relay BMW 528i 1997 E39 Workshop Manual

[x] Cancel search | Manufacturer: BMW, Model Year: 1997, Model line: 528i, Model: BMW 528i 1997 E39Pages: 1002

Page 31 of 1002

Downloaded from www.Manualslib.com manuals search engine

Spare parts kit

Carrying a basic set of spare parts can prevent a rninorbreak-

down from turning into a major repair annoyance. The list be-

low is a good place to start.

Spare parts kit

- basic

Polyribbed drive

belt(s)

BMW engine oil: one or two quarts

BMW engine coolant:

1 gallon of premixed 50150 BMW

anti-freeze and water

Fuse assortment:

7.5A. IOA, 1 5A, 20A, 30A. 50A

Radiator hoses: upper and lower

Spare parts

kit - additional contents

Exterior lighting bulbs: headlight, bralte light, turn signal,

and taillight

* Wiper blades or blade inserts

Brake fluid: new, unopened bottle, DOT

4 specification

Main relay for DME system

Page 100 of 1002

Downloaded from www.Manualslib.com manuals search engine

11 3-6

Cylinder Head Removal and Installation

- Disable ignition system by removing DME main relay. See

610 Component Locations for relay location.

WARNING-

. The ignition system produces high voltages that can be fa-

tal. Avoid contact with exposed terminals and use

exfreme

caution when working on a car with the ignition switched on

or the engine running.

Do not touch or disconnect ignition

components while

the engine is running or being cranked by the starter.

Failure to remove the DME main relay or attempting to

disa-

bie the fuel andignition systems by other methods may result

in damaoe to the enoine control module

(ECM).

- - Remove plastic cylinder head cover(s)

,,I . ,. .*,.,,&- - Remove coil grounding straps.

I CAUTION-

I nition system components. I

- Remove coils.

- Remove spark plugs from all cylinders.

NOTE-

Check the spark plugs for oil deposits that may indicate poor

cylinder sealing, then set them aside in order. Used spark

plugs should be reinstalled in the same cylinder from which

they were removed.

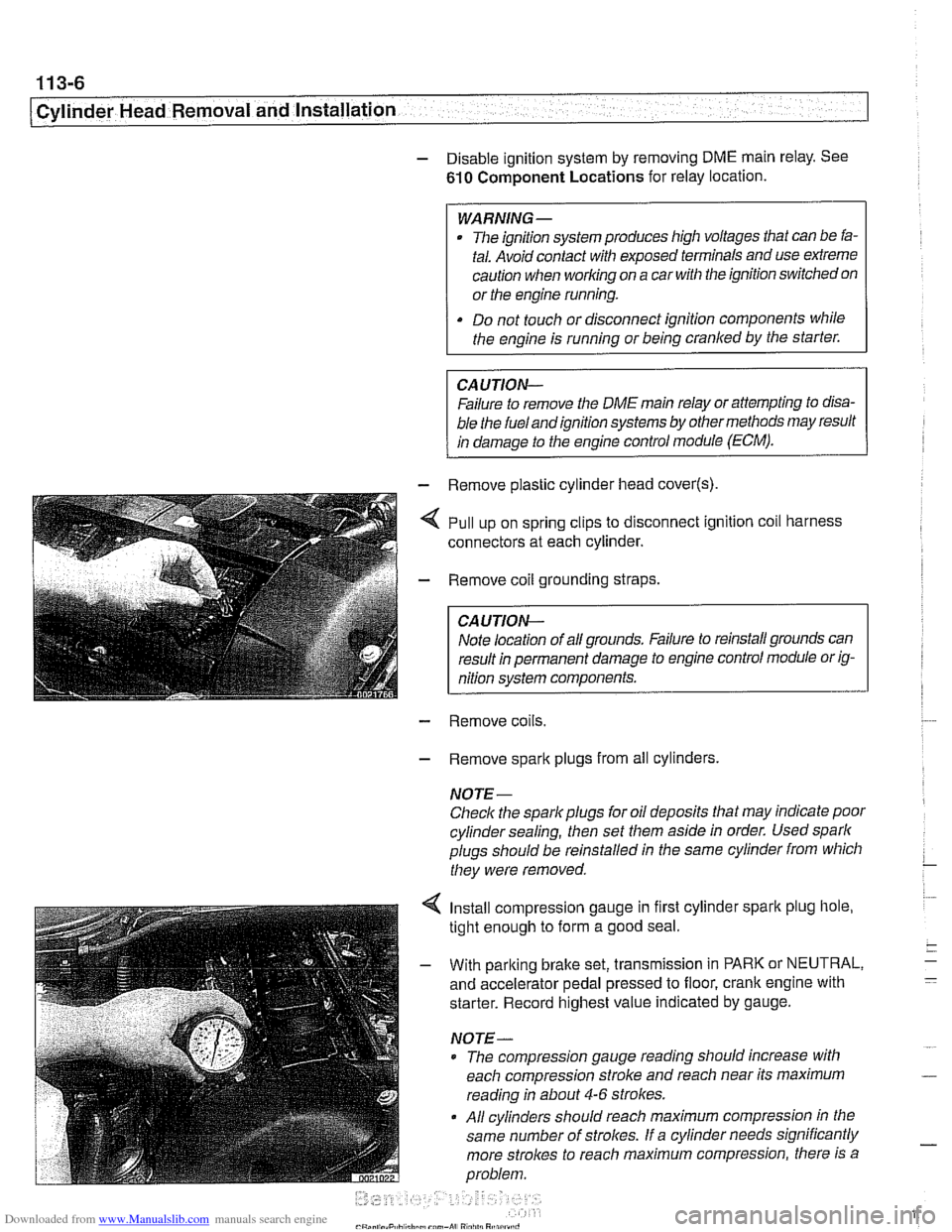

4 Install compression gauge in first cylinder spark plug hole,

tight enough to form a good seal.

- With parking brake set, transmission in PARK or NEUTRAL,

and accelerator pedal pressed to floor, crank engine with

starter. Record highest value indicated by gauge.

NOTE-

* The compression gauge reading should increase with

each compression stroke and reach near its maximum

reading in about

4-6 strokes.

All cylinders should reach maximum compression in the

same number of

strolces. If a cylinder needs significantly

more strokes to reach

maximum compression, there is a

problem.

Page 353 of 1002

Downloaded from www.Manualslib.com manuals search engine

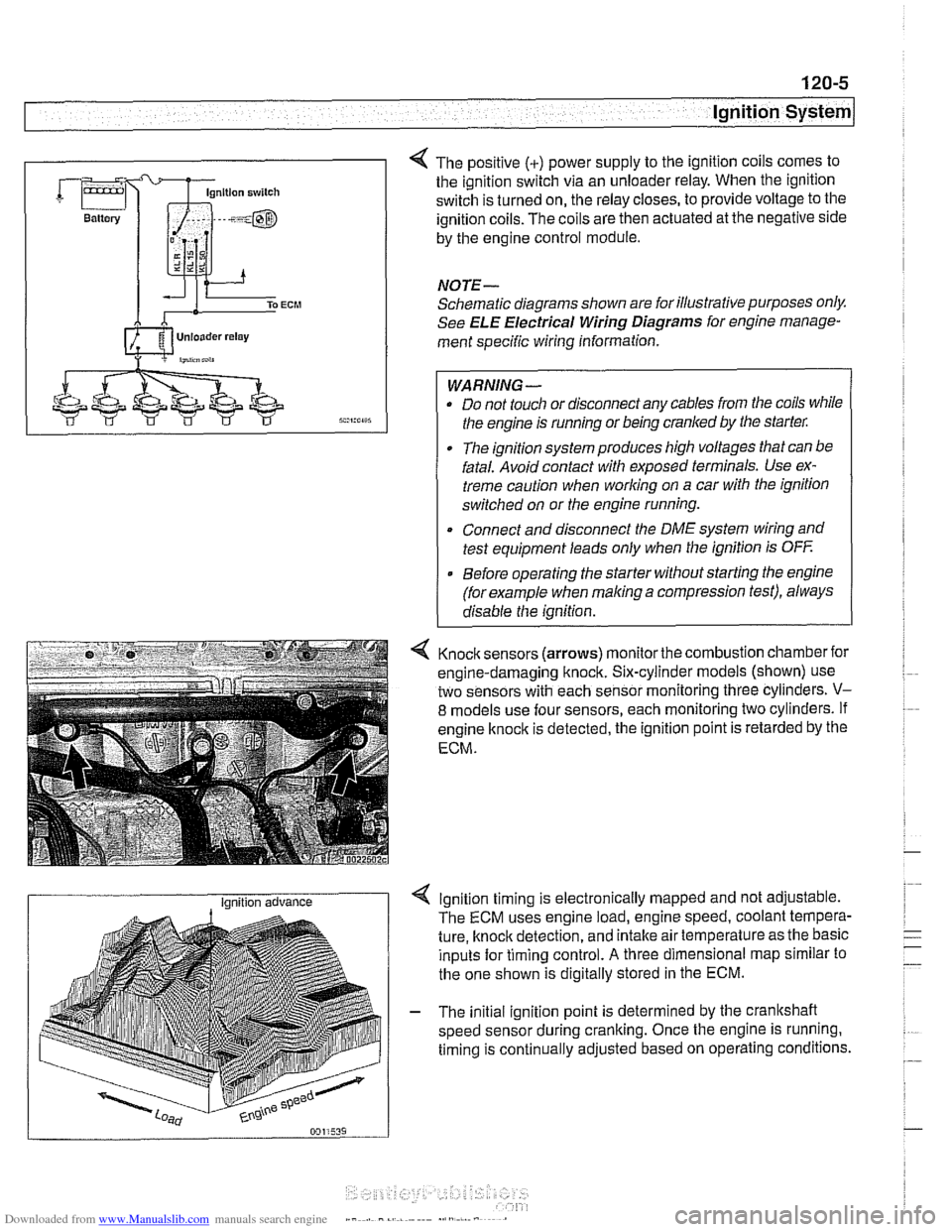

Lnition switch

4 The positive (+) power supply to the ignition coils comes to

the ignition switch via an unloader relay. When the ignition

switch is turned on, the relay closes, to provide voltage to the

ignition coils. The coils are then actuated at the negative side

by the engine control module.

NOTE-

Schematic diagrams shown are for illustrative purposes only.

See ELE Electrical Wiring Diagrams for engine manage-

ment specific wiring information.

WARNING- Do not touch or disconnect any cables from the coils while

the engine is running or being cranked by the starter:

The ignition system produces high voltages that can be

fatal. Avoid contact with exposed terminals. Use ex-

treme caution when

working on a car with the ignition

switched on or the engine running.

* Connect and disconnect the DME system wiring and

test equipment leads only when the ignition is

OFF

Before operating the starter without starting the engine

(for example when

making a compression test), always

disable the ignition.

4 Knock sensors (arrows) monitor the combustion chamber for

engine-damaging knock. Six-cylinder models (shown) use

two sensors with each sensor monitoring three cylinders.

V-

8 models use four sensors, each monitoring two cylinders. If

engine

knock is detected, the ignition point is retarded by the

ECM.

I Ignition advance Ignition timing is electronically mapped and not adjustable.

The ECM uses engine load, engine speed, coolant tempera-

ture, knock detection, and intake air temperature as the basic

inputs for timing control.

A three dimensional map similar to

the one shown is digitally stored in the ECM.

- The initial ignition point is determined by the crankshaft

speed sensor during cranking. Once the engine is running.

timing is continually adjusted based on operating conditions.

Page 358 of 1002

Downloaded from www.Manualslib.com manuals search engine

.-

ignition System

Disabling ignition system

The ignition system operates in a lethal voltage range and

should be disabled any time engine service or repair work is

being done that requires the ignition to be switched on.

The engine management system can be disabled by remov-

ing the DME main relay. The relay is located in the electronics

box (E-box) in the left rear of the engine

compartment, be.

neath the interior microfilter housing.

CAUTION- Relay locations may

vary. Use care when identifying relays.

See

610 Electrical Component Locations.

Checking for spark

CAUTION-

If

a spark test is done incorrecth damage to the Engine Con-

trol Module

(ECM) or the ignition coils may result.

NOTE-

Spark plug replacement is covered in 020 Maintenance.

Check~ng for spark is d~fflcult on englnes wlth d~str~butorless

ignition systems.

Try removing the spark plugs and inspecting for differences between them.

A poor-firing plug may be wet with fuel and/or ~. - ~

black and sooty, but not always. If a coil is not operating, the

engine management system will electrically disable the fuel

injector to that cylinder. The key is to look for differences be-

tween cylinders.

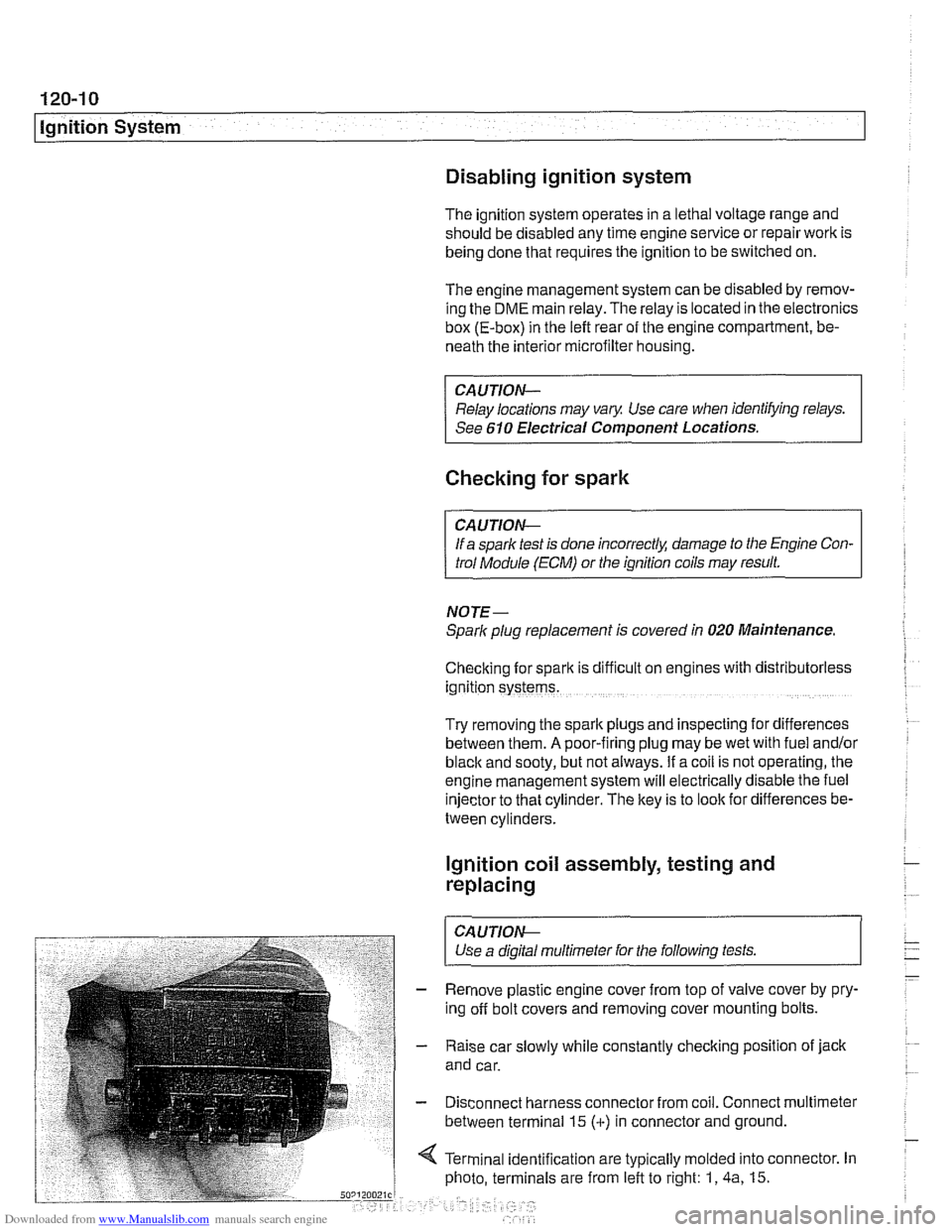

Ignition coil assembly, testing and

replacing

C4 UTION-

Use a digital multimeter for the following tests. I

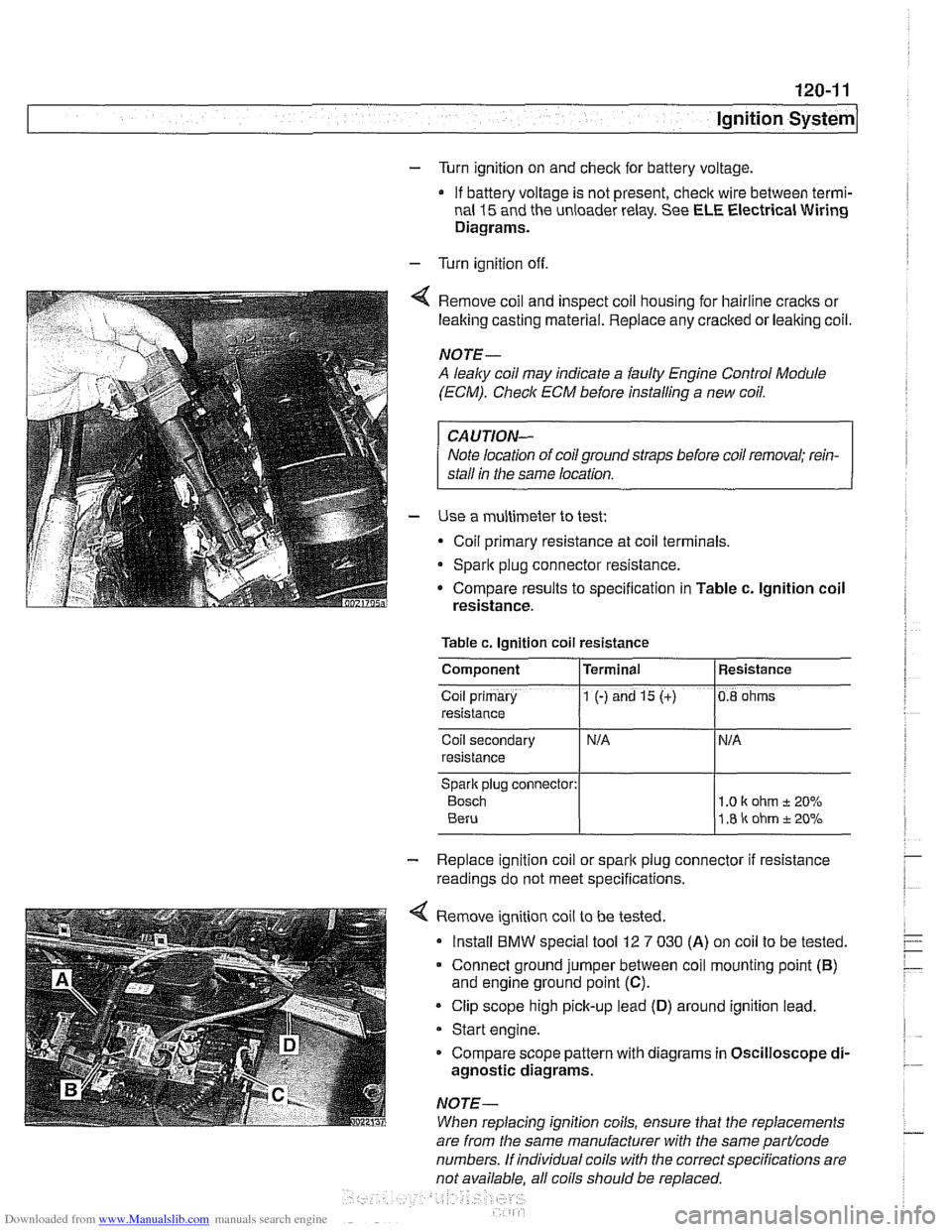

- Remove plastic engine cover from top of valve cover by pry-

ing off bolt covers and removing cover mounting bolts.

- Raise car slowly while constantly checking position of jack

and car.

- Disconnect harness connector from coil. Connect multimeter

between terminal 15

(+) in connector and ground.

4 Terminal identification are typically molded into connector. In

photo, terminals are from left to right: 1,

4a, 15.

Page 359 of 1002

Downloaded from www.Manualslib.com manuals search engine

Ignition System

- Turn ignition on and check for battery voltage,

If battery voltage is not present,

checlt wire between termi-

nal

15 and the unloader relay. See ELE Electrical Wiring

Diagrams.

- Turn ignition off.

Remove coil and inspect coil housing for hairline

cracks or

leaking casting material. Replace any

cracked or leaking coil.

NOTE-

A leaky coil may indicate a faulty Engine Control Module

(ECM). Check ECM before installing a new coil.

CAUTION-

Note location of coilground straps before coil removal; rein-

stall in the same location.

Use a multimeter to test:

Coil primary resistance at coil terminals.

Sparlt plug connector resistance.

* Compare results to specification in Table c. lgnition coil

resistance.

Table c. Ignition coil resistance

Coil secondary

resistance

Spark plug connector:

Bosch 1 .O I( ohm t 20%

1.8 ir ohm t 20%

Component

Co~l prlmary

resistance

- Replace ignition coil or sparlt plug connector if resistance

readings do not meet specifications.

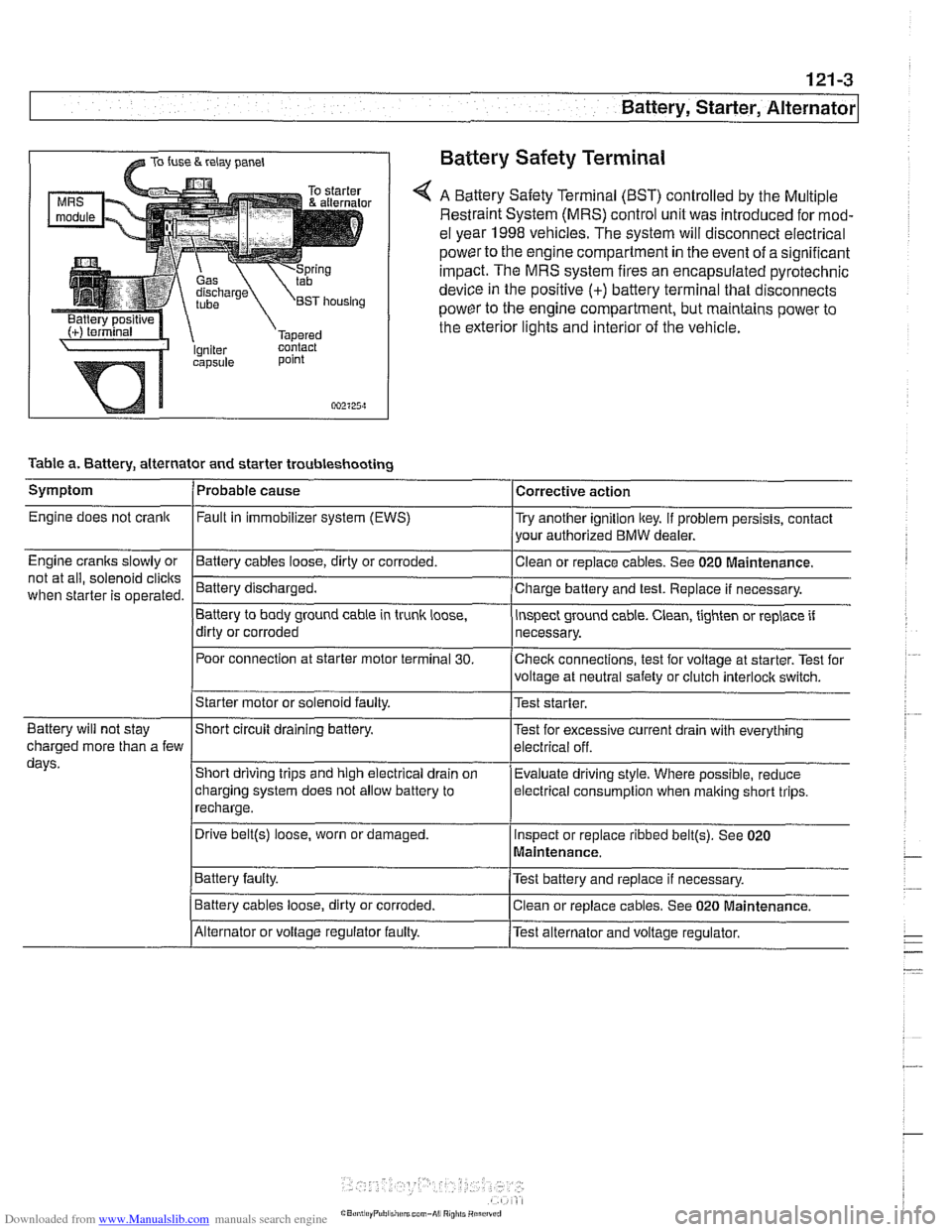

4 Remove ignition coil to be tested.

Install

BMW special tool 12 7 030 (A) on coil to be tested.

Connect ground jumper between coil mounting point

(B)

and engine ground point (C).

Clip scope high pick-up lead (D) around ignition lead.

Start engine.

Compare scope pattern with diagrams in Oscilloscope

di-

agnostic diagrams.

NOTE-

When replacing ignition coils, ensure that the replacements

Terminal

1 (-) and 15 (+)

are

from the same manufacturer with the same partlcode

numbers. If individual coils with the correct specifications are

not available. all coils should be

re~laced.

Resistance

0.8 ohms

Page 369 of 1002

Downloaded from www.Manualslib.com manuals search engine

Battery, Starter, ~lternatorl

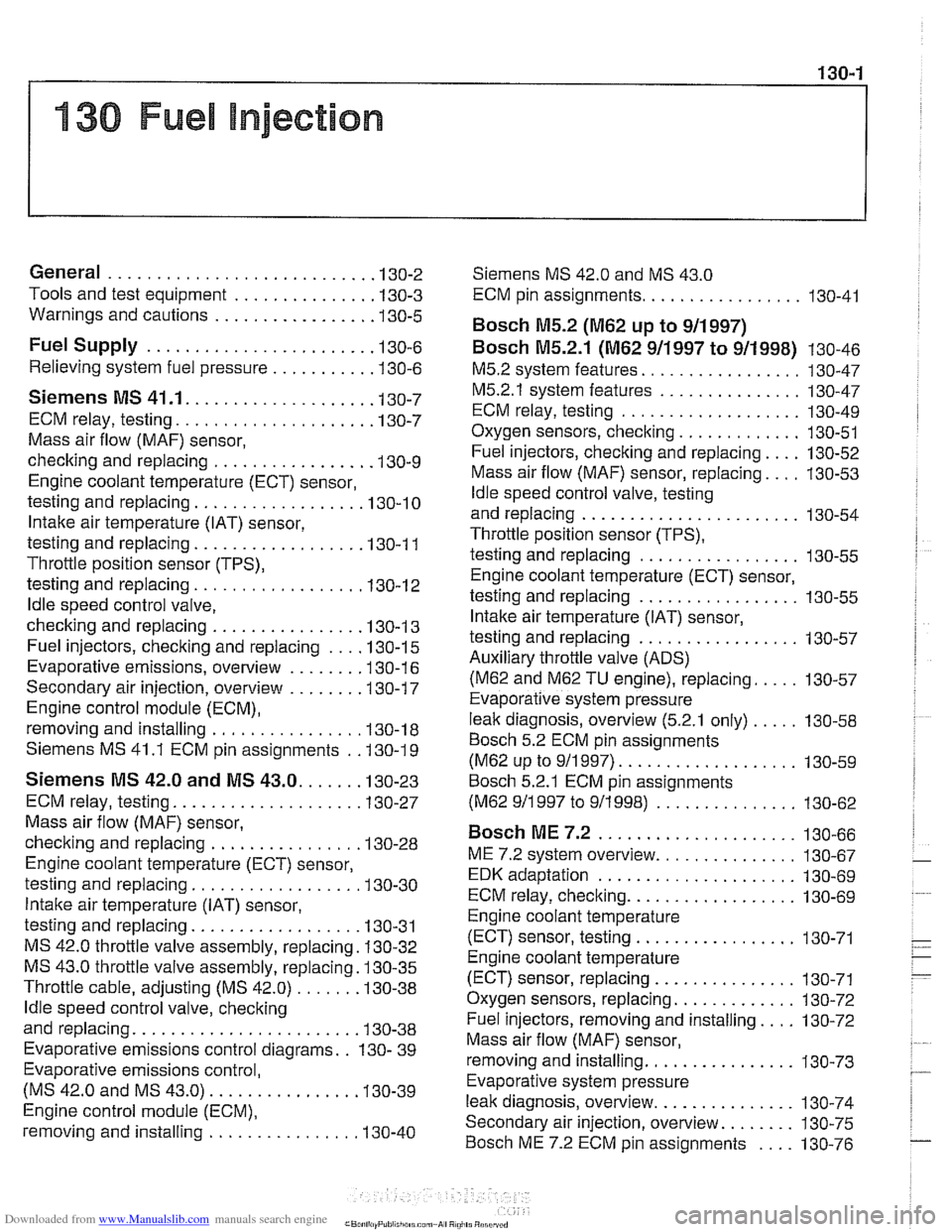

@ TO fuse & relay panel Battery Safety Terminal

A Battery Safety Terminal (BST) controlled by the Multiple

Restraint System (MRS) control unit was introduced for mod-

el year 1998

vehicles. The system will disconnect electrical

power to the engine compartment

in the event of a significant

impact. The MRS system fires an encapsulated pyrotechnic

device

in the positive (+) battery terminal that disconnects

power to the engine compartment, but maintains power to

the exterior lights and interior of the vehicle.

point

002125~1

Table a. Battery, alternator and starter troubleshooting

1-

/Starter motor or solenoid faulty. l~est starter.

Symptom

Engine does not crank

Engine cranks slowly or

not at all, solenoid

clicits

when starter is operated.

I I

Battery will not stay IShort circuit draining battery. l~est for excessive current drain with everything

Probable cause

Fault

in immobilizer system (EWS)

-Clean Battery cables loose, dirty or corroded.

Battery discharged.

Battery to body ground cable in trunk

loose,

dirty or corroded

Poor connection at starter motor terminal

30.

Corrective action

Try another ignition key. If problem persists, contact

your authorized BMW dealer.

or replace cables. See 020

~aintenance.

Charge battery and test. Replace if necessary.

inspect ground cable. Clean, tighten or replace if

necessary.

Checlc connections, test for voltage at starter. Test for

voltage at neutral safety or clutch

interloclc switch.

charged more than a few

days.

I~atter~ faulty. /Test battery and replace if necessary.

Short driving trips and high electrical drain

on

charging system does not allow battery to

recharge.

. I

I Battery cables loose, dirty or corroded. Iclean or replace cables. See 020 Maintenance.

Evaluate driving

style. Where possible, reduce

electrical

consumption when malting short trips.

Drive

belt@) loose, worn or damaged.

IAlternator or voltage regulator faulty. /Test alternator and voltage regulator.

Inspect

or replace ribbed

belt@). See 020

Maintenance.

Page 391 of 1002

Downloaded from www.Manualslib.com manuals search engine

130-1

130 Fuel injection

General ........................... .I3 0.2

Tools and test equipment .............. .I3 0.3

Warnings and cautions ................ .I3 0.5

Fuel Supply ....................... .I3 0.6

Relieving system fuel pressure .......... .I3 0.6

Siemens MS 41 . 1. ................... 1 30-7

ECM relay. testing .................... .I3 0.7

Mass air flow (MAF) sensor.

checking and replacing

................ .I3 0.9

Engine coolant temperature (ECT) sensor.

testing and replacing

.................. 130-10

Intake air temperature (IAT) sensor.

testing and replacing

................. .I3 0.1 1

Throttle position sensor (TPS).

testing and replacing

.................. 130-1 2

ldle speed control valve.

checking and replacing

............... .I3 0.1 3

Fuel injectors. checking and replacing .... 130-15

Evaporative emissions. overview ....... .I3 0.1 6

Secondary air injection. overview ....... .I3 0-17

Engine control module (ECM).

removing and installing

................ 130-18

Siemens MS 41.1 ECM pin assignments . .I3 0.19

Siemens MS 42.0 and MS 43.0. ..... .I3 0.23

ECM relay. testing ................... .I3 0.27

Mass air flow (MAF) sensor.

checking and replacing

............... .I3 0.28

Engine coolant temperature (ECT) sensor.

testing and replacing

................. .I3 0.30

Intake air temperature (IAT) sensor.

testing and replacing

................. .I3 0.31

MS 42.0 throttle valve assembly. replacing . 130-32

MS 43.0 throttle valve assembly. replacing . 130-35

Throttle cable. adjusting (MS 42.0) ...... .I3 0.38

ldle speed control valve. checking

and replacing

....................... .I3 0.38

Evaporative emissions control diagrams . . 130- 39

Evaporative emissions control.

(MS

42.0 and MS 43.0). .............. .I3 0.39

Engine control module (ECM).

removing and installing

................ 130-40

Siemens MS 42.0 and MS 43.0

ECM pin assignments ................. 130-41

Bosch M5.2 (M62 up to 911997)

BOSC~ M5.2.1 (M62 911997 to 911998) 130-46

M5.2 system features ................. 130-47

M5.2.1 system features ............... 130-47

ECM relay. testing ................... 130-49

Oxygen sensors. checking ............. 130-51

Fuel injectors. checking and replacing .... 130-52

Mass air flow (MAF) sensor. replacing .... 130-53

ldle speed control valve. testing

and replacing

....................... 130-54

Throttle position sensor (TPS).

testing and replacing

................. 130-55

Engine coolant temperature (ECT) sensor.

testing and replacing

................. 130-55

Intake air temperature (IAT) sensor.

testing and replacing

................. 130-57

Auxiliary throttle valve (ADS) (M62 and

M62 TU engine). replacing ..... 130-57

Evaporative system pressure

leak diagnosis. overview

(5.2.1 only) ..... 130-58

Bosch 5.2 ECM pin assignments

(M62 UP to 911 997) ................... 130-59

~osch 5.2.1 ECM pin assignments

(M62 911 997 to 911 998) ............... 130-62

BOSC~ ME 7.2 ..................... 1 30-66

ME 7.2 system overview ............... 130-67

EDK adaptation ..................... 130-69

ECM relay. checking .................. 130-69

Engine coolant temperature

(ECT) sensor. testing

................. 130-71

Engine coolant temperature

(ECT) sensor. replacing

............... 130-71

Oxygen sensors. replacing ............. 130-72

Fuel injectors. removing and installing .... 130-72

Mass air flow (MAF) sensor.

removing and installing

................ 130-73

Evaporative system pressure

leak diagnosis. overview

............... 130-74

Secondary air injection. overview ........ 130-75

Bosch ME 7.2 ECM pin assignments .... 130-76

Page 395 of 1002

Downloaded from www.Manualslib.com manuals search engine

Fuel Injection

Warnings and cautions

For personal safety, as well as the protection of sensitive

electronic components, adhere to the warnings and cautions

on the following pages.

WARNING-

Gasoline is highly flammable and its vapors are explosive.

Do not smoke or work on a car near heaters or other fire

hazards when diagnosing and repairing fuel system prob-

lems. Have a fire extinguisher available in case of an emer-

gency

Renew fuel system hoses, clamps and O-rings any

time they are removed.

When working on an open fuel system, wear suitable

hand protection, as prolonged contact

with fuel can

cause illnesses and skin disorders.

* The ignition system produces high voltages that can be

fatal. Avoid contact with exposed terminals. Use ex-

treme caution when

working on a car with the ignition

switched on or the engine running.

CAUTION-

- Disconnecting the battery may erase fault code($ storedin

memory Check for fault codes prior to disconnecting the

battery cables. Read the battery disconnection cautions in

001 General Warnings and Cautions.

a Connect and disconnect the DME system wiring and

1 test equipment leads only when the ignition is switched

off.

Wait at least 1 minute after turning off the ignition be-

fore removing the engine control module (ECM) con-

nector. If the connector is removed before this time,

residualpower in the system relay may damage the

control module.

Fuel system cleaners and other chemical additives oth-

er than those specifically recommended by BMW may

damage the catalytic converter, the oxygen sensor or

other fuel supply components.

* Do not connect any test equipment that delivers a 12-

volt power supply to terminal 15 (+) of the ignition coil.

The current flow may damage the ECM. In general,

connect test equipment only as specified by BMW or

the equipment maker.

Only use a digital

multirneter for electrical tests. Only

use an LED test light for

quiclc tests.

Page 396 of 1002

Downloaded from www.Manualslib.com manuals search engine

130-6

Fuel Injection

Fuel supply to the injection system is provided by a high pres-

sure electric pump mounted inside the fuel tank. The pump is

powered via the fuel pump relay. If the relay is faulty, the fuel

pump will not run and the engine will not start.

NOTE-

* Fuel delivery volume and fuel pressure are critical to prop-

er operation. Fuel pressure direcfly influences fuel deliv-

ery

Fuel pump relay, fuel pressure and fuel volume tests are

given in 160 Fuel Tank and Fuel Pump.

Relieving system fuel pressure

The fuel system retains fuel pressure in the system when the

engine is off. To prevent fuel from spraying on a hot engine,

system fuel pressure should be relieved beforedisconnecting

fuel lines. One method is to tightly wrap

ashop towel around a

fuel line fitting and loosen or disconnect the fitting. Cleanli-

ness is essential when working with fuel components. Thor-

oughly clean the unions before disconnecting fuel lines.

When system faults are detected, a diagnostic trouble code

(DTC) is stored in the engine control module (ECM). The MIL

also iiluminates if an emissions-related fault is detected

When faults arise, or if the malfunction indicator lamp (MIL) is

illuminated, begin troubleshooting by connecting BMW ser-

vice tester

DISplus. MoDiC, GTI or equivalent scan tool. The

capabilities of OBD

II software has the potential to save hours

of diagnostic time and to help avoid incorrect component re-

placement and possible damage to system components.

CAUTION-

- The tests in this section may set fault codes (DTCs) in the

ECM and illuminate the

MIL. Affer all testing is completed,

access and clear DJC fault memory using an

OED I1 or

BMW compatible scan tool. See OBD On-Board Diag-

nostics.

0 Only use a digital multimeter for electrical tests.

. Relay positions can vary Be sure to confirm relay posi-

tion by identifying the wiring in the socket using the wir-

ing diagrams found in ELE Electrical Wiring

Diagrams.

Page 397 of 1002

Downloaded from www.Manualslib.com manuals search engine

Fuel Injection 1

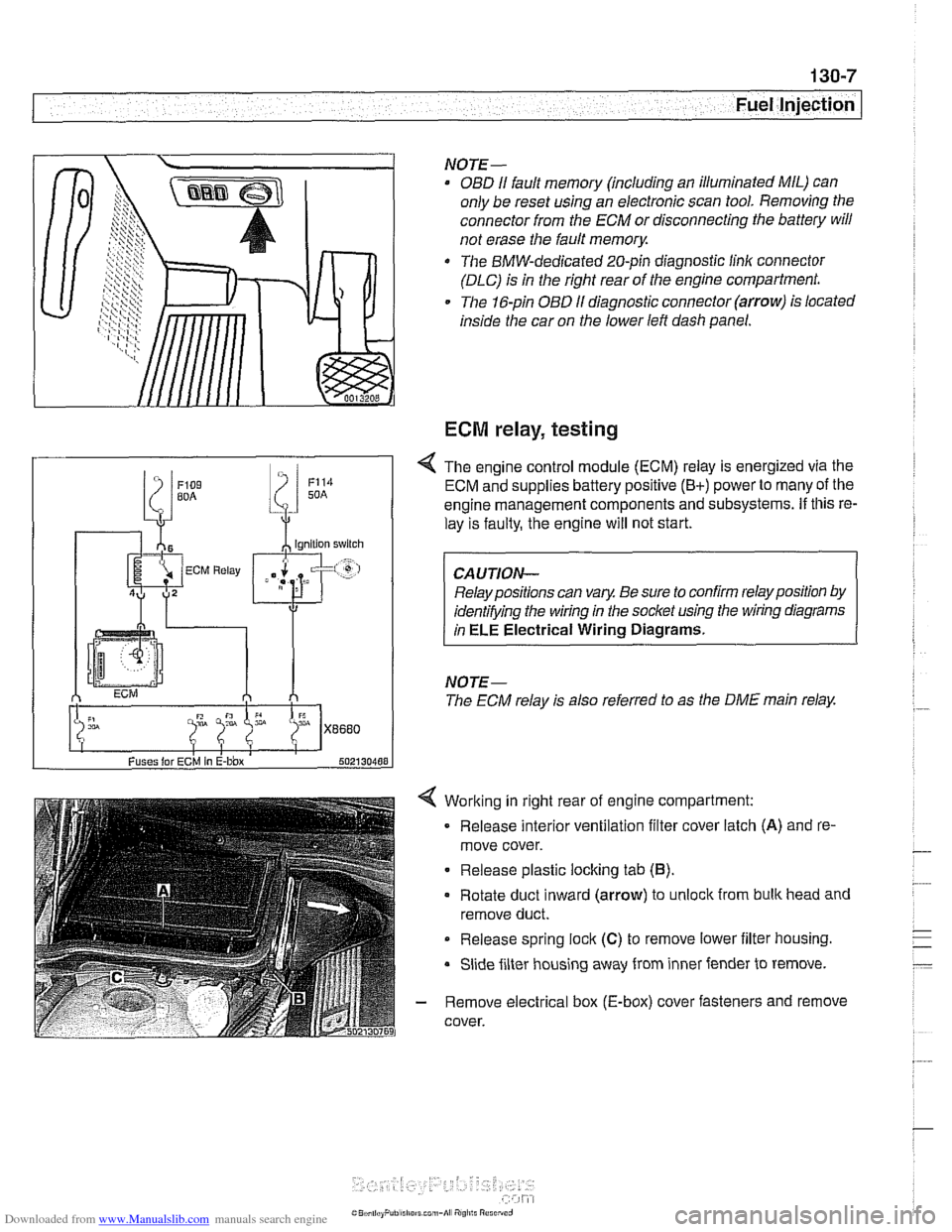

Working in right rear of engine compartment:

Release interior ventilation filter cover latch

(A) and re-

move cover.

Release plastic locking tab

(6).

Rotate duct inward (arrow) to unlock from bulk head and

remove duct.

Release spring

lock (C) to remove lower iilter housing.

Slide filter housing away from inner fender to remove.

- Remove electrical box (E-box) cover fasteners and remove

cover.

NOTE-

OBD I1 fault memory (including an illuminated MIL) can

only be reset using an electronic scan tool. Removing the

connector from the ECM or disconnecting the battery will

not erase the fault

memory.

The BMW-dedicated 20-pin diagnostic linlc connector

(DLC) is in the right rear of the engine compartment.

The 16-pin OBD

I1 diagnostic connector (arrow) is located

inside the car on the lower left dash panel.

ECM relay, testing

Fuses lor ECM In E-bbx 502130488

4 The engine control module (ECM) relay is energized via the

ECM and supplies battery positive

(B+) power to many of the

engine management components and subsystems.

If this re-

lay is faulty, the engine will not start.

Relay positions can vary. Be sure to confirm relay position by

identifying the wiring in the socket using the wiring diagrams

in

ELE Electrical Wiring Diagrams.

NOTE-

The ECM relay is also referred to as the DME main relay.