ecm BMW 528i 1998 E39 Workshop Manual

[x] Cancel search | Manufacturer: BMW, Model Year: 1998, Model line: 528i, Model: BMW 528i 1998 E39Pages: 1002

Page 35 of 1002

Downloaded from www.Manualslib.com manuals search engine

Maintenance

Service Interval lndicator (Sll)

The BMW Service Interval lndicator (SII) notifies the driver

when oil change and other service is required. The

Sll dis-

plays the phrase "OIL SERVICE"

or"INSPECTI0N" and 7

light emitting diodes (LEDs) in the Instrumentcluster: 5green,

one yellow and one red.

For the

1997 and later 5 Series, BMW introduced an oil

change interval based on fuel consumption. The advantages

of this system are:

Fuel consumption is an accurate method of determining

engine load and the need for service.

The processing electronics are simple.

Resetting of indicator before the scheduled time will not

affect the time to the next service.

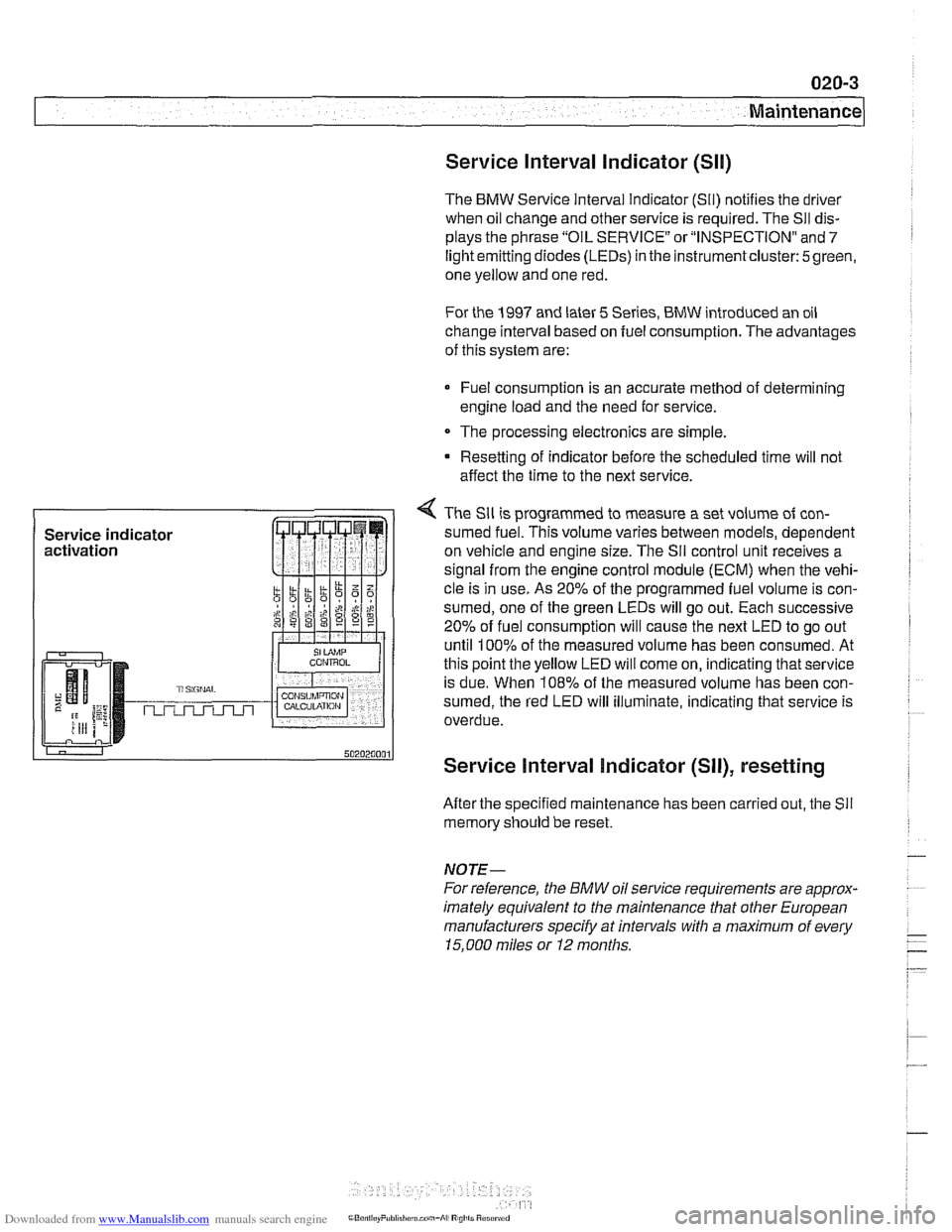

4 The Sll is programmed to measure a set volume of con-

sumed fuel. This volume varies between models, dependent

on vehicle and engine size. The

Sil control unit receives a

signal from the engine control module (ECM) when the vehi-

cle is in use. As

20% of the programmed fuel volume is con-

sumed, one of the green LEDs will go out. Each successive

20% of fuel consumption will cause the next LED to go out

until

100% of the measured volume has been consumed. At

this point the yellow LED will come on, indicating that service

is due. When

108% of the measured volume has been con-

sumed, the red LED will illuminate, indicating that service is

overdue.

Service Interval Indicator (SII), resetting

After the specified maintenance has been carried out, the Sll

memory should be reset.

NOTE-

For reference, the BMW oil service requirements are approx-

imately equivalent to the maintenance tliat other European

manufacturers specify at intervals with a maximum of every

15.000 miles or I2 months.

Page 51 of 1002

Downloaded from www.Manualslib.com manuals search engine

Maintenance

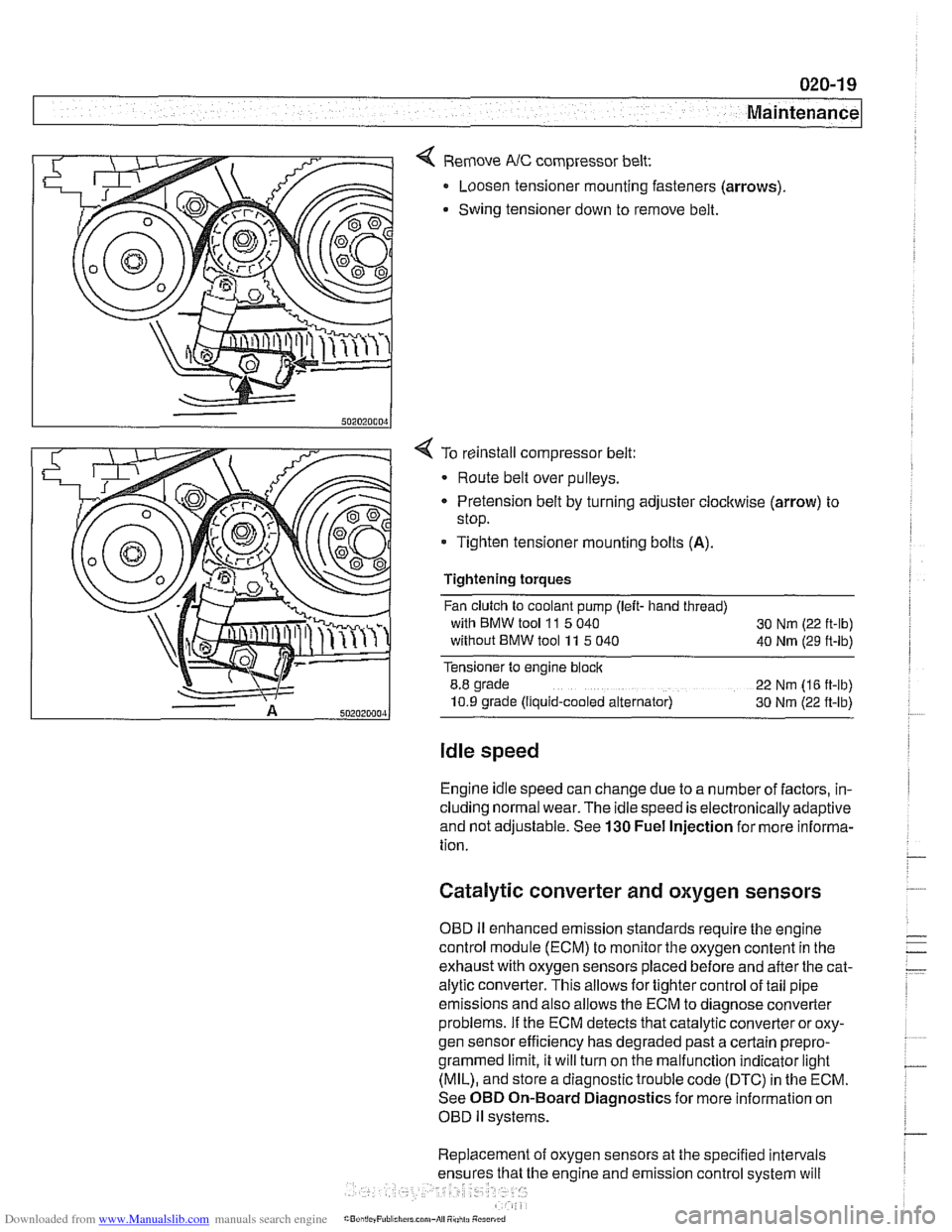

< Remove NC compressor belt:

Loosen tensioner mounting fasteners (arrows)

Swing tensioner down to remove belt.

4 To reinstall compressor belt:

Route belt over pulleys.

* Pretension belt by turning adjuster clockwise (arrow) to

stop.

- Tighten tensioner mounting bolts (A).

Tightening torques

Fan clutch to coolant pump (left- hand thread)

with BMW tool

11 5 040

30 Nm (22 ft-lb)

without BMW tool 11 5 040

40 Nm (29 ft-lb)

Tensioner to engine block

8.8 grade

22 Nm (16 ft-lb)

10.9 grade (Ilquid-cooled alternator) 30 Nm (22 ft-lb)

Idle speed

Engine idle speed can change due to a number of factors, in-

cluding normal wear. The idle speed is electronically adaptive

and not adjustable. See

130 Fuel Injection for more informa-

tion.

Catalytic converter and oxygen sensors

OBD II enhanced emission standards require the engine

control module (ECM) to monitor the oxygen content in the

exhaust with oxygen sensors placed before and after the cat-

alytic converter. This allows for tighter control of tail pipe

emissions and also allows the ECM to diagnose converter

problems. If the ECM detects that catalytic converter or oxy-

gen sensor efficiency has degraded past a certain

prepro-

grammed limit, it will turn on the malfunction indicator light

(MIL), and store a diagnostic trouble code (DTC) in the ECM.

See OBD On-Board Diagnostics for more information on

OBD

ll systems.

Replacement of oxygen sensors at the specified intervals

he engine and emission control system will

Page 70 of 1002

Downloaded from www.Manualslib.com manuals search engine

100-4

I Engine-General

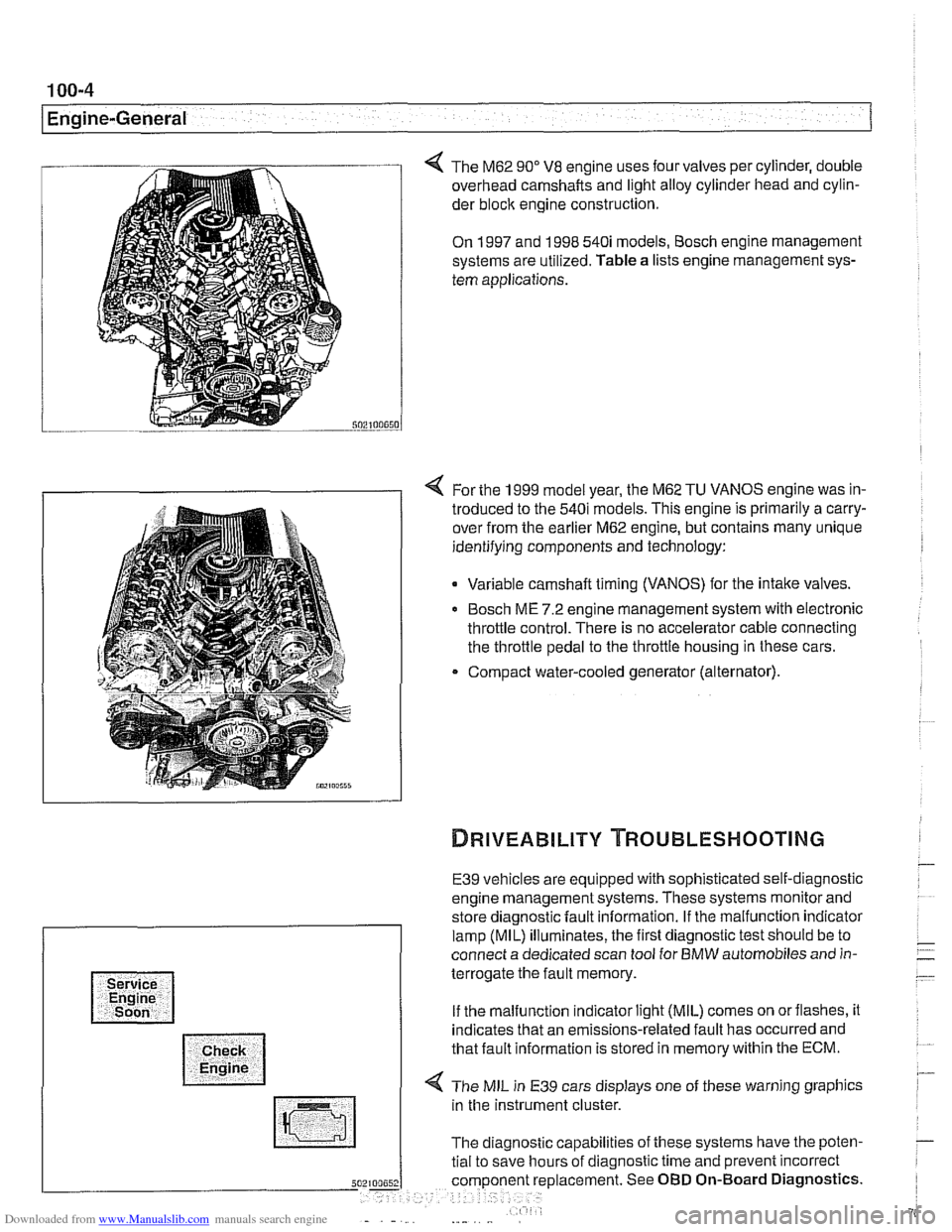

The M62 90" V8 engine uses four valves per cylinder, double

overhead camshafts and light alloy cylinder head and cylin-

der

bloclc engine construction.

On 1997 and 1998 540i models, Bosch engine management

systems are utilized. Table a lists engine management sys-

tem applications.

4 For the 1999 model year, the M62 TU VANOS engine was in-

troduced to the 540i models. This engine is primarily a carry-

over from the earlier M62 engine, but contains many unique

identifying components and technology:

Variable camshaft timing (VANOS) for the intake valves.

Bosch ME 7.2 engine management system with electronic

throttle control. There is no accelerator cable connecting

the throttle pedal to the throttle housing in these cars.

Compact water-cooled generator (alternator).

E39 vehicles are equipped with sophisticated self-diagnostic

engine management systems. These systems monitor and

store diagnostic fault information. If the malfunction indicator

lamp (MIL) illuminates, the first diagnostic test should be to

connect a dedicated scan tool for BMW automobiles and in-

terrogate the fault memory.

If the malfunction indicator light (MIL) comes on orflashes, it

indicates that an emissions-related fault has occurred and

that fault information is stored in memory within the ECM.

4 The MIL in E39 cars displays one of these warning graphics

in the instrument cluster.

The diagnostic capabilities of these systems have the poten-

tial to save hours of diagnostic time and prevent incorrect

5 placement. See OBD On-Board Diagnostics.

Page 71 of 1002

Downloaded from www.Manualslib.com manuals search engine

Two common causes of driveability problems are incorrect

system voltage and bad grounds.

System voltage

Digital motor electronics (DME) requires that the system (bat-

tery) voltage be maintained within a narrow range of DC volt-

age.

DC voltage levels beyond or below the operating range,

or any

AIC voltage in the electrical system can cause havoc.

When troubleshooting an illuminated MIL, make sure the bat-

tery is fully charged and capable of delivering all its power to

the electrical system. An undercharged battery can amplify

AIC alternator output ripple.

To

make a quick check of the battery charge, measure the

voltage across the battery terminals with all cables attached

and the ignition off.

Afully charged battery will measure 12.6

volts or slightly more, compared to 12.1 5 volts for a battery

with a 25% charge.

The DME system operates at low voltage and current levels,

making it sensitive to small increases in resistance. The elec-

trical system is routinely subjected to corrosion, vibration and

wear, so faults or corrosion in the wiring harness and connec-

tors are not uncommon. Check the battery terminals

forcorro-

sion or loose cable connections. See 121 Battery, Starter,

Alternator for additional information.

If a battery cable connection has no

v~sible faults but is still

suspect, measure the voltage drop across the connection. A

large drop indicates excessive resistance, meaning that the

connection is corroded, dirty, or damaged. Clean or repairthe

connection and retest.

NOTE-

For instructions on conducting a voltage drop test and other

general electrical troubleshooting information, see

600 Elec-

trical System-General.

Visually inspect all wiring, connectors, switches and fuses in

the system. Loose or damaged connectors can cause inter-

mittent problems, especially the small terminals in the ECM

connectors. Disconnect the wiring harness connectors to

check for corrosion, and use electrical cleaning spray to re-

move contaminants.

Main grounds

Good grounds are critical to proper DME operation. If a

ground connection has no visible faults but is still suspect.

measure the voltage drop across the connection. A large volt-

age drop means high resistance. Clean or repair the connec-

tion and retest.

LBuntr.yP~sbhnllcn.can#-AII A,~iltl Rcsrwsd

Page 99 of 1002

Downloaded from www.Manualslib.com manuals search engine

113-5

Cylinder Head Removal and Installation I

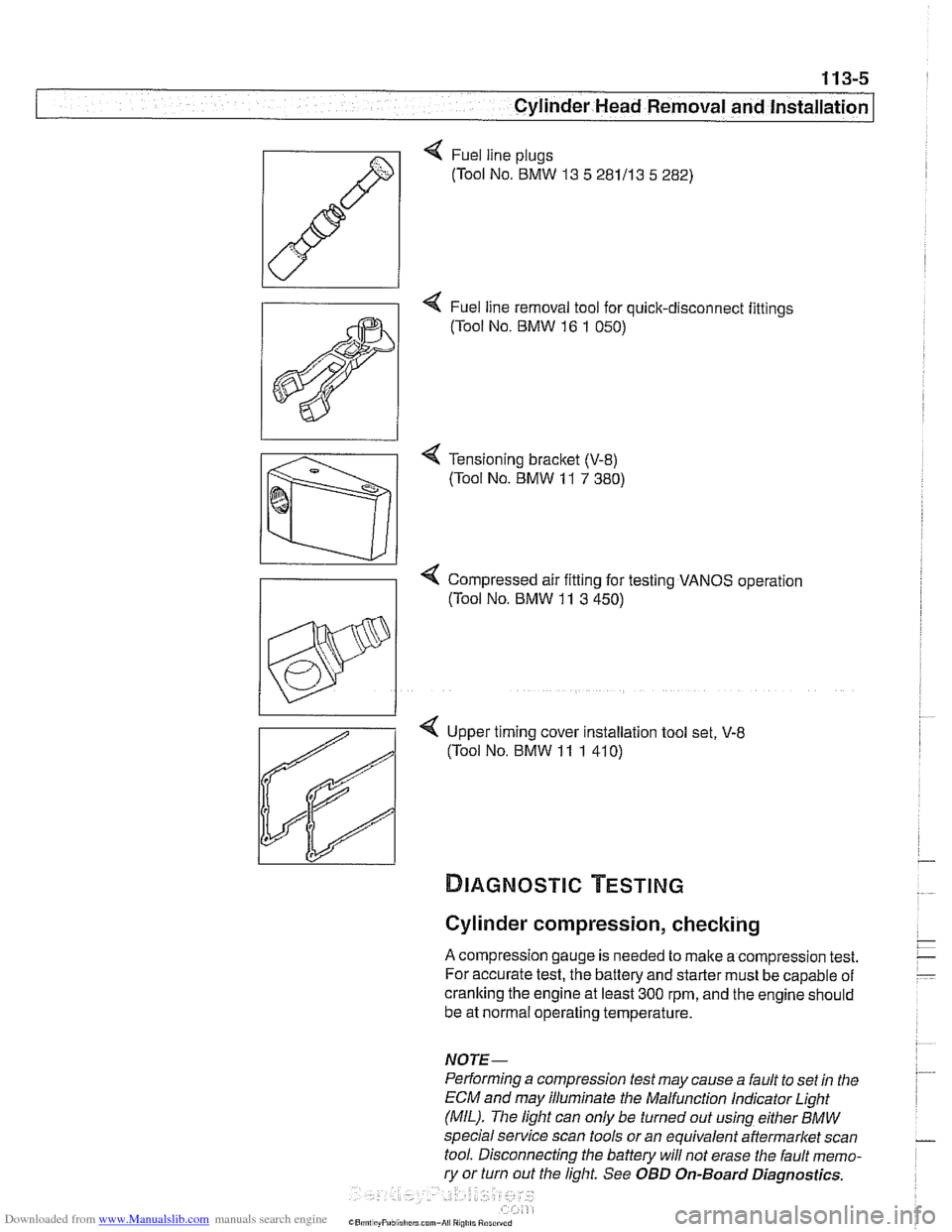

< Fuel line plugs

(Tool No.

BMW 13 5 281113 5 282)

4 Fuel line removal tool for quick-disconnect fittings

(Tool No.

BMW 16 1 050)

< Tensioning bracket (V-8)

(Tool No. BMW 11 7 380)

Compressed air fitting for testing VANOS operation

((Tool No.

BMW 11 3 450)

< Upper timing cover installation tool set, V-8

(Tool No. BMW 11 1 41 0)

Cylinder compression, checking

A compression gauge is needed to make a compression test.

For accurate test, the battery and starter must be capable of

cranking the engine at least

300 rpm, and the engine should

be at normal operating temperature.

NOTE-

Performing a compression test may cause a fault to set in the

ECM and may illuminate the Malfunction

Indicator Light

(MIL). The light can only be turned out using either

BMW

special service scan tools or an equivalent aftermarket scan

tool. Disconnecting the battery will not erase the fault memo-

ry or turn out the light. See OBD On-Board Diagnostics.

Page 100 of 1002

Downloaded from www.Manualslib.com manuals search engine

11 3-6

Cylinder Head Removal and Installation

- Disable ignition system by removing DME main relay. See

610 Component Locations for relay location.

WARNING-

. The ignition system produces high voltages that can be fa-

tal. Avoid contact with exposed terminals and use

exfreme

caution when working on a car with the ignition switched on

or the engine running.

Do not touch or disconnect ignition

components while

the engine is running or being cranked by the starter.

Failure to remove the DME main relay or attempting to

disa-

bie the fuel andignition systems by other methods may result

in damaoe to the enoine control module

(ECM).

- - Remove plastic cylinder head cover(s)

,,I . ,. .*,.,,&- - Remove coil grounding straps.

I CAUTION-

I nition system components. I

- Remove coils.

- Remove spark plugs from all cylinders.

NOTE-

Check the spark plugs for oil deposits that may indicate poor

cylinder sealing, then set them aside in order. Used spark

plugs should be reinstalled in the same cylinder from which

they were removed.

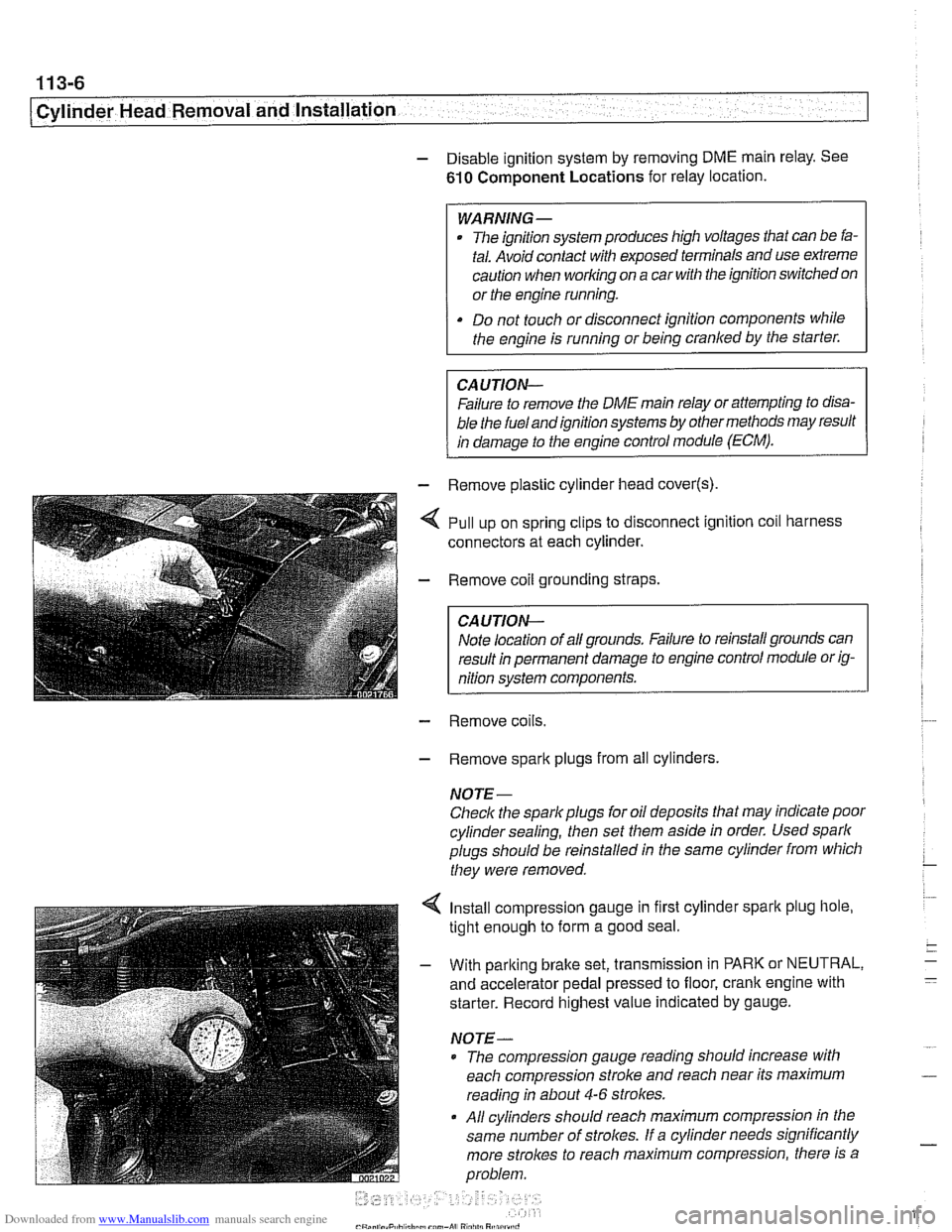

4 Install compression gauge in first cylinder spark plug hole,

tight enough to form a good seal.

- With parking brake set, transmission in PARK or NEUTRAL,

and accelerator pedal pressed to floor, crank engine with

starter. Record highest value indicated by gauge.

NOTE-

* The compression gauge reading should increase with

each compression stroke and reach near its maximum

reading in about

4-6 strokes.

All cylinders should reach maximum compression in the

same number of

strolces. If a cylinder needs significantly

more strokes to reach

maximum compression, there is a

problem.

Page 271 of 1002

Downloaded from www.Manualslib.com manuals search engine

Camshaft Timing Chain

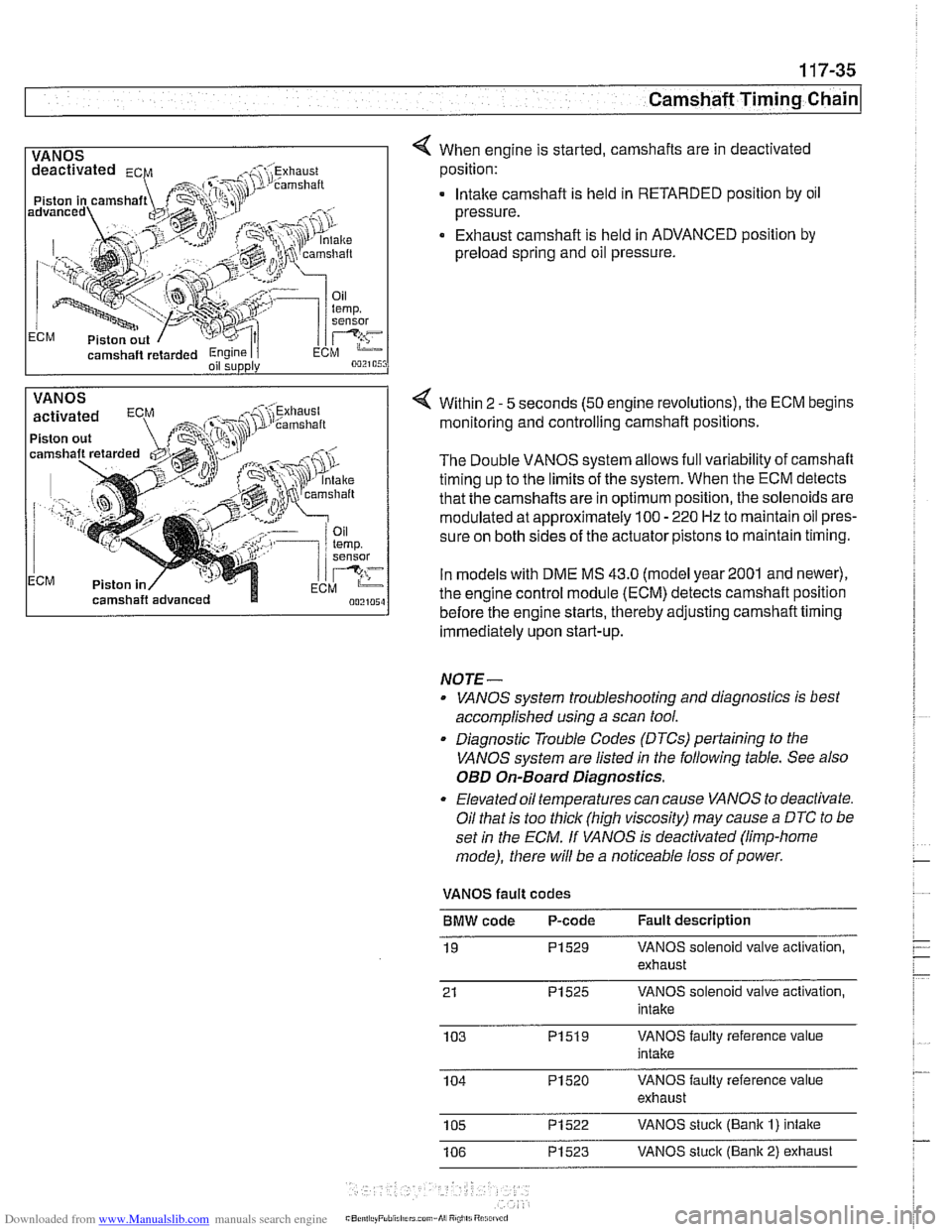

1 VANOS I 4 When engine is started, camshafts are in deactivated

camshaft

retarded Engine I i oil supply

position:

. lntalte camshaft is held in RETARDED position by oil

pressure.

Exhaust camshaft is held in ADVANCED position by

preload spring and oil pressure.

VANOS

Piston out

ECM Piston in Within 2

- 5

seconds (50 engine revolutions), the ECM begins

monitoring and controlling camshaft positions.

The Double VANOS system allows full variability of camshaft

timing up to the limits of the system. When the ECM detects

that the camshafts are in optimum position, the solenoids are

modulated at approximately 100

- 220 Hz to maintain oil pres-

sure on both sides of the actuator pistons to maintain timing.

In models with DME

MS 43.0 (model year2001 and newer),

the engine control module (ECM) detects camshaft position

before the engine starts, thereby adjusting camshaft timing

immediately upon start-up.

NOTE-

. VANOS system troubleshooting and diagnostics is best

accomplished using a scan tool.

. Diagnostic Trouble Codes (DTCs) pertaining to the

VANOS system are listed

in the following table. See also

OED On-Board Diagnostics.

Elevated oil temperatures can cause VANOS to deactivate.

Oil that is too thick (high viscosity) may cause

a DTC to be

set

in the ECM. If VANOS is deactivated (limp-home

mode), there will be a noticeable loss of power.

VANOS fault codes

BMW code P-code Fault description

19

PI529 VANOS solenoid valve activation,

exhaust

21

PI525 VANOS solenoid valve activation,

intake

103

PI519 VANOS faulty reference value

intake

104

PI520 VANOS faulty reference value

exhaust

105

PI522 VANOS stuck (Bank I) intake

106

PI523 VANOS stuck (Bank 2) exhaust

Page 352 of 1002

Downloaded from www.Manualslib.com manuals search engine

I lgnition System

Additional information about DTCs and engine management

system electronic system diagnosis is provided in

OBD On-

Board Diagnostics.

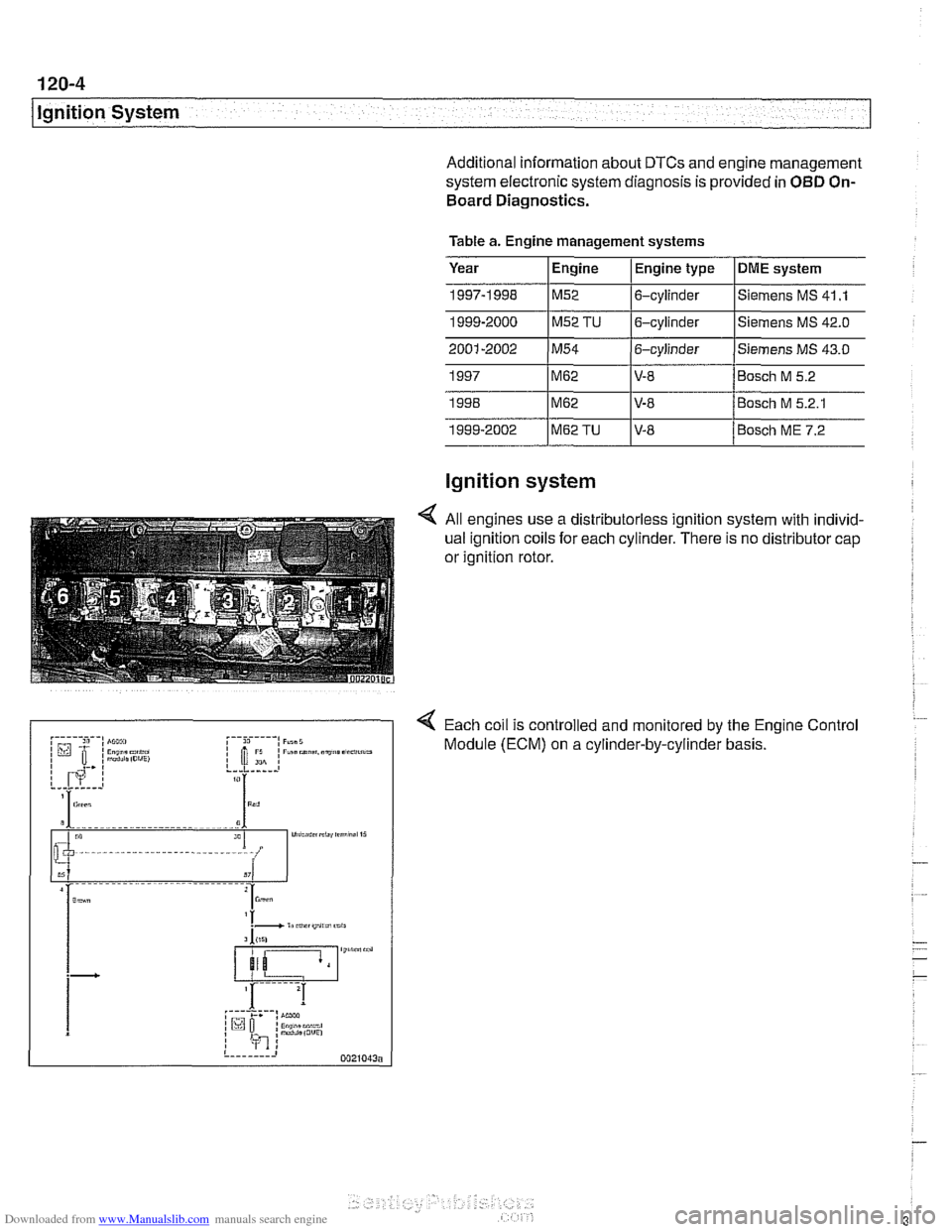

Table a. Engine management systems

Year

l~ngine I Engine type IDME svstem I - I - . . I

Ignition system

1997-1 998

1997

1998

1999-2002

4 All engines use a distributorless ignition system with individ-

ual ignition coils for each cylinder. There is no distributor cap

or ignition rotor.

4 Each coil is controlled and monitored by the Engine Control

Module (ECM) on a cylinder-by-cylinder basis.

1999-2000

1~52 TU 16-cylinder l~iemens MS

42.0

M62

M62

M62TU

Siemens MS 41 .I M52 6-cylinder

V-8

V-8 V-8 Bosch

M 5.2

Bosch M 5.2.1

Bosch ME 7.2

Page 353 of 1002

Downloaded from www.Manualslib.com manuals search engine

Lnition switch

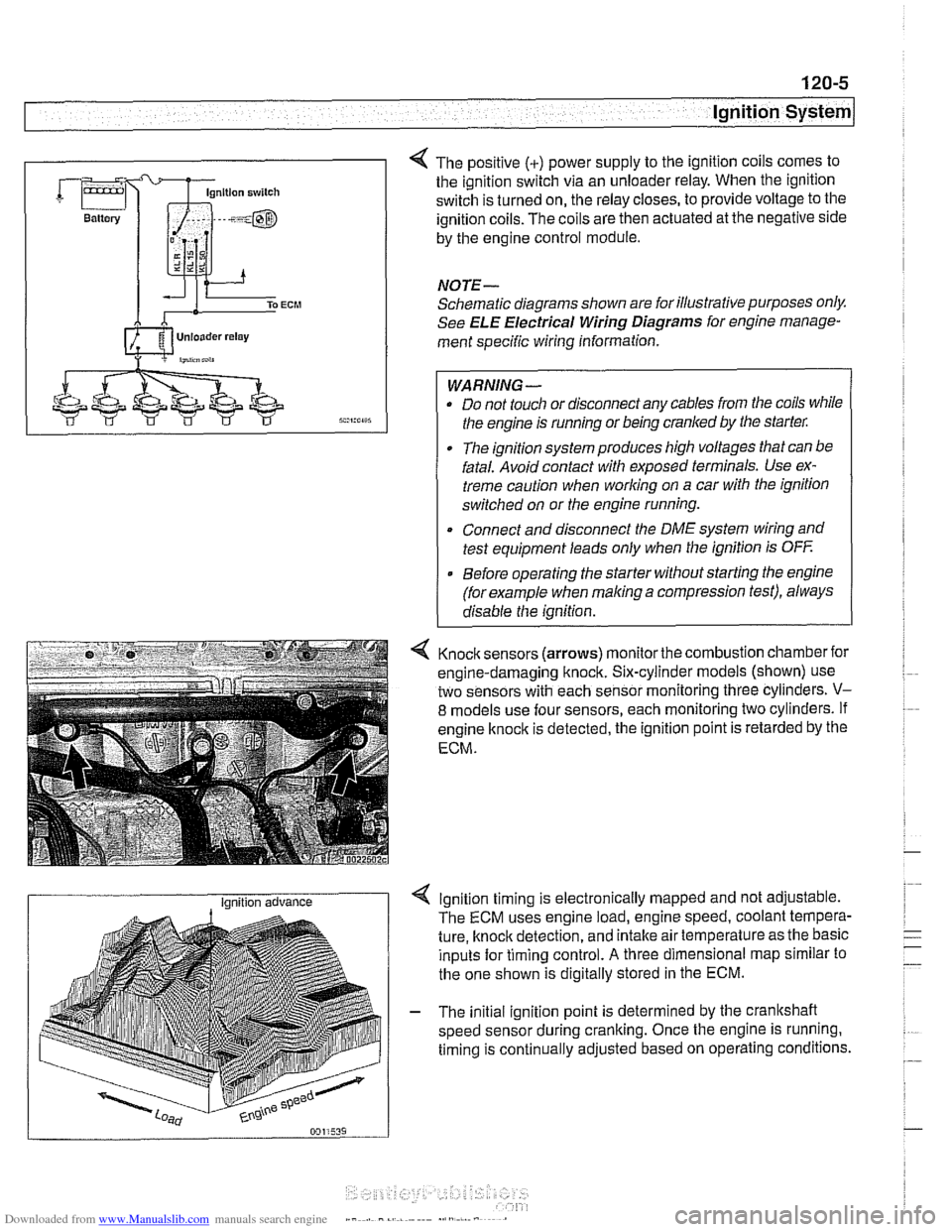

4 The positive (+) power supply to the ignition coils comes to

the ignition switch via an unloader relay. When the ignition

switch is turned on, the relay closes, to provide voltage to the

ignition coils. The coils are then actuated at the negative side

by the engine control module.

NOTE-

Schematic diagrams shown are for illustrative purposes only.

See ELE Electrical Wiring Diagrams for engine manage-

ment specific wiring information.

WARNING- Do not touch or disconnect any cables from the coils while

the engine is running or being cranked by the starter:

The ignition system produces high voltages that can be

fatal. Avoid contact with exposed terminals. Use ex-

treme caution when

working on a car with the ignition

switched on or the engine running.

* Connect and disconnect the DME system wiring and

test equipment leads only when the ignition is

OFF

Before operating the starter without starting the engine

(for example when

making a compression test), always

disable the ignition.

4 Knock sensors (arrows) monitor the combustion chamber for

engine-damaging knock. Six-cylinder models (shown) use

two sensors with each sensor monitoring three cylinders.

V-

8 models use four sensors, each monitoring two cylinders. If

engine

knock is detected, the ignition point is retarded by the

ECM.

I Ignition advance Ignition timing is electronically mapped and not adjustable.

The ECM uses engine load, engine speed, coolant tempera-

ture, knock detection, and intake air temperature as the basic

inputs for timing control.

A three dimensional map similar to

the one shown is digitally stored in the ECM.

- The initial ignition point is determined by the crankshaft

speed sensor during cranking. Once the engine is running.

timing is continually adjusted based on operating conditions.

Page 354 of 1002

Downloaded from www.Manualslib.com manuals search engine

120-6

lgnition System

lgnition system, troubleshooting

Troubleshooting ignition system faults should begin with an

interrogation of the On-Board Diagnostics (OBD

II) system.

The OBD

II system detects ignition system misfire and other

related faults. When faults are detected, the OBD

II system

stores a Diagnostic Trouble Code (DTC) in the Engine Con-

trol Module (ECM) along with other pertinent fault information.

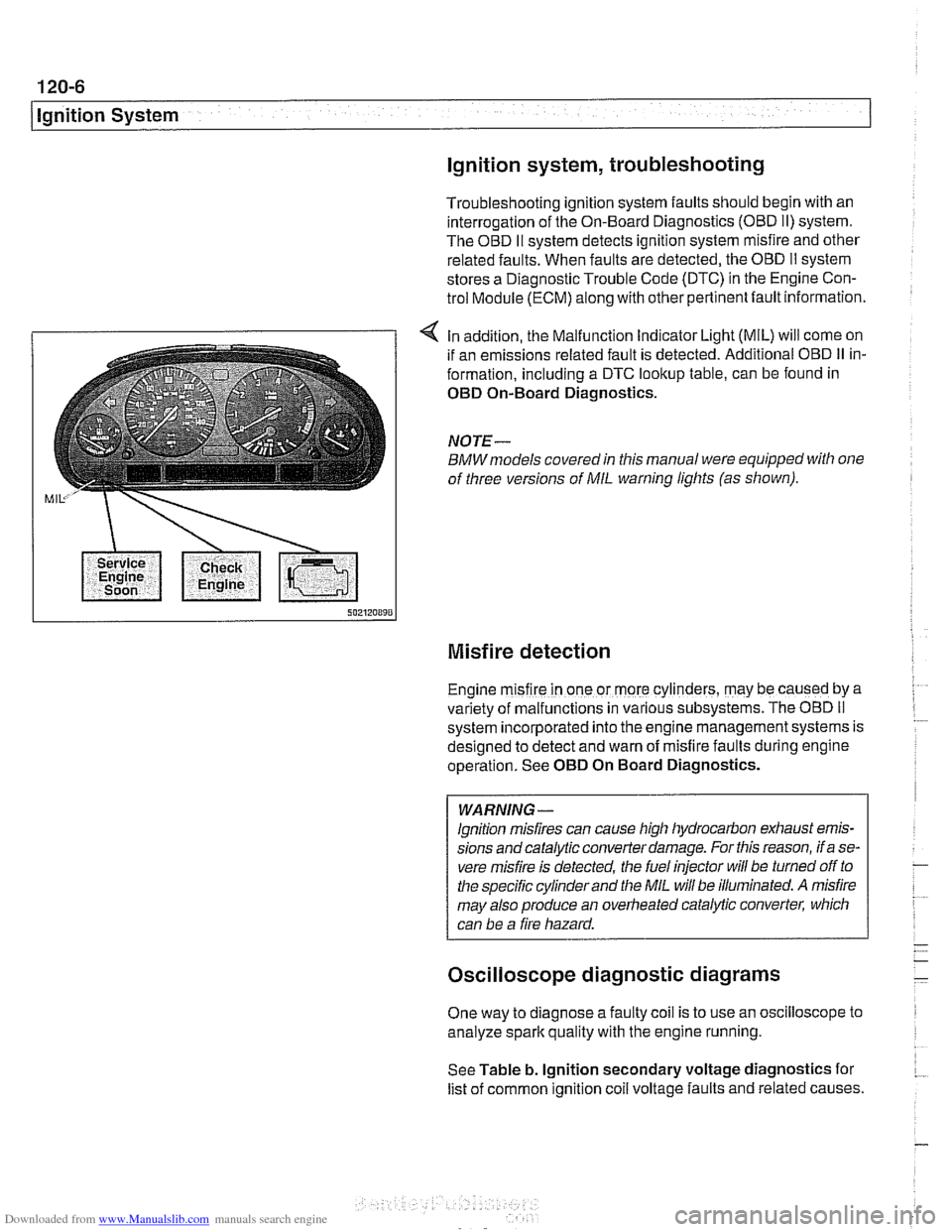

4 In addition, the Malfunction Indicator Light (MIL) will come on

if an emissions related fault is detected. Additional OBD

II in-

formation, including a DTC lookup table, can be found in

OED On-Board Diagnostics.

NOTE-

BMWmodels covered in this manual were equipped with one

of three versions of

MIL warning lights (as shown).

Misfire detection

Engine m~sfire in one or more cylinders, may be caused by a

var~ety of malfunctions in various subsystems. The OBD II

system ~ncorporated into the engine management systems is

des~gned to detect and warn of misfire faults during englne

operat~on. See OED On Board Diagnostics.

WARNING -

lgnition misfires can cause high hydrocarbon exhaust emis-

sions andcatalytic converter damage. For this reason, if a se-

vere misfire is detected, the fuel injector

will be turned off to

the specific cylinder and the

MIL will be illuminated. A misfire

may also produce an overheated catalytic converter, which

can be a fire hazard.

Oscilloscope diagnostic diagrams

One way to diagnose a faulty coil is to use an oscilloscope to

analyze spark quality with the engine running.

See Table b. lgnition secondary voltage diagnostics for

list of common ignition

coil voltage faults and related causes.