warning BMW 528i 1997 E39 Manual Online

[x] Cancel search | Manufacturer: BMW, Model Year: 1997, Model line: 528i, Model: BMW 528i 1997 E39Pages: 1002

Page 391 of 1002

Downloaded from www.Manualslib.com manuals search engine

130-1

130 Fuel injection

General ........................... .I3 0.2

Tools and test equipment .............. .I3 0.3

Warnings and cautions ................ .I3 0.5

Fuel Supply ....................... .I3 0.6

Relieving system fuel pressure .......... .I3 0.6

Siemens MS 41 . 1. ................... 1 30-7

ECM relay. testing .................... .I3 0.7

Mass air flow (MAF) sensor.

checking and replacing

................ .I3 0.9

Engine coolant temperature (ECT) sensor.

testing and replacing

.................. 130-10

Intake air temperature (IAT) sensor.

testing and replacing

................. .I3 0.1 1

Throttle position sensor (TPS).

testing and replacing

.................. 130-1 2

ldle speed control valve.

checking and replacing

............... .I3 0.1 3

Fuel injectors. checking and replacing .... 130-15

Evaporative emissions. overview ....... .I3 0.1 6

Secondary air injection. overview ....... .I3 0-17

Engine control module (ECM).

removing and installing

................ 130-18

Siemens MS 41.1 ECM pin assignments . .I3 0.19

Siemens MS 42.0 and MS 43.0. ..... .I3 0.23

ECM relay. testing ................... .I3 0.27

Mass air flow (MAF) sensor.

checking and replacing

............... .I3 0.28

Engine coolant temperature (ECT) sensor.

testing and replacing

................. .I3 0.30

Intake air temperature (IAT) sensor.

testing and replacing

................. .I3 0.31

MS 42.0 throttle valve assembly. replacing . 130-32

MS 43.0 throttle valve assembly. replacing . 130-35

Throttle cable. adjusting (MS 42.0) ...... .I3 0.38

ldle speed control valve. checking

and replacing

....................... .I3 0.38

Evaporative emissions control diagrams . . 130- 39

Evaporative emissions control.

(MS

42.0 and MS 43.0). .............. .I3 0.39

Engine control module (ECM).

removing and installing

................ 130-40

Siemens MS 42.0 and MS 43.0

ECM pin assignments ................. 130-41

Bosch M5.2 (M62 up to 911997)

BOSC~ M5.2.1 (M62 911997 to 911998) 130-46

M5.2 system features ................. 130-47

M5.2.1 system features ............... 130-47

ECM relay. testing ................... 130-49

Oxygen sensors. checking ............. 130-51

Fuel injectors. checking and replacing .... 130-52

Mass air flow (MAF) sensor. replacing .... 130-53

ldle speed control valve. testing

and replacing

....................... 130-54

Throttle position sensor (TPS).

testing and replacing

................. 130-55

Engine coolant temperature (ECT) sensor.

testing and replacing

................. 130-55

Intake air temperature (IAT) sensor.

testing and replacing

................. 130-57

Auxiliary throttle valve (ADS) (M62 and

M62 TU engine). replacing ..... 130-57

Evaporative system pressure

leak diagnosis. overview

(5.2.1 only) ..... 130-58

Bosch 5.2 ECM pin assignments

(M62 UP to 911 997) ................... 130-59

~osch 5.2.1 ECM pin assignments

(M62 911 997 to 911 998) ............... 130-62

BOSC~ ME 7.2 ..................... 1 30-66

ME 7.2 system overview ............... 130-67

EDK adaptation ..................... 130-69

ECM relay. checking .................. 130-69

Engine coolant temperature

(ECT) sensor. testing

................. 130-71

Engine coolant temperature

(ECT) sensor. replacing

............... 130-71

Oxygen sensors. replacing ............. 130-72

Fuel injectors. removing and installing .... 130-72

Mass air flow (MAF) sensor.

removing and installing

................ 130-73

Evaporative system pressure

leak diagnosis. overview

............... 130-74

Secondary air injection. overview ........ 130-75

Bosch ME 7.2 ECM pin assignments .... 130-76

Page 395 of 1002

Downloaded from www.Manualslib.com manuals search engine

Fuel Injection

Warnings and cautions

For personal safety, as well as the protection of sensitive

electronic components, adhere to the warnings and cautions

on the following pages.

WARNING-

Gasoline is highly flammable and its vapors are explosive.

Do not smoke or work on a car near heaters or other fire

hazards when diagnosing and repairing fuel system prob-

lems. Have a fire extinguisher available in case of an emer-

gency

Renew fuel system hoses, clamps and O-rings any

time they are removed.

When working on an open fuel system, wear suitable

hand protection, as prolonged contact

with fuel can

cause illnesses and skin disorders.

* The ignition system produces high voltages that can be

fatal. Avoid contact with exposed terminals. Use ex-

treme caution when

working on a car with the ignition

switched on or the engine running.

CAUTION-

- Disconnecting the battery may erase fault code($ storedin

memory Check for fault codes prior to disconnecting the

battery cables. Read the battery disconnection cautions in

001 General Warnings and Cautions.

a Connect and disconnect the DME system wiring and

1 test equipment leads only when the ignition is switched

off.

Wait at least 1 minute after turning off the ignition be-

fore removing the engine control module (ECM) con-

nector. If the connector is removed before this time,

residualpower in the system relay may damage the

control module.

Fuel system cleaners and other chemical additives oth-

er than those specifically recommended by BMW may

damage the catalytic converter, the oxygen sensor or

other fuel supply components.

* Do not connect any test equipment that delivers a 12-

volt power supply to terminal 15 (+) of the ignition coil.

The current flow may damage the ECM. In general,

connect test equipment only as specified by BMW or

the equipment maker.

Only use a digital

multirneter for electrical tests. Only

use an LED test light for

quiclc tests.

Page 400 of 1002

Downloaded from www.Manualslib.com manuals search engine

130-1 0

Fuel Injection

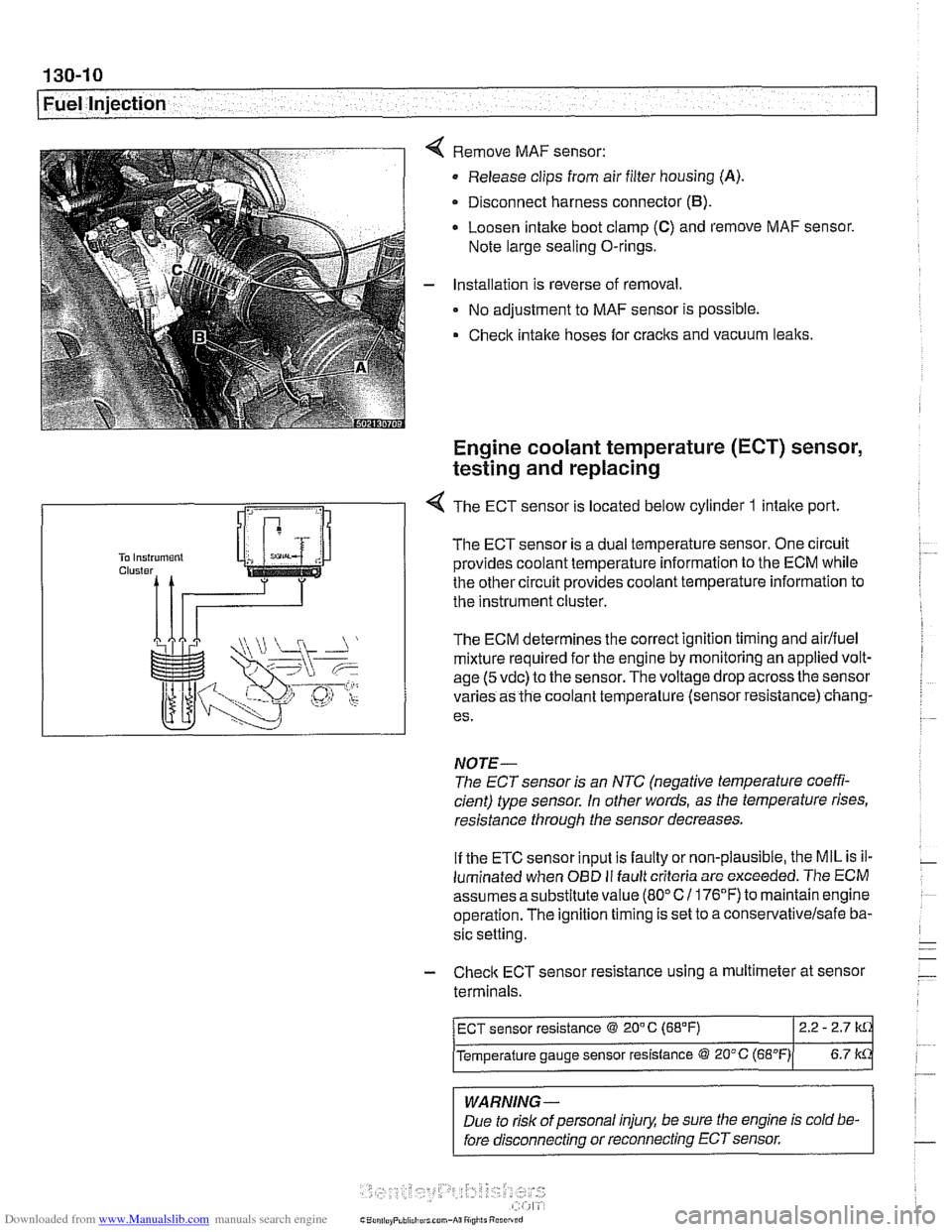

Remove MAF sensor:

Release clips from air filter housing

(A).

Disconnect harness connector (B).

Loosen intake boot clamp (C) and remove MAF sensor.

Note large sealing O-rings.

Installation is reverse of removal.

No adjustment to MAF sensor is possible.

Check intake hoses for cracks and vacuum leaks.

Engine coolant temperature (ECT) sensor,

testing and replacing

R

1 -4 The ECT sensor is located below cylinder 1 intake port

The ECT sensor is a dual temperature sensor. One circuit

provides coolant temperature information to the ECM while

the other circuit provides coolant temperature information to

the instrument cluster.

The ECM determines the correct ignition timing and

airlfuel

mixture required for the engine by monitoring an applied volt-

age

(5 vdc) to the sensor. The voltage drop across the sensor

varies as the coolant temperature (sensor resistance) chang-

es.

NOTE-

The ECT sensor is an NTC (negative temperature coeffi-

cient) type sensor. in other words, as the temperature rises,

resistance through the sensor decreases.

If the ETC sensor input is faulty or non-plausible, the MIL is il-

luminated when

OED II fault criteria are exceeded. The ECM

assumes asubstitute value

(80°C1 176°F) to maintainengine

operation. The ignition timing is set to a

conse~ativelsafe ba-

sic setting.

- Check ECT sensor resistance using a multimeter at sensor

terminals.

-

WARNING -

Due to risk of personal injury, be sure the engine is cold be-

fore disconnecting or reconnecting ECT sensor.

ECT sensor resistance @ 20" C (68°F) 2.2 - 2.7

Temperature gauge sensor resistance @ 20°C (~B"F)( 6.7 k

Page 405 of 1002

Downloaded from www.Manualslib.com manuals search engine

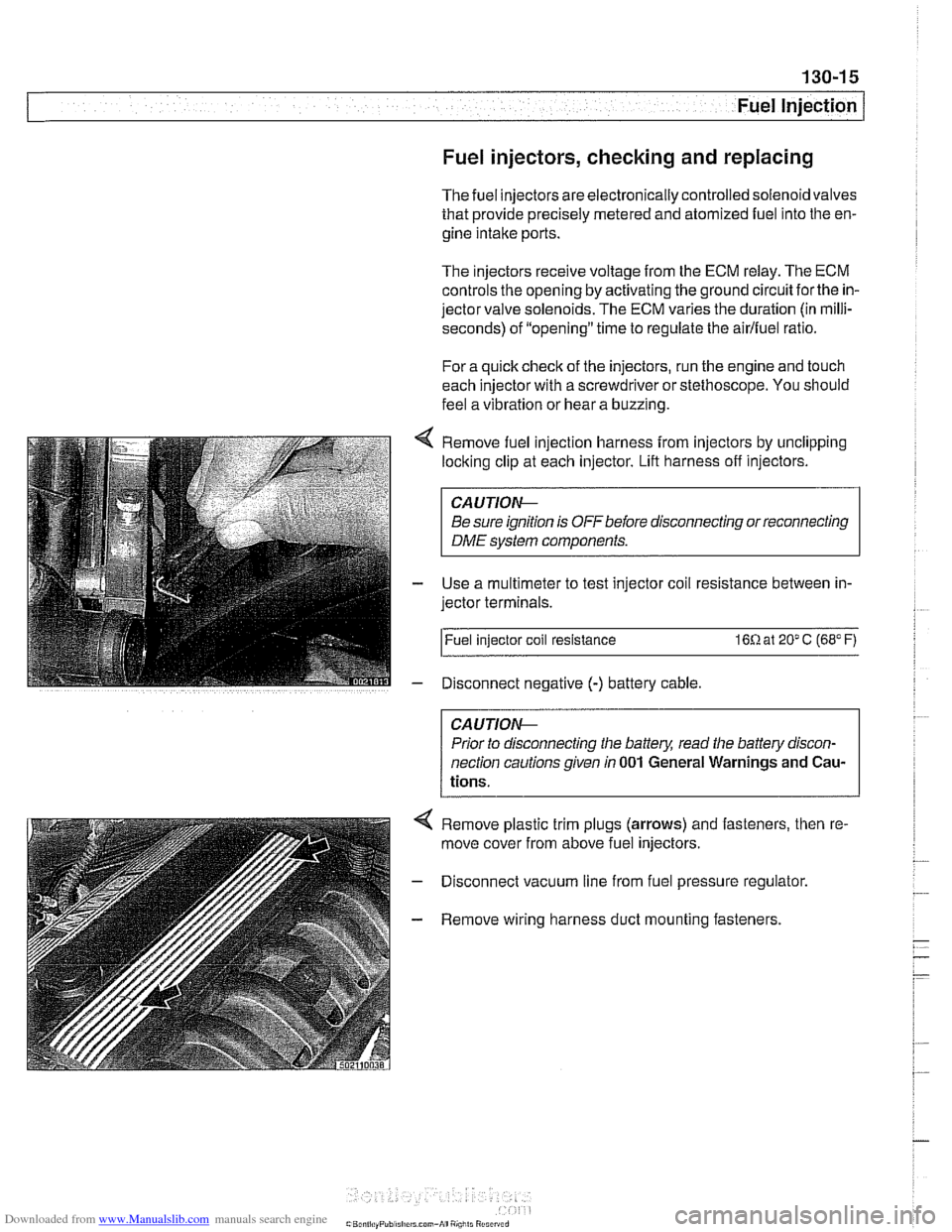

Fuel injectors, checking and replacing

The fuel injectors are electronically controlled solenoid valves

that provide precisely metered and atomized fuel into the en-

gine intake ports.

The injectors receive voltage from the ECM relay. The ECM

controls the opening by activating the ground circuit

forthe in-

jector valve solenoids. The ECM varies the duration (in milli-

seconds) of "opening" time to regulate the

airlfuel ratio.

For a quick

check of the injectors, run the engine and touch

each injector with a screwdriver or stethoscope. You should

feel a vibration or hear a buzzing

Remove fuel injection harness from injectors by unclipping

locking clip at each injector. Lift harness off injectors.

CA U JIOG

Be sure ignition is OFF before disconnecting or reconnecting

DME system components.

Use a multimeter to test injector coil resistance between in-

jector terminals.

l~uel injector coil resistance 16R at 20" C (68" F)

Disconnect negative

(-) battery cable

CAUTIOG

Prior to disconnecting the battery, read the battery discon-

nection cautionsgiven

in 001 General Warnings and Cau-

tions.

4 Remove plastic trim plugs (arrows) and fasteners, then re.

move cover from above fuel injectors.

- Disconnect vacuum line from fuel pressure regulator.

- Remove wiring harness duct mounting fasteners.

Page 406 of 1002

Downloaded from www.Manualslib.com manuals search engine

I Fuel Injection

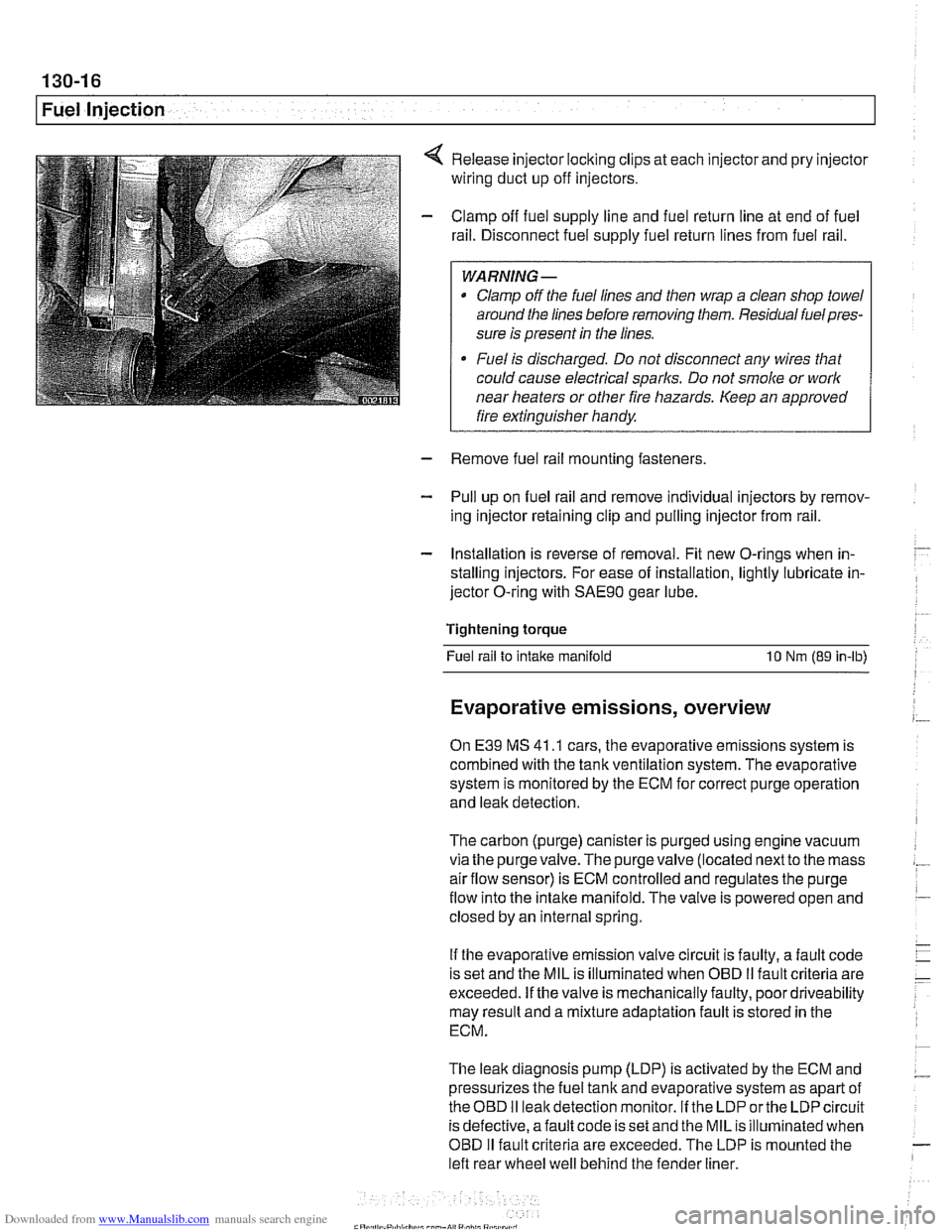

Release injector locking clips at each injector and pry injector

wiring duct up off injectors.

Clamp off fuel supply line and fuel return line at end of fuel

rail. Disconnect fuel supply fuel return lines from fuel rail.

WARNING -

Clamp off the fuel lines and then wrap a clean shop towel

around the lines before removing them. Residual

fuelpres-

sure is present in the lines.

Fuel is discharged. Do not disconnect any wires that

could cause electrical

sparks. Do not smoke or work

near heaters or other fire hazards. Keep an approved

I fire extinguisher handy. I

- Remove fuel rail mounting fasteners

- Pull up on fuel rail and remove individual injectors by remov-

ing injector retaining clip and pulling injector from rail.

- Installation is reverse of removal. Fit new O-rings when in-

stalling injectors. For ease of installation, lightly lubricate in-

jector O-ring with

SAE9O gear lube.

Tightening torque Fuel rail to

intake manifold 10 Nm (89 in-lb)

Evaporative emissions, overview

On E39 MS 41 .I cars, the evaporative emissions system is

combined with the tank ventilation system. The evaporative

system is monitored by the ECM for correct purge operation

and leak detection.

The carbon (purge) canister is purged using engine vacuum

via the

purgevalve.The purgevalve (located nextto the mass

airflow sensor) is ECM controlled and regulates the purge

flow into the intake manifold. The valve is powered open and

closed by an internal spring.

If the evaporative emission valve circuit is faulty, a fault code

is set and the MIL is illuminated when OBD

II fault criteria are

exceeded. If the valve is mechanically faulty, poor driveability

may result and a mixture adaptation fault is stored in the

ECM.

The leak diagnosis pump (LDP) is activated by the ECM and

pressurizes the fuel tank and evaporative system as apart of

theOED I1 leakdetection monitor. If the LDP orthe LDP circuit

is defective, afault code is set and the MIL is illuminated when

OBD

I1 fault criteria are exceeded. The LDP is mounted the

left rear wheel well behind the fender liner.

Page 408 of 1002

Downloaded from www.Manualslib.com manuals search engine

130-1 8

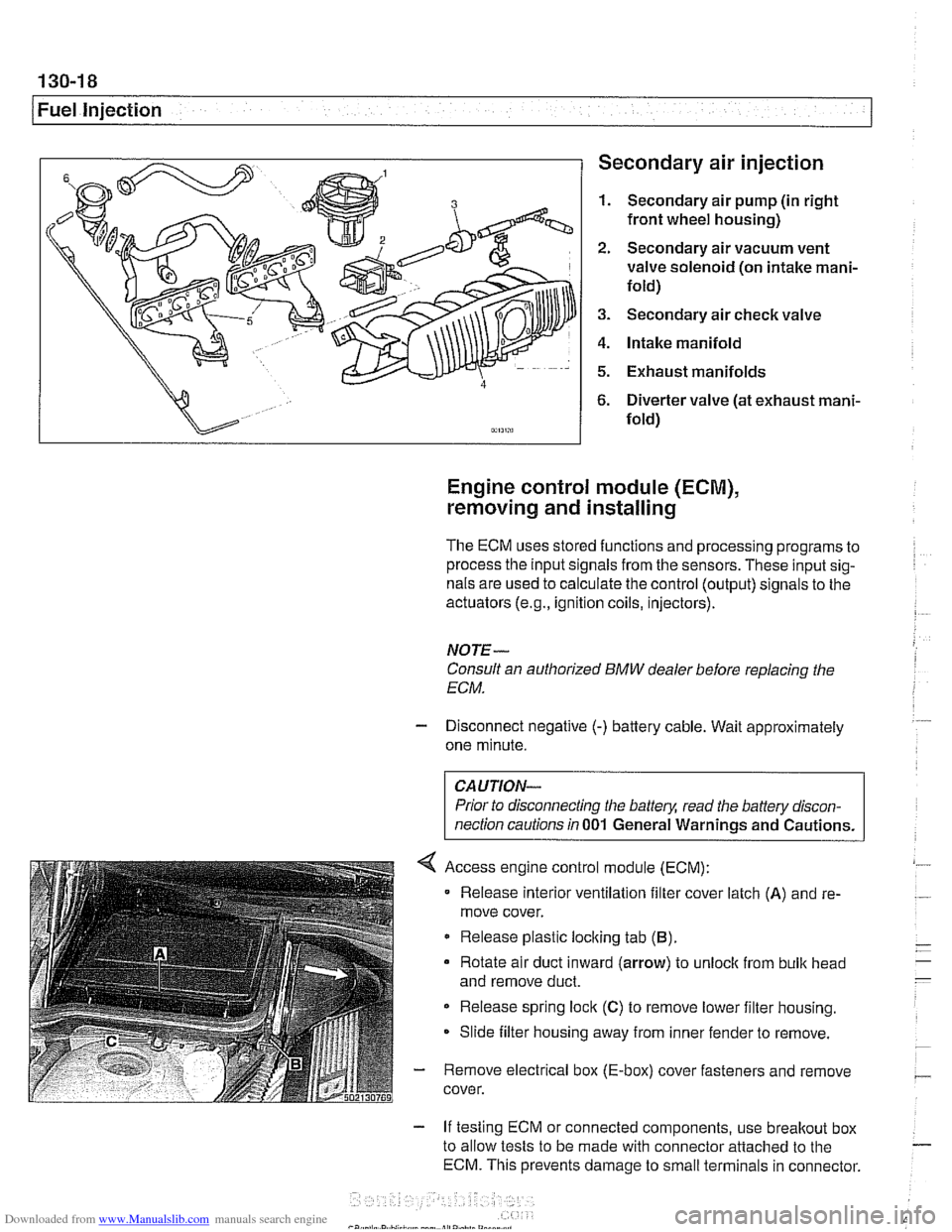

1 Fuel injection Secondary air injection

1. Secondary air pump (in right

front wheel housing)

2. Secondary air vacuum vent

valve solenoid (on intake mani-

fold)

3. Secondary air check valve

4. Intake manifold

5. Exhaust manifolds

6. Diverter valve (at exhaust mani-

fold)

Engine control module (ECM),

removing and installing

The ECM uses stored functions and processing programs to

process the input signals from the sensors. These input sig-

nals are used to calculate the control (output) signals to the

actuators

(e.g., ignition coils, injectors).

NOTE-

Consult an authorized BMW dealer before replacing the

ECM.

- Disconnect negative (-) battery cable. Wait approximately

one minute.

Prior to disconnecting the

battely, read the battery discon-

nection cautions in

001 General Warnings and Cautions.

Access engine control module (ECM):

Release interior ventilation filter cover latch

(A) and re-

move cover.

Release plastic locking tab

(B).

Rotate air duct inward (arrow) to unloclc from bulk head

and remove duct.

Release spring lock

(C) to remove lower filter housing.

Slide filter housing away from inner fender to remove.

- Remove electrical box (E-box) cover fasteners and remove

cover.

- If testing ECM or connected components, use breakout box

to allow tests to be made with connector attached to the

ECM. This prevents damage to small terminals in connector.

Page 420 of 1002

Downloaded from www.Manualslib.com manuals search engine

Fuel Injection

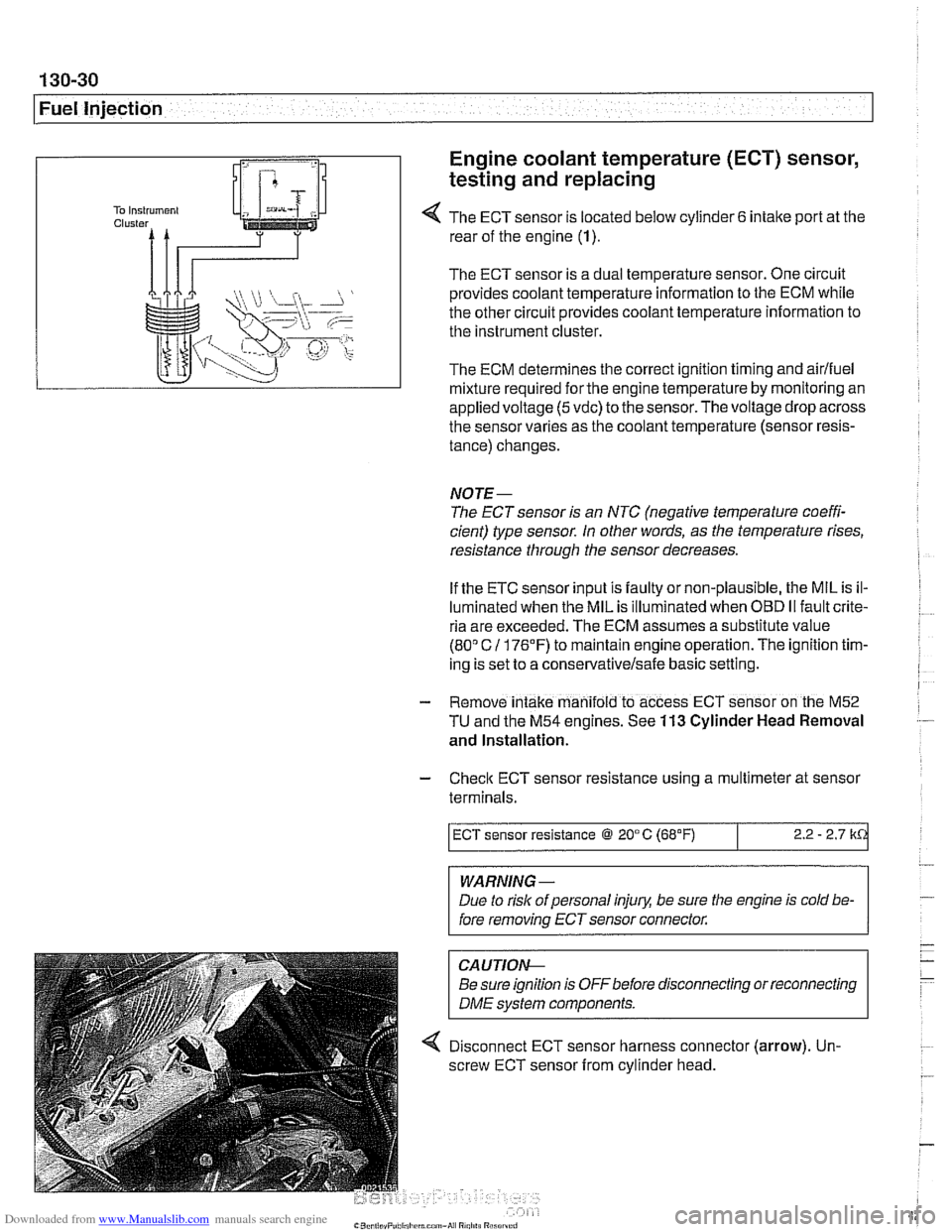

Engine coolant temperature

(ECT) sensor,

testing and replacing

4 The ECT sensor is located below cylinder 6 intake port at the

rear of the engine (1).

The ECT sensor is a dual temperature sensor. One circuit

provides coolant temperature information to the ECM while

the other circuit provides coolant temperature information to

the instrument cluster.

The ECM determines the correct ignition timing and airlfuel

mixture required

forthe engine temperature by monitoring an

appliedvoltage

(5vdc) to the sensor.Thevoltage drop across

the sensor varies as the coolant temperature (sensor resis-

tance) changes.

NOTE-

The ECT sensor is an NTC (negative temperature coeffi-

cient) type sensor. In other words, as the temperature rises,

resistance through the sensor decreases.

If the ETC sensor input is faulty or non-plausible, the MIL is il-

luminated when the MIL is illuminated when

OED II fault crite-

ria are exceeded. The ECM assumes a substitute value

(80" C 11 76'F) to maintain engine operation. The ignition tim-

ing is set to a

conservativelsafe basic setting.

- Remove intake manifold to access ECT sensor on the M52

TU and the M54 engines. See 113 Cylinder Head Removal

and Installation.

- Check ECT sensor resistance using a multimeter at sensor

terminals.

WARNING -

Due to rislc of personal injury, be sure the engine is cold be-

fore removing ECT sensor connector.

ECT sensor resistance @ 20°C (68°F)

CAUTIOI\C

Be sure ignition is OFFbefore disconnecting or reconnecting

DME svstem components.

2.2 - 2.7 k

4 Disconnect ECT sensor harness connector (arrow). Un-

screw ECT sensor from cylinder head.

Page 422 of 1002

Downloaded from www.Manualslib.com manuals search engine

Fuel Injection

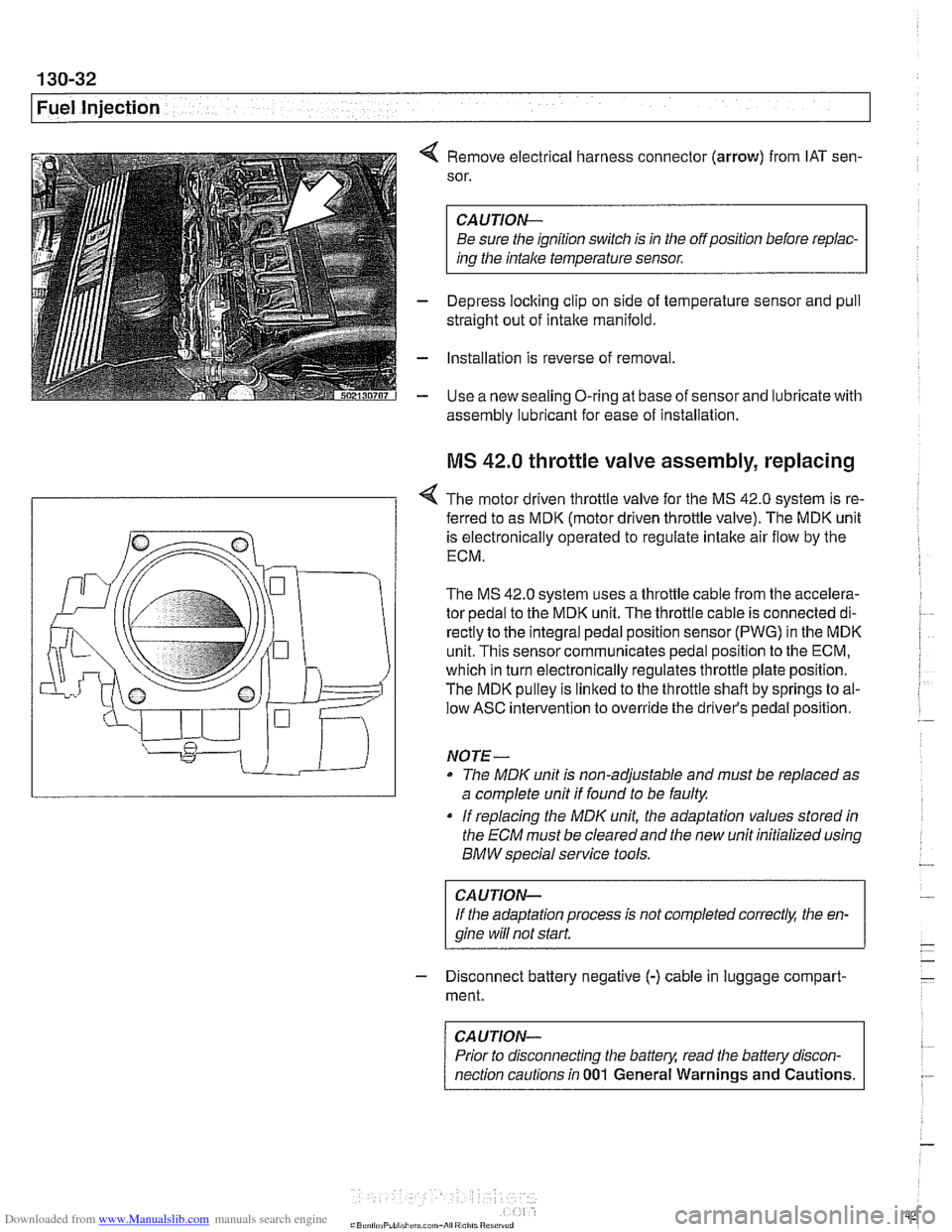

4 Remove electrical harness connector (arrow) from IAT sen-

sor.

CAUTION-

Be sure the ignition switch is in the off position before repiac-

ins the intake temperature sensor.

- Depress loclting clip on side of temperature sensor and pull

straight out of intake manifold.

- Installation is reverse of removal

- Use a new sealing O-ring at base of sensor and lubricate with

assembly lubricant for

ease of installation

MS 42.0 throttle valve assembly, replacing

< The motor driven throttle valve for the MS 42.0 system is re-

- ferred to as MDK (motor driven throttle valve). The MDK unit

is electronically operated to regulate intake air flow by the

ECM.

The

MS 42.0 system uses a throttle cable from the accelera-

tor pedal to the MDK unit. The throttle cable is connected di-

rectly to the integral pedal position sensor

(PWG) in the MDK

unit. This sensor communicates pedal position to the ECM,

which in turn electronically regulates throttle plate position.

The MDK pulley is linked to the throttle shaft by springs to al-

low ASC intervention to override the driver's pedal position.

NO TE -

The MDIC unit is non-adjustable and must be replaced as

a complete unit if found to be faulty.

if replacing the

MDK unit, the adaptation values stored in

the ECM must be clearedand the new unit initialized using

BMW special service tools.

CAUTION-

If the adaptation process is not completed correct& the en-

gine wiii

not start.

- Disconnect battery negative (-) cable in luggage compart-

ment.

CAUTION-

Prior to disconnecting the battern read the battely discon-

nection cautions in

001 General Warnings and Cautions.

Page 425 of 1002

Downloaded from www.Manualslib.com manuals search engine

Fuel Injection

MS 43.0 throttle valve assembly, replacing

The electronic throttle valve assembly forthe MS43.0 system

is referred to as

EDK (electronic throttle valve). There is no

mechanical (cable) link between the accelerator pedal and

the throttle plate.

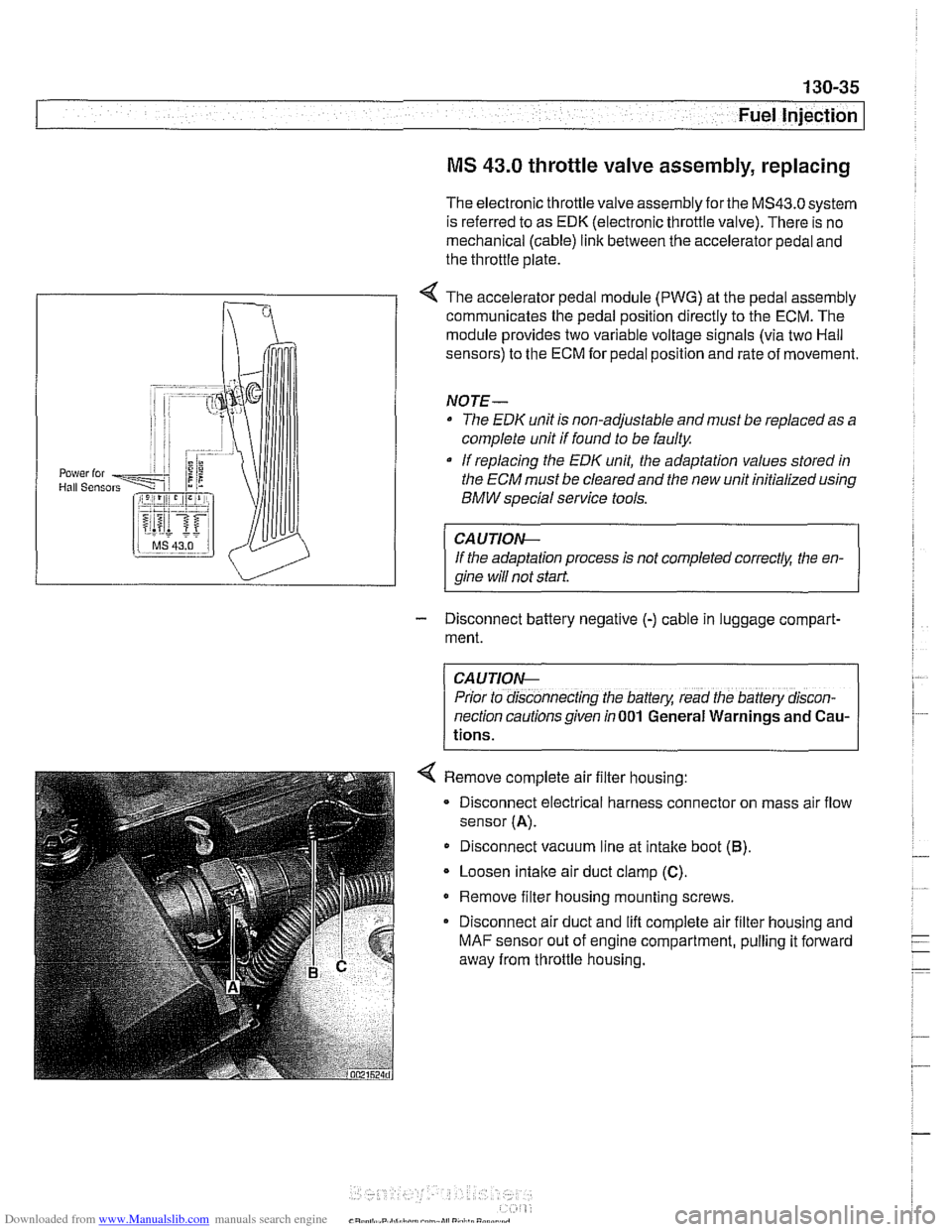

< The accelerator pedal module (PWG) at the pedal assembly

communicates the pedal position directly to the ECM. The

module provides two variable voltage signals (via two Hail

sensors) to the ECM for pedal position and rate of movement.

NOTE-

The EDK unit is non-adjustable and must be replaced as a

complete unit if found to be faulty

If replacing the

EDK unit, the adaptation values stored in

the

ECM must be cleared and the new unit initialized using

BMW special service tools.

CAUTIOIG

If the adaptation process is not completed correctk the en-

qine will not start

- Disconnect battery negative (-) cable in luggage compart-

ment.

CAUTION-

Prior to disconnecting the battery, read the battery discon-

nection cautions given in

001 General Warnings and Cau-

tions.

< Remove complete air filter housing:

- Disconnect electrical harness connector on mass air flow

sensor

(A).

Disconnect vacuum line at intake boot (6).

Loosen intaite air duct clamp (C).

Remove filter housing mounting screws.

Disconnect air duct and lift complete air filter housing and

MAF sensor out of engine compartment, pulling it forward

away from throttle housing.

Page 430 of 1002

Downloaded from www.Manualslib.com manuals search engine

130-40

Fuel Injection

Engine control module (ECM),

removing and installing

The ECM uses stored functions and processing programs to

process the input signals from the sensors. These input sig-

nals are used to calculate the control (output) signals to the

actuators

(e.g., ignition coils, injectors).

NOTE-

Consult an authorized BMW dealer before replacing the

ECM.

- Disconnect negative (-) battery cable. Wait approximately

one minute.

CAUTION-

Prior to disconnecting the batteg read the battery discon-

nection cautions

in 001 General Warnings and Cautions.

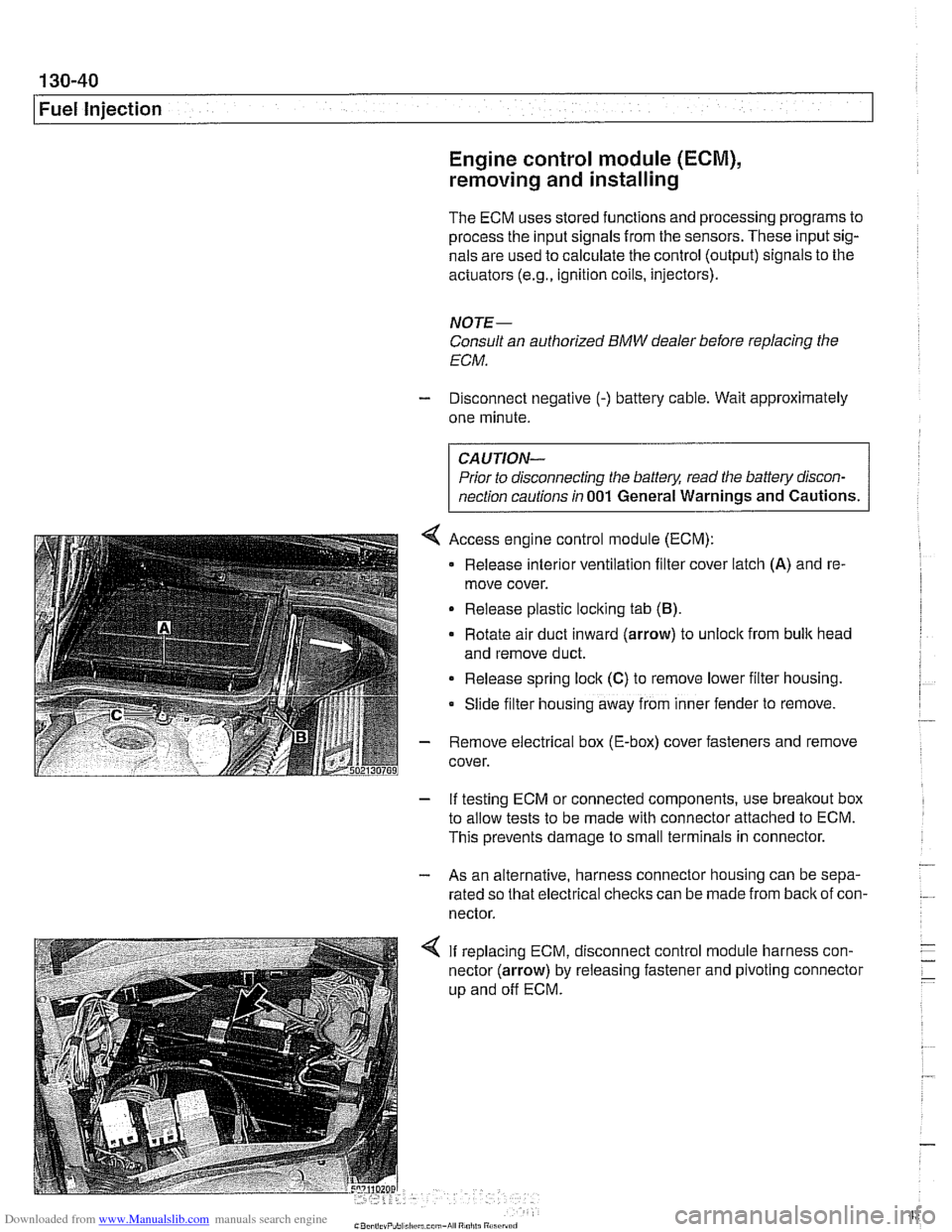

4 Access engine control module (ECM):

Release

interlor ventilation filter cover latch (A) and re-

move cover.

Release plastic loclting tab

(B).

Rotate air duct inward (arrow) to unloclt from bulk head

and remove duct.

Release spring lock

(C) to remove lower filter housing.

Slide

f~lter hous~ng away from inner fender to remove.

- Remove electrical box (E-box) cover fasteners and remove

cover.

- If testing ECM or connected components, use breakout box

to allow tests to be made with connector attached to ECM.

This prevents damage to small terminals in connector.

- - As an alternative, harness connector housing can be sepa-

rated so that electrical checks can be made from

back of con-

nector.

4 If replacing ECM, disconnect control module harness con-

nector (arrow) by releasing fastener and pivoting connector

up and off ECM.