiator and Cooling System

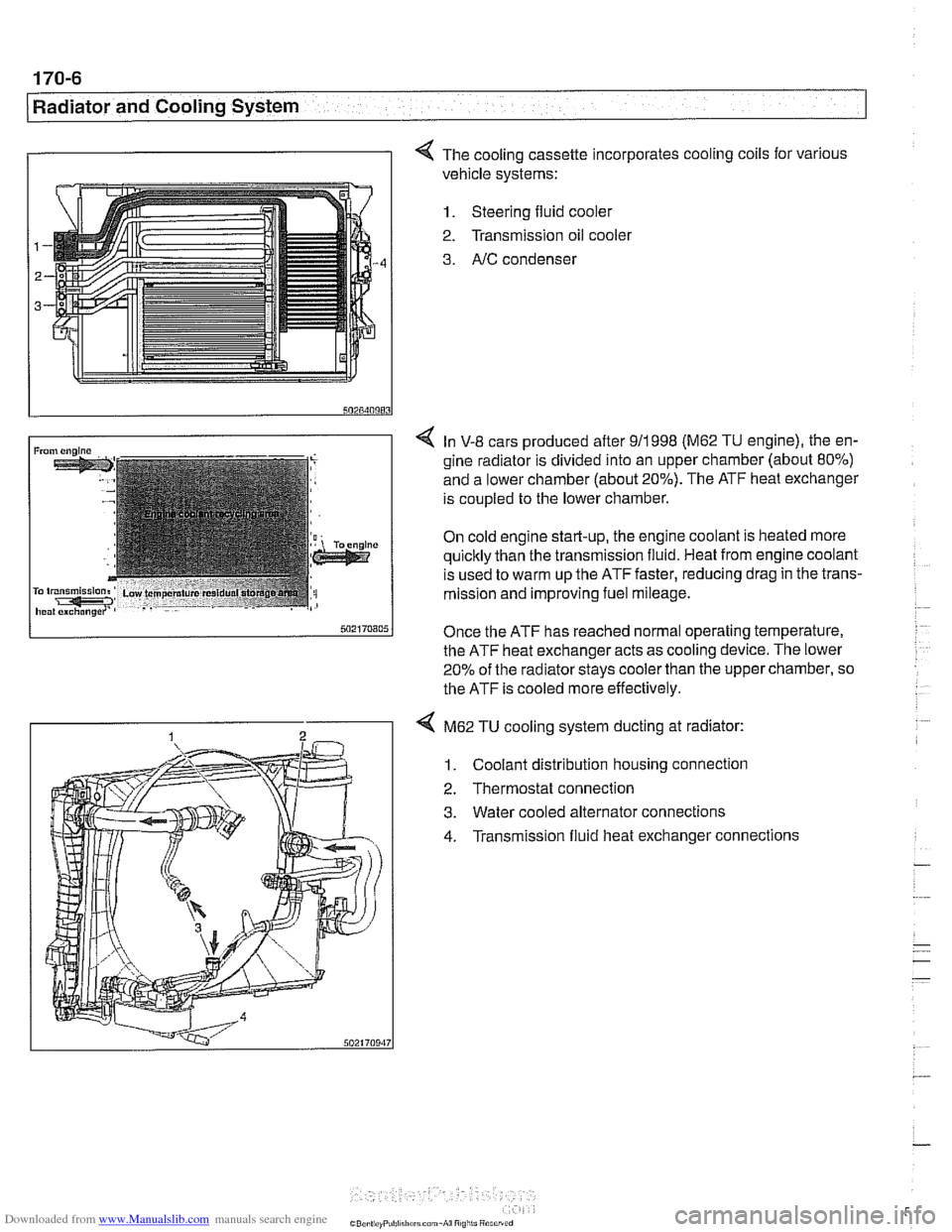

I I 4 The cooling cassette incorporates cooling coils for various

vehicle systems:

1. Steering fluid cooler

2. Transmission oil

coolel

3. AIC condenser

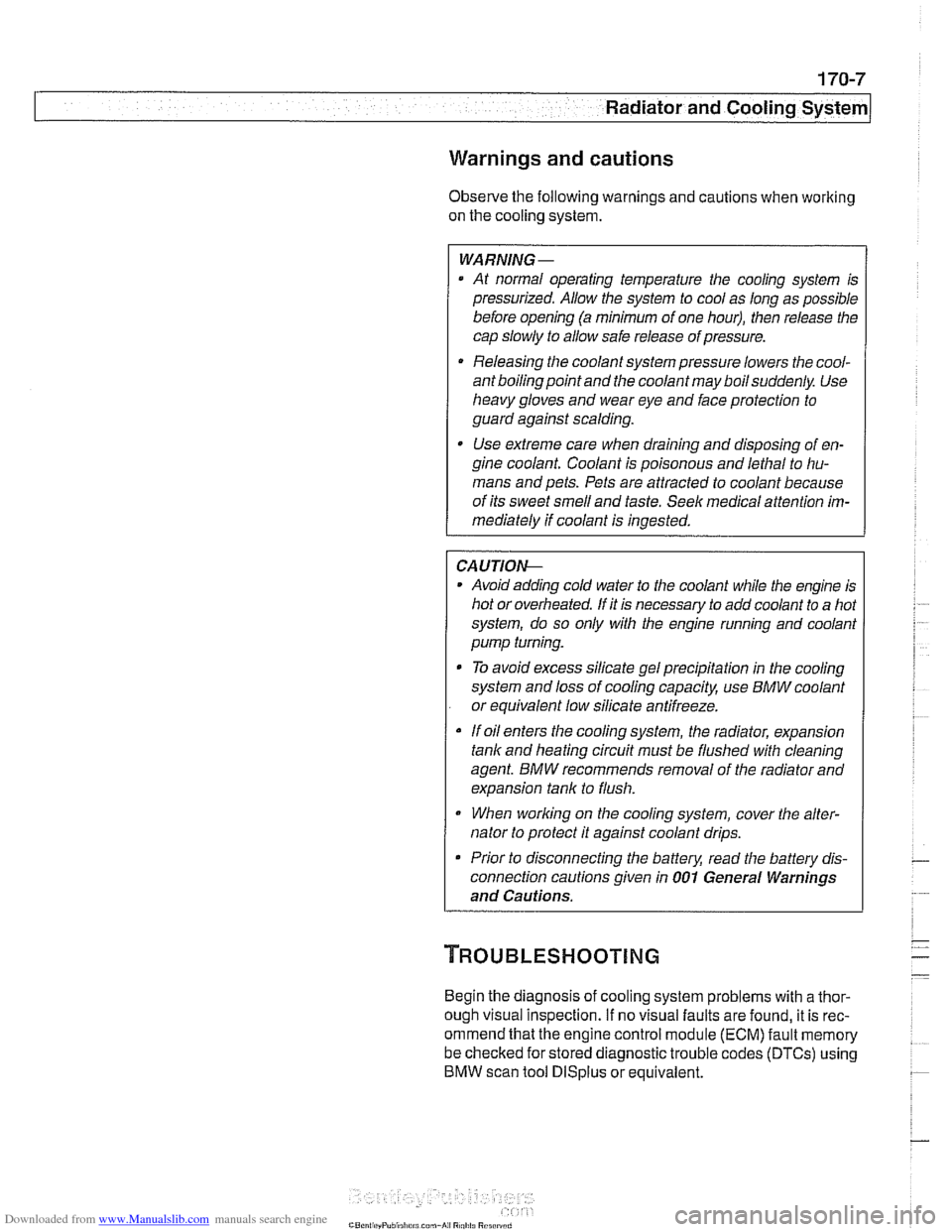

4 In V-8 cars produced after 911998 (M62 TU engine), the en-

gine radiator is divided into an upper chamber (about 80%)

and a lower chamber (about 20%). The ATF heat exchanger

is coupled to the lower chamber.

On cold engine start-up, the engine coolant is heated more

quicltly than the transmission fluid. Heat from engine coolant

is used to warm up the ATF faster, reducing drag in the trans-

mission and improving fuel mileage.

Once the ATF has reached normal operating temperature,

the ATF heat exchanger acts as cooling device. The lower

20% of the radiator

stays cooler than the upper chamber, so

the ATF is cooled more effectively.

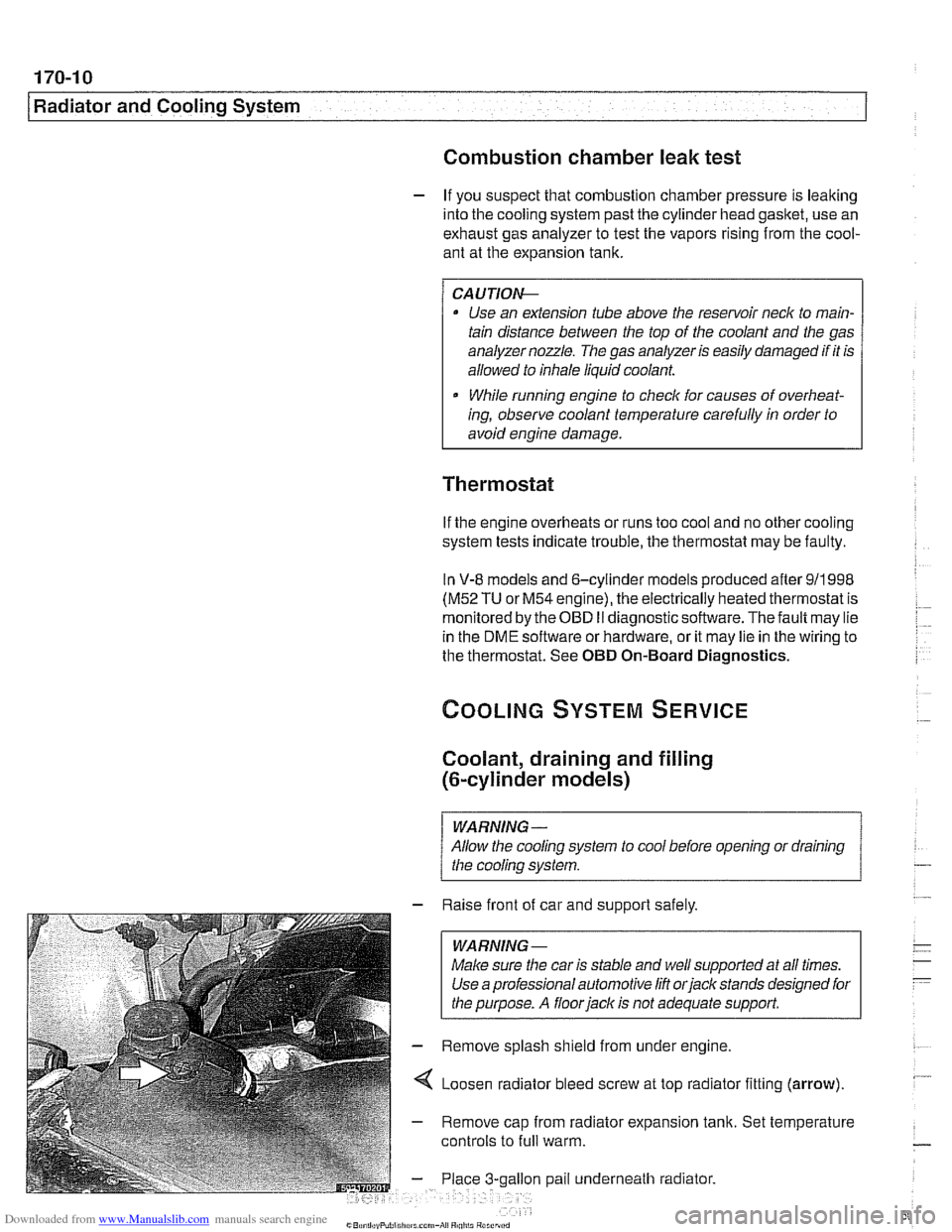

4 M62 TU cooling system ducting at radiator:

1. Coolant distribution housing connection

2. Thermostat connection

3. Water cooled alternator connections

4. Transmission fluid heat exchanger connections

Page 503 of 1002

Downloaded from www.Manualslib.com manuals search engine

Warnings and cautions

Obse~e the following warnings and cautions when worlting

on the cooling system.

WARNING -

. At normal operating temperature the cooling system is

pressurized. Allow the system to cool as long as possible

before opening (a minimum of one hour), then release the

cap slowly to allow safe release ofpressure.

a Releasing the coolant system pressure lowers the cool-

ant boilingpoint and the coolant may boil suddenly. Use

1 heavy and wear eye and face protection to

guard against scalding.

Use extreme care when draining and disposing of en-

gine coolant. Coolant is poisonous and lethal to hu-

mans andpets. Pets are attracted to coolant because

of its sweet smell and taste. Seek medical attention im-

mediately if coolant is ingested.

CAUTIOG

Avoid adding cold water to the coolant while the engine is

hot or overheated. If it is necessary to add coolant to a

hol

system, do so only with the engine running and coolanl

pump turning.

To avoid excess silicate gel precipitation in the cooling

system and loss of cooling capacity, use BMW coolant

or equivalent low silicate antifreeze.

a If oil enters the cooling system, the radiator, expansion

tank and heating circuit must be flushed with cleaning

agent. BMW recommends removal of the radiator and

expansion

tank to flush.

When

worlcing on the cooling system, cover the alter-

nator to protect it against coolant drips.

Prior to disconnecting the battery, read the battery dis-

connection cautions given in

001 General Warnings

and Cautions.

Begin the diagnosis of cooling system problems with a thor-

ough visual inspection.

If no visual faults are found, it is rec-

ommend that the engine control module (ECM) fault memory

be checked for stored diagnostic trouble codes

(DTCs) using

BMW scan tool

DlSplus or equivalent.

Page 506 of 1002

Downloaded from www.Manualslib.com manuals search engine

170-1 0

I Radiator and Cooling System

Combustion chamber leak test

- If you suspect that combustion chamber pressure is leaking

into the cooling system past the cylinder head gasket, use an

exhaust gas analyzer to test the vapors rising from the cool-

ant at the expansion tank.

CAUTIO&

Use an extension tube above the reservoir neclc to main-

tain distance between the top of the coolant and the gas

analyzer

nozzle. The gas analyzer is easily damaged if it is

allowed to inhale liquid coolant.

* While running engine to checlc for causes of overheat-

ing, observe coolant temperature carefully in order to

avoid engine damage.

Thermostat

If the engine overheats or runs too cool and no other cooling

system tests indicate trouble, the thermostat may be faulty.

In

V-8 models and 6-cvlinder models nroduced afler 911 998

(M52TU or M54 eng'ne), rheelecrricaily heated rhermostal IS

mon tored by [he OBD II diagnostlc software The fault may ic

in the DME software or hardware, or it may lie in the wiring to

the thermostat. See

OED On-Board Diagnostics.

Coolant, draining and filling

(6-cylinder models)

WARNING -

Allow the cooling system to cool before opening or draining

the cooling system.

- Raise front of car and support safely.

WARNING -

Make sure the car is stable and well supported at all times.

Use a professional automotive lift

orjack stands designed for

the purpose. A floor jack is not adequate support.

- Remove splash shield from under engine.

4 Loosen radiator bleed screw at top radiator fitting (arrow).

- Remove cap from radiator expansion tank. Set temperature

controls to

full warm.

gallon pail underneath radiator.

Page 508 of 1002

Downloaded from www.Manualslib.com manuals search engine

170-1 2

I Radiator and Cooling System

Tightening torques

Block drain plug to

block 25 Nm (1 8 ft-ib)

Radiator drain plug to radiator

2-3 Nm (18-27 in-lb)

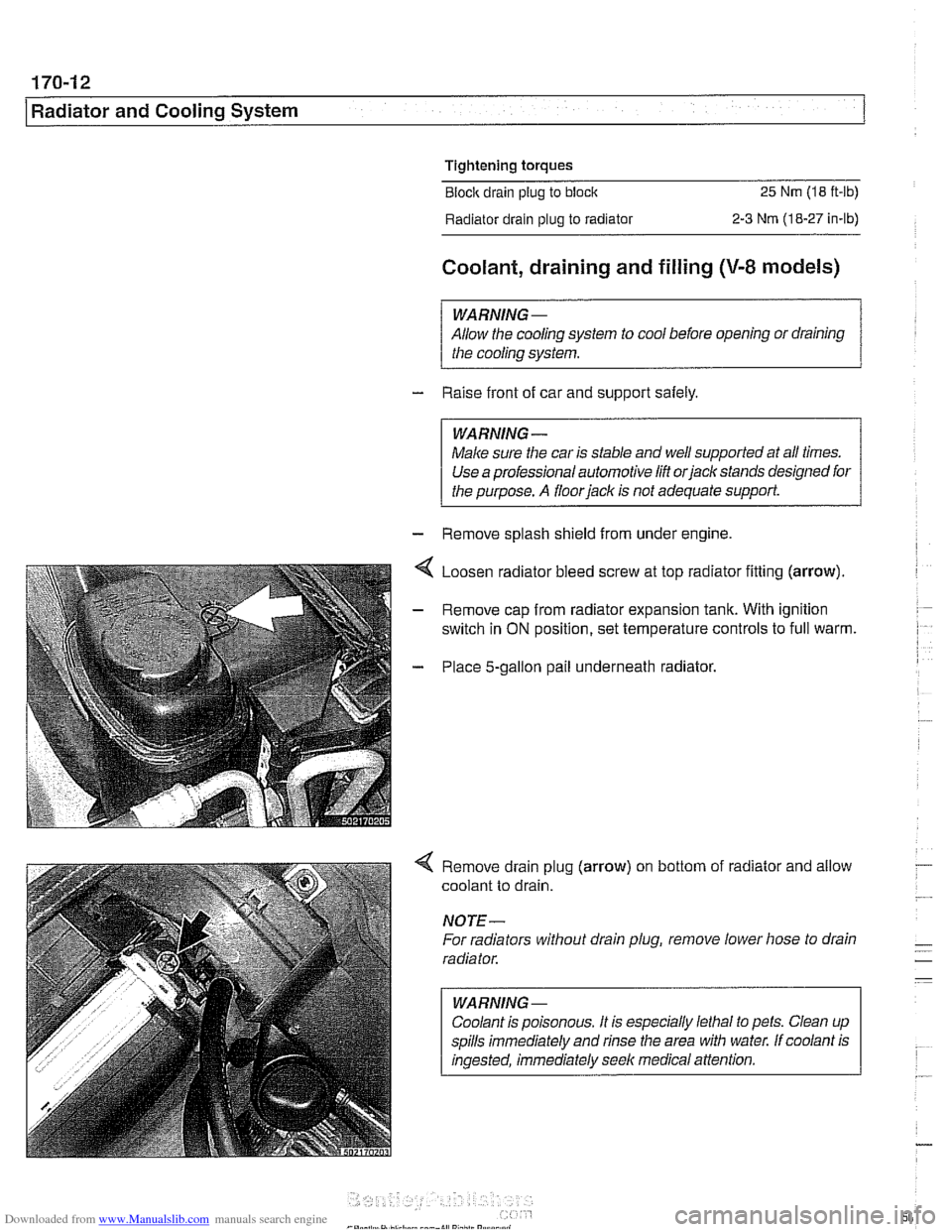

Coolant, draining and filling (V-8 models)

WARNING -

Allow the cooling system to cool before opening or draining

the cooling system.

- Raise front of car and support safely.

I WARNING- 1

Make sure the car is stable and well supported at all times.

Use a professional automotive lift

orjack stands designed for

I the purpose. A floorjack is not adequate support 1

- Remove splash shield from under engine.

Loosen radiator bleed screw at top radiator fining (arrow).

Remove cap from radiator expansion tank. With ignition

switch in

ON position, set temperature controls to full warm.

Place 5-gallon pail underneath radiator.

4 Remove drain plug (arrow) on bottom of radiator and allow

coolant to drain.

NOTE-

For radiators without drain plug, remove lower hose to drain

radiator.

WARNING

-

Coolant is poisonous. It is especially lethal to pets. Clean up

spills immediately and rinse the area with water. If coolant is

ingested, immediately seek medical attention.

Page 510 of 1002

Downloaded from www.Manualslib.com manuals search engine

Radiator and Cooling System

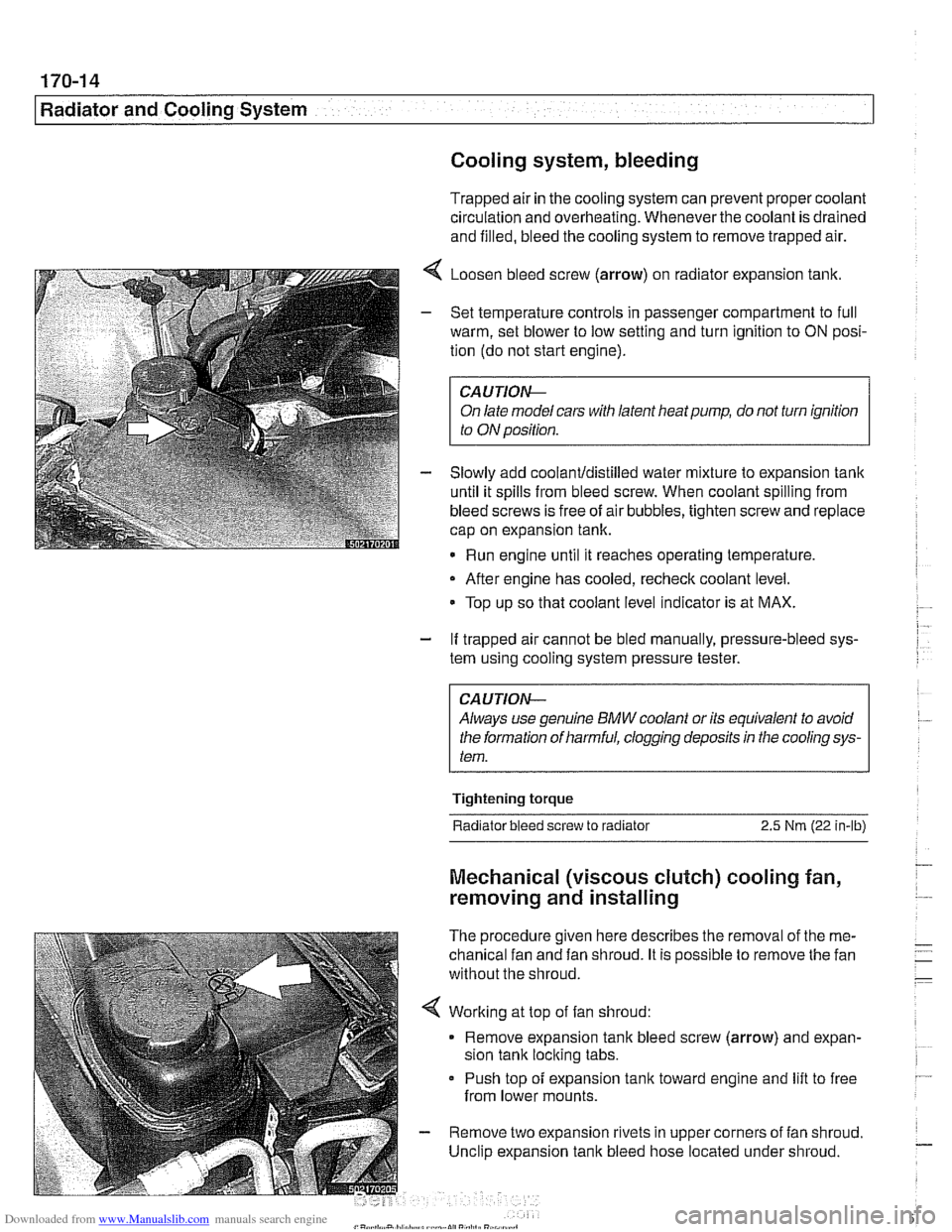

Cooling system, bleeding

Trapped air in the cooling system can prevent proper coolant

circulation and overheating. Wheneverthe coolant is drained

and filled, bleed the cooling system to remove trapped air.

4 Loosen bleed screw (arrow) on radiator expansion tank.

- Set temperature controls in passenger compartment to full

warm, set blower to low setting and turn ignition to

ON posi-

tion (do not start engine).

CAUTIOIG

On late model cars with latent heat pump, do not turn ignition

to ON position.

- Slowly add coolanUdistilled water mixture to expansion tank

until it spills from bleed screw. When coolant spilling from

bleed screws is free of air bubbles, tighten screw and replace

cap on expansion tank.

Run engine until it reaches operating temperature,

- After engine has cooled, recheck coolant level.

Top up so that coolant level indicator is at MAX.

- If trapped air cannot be bled manually, pressure-bleed sys-

tem using cooling system pressure tester.

CA UTlON--

Always use genuine BMW coolant or its equivalent to avoid

the formation of harmful, clogging deposits

in the cooling sys-

tem.

Tightening torque

Radiator bleed screw to radiator 2.5 Nm (22 in-lb)

Mechanical (viscous clutch) cooling fan,

removing and installing

The procedure given here describes the removal of the me-

chanical fan and fan shroud. It is possible to remove the fan

without the shroud.

< Working at top of fan shroud:

Remove expansion tank bleed screw (arrow) and expan-

sion tank locking tabs.

Push top of expansion

tank toward engine and lift to free

from lower mounts.

- Remove two expansion rivets in upper corners of fan shroud.

Unclip expansion tank bleed hose located under shroud.