fuse diagram BMW 528i 1997 E39 Workshop Manual

[x] Cancel search | Manufacturer: BMW, Model Year: 1997, Model line: 528i, Model: BMW 528i 1997 E39Pages: 1002

Page 397 of 1002

Downloaded from www.Manualslib.com manuals search engine

Fuel Injection 1

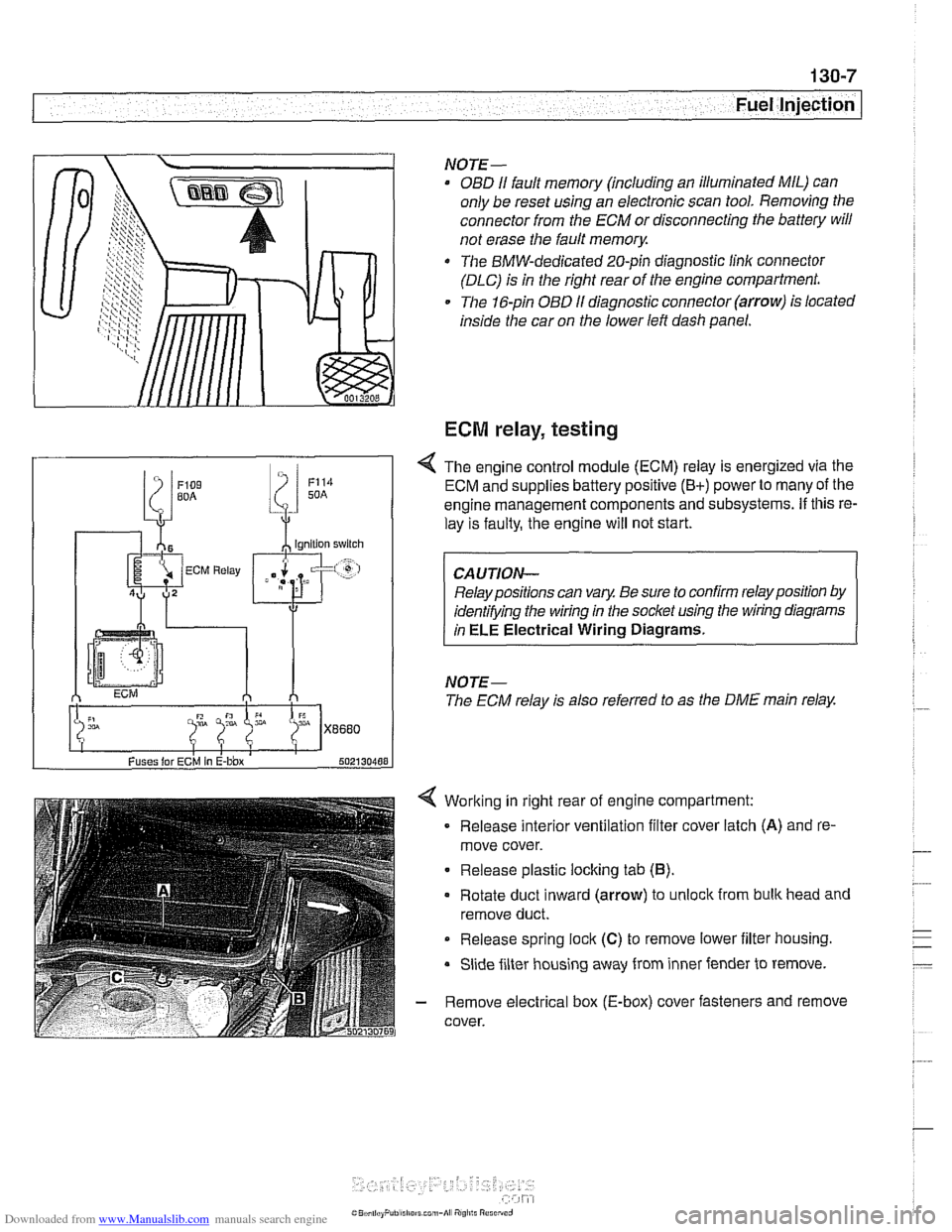

Working in right rear of engine compartment:

Release interior ventilation filter cover latch

(A) and re-

move cover.

Release plastic locking tab

(6).

Rotate duct inward (arrow) to unlock from bulk head and

remove duct.

Release spring

lock (C) to remove lower iilter housing.

Slide filter housing away from inner fender to remove.

- Remove electrical box (E-box) cover fasteners and remove

cover.

NOTE-

OBD I1 fault memory (including an illuminated MIL) can

only be reset using an electronic scan tool. Removing the

connector from the ECM or disconnecting the battery will

not erase the fault

memory.

The BMW-dedicated 20-pin diagnostic linlc connector

(DLC) is in the right rear of the engine compartment.

The 16-pin OBD

I1 diagnostic connector (arrow) is located

inside the car on the lower left dash panel.

ECM relay, testing

Fuses lor ECM In E-bbx 502130488

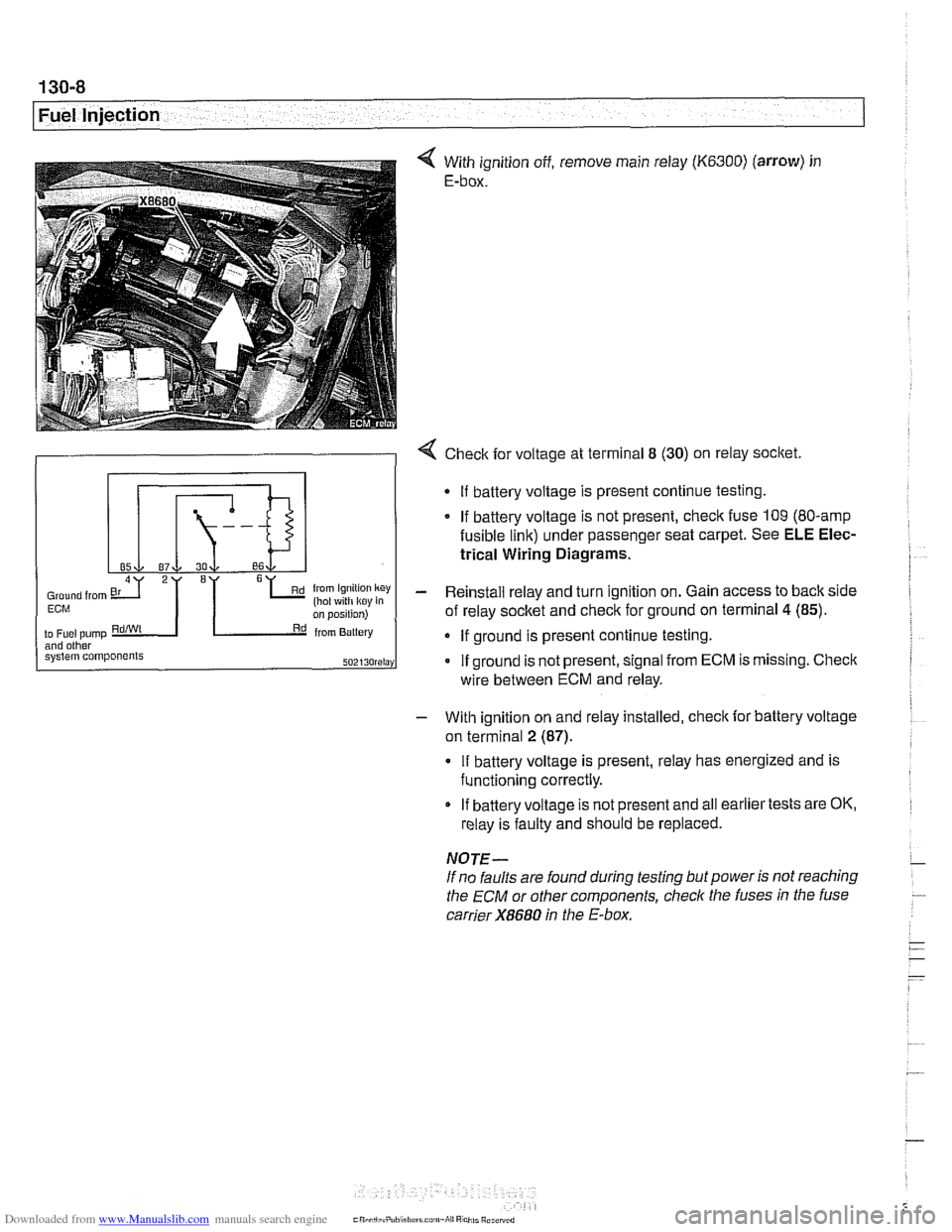

4 The engine control module (ECM) relay is energized via the

ECM and supplies battery positive

(B+) power to many of the

engine management components and subsystems.

If this re-

lay is faulty, the engine will not start.

Relay positions can vary. Be sure to confirm relay position by

identifying the wiring in the socket using the wiring diagrams

in

ELE Electrical Wiring Diagrams.

NOTE-

The ECM relay is also referred to as the DME main relay.

Page 398 of 1002

Downloaded from www.Manualslib.com manuals search engine

130-8

Fuel Injection

With ignition off, remove main relay (K6300) (arrow) in

E-box.

- With ignition on and relay installed, check for battery voltage

on terminal

2 (87).

4 Check for voltage at terminal 8 (30) on relay socket.

If battery voltage is present, relay has energized and is

functioning correctly.

Gmund from 6L (hot ~4th k~y key in Ern

2I '1

on position)

to

Fuel pump RdiWt Rd from Battery and other system components SOZI~O~~I~Y

If battery voltage is not present and all earlier tests are OK,

relay is faulty and should be replaced.

If

battery voltage is present continue testing.

If battery voltage is not present, check fuse 109 (80-amp

fusible link) under passenger seat carpet. See ELE Elec-

trical Wiring Diagrams.

- Reinstall relay and turn ignition on. Gain access to back side

of relay socket and check for ground on terminal

4 (85).

If ground is present continue testing.

If ground is not present, signal from ECM is missing. Check

NOTE-

If no faults are found during testing but power is not reaching

the

ECM or other components, check the fuses in the fuse

carrier

X8680 in the E-box.

wire

between ECM and relay.

Page 440 of 1002

Downloaded from www.Manualslib.com manuals search engine

130-50

Fuel Injection

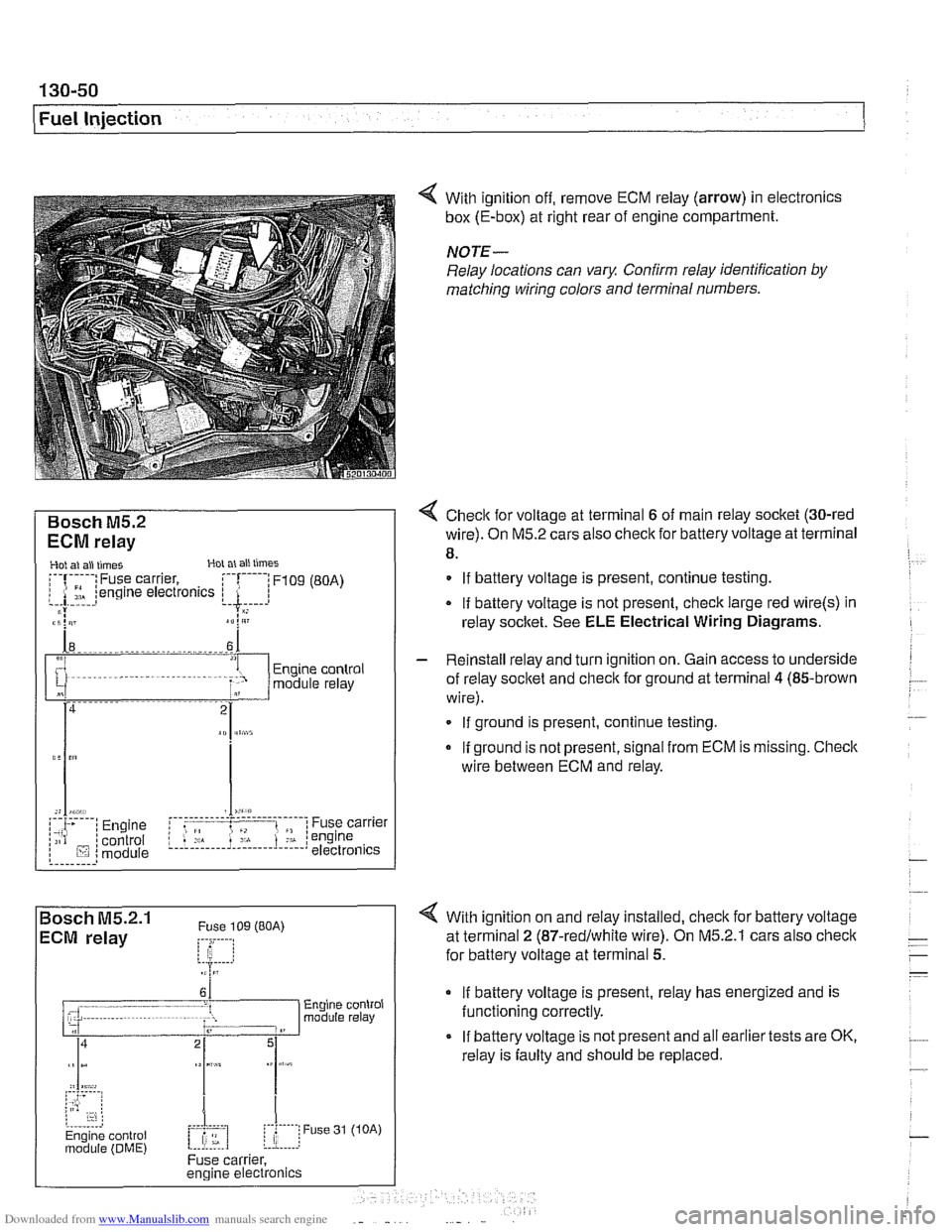

Bosch M5.2

ECM relay

1 HoL al ail iirnel XOL a1 ail limes

i--[-----i F109 (BOA) electronics I L.$.....: .I:

ECM relay . . . . . . . . . ,

8,s

:,

6 1 .. ... ~~.~~. . ...... .-, Engine control ii~~-~.~~..~ ........ ~~~~~~.~~~~:. module relay -;I

Of?

,c,;,,,

< With ignition off, remove ECM relay (arrow) in electronics

box (E-box) at right rear of engine compartment.

NOTE-

Relay locations can vary. Conh relay identification by

matcliing wiring colors and terminal numbers.

4 Check for voltage at terminal 6 of main relay socket (30-red

wire). On M5.2 cars also check for battery voltage at terminal

8.

. . . . . . . . . ,

If battery voltage is present, continue testing

.

If battery voltage is not present, check large red wire(s) in

relay socltet. See

ELE Electrical Wiring Diagrams.

%P,,tt

- Reinstall relay and turn ignition on. Gain access to underside

of relay socket and

checlc for ground at terminal 4 (85-brown

wire).

. . . . . . . . . . . . - - - - - - - - - . - - - . . l ,,-. ; Engine i f .: , ; Fuse carrier .,A . :engine /;is? /control L.!.!! .... 1.: ...... !.::..! I lij :module electronics If

ground is present, continue testing

If ground is not present, signal from ECM is missing. Checic

wire between ECM and relay.

4 With ignition on and relay installed, check for battery voltage

at terminal

2 (87-redlwhite wire). On M5.2.1 cars also checlc

for battery voltage at terminal 5.

If battery voltage is present, relay has energized and is

functioning correctly.

If battery voltage is not present and all earlier tests are OK,

relay is faulty and should be replaced.

Page 441 of 1002

Downloaded from www.Manualslib.com manuals search engine

130-51

Fuel Injection

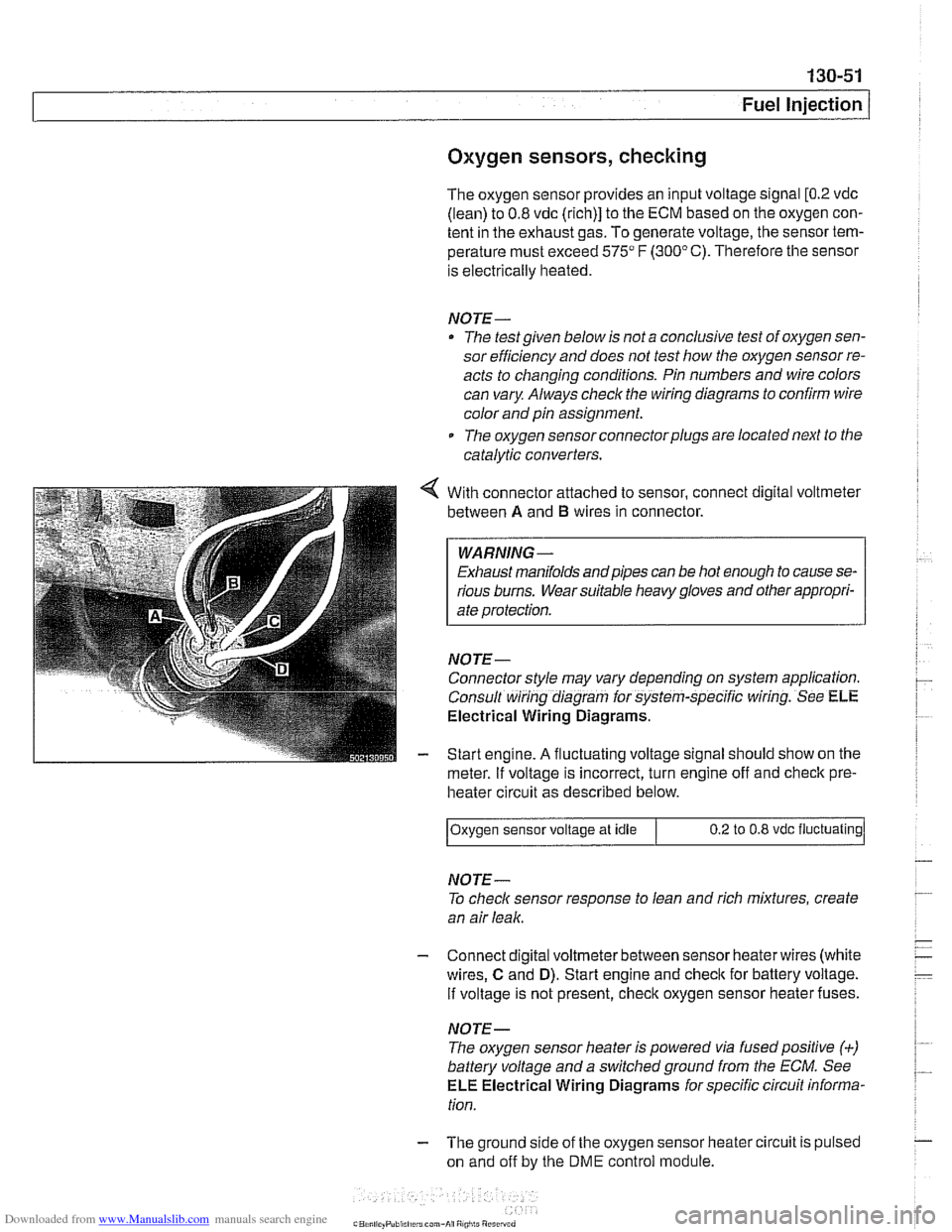

Oxygen sensors, checking

The oxygen sensor provides an input voltage signal [0.2 vdc

(lean) to 0.8 vdc (rich)] to the

ECM based on the oxygen con-

tent in the exhaust gas. To generate voltage, the sensor tem-

perature must exceed 575"

F (300" C). Therefore the sensor

is electrically heated.

NO JE -

The test given below is not a conclusive test of oxygen sen-

sor efficiency and does not test how the oxygen sensor re-

acts to changing conditions. Pin numbers and wire colors

can vary Always check the wiring diagrams to confirm wire

color and pin assignment.

0 The oxygen sensorconnectorplugs are locatednext to the

catalytic converters.

With connector attached to sensor, connect digital voltmeter

between

A and B wires in connector.

WARNING -

Exhaust manifolds andpipes can be hot enough to cause se-

rious burns. Wear suitable heavy gloves and other appropri-

ate protection.

NOJE-

Connector style may vary depending on system application.

Consult wiring diagram for system-specific wiring. See

ELE

Electrical Wiring Diagrams.

Start engine.

A fluctuating voltage signal should show on the

meter.

If voltage is incorrect, turn engine off and check pre-

heater circuit as described below.

NOJE-

To check sensor response to lean and rich mixtures, create

an air leak.

Oxygen sensor

voltage at idle

- Connect digital voltmeterbetween sensor heaterwires (white

wires,

C and D). Start engine and check for battery voltage.

If voltage is not present, check oxygen sensor heater fuses.

0.2 to 0.8 vdc fluctuating

NOJE-

The oxygen sensor heater is powered via fusedpositive (+)

battery voltage and a switchedground from the ECM. See

ELE Electrical Wiring Diagrams for specific circuit informa-

tion.

- The ground side of the oxygen sensor heater circuit is pulsed

on and off by the

DME control module.

Page 477 of 1002

![BMW 528i 1997 E39 Workshop Manual Downloaded from www.Manualslib.com manuals search engine

- Fuel Tank and Fuel pump]

Remove fuel pump

relay (arrow).

4 Connect relay socitet terminal 6 (redlviolet wire) to relay

socket termi BMW 528i 1997 E39 Workshop Manual Downloaded from www.Manualslib.com manuals search engine

- Fuel Tank and Fuel pump]

Remove fuel pump

relay (arrow).

4 Connect relay socitet terminal 6 (redlviolet wire) to relay

socket termi](/img/1/2822/w960_2822-476.png)

Downloaded from www.Manualslib.com manuals search engine

- Fuel Tank and Fuel pump]

Remove fuel pump

relay (arrow).

4 Connect relay socitet terminal 6 (redlviolet wire) to relay

socket terminal

2 (whitelblue wire) with a fused jumper wire.

After completing tests, remove jumper harness.

CA

UTIOG

Relay locations may vary Use care when identifying relays

and making electrical checks at

the fuse/relay panel. See

610 Electrical Component Locations for additional re-

lay information.

The fuel pump relay has a 1.5

md red/violet wire at

terminal

6 in the relay socket. Terminal2 has a 2.5md

white/blue wire. See ELE Electrical Wiring Diagrams

for additional wiring information.

NOTE-

* The fuel pump will run as soon as the jumper wire Is at-

tached.

The jumper wire should be 1.5

md (14 ga.) and include

an in-line fuse holder with a 15A fuse. To avoid

fuse/relay

panel damage from repeated connecting and disconnect-

ing, also include a toggle switch in the jumper harness.

- If pump does not run with jumper installed, fault could be in

fuel pump, fuses

F31 or F22 1 F54, or wiring to pump. Check

pump, fuses and its wiring as described below.

Fuel pump electrical circuit, testing

- The test given below assumes that the fuel pump relay circuit

is functioning correctly as described earlier. Access to the

pump is from below the rear seat bottom cushion.

- Remove rear seat lower cushion by lifting front edge off left

and right catches.

Page 995 of 1002

Downloaded from www.Manualslib.com manuals search engine

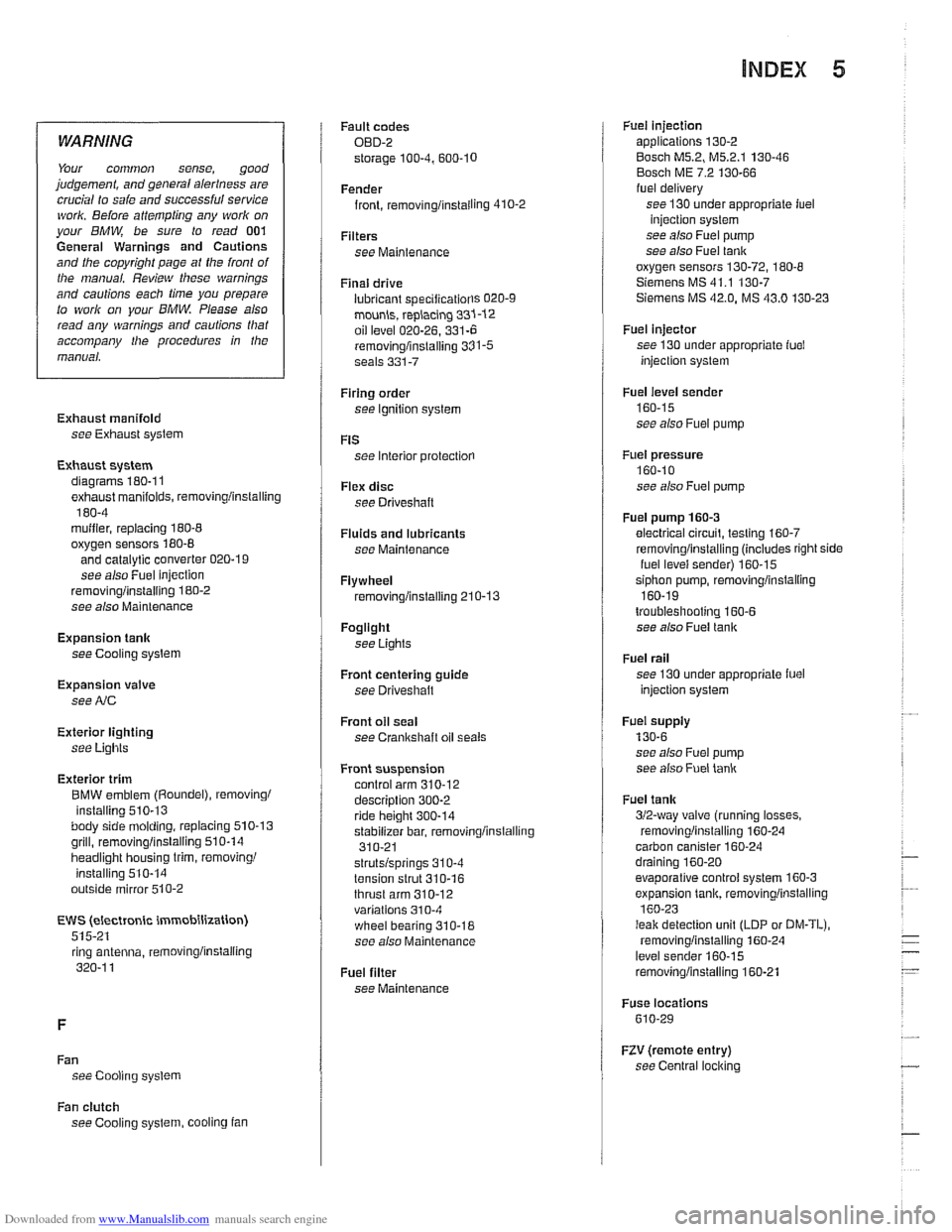

INDEX 5

WARNING

Your common sense, good

judgement, and general alerlness are

crucial lo

safe and successful service ivork. Before attempling any work on

your

BMW be sure lo read 001

General Warnings and Cautions

and the copyright page at the

fronl of

Ihe manual. Review these warnings

and

cautions each lime you prepare

to work on your BMW Please also

read any warnings and cautions tliat

accompany Nie procedures in the

manual.

Exhaust manifold see Exhaust system

Exhaust system diagrams

180.1 1

exhaust manifolds, removinglinstalling

180-4 muifier, replacing 180-8

oxygen sensors 180-8

and catalytic converter 020-1 9

see also Fuel injection

removinglinstalling 180-2

see also Maintenance

Expansion tank

see Cooling system

Expansion valve

see

NC

Exterior lighting

see

Lights

Exterior trim

BMW emblem

(Roundel), removing1

installing

510-13 body side molding, replacing 510.13

grill, removinglinsialiing 510-14

headlight housing trim, removing1

installing 510-14

outside mirror

510-2

EWS (electronic immobilization)

515-21 ring antenna,

iemovinglinstaiting

320-1 1

Fan see Cooling system Fault

codes

OBD-2

storage

100-4. 600.10

Fender

front, rernovinglinstailing

410-2

Filters see Maintenance

Final drive

lubricant

speciiicatiorls 020-9

mounh, replacing 331-12

oil level 020-26. 331-6

removinglinslalling 331-5 seals 331-7

Firing order

see Ignition system

FtS

see Interior protectiorl

Flex disc

see Driveshaft

Fluids and lubricants see Maintenance

Flywheel removinglinstalling 210-13

Fogllght

see Lights

Front centering guide see Driveshatt

Front oil seal

see

Crankshaft oil seals

Front suspension control arm

310-12 description 300-2

ride height 300-14

stabilizer bar, removinglinstalling

310-21

strutslsprings 31

0-4

tension strut 310-16

thrust arm 310-12 variations 310-4

wheel bearing 310-18

see also Maintenance

Fuel filter

see Maintenance

Fuet injection applications 130-2

Bosch M5.2, M5.2.1 130-46

Bosch ME 7.2 130-66 fuel delivery

see 130 under appropriate iuel

injection system

see also Fuel pump

see also

Fuet tank

oxygen sensors

130-72, 180-8

Siemens MS 41.1 130-7 Siemens MS 42.0. MS 43.0 130-23

Fuel injector

see 130 under appropriate fuel

injection system

Fuel level sender

160-15

see also Fuei pump

Fuel pressure

160-10

see also Fuel pump

Fuel pump

160-3

electrical circuit, testino 160-7

1

removinglinstalling (includes right side

iuel levei sender) 160-15

siphon pump, removinglinstaliing

160-19

troubleshooting 160-6 see also Fuel tank

Fuel rail

see 130 under appropriate iuel

injection system

Fuei supply

130-6

see also Fuei pump

see also

Fuet lank

Fuel

tank

312-way valve (running losses.

removinglinstalling

160-24 carbon canister 160-24

draining 160-20

evaporative control system 160-3

expansion tank, removinglinstalling

160-23

I

leak detection unit (LDP or DM-TL),

rernovinoiinstallino 160-24

level senier 160-15

removinglinstalling 160-21

Fuse locations

610-29

RV (remote entry)

see Central

locl(ing

Fan clutch

see Cooling system, cooling fan