Lamp control module BMW 528i 1997 E39 User Guide

[x] Cancel search | Manufacturer: BMW, Model Year: 1997, Model line: 528i, Model: BMW 528i 1997 E39Pages: 1002

Page 504 of 1002

Downloaded from www.Manualslib.com manuals search engine

170-8

I Radiator and Cooling System

Common cooling system faults can be grouped into one of 4

categories:

Cooling system

lealts

Poor coolant circulation

Radiator cooling fan faults

Electrical/electronic faults

Cooling system inspection

- Check that coolant pump drive belt tensioner is functioning

properly and that belt tension is correct. Belt tensioner sys-

tems for the different models are shown in

020 Maintenance.

- Check condition of coolant pump drive belt.

- Checlc coolant hoses for cracks or softness. Checlc clamps

for looseness. Check coolant level and check for evidence of

coolant

lealts from engine.

- Check that radiator fins are not blocked with dirt or debris.

Clean radiator using low-pressure water or compressed air.

Blow outward, from engine side out.

- To check coolant pump:

Remove mechanical cooling fan. See Mechanical

(vis.

cous clutch) cooling fan, removing and installing.

Remove drive belt from coolant pump pulley. See

020

Maintenance.

Firmly grasp opposite sides of pulley and check for play in

all directions.

Spin pulley and check that shaft runs smoothly without

play.

NOTE-

The coolant provides lubrication for the pump shaft, so an oc-

casional drop of coolant

lealing from the pump is acceptable.

If coolant drips steadily from the vent hole, replace the pump.

- At normal engine operating temperature, cooling system is

pressurized. This raises boiling point of coolant.

Leaks may

prevent system from becoming pressurized. If visual evi-

dence is inconclusive, pressure test cooling system as de-

scribed later to help pinpoint hard-to-find leaks.

- If cooling system is full of coolant and holds pressure:

- Use an appropriate scan tool to interrogate engine control

module (ECM) for radiator fan or DME control circuit faults.

Checlc for loose or worn drive belt.

0 Test for failed thermostat or coolant pump impeller. Some

pumps may be fitted with plastic impellers.

Page 514 of 1002

Downloaded from www.Manualslib.com manuals search engine

Tightening torques Block drain plug to block

25 Nm (18 ft-lb)

Radiator drain plug to radiator 2 - 3 Nm (18 - 27 in-lb)

Thermostat housing to

cylinder head 10 Nm (89 in-lb)

Thermostat, removing and installing

(V-8 models)

The electrically-heated thermostat is an integral parl of the

thermostat housing. The operation of the thermostat is moni-

tored by the engine control module (ECM).

- If a faulty thermostat is suspected, use appropriate scan tool

to interrogate ECM for stored fault codes.

- Drain radiator and engine block. See Coolant, draining and

filling

(V-8 models).

WARNING -

Allow cooling system to cool before opening or draining the

system.

- Disconnect mass air flow (MAF) sensor electrical harness

connector. Remove air intake duct together with MAF sensor.

- Remove mechanical cooltng fan and fan shroud. See Me-

chanical (viscous clutch) cooling fan, removing and

in-

stalling.

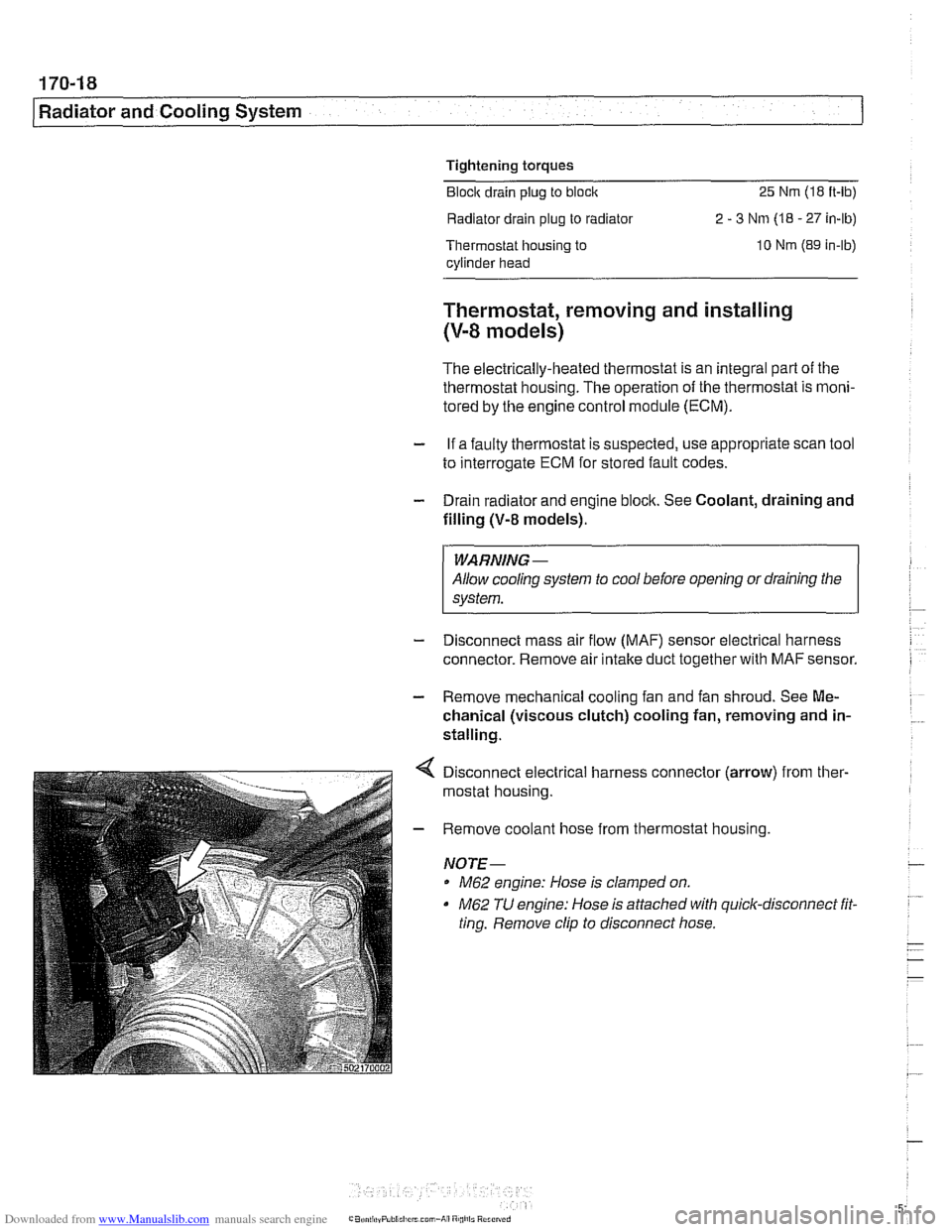

Disconnect electrical harness connector (arrow) from ther-

mostat housing.

Remove coolant hose from thermostat housing.

NOTE-

M62 engine: Hose is clamped on.

M62 TU engine: Hose is attached with quick-disconnect fit.

ting. Remove clip to disconnect hose.

Page 922 of 1002

Downloaded from www.Manualslib.com manuals search engine

l Seats

This repair group covers removal and installation of the front

and rear seat.

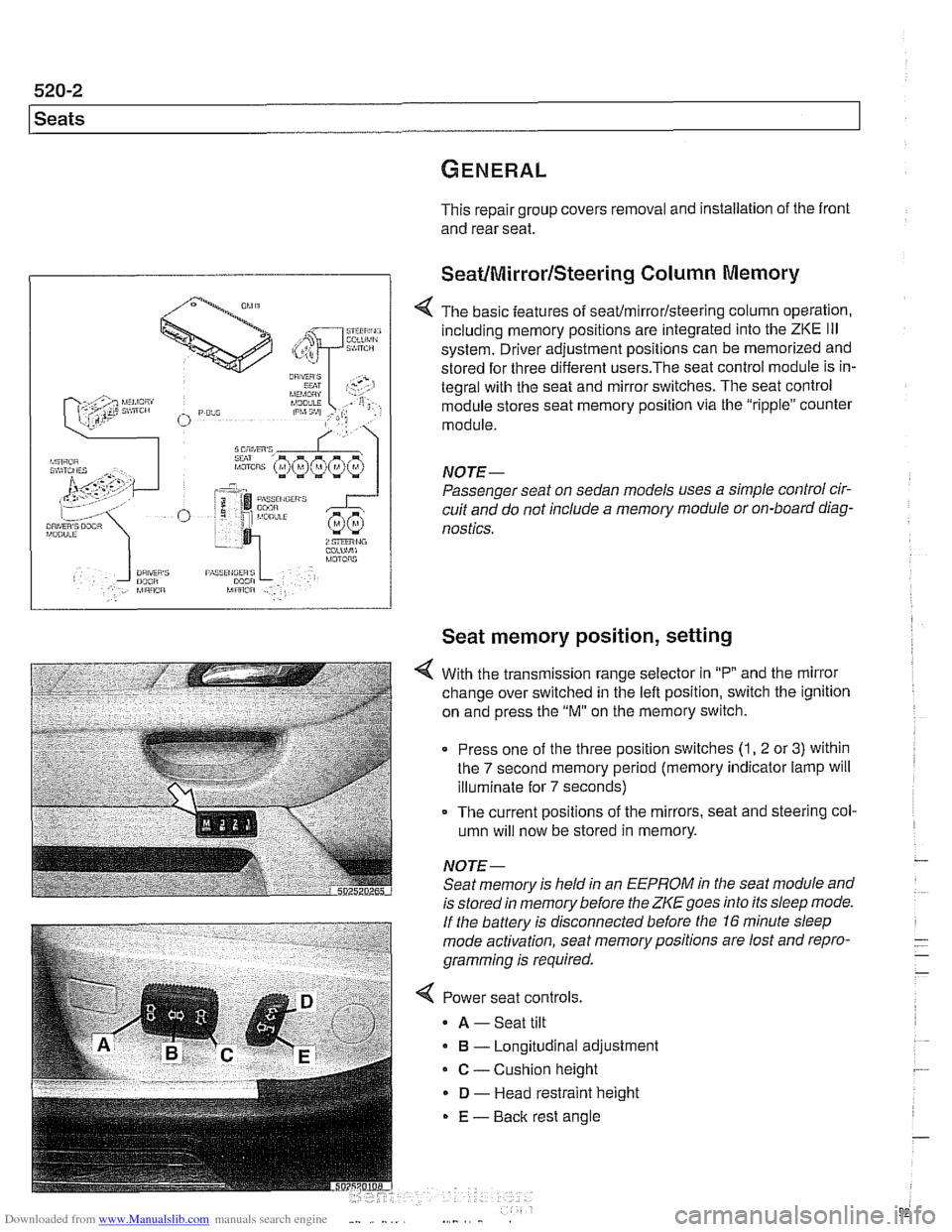

SeatIMirrorlSteering Column Memory

< The basic features of seaffmirrorlsteering column operation,

including memory positions are integrated into the

ZKE Ill

system. Driver adjustment positions can be memorized and

stored for three different

users.The seat control module is in-

tegral with the seat and mirror switches. The seat control

module stores seat memory position via the "ripple" counter

module.

NOTE-

Passenger seat on sedan models uses a simple control cir-

cuit and do not include a memory module or on-board diag-

nostics.

Seat memory position, setting

With the transmission range selector in "P and the mirror

change over switched in the left position, switch the ignition

on and press the

"M" on the memory switch.

Press one of the three position switches

(1, 2 or 3) within

the

7 second memory period (memory indicator lamp will

illuminate for

7 seconds)

- The current positions of the mirrors, seat and steering col-

umn will now be stored in memory.

NOTE- Seat memory is held in an

EEPROM in the seat module and

is stored in memory before the

ZKE goes into its sleep mode.

If the battery is disconnected before the 16 minute sleep

mode activation, seat memorypositions are lost and repro-

gramming is required.

< Power seat controls.

A -Seat tilt

B - Longitudinal adjustment

C - Cushion height

D - Head restraint height

E - Back rest angle

Page 989 of 1002

Downloaded from www.Manualslib.com manuals search engine

On-Board ~ia~nosticsl

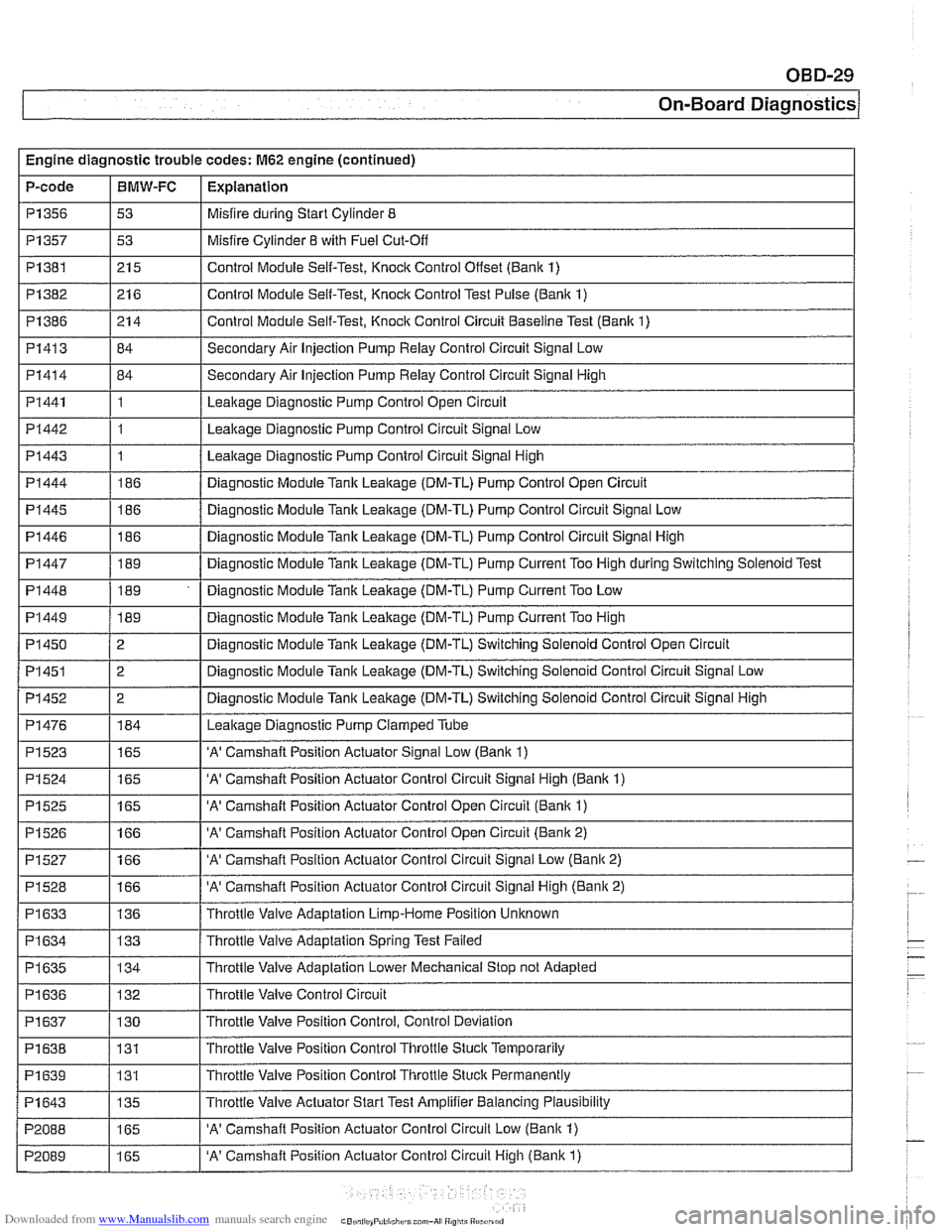

Engine diagnostic trouble codes: M62 engine (continued)

P-code

I I -

I I - -.

PI445 1186 / Diagnostic Module Tank Leakage (DM-TL) Pump Control Circuit Signal Low

PI357

PI382

PI386

PI413

PI414

PI441

PI442

PI443

PI444

P1356 1 53 I Misfire during Start Cylinder 8

BMW-FC

I P1523

I

I - -

1165 I 'A' Camshaft Position Actuator Signal Low (Banlc 1)

Explanation

P1381 1215 I Control Module Self-Test, Knock Control Onset (Bank 1)

53

21 6

21 4

84

84

1

1

1

186

PI 446

PI 447

PI 448

PI449

PI 450

PI451

PI452

PI476

Misfire Cylinder 8 with Fuel Cut-Off

Control Module Self-Test, Knock Control Test Pulse (Bank 1)

Control Module Self-Test, Knock Control Circuit Baseline Test (Bank 1)

Secondary Air Injection Pump Relay Control Circuit Signal Low

Secondary Air Injection Pump

Relay Control Circuit Signal High

Leakage Diagnostic Pump Control Open Circuit

Leakage Diagnostic Pump Control Circuit Signal Low

Leakage Diagnostic Pump Control Circuit Signal High

Diagnostic Module Tank Leakage (DM-TL) Pump Control Open Circuit

186

189

189

189

2

2

2

184

P1524

P1525

P1526

PI527

PI528

PI633

PI 634

PI 635

I I

PI 638 / 131 I Throttle Valve Position Control Throttle Stuck Temporarily

. -

Diagnostic Module Tank Leakage (DM-TL) Pump Control Circuit Signal High

Diagnostic Module

Tank Leakage (DM-TL) Pump Current Too High during Switching Solenoid Test

Diagnostic Module Tank Leakage (DM-TL) Pump Current Too Low

Diagnostic Module

Tank Leakage (DM-TL) Pump Current Too High

Diagnostic Module Tank Leakage (DM-TL) Switching Solenoid Control Open Circuit

Diagnostic Module

Tank Leakage (DM-TL) Switching Solenoid Control Circuit Signal Low

Diagnostic Module

Tank Leakage (DM-TL) Switching Solenoid Control Circuit Signal High

Leakaqe Diaqnostic Pump Clamped Tube

I I

165

165

166

166

166

136

133

134

'A' Camshaft Position Actuator Control Circuit Signal High (Banlc 1)

'A' Camshaft Position Actuator Control Open Circuit (Bank 1)

'A' Camshaft Position Actuator Control Open Circuit (Bank 2)

'A' Camshaft Position Actuator Control Circuit Signal Low (Bank 2)

'A' Camshaft Position Actuator Control Circuit Signal High (Bank 2)

Throttle Valve Adaptation Limp-Home Position Unknown

Throttle Valve Adaptation Spring Test Failed

Throttle Valve Adaptation Lower Mechanical Stop not Adapted

Throttle Valve Control Circuit

PI 636

PI639

P1643

P2088

P2089

PI 637 / 130 I Throttle Valve Position Control, Control Deviation

132

131

135

165

165 Throttle

Valve Position Control Thronle Stuck Permanently

Throttle Valve Actuator Start Test Amplifier Balancing Plausibility

'A' Camshaft Position Actuator Control Circuit Low (Banlc 1)

'A' Camshaft Position Actuator Control Circuit High (Bank 1)