Tightening torque BMW 528i 1997 E39 Workshop Manual

[x] Cancel search | Manufacturer: BMW, Model Year: 1997, Model line: 528i, Model: BMW 528i 1997 E39Pages: 1002

Page 8 of 1002

Downloaded from www.Manualslib.com manuals search engine

I General Warnings and Cautions

WARNINGS (continued)

. The air conditioning system is filled with chemical refrigerant,

which is hazardous. The AIC system should be serviced only by

trained technicians using approved refrigerant recoverylrecycling

equipment, trained in related safety precautions, and familiar with

regulations governing the discharging and disposal of automotive

chemical refrigerants.

. Do not expose any part of the AIC system to high temperatures

such as open flame. Excessive heat will increase system pres-

sure and may cause the system to burst.

Some aerosol tire inflators are highly flammable. Be extremely

cautious when repairing a tire that may have been inflated using

an aerosol tire inflator. Keep sparks, open flame or other sources

of ignition away

from the tire repair area. Inflate and deflate the

tire at least four

times before breaking the bead from the rim.

Completely remove the tire from the rim before attempting any re-

pair.

Cars covered by this manual are equipped with a supplemental

restraint system (SRS), that automatically deploys

airbags and

pyrotechnic seat belt tensioners

In the event oi a frontal or side

impact. These are explosive devices. Handled improperly or with-

out adequate safeguards, they can be accidently activated and

cause serious injury.

- The ignition system produces high voltages that can be fatal.

Avoid contact with exposed terminals and use extreme care when

working on a car with the engine running or the ignition switched

on.

. Place jack stands only at locations specified by the manufacturer.

The vehicle

illtino iack su~olied with the vehicle is intended fortire -. , . changes only. A heavy duty floor jack should be used lo lift vehicle

before installing

jacl( stands. See 010 General.

- Battery acid (electrolyte) can cause severe burns. Flush contact

area

with water, seek medical attention.

Aerosol cleaners and solvents may contain hazardous or deadly

vapors and are highly flammable. Use only in a well ventilated ar-

ea. Do not use on hot surfaces (engines, brakes, etc.).

Do not remove

coolant reservoir or radiator cap with the engine

hot. Danger of burns and engine damage.

CAUTIONS-

See also WARNINGS

- if you lack the slqills, tools and equipment, or a suitable worl(shop

for any procedure described in this manual, leave such repairs to

an authorized BMW dealer or other qualified shop.

BMW is constantly improving its cars and sometimes these

changes, both in parts and specifications, are made applicable to

earlier models. Therefore, part numbers listed in this manual are

for reference only. Always check with your authorized BMW deal-

er parts department for the latest information.

Before starting a job, make certain that you have all the neces-

sary tools and parts on hand. Read ail the instructions thorough-

ly, and do not attempt shortcuts. Use tools appropriate to the

work and use only replacement parts meeting BMW specifica-

tions.

Use pneumatic and electric tools only to loosen threaded parts

and fasteners. Never use these tools to tighten fasteners, espe-

cially on light alloy parts. Always use a torque wrench to tighten

fasteners to the tightening torque specification listed.

Be mindful of the environment and ecology. Before you drain the

crankcase, find out the proper way to dispose of the

oil. Do not

pour

oil onto the ground, down a drain, or into a stream, pond or

lake. Dispose of waste in accordance with Federal, State and

Local laws.

The control module for the anti-lock brake system

(ABS) cannot

withstand temperatures from a paint-drying booth or a heat

lamp

in excess of 203" F (95°C) and should not be subjected to tem-

peratures in excess of 185°F

(8S°C) for more than two hours.

- Before doing any electrical welding on cars equipped with ABS,

disconnect the battery negative

(-) terminal (ground strap) and

the ABS control module connector.

- Always make sure ignition is off before disconnecting battery.

Label battery cables before disconnecting. On some models, bat-

tery cables are not color coded.

Disconnecting the battery may erase fault code@) stored in control

module memory. Using special BMW diagnoslic equipment, check

lor

iauit codes prior to disconnecting the battery cables. If the mal-

I.mct on ndicator Ignt (MIL) s I. ..minaled. see OBD On-Board

Diaanostics

Tl11s iant is iuenlfted as lne Check Ena~ne oht

(1997-2000 models jor~ervlce Engine Soon light (2061 andlater

models). If any other system iaults have been detected (indicated

by an illuminated warning light), see an authorized BMW dealer.

If a normal

or rapid charger is used to charge battery, the battery

must be disconnected and removed from the vehicle in order to

avoid damaging the vehicle.

- Do not quick-charge the battery (for boost starting) for longer

than one minute. Wait at least one minute before boosting the

battery a second time.

* Connect and disconnect a battery charger only with the battery

charger switched off.

- Sealed or "maintenance free" batteries should be slow-charged

only, at an amperage rate that is approximately 10% of the bat-

tery's ampere-hour (Ah)

rating.

. Do not allow battery charging voltage to exceed 16.5 volts. If the

battery begins producing gas or boiling violently, reduce the

charging rate.

Boosting a sulfated battery at a high charging rate

can cause an explosion.

Page 11 of 1002

Downloaded from www.Manualslib.com manuals search engine

01 0-1

010 General

General ........................... .01 0.2

How to Use this Manual ............ .01 0.2

Warnings. cautions and notes ........... .0l 0.3

Getting Started .................... .0i 0.5

Safety ............................. .O1 0.5

Lifting the car ........................ .O1 0.5

Raising car ......................... .O1 0.5

Working under car .................... .O1 0.6

Advice for the Beginner ............ .O1 0.7

Planning ahead ...................... .O1 0.7

Workshop practices ................... .O1 0.7

Non-reusable fasteners ................ .O1 0.7

Tightening fasteners .................. .O1 0.8

Gaskets and seals .................... .O1 0.9

Electrical testing .................... .O1 0.10

Wire repairs ........................ .O1 0.10

Buying Parts ..................... .01 0.11

Genuine BMW parts ................. .O1 0.11

Non-returnable parts ................. .O1 0.11

Information you need to know .......... .0l 0.12

Service ........................... 01 0-1 3

TOOIS ............................. 010-13

Basic tool requirements ............... 01 0-1 4

Jack stands ......................... 01 0-1 6

Oil change equipment ................. 01 0-1 6

Torque wrench ...................... 01 0-17

Digital multimeter .................... 010-17

BMW special tools ................... 01 0-1 8

Emergencies ...................... 01 0-1 8

Changing a tire ...................... 01 0-1 8

Jump starting ....................... 01 0-1 9

Indicator and warning lights ............ 01 0-1 9

Towing ............................ 010-20

Spare parts kit ...................... 010-21

Page 18 of 1002

Downloaded from www.Manualslib.com manuals search engine

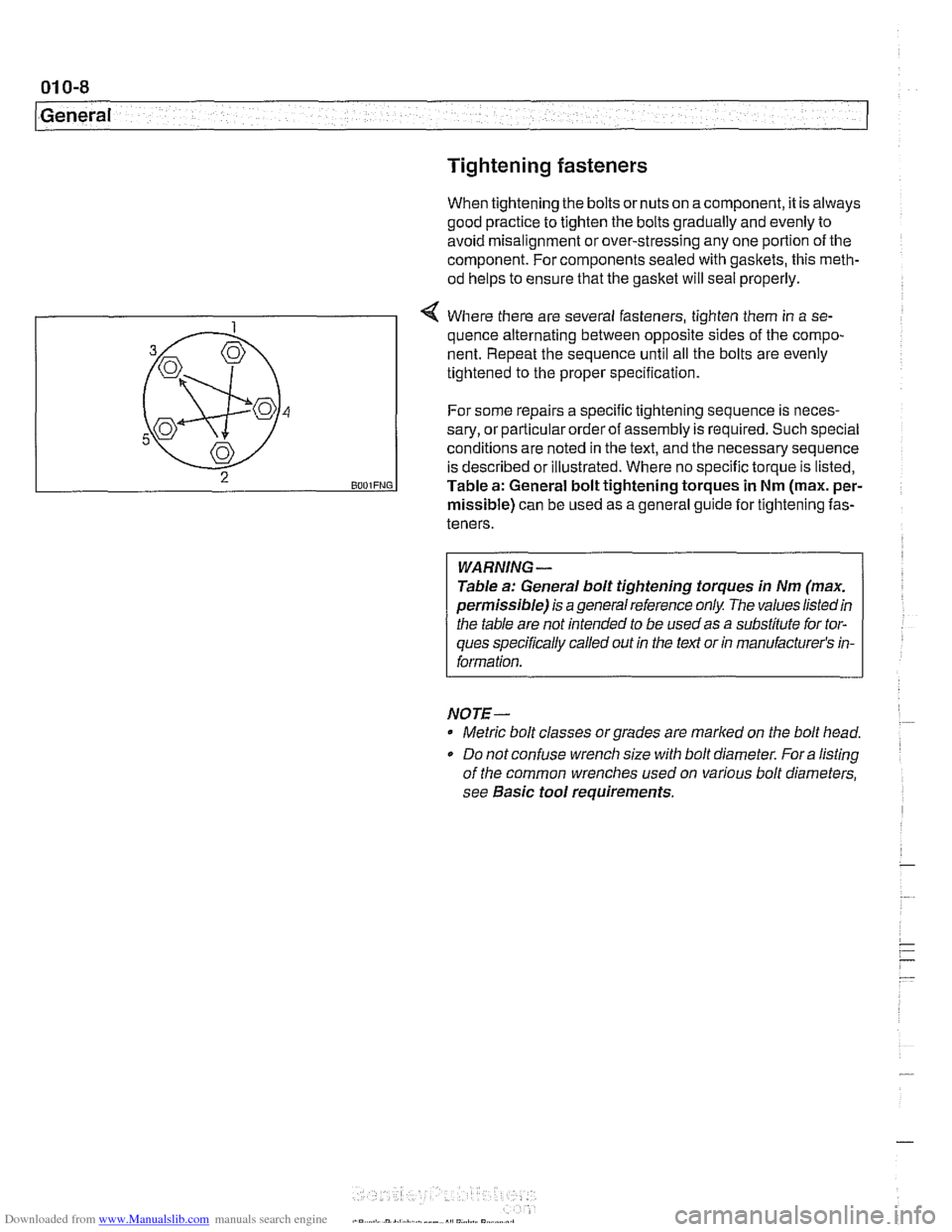

General Tightening fasteners

When tightening the bolts ornuts on acomponent, it is always

good practice to tighten the bolts gradually and evenly to

avoid misalignment or over-stressing any one portion of the

component. For components sealed with gaskets, this meth-

od helps to ensure that the

gasket will seal properly.

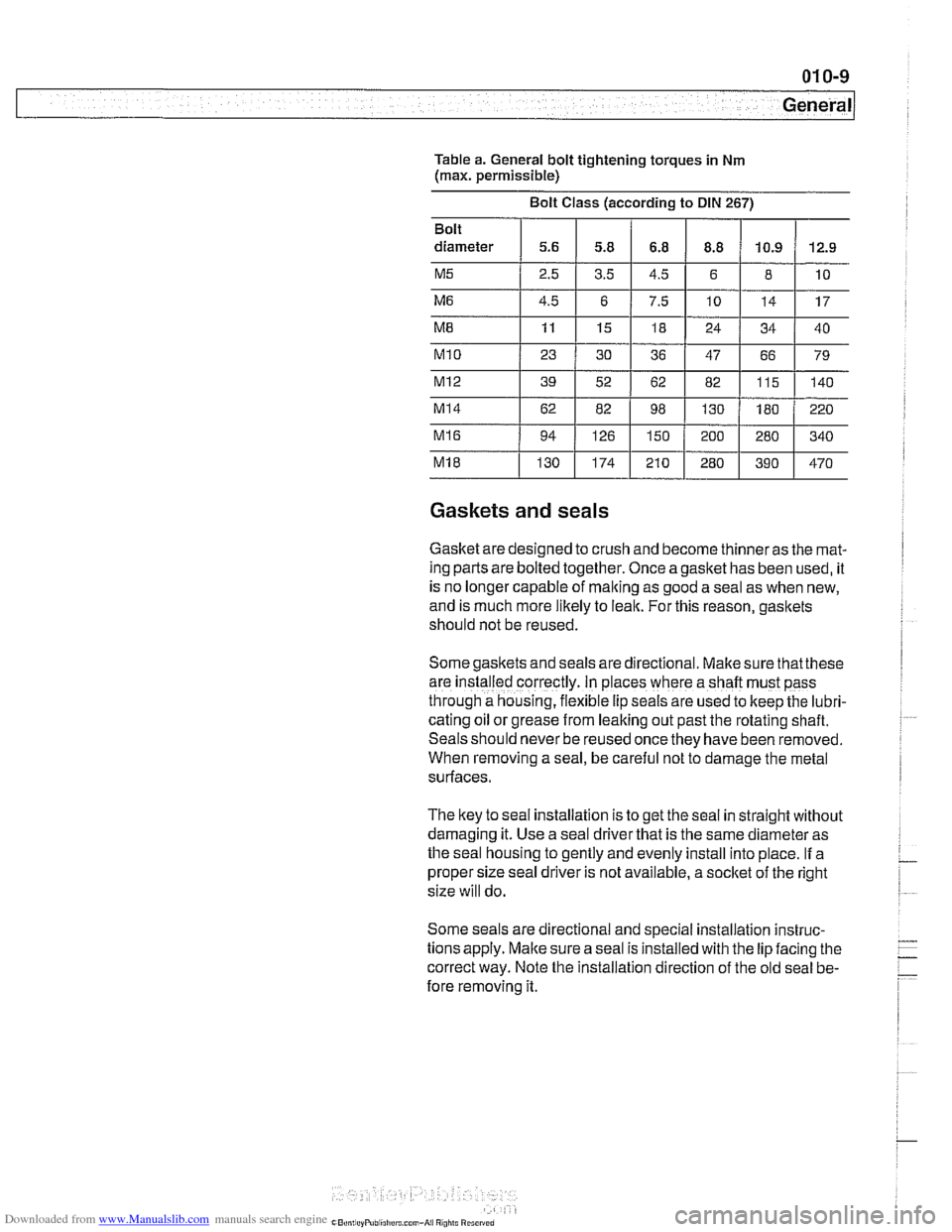

WARNING

-

Table a: General bolt tightening torques in Nm (max.

permissible) is

a general reference only The values listedin

the table are not intended to be usedas a substitute for tor-

ques specifically called out in the text or in manufacturer's in-

formation.

4 Where there are several fasteners, tighten them in a se-

NOTE-

* Metric bolt classes or grades are rnarlced on the bolt head.

* Do not confuse wrench size with bolt diameter. Fora listing

of the common wrenches used on various bolt

diameters,

see Basic tool requirements.

2 BOO~FNG

quence alternating between opposite sides of the compo-

nent. Repeat the sequence until all the bolts are evenly

tightened to the proper specification.

For some repairs a specific tightening sequence is

neces-

sary, or particular order of assembly is required. Such special

conditions are noted in the text, and the necessary sequence

is described or illustrated. Where no specific torque is listed,

Table

a: General bolt tightening torques in Nm (max. per-

missible) can be used as a general guide for tightening fas-

teners.

Page 19 of 1002

Downloaded from www.Manualslib.com manuals search engine

General

Table a. General bolt tightening torques in Nm

(max. permissible)

Bolt Class (according to DIN

267)

Gaskets and seals

Gasket aredesigned to crush and become thinner as the mat-

ing parts are bolted together. Once agasket has been used, it

is no longer capable

;f malting as good a seal as when new,

and is much more likely to leak.

Forthis reason, gaskets

should not be reused.

Some gaskets and seals are

d~rectional. Make sure thatthese

are

~nstalled correctly. In places where a shaft must pass

through a housing,

flex~ble lip seals are used to keep the lubri-

cating

011 or grease from leaking out past the rotatlng shaft.

Seals should never be reused once they have been removed.

When

rernovlng a seal, be careful not to damage the metal

surfaces.

The ltey to seal installation is to get the seal in straight without

damaging it. Use a seal driver that is the same diameter as

the seal housing to gently and evenly install into place.

If a

proper size seal driver is not available, a socket of the right

size will do.

Some seals are directional and special installation instruc-

tions apply. Make sure a seal is installed with the lip facing the

correct way. Note the installation direction of the old seal be-

fore removing it.

Page 29 of 1002

Downloaded from www.Manualslib.com manuals search engine

General

Cars with discharged or dead batteries can be jump-started

using the good battery from another car. See owner's manual

for proper instruction on jump starting. When jump-starling

the engine, always note the following warnings.

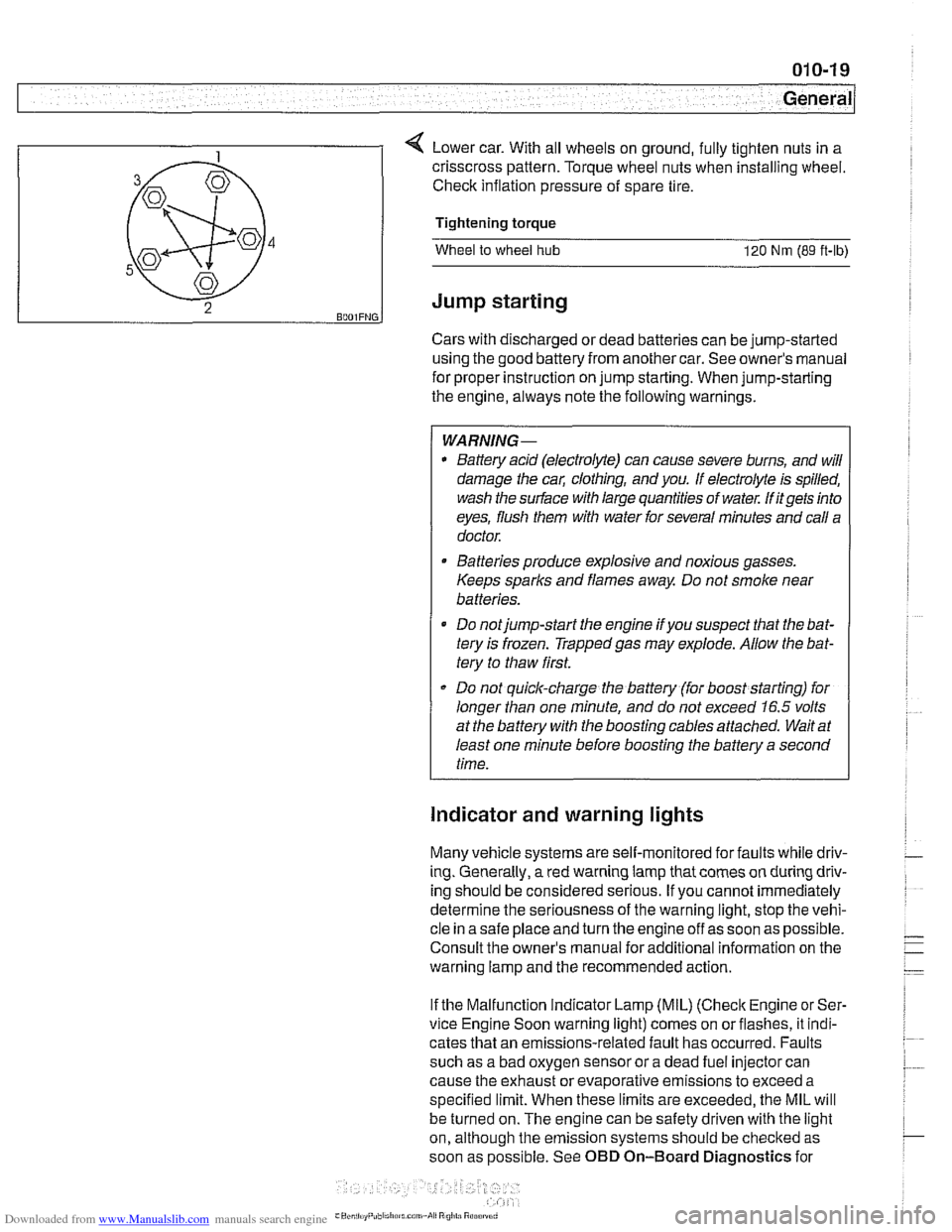

4 Lower car. With all wheels on ground, fully tighten nuts in a

WARNING-

* Battery acid (electrolyte) can cause severe burns, and will

damage the

cal; clothing, and you. If electrolyte is spilled,

wash the surface with large quantities of water.

M itgets into

eyes, flush them with water for several minutes and call a

doctor.

B4

5

43

2 BOOIFNG.

Batteries produce explosive and noxious gasses.

Keeps sparks and flames away. Do not smoke near

batteries.

Do notjump-start the engine

ifyou suspect that the bat-

tery is frozen. Trappedgas may explode. Allow the bat-

tery to thaw first.

Do not quick-charge the battery (for boost starting) for

longer than one minute, and do not exceed

16.5 volts

at the battery with the boosting cables attached. Wait at

least one minute before boosting the battery a second

time.

crisscross pattern.

Torque wheel nuts when installing wheel.

Check inflation pressure of spare tire.

Tightening torque

Wheel to wheel hub 120 Nm (89 ft-ib)

Jump starting

Indicator and warning lights

Many vehicle systems are self-monitored for faults while driv-

ing. Generally,

a red warning lamp that comes on during driv-

ing should be considered serious. If you cannot immediately

determine the seriousness of the warning light, stop the vehi-

cle in a safe place and turn the engine off as soon as possible.

Consult the owner's manual for additional information on the

warning lamp and the recommended action.

If the Malfunction Indicator Lamp (MIL)

(Check Engine or Ser-

vice Engine Soon warning light) comes on orflashes, it indi-

cates that an emissions-related fault has occurred. Faults

such as a bad oxygen sensor or a dead fuel injector can

cause the exhaust or evaporative emissions to exceed a

specified limit. When these limits are exceeded, the MIL will

be turned on. The engine can be safety driven with the light

on, although the emission systems should be

checked as

soon as possible. See OBD On-Board Diagnostics for

Page 46 of 1002

Downloaded from www.Manualslib.com manuals search engine

020-1 4

Maintenance

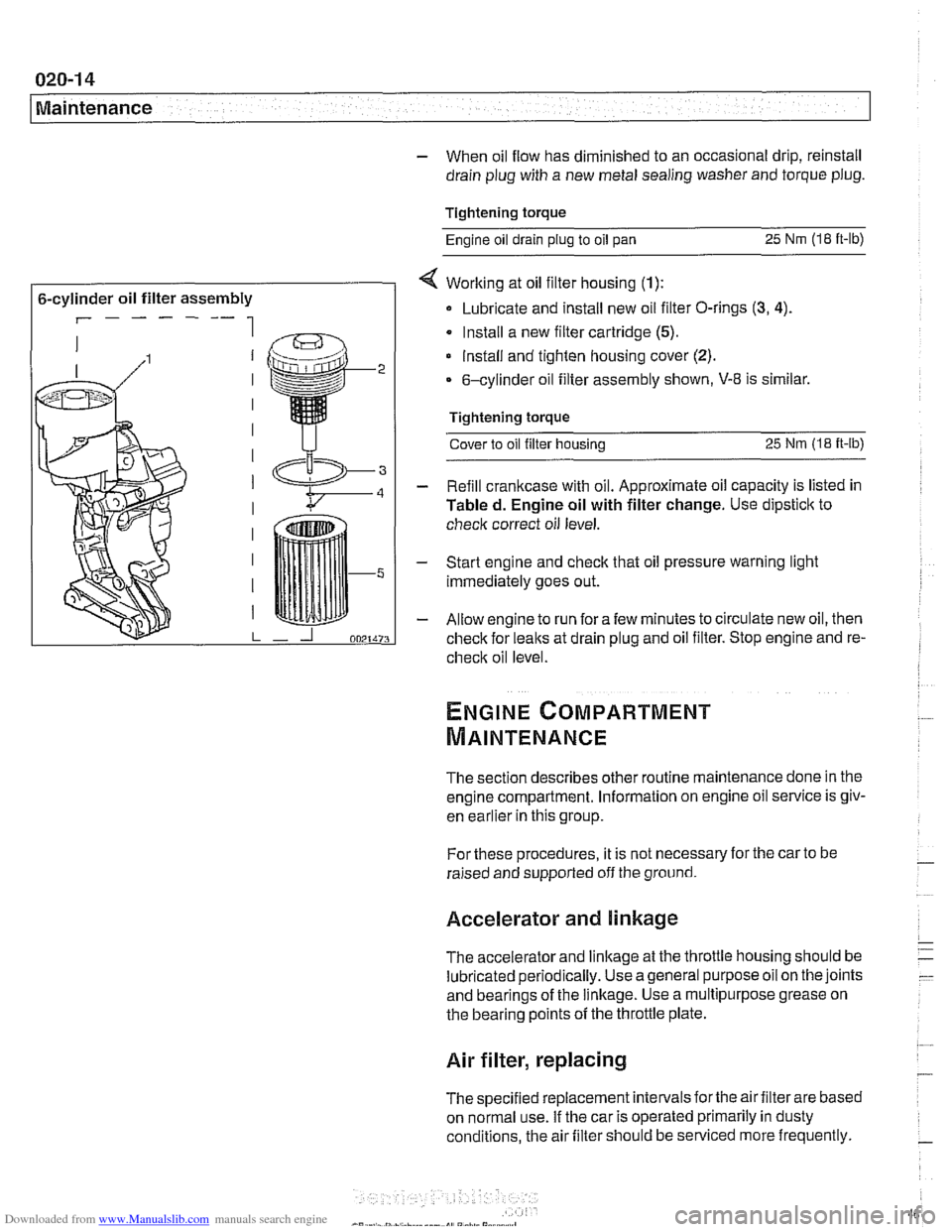

- When oil flow has diminished to an occasional drip, reinstall

drain plug with a new metal sealing washer and torque plug.

Tightening torque Engine oil drain plug to oil pan

25 Nrn (1.8 ft-lb)

6-cylinder oil filter assembly

r------ 1

< Working at oil filter housing (1):

Lubricate and install new oil filter O-rings (3, 4).

Install a new filter cartridge (5).

lnstall and tighten housing cover (2).

6-cylinder oil filter assembly shown, V-8 is similar.

Tightening torque Cover to oil filter housing

25 Nm (1.8 it-lb)

- Refill crankcase with oil. Approximate oil capacity is listed in

Tabled. Engine oil with filter change. Use dipstick to

check correct oil level.

- Start engine and check that oil pressure warning light

immediately goes out.

- Allow engine to run fora few minutes to circulate new oil, then

check for leaks at drain plug and oil filter. Stop engine and re-

check oil level

The section describes other routine maintenance done in the

engine compartment. Information on engine oil service is

giv-

enkar~ier inthis group.

For these procedures, it is not necessary for the car to be

raised and supported off the ground.

Accelerator and linkage

The accelerator and linkage at the throttle housing should be

lubricated periodically. Use ageneral purposeoil on the joints

and bearings of the linkage. Use a multipurpose grease on

the bearing points of the throttle plate.

Air filter, replacing

The specified replacement intervals forthe air filter are based

on normal use. If the car is operated primarily in dusty

conditions, the air filter should be serviced more frequently.

Page 51 of 1002

Downloaded from www.Manualslib.com manuals search engine

Maintenance

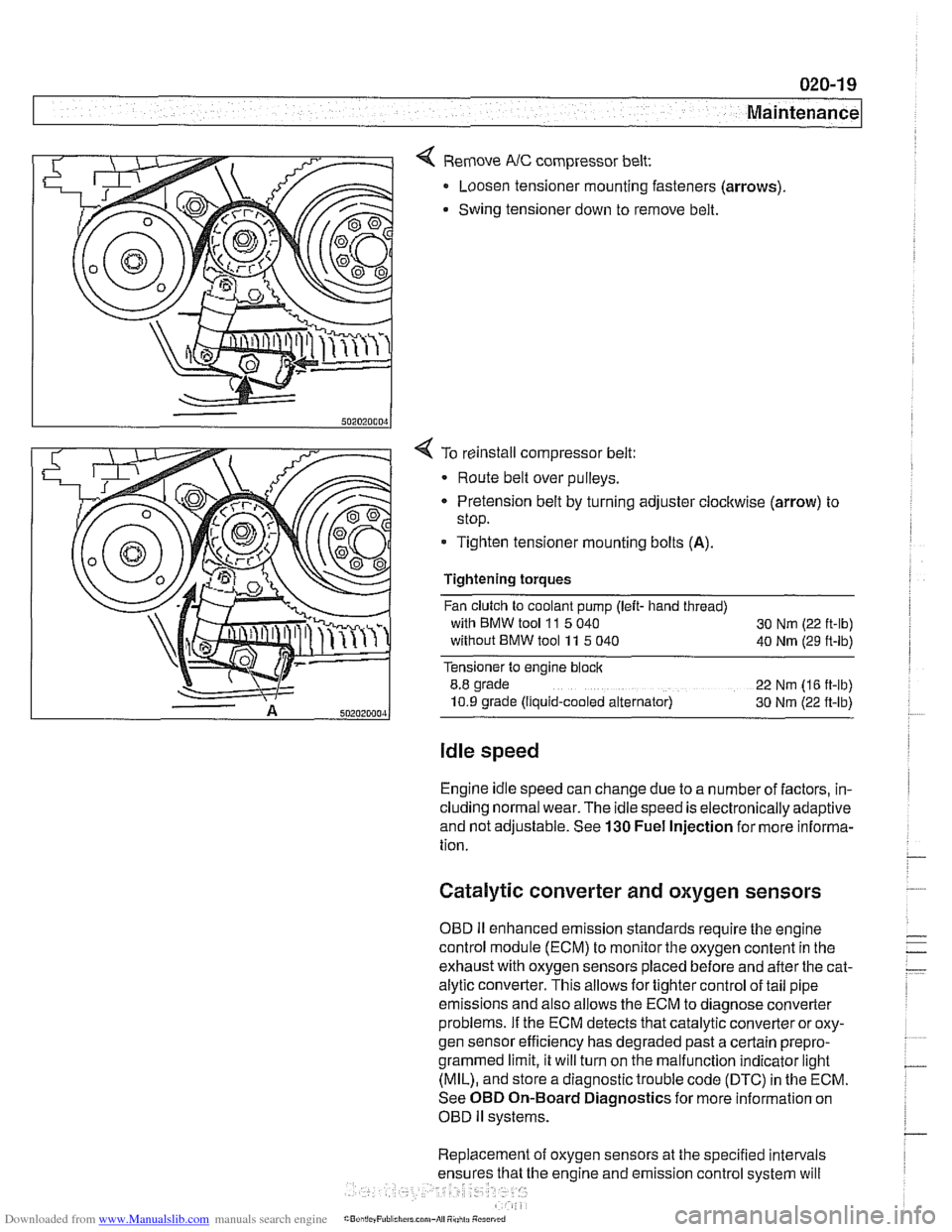

< Remove NC compressor belt:

Loosen tensioner mounting fasteners (arrows)

Swing tensioner down to remove belt.

4 To reinstall compressor belt:

Route belt over pulleys.

* Pretension belt by turning adjuster clockwise (arrow) to

stop.

- Tighten tensioner mounting bolts (A).

Tightening torques

Fan clutch to coolant pump (left- hand thread)

with BMW tool

11 5 040

30 Nm (22 ft-lb)

without BMW tool 11 5 040

40 Nm (29 ft-lb)

Tensioner to engine block

8.8 grade

22 Nm (16 ft-lb)

10.9 grade (Ilquid-cooled alternator) 30 Nm (22 ft-lb)

Idle speed

Engine idle speed can change due to a number of factors, in-

cluding normal wear. The idle speed is electronically adaptive

and not adjustable. See

130 Fuel Injection for more informa-

tion.

Catalytic converter and oxygen sensors

OBD II enhanced emission standards require the engine

control module (ECM) to monitor the oxygen content in the

exhaust with oxygen sensors placed before and after the cat-

alytic converter. This allows for tighter control of tail pipe

emissions and also allows the ECM to diagnose converter

problems. If the ECM detects that catalytic converter or oxy-

gen sensor efficiency has degraded past a certain

prepro-

grammed limit, it will turn on the malfunction indicator light

(MIL), and store a diagnostic trouble code (DTC) in the ECM.

See OBD On-Board Diagnostics for more information on

OBD

ll systems.

Replacement of oxygen sensors at the specified intervals

he engine and emission control system will

Page 52 of 1002

Downloaded from www.Manualslib.com manuals search engine

Maintenance

continue to operate as designed. Extending the replacement

interval may void the emission control warranty coverage.

See

180 Exhaust System for information on replacing the

oxygen sensors.

Tightening torque

Oxvoen sensor to exhaust

manifold 50 Nrn (37 ft-lb)

NOTE-

A special soclet for replacing the oxygen sensor is available

from most automotive parts stores. The soclet has

a groove

cut down one side to allow the sensor to be installed without

damaging the wire harness.

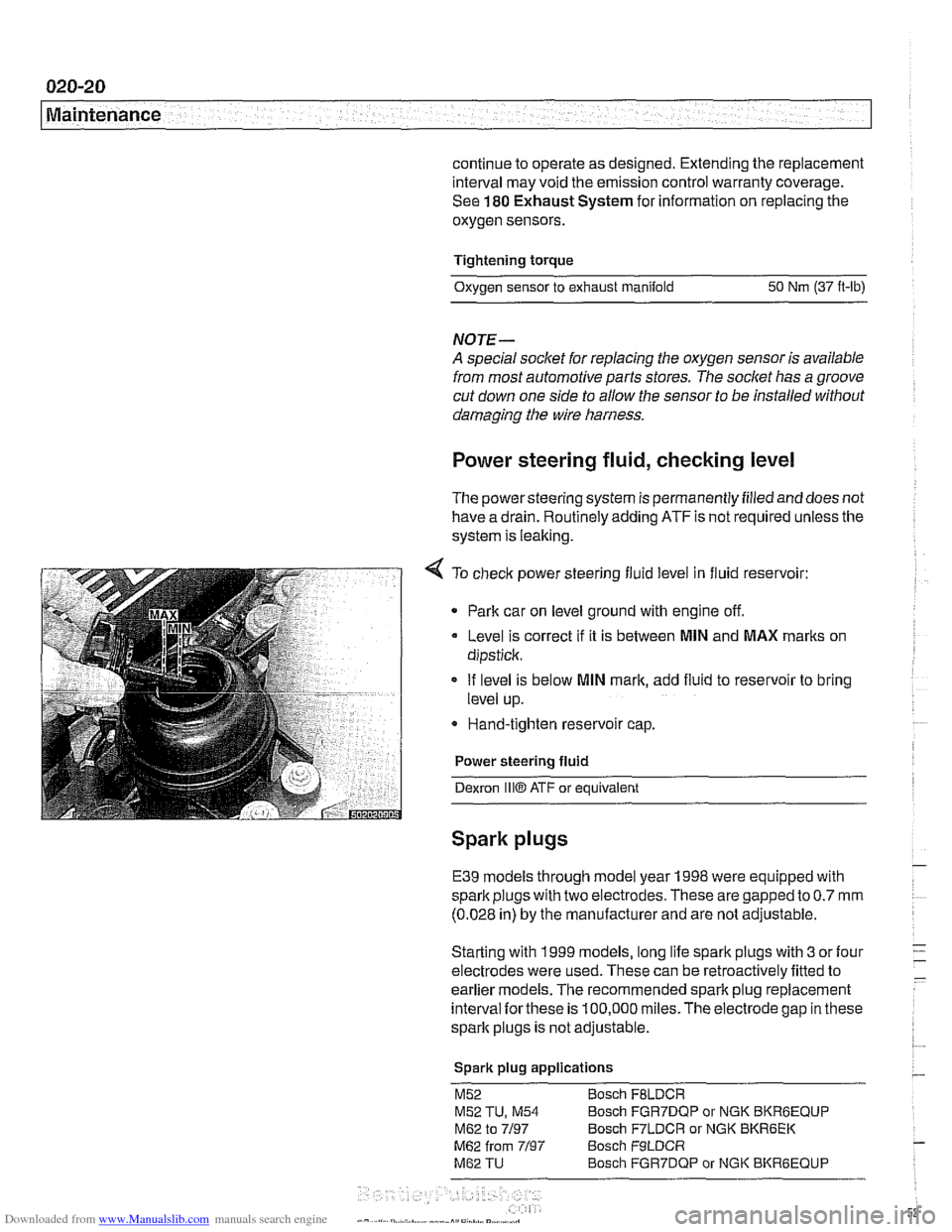

Power steering fluid, checking level

The power steering system is permanently filled and does not

have a drain. Routinely adding ATF is not required unless the

system is leaking.

4 To check power steering fluid level in fluid reservoir:

Park car on level ground with engine off.

Level is correct

if it is between MlN and MAX marks on

dipstick.

If level is below

MlN mark, add fluid to reservoir to bring

level up.

* Hand-tighten reservoir cap.

Power steering fluid

Dexron

1iiO ATF or equivalent

Spark plugs

E39 models through model year 1998 were equipped with

spark plugs with two electrodes. These are gapped to

0.7 mm

(0.028 in) by the manufacturer and are not adjustable.

Starting with 1999 models, long life spark plugs with

3 or four

electrodes were used. These can be retroactively fitted to

earlier

models. The recommended spark plug replacement

interval

forthese is 100,000 miles.The electrode gap in these

spark plugs is not adjustable.

Spark plug applications

M52 Bosch FBLDCR

M52 TU, M54 Bosch FGR7DQP or NGK BKRBEQUP

M62 to 7/97 Bosch F7LDCR or NGK BKR6EK

M62 from 7/97 Bosch F9LDCR

M62 TU Bosch FGR7DQP or NGK BKRGEQUP

Page 54 of 1002

Downloaded from www.Manualslib.com manuals search engine

020-22 Maintenance

1

- Installation is reverse of removal, bearing in mind the

following:

Lightly lubricate new

spark plug threads with

copper-based anti-seize compound.

Thread plugs into cylinder head by hand to prevent

cross-threading.

. Be sure to reinstall and tighten coil grounds.

Tightening torque Spark plug

to cylinder head 25 Nm (18 It-lb)

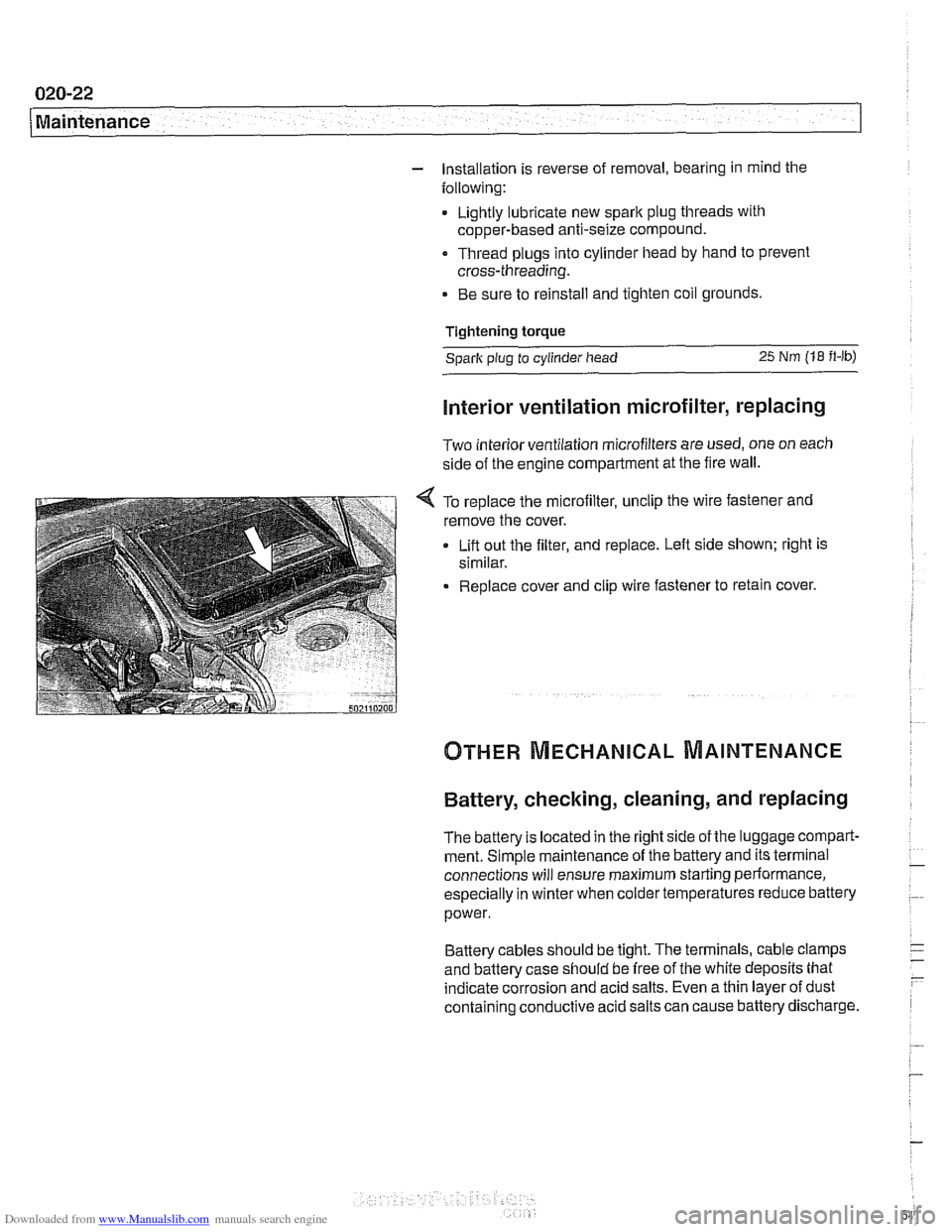

Interior ventilation microfilter, replacing

Two interior ventilation microfilters are used, one on each

side of the engine compartment at the fire wall.

< To replace the microfilter, unclip the wire fastener and

remove the cover.

Lift out the filter, and replace. Left side shown; right is

similar.

Replace cover and clip wire fastener to retain cover.

Battery, checking, cleaning, and replacing

The battery Is located in the right side of the luggage compart-

ment. Simple maintenance of the battery and its terminal

connections will ensure maximum starting periormance,

especially in winter when colder temperatures reduce battery

power.

Battery cables should be tight. The terminals, cable clamps

and battery case should be free of the white deposits that

indicate corrosion and acid salts. Even a thin layer of dust

containing conductive acid salts can cause battery discharge.

Page 58 of 1002

Downloaded from www.Manualslib.com manuals search engine

020-26

Maintenance

NOTE-

The parking brake may lose some of its effectiveness if it is

not used frequently This is due to corrosion build-up on the

parking brake drum. To remove corrosion, apply the parking

brake just until it begins to grip, then pull the lever up one

more stop (click). Drive the car approximately 400 meters

(1,300

ft.) and release the brake. To recheck the adjustment

of the parking brake see

340 Brakes.

Clutch fluid, checking

In cars equipped with manual transmission and clutch, the hy-

draulic clutch and the brake system share the same reservoir

and the same bralte fluid. Clutch fluid level and brake fluid lev-

el are checked at the same time.

NOTE-

* See 340 Brakes for more information.

See

210 Clutch for information on the clutch and the

hydraulic clutch operating system.

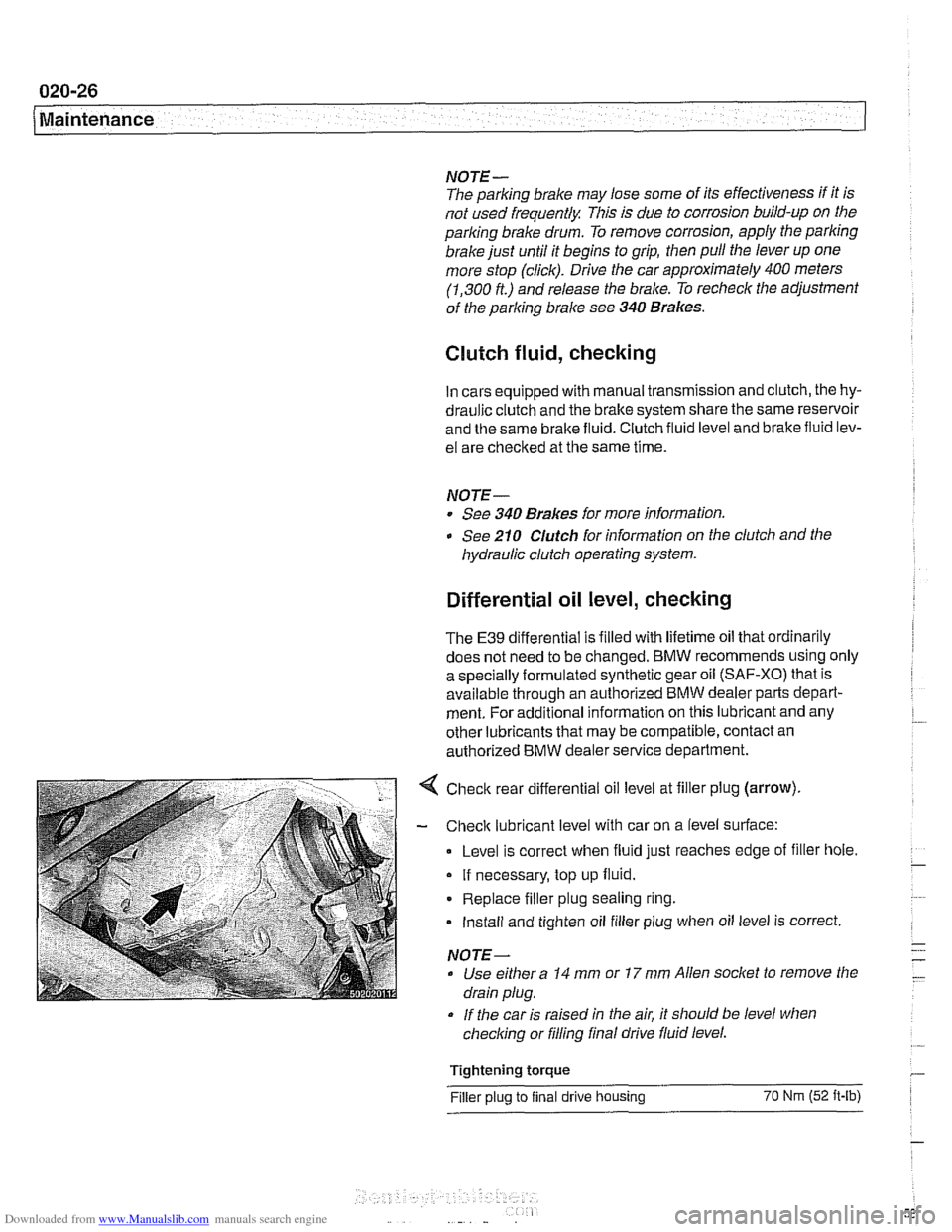

Differential oil level, checking

The E39 differential is filled with lifetime oil that ordinarily

does not need to be changed.

BMW recommends using only

a specially formulated synthetic gear oil

(SAF-XO) that is

available through an authorized

BM\N dealer parts depart-

ment. For additional information on this lubricant and any

other lubricants that may be compatible, contact an

authorized

BMW dealer service department.

< Check rear differential oil level at filler plug (arrow).

- Check lubricant level with car on a level surface:

Level is correct when fluid just reaches edge of filler hole.

If necessary, top up fluid.

Replace filler plug sealing ring.

Install and tighten oil filler plug when oil level is correct.

NOTE-

Use either a 14 mm or 17 mm Allen socket to remove the

drain plug.

If the car is raised in the air, it should be level when

checking or filling final drive fluid level.

Tightening torque

Filler plug to final drive housing 70 Nrn (52 it-lb)